Abstract

The article provides a comprehensive review of the latest developments in the field of laser surface hardening (LSH) and its modeling techniques. LSH is a crucial process for enhancing the surface properties of metals, particularly their hardness and wear resistance, without compromising their bulk properties. This review highlights the fundamental principles of LSH, the types of lasers used, and the key parameters influencing the hardening process. It delves into various modeling approaches, including finite element method (FEM) simulations, analytical models, and empirical models (using statistical methods), emphasizing the integration of advanced computational techniques such as machine learning and artificial intelligence to improve the accuracy and efficiency of LSH simulations. The review also explores practical applications across different industries, showcasing how LSH models have been used to solve real-world challenges in the automotive, aerospace, and tool manufacturing sectors. Finally, it addresses current limitations and outlines future research directions, suggesting potential areas for further advancements in the modeling and application of LSH processes.

1. Introduction

Laser surface hardening (LSH) is a sophisticated technique that is used to improve the hardness and wear resistance of metal surfaces. This process involves using a focused laser beam to heat the surface layer of a metal to a temperature above its transformation point, which is followed by rapid self-quenching as heat dissipates into the colder underlying material. The rapid heating and cooling result in a hardened surface layer without affecting the bulk properties of the metal, thus enhancing its surface performance while maintaining its overall structural integrity. The fundamental principle behind LSH is based on the precise control of thermal energy. By adjusting parameters such as the laser power, beam diameter, scanning speed, and interaction time, the depth and hardness of the treated layer can be tailored to meet specific requirements. The process typically induces martensitic transformation in steels, leading to a significant increase in hardness and wear resistance. This controlled process is particularly advantageous for components subjected to high wear and stress, such as gears, camshafts, and cutting tools [1].

The use of lasers in material processing dates back to the 1960s, shortly after the invention of the laser. Early experiments demonstrated the potential of laser technology for various applications, including welding, cutting, and surface treatment. However, it was not until the development of high-power continuous-wave lasers in the 1980s that LSH became a viable industrial process [2]. The initial use of LSH was primarily in the aerospace and automotive industries, where components required enhanced surface properties without compromising their overall mechanical integrity. Over the years, advancements in laser technology, such as the development of fiber lasers and diode lasers, have expanded the applicability and efficiency of LSH [3,4]. These advancements have allowed for greater precision, control, and consistency in surface-hardening processes, making LSH a critical technique in modern manufacturing [5].

Recent years have witnessed significant advancements in the modeling of laser surface-hardening processes. These models aim to predict the thermal, mechanical, and microstructural responses of metals to laser treatment [6]. The early models focused primarily on thermal analysis using simplified assumptions and empirical data to estimate temperature distributions [7]. However, with the advent of computational methods and increased computational power, more sophisticated models have been developed. The Finite Element Method (FEM) and Finite Difference Method (FDM) are among the most widely used techniques for simulating the laser-hardening process. These methods enable a detailed analysis of temperature fields, stress distributions, and phase transformations by solving the governing equations of heat transfer, fluid dynamics, and solid mechanics [8,9]. Additionally, advancements in materials science have led to the development of more accurate constitutive models that describe the behavior of metals under rapid heating and cooling conditions.

One of the key trends in recent research is the integration of different modeling approaches to capture the multifaceted nature of laser surface hardening. For example, combining thermal models with metallurgical models allows for a more comprehensive understanding of the phase transformations and microstructural evolution during the process [10]. Similarly, the incorporation of mechanical models helps to predict the development of residual stresses and their impact on the performance of the hardened layer [11]. Integrated models not only enhance predictive capabilities but also facilitate the optimization of process parameters. By simulating various scenarios, researchers can identify the optimal laser power, scanning speed, and beam diameter to achieve the desired surface characteristics [12]. This approach reduces the need for extensive experimental trials, saving time and resources while ensuring consistent and reliable results.

The primary objective of this review is to provide a comprehensive overview of recent advances in modeling the laser surface hardening. It will cover the latest developments in thermal, metallurgical, and mechanical modeling techniques, highlighting their applications and contributions to the field. The review will also discuss the challenges and limitations of current models as well as future directions for research.

2. Fundamentals of Laser Surface Hardening

This section includes an in-depth exploration of the mechanisms and principles underlying the LSH process. This includes the interaction of laser energy with metal surfaces, leading to rapid heating and phase transformations such as the formation of martensite. It covers different types of lasers used, like CO2, Nd, and fiber lasers, detailing their specific applications and benefits. Additionally, it discusses the critical aspects of heat transfer and thermal conductivity in metals, which are essential for achieving the desired hardening effect. The section also examines the control of laser parameters, such as power, scanning speed, and beam diameter, to optimize the process. Furthermore, it highlights practical applications across various industries, illustrating the advantages of LSH in enhancing the hardness and wear resistance of metal components while maintaining their bulk properties. Understanding the basic principles and mechanisms of laser–material interaction in LSH, along with the types of lasers used, is crucial for optimizing the process and achieving the desired material properties.

2.1. Basic Principles

The fundamental principles of LSH revolve around the precise control of thermal energy to induce beneficial phase transformations on metal surfaces [13]. The selection of appropriate laser types and process parameters is crucial to achieve optimal hardening results and extend the life and performance of metal components [14,15].

Laser surface hardening is a process that relies on the precise control of thermal energy delivered to a metal surface to alter its microstructure and improve its mechanical properties.

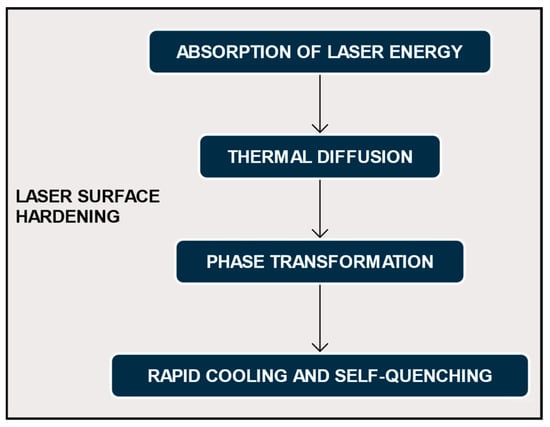

Figure 1.

The basic mechanism of LSH.

- Absorption of laser energy—The laser beam is focused on the metal surface, where the energy is absorbed, causing rapid heating. The absorption efficiency depends on the material’s surface condition and the wavelength of the laser. Metals typically have high reflectivity, so surface treatments like applying absorptive coatings can enhance energy absorption.

