Abstract

Nowadays, 3D printing technologies are among the rapidly developing technologies applied to manufacture even the most geometrically complex models, however no techniques dominate in the area of craniofacial applications. This study included 12 different anatomical structures of the mandible, which were obtained during the process of reconstructing data from the Siemens Somatom Sensation Open 40 system. The manufacturing process used for the 12 structures involved the use of 8 3D printers and 12 different polymer materials. Verification of the accuracy and radiological density was performed with the CT160Xi Benchtop tomography system. The most accurate results were obtained in the case of models manufactured using the following materials: E-Model (Standard Deviation (SD) = 0.145 mm), FullCure 830 (SD = 0.188 mm), VeroClear (SD = 0.128 mm), Digital ABS-Ivory (SD = 0.117 mm), and E-Partial (SD = 0.129 mm). In the case of radiological density, ABS-M30 was similar to spongious bone, PC-10 was similar to the liver, and Polylactic acid (PLA) and Polyethylene terephthalate (PET) were similar to the spleen. Acrylic resin materials were able to imitate the pancreas, kidney, brain, and heart. The presented results constitute valuable guidelines that may improve currently used radiological phantoms and may provide support to surgeons in the process of performing more precise treatments within the mandible area.

1. Introduction

Nowadays, 3D printing technology is among the rapidly developing methods applied to manufacture even the most geometrically complex models. Manufacturing a model with 3D printing techniques consists of adding materials layer-by-layer, thus gradually forming the desired shape [1,2]. The input model is designed by means of computer-aided design (CAD) systems [3,4] or reverse engineering (RE) methods [5,6] and is saved in standard triangulate language (STL) format. Before the actual object is manufactured, it is divided into layers. The single-layer thickness largely depends on the additive manufacturing method used. Depending on the manufacturing technology, as well as the dimensions of the object and the complexity of its geometry, manufacturing ready-made models using 3D printing techniques may take several hours or even several days. As a result, this manufacturing technology is mainly used for piece production [7,8,9]. At present, there is a wide variety of ways to manufacture models by applying 3D printing techniques (Table 1). Differences in their functioning occur mainly in the way subsequent layers are cured and the type of material used. Each 3D printer has specific characteristics and requirements related to the working conditions (e.g., material, environmental conditions, printing temperature, and finishing of the model) [1,2,10,11]. Models made with 3D printing techniques are used in the aviation [12,13,14], automotive [15,16], medical [17,18,19], and dental industries [20,21,22], as well as in architecture [23] and agriculture [24].

Table 1.

Additive manufacturing processes.

Materials currently used in the 3D printing process include metals [25,26], polymers [27,28,29], ceramics [30,31], and composites [32,33]. However, polymer materials have also been increasingly used. This is due to the wide availability of polymer materials with different mechanical properties related to biocompatibility with human tissues, among others. Polymers can be divided into thermoplastics and thermosets. Thermoplastics are polymers that can be heated above a certain temperature and which solidify when cooled down. Once solid, they can be remelted and reformed again. Thermoplastics are best suited for the production of ready-made products and test prototypes. Some thermoplastic materials have good mechanical properties, as well as high impact abrasion (e.g., polyetheretherketone (PEEK)) [34,35] and chemical resistance (e.g., polylactic acid (PLA)) [36]. Thermosetting resins cannot be melted and reshaped by heating once they are solidified. When subject to high temperatures they will decompose. Thermosetting resins are better suited for aesthetically critical applications because they can be used to produce smooth-surface parts, such as in injection molding. They generally have high stiffness but are more brittle than thermoplastics, so they are not suitable for functional applications [37,38,39]. The use of polymer materials in the medical industry has grown rapidly in recent years. At present, polymer materials are used to 3D print anatomical structures [40,41,42], surgical templates [43,44], implants [45,46], scaffolds [47,48], and tools for patient rehabilitation [49,50].

Recently, there has also been a significant increase in research on the accuracy of manufactured anatomical structures, including those used in surgical processes, e.g., in the craniofacial area. These studies mainly concern accurate dimensional and geometric analysis [41,51,52]. In the literature, research on changes in linear [51,52] and geometric dimensions [40,41,42] also applies to models made of polymer materials. Verification of characteristic linear dimensions is carried out using a caliper [53,54,55,56], coordinate machine [57,58], and measuring arm [59,60]. In the process of evaluating geometric errors, optical systems are used [41,42,61]. There are also publications that take into account the use of tomographic systems in the process of assessing the accuracy [62] and radiological density of 3D printed phantoms used in medical diagnostics [63,64,65]. In this case, the most frequently analyzed polymer materials are acrylonitrile butadiene styrene (ABS) [64,66,67], polylactic acid (PLA) [66,67,68,69], and acrylic resins [65,70].

