Elastoplastic Modeling of Kevlar® Composite Laminates: A Cyclic Loading Approach for In-Plane Characterization

Abstract

1. Introduction

- -

- Material characterization gaps: A significant deficiency pervades the literature, where most studies either lack comprehensive material characterization or completely omit experimental validation. As Nunes et al. [5] observed, this absence of thorough material characterization forces researchers to rely on disparate literature references for model calibration rather than developing systematic experimental datasets tailored to specific material systems and manufacturing processes. Even when characterization data are provided, critical manufacturing parameters including thermoforming pressure, temperature, and processing duration are frequently unreported, severely hampering reproducibility and independent validation efforts. This systematic lack of documentation creates a cascading effect that undermines the reliability of subsequent modeling and design applications, making it nearly impossible to establish confidence bounds for numerical predictions.

- -

- Material specification ambiguity: The specific type of Kevlar® fiber and matrix system employed are often unidentified or inadequately described, hindering comparative analysis and model transferability across different material systems. This ambiguity extends to weave architecture specifications, fiber surface treatments, and matrix composition ratios, all of which significantly influence mechanical response and failure mechanisms.

- -

- Geometric parameter justification: Specimen dimensions (width, length, and thickness) are typically presented without technical justification based on material microstructure or testing standards, potentially affecting the validity and reproducibility of experimental results.

| Rectangular Plate | Military Helmet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mechanical Property | Kevlar 29/Phenolic | Kevlar 29/Epoxy | Kevlar 29/Epoxy | Kevlar 29/Epoxy | Kevlar | Kevlar | Kevlar 129 | Kevlar | Kevlar | Kevlar 129 | Kevlar 29 |

| EL [GPa] | 18.5 | 18.5 | 7.618 | 10.06 | 18.5 | 18.5 | 22 | 18.5 | 18 | 22 | 18.5 |

| ET [GPa] | 18.5 | 18.5 | 11.05 | 10.06 | 18.5 | 18.5 | 22 | 18.5 | 18 | 22 | 18.5 |

| EN [GPa] | 1.47 (1) & 6.0 (2) | 6.0 | 6.0 | 6.0 | 6 | 6 | 9 | 6.0 | 4.5 | 9 | 6.0 |

| νLT | 0.25 | 0.25 | 0.18 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

| νLN = νNT | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 |

| GLT [GPa] | 0.77 | 0.77 | 2.123 | 0.77 | 5.43 | 5.43 | 0.77 | 0.77 | 0.77 | 0.77 | 0.77 |

| GLN [GPa] | 2.715 | 5.43 | 5.43 | 5.43 | 5.43 | 5.43 | 5.34 | 2.715 | 2.6 | 2.715 | 2.72 |

| GTN [GPa] | 2.715 | 5.43 | 5.43 | 5.43 | 0.77 | 0.77 | 5.34 | 2.715 | 2.6 | 2.715 | 2.72 |

| XLT [MPa] | 555 (4) | 1850 (3) | 400 | 425 | 800 | 555 | 555 | 800 | 555 | ||

| XLC [MPa] | - | 185 | 94 | 185 | 80 | - | 555 | 60 | 1200 | ||

| XTT [MPa] | 555 (4) | 1850 (3) | 530 | 425 | 800 | 555 | 555 | 800 | 555 | ||

| XTC [MPa] | - | 185 | 113 | 185 | 80 | - | 555 | 60 | 1200 | ||

| XNT [MPa] | 1200 | - | - | - | 1200 | 1200 | 1050 | - | 1200 | ||

| XNC [MPa] | - | - | - | - | 1200 | - | 1050 | - | 1200 | ||

| SLT [MPa] | 77 | - | - | - | 77 | 77 | 77 | 77 | 77 | ||

| SLN [MPa] | 1086 | - | - | - | 898 | 1086 | 1060 | 898 | 1086 | ||

| STN [MPa] | 1086 | - | - | - | 898 | 1086 | 1086 | 898 | 1086 | ||

| Sn [MPa] | 34.5 | - | 62.8 | 34.5 | 34.5 | 823.2 (4 plies) | 34.5 | - | |||

| Ss [MPa] | 9 | - | 22.9 | 9 | 9.0 | 588 (4 plies) | - | - | |||

| Sc [MPa] | - | 77 | 67 | 77 | - | - | - | - | |||

| ρ [kg/m3] | 1230 | 1440 | 1191 | 1025 | 1230 | 1230 | 1230 | 1230 | 1230 | 1230 | |

| Author | van Hoof [3] | Bresciani et al. [4] | Nunes et al. [5] | Scazzosi et al. [6] | Li et al. [7] | Umbharatwala and Goel [8] | Gower et al. [12] | Lee and Gong [11] | Tan et al. [9] | Li et al. [17] | Caçoilo et al. [10] |

| Concepts | |||||||||||

| EL = Young’s modulus in L direction ET = Young’s modulus in T direction EN = Young’s modulus in N direction νLT = Poisson’s ratio LT νLN = νNT = Poisson’s ratio LN & NT | GLT = Shear modulus in LT direction GLN = Shear modulus in LN direction GTN = Shear modulus in TN direction XLT = Tensile strength in the L direction XTT = Tensile strength in the T direction | XLC = Compression strength in the L direction XTC = Compression strength in the T direction XNT = Tensile strength in the N direction XNC = Compression strength in the N direction SLT = Shear strength in LT direction | SLN = Shear strength in LN direction STN = Shear strength in TN direction Sn = Interface strength in N direction Ss = Shear strength in the interface Sc = Shear strength in LT direction ρ = Density | ||||||||