- Thermal diffusion—The absorbed energy rapidly heats the surface layer of the metal to temperatures above its transformation point. This creates a thermal gradient, with the highest temperature at the surface and decreasing temperature with depth. The thermal energy diffuses into the material according to its thermal conductivity.

- Phase transformation—As the temperature of the surface layer rises, phase transformations occur. For example, in steels, the temperature may exceed the austenitization point, leading to the formation of austenite. Upon rapid cooling, this austenite transforms into martensite, which is a hard and brittle phase that enhances the surface hardness.

- Rapid cooling and self-quenching—The heated surface layer cools rapidly due to the heat conduction into the cooler underlying material and surrounding environment. This rapid cooling, or self-quenching, is crucial for the formation of martensite in steel. The cooling rate is much faster than traditional hardening methods, resulting in finer microstructures and higher hardness.

The process parameters, such as laser power, scanning speed, beam diameter, and interaction time, must be carefully controlled to achieve the desired hardening effect while minimizing defects like cracking or excessive distortion [20,21,22,23].

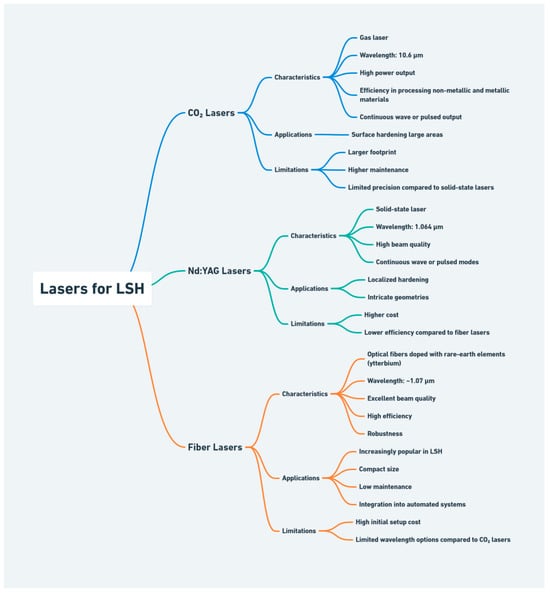

The choice of laser depends on factors such as the type of metal, the desired depth of hardening, the complexity of the part geometry, and the production environment. Figure 2 presents the most commonly used lasers in LSH [24,25,26,27].

Figure 2.

Lasers for LSH.

In the processing of specific materials using laser radiation, several key parameters must be precisely controlled to optimize the interaction and achieve desired results. These parameters include the following [28,29,30,31]:

- Wavelength—The wavelength of the laser is crucial because it determines the absorption efficiency of the material. For example, UV lasers (with wavelengths around 355 nm) are highly absorbed by many organic materials and polymers, making them ideal for delicate micromachining tasks. In contrast, infrared lasers (such as CO2 lasers at 10.6 µm) are better suited for cutting and engraving materials like plastics, wood, and glass due to their strong absorption in these materials.

- Power density—The power density, or the intensity of the laser beam, impacts the rate of material removal and the type of interaction (e.g., melting, vaporization, or ablation). High power densities (in the order of MW/cm2) can rapidly vaporize or melt materials, making them suitable for cutting and drilling metals and ceramics. Lower power densities (kW/cm2) are used for applications like engraving or surface modification where gentle removal of material is required.

- Pulse duration—The duration of the laser pulse significantly affects thermal diffusion and material response. Ultrafast lasers with femtosecond (fs) to picosecond (ps) pulse durations minimize thermal damage, making them perfect for high-precision applications in semiconductor fabrication and delicate medical devices. Nanosecond (ns) and continuous-wave (CW) lasers, with longer pulse durations, are used in applications requiring deeper penetration, such as welding and deep engraving of metals.

- Repetition rate—The repetition rate, which is the frequency at which laser pulses are emitted, determines the speed of the processing and thermal accumulation in the material. High repetition rates (kHz to MHz) are advantageous for rapid machining processes but can lead to thermal buildup and potential damage if not properly managed. Lower repetition rates allow for better thermal management in heat-sensitive materials.

- Beam quality—Beam quality, often quantified by the M2 factor, affects the ability to focus the laser to a small spot size, influencing precision and efficiency. A laser with a high-quality beam (low M2 value) can achieve a smaller focal spot and higher energy density, which is crucial for applications requiring fine detail and precision, such as microelectronics and the fine cutting of metals.

By carefully selecting and optimizing these parameters, the laser–material interaction can be precisely controlled, enabling efficient and high-quality processing across a wide range of materials.

2.2. Heat Transfer and Hardening Mechanisms

Laser surface hardening is a process that relies heavily on the principles of heat transfer and subsequent phase transformations within the metal being treated [32]. Understanding the intricacies of these mechanisms is essential for optimizing the hardening process and achieving the desired properties of the material. The key aspects of heat transfer in metals during LSH include thermal conductivity, heat capacity, and the thermal gradient established during the process.

Metals typically have high thermal conductivity, which means that they can transfer heat quickly from the heated surface layer to the cooler underlying material. This property is beneficial for LSH as it allows for rapid self-quenching, which is essential for forming a hardened layer without an extensive penetration of heat into the bulk material [5]. This heat conduction is described by Fourier’s law:

where q is the heat flux, k is the thermal conductivity of the metal, and ∇T is the temperature gradient.

The heat capacity of a metal determines how much energy is required to raise its temperature. During LSH, the high heat capacity of the metals ensures that the energy from the laser is used efficiently to achieve the necessary phase transformations.

A steep thermal gradient is established between the heated surface layer and the cooler bulk material. This gradient drives the rapid cooling or quenching necessary for hardening. The heat-affected zone (HAZ) is minimized, ensuring that the mechanical properties of the bulk material remain largely unchanged [1]. Thermal diffusivity (α) indicates how quickly heat spreads through the material and is defined as

where ρ is the density and Cp is the specific heat capacity.

Higher thermal diffusivity leads to a faster spread of heat, affecting the phase transformation dynamics.

The primary goal of LSH is to induce phase transformations in the metal surface that result in improved hardness and wear resistance. These transformations primarily involve changes in the crystal structure of the metal, leading to the formation of harder phases. The key processes are as follows [33]:

- Austenitization—In steels, LSH involves heating the surface to a temperature above the austenitization point (approximately 800 to 900 °C for most steels). At this temperature, the ferritic or pearlitic structure of the steel transforms into austenite, which is a face-centered cubic (FCC) structure that can dissolve more carbon.

- Martensitic transformation—As the laser moves away or the laser pulse ends, the surface cools rapidly due to the thermal gradient and the heat sinking effect of the bulk material. This rapid cooling, or quenching, does not allow time for the austenite to transform back to ferrite or pearlite. Instead, it transforms into martensite, which is a supersaturated solid solution of carbon in iron with a body-centered tetragonal (BCT) structure.

