Experimental Investigation of Nanodiamond Reinforcement in PU for Enhancing Mechanical, Scratch, Rheological, Thermal, and Shape-Memory Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of Composite Samples

2.3. XRD Test

2.4. Tensile Test

2.5. Scratch and Hardness Test

2.6. DSC and TGA Test

2.7. Rheological Test

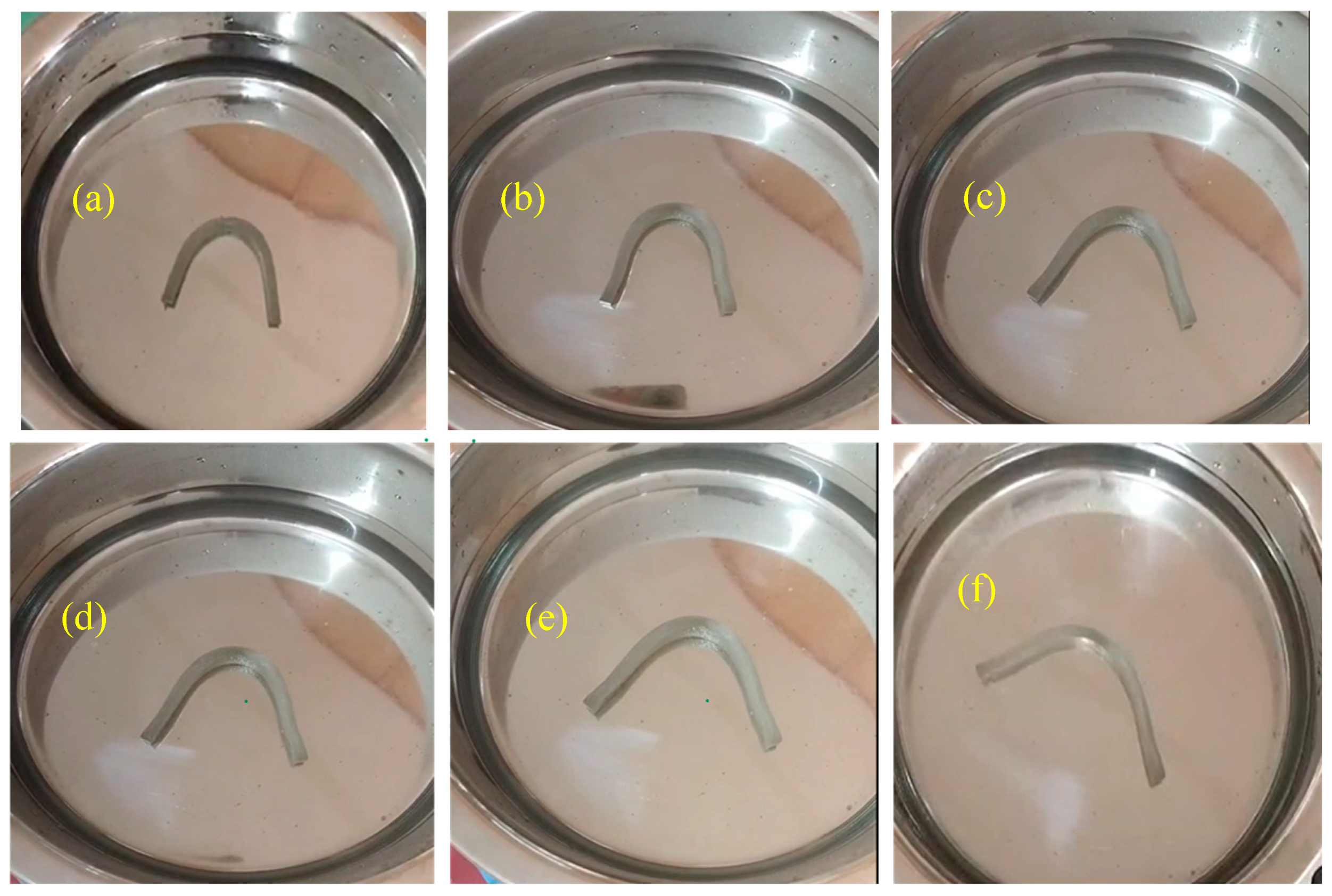

2.8. Heat-Responsive Shape-Memory Test

3. Results and Discussion

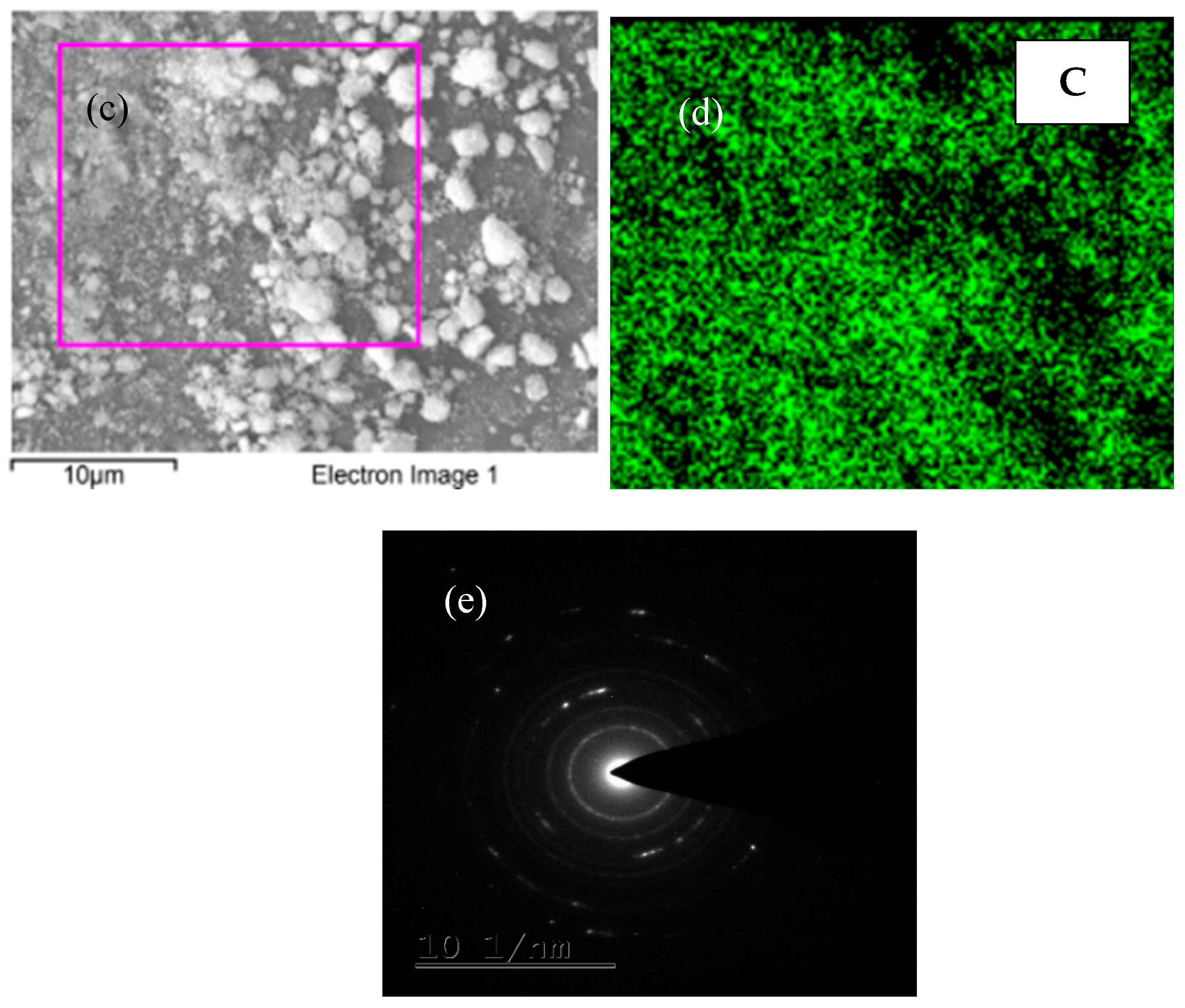

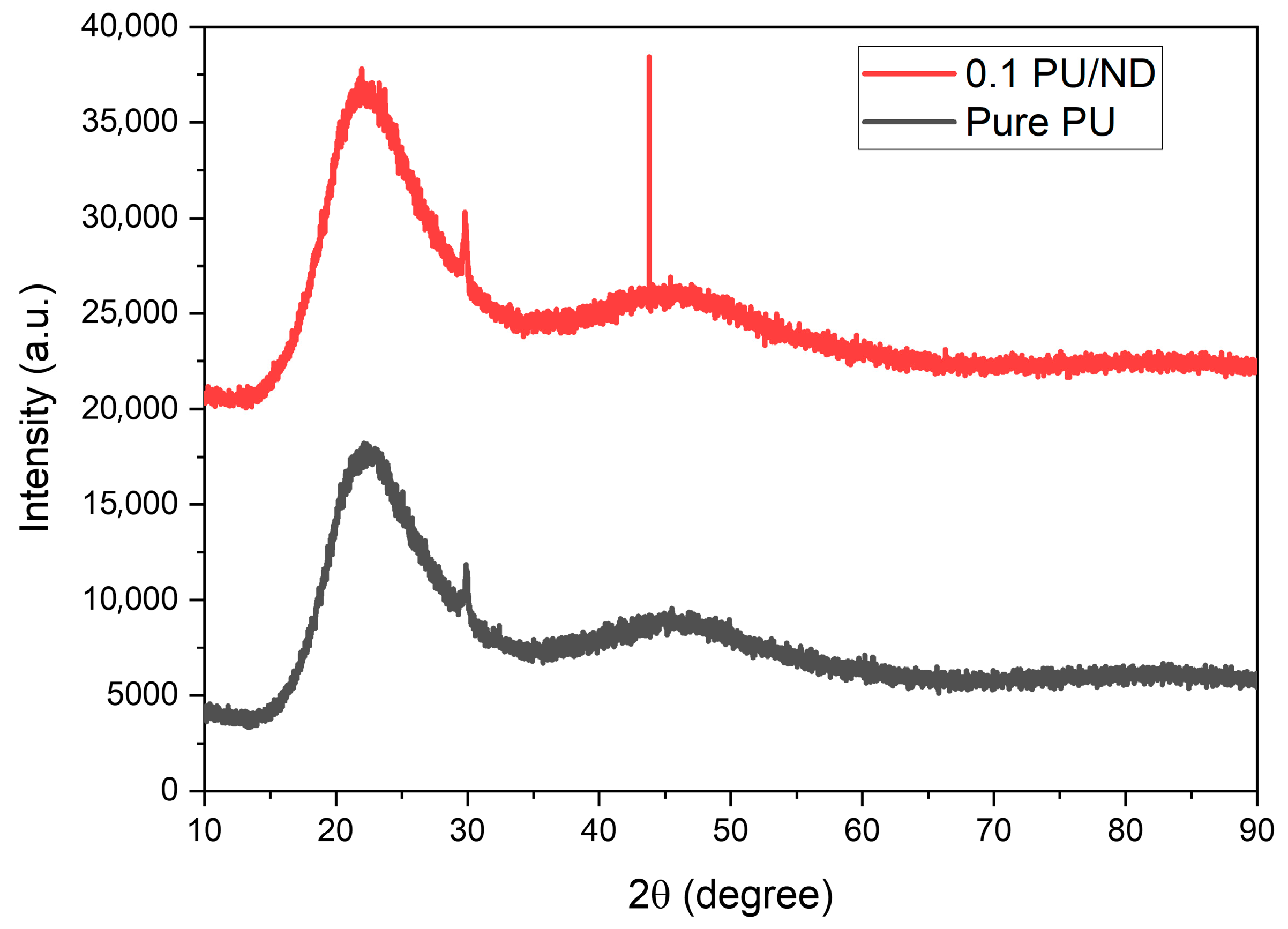

3.1. XRD Results

3.2. Tensile Properties

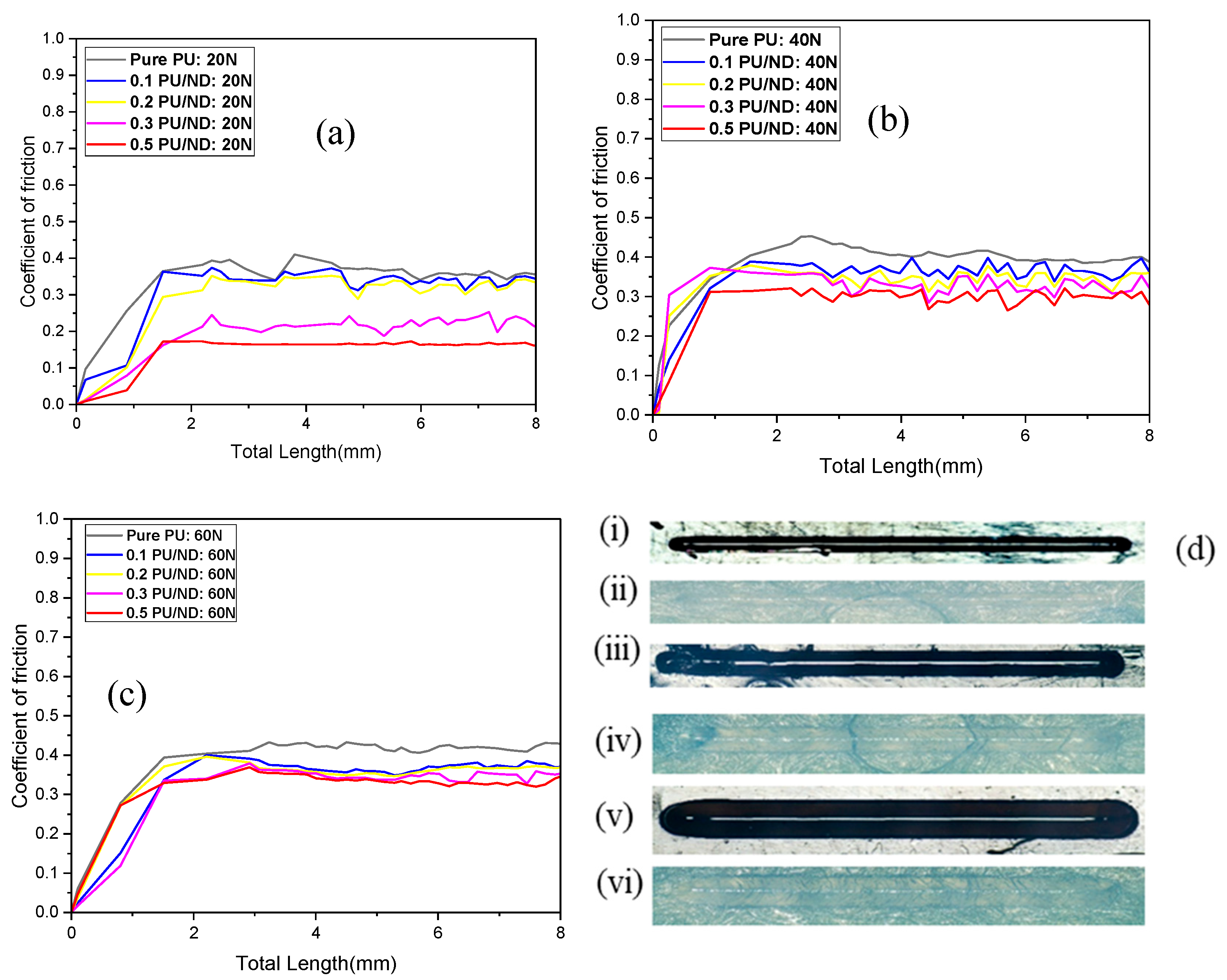

3.3. Scratch Test Results

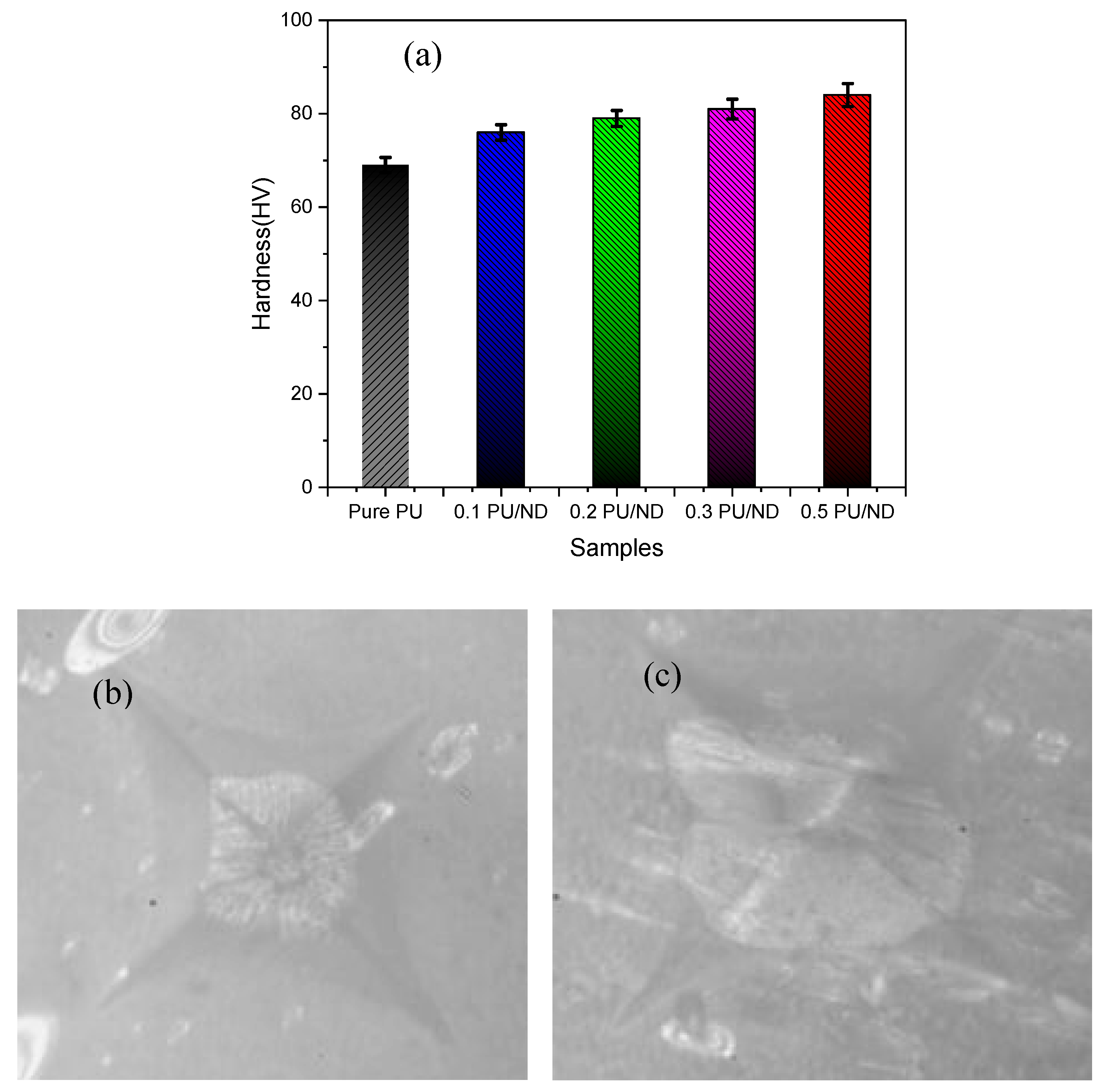

3.4. Hardness Results

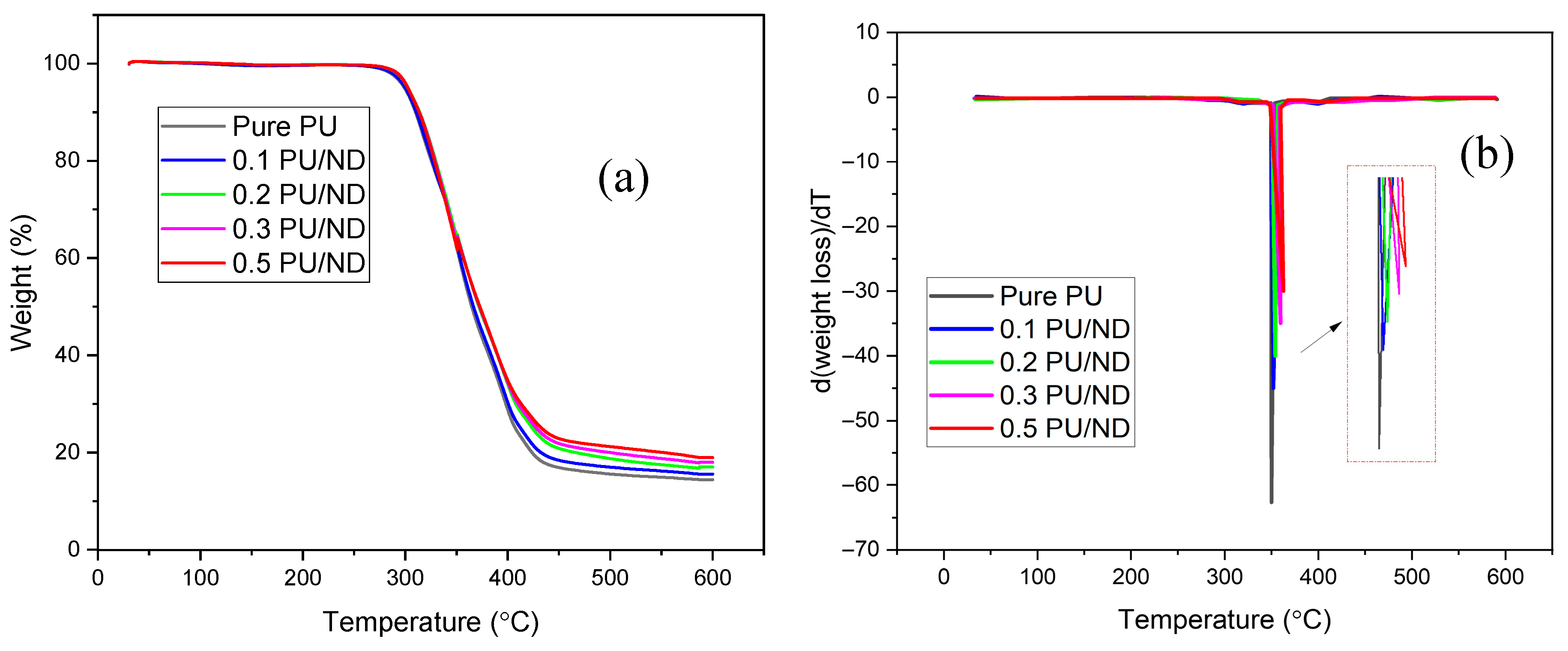

3.5. TGA Results

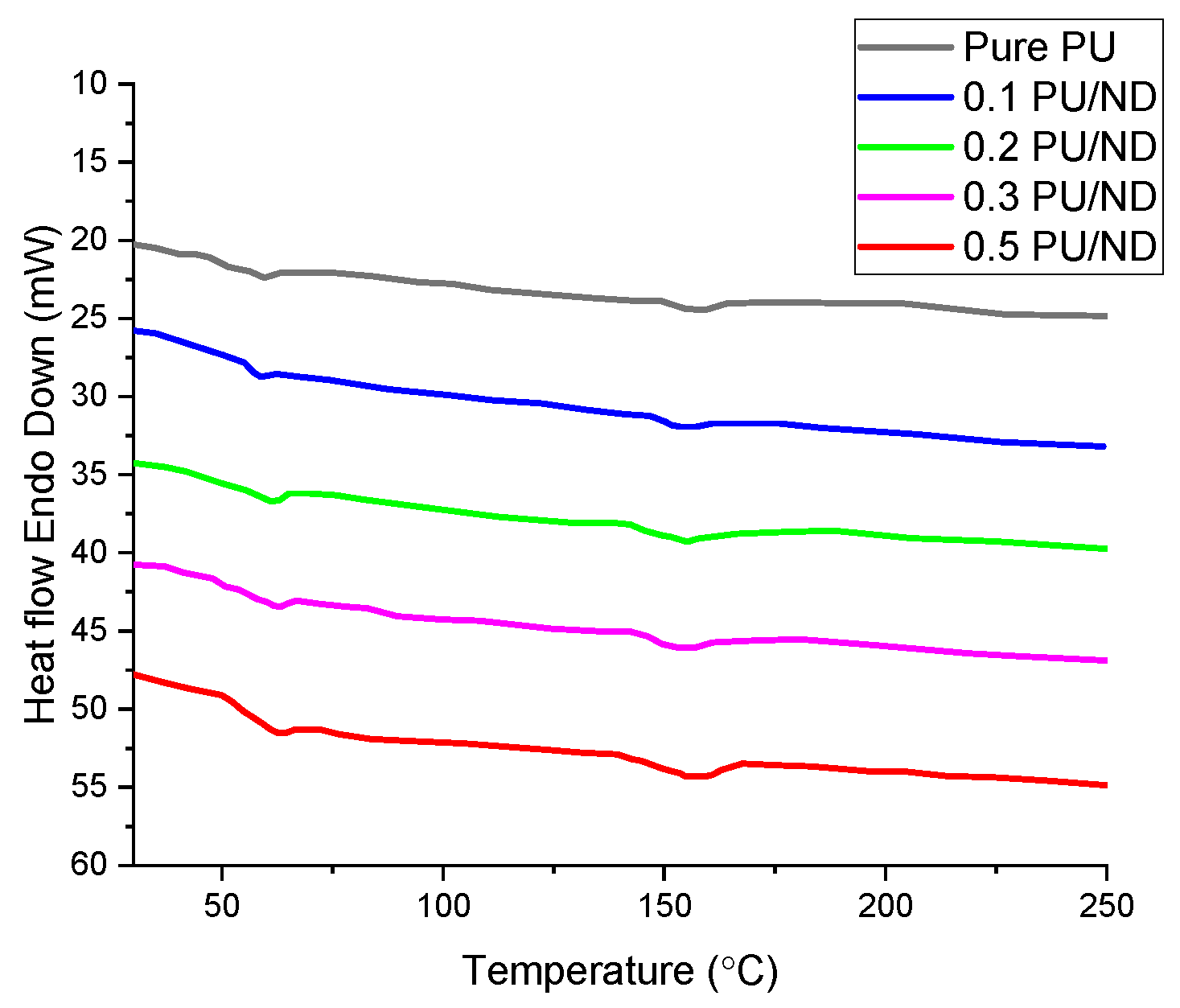

3.6. DSC Results

3.7. Rheological Properties

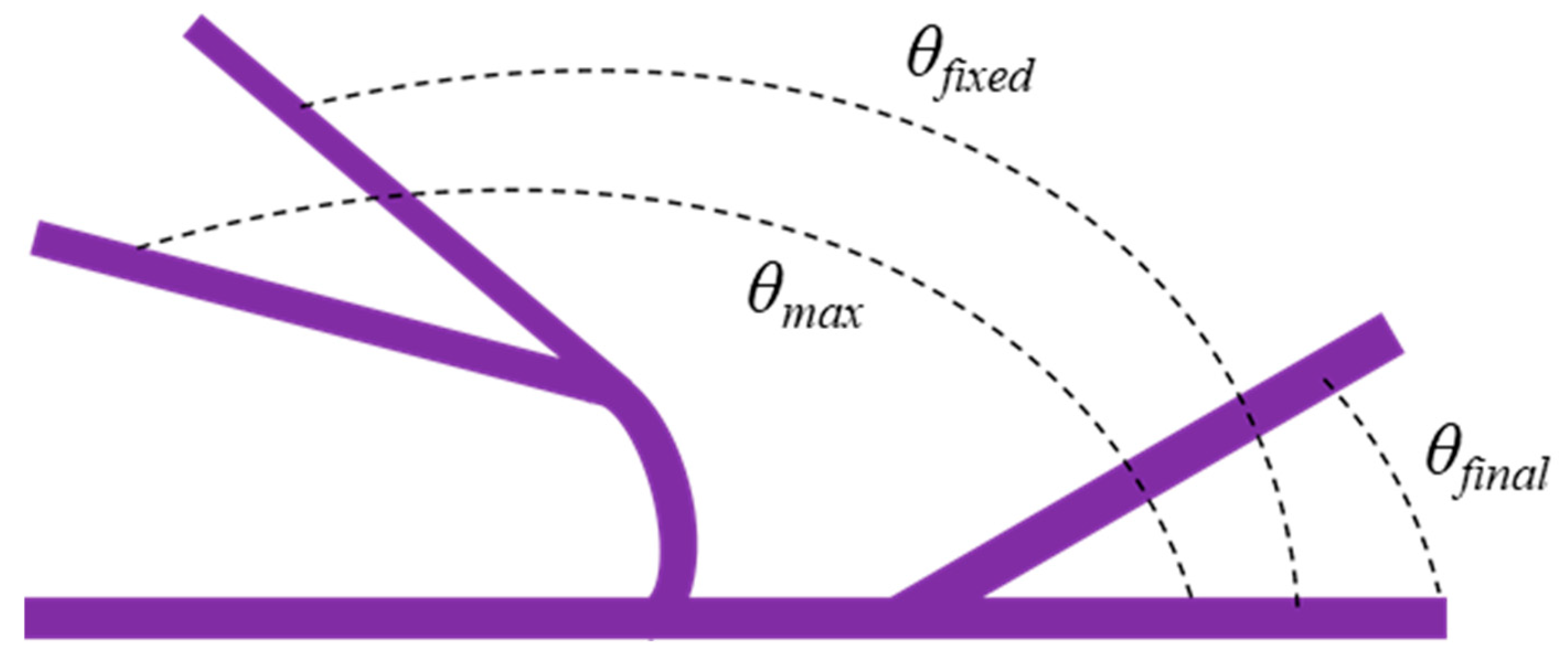

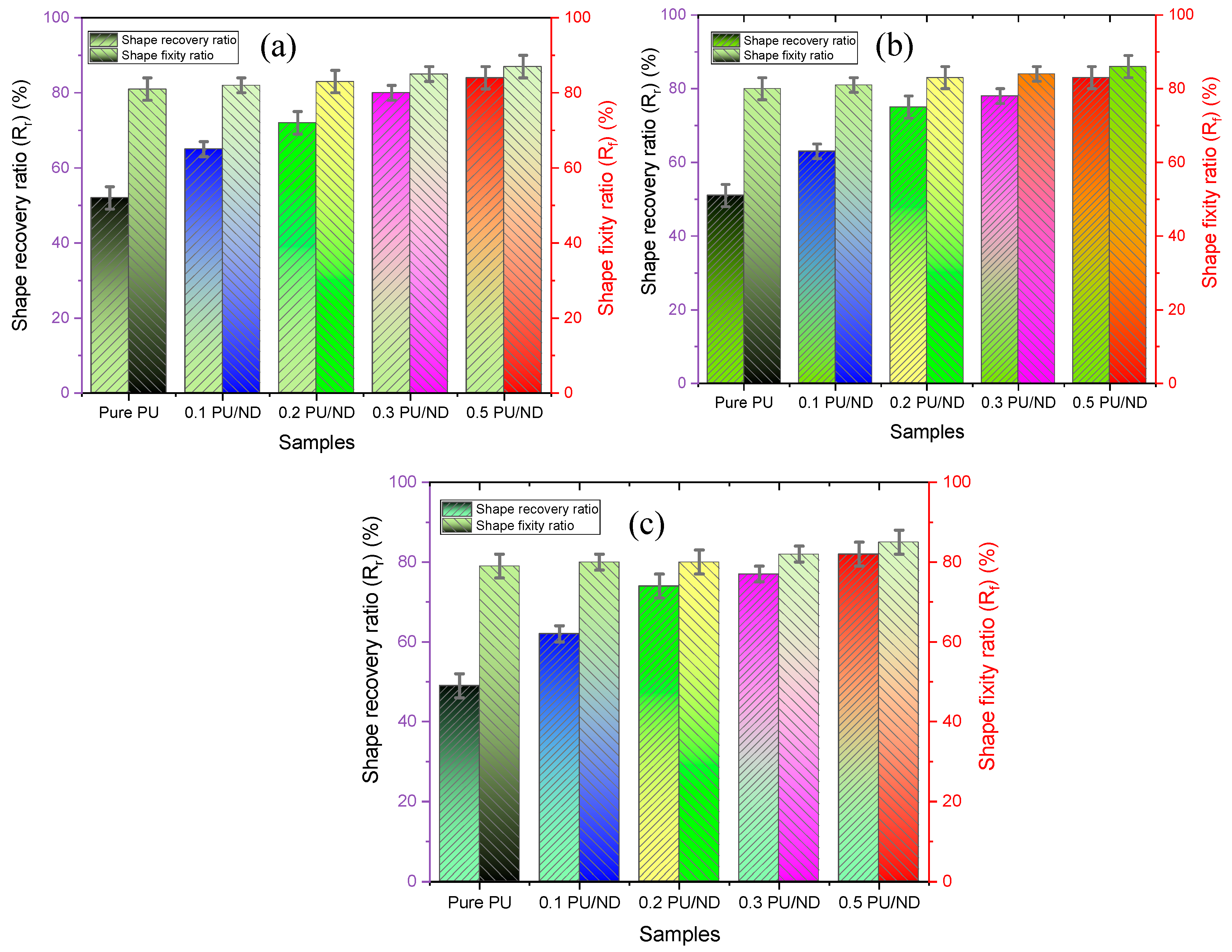

3.8. Shape-Memory Behavior

4. Conclusions

- Tensile strength increased by 114%, Young’s modulus by 11%, and hardness by 21%, while elongation at break decreased due to restricted chain mobility for 0.5 wt.% PU/ND.

- Coefficient of friction reduced by 56%, with shallower grooves observed for 0.5 wt.% PU/ND.