Even though new types of polymer materials [71,72] are being discovered and there is wide access to various 3D printing techniques [1,2], none of the currently used techniques dominate in the area of craniofacial applications. This mainly is due to the different properties of the polymer materials used in manufacturing diagnostic phantoms [68,69,70], which do not necessarily reflect the radiological density of human tissues and the requirements for accurate manufacturing of the anatomical structure or surgical template [48]. Currently, the literature lacks studies conducted on a wider group of polymer materials that at the same time take into account analyses of the radiological density and accuracy of manufactured anatomical structures. Research in this area will deepen the knowledge on the fields of medicine and technical sciences. As a result, it will be possible to select specific 3D printing techniques in terms of the accuracy of a model, so as to increase the precision of surgical procedures related to the craniofacial area, among others. Additionally, ensuring the assessment of radiological density will allow for future developments of mandible geometry phantoms to consist of elements with densities similar to those of human tissues and the most common cysts and tumors in the mandible area (e.g., inflammatory cysts or ameloblastomas). It is particularly important to initiate research on the development of tomography phantoms in the mandible area to more precisely diagnose tumorous lesions. Delayed diagnosis and detection of a tumor (e.g., place and volume) within the mandible area most often leads to removal of the pathogenic tissue, consisting of resectioning a part of the mandible bone. Reconstruction of the mandible geometry after resection, including on an iliac or fibular bone graft, does not allow for full functionality of the mandible because it is the only moving bone in the craniofacial area subjected to multidirectional dynamic loads during the biting and chewing process [41,43]. Therefore, it is important to analyze the available polymer materials, in terms of the radiological density and accuracy of manufacturing, in order to use these materials in the future and create radiological phantoms of the mandible to test the occurrence of various clinical pathologies in this area.

2. Materials and Methods

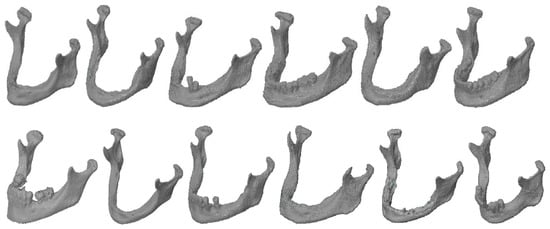

The study included 12 different anatomical structures of the mandible, the geometries of which were obtained by reconstructing digital imaging and communications in medicine (DICOM) data from the Siemens Somatom Sensation Open 40 Multi Detector Computed Tomography (MDCT) system scanner installed in the Regional Clinical Hospital No. 1 for all patients at the Frederic Chopin in Rzeszow. The Hospital gives permission to use the DICOM data as a part of the publication. The standard “head routine” protocol for diagnosing the craniofacial area was used in the measurement process. Then, in the course of reconstructing the mandible geometry using ITK-Snap software [72], segmented three-dimensional models were saved in STL format (Figure 1).

Figure 1.

The anatomical structures of the mandible.

The process of manufacturing the 12 anatomical mandible structures involved using 12 different polymer materials that are most commonly applied in the process of 3D printing of anatomical structures and elements when constructing radiological phantoms (Table 2). These structures were manufactured at the highest resolution possible for the 3D printers and with the model being fully filled inside. During printing, all models were oriented in the same way in the printer space, as shown in Figure 2a. The goal was to manufacture the side part of the mandible as accurately as possible, as it is the area to which surgical plates are most often bent when planning the procedure.

Table 2.

Selected polymer materials.

Figure 2.

The process of 3D printing and geometry digitalization: (a) Prusa MK3s 3D printer; (b) CT160Xi Benchtop tomography system.

Geometric accuracy and radiological density were verified with the CT160Xi Benchtop tomography system (Nikon Metrology, Herts, United Kingdom) (Figure 2b). The CT160Xi Benchtop tomography system is equipped with a lamp that generates an X-ray beam. It has a tungsten cathode and anode with an accelerating voltage range of 40–160 kV, an intensity range of 0–500 μA, and a maximum power of 60 W. The image is detected on the detector matrix and consists of 1900 (horizontal) × 1516 (vertical) pixels, which at the linear pixel size of 0.127 mm gives a surface size of 24.2 × 19.3 cm. In addition, the system includes a rotary table that allows for linear and angular movement and positioning of the measuring element. According to the Verein Deutscher Ingenieure (VDI)/Verband der Elektrotechnik (VDE) 2630 specifications, the accuracy of the computer tomography was verified. Computed tomography scans of the mandible were acquired at 80 kVp, 131 μA, and a voxel size 0.05 × 0.05 × 0.05 mm. The model in the tomograph space was oriented in the same way as shown in Figure 2a.

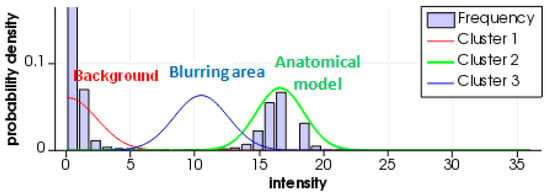

The anatomical structures of the mandible were reconstructed using ITK-Snap software. Using the prepared data, segmentation was performed using a Gaussian mixture model-based clustering algorithm [73]. This algorithm assumes that the distribution of each element in a random sample consists of a combination of less complex distributions that can be approximated to a Gaussian curve. Based on the analysis of the histogram showing the image pixel intensity distribution, the matching process was carried out (Figure 3).

Figure 3.

The process of grouping data for the Precimid 1170 material.

