Abstract

Oil and gas production wells generate large volumes of water mixed with hydrocarbons (dispersed and dissolved), salts (ions), and solids. This ‘produced water’ (PW) is a waste stream that must be disposed of appropriately. The presence of toxic hydrocarbons and ions in PW makes it unsuitable for surface discharge or disposal in groundwater resources. Thus, PW is often injected into deep geological formations as a disposal method. However, the supply of global water sources is diminishing, and the demand for water in industrial, domestic, and agricultural use in water-stressed regions makes PW a potentially attractive resource. PW also contains valuable elements like lithium and rare earth elements, which are increasing in global demand. This review article provides an overview of constituents present in PW, current technologies available to remove and recover valuable elements, and a case study highlighting the costs and economic benefits of recovering these valuable elements. PW contains a promising source of valuable elements. Developing technologies, such as ceramic membranes with selective sorption chemistry could make elemental recovery economically feasible and turn PW from a waste stream into a multi-faceted resource.

1. Introduction

The key role of the oil and natural gas industry in modern civilization is well known. Water is often injected into reservoirs to maintain well pressure and increase hydrocarbon recovery. The process also generates large volumes of liquid waste. Formation water (present in the reservoir) and injected water are produced along with hydrocarbon mixtures from oil and gas wells. Separation techniques are used to divide hydrocarbons from the other fluids known as produced water (PW) [1]. PW contains various organic and inorganic components that are specific to each area of production. Many contaminants that pollute soil and water bodies (both surface and underground) come from PW [2]. The management of PW presents a challenge concerning maintaining favorable economics of oil and gas extraction while protecting human health and the environment [3,4]. There have been attempts to treat PW in centralized wastewater treatment plants [5,6], but success has been challenging due to the large volumes of PW and high levels of dissolved impurities [3,7]. Deep well injection has been the common method for the disposal of PW; however, legislative constraints and a shortage of deep injection wells create challenges for PW handling [3,8,9]. Recent concerns have also been raised about earthquakes induced by deep well injection [10,11]. Recycling and discharging PW after appropriate treatment could be the best practice for the oil and gas industry [12,13].

There are benefits of reusing PW, as it reduces the disposal volume and can potentially reduce freshwater consumption [14,15,16]. Disposal costs are an additional rationale for reuse by the oil and gas industry [17,18], as partial reuse of PW often provides economic benefits [19]. The reuse of PW can be classified as internal or external based on the location where the water is reused [4,20]. PW recycling for oil and gas production wells is referred to as “internal” [3,15]. The amount of PW that is reused varies by location [17,19,21,22]. Internal reuse is rarely a long-term solution since PW volumes often exceed the well capacity requirements as wells mature or drilling is interrupted [15,20]. When PW is used for irrigation, livestock watering, and aquifer recharge, it is referred to as “external reuse”.

Various processing techniques can be used to treat and reuse PW. The type of technique depends mainly on the PW composition. The processing techniques evaluated for treating PW include electrocoagulation [16], chemical precipitation [19,23], thermal distillation [19], adsorption [6], advanced oxidation [6], membrane filtration [23,24,25,26,27], including mechanical vapor compression, forward osmosis (FO), reverse osmosis (RO) [3], membrane distillation (MD), electrodialysis [23,28], biological technologies [6,29], and other desalination technologies [3,15,20,29]. Various techniques can be employed to purify water to ensure it is suitable for disposal/reuse. The choice of techniques depends on various factors, including the amount of oil, organic content, suspended soil, and the elements present. Each technique has its advantages and disadvantages. The water obtained from these techniques can be reused for domestic supply, industry, irrigation, power generation, aquifer recharge, aquaculture, or drinking water [30,31]. Several articles in the literature summarize technologies for reusing PW [15,24]. One attractive proposition for PW reuse is crop irrigation in semiarid regions [31,32,33]. However, the presence of harmful contaminants has inhibited such applications to date [34,35,36]. As water is becoming more scarce throughout the world, the ability to reuse PW is being considered as a potential option [37].

The recovery of residual hydrocarbons and valuable inorganic components present in PW could help offset costs for PW treatment and reuse. Lithium present in PW could be used to meet the increased demands associated with electric vehicles and energy storage devices [38,39]. The need for scarce elements like lithium is expected to continue to grow, and it is already leading to investigations of alternate sources like seawater and PW [40,41,42,43]. PW at select locations has significantly higher concentrations of rare elements than seawater [40]. New technologies are needed that are being developed to enable recovering resources such as lithium present in PW.

The three primary objectives of this review are to:

- (a)

- Assess the composition of the constituents present in PW.

- (b)

- Summarize current technologies available to recover valuable resources from PW.

- (c)

- Highlight the economic benefits of recovering valuable resources from PW.

2. Composition of Produced Water

The properties of PW depend on various factors, including the location of the oil field, its geological formation, the lifetime of its reservoirs, the type of hydrocarbon product being produced, and the chemicals used in the extraction process [2,44]. PW is characterized by the amounts of dispersed oil, dissolved minerals and hydrocarbons, production chemicals and solids (including corrosion and scale inhibitors), solids and bacteria from the formation, waxes, and dissolved gases that are present [45].

2.1. Dispersed Oil

Various separation techniques are available for oil/water mixtures. However, some oil can be dispersed in PW in the form of emulsions, as no separation process is 100% effective [46]. The dispersed oil content depends on factors like the density of oil, the droplet shear history, the oil precipitation, the presence of surface-active material, and the oil-water interfacial tension [47].

2.2. Dissolved Organic Compounds

PW may also contain a variety of dissolved organic compounds, including organic acids, benzene, toluene, ethylbenzene, and xylenes (BTEX), polyaromatic hydrocarbons (PAHs) including naphthalene and phenantherene, dibenzothiophene (NPD), and phenols [47,48]. The amount of these dissolved organic compounds varies based on the site where the oil is extracted, the formation process of petroleum, the PW volume, and production age [47,49]. The amount of dissolved organic compounds depends on processing factors like pH, temperature, and pressure. The amount of dissolved organic compounds is not significantly affected by the salinity of PW [50].

2.3. Dissolved Formation Minerals

Various anions and cations, heavy metals, and radioactive materials are present in PW [44]. Common cations and anions include Na+, K+, Ca2+, Mg2+, Ba2+, Sr2+, Fe2+, Cl−, SO42−, CO32−, and HCO3−. Other ions may also be presented, including Li+, Eu3+, etc. [51,52]. Trace quantities of heavy metals such as Cd, Cr, Cu, Pb, Hg, Ni, Ag, and Zn can also be found in various forms in PW, depending on pH and other factors [45]. PW often contains naturally occurring radioactive material (NORM). The most common radioactive ions in PW are 226Radium and 228Radium. The buffering capacity, potential for scale formation, and salinity of PW are influenced by the ions present [45]. The salinity of PW ranges from a few to thousands of parts per million (ppm) [53,54]. For trace and radioactive elements, concentrations can be below the detectable detection limits [55]. Table 1 provides a range of values for these properties, including the range of concentrations for some of the common elements present in PW based on data collected from different oil fields worldwide.

Table 1.

A summary of the composition of produced water from various oil fields [51,56] (reproduced with permission).

3. Membrane Technologies for PW Treatment

Since the early 20th-century, the petroleum industry has been using membrane filtration for various applications, including gas/liquid separation and desalination [57,58]. Membrane filtration has developed into a reliable method for treating PW [59]. While there is existing literature regarding recent advancements in membrane technology, its applications for PW treatment are limited [15,45,60,61,62,63,64]. Membrane filtration is classified based on pore size as microfiltration (0.1–1 μm), ultra-filtration (0.01–0.1 μm) nanofiltration (0.001–0.01 μm) and reverse osmosis (0.0001–0.001 μm) [65,66]. Membranes systems can be operated in either a batch (dead-end) or continuous fashion. In a batch system, the retentate builds up on the membrane surface. By contrast, in continuous systems with cross flow, the purified water known as the permeate passes through the membrane pores, while the concentrated retentate flows out of the membrane module. Membranes can have different configurations, including flat-sheet and hollow fibers, depending on the operating requirements. Based on the construction material, membranes can be divided into two groups, namely polymeric or ceramic.

3.1. Removal of Oil and Hydrocarbons Using Membranes for Separation

An area of key interest is developing membranes for oil/water separation to obtain clean water. Membranes technologies appear promising for removing very small (<10 μm) and stable oil droplets [61]. The treatment of PW to obtain clean water is an evolving strategy to deal with water scarcity. The waste stream from the membrane filtration would contain oil, hydrocarbons, and a small amount of water. The separation of these hydrocarbon waste streams potentially adds additional economic value to PW treatment. The presence of oil, hydrocarbons, and solid particles can result in fouling of the surface of the membrane. Fouling is measured indirectly by measuring the decrease in flux through a membrane. Another factor that has an impact on membrane fouling is surface roughness. Fouling occurs in the ‘valleys’ of a membrane surface when the roughness is high. In cross-follow systems, surface roughness plays a vital role in fouling [67]. Novel membranes with anti-fouling and solvent resistance are constantly being developed [68]. One approach that has gained much interest are membranes with super-hydrophilic properties on the surface.