- Maximum degradation temperature increased from 350 °C to 362 °C, and char yield improved by 34% for 0.5 wt.% PU/ND.

- DSC results revealed that Tg rose from 65 °C to 68.6 °C, and Tm slightly increased from 161 to 168 ± 2 °C, indicating enhanced chain rigidity and ordering for 0.5 wt.% PU/ND.

- Rheological tests showed a decrease in damping factor (tan δ) by 89% for 0.5 wt.% PU/ND, reflecting improved elasticity.

- Shape-memory performance improved notably, with higher shape fixity and recovery ratios for all PU/ND composites, and the 0.5 wt.% ND sample showing the best overall enhancement due to optimal filler–matrix interactions and physical crosslinking.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PU | Polyurethane |

| ND | Nanodiamond |

| SMP | Shape-Memory Polymer |

| DSC | Differential Scanning Calorimetry |

| TGA | Thermogravimetric Analysis |

| XRD | X-ray Diffraction |

| SEM | Scanning Electron Microscope |

| TEM | Transmission Electron Microscopy |

| EDX | Energy Dispersive X-ray |

| SAED | Selected Area Electron Diffraction |

| COF | Coefficient of Friction |

| Tg | Glass Transition Temperature |

| Tm | Melting Temperature |

| Tonset | Onset Temperature |

