Mechanical and Adhesive Properties of Hydrothermally Treated Bamboo Composites Reinforced with Phenolic Resin: Effect of Impregnation with Silica Nanoparticles

Abstract

1. Introduction

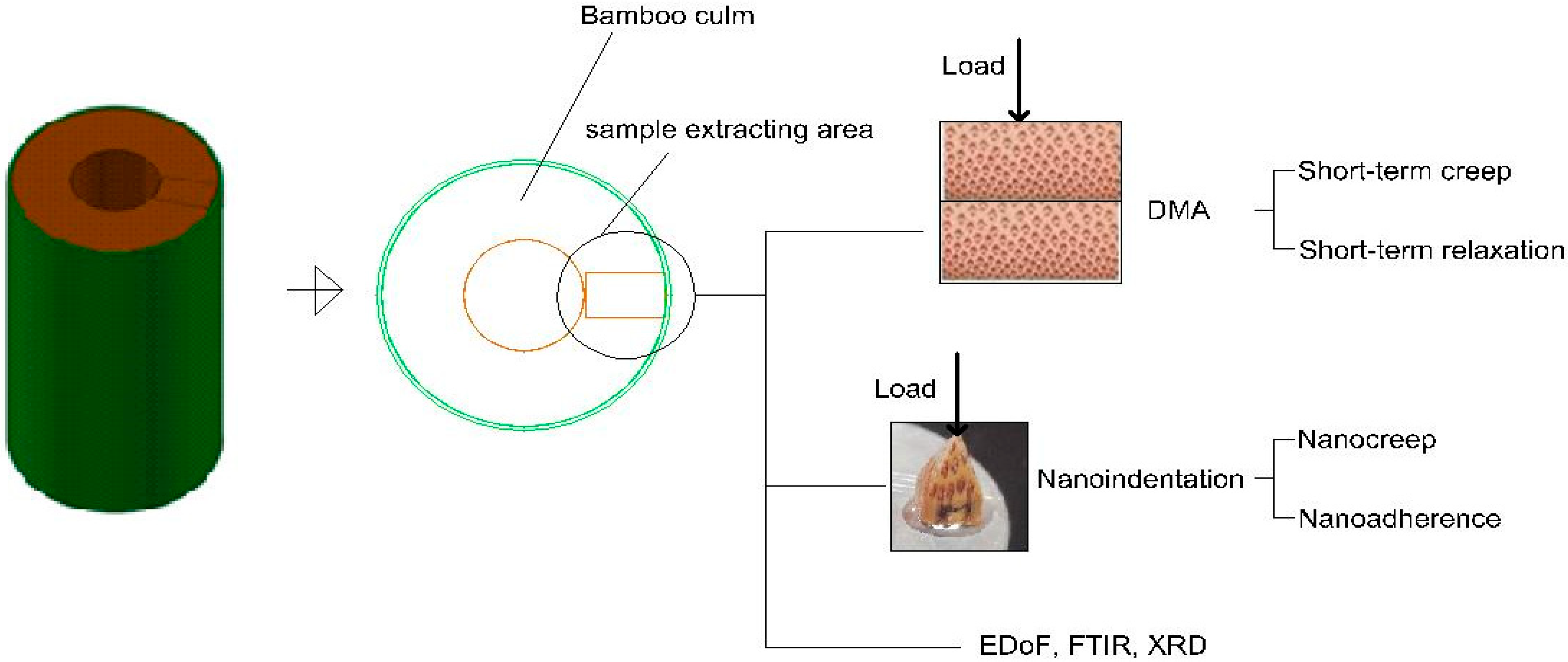

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation, Thermal Treatment and Resin Coating

- -

- Batch GB-0-N underwent a treatment protocol beginning with brush-coating of the conical surface using thermosetting phenolic resin BR2130. Immediately following coating application, samples were transferred to a vacuum oven where simultaneous resin impregnation and curing occurred under a residual pressure of 10 mbar at 130 °C for 4 h, ensuring complete integration of the resin into the bamboo matrix.

- -

- An additional hot water treatment was applied to some samples: immersion in pure water at 70 °C for 15 min. This specific temperature and treatment duration were selected based on observations of bamboo bending techniques employed by several Chinese companies. This treatment led to the creation of batch GB-W-N, which was treated with the resin according to the same protocol as GB-0-N after immersion. For each sample, 10 points were evaluated by nanoindentation.