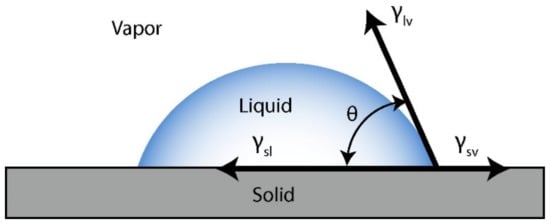

Increasing the hydrophilic surfaces of membranes makes them resistant to fouling caused by the presence of organic compounds and microorganisms. The hydrophilicity on the surface of the membrane can lead to the formation of a thin water layer attached by hydrogen bonding [69]. This layer prevents hydrophobic compounds from approaching the surface, thus preventing fouling. Contact angle θ measurements of water droplets on a membrane surface provide an indirect measure of hydrophilicity, as illustrated in Figure 1.

Figure 1.

Simplified representation of contact angle determination.

The addition of alumina nanoparticles into a membrane made with polyvinylidene fluoride (PVDF) increased the hydrophilicity compared to an unmodified membrane, which increased flux and provided a 98% oil rejection rate [70]. Modifying polyethersulfone membranes with zwitterionic polymer has been shown to alleviate fouling behavior when tested with PW from the Permian Basin [71]. After the membrane has been utilized, the membrane is backwashed with water. The source of the water that is used in backwashing also impacts fouling on the membrane surface [72]. Studies have shown that 90% of the initial flux was recovered when pure water was used to backwash; while using a surfactant solution with a pH of 10 recovered 100% of the flux [70].

When designing and operating a membrane system, a key factor is the type of membrane used. Polymeric membranes are often subjected to fouling directly, but they can also be damaged indirectly when cleaning chemicals are used to reverse the fouling behavior. Polymeric membranes require strict pretreatments, such as particle removal and removal of oxidants, such as chlorine. Despite the strict pretreatment requirements, they eventually need to be replaced due to damage caused either by foulants or the chemicals used for cleaning. Meanwhile, ceramic membranes have been widely used because they can withstand high temperatures, chemical treatments, and cleaning. Ceramic membranes are an emerging technology for oil/water separation [60,73,74,75]. Like other membranes, they utilize size exclusion for separation. Ceramic membranes can be made using carbon, silica, or metal oxides. Investigations have been conducted using polysulfone membranes with different additives in both batch and cross-flow systems. Ceramic membranes had higher fluxes and rejection with synthetic PW than when real PW was tested [76,77,78]. The cause for this difference is likely due to the complexity of the feed stream, oil droplet size distribution, and pH. Ceramic membranes were tested using PW from an American Petroleum Institute (API) unit [79], which showed an oil removal of 95%. Over 95% of the flux was recovered after backwashing, while only 40–50% of the flux was recovered when chemical cleaning was done [79]. The addition of hydrophilic silica onto the alumina microfiltration membrane has shown increased oil rejection [80]. Although a ceramic membrane can be used for micro, ultra, or nanofiltration with higher flux, there are certain drawbacks [38,80]. Some of the disadvantages include the high production cost and weight. Polymeric membranes are affected (even damaged) by the presence of solvents, while ceramic membranes are highly resilient. Researchers are working on developing ceramic/polymeric hybrid membranes [24,60].

3.2. Removal of Solutes Using Membranes

There are various solutes (ions) present in PW, some of which are valuable and others that are toxic. Boron present in PW, even at low concentrations, is detrimental to crops [81]. Traditional processes like evaporation and precipitation would not be convenient for targeted removal or enhancement [82,83]. Much research has been focused on developing membranes with anti-fouling properties, but limited attention has been focused on the selective separation of specific solutes [84,85,86]. The main drawback with the separation of a particular solute using the membrane separation process is the solute-specific selectivity of the membrane [87,88]. The selective separation of a solute could be enhanced by altering the solubility and diffusivity of the solute through the polymer [89,90,91,92,93]. Thereby membranes can be designed with solute-tailored selectivity, which would aid in targeted removal of harmful components and enrichment of other compounds.

The use of ion channels has exhibited rapid transport of particular ions and increased ionic selectivity. Potassium ion channels showed high selectivity over sodium [91,94]. The selectivity for a particular ion was achieved by combining exact pore sizes and tuning molecular interactions. Ligands, crown ethers, and other compounds have shown high selectivity in removing specific ions from aqueous phases using solvent extraction techniques [40]. This concept has been used to develop membranes that can selectively remove specific ions using grafting ligands, “ion-imprinted” membranes, and liquid membranes containing ion-chelating crown ether functionalities [95,96,97,98,99,100,101,102]. Although these techniques have improved selectively, there are also drawbacks. In the case of ion-chelating crown ethers, the unbound ether could leach out. More research is needed before these new strategies can be used for treatment processes.

3.3. Membrane Distillation

A promising technology being developed for desalination is membrane distillation (MD), especially from seawater and brackish water. This process is thermally-driven, with water vapor molecules passing through a porous hydrophobic membrane. MD has many advantages, such as high rejection of inorganic ions, macromolecules, and other non-volatile compounds, operation at low temperatures, and less demanding membrane material requirements [103]. MD can be operated below boiling temperatures and combined with other technologies to develop an integrated system. MD can also use waste heat from other processes or alternative energy (i.e., solar, geothermal, etc.) sources that can easily be integrated at oil and gas sites to warm the feed stream. MD effectively separates radioactive material from wastewater [104]. The drawbacks of MD are low permeate flux (compared to other membrane processes) and high susceptibility to concentration, heat losses, fouling, air entrapment, and feed temperature [105].

Mass transfer in MD is expressed by both convective and diffusive water transport models. Though the vapor pressure gradient drives the mechanism forward, membrane and system characteristics can potentially resist the mass transfer [8,106,107]. The “dusty gas model” has been used to describe mass transfer across the membrane [103,108], which includes the following assumptions:

- The Knudsen diffusion model: in membranes with pores less than 0.5–15 μm, this model is used when the molecular mean free path is larger than the capillary. In this case, the likelihood of molecular collision with the membrane wall is greater than that of molecule-molecule collision.

- Poiseuille’s Law or Viscous flow theory: the air pressure in the system maintains a constant pressure across the membrane, thereby degassing the feed and permeate flows and increasing permeability by decreasing the molecular diffusion resistance and increasing viscous flux.

- Molecular diffusion transition: represents the movement of the molecules from high to low concentration regions due to a pressure gradient. This is the preferred model in MD when the collision between molecules is more likely than the collision of molecules with the cell wall.

Several process flow configurations have been developed for MD. In all configurations, the feed side of the flow directly contacts the membrane, although the permeate side condenses using different approaches. Four MD setups have been used [103,107,109]:

- Direct Contact Membrane Distillation (DCMD): DCMD operations have both sides of the membrane in direct contact with liquid phases. The heated feed solution and cooled permeate streams flow across opposite sides counter currently. This is the most common MD setup.

- Air Gap Membrane Distillation (AGMD): In AGMD configurations, an air gap between the surface of the membrane and the cooling plate on the permeate side of the membrane is used that decreases conductive heat losses.

- Vacuum Membrane Distillation (VMD)–VMD configurations use a vacuum located on the permeate side of the membrane as the driving force for condensation. The vapor is collected and then externally condensed.

- Sweeping Gas Membrane Distillation (SGMD)–SGMD technologies utilize a cold sweeping gas phase to pull the vapor molecules away from the membrane, which are then condensed in a separate device.

PW treatment with MD has been investigated [110,111,112,113,114]. The major cost is typically thermal energy, which depends on the amount of dissolved solids [115]. The cost of thermal energy can be reduced significantly by using alternate energy sources that are often present at oil and gas wells [110]. Techno-economic assessments have found that the costs of PW treatment can be cheaper than injecting it into a disposal well [115]. MD can be combined with other processes to achieve desired treatment objectives.

3.4. Electrodialysis

Electrodialysis (ED) utilizes the principle that cations move towards the cathode and anions move towards the anode when a direct current (electric charge) is applied, along with ion-exchange membranes that allow only specific ions to pass through. A typical ED setup comprises multiple ion (cation/anion) exchange membranes sandwiched between an anode and cathode. The ion-exchange membranes are alternated between cationic and anionic membranes. The feed is allowed to flow between the membrane, and when an electric charge is applied in the presence of an ion-exchange membrane, it allows anions to reach the anode and cations to the cathode; hence a concentrated (with ions) and dilute stream (free of any ions) would be achieved [116]. Scaling and fouling in ED can be reversed by switching the polarity of the electrodes. This process is called electrodialysis reversal (EDR). Hence the reversal process aid in cleaning the membrane and increasing the life of the membrane used [117,118].