| Rf | Shape Fixity Ratio |

| Rr | Shape Recovery Ratio |

| G′ | Storage Modulus |

| G′′ | Loss Modulus |

| tan δ | Loss Factor (Damping Factor) |

References

- Ragab, M.M.; Othman, H.; Hassabo, A.G. Natural polymers and their application in the textile sector. J. Text. Color. Polym. Sci. 2025, 22, 93–113. [Google Scholar] [CrossRef]

- Dallaev, R. Smart and Biodegradable Polymers in Tissue Engineering and Interventional Devices: A Brief Review. Polymers 2025, 17, 1976. [Google Scholar] [CrossRef] [PubMed]

- Jin, Z.; Wei, X.; He, X.; Wang, Z.; Zhao, Z.; He, H.; Yang, Y.N.; Chen, N. Research Progress and Emerging Directions in Stimulus Electro-Responsive Polymer Materials. Materials 2024, 17, 4204. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Lv, H.; Lan, X.; Leng, J.; Du, S. Review of Electro-Active Shape-Memory Polymer Composite. Compos. Sci. Technol. 2009, 69, 2064–2068. [Google Scholar] [CrossRef]

- Basak, S.; Laha, A. Stimuli-Responsive Smart and Functional Textiles. In Smart and Functional Textiles; Springer: Singapore, 2023; p. 355. [Google Scholar]

- Chandaka, S.K.; Das, A.; Laskar, P. Emergence of shape memory polymers as a new material for diverse applications. RSC Adv. 2025, 15, 31210–31229. [Google Scholar] [CrossRef]