- -

- GB-0: Resin impregnation and hot pressing at 130 °C for 30 min, followed by vacuum drying for 3 h and 30 min.

- -

- GB-W: Hydrothermal treatment (immersion at 70 °C for 15 min), followed by resin impregnation, pressing, and drying according to the same protocol as GB-0.

2.3. Energy Dispersive X-Ray Spectroscopy (EDX)

2.4. DMA and Mathematical Models of Short-Term Creep and Relaxation

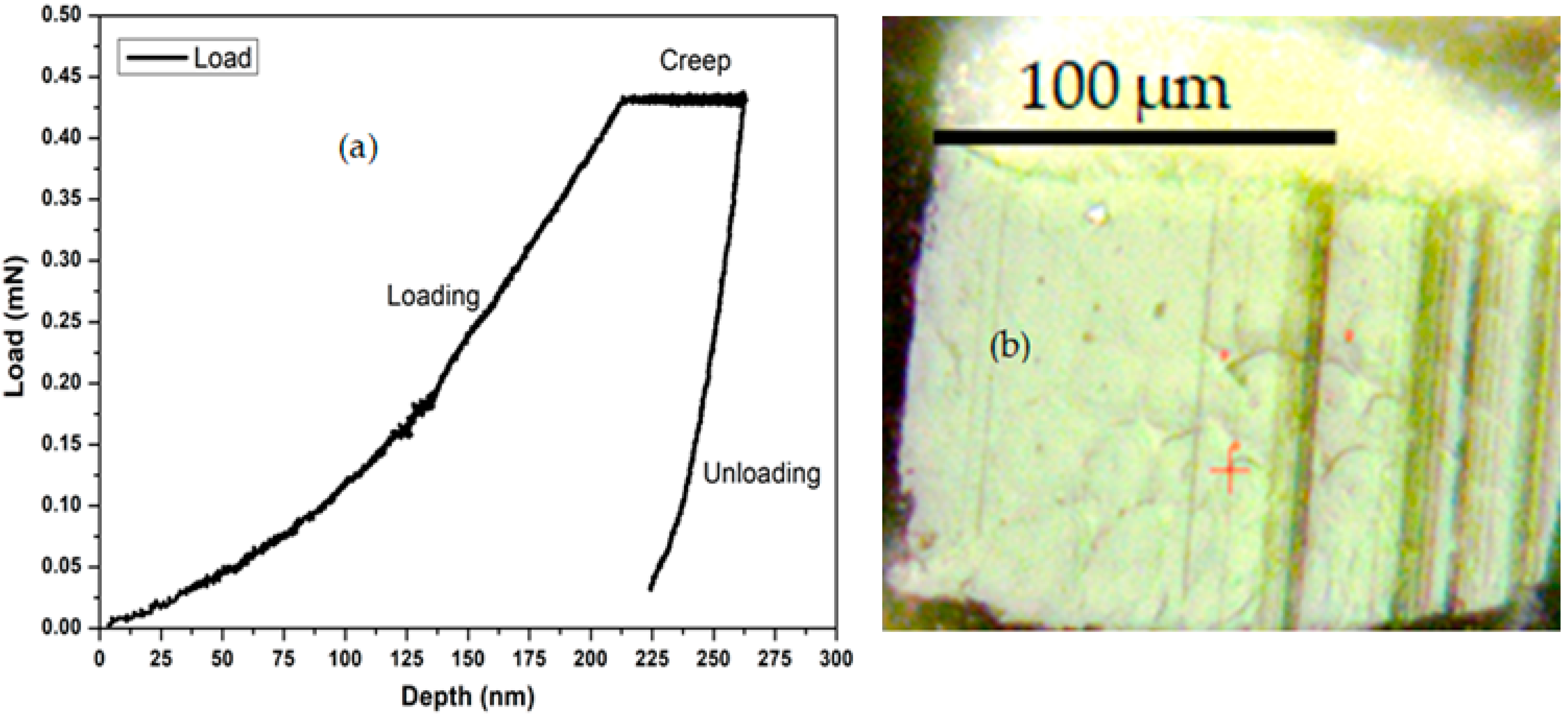

2.5. Nanoindentation

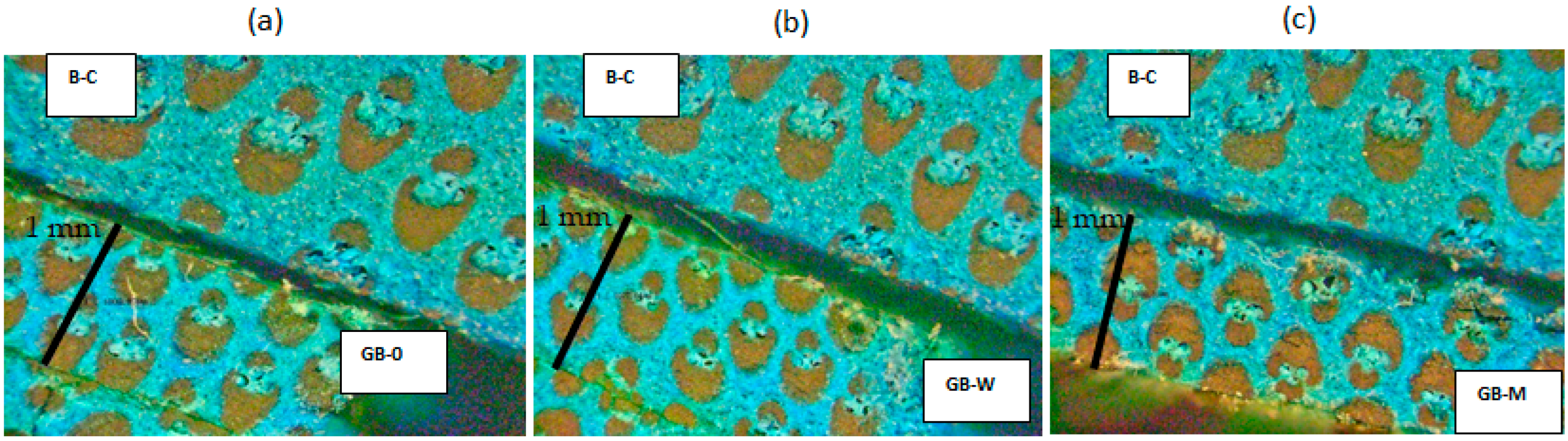

2.6. Extended Depth of Field Microscope (EDoF)

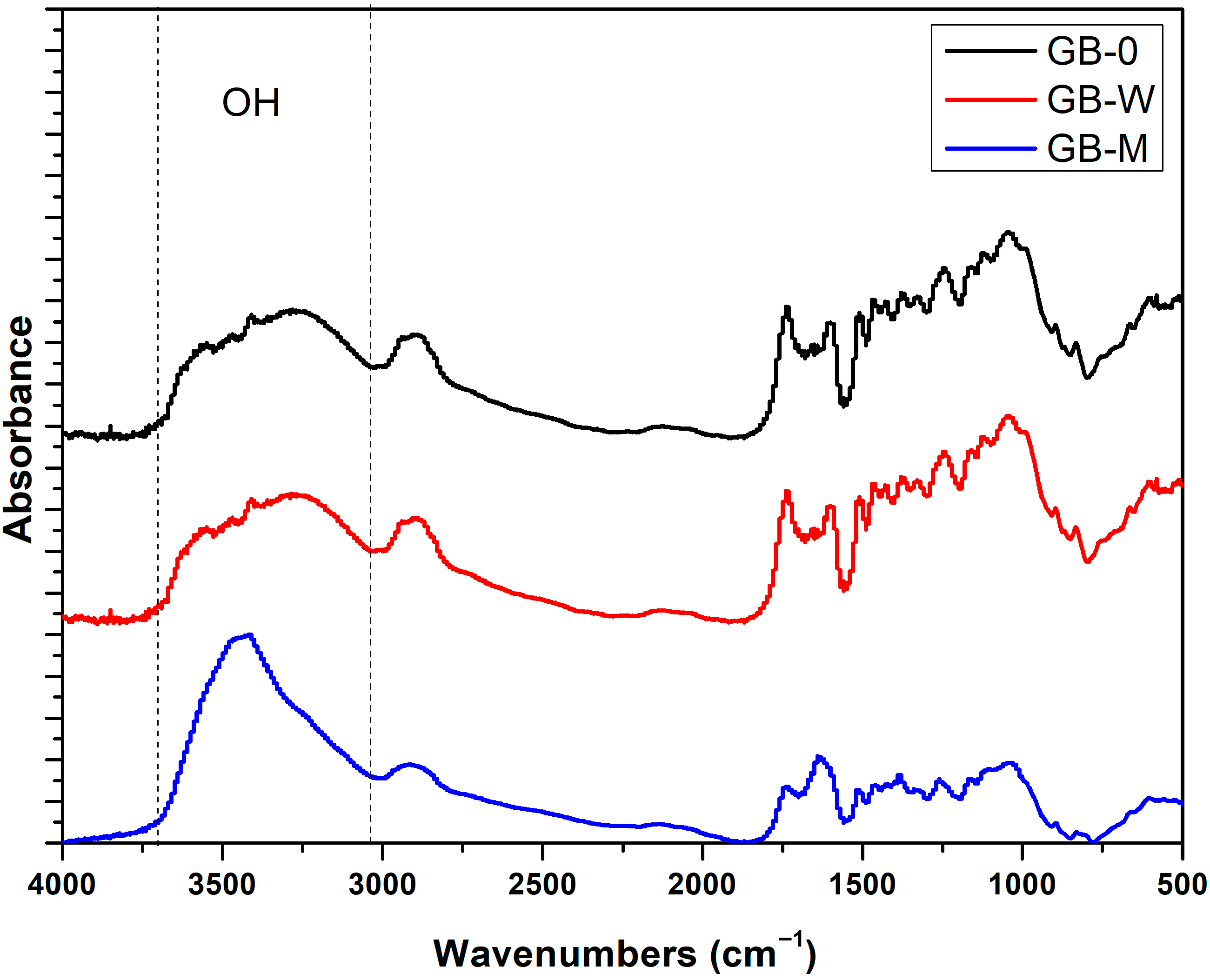

2.7. XRD

2.8. FTIR

3. Results and Discussion

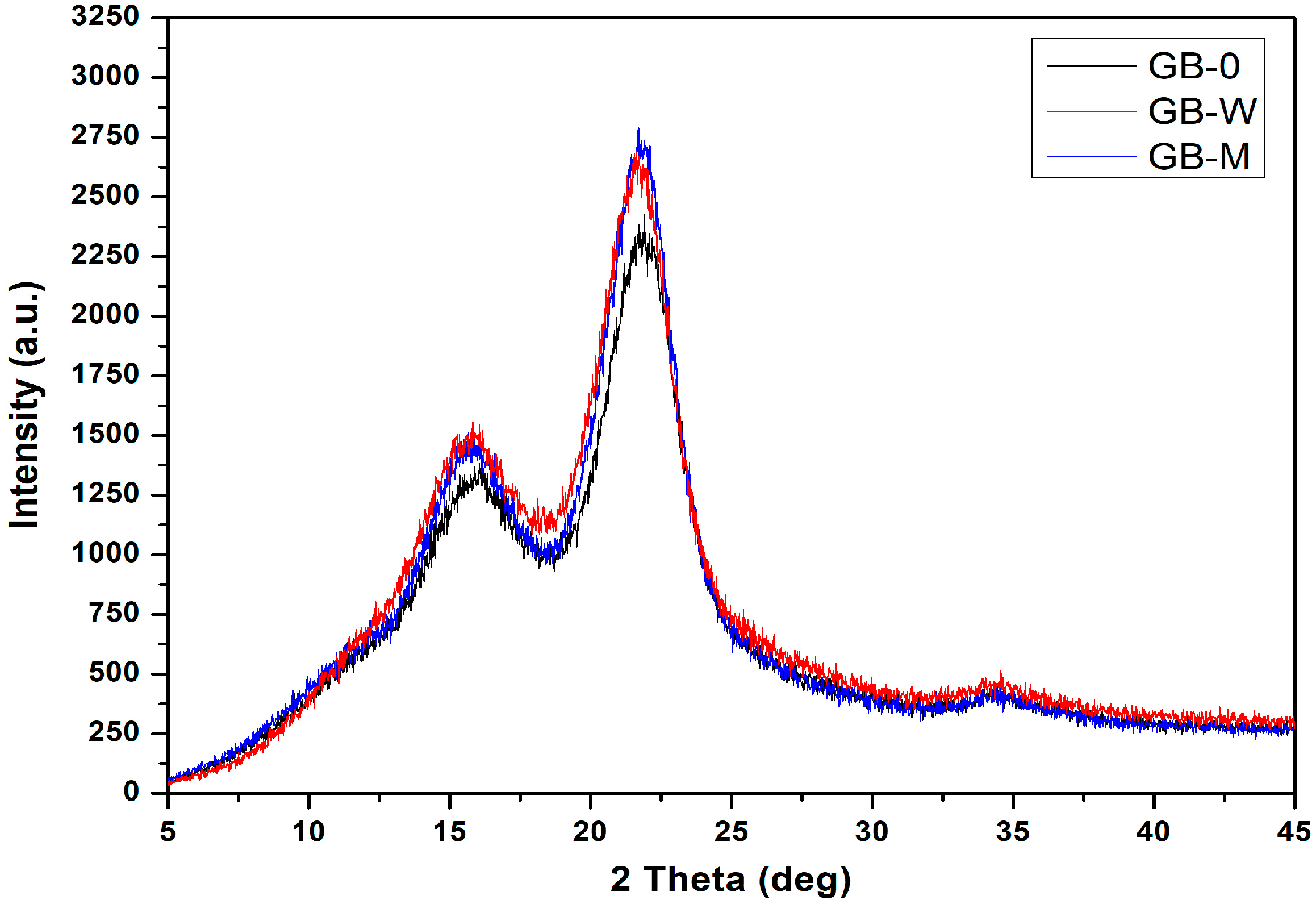

3.1. Cristallinity

3.2. Short-Term Creep and Relaxation

3.3. Nanocreep and Nanoadherence