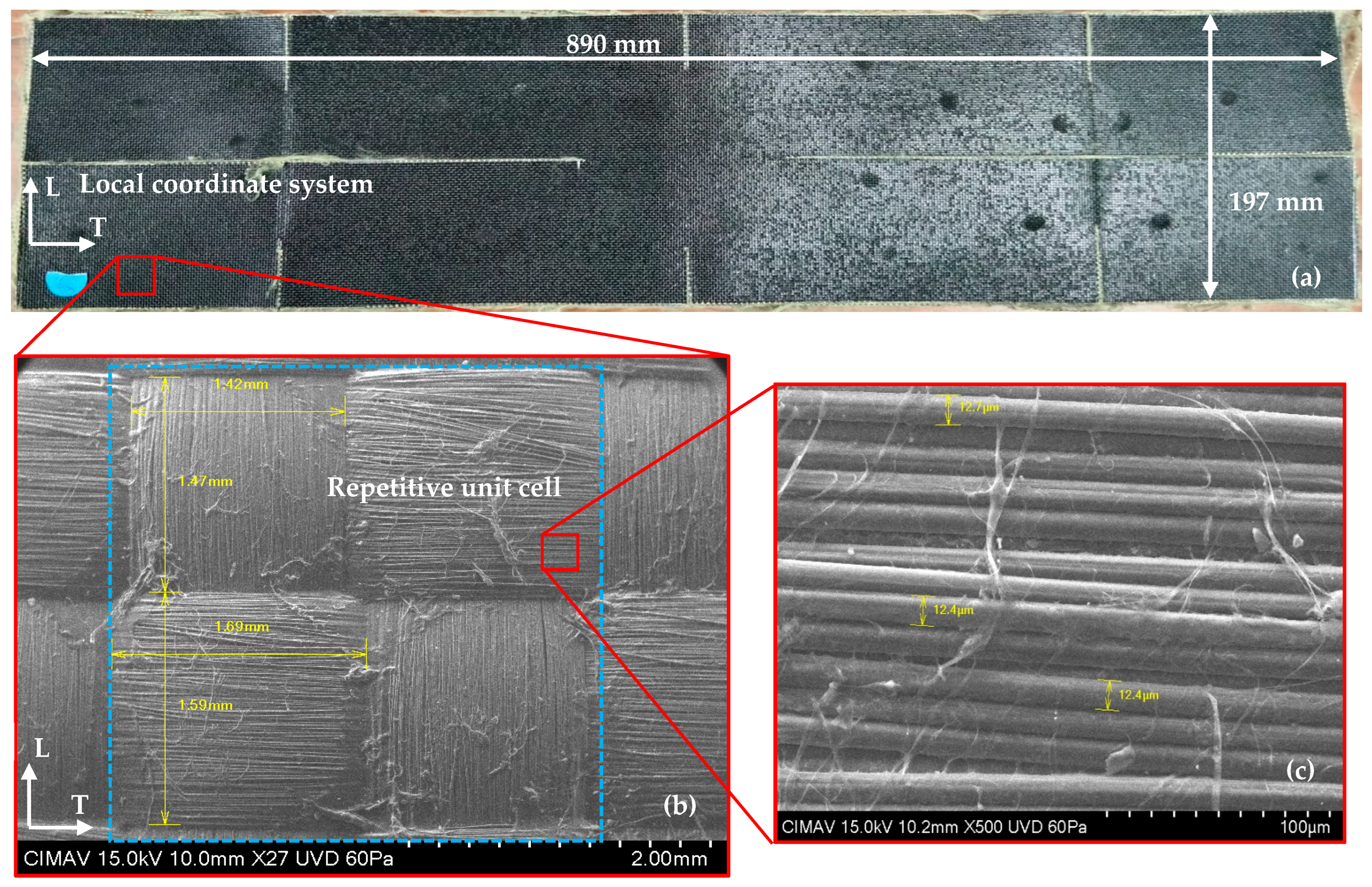

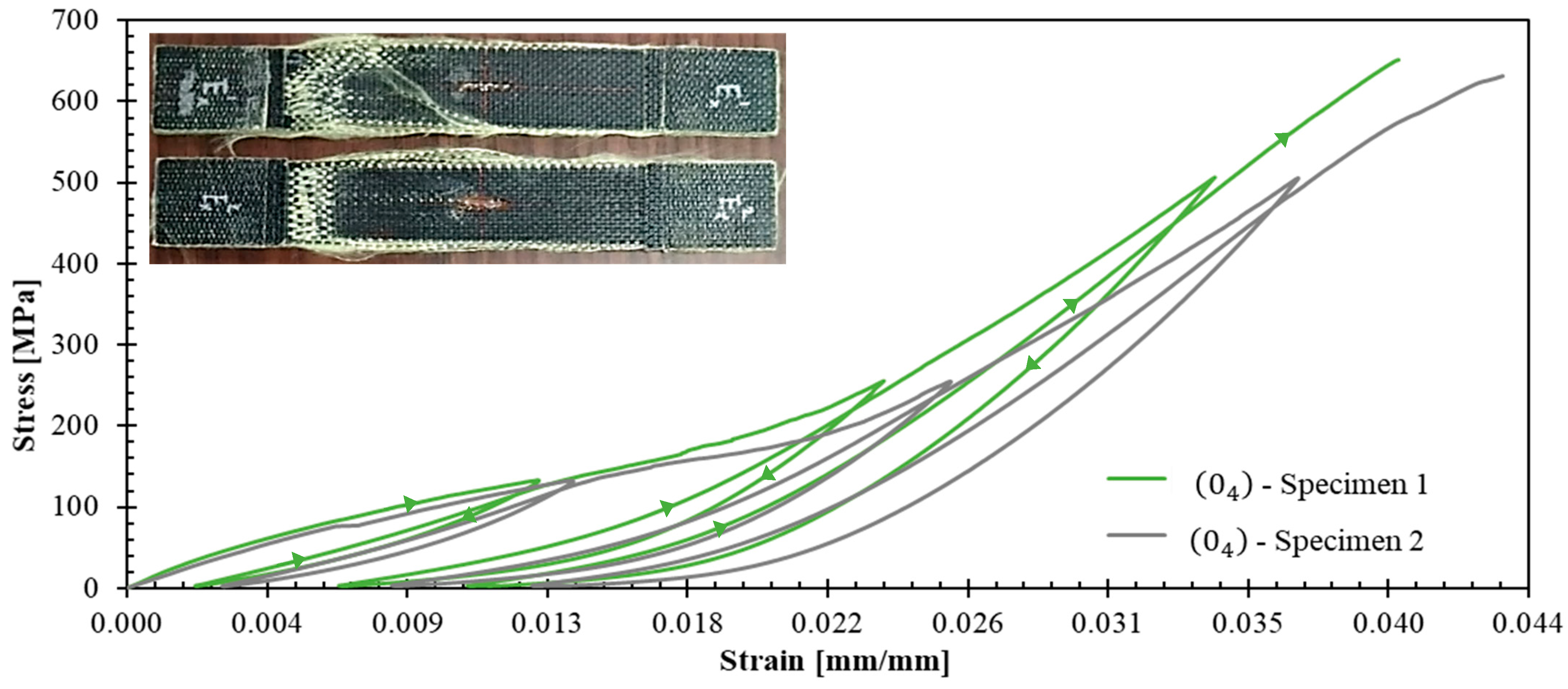

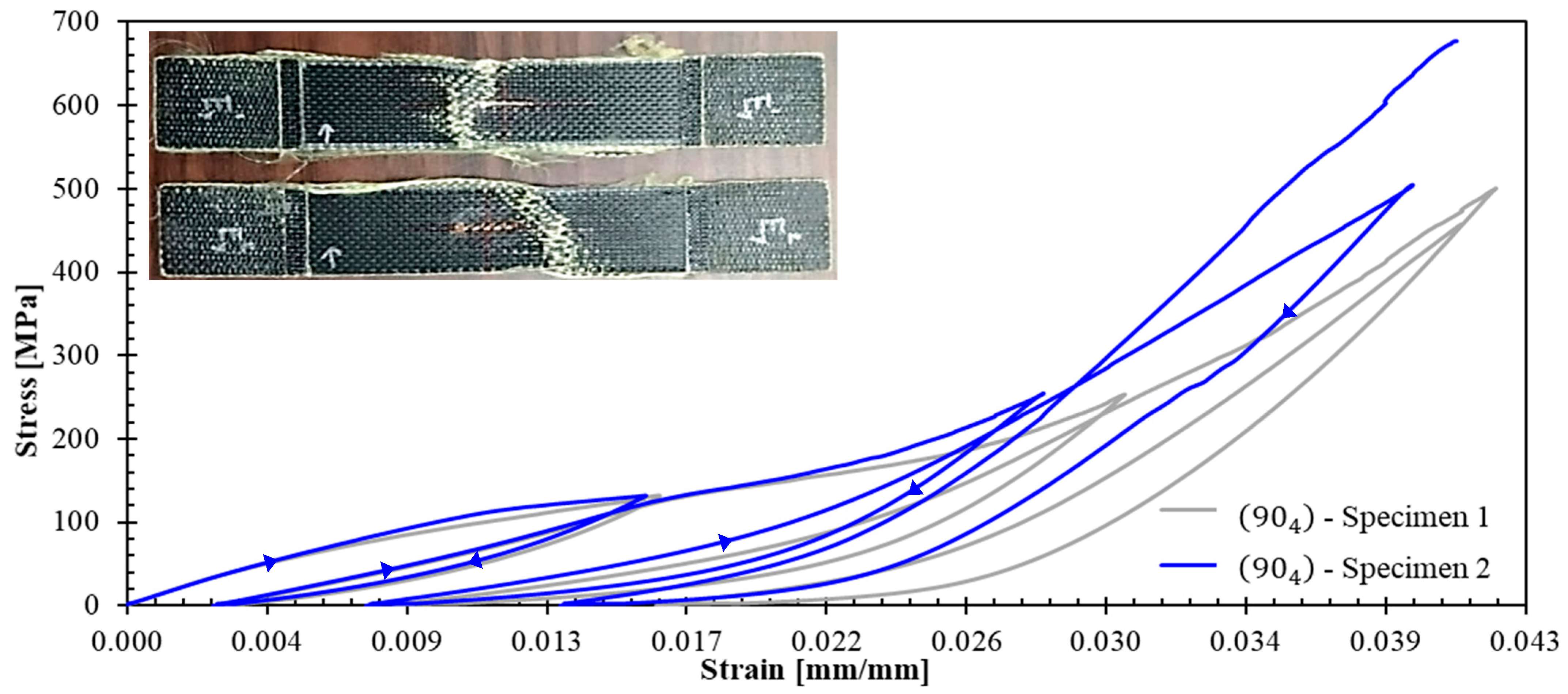

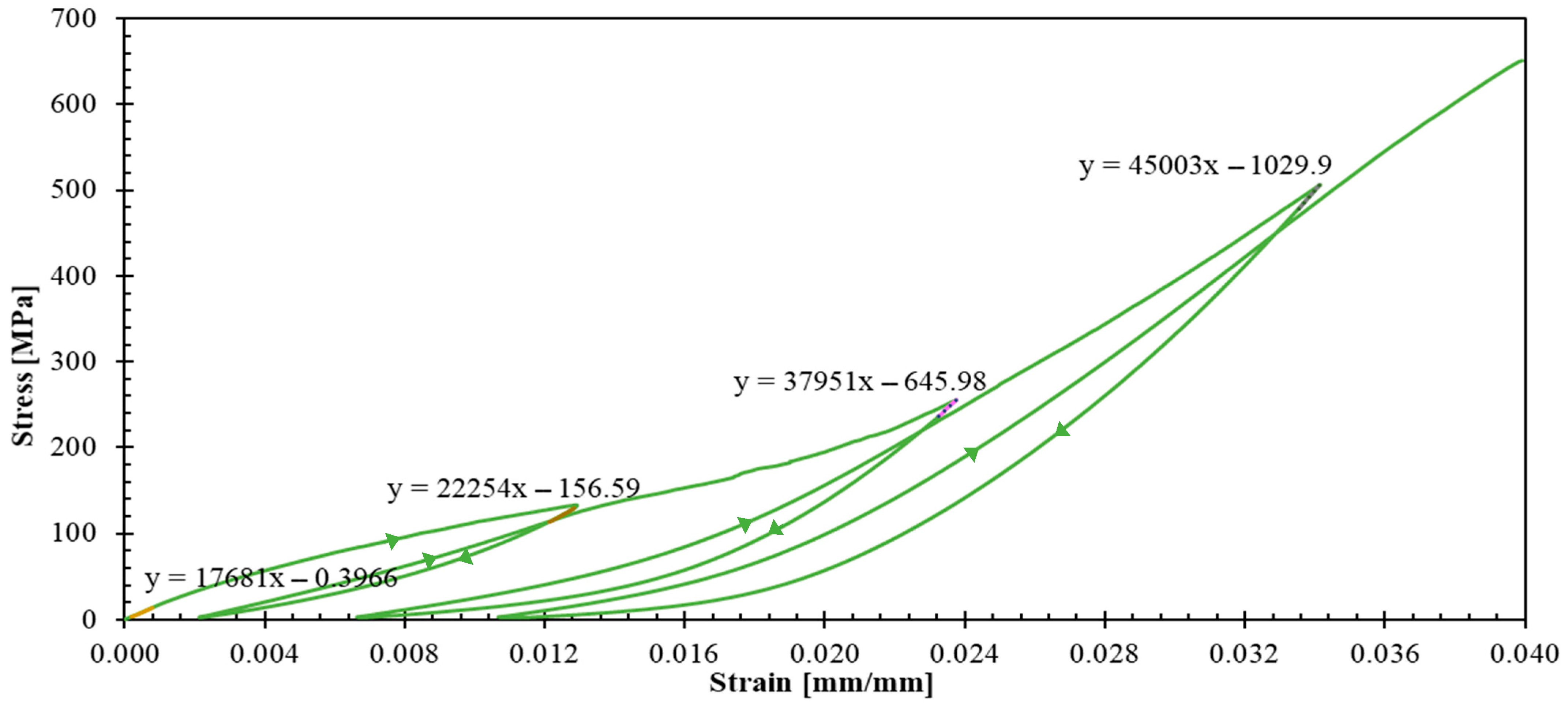

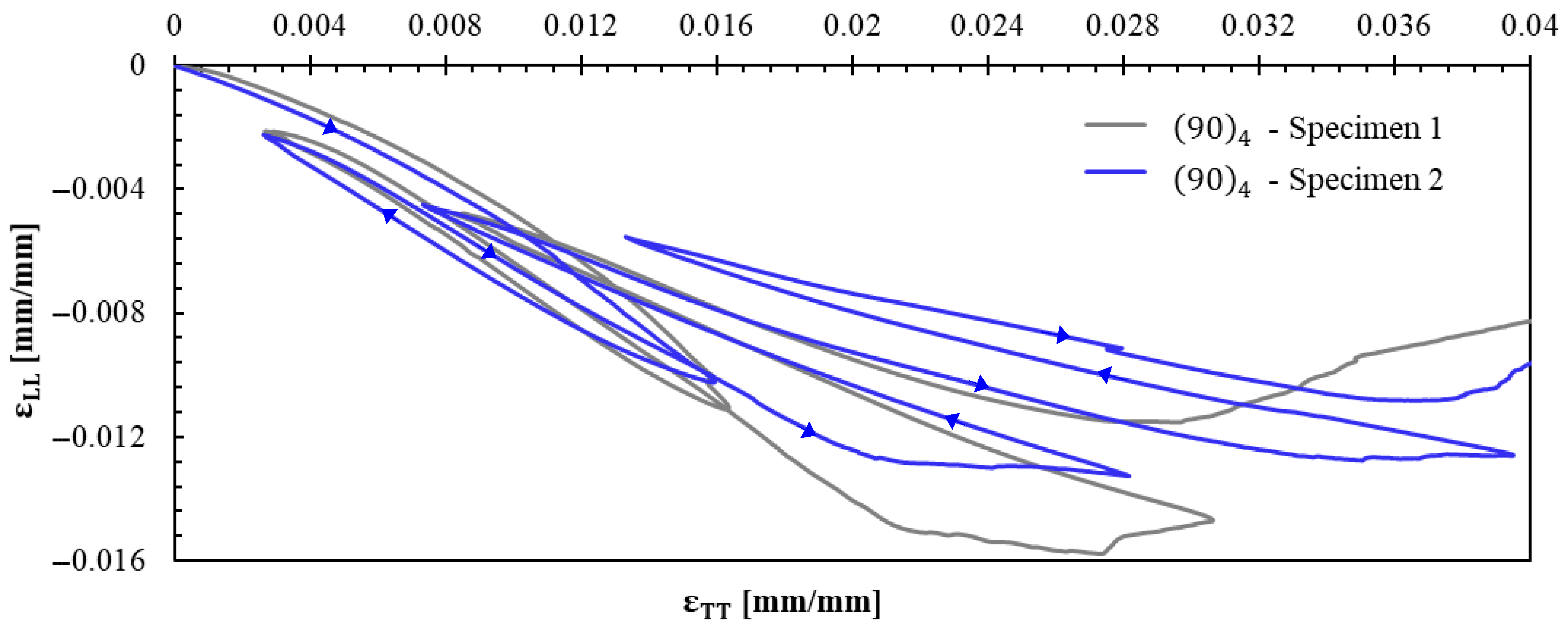

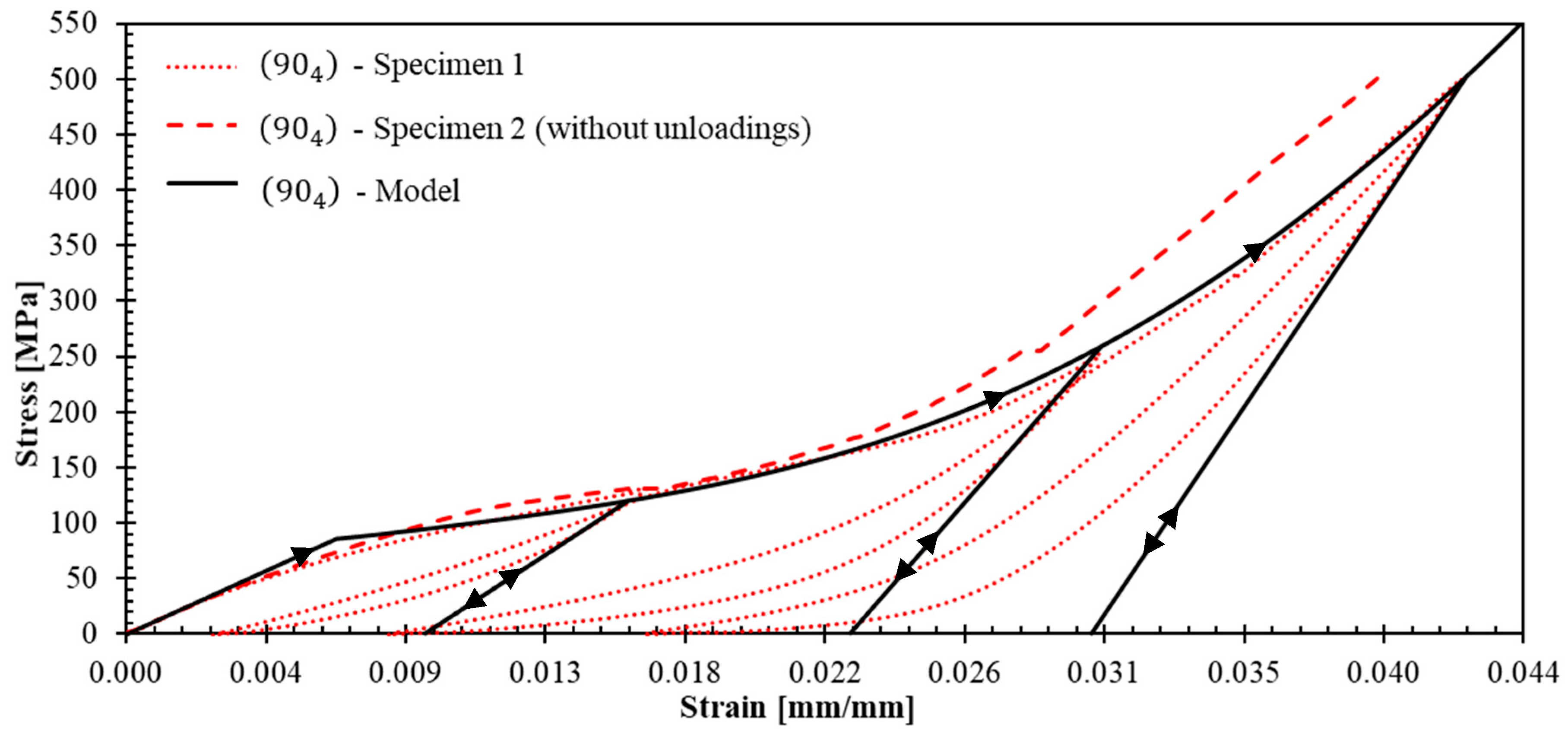

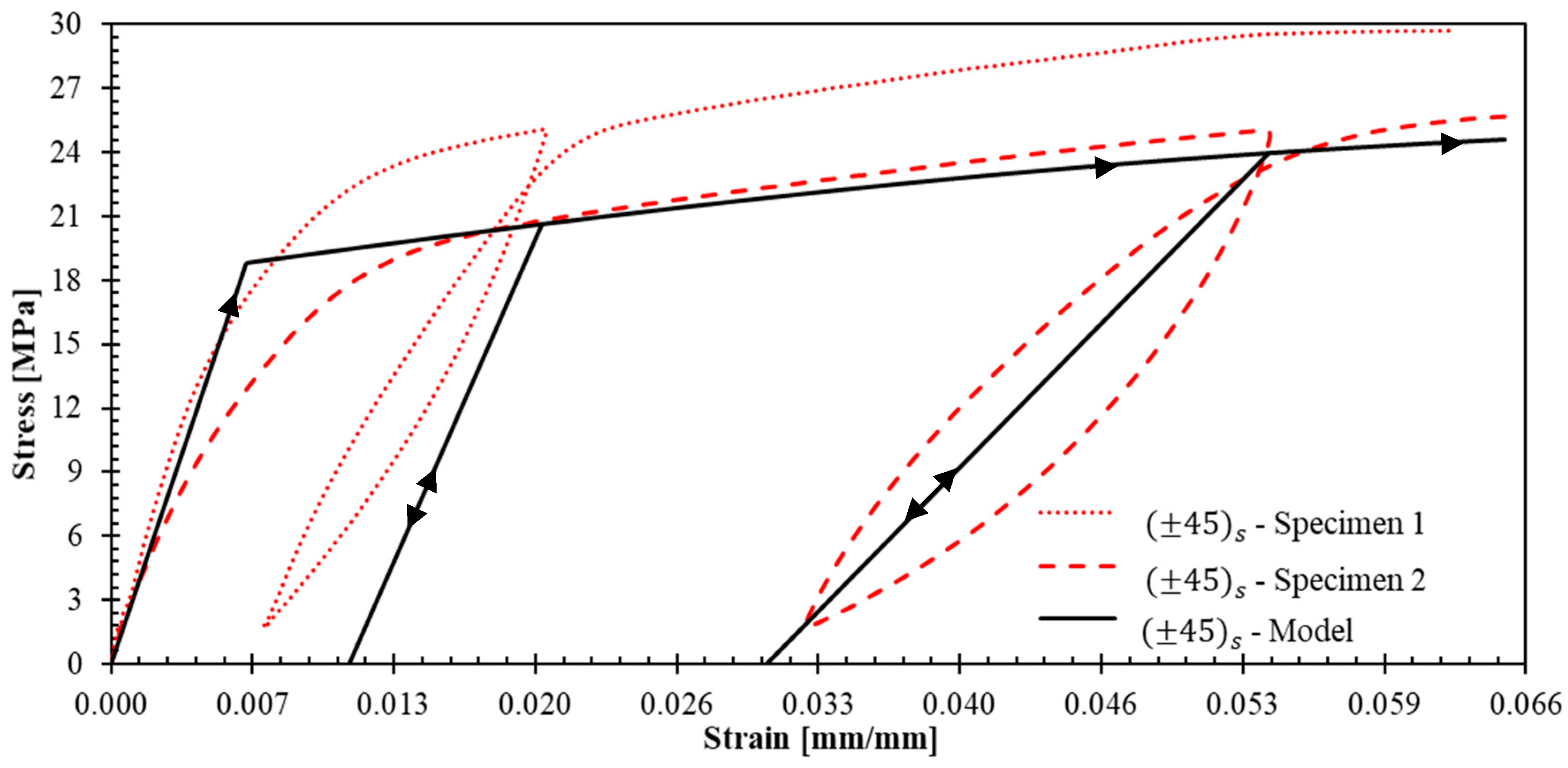

- Fundamental characterization: Developing a robust experimental methodology to characterize in-plane behavior through controlled tensile tests with unloading–reloading cycles on symmetric laminates , , and directions. Virtually all the laminate volume is subjected to an in-plane stress state; through-thickness stresses are confined in the free-edge effect regions (these regions are less than 2 thicknesses wide [26]). For the in-plane modeling, characterizing the material behavior in different directions is essential due to the orthotropic nature of woven fabrics, which exhibit direction-dependent mechanical properties. This directional characterization will enable estimation of stress–strain response for any symmetric laminate configuration.