- Wang, C.C.; Huang, W.M.; Ding, Z.; Zhao, Y.; Purnawali, H. Cooling-/Water-Responsive Shape Memory Hybrids. Compos. Sci. Technol. 2012, 72, 1178–1182. [Google Scholar] [CrossRef]

- Yu, K.; Liu, Y.; Leng, J. Shape Memory Polymer/CNT Composites and Their Microwave Induced Shape Memory Behaviors. RSC Adv. 2014, 4, 2961–2968. [Google Scholar] [CrossRef]

- Fang, Y.; Ni, Y.; Leo, S.Y.; Taylor, C.; Basile, V.; Jiang, P. Reconfigurable Photonic Crystals Enabled by Pressure-Responsive Shape-Memory Polymers. Nat. Commun. 2015, 6, 7416. [Google Scholar] [CrossRef]

- Basak, S.; Bandyopadhyay, A. Solvent Responsive Shape Memory Polymers-Evolution, Current Status, and Future Outlook. Macromol. Chem. Phys. 2021, 222, 2100195. [Google Scholar] [CrossRef]

- Sanaka, R.; Sahu, S.K. Influence of Nanofiller Addition on the Mechanical, Thermal, and Shape Recovery Behavior of Shape Memory Polymer Nanocomposite: A Brief Review. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Hassan, A.; Karazi, Y.; Xie, W.; Chau, W.M.; Petrš, J.; Dahy, H. Shape memory polymer biocomposites for thermoresponsive self-configurable sustainable architectural applications. Compos. Commun. 2025, 53, 102222. [Google Scholar] [CrossRef]