3.4. Resin Penetration in Bamboo

3.5. Affinity of Different Bamboo Types with Phenolic Resin

3.6. Infiltration of the Silicate Network and Magnetite into the Bamboo Matrix

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Chen, X.; Li, Y.; Liu, H.; Huang, B.; Fang, C. Thermo-hygro mechanical flattening of bamboo with intact wall structure: Synergistic enhancement of mechanical properties and dimensional stability. Compos. Part B Eng. 2025, 303, 112582. [Google Scholar] [CrossRef]

- Al-Rukaibawi, L.S.; Károlyi, G. Through-thickness distribution of bamboo tensile strength parallel to fibres. SN Appl. Sci. 2023, 5, 174. [Google Scholar] [CrossRef]

- Amatosa, T.A.; Loretero, M.E.; Manilhig, M.G.; Laksono, A.D.; Yen, Y. Determination of thermal properties and fire retardant ability of Philippine bamboo as natural thermal insulation. Int. J. Appl. Eng. Res. 2019, 14, 1764–1771. [Google Scholar]

- Boucher, P.; Fréchard, V.; Ramirez-Cardona, D.; Ouellet-Plamondon, C. Overcoming Challenges in Bamboo Connections: A Review of Mechanical Properties and Structural Considerations. In Bio-Based Building Materials, Proceedings of ICBBM 2025, Rio de Janeiro, Brazil, 17–20 June 2025; Amziane, S., Filho, R.D.T., da Gloria, M.Y.R., Page, J., Eds.; RILEM Bookseries; Springer: Cham, Switzerland, 2025; Volume 60. [Google Scholar] [CrossRef]

- Wang, Z.; Li, H.; Zhou, W.; Ying, L. Study on basic mechanical properties of parallel Neosinocalamus affinis bamboo stand lumber. Structures 2025, 78, 109254. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, L.; Bao, M.; Lin, F.; Wu, X.; Li, Y.; Gong, Y.; Gu, W.; Zhang, W. Physical and mechanical properties and microstructure characterization of thermally modified flattened bamboo (Phyllostachys edulis) material. Forests 2025, 16, 694. [Google Scholar] [CrossRef]

- Xie, X.; Zhao, Y.; Mao, S.; Li, Y. Fabrication of a novel curved bamboo component based on flattened bamboo: Process analysis and bending property investigation. Constr. Build. Mater. 2025, 464, 140235. [Google Scholar] [CrossRef]

- Bai, T.; Yan, J.; Lu, J.; Zhou, J.; Yao, H.; He, X.; Gu, S.; Tong, Z.; Shi, S.Q.; Li, J.; et al. Engineering transverse cell deformation of bamboo by controlling localized moisture content. Nat. Commun. 2025, 16, 4077. [Google Scholar] [CrossRef]