Then, a group of pixels representing the anatomical structure of the mandible was selected and subjected to geometric reconstruction using the active contour algorithm. This algorithm adjusts the contour to the outline of the anatomical structure determined in the segmentation process, allowing us in the end to fully reconstruct the geometry of the mandible.

3. Results

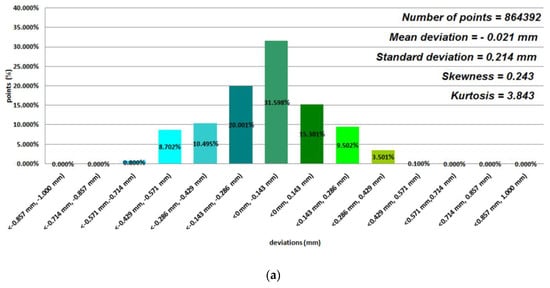

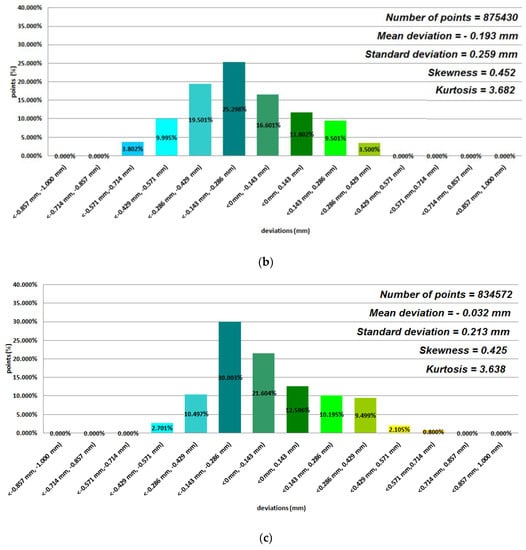

Data representing 12 models of anatomical mandible structures were used to assess the manufacturing accuracy with the Focus Inspection software for the 12 selected polymer materials (Figure 4, Figure 5, Figure 6 and Figure 7), while the radiological density was assessed using ITK-Snap software (Table 3). Until now, no studies on such a wide range of polymer materials have been presented in one publication.

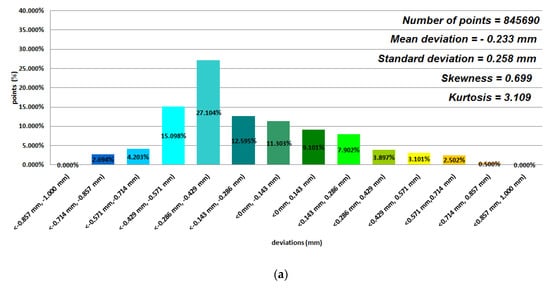

Figure 4.

Histograms representing average results of the 12 mandible structures: (a) ABS M-30 material; (b) PC-10 material; (c) Polylactic acid (PLA) material.

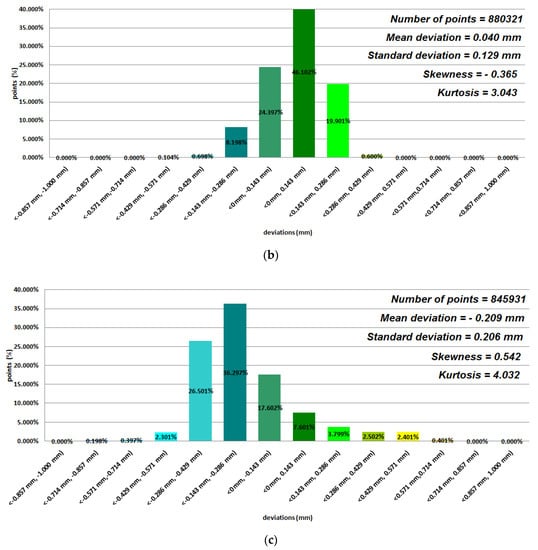

Figure 5.

Histograms representing average results of the 12 mandible structures: (a) Polyethylene terephthalate (PET) material; (b) E-Partial material; (c) E-Denstone material.

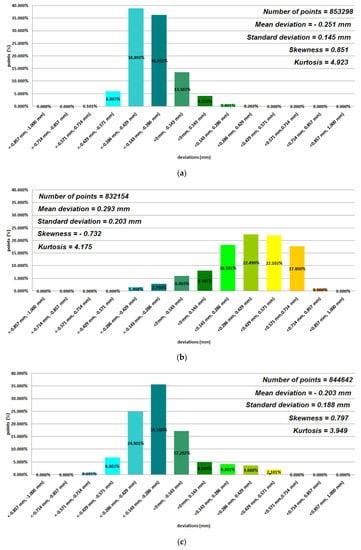

Figure 6.

Histograms representing average results of the 12 mandible structures: (a) E-Model material; (b) Precimid 1170 material; (c) FullCure 830 material.

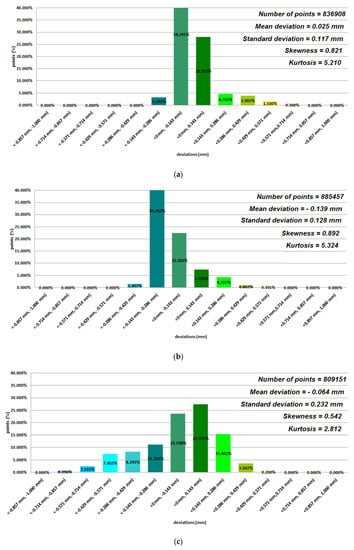

Figure 7.