- Pradhan, S.; Sahu, S.K.; Pramanik, J.; Badgayan, N.D. An Insight into Mechanical & Thermal Properties of Shape Memory Polymer Reinforced with Nanofillers; a Critical Review. Mater. Today Proc. 2022, 50, 1107–1112. [Google Scholar] [CrossRef]

- Gopinath, S.; Adarsh, N.N.; Radhakrishnan Nair, P.; Mathew, S. Recent Trends in Thermo-Responsive Elastomeric Shape Memory Polymer Nanocomposites. Polym. Compos. 2023, 44, 4433–4458. [Google Scholar] [CrossRef]

- Kausar, A. Effect of Nanofillers on Polyurethane/Polystyrene Matrix Nanocomposites: Characteristics and Forthcoming Developments. J. Plast. Film Sheeting 2022, 38, 438–457. [Google Scholar] [CrossRef]

- Sanaka, R.; Sahu, S.K. Experimental Investigation into Mechanical, Thermal, and Shape Memory Behavior of Thermoresponsive PU/MXene Shape Memory Polymer Nanocomposite. Heliyon 2024, 10, e23793. [Google Scholar] [CrossRef] [PubMed]

- Sahu, S.K.; Sreekanth, P.R.; Saxena, K.K.; Ma, Q. Effect of Graphene Reinforcement on the Tensile and Flexural Properties of Thermoplastic Polyurethane Nanocomposite Using Experimental and Simulation Approach. Adv. Mater. Process. Technol. 2024, 1–17. [Google Scholar] [CrossRef]