PW from five different states in the US was simulated and treated using ED to remove the salts present. The increase in voltage increased the salt removal for all the PWs linearly. Ions with a higher charge (+/−) were removed faster than ones with lower charges. ED was able to reduce the total dissolved salt (TDS) content for all the PW samples. The ones with low TDS were treatable to the extent required for drinking. In comparison, PW with high TDS was harder to treat, requiring higher power and more cycles for lower salt removal [119]. There are certain drawbacks to using this approach, such as scaling/fouling on the membrane, concentration polarization, and electricity requirement for the treatment process (increasing cost), especially when treating PW [117,118,120,121,122,123,124]. Hence, coupling renewable sources of energy (solar, wind) with ED would reduce the cost of energy consumption. Investigations have shown that softening PW to reduce the concentration of ions that cause scaling as a preliminary step, followed by ED, reduced scaling on the membrane surface to obtain purified water [125]. Using a pulsed electric field (PEF) instead of a continuous electric field has been shown to reduce fouling, concentration polarization, and performance enhancement [120,126,127]. Most of the studies are looking at the complete desalination of the PW, as this technique cannot distinguish the type of ions/elements being removed. However, some studies investigate the preferential removal of a specific group of ions (ions of the same charge) by developing selective membranes, optimizing operating conditions, etc. [123,128,129]. Leading to the need for developing a wider spectrum of membranes and operating conditions for selective separation.

4. Adsorption for the Treatment of Produced Water

The presence of harmful organic contaminants in PW makes it challenging to dispose of and reuse. Some toxic substances found in PW include BTEX, PAHs, NPD, and phenols [47,48]. As discussed in the previous section, the presence of organic compounds leads to fouling on the membrane surface by reducing the membrane’s performance. This section describes different materials used to adsorb organic contaminants from water. Adsorption is often the cheapest method to remove pollutants from wastewater [130].

The most commonly used adsorbent is activated carbon [131]. Activated carbon has a porous and solid structure with a high surface area-to-volume ratio. It possesses good thermal, light, and mechanical stability. Activated carbon has a high capacity for adsorption of various species, which is why it is widely used in wastewater treatment to remove both ions and organic contaminants. Activated carbon can be used to remove BTEX and free hydrocarbons present in PW [60].

Surface modifications to activated carbon have been found to increase adsorption capacity. Based on the pollutant and its charge, the activated carbon is suitability modified to assist in the adsorption using the mechanism of ionic exchange or size exclusion [132,133,134,135]. For example, activated carbon has been modified with surfactants including sodium dodecyl sulfate and the cetyltrimethy lammonium bromide to improve the removal efficiency of Cd from wastewater. The modifications increased the porosity and surface area, which improved Cd removal efficiency (98%) relative to its counterparts [136]. Activated carbon is typically produced from biomass, but researchers have also investigated converting tires and PET bottles into activated carbon [137,138]. Using waste material to prepare activated carbon reduces the waste generated and can treat PW. Several effluents contain a large amount of inorganic salts, which affect adsorption efficacy. The presence of some salts enhances the rate of adsorption, while others reduce the rate of adsorption. Therefore it is necessary to understand the impact of inorganic salts on the adsorption process for applications such as PW treatment.

Another widely used adsorbent for water treatment is zeolite [139]. Zeolites may be either natural or synthetic [140,141]. Clinoptilolite is the most abundant natural zeolite that has been used for water and wastewater treatment because it is inexpensive and possesses a high surface area-to-volume ratio and ion exchange capacity [142,143]. Synthetic zeolites can remove heavy metals, water hardness, ammoniacal nitrogen, and COD [144,145,146]. Comparative studies have been conducted between activated carbon and zeolites for removing pollutants from wastewater that indicate promise [139,145,147].

Clays (montmorillonite, bentonite, etc.) are also adsorbents used to treat wastewater streams, either as natural or organoclays. Organoclay is produced by altering the clay surface with a modifying agent (e.g., quaternary amines, polymers, etc.). Organoclay can be used along with other sorbents like activated carbon to reduce hydrocarbon concentrations to levels below the required water quality standards [148]. Field studies using polymer modified bentonite have been used to successfully treat PW [149]. This organoclay reduced the total petroleum hydrocarbon, oil, and grease to non-detectable levels, while soluble hydrocarbons (BTEX) were reduced to below detection limits with the addition of activated carbon for polishing.

Ion exchange resins have been used to remove organic/inorganic compounds from PW [60,150,151,152]. Other adsorbents like starch, alginate, chitin, chitosan, and other bio-derived adsorbents have been used to treat wastewater from other industrial wastes [153,154,155]. Adsorption processes are run in both batch and continuous systems [156]. However, fixed bed adsorption columns in continuous operation are most commonly used due to ease of operation, simplicity, removal efficiency, and regeneration potential [157,158,159,160]. The advantages of using fixed-bed adsorption make it a good option for treating PW.

5. Proposed Approach to Recover Valuable Elements

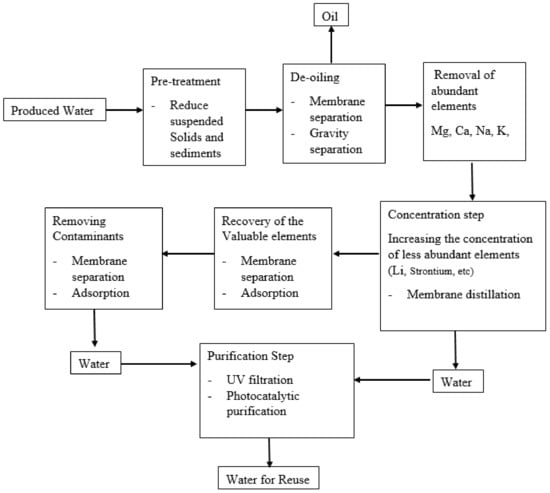

PW has valuable elements, including crude oil, inorganic compounds, and water. Myers [30] discusses how PW is treated for reuse while increasing oil production. The treatment process is multistep, where oil, solids, gas, and salts are removed to ensure water meets the quality required for industrial, domestic, irrigation, or livestock use. The treatment technology selection for the recovery process depends on the composition of PW, the water reuse standards, the cost of treatment, and the net environmental benefits. We propose a separation train, as shown in Figure 2, for an integrated treatment and resource recovery process. The proposed treatment train would recover oil and elements/minerals and make the PW fit for reuse. Since the composition of PW varies, the value of recovery will vary at different wells. PW injected into deep wells may possess considerable value in terms of carbon and high-value elements/minerals. PW may be an attractive alternative resource for some of these high-value elements.

Figure 2.

Schematic of a process train for the separation and recovery of high-value elements.

6. Economic Assessment

The proposed technologies could improve profitability via at least four different mechanisms: (1) reduced injection costs via increased fluid density following oil/water separation, (2) reduced disposal costs for PW that is treated and released, (3) increased land productivity via irrigation, and (4) development of a new market for rare earth and other valuable co-products. According to over two dozen customer interviews conducted with oil and gas industry experts and industry observers, issues with PW treatment involve ownership/liability, transportation, and disposal logistics. The expenses incurred for handling PW treatment and other byproducts vary by region. In the Marcellus Shale (PA, USA), there are limited Class-2 Deep injection wells (Underground Injection Control Wells, UICs). Apart from UICs, there is an increased interest in the treatment and re-utilization of PW waste since procuring source water for fracturing operations is becoming increasingly difficult. New legislation has also been passed in Texas to entice the treatment and recycling of PW instead of injection.

The treatment of PW would appear to be a great alternative to alleviate these problems. Surprisingly, only 10% of PW is treated in modular and permanent treatment systems, while 90% is injected. The treatment of PW is currently not profitable or sustainable as a business model using available technologies. Generating value from PW through the extraction of critical minerals and REEs brings forth a promising opportunity in this space. Metals such as lithium, magnesium, strontium, vanadium, neodymium, calcium are highly demanded in the medical, consumer electronics, and magnets industries, where they are used to produce artificial bones, batteries, and aerospace-grade metals.

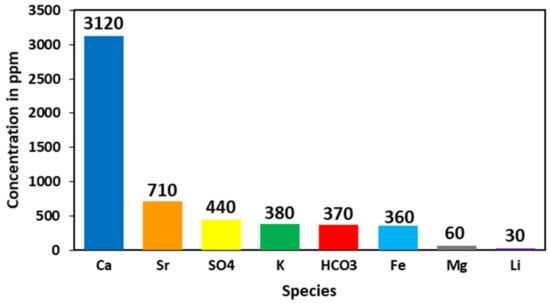

Figure 3 displays the most significant constituents across 70 wells collected and anonymized from the Permian Basin. The data on the graphs were provided by a mid-stream chemical processing company in Texas. There are substantial traces of Strontium (Sr2+), Calcium (Ca2+), sulfate (SO42−), potassium (K+), bicarbonate (HCO3−), Magnesium (Mg2+), and lithium (Li+) in the Permian Basin PWs. It is possible that formations in Oklahoma and Texas could benefit from the technologies developed in this research.

Figure 3.

Ionic composition of 70 Permian Wells.

The size of the potential market in the Permian basin alone can be estimated using these data. Table 2 identifies the most profitable minerals with their respective concentrations, market price per dry metric ton unit, and potential yearly metal mass extracted, as well as the revenue generated by the metals per year per well.