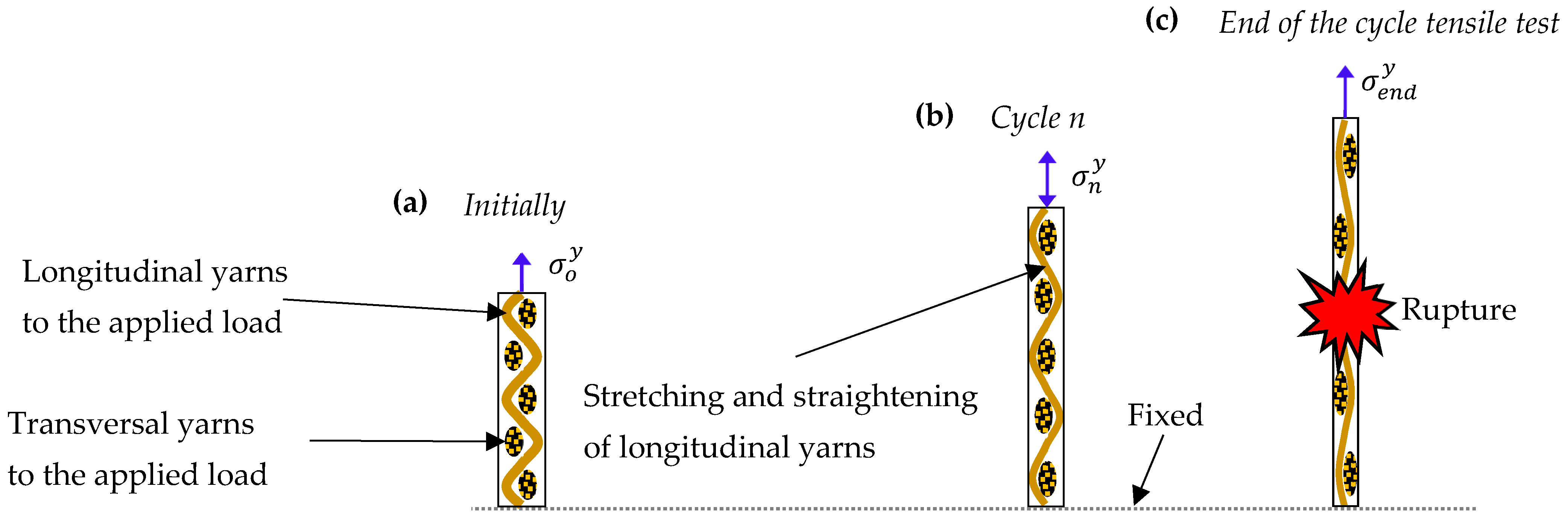

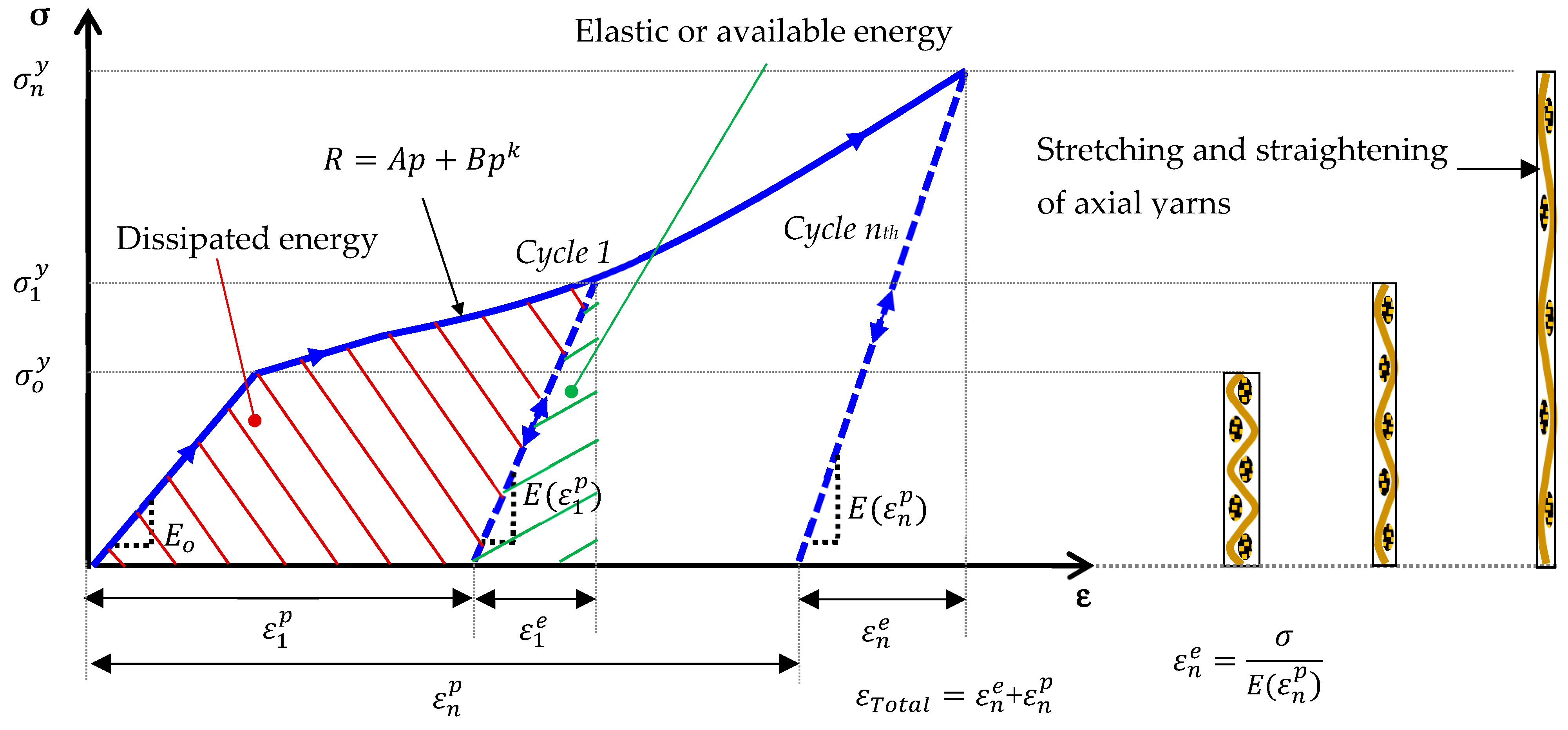

- Plastic strain quantification: Systematically quantifying irreversible strains and material stiffening effects during cyclic loading to establish the foundation for energy absorption calculations in impact applications. This includes developing methodologies to separate elastic and plastic strain components and understanding the mechanisms responsible for progressive stiffness evolution.

- Constitutive model development: Developing a constitutive model incorporating Hill’s yield criterion adapted for orthotropic materials and a hardening function accounting for equivalent plastic strains and progressive yarn stiffening effects. The model will capture both the nonlinear hardening behavior and the evolution of elastic properties observed experimentally.

- Model validation and application: Validating the proposed model through comprehensive testing of various laminates with different fiber orientations, assessing prediction accuracy, and identifying limitations related to delamination and ultimate failure prediction. This validation will establish the model’s applicability range and provide guidance for practical implementation.

2. Materials and Methods

2.1. Materials

2.1.1. Fibers

2.1.2. Matrix

2.2. Methods

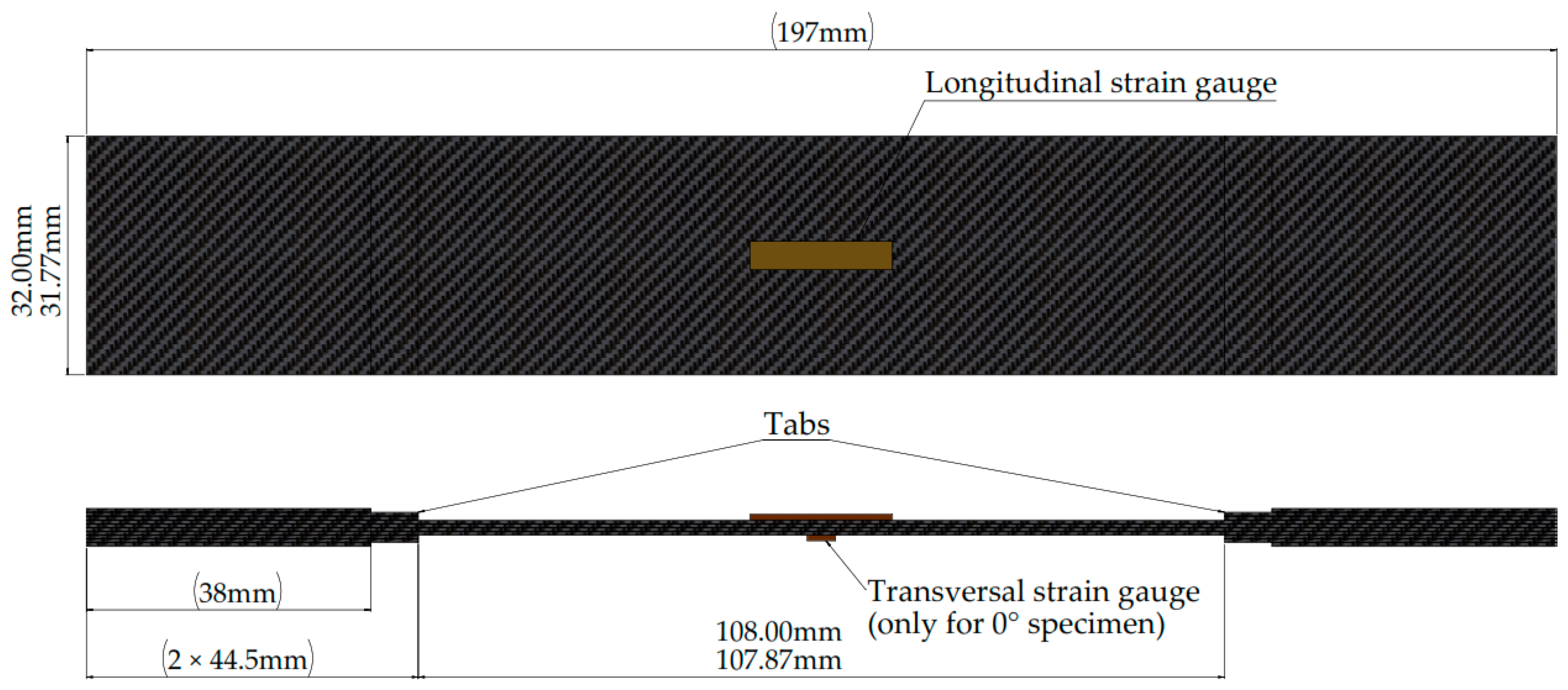

- Laminate. Three primary specimens were fabricated and tested: , , and .

- The methodology to determine the in-plane shear modulus , using a specimen was also presented in the study done by Canceco et al. [13].

- Primary consolidation: 192 °C, 10.12 MPa for 10.5 min.

- Tab reinforcement: 192 °C, 20.67 MPa for 20 min (applied specifically to tab regions to prevent debonding during testing).

- Strain measurement. Specimens were instrumented with EP-08-500GB-120 strain gauges (Micro-Measurements®, Raleigh, NC, USA) for precise strain monitoring during testing.

- Mechanical testing system. All tests were conducted using an Instron® model 3382 universal testing system (Instron®, Norwood, MA, USA) equipped with mechanical wedge-action tension grips (type 2716-003) with a maximum load capacity of 10 t.