- Hardening mechanism—Martensite is significantly harder and more brittle than the original phases. The hardness of martensite is primarily due to its distorted lattice structure, which impedes the movement of dislocation. The formation of martensite increases the hardness and wear resistance of the metal surface. The depth of the hardened layer depends on factors such as laser power, scanning speed, and the thermal properties of the metal.

- Tempering—Sometimes, a post-hardening tempering process is applied to relieve some of the internal stresses and increase the toughness of the hardened layer. Tempering involves reheating the material to a lower temperature (typically between 150 and 500 °C) and then cooling it slowly.

Achieving the desired hardness and surface properties through LSH requires the careful control and optimization of process parameters, including the following [1]:

- ○

- Laser power—determines the amount of energy delivered to the surface. The higher power increases the depth of penetration and the rate of heating.

- ○

- Scanning speed—affects the interaction time between the laser and the material. Faster scanning speeds reduce the heat input per unit area, leading to a shallower hardened layer.

- ○

- Beam diameter—controls the area of the surface being treated. Smaller beam diameters provide higher energy density, resulting in deeper and more intense hardening.

- ○

- Pulse duration (in pulsed lasers)—influences the thermal cycle experienced by the material. Shorter pulses can achieve higher peak temperatures and rapid cooling rates.

The fundamentals of laser surface hardening involve intricate heat transfer mechanisms and complex phase transformations that enhance the surface properties of metals. Understanding these principles is essential for optimizing the process to achieve specific material characteristics. The proper control of thermal conductivity, heat generation, and phase transformations ensures effective hardening, making LSH a powerful tool in modern materials engineering.

3. Modeling Techniques for Laser Surface Hardening

The LSH modelling techniques encompass a range of approaches aimed at predicting and optimizing the outcomes of the process. These techniques can be broadly classified into analytical methods, empirical models, FEM models, and data-driven models, each offering unique insights and advantages. Table 1 presents the different aspects of modeling of LSH by different methods.

Table 1.

Modeling methods for laser surface hardening.

The Finite Element Method (FEM) is a numerical technique used to solve complex engineering and physical problems. It involves subdividing a large system into smaller, simpler parts, which are called finite elements. The simple equations that model these finite elements are then assembled into a larger system of equations that models the entire problem. This method is widely used in structural analysis, heat transfer, fluid dynamics, and many other areas of engineering and applied science.

The main steps in FEM modeling include [34,35,36]

- Discretization—dividing the structure into a finite number of elements.

- Element selection—choosing the appropriate element type (e.g., 1D, 2D, or 3D elements).

- Defining material properties—assigning properties like elasticity, thermal conductivity, etc., to each element.

- Applying boundary conditions—specifying constraints and loads.

- Formulating the element equations—deriving the equations governing the behavior of each element.

- Assembly of global equations—combining all element equations into a global system that models the entire structure.

- Solving the equations—using numerical methods to solve the global system of equations.

- Post-processing—interpreting the results to analyze stress, deformation, temperature distribution, etc.

Laser surface hardening involves the use of a laser beam to heat the surface of a material to a high temperature, which is followed by rapid cooling. This process increases the hardness and wear resistance of the surface layer without affecting the bulk properties of the material. FEM is a powerful tool in the field of LSH, providing detailed insight into the thermal, structural, and microstructural changes that occur during the process.

FEM can be considered to use in the following aspects of LSH:

- Thermal and structural analysis—for the simulation of the temperature distribution and stress fields in components undergoing LSH. This helps to understand the effects of different laser parameters on the hardness and residual stress distribution [37].

- Microstructural evolution—modeling the phase transformations and microstructural changes in the material during and after LSH. This aids in predicting the hardness and mechanical properties of the treated surface [38].

- Optimization of process parameters—assists in determining the optimal laser power, scanning speed, and other parameters. FEM simulations are conducted to find the best combination of laser power and scanning speed that achieves maximum hardness with minimal thermal distortion [39].

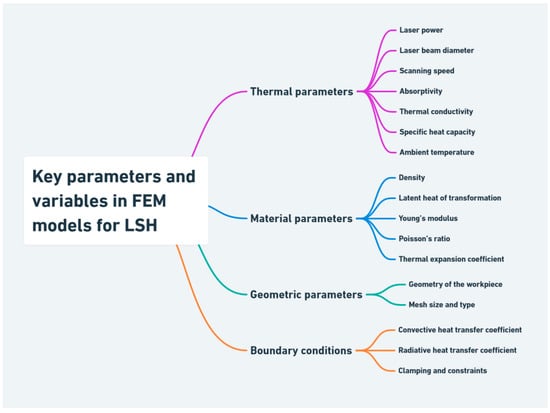

In FEM models related to LSH, several key parameters and variables are critical to accurately simulate the process and predict outcomes, as can be seen in Figure 3.

Figure 3.

Key parameters and variables in FEM models for LSH.

These parameters and variables can be categorized into thermal, material, geometric, and boundary conditions groups [40,41,42]:

- Thermal parameters

- Laser power—the amount of energy supplied by the laser per unit time. It directly affects the temperature distribution and the depth of hardening.

- Laser beam diameter—the diameter of the laser spot on the material’s surface. It influences the area of heat application.

- Scanning speed—the speed at which the laser moves across the surface of the material. Higher speeds can result in shallower heat penetration, while slower speeds allow deeper heating.

- Absorptivity—the fraction of laser energy absorbed by the material’s surface. This depends on the material properties and surface conditions.

- Thermal conductivity—the ability of the material to conduct heat. It influences how heat spreads through the material.

- Specific heat capacity—the amount of heat required to raise the temperature of the material by one degree. It affects the rate of temperature change.

- Ambient temperature—the initial temperature of the material before laser application. It serves as the baseline for temperature calculations.

- Material parameters

- Density—the mass per unit volume of the material. It affects the thermal inertia and heat capacity of the material.

- Latent heat of transformation—the heat required for phase transformations, such as from austenite to martensite in steel.

- Young’s modulus—the material’s stiffness, influencing the stress and deformation response during thermal expansion and contraction.

- Poisson’s ratio—the ratio of transverse strain to axial strain, affecting the material’s deformation behavior.

- Thermal expansion coefficient—the rate at which the material expands or contracts with temperature changes.

- Geometric parameters

- Geometry of the workpiece—the shape and size of the material being treated. Complex geometries require more detailed meshing and modeling.

- Mesh size and type—the size and type of elements used in the FEM model. Smaller mesh sizes provide higher accuracy but increase computational cost.