Table 2.

Potential market benefits obtained from the sale of mineral extractions.

Table 3 provides data on the wells used for these calculations, and the actual calculations were done from assumptions in Table 4. The revenue estimations are presented in Table 5, which along with yearly revenue, highlights the PW volume handled and the metal mass extracted for the potential addressable (PAM), total addressable (TAM), serviceable available (SAM), and serviceable obtainable markets (SOM). Table 2 assumes a baseline collection efficiency of 95% and Table 3 assumes a PW volume limit of 10% and market capitalization of 1%. These assumptions would lead to the SOM revenue of $103,000,000 for the state of Texas alone.

Table 3.

Well Estimations for Texas (Permian Basin).

Table 4.

Market segmentation.

Table 5.

Potential market size.

7. Conclusions

This paper summarizes the components present in PW, describes technologies being developed to treat PW and discusses approaches to recover valuable resources (hydrocarbons and valuable elements) present in PW. Membrane technology and adsorption processes are widely used to remove pollutants and recover valuable materials from PW. Fouling on membrane surfaces is a significant issue, along with specific selectivity; hence, more work is needed in these areas. For adsorption, new materials are being developed that provide selectivity for the recovery of key elements. The economic assessment of PW from the Permian Basin provides an example of the benefits of recovering elements present in PW. A single separation process is unlikely to achieve all necessary treatment objectives for any PW. However, by combining these separation techniques into a treatment train and recovering hydrocarbons and other elements, the economic feasibility of PW treatment is greater improved. Economical treatment of PW could help alleviate water scarcity issues in oil and gas producing regions. The treatment technologies needed for a given PW depend on the chemical composition, pollutant concentrations, water reuse standards, costs of treatment, and net environmental benefits.

Author Contributions

This review article was conceptualized by D.J.L., M.A.M., S.K., M.J.K. and C.P.A. The compilation literature review was done by M.A.M., A.G., G.M., S.X., D.J.L. and M.S. The economic assessment was done by D.J.L. The writing—original draft preparation was done by M.A.M. The writing—review and editing, A.G., G.M., S.X., D.J.L., M.S., S.K., M.J.K. and C.P.A. The funding for this work was acquired by S.K., M.J.K., D.J.L. and C.P.A. All authors have read and agreed to the published version of the manuscript.

Funding

This material is based on work supported by the National Science Foundation under Grant No. OIA-1946093, the Oklahoma Center for the Advancement of Science and Technology under Grant No. AR20-041, and the U.S. Environmental Protection Agency under Grant SV839490.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ekins, P.; Vanner, R.; Firebrace, J. Zero emissions of oil in water from offshore oil and gas installations: Economic and environmental implications. J. Clean. Prod. 2007, 15, 1302–1315. [Google Scholar] [CrossRef]

- Veil, J.A.; Puder, M.G.; Elcock, D.; Redweik, R.J., Jr. A White Paper Describing Produced Water from Production of Crude Oil, Natural Gas, and Coal Bed Methane; Argonne National Lab.: Lemont, IL, USA, 2004. [Google Scholar]

- Gregory, K.B.; Vidic, R.D.; Dzombak, D.A. Water Management Challenges Associated with the Production of Shale Gas by Hydraulic Fracturing. Elements 2011, 7, 181–186. [Google Scholar] [CrossRef]

- Vidic, R.D.; Brantley, S.L.; Vandenbossche, J.M.; Yoxtheimer, D.; Abad, J.D. Impact of Shale Gas Development on Regional Water Quality. Science 2013, 340, 1235009. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ferrar, K.J.; Michanowicz, D.R.; Christen, C.L.; Mulcahy, N.; Malone, S.L.; Sharma, R.K. Assessment of Effluent Contaminants from Three Facilities Discharging Marcellus Shale Wastewater to Surface Waters in Pennsylvania. Environ. Sci. Technol. 2013, 47, 3472–3481. [Google Scholar] [CrossRef] [PubMed]

- Butkovskyi, A.; Bruning, H.; Kools, S.A.E.; Rijnaarts, H.H.M.; Van Wezel, A.P. Organic Pollutants in Shale Gas Flowback and Produced Waters: Identification, Potential Ecological Impact, and Implications for Treatment Strategies. Environ. Sci. Technol. 2017, 51, 4740–4754. [Google Scholar] [CrossRef]

- Lutz, B.D.; Lewis, A.N.; Doyle, M.W. Generation, transport, and disposal of wastewater associated with Marcellus Shale gas development. Water Resour. Res. 2013, 49, 647–656. [Google Scholar] [CrossRef]

- Vandecasteele, I.; Rivero, I.M.; Sala, S.; Baranzelli, C.; Barranco, R.; Batelaan, O.; Lavalle, C. Impact of shale gas development on water resources: A case study in northern Poland. Environ. Manag. 2015, 55, 1285–1299. [Google Scholar] [CrossRef] [Green Version]

- Olsson, O.; Weichgrebe, D.; Rosenwinkel, K.-H. Hydraulic fracturing wastewater in Germany: Composition, treatment, concerns. Environ. Earth Sci. 2013, 70, 3895–3906. [Google Scholar] [CrossRef]

- Ellsworth, W.L. Injection-Induced Earthquakes. Science 2013, 341, 1225942. [Google Scholar] [CrossRef]

- Weingarten, M.; Ge, S.; Godt, J.W.; Bekins, B.A.; Rubinstein, J.L. High-rate injection is associated with the increase in U.S. mid-continent seismicity. Science 2015, 348, 1336–1340. [Google Scholar] [CrossRef] [Green Version]

- Rahm, B.G.; Bates, J.T.; Bertoia, L.R.; Galford, A.E.; Yoxtheimer, D.A.; Riha, S.J. Wastewater management and Marcellus Shale gas development: Trends, drivers, and planning implications. J. Environ. Manag. 2013, 120, 105–113. [Google Scholar] [CrossRef] [PubMed]

- Nicot, J.-P.; Scanlon, B.R.; Reedy, R.C.; Costley, R.A. Source and Fate of Hydraulic Fracturing Water in the Barnett Shale: A Historical Perspective. Environ. Sci. Technol. 2014, 48, 2464–2471. [Google Scholar] [CrossRef] [PubMed]

- Hayes, T.; Severin, B.F.; Engineer, P.; Okemos, M. Barnett and Appalachian Shale water management and reuse technologies. Contract 2012, 8122. Available online: https://www.beg.utexas.edu/files/publications/contract-reports/CR2012-Hayes-1.pdf (accessed on 5 October 2021).

- Shaffer, D.L.; Arias Chavez, L.H.; Ben-Sasson, M.; Romero-Vargas Castrillón, S.; Yip, N.Y.; Elimelech, M. Desalination and Reuse of High-Salinity Shale Gas Produced Water: Drivers, Technologies, and Future Directions. Environ. Sci. Technol. 2013, 47, 9569–9583. [Google Scholar] [CrossRef] [PubMed]

- Kausley, S.B.; Malhotra, C.P.; Pandit, A.B. Treatment and reuse of shale gas wastewater: Electrocoagulation system for enhanced removal of organic contamination and scale causing divalent cations. J. Water Process Eng. 2017, 16, 149–162. [Google Scholar] [CrossRef]

- Rassenfoss, S. From Flowback to Fracturing: Water Recycling Grows in the Marcellus Shale. J. Pet. Technol. 2011, 63, 48–51. [Google Scholar] [CrossRef]

- Jiang, Q.; Rentschler, J.; Perrone, R.; Liu, K. Application of ceramic membrane and ion-exchange for the treatment of the flowback water from Marcellus shale gas production. J. Membr. Sci. 2013, 431, 55–61. [Google Scholar] [CrossRef]

- Mantell, M.E. Produced water reuse and recycling challenges and opportunities across major shale plays. In Proceedings of the Hydraulic Fracturing Study: March 2011 Technical Workshop #4 on Water Resources Management, Arlington, VA, USA, 29–30 March 2011. [Google Scholar]

- He, C.; Zhang, T.; Zheng, X.; Li, Y.; Vidic, R.D. Management of Marcellus Shale Produced Water in Pennsylvania: A Review of Current Strategies and Perspectives. Energy Technol. 2014, 2, 968–976. [Google Scholar] [CrossRef]

- Clark, C.E.; Horner, R.M.; Harto, C.B. Life Cycle Water Consumption for Shale Gas and Conventional Natural Gas. Environ. Sci. Technol. 2013, 47, 11829–11836. [Google Scholar] [CrossRef]

- Skalak, K.J.; Engle, M.A.; Rowan, E.L.; Jolly, G.D.; Conko, K.M.; Benthem, A.J.; Kraemer, T.F. Surface disposal of produced waters in western and southwestern Pennsylvania: Potential for accumulation of alkali-earth elements in sediments. Int. J. Coal Geol. 2014, 126, 162–170. [Google Scholar] [CrossRef]