Histograms representing average results of the 12 mandible structures: (a) Digital ABS-Ivory material; (b) VeroClear material; (c) RGD720 material.

Table 3.

Statistical parameters representing average Hounsfield (HU) values of 12 mandible models.

Based on the average statistical analysis of the mandible structure accuracies for the selected 12 polymers materials, the mean deviation, standard deviation, skewness, and kurtosis were determined with histograms. The normality of the data was assessed with the Shapiro–Wilk test (Figure 4, Figure 5, Figure 6 and Figure 7) and the value of the statistics test was W = 0.806 (p = 0.05 and n = 12). This value was higher than the critical value, and as a result we did not reject the hypothesis of the normal distribution. Accordingly, all obtained distributions were treated as normal. Each of the presented distributions was unimodal. The best results were obtained for models manufactured using the following materials: E-Model (Standard Deviation (SD) = 0.145 mm), FullCure 830 (SD = 0.188 mm), VeroClear (SD = 0.128 mm), Digital ABS-Ivory (SD = 0.117 mm), and E-Partial (SD = 0.129 mm). However, regarding the mean deviation values for the E-Model and FullCure 830 materials, these showed significant differences from the nominal value of −0.251 mm and −0.203 mm, respectively. This may have been influenced by their fastest shrinkage material process compared to other polymer materials. The highest value of the standard deviation was observed in the case of manufacturing models using FDM and MEM techniques (in the case of Polyethylene terephthalate (PET) and PC-10 materials). This may have also been influenced by the layer thickness. The obtained results were characterized with a positive skew. Only in the case of Precimid 1170 and E-Partial material was a negative skew observed (−0.732 and −0.365, respectively). Regarding kurtosis values, it can be seen that the data distributions were mainly leptokurtic. The exception was the model printed using RGD 720 material. It was noticed that when using the same 3D printer and parameters (orientation in the 3D printer space and layer thickness) but a different material (e.g., in the Fortus 360-mc or Objet350 Connex 3 cases), the accuracy of the printed model changed (Figure 4a,b and Figure 7).

Radiological densities were determined for the most characteristic human tissues [64]. By comparing the obtained results in Table 3, some materials can be assigned to specific human tissues. In the case of materials made using FDM and MEM techniques, ABS-M30 imitated radiological densities similar to those of spongious bone, while PC-10 imitated radiological densities similar to the liver. In the case of the PLA and PET material results in Table 3, these were very similar to the spleen. Considering acrylic resin materials, all radiological densities were between 20 HU and 40 HU. This value imitated the pancreas, kidney, brain, and heart. In the case of the Precimid 1170 material, it characterized the muscle.

When comparing the radiographic densities of the most known tumors and cysts for the mandibular area [74], E-Partial, E-Model, and E-Denstone imitated densities similar to those of ameloblastomas, nasopalatine duct cysts, and inflammatory cysts, respectively. RGD 720 and FullCure 830 imitated dentigerous cysts and keratocystic odontogenic tumors, respectively. The central giant cell lesion radiological density was imitated with the PC-10 material.

4. Discussion

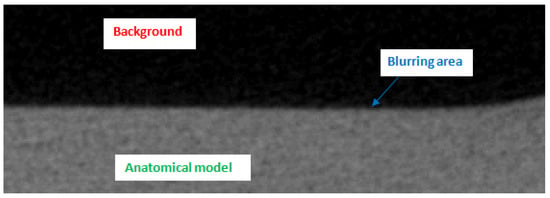

In view of the current research being conducted globally, we established that the main factors affecting the quality of the obtained radiological density and accuracy in mapping the geometries of anatomical structures do not solely result from the type of material used in the 3D printing process. In particular, the credibility of the obtained research results was also affected by the digitization stage and the processing of volumetric data [75,76,77]. In the case of carrying out diagnostics using a tomographic system, the measurement parameters (including tube potential, tube current, or pitch) and image reconstruction (including voxel size, convolution kernel, slice thickness) play important roles [75,77,78]. The spatial resolution of the image, which is also related to the voxel dimension, plays a particularly important part in reliably assessing the radiological density and accuracy of a geometric representation [76,78]. As a result of applying data characterized by voxel dimensions measuring 0.05 × 0.05 × 0.05 mm, the partial volume artifact was minimized. As shown in Figure 3, the normal distribution based on the segmentation algorithm that defines the blurring area covers only a small fraction of the pixels representing the image. As a result, it was possible to more accurately indicate the boundary between the background and the pixels defining the anatomical structure of the mandible on the tomographic image (Figure 8). This procedure made it possible not to understate or overestimate the volume of the model geometry subjected to the reconstruction process from tomographic images, and allowed us to estimate the radiological density of the material with greater accuracy.

Figure 8.

A part of the tomography image with specified areas for the Precimid 1170 material.