- Boundary conditions

- Convective heat transfer coefficient—the rate of heat transfer between the material surface and the surrounding environment, which is typically affected by cooling mediums like air or water.

- Radiative heat transfer coefficient—the material’s emissivity, affecting heat loss due to radiation.

- Clamping and constraints—the mechanical constraints applied to the workpiece, which can affect stress and deformation during heating and cooling.

Analytical models for LSH are also essential for predicting and optimizing the process without the need for extensive experimental trials. These models typically involve mathematical formulations that describe the thermal, metallurgical, and mechanical phenomena that occur during LSH. The key steps involved in this process are the following:

- Problem definition.

- Simplifying assumptions.

- Heat source modeling.

- Governing equations.

- Boundary and initial conditions.

- Analytical solution.

- Phase transformation modeling (if applicable).

- Stress and strain analysis (if applicable).

- Validation and verification.

- Optimization.

The most used analytical modeling techniques used in LSH are the following [1,41,43,44]:

- Heat transfer models (based on Fourier’s law of heat conduction and surface heat flux)—to predict the temperature distribution in the material during and after laser heating.

- Phase transformation models (based on the Johnson–Mehl–Avrami–Kolmogorov (JMAK) equation and Time–Temperature–Transformation (TTT) and Continuous Cooling Transformation (CCT) diagrams)—to describe the phase changes occurring in the material due to the rapid heating and cooling cycles of LSH.

- Stress and deformation models (based on Thermo-Elastic–Plastic stress analysis and von Mises yield criterion)—to evaluate the residual stresses and deformations induced by the thermal cycles of LSH.

- Combined analytical models—to integrate heat transfer, phase transformation, and stress analysis into a comprehensive model.

Empirical and data-driven models are also essential in understanding and optimizing LSH processes. These models rely on experimental data and advanced statistical or machine learning techniques to predict outcomes and improve process parameters [45,46,47]. The modeling of LSH using empirical models involves using experimental data to develop mathematical relationships that predict the outcomes of the hardening process. These models rely on statistical methods and regression analysis to correlate input parameters with desired outputs such as the hardness profiles, depth of the hardened layer, and residual stresses. The general steps involved in this process are outlined below:

- Problem definition and data collection.

- Data preprocessing.

- Feature selection and engineering.

- Model development.

- Model evaluation.

- Model validation.

- Model deployment.

- Model monitoring and maintenance.

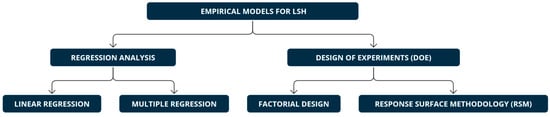

Figure 4 presents the important methods used in empirical models.

Figure 4.

The methods used in empirical models for LSH.

The key techniques are following:

- Regression Analysis [48]

- Linear regression—establishes a linear relationship between input variables (e.g., laser power, scanning speed) and output variables (e.g., hardness, depth of hardening).

- Multiple regression—extends linear regression to include multiple input variables, providing a more comprehensive model of the LSH process.

- Design of Experiments (DoE) [49,50]

- Factorial design—investigates the effect of two or more factors by systematically varying them and measuring the output responses.

- Response Surface Methodology (RSM)—uses statistical techniques to model and optimize processes. RSM helps in developing empirical models by fitting a polynomial equation to the experimental data.

Data-driven models are used to model and optimize LSH processes based on large datasets. Key methods in this area include the following:

- Artificial Neural Network (ANN)—computational models inspired by the human brain, capable of capturing non-linear relationships between input and output variables [51,52].

- Support Vector Machine (SVM)—supervised learning models used for classification and regression tasks. They find the hyperplane that best separates the data into different classes [53].

- Random Forest (RF)—ensemble learning methods that use multiple decision trees to improve prediction accuracy and control overfitting [54].

- Genetic Algorithm (GA)—optimization techniques based on the principles of natural selection and genetics. They iteratively evolve solutions to optimize complex processes [55].

- K-Nearest Neighbor (KNN)—non-parametric method used for classification and regression by finding the closest training examples in the feature space [56].

Empirical and data-driven models play a crucial role in advancing laser surface-hardening techniques. Empirical models, such as regression analysis and DoE, provide a straightforward approach to understanding and optimizing the LSH process based on experimental data. In contrast, data-driven models, including ANNs, SVMs, RFs, GAs, and KNNs, leverage machine learning and AI to handle complex, non-linear relationships and large datasets. These models offer significant advantages in prediction accuracy and process optimization, ultimately enhancing the performance and reliability of LSH-treated materials.

The integration of machine learning (ML) and artificial intelligence (AI) into LSH models has revolutionized the way these processes are analyzed, optimized, and controlled. AI and ML techniques provide advanced tools for predictive modeling, process optimization, and real-time monitoring, leading to enhanced performance and efficiency.

The most important components of the integration of AI and ML in LSH include the following [57,58]:

- Data collection and preprocessing

- Data sources—experimental data, historical process data, and simulation results.

- Preprocessing—cleaning, normalizing, and transforming data to ensure quality and consistency. This step may involve handling missing values, outlier detection, and feature scaling.

- Feature selection and engineering

- Feature selection—identifying the most relevant input parameters (e.g., laser power, scanning speed, beam diameter) that significantly influence the LSH process.

- Feature engineering—creating new features based on domain knowledge to improve model performance. This might include interaction terms or domain-specific transformations.

- Model development and training

- Supervised learning—using labeled data to train models that can predict outcomes like surface hardness, roughness, and microstructural changes.

- Unsupervised learning—identifying patterns and relationships in data without explicit labels, useful for clustering similar process conditions or anomaly detection.

- Reinforcement learning—developing models that learn optimal process strategies through trial and error, receiving feedback from the environment.

- Model validation and testing

- Cross-validation—splitting data into training and validation sets to evaluate model performance and prevent overfitting.

- Performance metrics—using metrics such as Mean Squared Error (MSE), R-squared, and accuracy to assess model predictions.

- Deployment and integration

- Real-time monitoring—implementing models in real-time control systems to adjust process parameters dynamically based on live data.

- Feedback loops—continuously updating models with new data to improve accuracy and adapt to changing conditions.

The integration of ML and AI into LSH models has significantly enhanced the accuracy, efficiency, and control of these processes.

4. Applications of LSH Models

Laser surface-hardening models are indispensable tools in various high-precision industries, including automotive, aerospace, and beyond. In the automotive industry, LSH models help with optimizing the hardening process of engine components, gears, and drive shafts, resulting in enhanced wear resistance and prolonged service life. Aerospace applications benefit from LSH models by improving the performance and durability of critical components such as turbine blades and landing gear. Additionally, other industries, including heavy machinery and tooling, leverage LSH models to enhance surface properties, ensure consistent quality, and achieve cost-effective manufacturing solutions. This section delves into the specific applications of LSH models across these industries, demonstrating their pivotal role in advancing technological capabilities and material performance.