- Tang, T.; Fang, C.; Sui, Z.; Fu, C.; Li, X. Hygrothermal treatment improves the dimensional stability and visual appearance of round bamboo. Polymers 2025, 17, 747. [Google Scholar] [CrossRef]

- Du, J.; Yang, K.-L.; Yuan, Z.-Q.; Liu, Z.M.; Li, X.Y.; Liu, S.J.; Li, C.C.; Meng, S.T.; Wu, R.M. Effect of physical treatment methods on the properties of natural bamboo materials. Constr. Build. Mater. 2023, 394, 132170. [Google Scholar] [CrossRef]

- Ali, M.R.; Abdullah, U.H.; Ashaari, Z.; Hamid, N.H.; Hua, L.S. Hydrothermal modification of wood: A review. Polymers 2021, 13, 2612. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Peng, H.; Niu, S.; Liu, X.; Li, Y. Effect of high-temperature hydrothermal treatment on chemical, mechanical, physical, and surface properties of Moso bamboo. Forests 2022, 13, 712. [Google Scholar] [CrossRef]

- Saikia, P.; Dutta, D.; Kalita, D.; Bora, J.J.; Goswami, T. Improvement of mechano-chemical properties of bamboo by bio-chemical treatment. Constr. Build. Mater. 2015, 101, 1031–1036. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, X.; Li, H.; Yin, C.; Huang, T.; Wan, J.; Ni, K.; Du, G.; Yang, L. High-performance glued-bamboo through activation of chemical bonding interface. Coll. Surf. A Physicochem. Eng. Asp. 2024, 701, 134874. [Google Scholar] [CrossRef]

- Jimenez, J.P.; Ramos, J.E.C. Glue-bond performance of oil-heat-treated bamboo using cold-setting and thermosetting adhesives for engineered bamboo applications. Adv. Bamboo Sci. 2025, 11, 100140. [Google Scholar] [CrossRef]

- Ji, S.; Mou, Q.; Yuan, G.; Ren, H.; Li, X. Dowel-bearing behavior of bamboo scrimber for bolted-type joint. Ind. Crops Prod. 2023, 193, 116178. [Google Scholar] [CrossRef]

- Malkowska, D.; Norman, J.; Trujillo, D. Theoretical and experimental study on laterally loaded nailed bamboo connection. Constr. Build. Mater. 2022, 342, 127971. [Google Scholar] [CrossRef]

- Wang, F.; Yang, J. Experimental and numerical investigations on load-carrying capacity of dowel-type bolted bamboo joints. Eng. Struct. 2020, 209, 109952. [Google Scholar] [CrossRef]

- Song, S.; Qiao, J.; Hao, X.; Li, T.; Li, X.; Xu, K.; Li, X.; Wu, Y. Effect of drying temperature on the curing properties of phenolic resin-impregnated heat-treated bamboo bundles. Wood Mater. Sci. Eng. 2025, 20, 281–290. [Google Scholar] [CrossRef]

- Ji, X.; Wang, J.; Wang, Z.; Mao, B.; Cao, Y.; Xie, Y.; Yan, Y. Epoxy-POSS toughened phenol-formaldehyde resin adhesive and its enhancement on the interfacial bonding strength of bamboo based composite. Polym. Compos. 2025, 46, 870–885. [Google Scholar] [CrossRef]

- Yu, Y.-L.; Huang, X.-A.; Yu, W.-J. High performance of bamboo-based fiber composites from long bamboo fiber bundles and phenolic resins. J. Appl. Polym. Sci. 2014, 131, 40371. [Google Scholar] [CrossRef]

- Yang, Z.; Meng, X.; Zeng, G.; Wei, J.; Wang, C.; Yu, W. Effect of resin content on the structure, water resistance and mechanical behavior of high-density bamboo scrimbers. Polymers 2024, 16, 797. [Google Scholar] [CrossRef]

- Gao, X.; Zhu, D.; Fan, S.; Rahman, M.Z.; Guo, S.; Chen, F. Structural and mechanical properties of bamboo fiber bundle and fiber/bundle reinforced composites: A review. J. Mater. Res. Technol. 2022, 19, 1162–1190. [Google Scholar] [CrossRef]

- Mousavi, S.R.; Faraj Nejad, S.; Jafari, M.; Paydayesh, A. Polypropylene/ethylene propylene diene monomer/cellulose nanocrystal ternary blend nanocomposites: Effects of different parameters on mechanical, rheological, and thermal properties. Polym. Compos. 2021, 42, 4187. [Google Scholar] [CrossRef]