By analyzing the literature, the radiological density of selected polymer materials can be assessed [64,65,66,67]. However, there have been no studies carried out on such a wide range of polymer materials. Furthermore, 3D printing is becoming increasingly available and offers new opportunities to tailor phantoms for specific clinical and research purposes, including radiotherapy [63,64,65]. It is particularly important to initiate research on developing tomography phantoms of the mandible area to more precisely diagnose tumorous lesions.

5. Conclusions

Currently, 3D printing techniques play important roles in the medical and dental industries. Due to the wide availability of polymer materials used in the 3D printing process, it is possible to manufacture anatomical structures, surgical templates, implants, scaffolds, and tools that support patient rehabilitation. In the present research, the accuracy levels of the mandible anatomical structures and the radiological densities of 12 polymer materials were assessed. The results constitute valuable guidelines that may improve the currently used radiological phantoms and may provide support to surgeons when performing more precise treatments within the craniofacial area. The obtained results are a starting point and further studies should extend the research on the impacts of changing the contrast and spatial resolution of DICOM data on dimensional and geometric accuracy, as well as radiological density.

Author Contributions

Conceptualization, P.T. and G.B.; methodology, P.T., G.B., and Ł.P.; software, P.T., Ł.P.; formal analysis, P.T. and Ł.P.; investigation, P.T.; writing—original draft preparation, P.T.; writing—review and editing, G.B.; visualization, P.T.; supervision, P.T. and G.B. All authors have read and agreed to the published version of the manuscript.

Funding

Project financing through the program of “Podkarpackie Innovation Center” named “Regional Operational Program of the Podkarpackie Voivodeship” in 2014–2020, project number F3_17, to a financing amount of 10,286,000 PLN.

Acknowledgments

The authors would like to thank the Regional Clinical Hospital No. 1 in Rzeszow for the DICOM data for 12 patients obtained on the Siemens Somatom Sensation Open 40 scanner installed in this clinic.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gebhard, A. Rapid Prototyping; Hanser: Munich, Germany, 2003. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2014. [Google Scholar]

- Boboulos, M. CAD-CAM and Rapid Prototyping Application Evaluation. 2010. Available online: http://sietm.com/wp-content/uploads/2015/03/cad-cam-rapid-prototyping-application-evaluation.pdf (accessed on 19 October 2020).

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Raja, V.; Kiran, J.F. Reverse Engineering—An Industrial Perspective; Springer: New York, NY, USA, 2010. [Google Scholar]

- Bidanda, B.; Bartolo, P. Virtual Prototyping & Bio Manufacturing in Medical Applications; Springer: New York, NY, USA, 2008. [Google Scholar]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Melchels, F.P.; Domingos, M.A.; Klein, T.J.; Malda, J.; Bartolo, P.J.; Hutmacher, D.W. Additive manufacturing of tissues and organs. Prog. Polym. Sci. 2012, 37, 1079–1104. [Google Scholar] [CrossRef]

- Melchels, F.P.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B-Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Gisario, A.; Kazarian, M.; Martina, F.; Mehrpouya, M. Metal additive manufacturing in the commercial aviation industry: A review. J. Manuf. Syst. 2019, 53, 124–149. [Google Scholar] [CrossRef]

- Chu, M.Q.; Wang, L.; Ding, H.Y.; Sun, Z.G. Additive manufacturing for aerospace application. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2015; pp. 457–461. [Google Scholar]

- Rokicki, P.; Budzik, G.; Kubiak, K.; Dziubek, T.; Zaborniak, M.; Kozik, B.; Bernaczek, J.; Przeszlowski, L.; Nowotnik, A. The assessment of geometric accuracy of aircraft engine blades with the use of an optical coordinate scanner. Aircr. Eng. Aerosp. Tec. 2016, 88, 374–381. [Google Scholar] [CrossRef]

- Leal, R.; Barreiros, F.M.; Alves, L.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive manufacturing tooling for the automotive industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676. [Google Scholar] [CrossRef]

- Lecklider, T. 3D printing drives automotive innovation. Eval. Eng. 2017, 56, 16–20. [Google Scholar]

- Ciocca, L.; Mazzoni, S.; Fantini, M.; Persiani, F.; Baldissara, P.; Marchetti, C.; Scotti, R. A CAD/CAM-prototyped anatomical condylar prosthesis connected to a custom-made bone plate to support a fibula free lap. Med. Biol. Eng. Comput. 2012, 50, 743–749. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Ke, C.-J.; Yen, K.-C.; Hsieh, H.-C.; Sun, J.-S.; Lin, F.-H. 3D porous calcium-alginate scaffolds cell culture system improved human osteoblast cell clusters for cell therapy. Theranostics 2015, 5, 643–655. [Google Scholar] [CrossRef] [PubMed]

- Turek, P.; Budzik, G.; Oleksy, M.; Bulanda, K. Polymer materials used in medicine processed by additive techniques. Polimery 2020, 65, 510–515. [Google Scholar] [CrossRef]

- Faber, J.; Berto, P.M.; Quaresma, M. Rapid prototyping as a tool for diagnosis and treatment planning for maxillary canine impaction. Am. J. Orthod. Dentofac. Orthop. 2006, 129, 583–589. [Google Scholar] [CrossRef]