4.1. Automotive Industry

The applications of laser surface hardening in the automotive industry are multifaceted and offer significant improvements in the performance and longevity of various automotive components. Laser surface hardening is a process that uses laser technology to improve the surface properties of metals, enhancing their hardness, wear resistance, and overall durability.

One notable application of optimizing critical process parameters is enhancing heavily loaded parts such as the shafts and rims of railway car wheels. This process significantly extends the lifespan of these components by optimizing the depth, structure, and hardness of the treated surfaces. The optimization of these parameters is essential for improving fatigue strength, minimizing rolling noise, and achieving better stress distribution. For example, the optimization of railway wheel web profiles using a bidirectional evolutionary structural optimization (BESO) algorithm can lead to a more uniform stress distribution and improved volume and stress states [59]. Similarly, cold-rolling processes have been optimized to enhance the fatigue strength of railway axles, improving their lifespan even in the presence of defects [60].

Laser surface hardening is also used to improve the tribological properties, corrosion resistance, and surface hardness of aluminum composites. This process creates dense layers without large-scale cracks or voids, resulting in lower friction coefficients and enhanced corrosion resistance. For instance, the laser surface texturing of aluminum alloy has been shown to significantly improve surface hardness and corrosion resistance by refining the microstructure and reducing pitting corrosion [61]. Moreover, laser alloying techniques have been effective in enhancing the surface properties of various alloys, as demonstrated by the improved hardness and corrosion resistance of laser-treated Ti6Al4V surfaces [62].

In the context of steel surfaces, laser hardening has been shown to significantly increase hardness and reduce surface roughness and wear rates. For example, the laser surface hardening of various steels, such as AISI 1541 and 30CrMnSiNi2A, can result in considerable improvements in surface properties. A study on AISI 1541 steel demonstrated that laser hardening can enhance the hardness due to the formation of martensite and other phases with a significant reduction in surface roughness and wear rates [63]. Another study showed that laser treatment on low-carbon steel substrates resulted in improved wear resistance and increased surface hardness [64].

Furthermore, laser surface modification techniques, such as laser glazing, are effective in enhancing the surface properties of materials to withstand excessive load, wear, fatigue, bending, and friction. These enhancements are crucial for applications like bearings, railroad rails, and thermal barrier coatings. For example, the laser surface modification of yttria-stabilized zirconia (YSZ) thermal barrier coatings significantly improves surface roughness and hardness, enhancing their performance under high thermal stress [65]. Additionally, laser surface-texturing techniques have been shown to improve tribological performance and mechanical interlocking, making them suitable for bearings and other load-bearing applications [66].

Specific research has also focused on the laser-hardening process of engine camshaft cams, emphasizing the impact of process parameters on microstructure and microhardness. This includes the effects of low-temperature tempering post-hardening, which is crucial for ensuring the longevity and reliability of engine components. For example, an experimental study demonstrated that laser hardening significantly improves the hardness of carbon steel, non-malleable cast iron, and X20Cr13 materials by optimizing laser power and scan speed, enhancing the durability of automotive components [67]. Additionally, research on the influence of operating parameters on laser-hardened surfaces highlighted the importance of precise control over laser parameters to achieve optimal surface hardness and morphology [68].

Additionally, the use of laser-dimpled hard-coated surfaces in the automotive industry has been shown to exhibit excellent abrasion resistance and significantly improved service life. These surfaces can achieve up to five times higher abrasive wear resistance compared to traditional substrates with high surface microhardness values of up to 700 HV. For example, the laser surface treatment of AlMg5 aluminum alloy significantly improved its microhardness and wear resistance through the introduction of titanium and iron powders, achieving substantial enhancements in mechanical properties [69]. Additionally, research on P20 steel processed by laser surface engineering demonstrated significant improvements in wear resistance and thermal cracking resistance, further highlighting the effectiveness of laser treatments in enhancing surface properties [70].

Overall, the application of laser surface-hardening models in the automotive industry demonstrates a promising avenue for enhancing the performance and durability of critical automotive components, ensuring better efficiency and reliability in various automotive applications.

4.2. Aerospace and Other Industries

In the aerospace sector, components are often exposed to extreme environmental conditions and mechanical stresses. Laser surface hardening improves the tribological properties and corrosion resistance of materials such as aluminum composites, resulting in enhanced hardness, reduced friction coefficients, and better corrosion resistance. For example, laser surface treatment on AlMg5 aluminum alloy demonstrated significant improvements in microhardness and wear resistance, which was attributed to the introduction of a mixture of titanium and iron powders [69]. Additionally, laser treatments on A380/SiCp aluminum composites refined the microstructure and improved both surface hardness and corrosion resistance [71].

Laser surface hardening is crucial for high-strength steel components used in aerospace applications. For example, the process applied to 30CrMnSiNi2A ultra-high strength steel results in a significant increase in hardness and a reduction in surface roughness and wear rate, making these components more durable and reliable. Research indicates that laser transformation hardening effectively enhances the hardness and tribological properties of various steel grades, including high-strength steels, through controlled heating and self-quenching processes. This leads to a uniform hardened surface with improved mechanical properties [72]. Additionally, the use of combined nitriding and laser-hardening techniques has been shown to significantly increase the surface hardness and wear resistance of high-strength steels, making them suitable for demanding aerospace applications [73].

Laser shock processing and laser coating treatments are used in aerospace manufacturing to enhance surface properties, including hardness and fatigue resistance. These processes are critical for components that must endure high operational loads and stresses. For instance, laser shock peening (LSP) is an advanced technique that significantly improves the mechanical properties of materials by inducing beneficial compressive residual stresses, leading to enhanced hardness and fatigue resistance. This is particularly important for aeronautical components subjected to extreme service conditions [74]. Additionally, laser-cladding treatments have been shown to improve the corrosion resistance and surface hardness of materials, making them suitable for harsh operational environments [75].

Laser surface-hardening models are used to develop light-absorbing coatings for medium-carbon alloy steel, significantly improving the structuring of surface layers during laser hardening. This application is particularly valuable for components in the oil and gas industry that require enhanced hardness and wear resistance. For instance, experimental investigations have demonstrated the effectiveness of laser surface hardening in improving the hardness and wear resistance of medium-carbon steels. A study on the laser surface hardening of AISI 1045 steel revealed a significant increase in surface hardness and wear resistance, making it suitable for high-stress applications in the oil and gas sector [76]. Additionally, the modeling of laser-hardened surface microstructures has shown improvements in surface quality and structural integrity, which are crucial for the demanding environments in the oil and gas industry [77].