- Gurreri, L.; Tamburini, A.; Cipollina, A.; Micale, G. Electrodialysis Applications in Wastewater Treatment for Environmental Protection and Resources Recovery: A Systematic Review on Progress and Perspectives. Membranes 2020, 10, 146. [Google Scholar] [CrossRef]

- Alzahrani, S.; Mohammad, A.W. Challenges and trends in membrane technology implementation for produced water treatment: A review. J. Water Process Eng. 2014, 4, 107–133. [Google Scholar] [CrossRef]

- Munirasu, S.; Haija, M.A.; Banat, F. Use of membrane technology for oil field and refinery produced water treatment—A review. Process Saf. Environ. Prot. 2016, 100, 183–202. [Google Scholar] [CrossRef]

- Kong, F.-x.; Chen, J.-f.; Wang, H.-m.; Liu, X.-n.; Wang, X.-m.; Wen, X.; Chen, C.-m.; Xie, Y.F. Application of coagulation-UF hybrid process for shale gas fracturing flowback water recycling: Performance and fouling analysis. J. Membr. Sci. 2017, 524, 460–469. [Google Scholar] [CrossRef]

- He, C.; Wang, X.; Liu, W.; Barbot, E.; Vidic, R.D. Microfiltration in recycling of Marcellus Shale flowback water: Solids removal and potential fouling of polymeric microfiltration membranes. J. Membr. Sci. 2014, 462, 88–95. [Google Scholar] [CrossRef]

- Căprărescu, S.; Modrogan, C.; Purcar, V.; Dăncilă, A.M.; Orbuleț, O.D. Study of Polyvinyl Alcohol-SiO2 Nanoparticles Polymeric Membrane in Wastewater Treatment Containing Zinc Ions. Polymers 2021, 13, 1875. [Google Scholar] [CrossRef]

- Estrada, J.M.; Bhamidimarri, R. A review of the issues and treatment options for wastewater from shale gas extraction by hydraulic fracturing. Fuel 2016, 182, 292–303. [Google Scholar] [CrossRef]

- Myers, J.E. Chevron San Ardo Facility Unit (SAFU) Beneficial Produced Water Reuse for Irrigation. In Proceedings of the SPE International Conference on Health, Safety, and Environment, Long Beach, CA, USA, 17–19 March 2014. [Google Scholar]

- Gray, M. Reuse of Produced Water in the Oil and Gas Industry. In Proceedings of the SPE International Conference and Exhibition on Health, Safety, Environment, and Sustainability, Online, 27–31 July 2020. [Google Scholar]

- Council, G.W.P. Produced Water Report: Regulations, Current Practices, and Research Needs; Ground Water Protection Council, Inc.: Oklahoma City, OK, USA, 2019. [Google Scholar]

- Suwaileh, W.; Johnson, D.; Hilal, N. Membrane desalination and water re-use for agriculture: State of the art and future outlook. Desalination 2020, 491, 114559. [Google Scholar] [CrossRef]

- Kondash, A.J.; Redmon, J.H.; Lambertini, E.; Feinstein, L.; Weinthal, E.; Cabrales, L.; Vengosh, A. The impact of using low-saline oilfield produced water for irrigation on water and soil quality in California. Sci. Total Environ. 2020, 733, 139392. [Google Scholar] [CrossRef]

- Miller, H.; Trivedi, P.; Qiu, Y.; Sedlacko, E.M.; Higgins, C.P.; Borch, T. Food crop irrigation with oilfield-produced water suppresses plant immune response. Environ. Sci. Technol. Lett. 2019, 6, 656–661. [Google Scholar] [CrossRef]

- Bañuelos, G.; Lin, Z.-Q. Reuse of agricultural drainage water in central California: Phytosustainability in soil with high levels of salinity and toxic trace elements. Geol. Soc. Lond. Spec. Publ. 2006, 266, 79–88. [Google Scholar] [CrossRef]

- Melo, M.; Schluter, H.; Ferreira, J.; Magda, R.; Júnior, A.; de Aquino, O. Advanced performance evaluation of a reverse osmosis treatment for oilfield produced water aiming reuse. Desalination 2010, 250, 1016–1018. [Google Scholar] [CrossRef]

- Martin, G.; Rentsch, L.; Höck, M.; Bertau, M. Lithium market research–global supply, future demand and price development. Energy Storage Mater. 2017, 6, 171–179. [Google Scholar] [CrossRef]

- Swain, B. Recovery and recycling of lithium: A review. Sep. Purif. Technol. 2017, 172, 388–403. [Google Scholar] [CrossRef]

- Jang, E.; Jang, Y.; Chung, E. Lithium recovery from shale gas produced water using solvent extraction. Appl. Geochem. 2017, 78, 343–350. [Google Scholar] [CrossRef]

- Nishihama, S.; Onishi, K.; Yoshizuka, K. Selective recovery process of lithium from seawater using integrated ion exchange methods. Solvent Extr. Ion Exch. 2011, 29, 421–431. [Google Scholar] [CrossRef]

- Chitrakar, R.; Kanoh, H.; Miyai, Y.; Ooi, K. Recovery of lithium from seawater using manganese oxide adsorbent (H1. 6Mn1. 6O4) derived from Li1. 6Mn1. 6O4. Ind. Eng. Chem. Res. 2001, 40, 2054–2058. [Google Scholar] [CrossRef]

- Ryu, T.; Shin, J.; Ryu, J.; Park, I.; Hong, H.; Kim, B.-G.; Chung, K.-S. Preparation and characterization of a cylinder-type adsorbent for the recovery of lithium from seawater. Mater. Trans. 2013, 54, 1029–1033. [Google Scholar] [CrossRef] [Green Version]

- Fillo, J.; Koraido, S.; Evans, J. Sources, characteristics, and management of produced waters from natural gas production and storage operations. In Produced Water; Springer: Boston, MA, USA, 1992; pp. 151–161. [Google Scholar]

- Hansen, B.; Davies, S. Review of potential technologies for the removal of dissolved components from produced water. Chem. Eng. Res. Des. 1994, 72, 176–188. [Google Scholar]

- Johnsen, S.; Røe Utvik, T.I.; Garland, E.; de Vals, B.; Campbell, J. Environmental Fate And Effect Of Contaminants In Produced Water. In Proceedings of the SPE International Conference on Health, Safety, and Environment in Oil and Gas Exploration and Production, Calgary, AB, Canada, 29–31 March 2004. [Google Scholar]

- Stephenson, M. A survey of produced water studies. In Produced Water; Springer: Boston, MA, USA, 1992; pp. 1–11. [Google Scholar]

- Faksness, L.-G.; Grini, P.G.; Daling, P.S. Partitioning of semi-soluble organic compounds between the water phase and oil droplets in produced water. Mar. Pollut. Bull. 2004, 48, 731–742. [Google Scholar] [CrossRef]

- Li, L.-B.; Yan, S.; Zeng, X.-D.; Lin, D.-Q. Analysis of organic compounds in oilfield produced water. Petrochem. Technol. 2002, 31, 472–475. [Google Scholar]

- Bostick, D.T. Characterization of Soluble Organics in Produced Water; ORNL Oak Ridge National Laboratory (US): Oak Ridge, TN, USA, 2002. [Google Scholar]

- Tibbetts, P.; Buchanan, I.; Gawel, L.; Large, R. A comprehensive determination of produced water composition. In Produced Water; Springer: Boston, MA, USA, 1992; pp. 97–112. [Google Scholar]

- Tian, L.; Chang, H.; Tang, P.; Li, T.; Zhang, X.; Liu, S.; He, Q.; Wang, T.; Yang, J.; Bai, Y.; et al. Rare Earth Elements Occurrence and Economical Recovery Strategy from Shale Gas Wastewater in the Sichuan Basin, China. ACS Sustain. Chem. Eng. 2020, 8, 11914–11920. [Google Scholar] [CrossRef]

- Pitre, R. Produced water discharges into marine ecosystems. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 7–9 May 1984. [Google Scholar]

- Neff, J.M. Bioaccumulation in Marine Organisms: Effect of Contaminants from Oil Well Produced Water; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Gäfvert, T.; Færevik, I.; Rudjord, A.L. Assessment of the discharge of NORM to the North Sea from produced water by the Norwegian oil and gas industry. In Radioactivity in the Environment; Povinec, P.P., Sanchez-Cabeza, J.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2006; Volume 8, pp. 193–205. [Google Scholar]

- Klemz, A.C.; Weschenfelder, S.E.; Lima de Carvalho Neto, S.; Pascoal Damas, M.S.; Toledo Viviani, J.C.; Mazur, L.P.; Marinho, B.A.; Pereira, L.d.S.; da Silva, A.; Borges Valle, J.A.; et al. Oilfield produced water treatment by liquid-liquid extraction: A review. J. Pet. Sci. Eng. 2021, 199, 108282. [Google Scholar] [CrossRef]

- Ho, W.; Sirkar, K. Membrane Handbook; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Weller, S.; Steiner, W.A. Separation of Gases by Fractional Permeation through Membranes. J. Appl. Phys. 1950, 21, 279–283. [Google Scholar] [CrossRef]