- Kwon, S.Y.; Kim, Y.; Ahn, H.-W.; Kim, K.-B.; Chung, K.-R.; Sunny, S.-H.K. Computer-Aided Designing and Manufacturing of Lingual Fixed Orthodontic Appliance Using 2D/3D Registration Software and Rapid Prototyping. Int. J. Dent. 2014, 2014, 164164. [Google Scholar] [CrossRef]

- Martorelli, M.; Gerbino, S.; Giudice, M.; Ausiello, P. A comparison between customized clear and removable orthodontic appliances manufactured using RP and CNC techniques. Dent. Mater. 2013, 29, e1–e10. [Google Scholar] [CrossRef]

- Gibson, I.; Kvan, T.; Ming, L.W. Rapid prototyping for architectural models. Rapid Prototyp. J. 2002, 8, 91–95. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Using additive manufacturing applications for design and development of food and agricultural equipments. Int. J. Mater. Prod. Technol. 2019, 58, 225–238. [Google Scholar] [CrossRef]

- Niu, X.; Singh, S.; Garg, A.; Singh, H.; Panda, B.; Peng, X.; Zhang, Q. Review of materials used in laser-aided additive manufacturing processes to produce metallic products. Front. Mech. Eng. 2019, 14, 1–17. [Google Scholar] [CrossRef]

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototy. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Dziubek, T.; Oleksy, M. Application of ATOS II optical system in the techniques of rapid prototyping of epoxy resin-based gear models. Polimery 2017, 62, 44–52. [Google Scholar] [CrossRef]

- García-Martínez, H.; Ávila-Navarro, E.; Torregrosa-Penalva, G.; Rodriguez-Martinez, A.; Blanco-Angulo, C.; de la Casa-Lillo, M. Low-Cost Additive Manufacturing Techniques Applied to the Design of Planar Microwave Circuits by Fused Deposition Modeling. Polymers 2020, 12, 1946. [Google Scholar] [CrossRef] [PubMed]

- Zanjanijam, A.R.; Major, I.; Lyons, J.G.; Lafont, U.; Devine, D.M. Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships. Polymers 2020, 12, 1665. [Google Scholar] [CrossRef] [PubMed]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive manufacturing of ceramic-based materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Deckers, J.; Vleugels, J.; Kruth, J.-P. Additive manufacturing of ceramics: A review. J. Ceram. Sci. Technol. 2014, 5, 245–260. [Google Scholar]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Manapat, J.Z.; Chen, Q.; Ye, P.; Advincula, R.C. 3D printing of polymer nanocomposites via stereolithography. Macromol. Mater. Eng. 2017, 302, 1600553. [Google Scholar] [CrossRef]

- Berretta, S.; Evans, K.; Ghita, O. Additive manufacture of PEEK cranial implants: Manufacturing considerations versus accuracy and mechanical performance. Mater. Des. 2018, 139, 141–152. [Google Scholar] [CrossRef]

- Chen, P.; Cai, H.; Li, Z.; Li, M.; Wu, H.; Su, J.; Wen, S.; Zhou, Y.; Liu, J.; Wang, C.; et al. Crystallization Kinetics of Polyetheretherketone during High Temperature-Selective Laser Sintering. Addit. Manuf. 2020, 36, 101615. [Google Scholar] [CrossRef]

- Kozior, T.; Mamun, A.; Trabelsi, M.; Sabantina, L.; Ehrmann, A. Quality of the Surface Texture and Mechanical Properties of FDM Printed Samples after Thermal and Chemical Treatment. Stroj. Vestn.-J. Mech. Eng. 2020, 66, 105–113. [Google Scholar]

- Dizon, J.R.C.; Espera, A.H., Jr.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Layani, M.; Wang, X.; Magdassi, S. Novel materials for 3D printing by photopolymerization. Adv. Mater. 2018, 30, 1706344. [Google Scholar] [CrossRef] [PubMed]

- Patel, D.K.; Sakhaei, A.H.; Layani, M.; Zhang, B.; Ge, Q.; Magdassi, S. Highly stretchable and UV curable elastomers for digital light processing based 3D printing. Adv. Mater. 2017, 29, 1606000. [Google Scholar] [CrossRef] [PubMed]

- Budzik, G.; Burek, J.; Bazan, A.; Turek, P. Analysis of the accuracy of reconstructed two teeth models manufactured using the 3DP and FDM technologies. Stroj. Vestn.-J. Mech. Eng. 2016, 62, 11–20. [Google Scholar] [CrossRef][Green Version]

- Budzik, G.; Turek, P.; Dziubek, T.; Gdula, M. Elaboration of the measuring procedure facilitating precision assessment of the geometry of mandible anatomical model manufactured using additive methods. Meas. Control. 2020, 53, 181–191. [Google Scholar] [CrossRef]

- Turek, P. Automatic the process of designing and manufacturing polymeric models of anatomical structures of mandible with Industry 4.0 convention. Polimery 2019, 64, 522–529. [Google Scholar] [CrossRef]

- Pietruski, P.; Majak, M.; Swiatek-Najwer, E.; Popek, M.; Szram, D.; Jaworowski, J. Accuracy of experimental mandibular osteotomy using the image-guided sagittal saw. Int J. Oral Maxillofac. Surg. 2016, 45, 793–800. [Google Scholar] [CrossRef]