In the microelectronics industry, laser-induced processing is used to create controlled surface deposits with specific characteristics, enhancing the functionality and durability of electronic components. For example, the use of Laser-Induced Forward Transfer (LIFT) for solder paste deposition enables precise control over printed volumes, improving the reliability and resolution of solder joints on PCBs [78]. Additionally, the laser-induced deposition of nanostructured copper microwires on composite surfaces enhances the electrical and structural properties of the deposits, which is crucial for developing advanced electronic devices [79].

The feasibility of underwater laser surface hardening has been explored for tool steel, demonstrating the process’s effectiveness in both water and air environments. This technique is crucial for applications requiring precise control over the hardening process to achieve desired material properties. For example, the laser surface hardening of AISI 1055 steel under submerged conditions showed that underwater laser hardening could produce better surface mechanical properties due to the additional cooling effect by water [80]. Furthermore, research has confirmed that underwater laser surface hardening is feasible and can achieve comparable or superior hardness levels compared to conventional methods [81].

In manufacturing, LSH enhances the surface integrity of materials used in precision engineering. Numerical simulations and experimental verifications have shown significant reductions in surface roughness and improvements in microhardness, which are critical for high-precision manufacturing [82].

5. Recent Advances in Laser Surface-Hardening Modeling

Modeling techniques for laser surface hardening have been explored through various approaches, each aiming to optimize and validate the process for different industrial applications. The following sections present different approaches.

5.1. Finite Element Method (FEM) Simulations

Laser surface hardening is a sophisticated process that benefits significantly from advanced modeling techniques, particularly the Finite Element Method (FEM). FEM simulations are instrumental in optimizing the laser-hardening process by predicting temperature distributions, hardness profiles, and the overall effectiveness of the treatment.

For instance, Syed et al. highlight the importance of simulations in determining optimal conditions for laser hardening, emphasizing the role of heat distribution and intensity profiles in achieving desired hardness levels [83].

Orazi et al. further elaborate on a simplified approach to laser surface-hardening modeling, which neglects austenite homogenization due to insufficient carbon diffusion and is validated through nano-hardness measurements on C45 carbon steel samples [12].

Anusha et al. developed an integrated statistical mathematical model using Response Surface Methodology (RSM) coupled with FEM to optimize the process on cylindrical steel rods, achieving uniform hardened layers and eliminating inter-pass tempering effects [84]. This approach was validated experimentally, showing good agreement with simulated thermal profiles [85].

Tarchoun et al. conducted numerical and experimental investigations using a 3D FEM thermal analysis to evaluate the effects of heating parameters and scanning patterns on AISI 4340 steel, demonstrating the model’s accuracy in predicting temperature distribution and hardness profiles [86].

Martinovs et al. utilized COMSOL Multiphysics to reduce the number of experiments by replacing them with numerical calculations, determining optimal laser parameters and predicting the thickness of the hardened layer [87].

Yang and Harris introduced a direct scan-to-model strategy for translating 3D laser scanning data into FEM, which helps in identifying and updating damaged parts of a structure, thus reducing computational costs [88].

Nikolidakis and Antoniadis developed a 3D simulation model for nanosecond pulsed laser engraving using FEM, validated through extensive experiments, to predict the final geometry of the workpiece and optimize the process [89].

Barath et al. addressed the challenge of achieving uniform hardness in complex geometries by using an iterative numerical approach to modulate laser power, ensuring a constant surface temperature throughout the process zone [90].

El-Batahgy et al. provide a comprehensive study on the effects of laser surface hardening on tool steels, specifically AISI M2 high-speed steel. The study encompasses both experimental and numerical analyses, aiming to optimize laser processing parameters to enhance surface hardness and wear resistance, which are critical for high-precision manufacturing applications [91].

Nguyen and Yang present a sequential method to accurately estimate surface absorptivity during laser surface hardening. This method was validated using experimental temperature data from previous studies. The results confirm the method’s capability in providing precise estimations of surface absorptivity, which is crucial for optimizing the laser-hardening process [92].

Fortunato et al. evaluate the reflectivity coefficient for AISI420B steel coated with graphite and treated with a diode laser, providing a temperature-dependent value suitable for simulating the laser hardening of carbon steels [93].

Evdokimov et al. present a Finite Element Method (FEM) model to simulate laser surface hardening with an inclined laser beam. The study investigates how the angle of the laser beam affects the heat distribution and phase transformations in the material. The model’s predictions are validated against the experimental data, showing good agreement. The findings suggest that adjusting the laser beam’s inclination can optimize the hardening process, providing valuable insights for manufacturing applications [94].

Lastly, Abdelhak and Obayya’s adaptive numerical approach based on FEM for analyzing vertical cavity surface emitting lasers (VCSELs) demonstrates the method’s versatility and efficiency in handling complex structures with low computational resources [95].

Collectively, these studies underscore the critical role of FEM in enhancing the precision, efficiency, and predictability of laser surface-hardening processes across various applications and materials.

Table 2 presents a summary of various aspects of selected articles in the field of application of the FEM method.

Table 2.

Analysis of selected articles in the field of FEM use.

5.2. Analytical Models

Analytical models help in predicting the outcomes of laser surface hardening by considering various parameters such as laser power, scan speed, and material properties.

For example, the study by Korostelev emphasizes the importance of surface heating temperature, showing that heating to a temperature 200–250 K below the melting point can significantly increase hardness by 10–15 HRC units due to thermal stresses and phase transformation kinetics [96].

Similarly, Nath et al. derived an analytical solution for temperature variation in a semi-infinite workpiece heated by repetitive laser pulses, demonstrating that the depth of hardness increases with the number of laser pulses at low frequencies, which enhances the homogeneity of the microstructure [97].

The work by Sistaninia et al. compares Lagrangian and Eulerian formulations for solving thermoelastic temperature, displacement, and stress in heat transfer during laser surface hardening, highlighting that the Eulerian formulation, which treats the heat flux as fixed in space, increases computational efficiency and aligns well with analytical solutions for uncoupled heat conduction problems [98].

Additionally, the study by Han et al. investigates the microlayer surface hardening process by laser melting of Fe–Ni–Cr powder with AISI D2 tool steel, showing that parametric studies involving the laser power, scan rate, and layer number are essential for achieving the desired hardness profile [99].

The research by Horník et al. compares the effects of laser surface hardening on two types of graphite cast iron, revealing that while gray cast iron achieves a higher hardened depth, ductile cast iron exhibits higher hardness [100].