- Gohar, G.A.; Akhtar, A.; Raza, H.; Mustafa, G.; Fatima, M.; Rehman, H.U.; Aslam, M.W.; ul Haq, A.; Manzoor, W. Achieving Enhanced Tensile Properties of Polyurethane-Multiwall Carbon Nanotubes Nanocomposites. Nano Express 2023, 4, 45013. [Google Scholar] [CrossRef]

- Abbas, S.A.; Younas, T.; Anwar, M.A. Investigation on Mechanical Properties of Graphene-Polyurethane Nanocomposites. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Sanya, China, 13–15 October 2021; Volume 1067, p. 12116. [Google Scholar]

- Albozahid, M.; Naji, H.Z.; Alobad, Z.K.; Wychowaniec, J.K.; Saiani, A. Thermal, Mechanical, and Morphological Characterisations of Graphene Nanoplatelet/Graphene Oxide/High-Hard-Segment Polyurethane Nanocomposite: A Comparative Study. Polymers 2022, 14, 4224. [Google Scholar] [CrossRef]

- Namathoti, S.; Vakkalagadda, M.R.K. Mechanical and Shape Recovery Characterization of MWCNTs/HNTs-Reinforced Thermal-Responsive Shape-Memory Polymer Nanocomposites. Polymers 2023, 15, 710. [Google Scholar] [CrossRef]

- Thiyagu, C.; NarendraKumar, U. Effect of Graphene on Thermal, Mechanical, and Shape Memory Properties of Polyurethane Nanocomposite. Appl. Phys. A 2022, 128, 937. [Google Scholar] [CrossRef]

- Nugroho, W.T.; Dong, Y.; Pramanik, A. Mechanical and Shape Memory Properties of Additively Manufactured Polyurethane (PU)/Halloysite Nanotube (HNT) Nanocomposites. Nanomaterials 2024, 14, 1373. [Google Scholar] [CrossRef] [PubMed]

- Pourmohammadi-Mahunaki, M.; Haddadi-Asl, V.; Roghani-Mamaqani, H.; Koosha, M.; Yazdi, M. Preparation of Polyurethane Composites Reinforced with Halloysite and Carbon Nanotubes. Polym. Compos. 2021, 42, 450–461. [Google Scholar] [CrossRef]

- Manap, A.; Mahalingam, S.; Vaithylingam, R.; Abdullah, H. Mechanical, Thermal and Morphological Properties of Thermoplastic Polyurethane Composite Reinforced by Multi-Walled Carbon Nanotube and Titanium Dioxide Hybrid Fillers. Polym. Bull. 2021, 78, 5815–5832. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Sheng, G. Nanodiamond-Reinforced Polyurethane Micro/Nanofiber Membrane for UV Protection in Multifunctional Textiles. ACS Appl. Nano Mater. 2024, 7, 12323–12333. [Google Scholar] [CrossRef]

- Kumar, D.; Bansal, S.A.; Kumar, N.; Jindal, P. Two-Step Synthesis of Polyurethane/Multi-Walled Carbon Nanotubes Polymer Composite to Achieve High Percentage Particle Reinforcement for Mechanical Applications. J. Compos. Mater. 2021, 55, 2877–2885. [Google Scholar] [CrossRef]

- Pourmohammadi-Mahunaki, M.; Haddadi-Asl, V.; Roghani-Mamaqani, H.; Koosha, M.; Yazdi, M. Halloysite-Reinforced Thermoplastic Polyurethane Nanocomposites: Physico-Mechanical, Rheological, and Thermal Investigations. Polym. Compos. 2020, 41, 3260–3270. [Google Scholar] [CrossRef]

- Ebrahimi, A.H.; Sahebian, S. Influence of Functional Carbon Nanotube and Multi-Cyclic Shape Memory Performance on Thermally Triggered Polyurethane Nanocomposites. Polym. Compos. 2022, 43, 8925–8934. [Google Scholar] [CrossRef]

- Prasad, M.B.; Sahu, S.K. Tensile and Flexural Properties of Thermoplastic Polyurethane Reinforced with Nanodiamond Using Experimental and FEM Method. J. Mech. Sci. Technol. 2025, 1–8. [Google Scholar] [CrossRef]

- González, M.; Ardanuy, M.; Rodríguez, R.; Jovančić, P. Polyurethane Shape Memory Filament Yarns: Melt Spinning, Carbon-Based Reinforcement, and Characterization. Text. Res. J. 2022, 93, 957–970. [Google Scholar] [CrossRef]

- Dong, F.; Yang, X.; Guo, L.; Qian, Y.; Sun, P.; Huang, Z.; Xu, X.; Liu, H. A Tough, Healable, and Recyclable Conductive Polyurethane/Carbon Nanotube Composite. J. Colloid Interface Sci. 2023, 631, 239–248. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X.; Jiang, H.; Ge, M.; Su, X.; Zou, M.; Li, G. Carbon Nanotubes Grafted by Polyurethane Chains with Dopamine-Mediation to Enhance the Mechanical and Damping Properties of Polyurethane Elastomer. Polymer 2023, 280, 126041. [Google Scholar] [CrossRef]

- Jing, X.; Duan, Y.; Xie, F.; Zhang, C.; Chen, S. Polyurethane with Nano-SiO2 Based Surface Sizing Method for 3D Printed Carbon Fiber Reinforced Nylon 6 Composites. Polym. Compos. 2023, 44, 1546–1561. [Google Scholar] [CrossRef]

- Chen, Q.; Li, X.; Yang, Z.; Meng, X.; Zhao, Y.; Kang, M.; Li, Q.; Wang, J.; Wang, J.; Wang, J. The Reinforcement of Polyurethane by Mini-Sized Graphene with Superior Performances. Chem. Eng. J. 2024, 482, 148668. [Google Scholar] [CrossRef]

- Li, L.; Xu, L.; Ding, W.; Lu, H.; Zhang, C.; Liu, T. Molecular-Engineered Hybrid Carbon Nanofillers for Thermoplastic Polyurethane Nanocomposites with High Mechanical Strength and Toughness. Compos. Part B Eng. 2019, 177, 107381. [Google Scholar] [CrossRef]

- Zhao, H.; He, D.; Xu, H.; Wang, Y.; Wang, W.; Shan, Z. Comprehensive Characterization of 3D-Printed TPU/Carbon Black Composites: Morphological, Thermal, and Mechanical Properties. Mater. Today Commun. 2024, 41, 111099. [Google Scholar] [CrossRef]

- Bronzeri, L.B.; Gauche, C.; Gudimard, L.; Courtial, E.J.; Marquette, C.; Felisberti, M.I. Amphiphilic and segmented polyurethanes based on poly (ε-caprolactone) diol and poly (2-ethyl-2-oxazoline) diol: Synthesis, properties, and a preliminary performance study of the 3D printing. Eur. Polym. J. 2021, 151, 110449. [Google Scholar] [CrossRef]

- Zhu, R.; Wang, X.; Yang, J.; Wang, Y.; Zhang, Z.; Hou, Y.; Lin, F.; Li, Y. Influence of hard segments on the thermal, phase-separated morphology, mechanical, and biological properties of polycarbonate urethanes. Appl. Sci. 2017, 7, 306. [Google Scholar] [CrossRef]

- Dou, H.M.; Ding, J.H.; Chen, H.; Wang, Z.; Zhang, A.F.; Yu, H.B. Bio-based, biodegradable and amorphous polyurethanes with shape memory behavior at body temperature. RSC Adv. 2019, 9, 13104–13111. [Google Scholar] [CrossRef]

- Murakami, H.; Nishiide, R.; Ohira, S.; Ogata, A. Synthesis of MDI and PCL-diol-based polyurethanes containing [2] and [3] rotaxanes and their properties. Polymer 2014, 55, 6239–6244. [Google Scholar] [CrossRef]

- Petrović, Z.S.; Milić, J.; Zhang, F.; Ilavsky, J. Fast-responding bio-based shape memory thermoplastic polyurethanes. Polymer 2017, 121, 26–37. [Google Scholar] [CrossRef]

- Staszczak, M.; Urbański, L.; Cristea, M.; Ionita, D.; Pieczyska, E.A. Investigation of Shape Memory Polyurethane Properties in Cold Programming Process Towards Its Applications. Polymers 2024, 16, 219. [Google Scholar] [CrossRef]

- Kato, T.; Matsumoto, T.; Hongo, C.; Nishino, T. Mechanical and Thermal Properties of Cellulose Nanofiber Composites with Nanodiamond as Nanocarbon Filler. Nanocomposites 2018, 4, 127–136. [Google Scholar] [CrossRef]

- Jee, A.Y.; Lee, M. Surface Functionalization and Physicochemical Characterization of Diamond Nanoparticles. Curr. Appl. Phys. 2009, 9, e144–e147. [Google Scholar] [CrossRef]

- Tobushi, H.; Hara, H.; Yamada, E.; Hayashi, S. Thermomechanical properties in a thin film of shape memory polymer of polyurethane series. Smart Mater. Struct. 1996, 5, 483. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- ISO 178:2019; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2019.