- Farias, T.P.; Dias, F.L.; Sousa, B.A.; Galvão, M.S.; Bispo, D.; Pastl, A.C. Prototyping: Major Advance in Surgical Planning and Customizing Prostheses in Patients with Bone Tumors of the Head and Neck. Int. J. Clin. Med. 2013, 4, 1–7. [Google Scholar] [CrossRef]

- Singh, S.; Prakash, C. 3D printing of polyether-ether-ketone for biomedical application. Eur. Polym. J. 2019, 114, 234–248. [Google Scholar] [CrossRef]

- Tan, X.P.; Tan, Y.J.; Chow, C.S.L.; Tor, S.B.; Yeong, W.Y. Metallic powder-bed based 3D printing of cellular scaffolds for orthopedic implants: A state-of-the-art review on manufacturing, topological design, mechanical properties and biocompatibility. Mater. Sci. Eng. C 2017, 76, 1328–1343. [Google Scholar] [CrossRef]

- Kozakiewicz, M. Computer-aided orbital wall defects treatment by individual design ultrahigh molecular weight polyethylene implants. J. Craniomaxillofac. Surg. 2014, 42, 283–289. [Google Scholar] [CrossRef]

- Martelli, N.; Serrano, C.; van den Brink, H.; Pineau, J.; Prognon, P.; Borget, I.; El Batti, S. Advantages and disadvantages of 3-dimensional printing in surgery: A systematic review. Surgery 2016, 159, 1485–1500. [Google Scholar] [CrossRef] [PubMed]

- Tutak, J.S. Design of ELISE robot for the paretic upper limb of stroke survivors. J. Vibroeng. 2016, 18, 4069–4085. [Google Scholar] [CrossRef]

- Barrios-Muriel, J.; Romero-Sánchez, F.; Alonso-Sánchez, F.J.; Rodríguez Salgado, D. Advances in orthotic and prosthetic manufacturing: A technology review. Materials 2020, 13, 295. [Google Scholar] [CrossRef] [PubMed]

- Salmi, M.; Paloheimo, K.-S.; Tuomi, J.; Wolff, J.; Mäkitie, A. Accuracy of medical models made by additive manufacturing (rapid manufacturing). J. Craniomaxillofac. Surg. 2013, 41, 603–609. [Google Scholar] [CrossRef] [PubMed]

- El-Katatny, I.; Masood, S.H.; Morsi, Y.S. Error analysis of FDM fabricated medical replicas. Rapid Prototyp. J. 2010, 16, 36–43. [Google Scholar] [CrossRef]

- Ibrahim, D.; Broilo, T.L.; Heitz, C.; de Oliveira, M.G.; de Oliveira, H.W.; Nobre, S.M.W.; Gomes dos Santos Filho, J.H.; Silva, D.N. Dimensional error of selective laser sintering, threedimensional printing and PolyJet™ models in the reproduction of mandibular anatomy. J. Craniomaxillofac. Surg. 2009, 37, 167–173. [Google Scholar] [CrossRef] [PubMed]

- Nizam, A.; Gopal, R.N.; Naing, L.; Hakim, A.B.; Samsudin, A.R. Dimensional accuracy of the skull models produced by rapid prototyping technology using stereolithography apparatus. Arch. Orofac Sci. 2006, 1, 60–66. [Google Scholar]

- Safira, L.C.; Bastos, l.C.; Beal, V.E.; de Azevedo, R.A.; Francischone, C.E.; Sarmento, V.A. Accuracy of rapid prototyping biomodels plotted by three dimensional printing technique: Ex vivo study. Adv. Comput. Tomogr. 2013, 2, 41–45. [Google Scholar] [CrossRef]

- Silva, D.N.; de Oliveira, M.G.; Meurer, E.; Meurer, M.I.; Lopes da Silva, J.V.; Santa-Bárbara, A. Dimensional error in selective laser sintering and 3D-printing of 164 models for craniomaxillary anatomy reconstruction. J. Craniomaxillofac. Surg. 2008, 36, 443–449. [Google Scholar] [CrossRef]

- Primo, B.T.; Presotto, A.C.; de Oliveira, H.W.; Gassen, H.T.; Miguens, S.A.Q., Jr.; Silva, A.N., Jr.; Hernandez, P.A.G. Accuracy assessment of prototypes produced Rusing multi-slice and cone-beam computed tomography. Int. J. Oral Maxillofac. Surg. 2012, 41, 1291–1295. [Google Scholar] [CrossRef] [PubMed]

- Santolaria, J.; Jiménez, R.; Rada, M.; Loscos, F. Error compensation method for improving the accuracy of biomodels obtained from CBCT data. Med. Eng. Phys. 2014, 36, 397–404. [Google Scholar] [CrossRef] [PubMed]

- Olszewski, R.; Szymor, P.; Kozakiewicz, M. Accuracy of three-dimensional, paper-based models generated using a low-cost, three-dimensional printer. J. Craniomaxillofac. Surg. 2014, 42, 1847–1852. [Google Scholar] [CrossRef]