Chaudhari et al. focus on the hardening of titanium surfaces using laser carburizing, where the formation of a TiC layer significantly enhances hardness and wear resistance with TiC grains being much finer than the substrate grains [101].

Han et al. used the Voronoi method to establish a random polycrystalline model of the matrix, incorporating grain heterogeneity based on nanoindentation results. This model, combined with a thermo-mechanical coupling model, helps in understanding the effects of laser power and scanning speed on residual stress with the Box–Behnken Design method and Monte Carlo sampling used for sensitivity analysis [102].

Zhang et al. used finite element simulations combined with the Kriging model to analyze the temperature field and predict the depth of the hardened layer in pitch bearing raceways, demonstrating the model’s accuracy in reflecting the relationship between process parameters and output responses [103].

Anusha et al. developed an integrated statistical mathematical model using Response Surface Methodology (RSM) coupled with Finite Element Method (FEM) to optimize LSH on cylindrical steel rods, achieving uniform hardened layers and eliminating inter-pass tempering effects [84].

Collectively, these studies underscore the critical role of analytical models in optimizing laser surface-hardening processes, ensuring enhanced material properties and efficient industrial applications.

Table 3 presents a summary of various aspects of selected articles in the field of the application of the analytical methods.

Table 3.

Analysis of selected articles in the field of use of analytical methods.

5.3. Empirical and Data-Driven Models

Empirical models of LSH are essential for optimizing process parameters and predicting outcomes without relying on extensive trial and error. These models typically incorporate various parameters such as laser power, scanning speed, and rotational speed to predict the hardness profile and depth of the hardened layer.

Orazi et al. presented a simplified approach for laser surface hardening modeling, which neglects austenite homogenization due to insufficient carbon diffusion during the heating phase, which is verified through nano-hardness measurements on C45 carbon steel samples [12].

Martinez et al. developed both semi-empirical and numerical models to control the laser-hardening process on AISI 1045 steel, which is validated through experimental tests measuring surface temperature and hardness [104]. Another study by the same authors focused on a semi-empirical model to predict the thermal field and thickness of the heat-affected zone, considering unknown heat sinks and material absorptivity changes during rapid heating [105].

Data-driven modeling of laser surface hardening (LSH) is an advanced approach that leverages computational techniques and machine learning to optimize and predict the outcomes of the hardening process. This method is particularly beneficial given the complexity and multitude of parameters involved in LSH, such as laser power, scanning speed, and irradiation time.

For instance, Lesyk et al.’s study on AISI 1045 steel demonstrated that optimized laser parameters could significantly enhance surface hardness by over 200% [76].

Mosavi et al. created a mathematical model to calculate the temperature distribution during LSH, which is crucial for understanding the phase transformations and ensuring consistent hardening [106].

Derouiche et al. explored data-driven models for predicting hardness post-quenching in induction hardening, demonstrating the efficacy of artificial intelligence in providing accurate approximations even with limited data [107].

Vittorietti et al. propose a new approach to determine phenomenological or physical relations between microstructure features and the mechanical behavior of metals bridging advanced statistics and materials science in a study of the effect of hard precipitates on the hardening of metal alloys [108]. The study applied Functional Principal Component Analysis (FPCA) to analyze the variability in stress–strain curves, treating these curves as realizations of a functional model.

Czupryński et al. used numerical simulations and infrared thermography to correlate thermal conditions with the microstructural characteristics of the hardened layers, emphasizing the role of laser power density in controlling layer thickness and hardness [109].

Table 4 presents a summary of various aspects of selected articles in the field of empirical and data-driven models.

Table 4.

Analysis of selected articles in the field of use of empirical and data-driven models.

5.4. Machine Learning and AI Integration

The integration of machine learning (ML) and artificial intelligence (AI) in laser surface hardening has been extensively explored across various scientific studies, highlighting its potential to enhance the process efficiency and surface quality.

One study by Matej Babič focuses on using Support Vector Machines and multiple regression to predict surface roughness in robot laser surface hardening, emphasizing the importance of different parameters in the robot laser cell [110].

Another paper by Babič et al. merges genetic algorithms and convolutional neural networks to analyze the surface roughness of tool steel EN100083-1, demonstrating the benefits of RLH in terms of cost reduction and process flexibility [111].

Ravnikar et al. investigate the effects of laser pulse duration and graphite absorbers on the microstructure and microhardness of C45 carbon steel, using acoustic emission signals and ML for monitoring and classification [112].

Steege et al. introduce predictive modeling for laser surface texturing (LST) using Artificial Neural Networks and Random Forests, which can predict surface topography with high accuracy despite limited data [113].

Kechagias et al. present a methodology for optimizing the topology and learning parameters of Feed-Forward and Backpropagation Artificial Neural Networks (FFBP-ANNs) to accurately predict the surface roughness of laser-cut edges. The methodology utilizes the Taguchi Design of Experiments (TDE) to reduce the number of trials needed to determine optimal neurons in the hidden layer and training parameter values. By examining nine combinations of four variables, the study aims to minimize Mean Squared Error (MSE) and maximize the overall regression index (Rall). The optimized FFBP-ANN successfully predicts surface roughness in various cut depths during the laser cutting of thin thermoplastic plates [114].

Jerniti et al. present a comprehensive modeling approach for predicting hardened surface attributes in AISI 4340 steel using both regression equations and ANN, highlighting the importance of laser power, beam scanning speed, and workpiece rotational speed [115].

Mathew et al. develop an intelligent system based on ML to predict residual stress distribution in laser shock peening (LSP), using ANNs within a Bayesian framework for robust prediction and optimization [116].

Billaud et al. develop an ANN-based model for quality estimation in laser surface transformation hardening, demonstrating its effectiveness in predicting hardened surface characteristics under varying conditions [117].

Sohrabpoor et al. compare Artificial Neural Networks and adaptive neuro-fuzzy inference systems in predicting the characteristics of laser-textured 316L stainless steel, emphasizing the superiority of ANFIS in prediction accuracy [118].

Ponticelli et al. propose a Genetic Algorithm-optimized model for controlling the fatigue life of AISI 1040 steel after laser hardening, demonstrating significant improvements in fatigue life and predictive accuracy [119].

Wu et al. demonstrate the use of Artificial Neural Networks to model and predict the surface quality of H13 tool steel after laser polishing, achieving high predictive accuracy for surface topography parameters [120].

Baronti et al. apply Artificial Neural Networks and generative adversarial networks to predict the functional response of laser-textured surfaces, specifically focusing on wettability and surface roughness parameters [121].