- Boggarapu, V.; Namathoti, S.; Avvari, V.D.; Peddakondigalla, V.B.; Shanmugam, R.; Ponnamma, D.; Sreekanth, P.R. Influence of Shelf-Life Duration on Mechanical, Thermal and Shape Recovery Motion Derivatives of Shape Memory Polyurethane. Results Eng. 2024, 21, 101819. [Google Scholar] [CrossRef]

- Zhang, R.; Tian, J.; Wu, Y.; Chou, W.; Yang, J.; Xue, P. An Investigation on Shape Memory Behaviors of UHMWPE-Based Nanocomposites Reinforced by Graphene Nanoplatelets. Polym. Test. 2021, 99, 107217. [Google Scholar] [CrossRef]

- Sahu, Y.K.; Arjunan, T.V.; Singh, S.; Vishwas, S. Investigation of shape memory and mechanical properties of MWCNT and graphene nano filler reinforced epoxy composite. J. Polym. Res. 2025, 32, 298. [Google Scholar] [CrossRef]

- Gopinath, S.; Adarsh, N.N.; Nair, P.R.; Mathew, S. One-Way Thermo-Responsive Shape Memory Polymer Nanocomposite Derived from Polycaprolactone and Polystyrene-Block-Polybutadiene-Block-Polystyrene Packed with Carbon Nanofiber. Mater. Today Commun. 2020, 22, 100802. [Google Scholar] [CrossRef]

- Kumar, R.; Rezapourian, M.; Rahmani, R.; Maurya, H.S.; Kamboj, N.; Hussainova, I. Bioinspired and Multifunctional Tribological Materials for Sliding, Erosive, Machining, and Energy-Absorbing Conditions: A Review. Biomimetics 2024, 9, 209. [Google Scholar] [CrossRef]

- Boey, J.Y.; Lee, C.K.; Tay, G.S. Factors Affecting Mechanical Properties of Reinforced Bioplastics: A Review. Polymers 2022, 14, 3737. [Google Scholar] [CrossRef]

- Farshidfar, A.; Bazgir, S.; Katbab, A.A.; Vaziri, A. Manipulation of Mechanical and Thermal Properties of Graphene Oxide/Nanoclay/Unsaturated Polyester Hybrid Nanocomposites by the Surface Chemistry and Nanofiller Composition. Polym. Test. 2023, 120, 107951. [Google Scholar] [CrossRef]

- Pielichowski, K.; Leszczyńska, A.; Njuguna, J. Mechanisms of Thermal Stability Enhancement in Polymer Nanocomposites. In Optimization of Polymer Nanocomposite Properties; Wiley: Hoboken, NJ, USA, 2010; pp. 195–210. [Google Scholar]

- Terzopoulou, Z.; Tarani, E.; Kasmi, N.; Papadopoulos, L.; Chrissafis, K.; Papageorgiou, D.G.; Papageorgiou, G.Z.; Bikiaris, D.N. Thermal Decomposition Kinetics and Mechanism of In-Situ Prepared Bio-Based Poly (Propylene 2, 5-Furan Dicarboxylate)/Graphene Nanocomposites. Molecules 2019, 24, 1717. [Google Scholar] [CrossRef]

- Ronkay, F.; Molnár, B.; Nagy, D.; Szarka, G.; Iván, B.; Kristály, F.; Mertinger, V.; Bocz, K. Melting Temperature versus Crystallinity: New Way for Identification and Analysis of Multiple Endotherms of Poly (Ethylene Terephthalate). J. Polym. Res. 2020, 27, 372. [Google Scholar] [CrossRef]

- Norouzi, A.; Lay, E.N.; Hosseinkhani, A.; Chapalaghi, M. Functionalized Nanodiamonds in Polyurethane Mixed Matrix Membranes for Carbon Dioxide Separation. Results Mater. 2022, 13, 100243. [Google Scholar] [CrossRef]

- Arrigo, R.; Malucelli, G. Rheological Behavior of Polymer/Carbon Nanotube Composites: An Overview. Materials 2020, 13, 2771. [Google Scholar] [CrossRef]

- Islam, R.; Maparathne, S.; Chinwangso, P.; Lee, T.R. Review of Shape-Memory Polymer Nanocomposites and Their Applications. Appl. Sci. 2025, 15, 2419. [Google Scholar] [CrossRef]

- Kausar, A. Nanodiamond Reinforced Shape Memory Nanocomposites—Versatile Features and Promises. Polym.-Plast. Technol. Mater. 2025, 64, 88–104. [Google Scholar] [CrossRef]

| PU Chemical Structure | Filler Material | Property Evaluated | Important Outcomes | Reference |

|---|---|---|---|---|

| Not disclosed | Carbon black (CB) and MWCNTs | Mechanical & shape-memory properties | MWCNTs demonstrated improved shape-memory performance, increased the fixity ratio to 97% and boosted Tg by 10 °C. | [31] |

| Not disclosed | Carbon nanotube (CNTs) | Tensile test | The nanocomposite demonstrated a tensile strength of 15.4 MPa and an elongation at break of 420% Compared to pure PU. | [32] |

| Not disclosed | Carbon nanotubes (CNTs) | Tensile test | The tensile strength and elongation at break increased by 97% and 25%, respectively. | [33] |

| Not disclosed | Nano-silicon dioxide (SiO2) | Tensile & flexural test | Nano-SiO2 achieved notable increases in flexural strength (33.87%), tensile strength (20.75%), and interlaminar shear strength (66.54%) over neat | [34] |

| Not disclosed | Mini-sized graphene (mg) | Tensile test and thermal analysis | Improved tensile strength by 81%, modulus by 126.7%, and elongation by 605%, while also enhancing thermal conductivity by 17 times (4.24 W/m·K) compared to PU. | [35] |

| Not disclosed | Carbon nanotube (CNT) & graphene (G) | Tensile test | Tensile strength reaching 69.5 MPa and toughness 246.2 MJ/m3, corresponding to 1.9- and 2.9-fold increases, respectively, over pure TPU. | [36] |

| Not disclosed | Carbon black (CB) | Thermal and mechanical properties | Thermal stability increased from 220 °C to 270 °C with CB addition, and 5 wt.% CB demonstrated the highest mechanical qualities (8.02 MPa tensile strength, 434.25% elongation). | [37] |

| Soft segment: Poly (ε-caprolactone) diol (PCL-diol) and Poly(2-ethyl-2-oxazoline) diol (PEtOx-diol) Hard segment: Diisocyanate Chain extender: 1,4-butanediol (BDO) | None | Thermal properties (DSC, TGA). Dynamic mechanical analysis (DMA) | A melting peak near 50–60 °C (typical for crystalline PCL). The intensity decreased as PEtOx content increased. | [38] |

| Soft segment: Poly (1,6-hexanediol carbonate) diol (PCDL, Mn; ≈ 2000 Da) Hard segment: 1,6-hexamethylene diisocyanate (HDI) Chain extender: 1,4-butanediol (BDO) | None | Thermal stability (TGA) | Decomposition onset ≈ 320–360 °C, major weight loss up to 430 °C. | [39] |

| Soft segment: Polycaprolactone (PCL) diol (Mn = 1000 g mol−1) Hard segment: Diphenylmethane diisocyanate-50 (MDI-50) chain extender: None | None | Shape-memory testing (thermo-responsive) | All bio-PUs showed excellent shape-memory performance. Best sample (PLA:PCL = 2:1) and noted a 98% recovery, full recovery in 15 s at 37 °C. | [40] |

| Soft segment: Poly (ε-caprolactone) diol (PCL, Mn ≈ 2000 g/mol) Hard segment: 4,4′-Diphenylmethane diisocyanate (MDI) Chain extender: 1,4-butanediol (BD) | None | TGA, DSC | Rotaxanes retarded recrystallization of PCL domains (less sharp melting peaks). No significant change in Tg across PU0–PU2. | [41] |

| Soft segment: Bio-based PHNA diols (polyhydroxynonanoate diols) Hard segment: 4,4′-Diphenylmethane diisocyanate (MDI) Chain extender: 1,4-Butanediol (BDO) | None | Shape-memory behavior | Shape-memory transition temperature (Ttrans): tunable between 32 and 51 °C, near body temperature. | [42] |