- Szymor, P.; Kozakiewicz, M.; Olszewski, R. Accuracy of open-source software segmentation and paper-based printed three-dimensional models. J. Craniomaxillofac. Surg. 2016, 44, 202–209. [Google Scholar] [CrossRef] [PubMed]

- Huotilainen, E.; Jaanimets, R.; Valášek, J.; Marcián, P.; Salmi, M.; Tuomi, J.; Mäkitie, A.; Wolff, J. Inaccuracies in additive manufactured medical skull models caused by the DICOM to STL conversion process. J. Craniomaxillofac. Surg. 2014, 42, e259–e265. [Google Scholar] [CrossRef]

- Reyes, A.; Turkyilmaz, I.; Prihoda, T.J. Accuracy of surgical guides made from conventional and a combination of digital scanning and rapid prototyping techniques. J. Prosthet. Dent. 2015, 113, 295–303. [Google Scholar] [CrossRef]

- Tino, R.; Yeo, A.; Leary, M.; Brandt, M.; Kron, T. A systematic review on 3d-printed imaging and dosimetry phantoms in radiation therapy. Technol. Cancer Res. Treat. 2019, 18, 1–14. [Google Scholar] [CrossRef]

- Bibb, R.; Thompson, D.; Winder, J. Computed tomography characterisation of additive manufacturing materials. Med. Eng. Phys. 2011, 33, 590–596. [Google Scholar] [CrossRef]

- Leary, M.; Kron, T.; Keller, C.; Franich, R.; Lonski, P.; Subic, A.; Brandt, M. Additive manufacture of custom radiation dosimetry phantoms: An automated method compatible with commercial polymer 3d printers. Mater. Design 2015, 86, 487–499. [Google Scholar] [CrossRef]

- Craft, D.F.; Kry, S.F.; Balter, P.; Salehpour, M.; Woodward, W.; Howell, R.M. Material matters: Analysis of density uncertainty in 3D printing and its consequences for radiation oncology. Med. Phys. 2018, 45, 1614–1620. [Google Scholar] [CrossRef]

- Solc, J.; Vrba, T.; Burianova, L. Tissue-equivalence of 3D-printed plastics for medical phantoms in radiology. J. Instrum. 2018, 13, P09018. [Google Scholar] [CrossRef]

- Kamomae, T.; Shimizu, H.; Nakaya, T.; Okudaira, K.; Aoyama, T.; Oguchi, H.; Komori, M.; Kawamura, M.; Ohtakara, K.; Monzen, H.; et al. Three-dimensional printer-generated patient-specific phantom for artifical in vivo dosimetry in radiotherapy quality assurance. Phys. Med. 2017, 44, 205–2011. [Google Scholar] [CrossRef] [PubMed]

- Alssabbagh, M.; Tajuddin, A.A.; Abdulmanap, M.; Zainon, R. Evaluation of 3D printing materials for fabrication of a novel multifunctional 3D thyroid phantom for medical dosimetry and image quality. Radiat. Phys. Chem. 2017, 135, 106–112. [Google Scholar] [CrossRef]

- Gear, J.I.; Long, C.; Rushforth, D.; Chittenden, S.J.; Cummings, C.; Flux, G.D. Development of patient-specific molecular imaging phantoms using a 3D printer. Med. Phys. 2014, 41, 082502. [Google Scholar] [CrossRef] [PubMed]

- Jasiuk, I.; Abueidda, D.W.; Kozuch, C.; Pang, S.; Su, F.Y.; McKittrick, J. An overview on additive manufacturing of polymers. JOM 2018, 70, 275–283. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. 3D printed medical parts with different materials using additive manufacturing. Clin. Epidemiol. Glob. Health 2020, 8, 215–223. [Google Scholar] [CrossRef]

- Yushkevich, P.A.; Piven, J.; Hazlett, H.C.; Smith, R.G.; Ho, S.; Gee, J.C.; Gerig, G. User-guided 3D active contour segmentation of anatomical structures: Significantly improved efficiency and reliability. Neuroimage 2006, 31, 1116–1128. [Google Scholar] [CrossRef]

- Champion, A.F.; Curiel, T.M.; Diecidue, R.J. Analysis of computed tomography Hounsfield units of benign lesions in the maxillofacial region: Is there a correlation? Eur. J. Oral Maxillofac. Surg. 2020, 4, 45–48. [Google Scholar] [CrossRef]

- Budzik, G.; Turek, P.; Traciak, J. The influence of change in slice thickness on the accuracy of reconstruction of cranium geometry. Proc. Inst. Mech. Eng. H 2017, 231, 197–202. [Google Scholar] [CrossRef]

- Alsleem, H.; Davidson, R. Factors affecting contrast-detail performance in computed tomography: A review. J. Med. Imaging Radiat Sci. 2013, 44, 62–70. [Google Scholar] [CrossRef]

- Ford, J.M.; Decker, S.J. Computed tomography slice thickness and its effects on three-dimensional reconstruction of anatomical structures. J. Forensic Radiol. Imaging 2016, 4, 43–46. [Google Scholar] [CrossRef]

- Romans, L. Computed Tomography for Technologists: A Comprehensive Text; Wolters Kluwer: Baltimore, MD, USA, 2011. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).