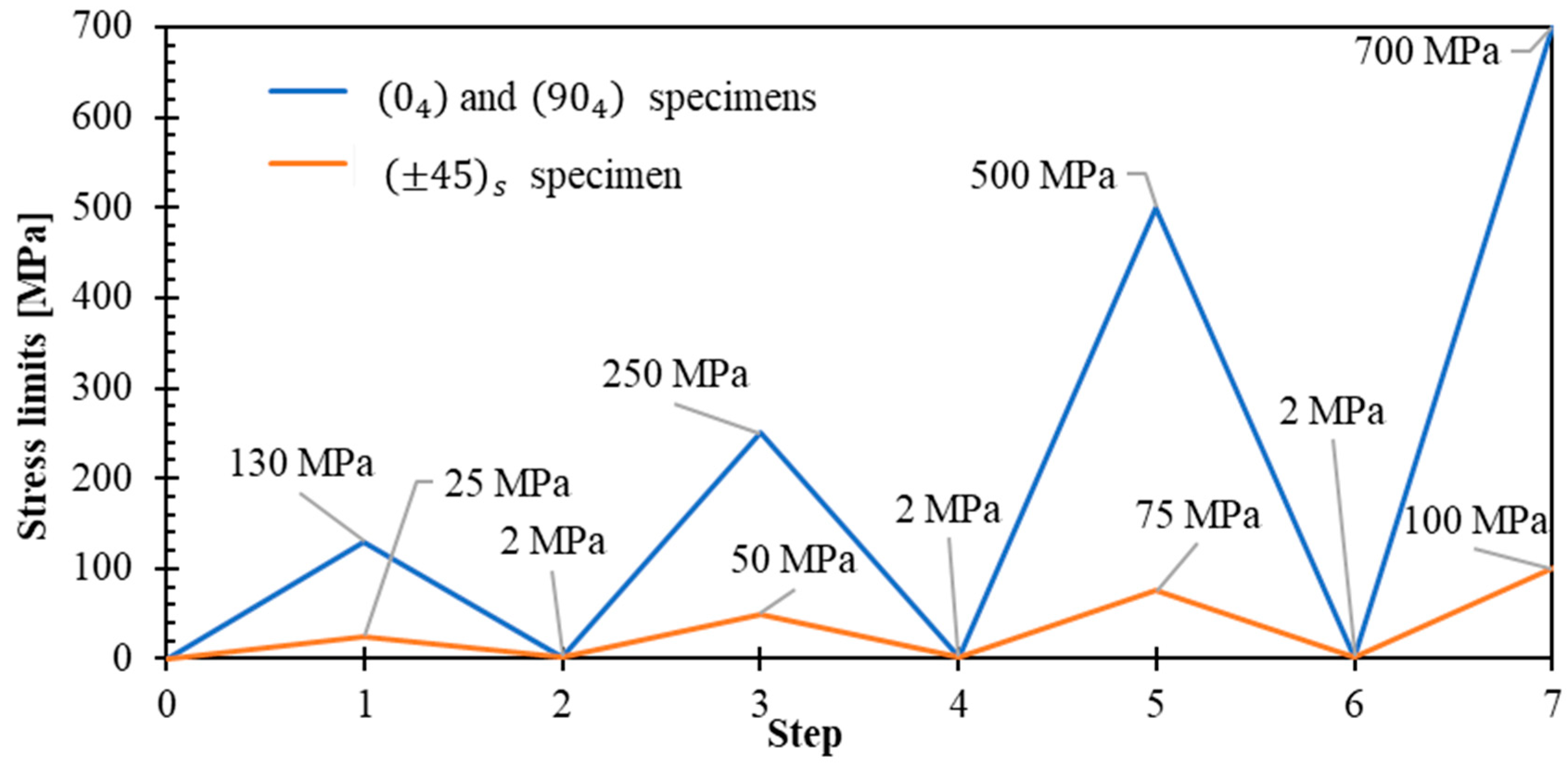

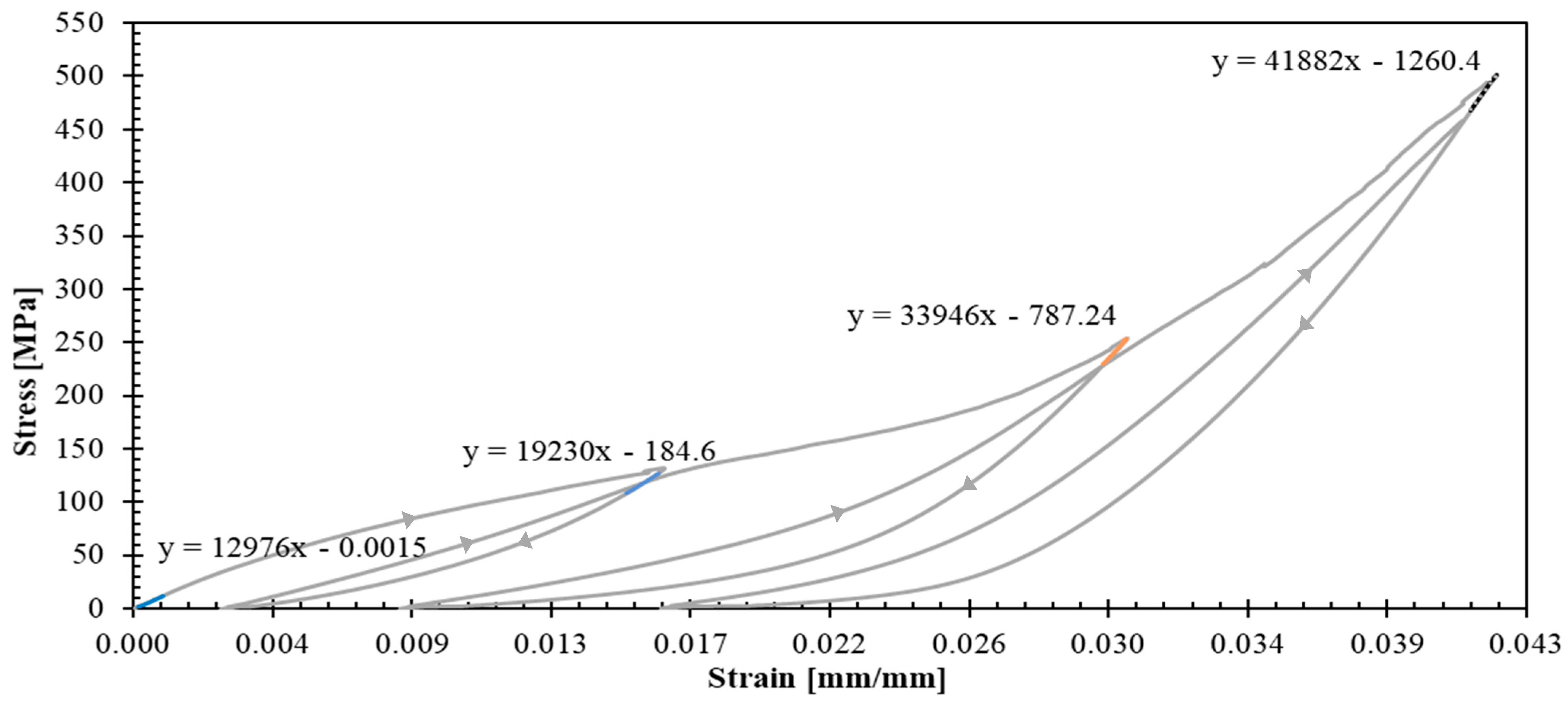

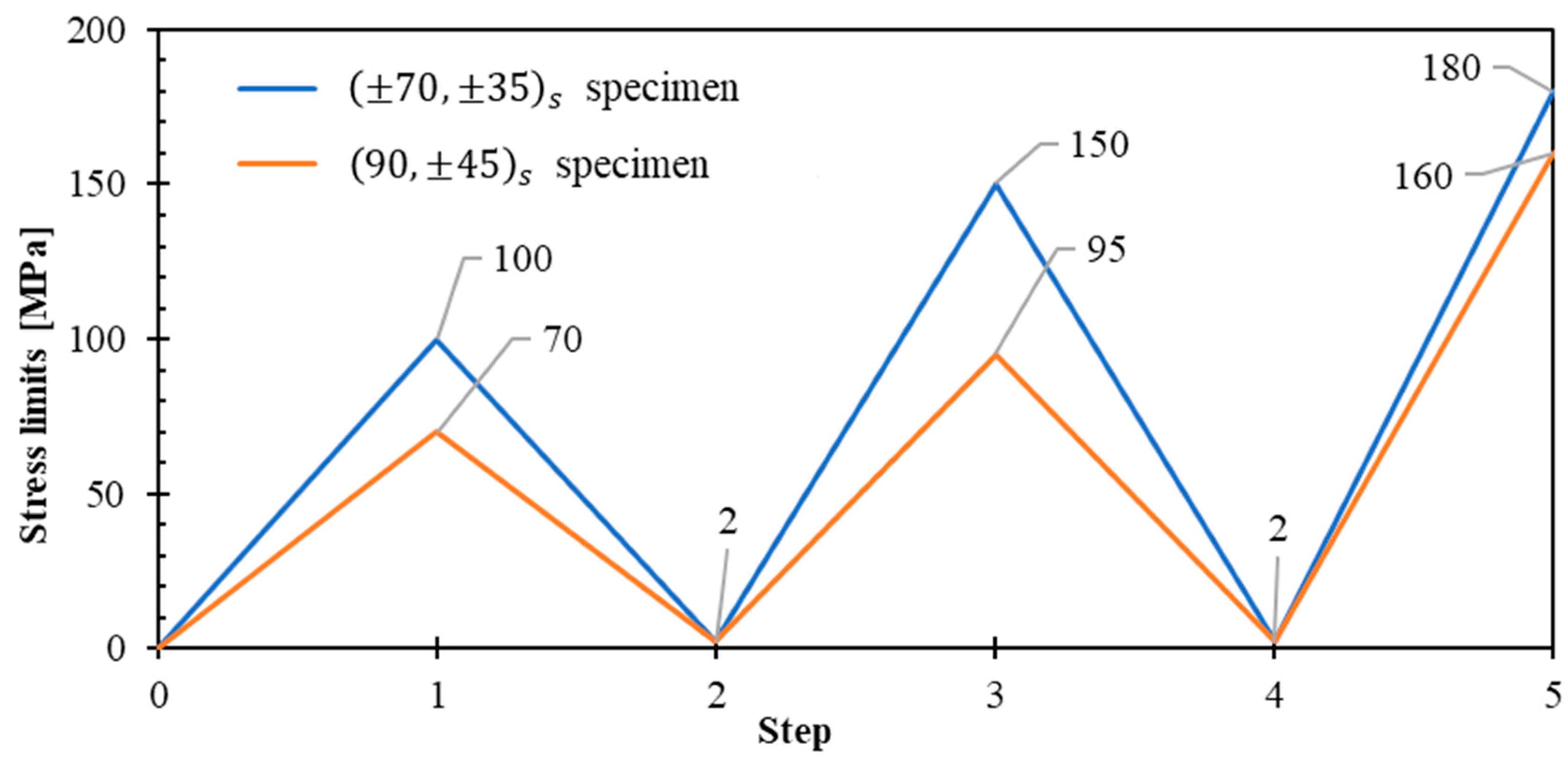

- Loading conditions. All tensile tests employed strain-rate control with stress-delimited unloading–reloading cycles for , , and directions (Figure 3). Key testing parameters included:

- Strain rate: 100%/min (selected to minimize viscous effects for ballistic application relevance while retaining a plasticity-based modeling approach). The universal testing system used is electromechanical equipment; therefore, higher strain rates cannot be achieved. Higher strain-rate testing would be beneficial and could be achieved using a split Hopkinson pressure bar (SHPB) or hydraulic devices (102 s−1 to 104 s−1 [29]); however, these equipment are not available in our laboratory. Dynamic testing on woven composites has been previously conducted using SHPB techniques [30,31], and the strain-rate dependent behavior of Kevlar® fibers is well documented [32,33].