- Bernardo, P.; Drioli, E. Membrane technology: Latest applications in the refinery and petrochemical field. Compr. Membr. Sci. Eng. 2010, 4, 211–239. [Google Scholar] [CrossRef]

- Fakhru’l-Razi, A.; Pendashteh, A.; Abdullah, L.C.; Biak, D.R.A.; Madaeni, S.S.; Abidin, Z.Z. Review of technologies for oil and gas produced water treatment. J. Hazard. Mater. 2009, 170, 530–551. [Google Scholar] [CrossRef]

- Igunnu, E.T.; Chen, G.Z. Produced water treatment technologies. Int. J. Low-Carbon Technol. 2012, 9, 157–177. [Google Scholar] [CrossRef] [Green Version]

- Robinson, D. Oil and gas: Treatment and discharge of produced waters onshore. Filtr. + Sep. 2013, 50, 40–46. [Google Scholar] [CrossRef]

- Ashaghi, K.; Ebrahimi, M.; Czermak, P. Ceramic ultra-and nanofiltration membranes for oilfield produced water treatment: A mini review. Open Environ. J. 2007, 1, 1–8. [Google Scholar] [CrossRef]

- Diya’uddeen, B.H.; Daud, W.M.A.W.; Abdul Aziz, A.R. Treatment technologies for petroleum refinery effluents: A review. Process Saf. Environ. Prot. 2011, 89, 95–105. [Google Scholar] [CrossRef]

- Judd, S. The MBR Book: Principles and Applications of Membrane Bioreactors for Water and Wastewater Treatment; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Eyvaz, M.; Arslan, S.; İmer, D.; Yüksel, E.; Koyuncu, İ. Forward Osmosis Membranes–A Review: Part I. In Osmotically Driven Membrane Processes-Approach, Development and Current Status; IntechOpen: London, UK, 2018; pp. 11–40. [Google Scholar]

- Vrijenhoek, E.M.; Hong, S.; Elimelech, M. Influence of membrane surface properties on initial rate of colloidal fouling of reverse osmosis and nanofiltration membranes. J. Membr. Sci. 2001, 188, 115–128. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, D.; Jiang, L.; Jin, J. Recent progress in developing advanced membranes for emulsified oil/water separation. NPG Asia Mater. 2014, 6, e101. [Google Scholar] [CrossRef]

- Hadidi, M.; Zydney, A.L. Fouling behavior of zwitterionic membranes: Impact of electrostatic and hydrophobic interactions. J. Membr. Sci. 2014, 452, 97–103. [Google Scholar] [CrossRef]

- Li, Y.S.; Yan, L.; Xiang, C.B.; Hong, L.J. Treatment of oily wastewater by organic–inorganic composite tubular ultrafiltration (UF) membranes. Desalination 2006, 196, 76–83. [Google Scholar] [CrossRef]

- Babayev, M.; Du, H.; Botlaguduru, V.S.V.; Kommalapati, R.R. Zwitterion-Modified Ultrafiltration Membranes for Permian Basin Produced Water Pretreatment. Water 2019, 11, 1710. [Google Scholar] [CrossRef] [Green Version]

- Chang, H.; Li, T.; Liu, B.; Chen, C.; He, Q.; Crittenden, J.C. Smart ultrafiltration membrane fouling control as desalination pretreatment of shale gas fracturing wastewater: The effects of backwash water. Environ. Int. 2019, 130, 104869. [Google Scholar] [CrossRef]

- Emani, S.; Uppaluri, R.; Purkait, M.K. Microfiltration of oil–water emulsions using low cost ceramic membranes prepared with the uniaxial dry compaction method. Ceram. Int. 2014, 40, 1155–1164. [Google Scholar] [CrossRef]

- Alpatova, A.; Kim, E.-S.; Dong, S.; Sun, N.; Chelme-Ayala, P.; El-Din, M.G. Treatment of oil sands process-affected water with ceramic ultrafiltration membrane: Effects of operating conditions on membrane performance. Sep. Purif. Technol. 2014, 122, 170–182. [Google Scholar] [CrossRef]

- Deriszadeh, A.; Husein, M.M.; Harding, T.G. Produced water treatment by micellar-enhanced ultrafiltration. Environ. Sci. Technol. 2010, 44, 1767–1772. [Google Scholar] [CrossRef]

- Chakrabarty, B.; Ghoshal, A.; Purkait, M. Ultrafiltration of stable oil-in-water emulsion by polysulfone membrane. J. Membr. Sci. 2008, 325, 427–437. [Google Scholar] [CrossRef]

- Chakrabarty, B.; Ghoshal, A.; Purkait, M. Cross-flow ultrafiltration of stable oil-in-water emulsion using polysulfone membranes. Chem. Eng. J. 2010, 165, 447–456. [Google Scholar] [CrossRef]

- Madaeni, S.; Gheshlaghi, A.; Rekabdar, F. Membrane treatment of oily wastewater from refinery processes. Asia-Pac. J. Chem. Eng. 2013, 8, 45–53. [Google Scholar] [CrossRef]

- Abadi, S.R.H.; Sebzari, M.R.; Hemati, M.; Rekabdar, F.; Mohammadi, T. Ceramic membrane performance in microfiltration of oily wastewater. Desalination 2011, 265, 222–228. [Google Scholar] [CrossRef]

- Liu, R.; Raman, A.K.Y.; Shaik, I.; Aichele, C.; Kim, S.-J. Inorganic microfiltration membranes incorporated with hydrophilic silica nanoparticles for oil-in-water emulsion separation. J. Water Process Eng. 2018, 26, 124–130. [Google Scholar] [CrossRef]

- Brdar-Jokanović, M. Boron toxicity and deficiency in agricultural plants. Int. J. Mol. Sci. 2020, 21, 1424. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Flexer, V.; Baspineiro, C.F.; Galli, C.I. Lithium recovery from brines: A vital raw material for green energies with a potential environmental impact in its mining and processing. Sci. Total Environ. 2018, 639, 1188–1204. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Mo, Y.; Qing, W.; Shao, S.; Tang, C.Y.; Li, J. Membrane-based technologies for lithium recovery from water lithium resources: A review. J. Membr. Sci. 2019, 591, 117317. [Google Scholar] [CrossRef]

- Tong, T.; Wallace, A.F.; Zhao, S.; Wang, Z. Mineral scaling in membrane desalination: Mechanisms, mitigation strategies, and feasibility of scaling-resistant membranes. J. Membr. Sci. 2019, 579, 52–69. [Google Scholar] [CrossRef]

- Goh, P.; Lau, W.; Othman, M.; Ismail, A. Membrane fouling in desalination and its mitigation strategies. Desalination 2018, 425, 130–155. [Google Scholar] [CrossRef]

- Miller, D.J.; Dreyer, D.R.; Bielawski, C.W.; Paul, D.R.; Freeman, B.D. Surface modification of water purification membranes. Angew. Chem. Int. Ed. 2017, 56, 4662–4711. [Google Scholar] [CrossRef] [Green Version]

- Werber, J.R.; Deshmukh, A.; Elimelech, M. The critical need for increased selectivity, not increased water permeability, for desalination membranes. Environ. Sci. Technol. Lett. 2016, 3, 112–120. [Google Scholar] [CrossRef]

- Epsztein, R.; DuChanois, R.M.; Ritt, C.L.; Noy, A.; Elimelech, M. Towards single-species selectivity of membranes with subnanometre pores. Nat. Nanotechnol. 2020, 15, 426–436. [Google Scholar] [CrossRef]

- Paul, D.R. Reformulation of the solution-diffusion theory of reverse osmosis. J. Membr. Sci. 2004, 241, 371–386. [Google Scholar] [CrossRef]

- Yasuda, H.; Lamaze, C.E.; Ikenberry, L.D. Permeability of solutes through hydrated polymer membranes. Part I. Diffusion of sodium chloride. Die Makromol. Chem. 1968, 118, 19–35. [Google Scholar] [CrossRef]

- Park, H.B.; Kamcev, J.; Robeson, L.M.; Elimelech, M.; Freeman, B.D. Maximizing the right stuff: The trade-off between membrane permeability and selectivity. Science 2017, 356, eaab0530. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wijmans, J.G.; Baker, R.W. The solution-diffusion model: A review. J. Membr. Sci. 1995, 107, 1–21. [Google Scholar] [CrossRef]

- Lonsdale, H.K.; Merten, U.; Riley, R.L. Transport properties of cellulose acetate osmotic membranes. J. Appl. Polym. Sci. 1965, 9, 1341–1362. [Google Scholar] [CrossRef]

- Doyle, D.A.; Cabral, J.M.; Pfuetzner, R.A.; Kuo, A.; Gulbis, J.M.; Cohen, S.L.; Chait, B.T.; MacKinnon, R. The Structure of the Potassium Channel: Molecular Basis of K+ Conduction and Selectivity. Science 1998, 280, 69–77. [Google Scholar] [CrossRef] [Green Version]