- Kazemi, M.; Shanmugam, L.; Lu, D.; Wang, X.; Wang, B.; Yang, J. Mechanical properties and failure modes of hybrid fiber reinforced polymer composites with a novel liquid thermoplastic resin, Elium®. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105523. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Durability of bamboo-glass fiber reinforced matrix hybrid composites. Compos. Sci. Technol. 2003, 63, 375–387. [Google Scholar] [CrossRef]

- Wang, Y.; Jia, S.; Ling, Z.; Ma, J.; Ma, X.; Fang, C. Balancing the strength and toughness in delignified bamboo through the changing of silicon composition. Mater. Des. 2024, 247, 113408. [Google Scholar] [CrossRef]

- Lou, Z.; Han, X.; Liu, J.; Ma, Q.; Yan, H.; Yuan, C.; Yang, L.; Han, H.; Weng, F.; Li, Y. Nano-Fe3O4/bamboo bundles/phenolic resin oriented recombination ternary composite with enhanced multiple functions. Compos. Part B Eng. 2021, 226, 109335. [Google Scholar] [CrossRef]

- He, L.; Bao, G.; Yu, X.; Zhang, X.; Jin, X.; Yu, Z.; Zhang, R.; Qin, D. Synergistic enhancement of flame retardancy, mechanical properties, dimensional stability, and mold resistance in bamboo via silica mineralization and hydrophobic treatment. Chem. Eng. J. 2025, 510, 161505. [Google Scholar] [CrossRef]

- Foadieng, E.; Fouotsa, W.C.M.; Azeufack, T.U.G.; Talla, P.K.; Fogue, M. Mechanical Behavior of Pericopsis elata Relative to Age during Growth. Adv. Mater. Sci. Eng. 2021, 2021, 4374181. [Google Scholar] [CrossRef]

- Tabor, D. Moh’s hardness scale—A physical interpretation. Proc. Phys. Soc. B 1954, 67, 249–257. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Salem, K.S.; Kasera, N.K.; Rahman, A.; Jameel, H.; Habibi, Y.; Eichhorn, S.J.; French, A.D.; Pal, L.; Lucia, L.A. Comparison and assessment of methods for cellulose crystallinity determination. Chem. Soc. Rev. 2023, 52, 6417–6446. [Google Scholar] [CrossRef]

- Hu, M.; Wang, C.; Lu, C.; Anuar, N.I.S.; Yousfani, S.H.S.; Jing, M.; Chen, Z.; Zakaria, S.; Zuo, H. Investigation on the classified extraction of the bamboo fiber and its properties. J. Nat. Fibers 2022, 17, 1798–1808. [Google Scholar] [CrossRef]

- Zheng, J.; Aziz, T.; Fan, H.; Haq, F.; Khan, F.U.; Ullah, R.; Ullah, B.; Khattak, N.S.; Wei, J. Synergistic impact of cellulose nanocrystals with multiple resins on thermal and mechanical behavior. Z. Phys. Chem. 2021, 235, 1247–1262. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, Y.; Zhang, Y.; Yu, W. Enhanced mechanism of physical and mechanical properties of bamboo scrimber prepared by roller-pressing impregnation method. Ind. Crops Prod. 2025, 223, 119962. [Google Scholar] [CrossRef]

- Fuentes, C.A.; Brughmans, G.; Tran, L.Q.N.; Dupont-Gillain, C.; Verpoest, I.; Van Vuure, A. Mechanical behaviour and practical adherence at a bamboo composite interface: Physical adherence and mechanical interlocking. Compos. Sci. Technol. 2015, 109, 40–47. [Google Scholar] [CrossRef]

- Xie, J.; Qi, J.; Hu, T.; De Hoop, C.F.; Hse, C.Y.; Shupe, T.F. Effect of fabricated density and bamboo species on physical-mechanical properties of bamboo fiber bundle reinforced composites. J. Mater. Sci. 2016, 51, 7480–7490. [Google Scholar] [CrossRef]

- Shi, L.; Shen, X.; Qi, H.; Zhang, X.; Shu, R. Functionalized lignin magnetic composites and their absorption capability for methylene blue and methyl orange in aqueous solution. Iran. Polym. J. 2025, 34, 339–353. [Google Scholar] [CrossRef]