- Minimum stress threshold: 2 MPa (established for safety to prevent compression-induced buckling).

- Test environment: ambient laboratory conditions.

- Cyclic loading strategy. The stress-controlled unloading–reloading protocol was specifically designed for each laminate orientation to characterize:

- Elastic and plastic strain components.

- Material stiffening effects during loading cycles.

- Hysteresis behavior and energy dissipation mechanisms.

3. Results

4. Elastoplastic Constitutive Model Development

- Strain hardening in specimens and .

- Nonlinear response beyond the yield stress with plastic strains in all the three tested laminates.

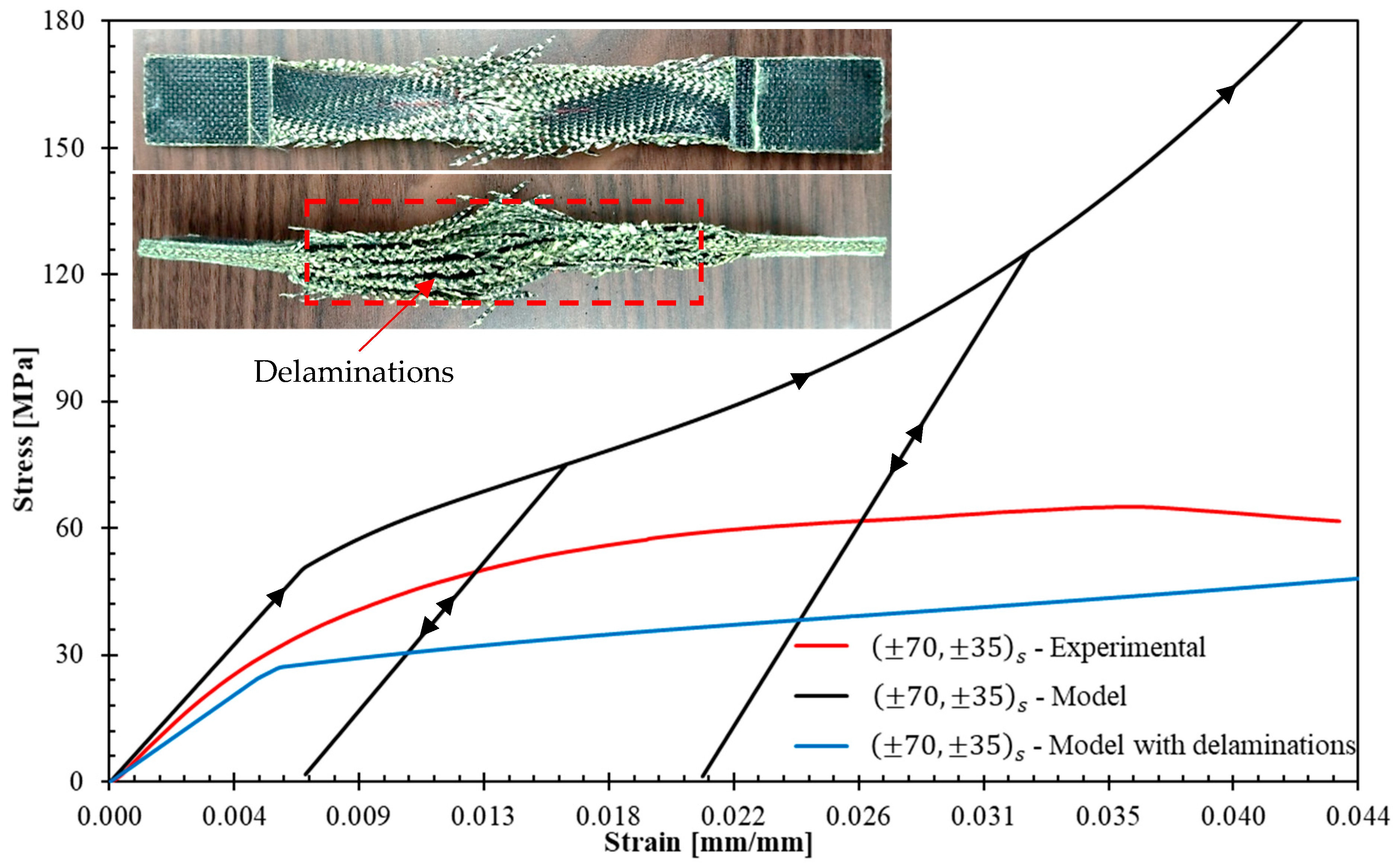

- Progressive evolution of apparent elastic moduli—increasing in specimens and due to yarn straightening effects, while decreasing in specimen .

- Directions and represent the principal longitudinal and transversal orthotropy directions within the lamina plane, while direction corresponds to the through-thickness direction. A plane stress state is adopted, which implies that .

- The Hill equivalent stress and initial yield stress are defined as follows [37].where , , , and are parameters that depend on the yield stresses in the orthotropy directions and will be defined later.

- A Hill plasticity criterion with hardening is adopted [37]. The yield function is:where is the hardening function defined by:The hardening function presented in Equation (3) constitutes a first originality of the model, where, , , and are hardening parameters that must be identified and is the equivalent plastic strain and will be expressed later.

- Associated plasticity is considered, which implies that the plastic potential is equal to the yield function [38]. A normal flow rule is assumed, so the infinitesimal variations of the plastic strain vector :where vector is defined by:where the superscript denotes transposition.

- The elastic behavior relates to the in-plane stress vector with the elastic strain vector :where is the elastic stiffness matrix in the material principal axes system, it is defined by:

- The plasticity-induced changes in elastic moduli and Poisson’s ratios (, ) are modeled according to the following expressions (Equation (8)):where , , , and are elastic properties derived from the initial slope of the axial stress–strain curves from laminates , , and ; , , , and are stiffening parameters that must be determined. It is worth mentioning that damage is not considered in the model and to reproduce the decrease in the apparent modulus of the laminate, must be negative.

- The total strain vector is equal to the sum of the elastic and plastic strain vectors.

- In an infinitesimal plastic process, the variation of equivalent plastic strain is derived from the consistency condition , the flow rule (Equation (4) and Equation (5)), and the elastic behavior (Equation (6)):To identify the model parameters, first, it is useful to observe that, according to Figure 13, for tests with , the plastic deformation variations . According to Equation (8) and Equation (9), in those tests one obtains , which means that one should chose . The parameters , , and that appear in the yield function (Equation (2)) are related to the initial yield stresses , , and that would be directly measured in tensile tests with laminates and and with a shear test with a laminate (these latter tests were not performed in this work):The computational implementation employs classical laminated plate theory for symmetric laminates under uniaxial tension, with the complete system of equations solved using SCILAB software. Parameter identification follows a least-squares optimization approach, fitting theoretical predictions to experimental data from representative stress–strain curves (Figure 9, Figure 10 and Figure 12) and apparent elastic moduli measured during unloading cycles. The parameters , , , , , , , , , and are identified and presented in Table 2.