- Izatt†, R.M.; Lindh, G.C.; Clark, G.A.; Nakatsuji, Y.; Bradshaw, J.S.; Lamb, J.D.; Christensen, J.J. Proton-ionizable crown compounds: 5. Macrocycle-mediated proton-coupled transport of alkali metal cations in H2O CH2Cl2 H2O liquid membrane systems. J. Membr. Sci. 1987, 31, 1–13. [Google Scholar] [CrossRef]

- Hidefumi, S.; Keiichi, K.; Minoru, T.; Toshiyuki, S. Selective Lithium Ion Transport through Hollow-Fiber Membrane Containing Easily-Dissociable 14-Crown-4 Derivative. Bull. Chem. Soc. Jpn. 1989, 62, 3394–3396. [Google Scholar] [CrossRef] [Green Version]

- Hamilton, C.J.; Murphy, S.M.; Tighe, B.J. Synthetic hydrogels (10): Anomalous transport behaviour in crown ether-containing hydrogel membranes. Polymer 2000, 41, 3651–3658. [Google Scholar] [CrossRef]

- Sun, D.; Zhu, Y.; Meng, M.; Qiao, Y.; Yan, Y.; Li, C. Fabrication of highly selective ion imprinted macroporous membranes with crown ether for targeted separation of lithium ion. Sep. Purif. Technol. 2017, 175, 19–26. [Google Scholar] [CrossRef]

- Lu, J.; Qin, Y.; Zhang, Q.; Wu, Y.; Cui, J.; Li, C.; Wang, L.; Yan, Y. Multilayered ion-imprinted membranes with high selectivity towards Li+ based on the synergistic effect of 12-crown-4 and polyether sulfone. Appl. Surf. Sci. 2018, 427, 931–941. [Google Scholar] [CrossRef]

- Kimura, K.; Yoshinaga, M.; Kitazawa, S.; Shono, T. Synthesis of poly(vinyl alcohol)-based poly(crown ether)s and permeability of their polymeric membranes. J. Polym. Sci. Polym. Chem. Ed. 1983, 21, 2777–2785. [Google Scholar] [CrossRef]

- Tunca, U.; Yagci, Y. Crown ether-containing polymers. Prog. Polym. Sci. 1994, 19, 233–286. [Google Scholar] [CrossRef]

- Alexandratos, S.D.; Stine, C.L.; Sachleben, R.A.; Moyer, B.A. Immobilization of lithium-selective 14-crown-4 on crosslinked polymer supports. Polymer 2005, 46, 6347–6352. [Google Scholar] [CrossRef]

- Lawson, K.W.; Lloyd, D.R. Membrane distillation. J. Membr. Sci. 1997, 124, 1–25. [Google Scholar] [CrossRef]

- Zakrzewska-Trznadel, G.; Harasimowicz, M.; Chmielewski, A.G. Concentration of radioactive components in liquid low-level radioactive waste by membrane distillation. J. Membr. Sci. 1999, 163, 257–264. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Membrane distillation: A comprehensive review. Desalination 2012, 287, 2–18. [Google Scholar] [CrossRef]

- Schofield, R.; Fane, A.; Fell, C. Heat and mass transfer in membrane distillation. J. Membr. Sci. 1987, 33, 299–313. [Google Scholar] [CrossRef]

- Kebria, M.R.S.; Rahimpour, A. Membrane distillation: Basics, advances, and applications. In Advances in Membrane Technologies; IntechOpen: London, UK, 2020. [Google Scholar]

- Srisurichan, S.; Jiraratananon, R.; Fane, A. Mass transfer mechanisms and transport resistances in direct contact membrane distillation process. J. Membr. Sci. 2006, 277, 186–194. [Google Scholar] [CrossRef]

- Alklaibi, A.M.; Lior, N. Membrane-distillation desalination: Status and potential. Desalination 2005, 171, 111–131. [Google Scholar] [CrossRef]

- Macedonio, F.; Ali, A.; Poerio, T.; El-Sayed, E.; Drioli, E.; Abdel-Jawad, M. Direct contact membrane distillation for treatment of oilfield produced water. Sep. Purif. Technol. 2014, 126, 69–81. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Produced water treatment: Application of Air Gap Membrane Distillation. Desalination 2013, 309, 46–51. [Google Scholar] [CrossRef]

- Yao, M.; Woo, Y.C.; Tijing, L.D.; Choi, J.-S.; Shon, H.K. Effects of volatile organic compounds on water recovery from produced water via vacuum membrane distillation. Desalination 2018, 440, 146–155. [Google Scholar] [CrossRef] [Green Version]

- Thakur, A.K.; Hsieh, I.M.; Islam, M.R.; Lin, B.; Chen, C.-C.; Malmali, M. Performance of sweeping gas membrane distillation for treating produced water: Modeling and experiments. Desalination 2020, 492, 114597. [Google Scholar] [CrossRef]

- Al-Salmi, M.; Laqbaqbi, M.; Al-Obaidani, S.; Al-Maamari, R.S.; Khayet, M.; Al-Abri, M. Application of membrane distillation for the treatment of oil field produced water. Desalination 2020, 494, 114678. [Google Scholar] [CrossRef]

- Tavakkoli, S.; Lokare, O.R.; Vidic, R.D.; Khanna, V. A techno-economic assessment of membrane distillation for treatment of Marcellus shale produced water. Desalination 2017, 416, 24–34. [Google Scholar] [CrossRef]

- Al-Amshawee, S.; Yunus, M.Y.B.M.; Azoddein, A.A.M.; Hassell, D.G.; Dakhil, I.H.; Hasan, H.A. Electrodialysis desalination for water and wastewater: A review. Chem. Eng. J. 2020, 380, 122231. [Google Scholar] [CrossRef]

- Strathmann, H. Electrodialysis, a mature technology with a multitude of new applications. Desalination 2010, 264, 268–288. [Google Scholar] [CrossRef]

- Campione, A.; Gurreri, L.; Ciofalo, M.; Micale, G.; Tamburini, A.; Cipollina, A. Electrodialysis for water desalination: A critical assessment of recent developments on process fundamentals, models and applications. Desalination 2018, 434, 121–160. [Google Scholar] [CrossRef]

- Sirivedhin, T.; McCue, J.; Dallbauman, L. Reclaiming produced water for beneficial use: Salt removal by electrodialysis. J. Membr. Sci. 2004, 243, 335–343. [Google Scholar] [CrossRef]

- Sosa-Fernandez, P.A.; Post, J.W.; Ramdlan, M.S.; Leermakers, F.A.M.; Bruning, H.; Rijnaarts, H.H.M. Improving the performance of polymer-flooding produced water electrodialysis through the application of pulsed electric field. Desalination 2020, 484, 114424. [Google Scholar] [CrossRef]

- Guolin, J.; Xiaoyu, W.; Chunjie, H. The effect of oilfield polymer-flooding wastewater on anion-exchange membrane performance. Desalination 2008, 220, 386–393. [Google Scholar] [CrossRef]

- Zuo, X.; Wang, L.; He, J.; Li, Z.; Yu, S. SEM-EDX studies of SiO2/PVDF membranes fouling in electrodialysis of polymer-flooding produced wastewater: Diatomite, APAM and crude oil. Desalination 2014, 347, 43–51. [Google Scholar] [CrossRef]

- Sosa-Fernandez, P.A.; Post, J.W.; Leermakers, F.A.M.; Rijnaarts, H.H.M.; Bruning, H. Removal of divalent ions from viscous polymer-flooding produced water and seawater via electrodialysis. J. Membr. Sci. 2019, 589, 117251. [Google Scholar] [CrossRef]

- Xia, Q.; Guo, H.; Ye, Y.; Yu, S.; Li, L.; Li, Q.; Zhang, R. Study on the fouling mechanism and cleaning method in the treatment of polymer flooding produced water with ion exchange membranes. RSC Adv. 2018, 8, 29947–29957. [Google Scholar] [CrossRef] [Green Version]

- Finklea, H.; Lin, L.-S.; Khajouei, G. Electrodialysis of softened produced water from shale gas development. J. Water Process Eng. 2022, 45, 102486. [Google Scholar] [CrossRef]

- Malek, P.; Ortiz, J.M.; Richards, B.S.; Schäfer, A.I. Electrodialytic removal of NaCl from water: Impacts of using pulsed electric potential on ion transport and water dissociation phenomena. J. Membr. Sci. 2013, 435, 99–109. [Google Scholar] [CrossRef] [Green Version]

- Cifuentes-Araya, N.; Pourcelly, G.; Bazinet, L. Multistep mineral fouling growth on a cation-exchange membrane ruled by gradual sieving effects of magnesium and carbonate ions and its delay by pulsed modes of electrodialysis. J. Colloid Interface Sci. 2012, 372, 217–230. [Google Scholar] [CrossRef]

- Nativ, P.; Fridman-Bishop, N.; Nir, O.; Lahav, O. Dia-nanofiltration-electrodialysis hybrid process for selective removal of monovalent ions from Mg2+ rich brines. Desalination 2020, 481, 114357. [Google Scholar] [CrossRef]