- Prabhakar, M.N.; Venakat Chalapathi, K.; Rehman, S.A.U.; Song, J.-I. Effect of a synthesized chitosan flame retardant on the flammability, thermal properties, and mechanical properties of vinyl ester/bamboo nonwoven fiber composites. Cellulose 2021, 28, 11625–11643. [Google Scholar] [CrossRef]

- Huang, Y.; Lin, Q.; Yang, C.; Bian, G.; Zhang, Y.; Yu, W. Multi-scale characterization of bamboo bonding interfaces with phenol-formaldehyde resin of different molecular weight to study the bonding mechanism. J. R. Soc. Interface 2020, 17, 20190755. [Google Scholar] [CrossRef] [PubMed]

- Collin, B.; Doelsch, E.; Keller, C.; Panfili, F.; Meunier, J.-D. Distribution and variability of silicone, copper and zinc in different bamboo species. Plant Soil 2012, 351, 377–387. [Google Scholar] [CrossRef]

| 2θ (°) | GB-0 XRD Intensity (a.u.) | Cristallinity (%) | GB-W XRD Intensity (a.u.) | Cristallinity (%) | GB-M XRD Intensity (a.u.) | Cristallinity (%) |

|---|---|---|---|---|---|---|

| 15 | 1157 | 12.88 | 1408 | 21.24 | 1358 | 27.91 |

| 18.5 | 1008 | - | 1109 | 979 | ||

| 22 | 2164 | 53.56 | 2453 | 54.79 | 2707 | 63.84 |

| Tests | Samples | MOE (MPa) | (MPa·minα) | Initial Strain (%) | |

|---|---|---|---|---|---|

| Creep | GB-0 | 38,284 | 0.235 * | 4464 * | 0.01306 |

| GB-W | 36,405 | 0.295 * | 3452 * | 0.01373 | |

| GB-M | 38,423 | 0.265 * | 3920 * | 0.01301 | |

| Relaxation | GB-0 | 38,274 | 0.591 * | 981,892 * | - |

| GB-W | 38,780 | 0.584 * | 807,662 * | - | |

| GB-M | 38,423 | 0.538 * | 805,271 * | - |

| Samples | MOE (MPa) | (MPa·minα) | |

|---|---|---|---|

| GB-0 | 12,664 | 0.453 * | 0.864 * |

| GB-W | 8992 | 0.389 * | 1.555 * |

| GB-M | 10,317 | 0.506 * | 0.944 * |

| Specimens | Cubic Fit | Adherence Function |

|---|---|---|

| GB-0 * | 102.07 + 391.16L − 846.03 + 815.91 | 102.07L + 195.58 − 282.01 + 203.98 + C |

| GB-W * | 104.28 + 449.57L− 879.03 + 807.82 | 104.28L + 224.79 − 293.01 + 201.96 + C |

| GB-M * | 101.98 + 487.65L − 1128.12 + 1139.11 | 101.98L + 243.83 − 376.04 + 284.78 + C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bessala, L.F.B.; Li, Y. Mechanical and Adhesive Properties of Hydrothermally Treated Bamboo Composites Reinforced with Phenolic Resin: Effect of Impregnation with Silica Nanoparticles. Polymers 2025, 17, 2989. https://doi.org/10.3390/polym17222989

Bessala LFB, Li Y. Mechanical and Adhesive Properties of Hydrothermally Treated Bamboo Composites Reinforced with Phenolic Resin: Effect of Impregnation with Silica Nanoparticles. Polymers. 2025; 17(22):2989. https://doi.org/10.3390/polym17222989

Chicago/Turabian StyleBessala, Lionnel Frederique Bidzanga, and Yanjun Li. 2025. "Mechanical and Adhesive Properties of Hydrothermally Treated Bamboo Composites Reinforced with Phenolic Resin: Effect of Impregnation with Silica Nanoparticles" Polymers 17, no. 22: 2989. https://doi.org/10.3390/polym17222989

APA StyleBessala, L. F. B., & Li, Y. (2025). Mechanical and Adhesive Properties of Hydrothermally Treated Bamboo Composites Reinforced with Phenolic Resin: Effect of Impregnation with Silica Nanoparticles. Polymers, 17(22), 2989. https://doi.org/10.3390/polym17222989