5. Model Accuracy Assessment for Alternative Laminates

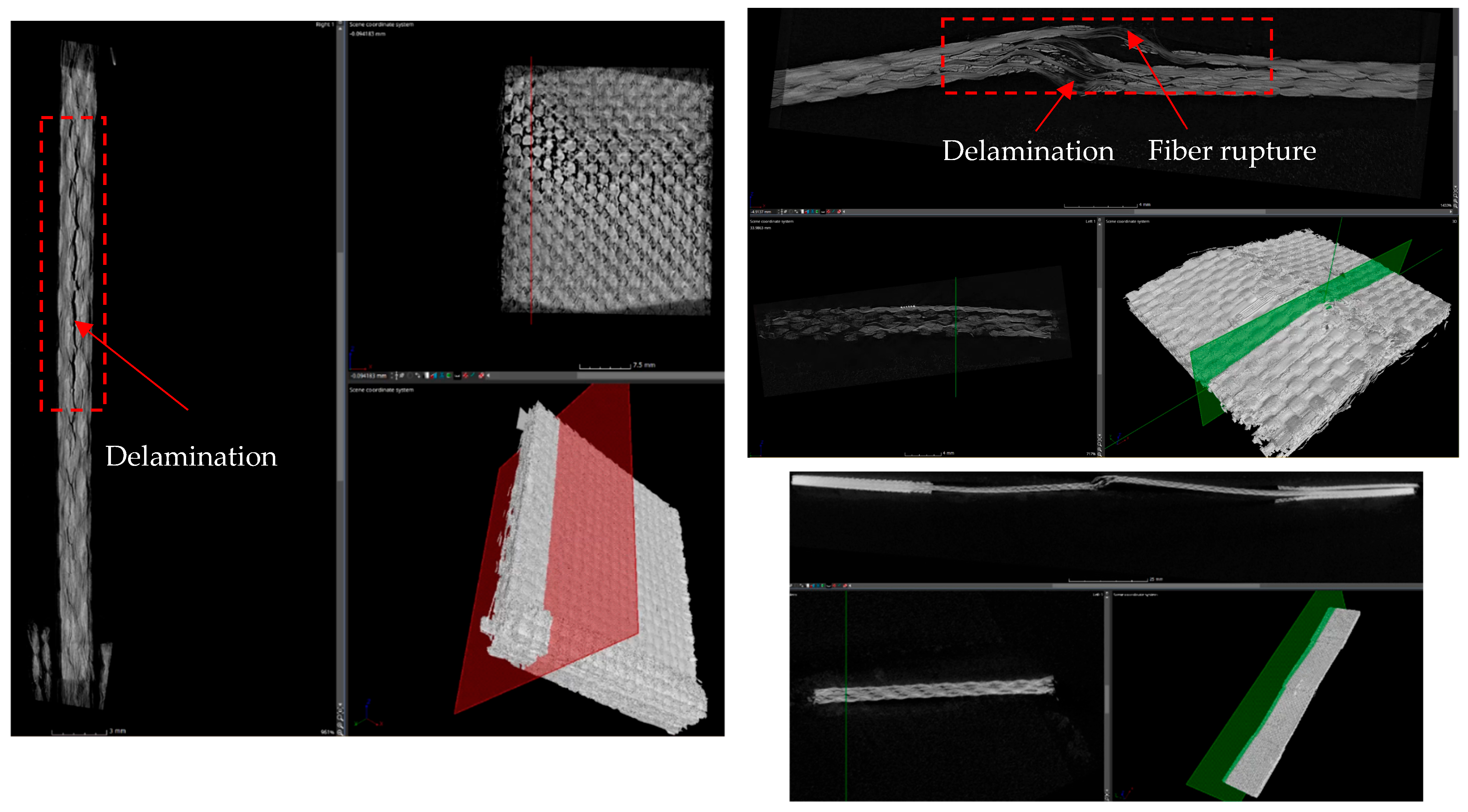

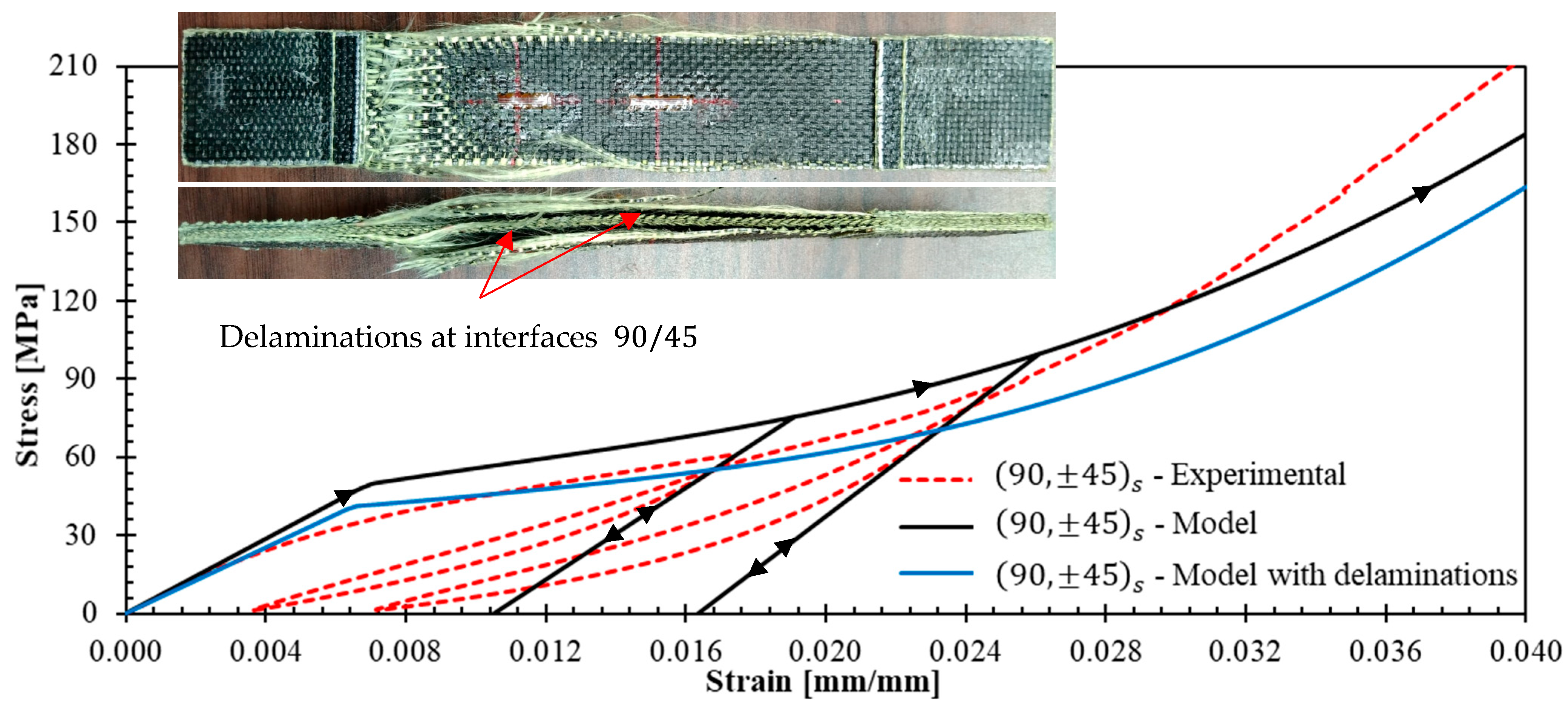

- Laminate with delaminations is modeled by the set of the following five parallel sub-laminates: , , , , and .

- Laminate with delaminations is simulated by the set of three parallel sub-laminates: , , and .

6. Conclusions

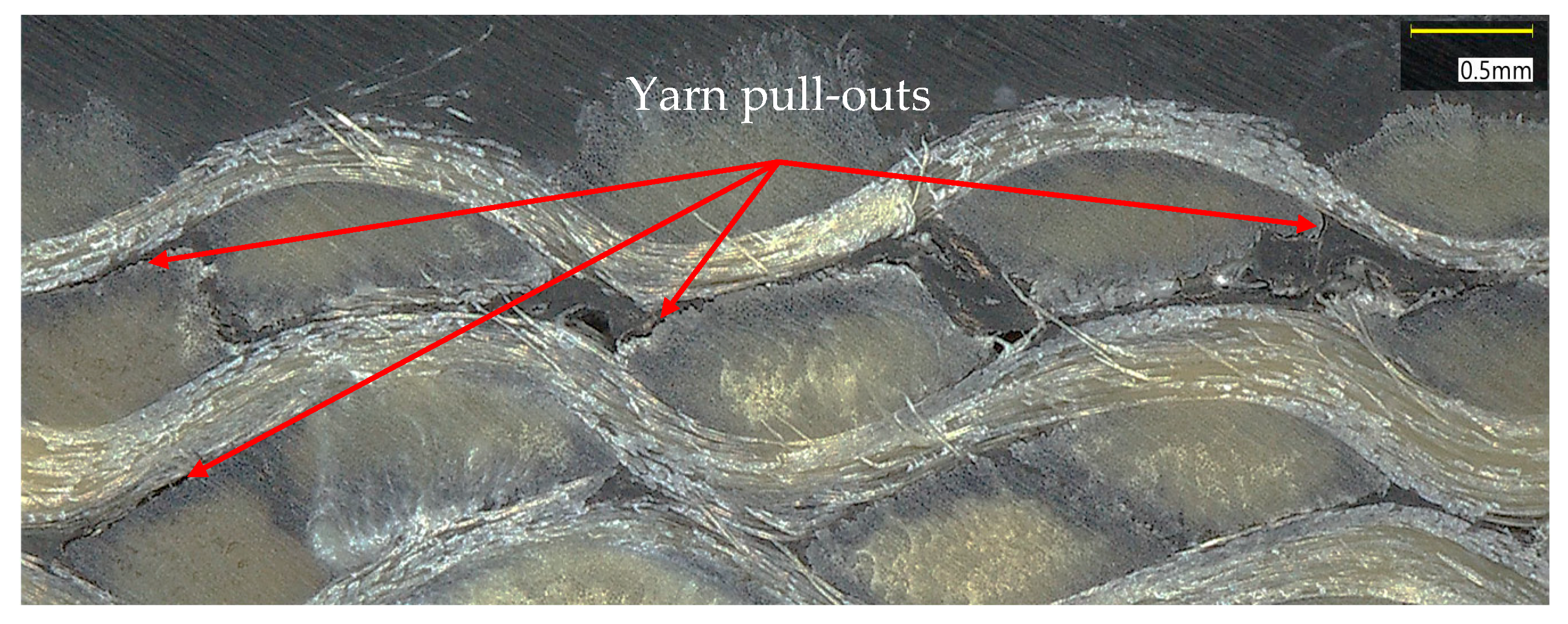

- Cyclic tensile tests at 100%/min strain rate revealed distinct mechanical behaviors: fiber-dominated directions ( and ) exhibited nonlinear hardening and progressive yarn stiffening, whilst the shear-dominated specimen demonstrated a compliance increase. Hysteresis loops observed across all orientations indicate energy dissipation caused by damage of matrix/yarn interfaces and friction during the sliding of yarns within the matrix.

- A novel elastoplastic model was successfully developed incorporating Hill’s yield criterion for orthotropic materials, a hardening function accounting for accumulated plastic strains, and progressive stiffening mechanisms, representing yarn straightening effects. The model accurately predicts stress–strain behavior for symmetric laminates with various ply orientations.

- Validation tests with other laminates [ and ] showed good agreement between model predictions and experimental behavior. However, limitations include premature free-edge delamination in diverse orientations due to high interlaminar stresses, inability to predict ultimate failure. Despite these limitations, experimental curves remained within model predictions.

- Future work will focus on determining interlaminar stresses using a layerwise theory, incorporating the through-thickness mechanical properties presented by Canceco et al. [41] and the findings from this manuscript. Delamination initiation and propagation can be simulated using a cohesive zone model, which requires additional parameters and more in-depth investigation. This comprehensive modeling strategy can be implemented in future studies using commercial finite element software.

- Additional specimens are required for testing in all three directions to develop a statistically robust model with appropriate confidence intervals and variability assessment. Unfortunately, insufficient material is available to conduct these additional tests due to constraints in the as-received fabric geometry. Nevertheless, the model successfully captures key phenomena occurring in the material, including yarn stiffening during each unloading cycle and nonlinear behavior beyond the yield stress.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Daniel, I.M.; Ishai, O. Engineering Mechanics of Composite Materials; Oxford university press: New York, NY, USA, 2006. [Google Scholar]

- COMSOL Multiphysics. Composite Materials Module. User Guide. Available online: https://doc.comsol.com/6.0/doc/com.comsol.help.compmat/CompositeMaterialsModuleUsersGuide.pdf (accessed on 14 August 2025).