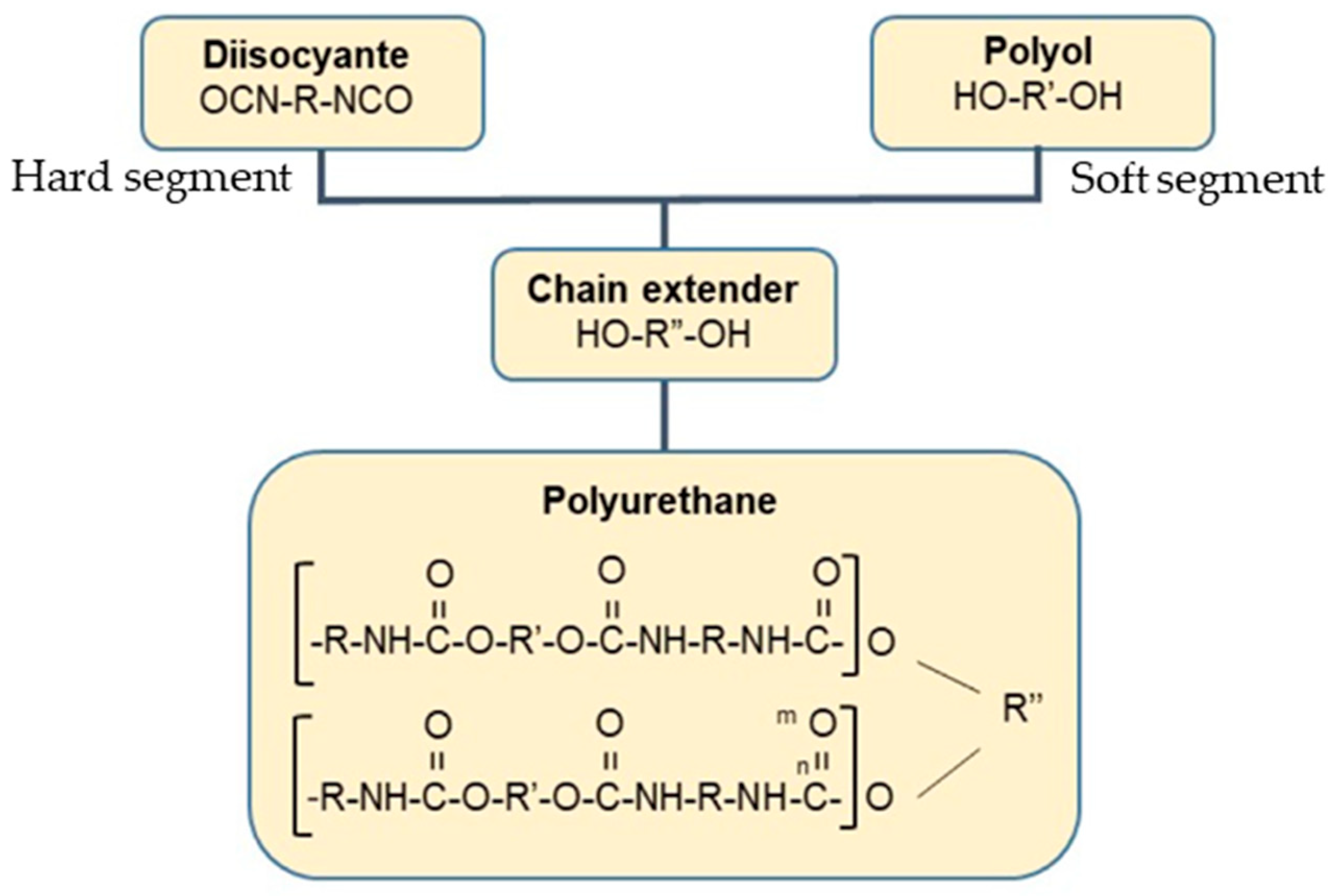

| Soft segment: Polyol (HO-R’-OH) Hard segment: Diisocyanate (OCN-R-NCO) Chain extender: HO-R’’-OH | None | Thermomechanical characterization, shape-memory behavior | Glass transition temperature (Tg) ≈ 65 °C. Shape fixity ratio: ~90%, Shape recovery ratio: ~93% at room temp. | [43] |

| Cycle 1 | Cycle 2 | Cycle 3 | Cycle 1 | Cycle 2 | Cycle 3 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Samples | Rf (%) | Error (%) | Rf (%) | Error (%) | Rf (%) | Error (%) | Rr (%) | Error (%) | Rr (%) | Error (%) | Rr (%) | Error (%) |

| Pure PU | 81 | 3 | 80 | 3 | 79 | 3 | 52 | 3 | 51 | 3 | 49 | 3 |

| 0.1 PU/ND | 82 | 2 | 81 | 2 | 80 | 2 | 65 | 2 | 63 | 2 | 62 | 2 |

| 0.2 PU/ND | 83 | 3 | 83 | 3 | 80 | 3 | 72 | 3 | 75 | 3 | 74 | 3 |

| 0.3 PU/ND | 85 | 2 | 84 | 2 | 82 | 2 | 80 | 2 | 78 | 2 | 77 | 2 |

| 0.5 PU/ND | 87 | 3 | 86 | 3 | 85 | 3 | 84 | 3 | 83 | 3 | 82 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prasad, M.B.; Alrasheedi, N.H.; Sreekanth, P.S.R.; Louhichi, B.; Sahu, S.K.; Badgayan, N.D. Experimental Investigation of Nanodiamond Reinforcement in PU for Enhancing Mechanical, Scratch, Rheological, Thermal, and Shape-Memory Properties. Polymers 2025, 17, 2947. https://doi.org/10.3390/polym17212947

Prasad MB, Alrasheedi NH, Sreekanth PSR, Louhichi B, Sahu SK, Badgayan ND. Experimental Investigation of Nanodiamond Reinforcement in PU for Enhancing Mechanical, Scratch, Rheological, Thermal, and Shape-Memory Properties. Polymers. 2025; 17(21):2947. https://doi.org/10.3390/polym17212947

Chicago/Turabian StylePrasad, Markapudi Bhanu, Nashmi H. Alrasheedi, P. S. Rama Sreekanth, Borhen Louhichi, Santosh Kumar Sahu, and Nitesh Dhar Badgayan. 2025. "Experimental Investigation of Nanodiamond Reinforcement in PU for Enhancing Mechanical, Scratch, Rheological, Thermal, and Shape-Memory Properties" Polymers 17, no. 21: 2947. https://doi.org/10.3390/polym17212947

APA StylePrasad, M. B., Alrasheedi, N. H., Sreekanth, P. S. R., Louhichi, B., Sahu, S. K., & Badgayan, N. D. (2025). Experimental Investigation of Nanodiamond Reinforcement in PU for Enhancing Mechanical, Scratch, Rheological, Thermal, and Shape-Memory Properties. Polymers, 17(21), 2947. https://doi.org/10.3390/polym17212947