- Conforti, K.M.; Bazant, M.Z. Continuous ion-selective separations by shock electrodialysis. AIChE J. 2020, 66, e16751. [Google Scholar] [CrossRef]

- Albayati, T.M.; Sabri, A.A.; Alazawi, R.A. Separation of methylene blue as pollutant of water by SBA-15 in a fixed-bed column. Arab. J. Sci. Eng. 2016, 41, 2409–2415. [Google Scholar] [CrossRef]

- Babel, S.; Kurniawan, T.A. Low-cost adsorbents for heavy metals uptake from contaminated water: A review. J. Hazard. Mater. 2003, 97, 219–243. [Google Scholar] [CrossRef]

- Beltrame, K.K.; Cazetta, A.L.; de Souza, P.S.; Spessato, L.; Silva, T.L.; Almeida, V.C. Adsorption of caffeine on mesoporous activated carbon fibers prepared from pineapple plant leaves. Ecotoxicol. Environ. Saf. 2018, 147, 64–71. [Google Scholar] [CrossRef] [PubMed]

- Enniya, I.; Rghioui, L.; Jourani, A. Adsorption of hexavalent chromium in aqueous solution on activated carbon prepared from apple peels. Sustain. Chem. Pharm. 2018, 7, 9–16. [Google Scholar] [CrossRef]

- Laksaci, H.; Khelifi, A.; Trari, M.; Addoun, A. Synthesis and characterization of microporous activated carbon from coffee grounds using potassium hydroxides. J. Clean. Prod. 2017, 147, 254–262. [Google Scholar] [CrossRef]

- Yang, K.; Jiang, Y.; Yang, J.; Lin, D. Correlations and adsorption mechanisms of aromatic compounds on biochars produced from various biomass at 700 C. Environ. Pollut. 2018, 233, 64–70. [Google Scholar] [CrossRef]

- Nadeem, M.; Mahmood, A.; Shahid, S.; Shah, S.; Khalid, A.; McKay, G. Sorption of lead from aqueous solution by chemically modified carbon adsorbents. J. Hazard. Mater. 2006, 138, 604–613. [Google Scholar] [CrossRef]

- Acosta, R.; Nabarlatz, D.; Sánchez-Sánchez, A.; Jagiello, J.; Gadonneix, P.; Celzard, A.; Fierro, V. Adsorption of Bisphenol A on KOH-activated tyre pyrolysis char. J. Environ. Chem. Eng. 2018, 6, 823–833. [Google Scholar] [CrossRef]

- Mendoza-Carrasco, R.; Cuerda-Correa, E.M.; Alexandre-Franco, M.F.; Fernández-González, C.; Gómez-Serrano, V. Preparation of high-quality activated carbon from polyethyleneterephthalate (PET) bottle waste. Its use in the removal of pollutants in aqueous solution. J. Environ. Manag. 2016, 181, 522–535. [Google Scholar] [CrossRef]

- Pandey, S.; Fosso-Kankeu, E.; Spiro, M.J.; Waanders, F.; Kumar, N.; Ray, S.S.; Kim, J.; Kang, M. Equilibrium, kinetic, and thermodynamic studies of lead ion adsorption from mine wastewater onto MoS2-clinoptilolite composite. Mater. Today Chem. 2020, 18, 100376. [Google Scholar] [CrossRef]

- Malekmohammadi, S.; Mirbagheri, A.; Ehteshami, M. Comparison of silica, activated carbon, and zeolite adsorbents in the removal of ammonium, iron, COD, turbidity and phosphate pollutants, and investigating the effect of discharge on the removal of pollutants. Int. J. Humanit. Cult. Stud. (IJHCS) 2016, 3, 667–679, ISSN 2356-5926. [Google Scholar]

- Bandura, L.; Woszuk, A.; Kołodyńska, D.; Franus, W. Application of Mineral Sorbents for Removal of Petroleum Substances: A Review. Minerals 2017, 7, 37. [Google Scholar] [CrossRef] [Green Version]

- Hamidpour, M.; Kalbasi, M.; Afyuni, M.; Shariatmadari, H.; Holm, P.E.; Hansen, H.C.B. Sorption hysteresis of Cd(II) and Pb(II) on natural zeolite and bentonite. J. Hazard. Mater. 2010, 181, 686–691. [Google Scholar] [CrossRef]

- Yang, X.; Yang, S.; Yang, S.; Hu, J.; Tan, X.; Wang, X. Effect of pH, ionic strength and temperature on sorption of Pb(II) on NKF-6 zeolite studied by batch technique. Chem. Eng. J. 2011, 168, 86–93. [Google Scholar] [CrossRef]

- Vega, D.P.; González, C.; Escalante, C.A.; Gallego, J.; Salamanca, M.; Manrique-Losada, L. Use of faujasite-type zeolite for ion adsorption in municipal wastewater. Tecnol. Cienc. Agua 2018, 9, 184–208. [Google Scholar]

- Payne, K.B.; Abdel-Fattah, T.M. Adsorption of Divalent Lead Ions by Zeolites and Activated Carbon: Effects of pH, Temperature, and Ionic Strength. J. Environ. Sci. Health Part A 2004, 39, 2275–2291. [Google Scholar] [CrossRef]

- Paliulis, D. Removal of Formaldehyde from Synthetic Wastewater Using Natural and Modified Zeolites. Pol. J. Environ. Stud. 2016, 25, 251–257. [Google Scholar] [CrossRef]

- Al-Haddad, A.; Chmielewska, E.; Al-Radwan, S. A brief comparable lab. examination for oil refinery wastewater treatment using the zeolitic and carbonaceous adsorbents. Pet. Coal 2007, 49, 21–26. [Google Scholar]

- Doyle, D.; Brown, A. Produced water treatment and hydrocarbon removal with organoclay. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 17–19 October 2000. [Google Scholar]

- Doyle, D.; Brown, A. Field test of produced water treatment with polymer modified bentonite. In Proceedings of the SPE Rocky Mountain Regional Meeting, Long Beach, CA, USA, 25–27 June 1997. [Google Scholar]

- Arthur, J.D.; Langhus, B.G.; Patel, C. Technical Summary of Oil & Gas Produced Water Treatment Technologies; All Consulting, LLC: Tulsa, OK, USA, 2005. [Google Scholar]

- Jan, R.; Reed, T. New caustic process for softening produced water for steam generation. SPE Prod. Eng. 1992, 7, 199–202. [Google Scholar] [CrossRef]

- Hendges, L.T.; Costa, T.C.; Temochko, B.; Gómez González, S.Y.; Mazur, L.P.; Marinho, B.A.; da Silva, A.; Weschenfelder, S.E.; de Souza, A.A.U.; de Souza, S.M.A.G.U. Adsorption and desorption of water-soluble naphthenic acid in simulated offshore oilfield produced water. Process Saf. Environ. Prot. 2021, 145, 262–272. [Google Scholar] [CrossRef]

- Nasrollahzadeh, M.; Sajjadi, M.; Iravani, S.; Varma, R.S. Starch, cellulose, pectin, gum, alginate, chitin and chitosan derived (nano)materials for sustainable water treatment: A review. Carbohydr. Polym. 2021, 251, 116986. [Google Scholar] [CrossRef] [PubMed]

- Sajjadi, M.; Ahmadpoor, F.; Nasrollahzadeh, M.; Ghafuri, H. Lignin-derived (nano)materials for environmental pollution remediation: Current challenges and future perspectives. Int. J. Biol. Macromol. 2021, 178, 394–423. [Google Scholar] [CrossRef] [PubMed]

- Sirajudheen, P.; Poovathumkuzhi, N.C.; Vigneshwaran, S.; Chelaveettil, B.M.; Meenakshi, S. Applications of chitin and chitosan based biomaterials for the adsorptive removal of textile dyes from water—A comprehensive review. Carbohydr. Polym. 2021, 273, 118604. [Google Scholar] [CrossRef] [PubMed]

- Kamińska, G.; Bohdziewicz, J. Potential of various materials for adsorption of micropollutants from wastewater. Environ. Prot. Eng. 2016, 42, 161–178. [Google Scholar]

- Alardhi, S.M.; Albayati, T.M.; Alrubaye, J.M. Adsorption of the methyl green dye pollutant from aqueous solution using mesoporous materials MCM-41 in a fixed-bed column. Heliyon 2020, 6, e03253. [Google Scholar] [CrossRef] [Green Version]

- Patel, H. Fixed-bed column adsorption study: A comprehensive review. Appl. Water Sci. 2019, 9, 45. [Google Scholar] [CrossRef] [Green Version]

- Albayati, T.M.; Kalash, K.R. Polycyclic aromatic hydrocarbons adsorption from wastewater using different types of prepared mesoporous materials MCM-41in batch and fixed bed column. Process Saf. Environ. Prot. 2020, 133, 124–136. [Google Scholar] [CrossRef]

- Crini, G.; Lichtfouse, E. Advantages and disadvantages of techniques used for wastewater treatment. Environ. Chem. Lett. 2019, 17, 145–155. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).