- Hoof, J.V. Modelling of Impact Induced Delamination in Composite Materials. Ph.D. Thesis, Ottawa-Carleton Institute for Mechanical and Aerospace Engineering, Ottawa, ON, Canada, 1999. [Google Scholar]

- Bresciani, L.M.; Manes, A.; Ruggiero, A.; Iannitti, G.; Giglio, M. Experimental tests and numerical modelling of ballistic impacts against Kevlar 29 plain-woven fabrics with an epoxy matrix: Macro-homogeneous and Meso-heterogeneous approaches. Compos. Part B Eng. 2016, 88, 114–130. [Google Scholar] [CrossRef]

- Nunes, S.G.; Scazzosi, R.; Manes, R.; Amico, R.C.; de Amorim Júnior, W.F.; Giglio, M. Influence of projectile and thickness on the ballistic behavior of aramid composites: Experimental and numerical study. Int. J. Impact Eng. 2019, 132, 103307. [Google Scholar] [CrossRef]

- Scazzosi, R.; Manes, A.; Petrone, G.; Giglio, M. Two different modelling approaches for fabric composites subjected to ballistic impact. IOP Conf. Ser. Mater. Sci. Eng. 2018, 406, 012051. [Google Scholar] [CrossRef]

- Li, Z.; Xue, Y.; Sun, B.; Gu, B. Hybrid ratio optimizations on ballistic penetration of carbon Kevlar UHMWPE fiber laminates. Int. J. Mech. Sci. 2023, 258, 108585. [Google Scholar] [CrossRef]

- Umbharatwala, M.D.; Goel, M.D. Experimental, numerical and analytical prediction of ballistic resistance of indigenously developed zirconia toughened alumina, Kevlar® and CFRP composite. Compos. Part B Eng. 2024, 282, 111582. [Google Scholar] [CrossRef]

- Tan, L.B.; Tse, K.M.; Lee, H.P.; Tan, V.B.C.; Lim, S.P. Performance of an advanced combat helmet with different interior cushioning systems in ballistic impact: Experiments and finite element simulations. Int. J. Impact Eng. 2012, 50, 99–112. [Google Scholar] [CrossRef]

- Caçoilo, A.; Mourão, R.; Teixeira-Dias, F.; Azevedo, A.; Coghe, F.; Valente, R. Modelling ballistic impact on military helmets: The relevance of projectile plasticity. Def. Technol. 2021, 17, 1699–1711. [Google Scholar] [CrossRef]

- Lee, H.; Gong, S. Finite element analysis for the evaluation of protective functions of helmets against ballistic impact. Comput. Methods Biomech. Biomed. Eng. 2010, 13, 537–550. [Google Scholar] [CrossRef] [PubMed]

- Gower, H.; Cronin, D.; Plumtree, A. Ballistic impact response of laminated composite panels. Int. J. Impact Eng. 2008, 35, 1000–1008. [Google Scholar] [CrossRef]

- de la Cruz, C.R.A.; Gallardo, C.; Diaz, D.; Aviles, Z.L.A.; Barrera, P.; Ramirez, H.J.M. In-Plane Mechanical Characterization of a Kevlar® Composite. Fibers 2024, 12, 38. [Google Scholar] [CrossRef]

- Duan, Y.; Keefe, M.; Bogetti, T.A.; Cheeseman, B.A.; Powers, B. A numerical investigation of the influence of friction on energy absorption by a high-strength fabric subjected to ballistic impact. Int. J. Impact Eng. 2006, 32, 1299–1312. [Google Scholar] [CrossRef]

- Guoqi, Z.; Goldsmith, W.; Dharan, C.H. Penetration of laminated Kevlar by projectiles—I. Experimental investigation. Int. J. Solids Struct. 1992, 29, 399–420. [Google Scholar] [CrossRef]

- Shim, V.P.W.; Lim, C.T.; Foo, K.J. Dynamic mechanical properties of fabric armour. Int. J. Impact Eng. 2001, 25, 1–15. [Google Scholar] [CrossRef]

- Li, Y.Q.; Li, X.G.; Gao, X.-L. Modeling of Advanced Combat Helmet Under Ballistic Impact. J. Appl. Mech. 2015, 82, 111004. [Google Scholar] [CrossRef]

- Hoof, J.V.; Cronin, D.S.; Worswick, M.J.; Williams, K.; Nandlall, D. Numerical head and composite helmet models to predict blunt trauma. In Proceedings of the 19th International Symposium of Ballistics, Interlaken, Switzerland, 7–11 May 2001; IBS (International Ballistics Society): Thun, Switzerland. [Google Scholar]

- Audibert, C.; Andreani, A.-S.; Lainé, É.; Grandidier, J.-C. Mechanical characterization and damage mechanism of a new flax-Kevlar hybrid/epoxy composite. Compos. Struct. 2018, 195, 126–135. [Google Scholar] [CrossRef]

- Sun, C.; Chen, J. A Simple Flow Rule for Characterizing Nonlinear Behavior of Fiber Composites. J. Compos. Mater. 1989, 23, 1009–1020. [Google Scholar] [CrossRef]

- Goyal, D.; Whitcomb, J.D.; Tang, X. Validation of full 3D and equivalent tape laminate modeling of plasticity induced non-linearity in 2 × 2 braided composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 747–760. [Google Scholar] [CrossRef]

- Vogler, M.; Rolfes, R.; Camanho, P. Modeling the inelastic deformation and fracture of polymer composites—Part I: Plasticity model. Mech. Mater. 2013, 59, 50–64. [Google Scholar] [CrossRef]

- Camanho, P.; Bessa, M.; Catalanotti, G.; Vogler, M.; Rolfes, R. Modeling the inelastic deformation and fracture of polymer composites—Part II: Smeared crack model. Mech. Mater. 2013, 59, 36–49. [Google Scholar] [CrossRef]

- Tan, W.; Falzon, B.G. Modelling the nonlinear behaviour and fracture process of AS4/PEKK thermoplastic composite under shear loading. Compos. Sci. Technol. 2016, 126, 60–77. [Google Scholar] [CrossRef]

- Van Paepegem, W.; De Baere, I.; Degrieck, J. Modelling the nonlinear shear stress–strain response of glass fibre-reinforced composites. Part II: Model development and finite element simulations. Compos. Sci. Technol. 2006, 66, 1465–1478. [Google Scholar]

- Diaz, A.D.; Caron, J.-F.; Carreira, R.P. Software application for evaluating interfacial stresses in inelastic symmetrical laminates with free edges. Compos. Struct. 2002, 58, 195–208. [Google Scholar] [CrossRef]

- Hoa, S.V.; Gay, D.; Tsai, S. Composite Materials: Design and Applications; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Siviour, C.R.; Jordan, J.L. High Strain Rate Mechanics of Polymers: A Review. J. Dyn. Behav. Mater. 2016, 2, 15–32. [Google Scholar] [CrossRef]

- Ghiaskar, A.; Nouri, M.D. Numerical and experimental investigation of impact strength and fracture mechanism of Kevlar and Hemp elastomeric thin biocomposite laminate under high-velocity impact: A comparative study. Mater. Today Commun. 2023, 37, 106935. [Google Scholar] [CrossRef]

- Pankow, M.; Salvi, A.; Waas, A.; Yen, C.; Ghiorse, S. Split Hopkinson pressure bar testing of 3D woven composites. Compos. Sci. Technol. 2011, 71, 1196–1208. [Google Scholar] [CrossRef]

- Yazici, M. Loading Rate Sensitivity of High Strength Fibers and Fiber/Matrix Interfaces. J. Reinf. Plast. Compos. 2008, 28, 1869–1880. [Google Scholar] [CrossRef]

- Zhu, D.; Mobasher, B.; Erni, J.; Bansal, S.; Rajan, S. Strain rate and gage length effects on tensile behavior of Kevlar 49 single yarn. Compos. Part A Appl. Sci. Manuf. 2012, 43, 2021–2029. [Google Scholar] [CrossRef]

- Askeland, D.R.; Phulé, P.P.; Wright, W.J.; Bhattacharya, D.K. The Science and Engineering of Materials; CL Engineering: Stamford, CT, USA, 2010. [Google Scholar]

- Clegg, R.; White, D.; Riedel, W.; Harwick, W. Hypervelocity impact damage prediction in composites: Part I—Material model and characterisation. Int. J. Impact Eng. 2006, 33, 190–200. [Google Scholar] [CrossRef]

- Ito, M.; Chou, T.-W. An Analytical and Experimental Study of Strength and Failure Behavior of Plain Weave Composites. J. Compos. Mater. 1998, 32, 2–30. [Google Scholar] [CrossRef]

- Hill, R. A theory of the yielding and plastic flow of anisotropic metals. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1948, 193, 281–297. [Google Scholar]

- Lemaitre, J.; Chaboche, J.-L. Mechanics of Solid Materials; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar]

- Carreira, R.; Caron, J.; Diaz, A.D. Model of multilayered materials for interface stresses estimation and validation by finite element calculations. Mech. Mater. 2002, 34, 217–230. [Google Scholar] [CrossRef]

- Caron, J.; Diaz, A.D.; Carreira, R.; Chabot, A.; Ehrlacher, A. Multi-particle modelling for the prediction of delamination in multi-layered materials. Compos. Sci. Technol. 2006, 66, 755–765. [Google Scholar] [CrossRef]

- Canceco de la Cruz, R.A.; Díaz, A.D.; Barrera, G.P.; Ramírez, J.M.H. Caracterización mecánica a través del espesor de un compuesto de Kevlar. In Memorias del Congreso Internacional de Metalurgia y Materiales; Tecnológico Nacional de México: Saltillo Coahuila, Mexico, 2024. [Google Scholar]

| [MPa]: 14 103 | [GPa]: 5.32 103 | [MPa]: 97.7 | [GPa]: 2.88 |

| [MPa]: 13 103 | [GPa]: 3.92 103 | [MPa]: 85.8 | [GPa]: 3.41 105 |

| [MPa]: 0.802 103 | [GPa]: −9.0 | [MPa]: 9.5 | [-]: 1.4 |

| [-]: 0.36 | – | – | [-]: 4.1 |

| - | Laminate | ||||||

|---|---|---|---|---|---|---|---|

| Interface Stresses | |||||||

| +70/−70 | −70/+35 | +35/−35 | −35/−35 | 90/+45 | +45/−45 | −45/−45 | |

| (MPa) | 1.42 | 0.35 | 0.86 | 0.00 | 0.49 | 0.07 | 0.00 |

| (MPa) | 0.30 | 0.01 | 0.02 | 0.02 | 0.02 | 0.04 | 0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Canceco de la Cruz, R.A.; Zúñiga Avilés, L.A.; Plascencia Barrera, G.; Díaz Díaz, A.; Herrera Ramírez, J.M. Elastoplastic Modeling of Kevlar® Composite Laminates: A Cyclic Loading Approach for In-Plane Characterization. Polymers 2025, 17, 2235. https://doi.org/10.3390/polym17162235

Canceco de la Cruz RA, Zúñiga Avilés LA, Plascencia Barrera G, Díaz Díaz A, Herrera Ramírez JM. Elastoplastic Modeling of Kevlar® Composite Laminates: A Cyclic Loading Approach for In-Plane Characterization. Polymers. 2025; 17(16):2235. https://doi.org/10.3390/polym17162235

Chicago/Turabian StyleCanceco de la Cruz, Rene Alejandro, Luis Adrián Zúñiga Avilés, Gabriel Plascencia Barrera, Alberto Díaz Díaz, and José Martin Herrera Ramírez. 2025. "Elastoplastic Modeling of Kevlar® Composite Laminates: A Cyclic Loading Approach for In-Plane Characterization" Polymers 17, no. 16: 2235. https://doi.org/10.3390/polym17162235

APA StyleCanceco de la Cruz, R. A., Zúñiga Avilés, L. A., Plascencia Barrera, G., Díaz Díaz, A., & Herrera Ramírez, J. M. (2025). Elastoplastic Modeling of Kevlar® Composite Laminates: A Cyclic Loading Approach for In-Plane Characterization. Polymers, 17(16), 2235. https://doi.org/10.3390/polym17162235