Heath et al. showed the use of the neural network modeling to accurately predict the 3D surface profile of the laser-machined surface after exposure to various spatial intensity profiles [122].

Collectively, these studies underscore the critical role of ML and AI in optimizing laser surface-hardening processes, enabling precise control over surface properties and enhancing overall process efficiency. The integration of advanced predictive models and intelligent systems not only improves the accuracy of surface property predictions but also facilitates the development of more efficient and reliable laser-hardening techniques, paving the way for significant advancements in material engineering and manufacturing.

Table 5 presents a summary of various aspects of selected articles in the field of the application of the ML and AI.

Table 5.

Analysis of selected articles in the field of use of ML and AI.

6. Surface Properties and Testing Methods

Understanding the surface properties of materials treated with LSH is crucial for ensuring their performance and reliability in various applications. This section explores the essential methods used to evaluate these properties, focusing on microstructural analysis, mechanical testing, and electrochemical properties.

6.1. Microstructural Analysis

To analyze microstructural changes due to LSH, a variety of advanced techniques are employed. These methods provide detailed insights into the alterations in the microstructure of materials, which can significantly influence their mechanical properties.

Optical microscopy is used to observe the overall microstructure and surface morphology of the hardened layer (to examine the grain structure, phase distribution, and defects). In the study of AISI 4130 steel, optical microscopy was used to evaluate the microstructure after laser surface hardening [123].

Scanning Electron Microscopy (SEM) is used to provide high-resolution images of the microstructural features. SEM is used to examine finer details such as grain boundaries, secondary phases, and surface morphology. FESEM, for example, was employed to analyze the changes in AISI 420 steel post-laser hardening [124].

Transmission Electron Microscopy (TEM) is used to observe internal microstructural features at the atomic level. TEM is used to study dislocations, phase transformations, and crystallographic defects. TEM, along with Scanning Electron Microscopy (SEM), can be used to analyze the surface topography and grain size of materials treated by LSH. This combined approach provides comprehensive insights into how laser treatment affects the microstructure [125].

X-ray Diffraction (XRD) is used to determine the crystalline structure and phase composition. XRD is used to detect phase transformations induced by LSH, which can significantly alter the material’s properties. For example, it can reveal the formation of martensite, a hard phase, in steel after laser hardening [126]. XRD can provide information about the texture of polycrystalline materials, which can affect their mechanical properties. Texture analysis helps in optimizing the laser hardening process for improved performance [127].

To analyze the elemental composition and the distribution of elements within the laser-treated zones, Energy-Dispersive X-ray Spectroscopy (EDS or EDX) can be used.

X-ray Photoelectron Spectroscopy (XPS) is used to investigate the chemical state and composition of the surface and to analyze oxide layers and other surface modifications. XPS was used, for example, to study the phase composition of oxide layers formed on laser-treated steels [128].

Finite Element Analysis (FEA) is used to simulate the thermal and mechanical effects of laser surface hardening and to predict the temperature distribution, phase transformations, and residual stresses. For example, 3D FEM thermal analysis was conducted to study different laser scanning patterns on AISI 4340 steel [86].

To measure surface roughness and topography and to assess the quality and uniformity of the hardened surface, surface profilometry is used. Different optical profilometry techniques are used to evaluate the surface topography of materials post-treatment. For example, a study conducted on Ti6Al4V titanium alloy after finish turning under dry machining conditions compared various optical profilometry methods to assess the surface texture properties [129].

Thermal analysis can be used to evaluate the thermal effects and efficiency of the laser-hardening process and to optimize laser parameters for improved hardening efficiency. Maharjan et al. proposed a simplified approach to model laser surface hardening by focusing on thermal efficiency [130].

6.2. Mechanical Testing

LSH significantly improves the wear resistance, hardness, and fatigue life of treated materials. To evaluate these improvements, various testing methods are employed:

- Wear testing—Wear resistance is often assessed using tribological tests such as the pin-on-disk or pin-on-plate methods. These tests involve sliding a pin of a hard material against the hardened surface under controlled conditions to measure wear rates and friction coefficients. For example, Furlani et al. used a reciprocating wear test to evaluate the wear resistance of laser-hardened low carbon steel [64].

- Hardness testing—The hardness of laser-hardened surfaces is typically measured using microhardness testers like Vickers, Rockwell or Knoop hardness tests. These tests apply a specific load to an indenter, which penetrates the surface, and the size of the indentation is used to calculate hardness. Chaudhari et al. measured the hardness of a TiC layer on titanium substrate, finding a significant increase compared to untreated titanium [101].

- Fatigue testing (rotating bending, axial, four-point bending)—Fatigue life is assessed using cyclic loading tests that simulate the operational conditions of the material. These tests help in understanding the endurance limit and the number of cycles to failure. Fatigue properties can be improved by the introduction of compressive residual stresses and refined microstructures, as seen in studies like the one by Han et al. on austempered ductile iron [131].

6.3. Electrochemical Properties

LSH not only enhances the mechanical properties but also impacts the electrochemical properties of materials, which are crucial for applications involving corrosion resistance and overall durability in aggressive environments. The electrochemical properties affected by LSH are the following:

- Corrosion resistance—LSH can refine the surface microstructure, leading to a more uniform and compact layer, which is less susceptible to corrosion. The formation of hard phases such as martensite and carbides during LSH can improve corrosion resistance by creating a protective barrier against corrosive agents. Compressive residual stresses induced by LSH can reduce the tendency for crack initiation and propagation, enhancing the material’s resistance to stress corrosion cracking.

- Passivation behavior—LSH can enhance the formation and stability of protective oxide layers on the surface, which act as barriers to corrosion. The rapid heating and cooling during LSH can alter the surface chemistry, promoting the formation of more corrosion-resistant phases.

Research has shown that LSH-treated materials often exhibit superior corrosion resistance compared to untreated materials. For example, LSH-treated AISI 420 stainless steel demonstrated improved resistance to pitting corrosion due to a refined microstructure and stable passive film formation [132]. The enhanced corrosion resistance is attributed to the formation of a uniform and compact martensitic layer, the reduction in surface roughness, and the presence of compressive residual stresses.

LSH can enhance the passivation behavior of materials like stainless steels and titanium alloys. Studies have reported increased passivation current densities and wider passive regions in potentiodynamic polarization tests. For instance, LSH improved the passivation and potentiodynamic polarization behavior of Selective Laser Melted 17-4PH stainless steel, resulting in enhanced corrosion resistance in NaCl solutions [133]. The rapid cooling rates in LSH promote the formation of stable and adherent passive films, which protect the underlying material from corrosive attacks. This is attributed to the fine microstructure and minimal non-metallic inclusions formed during the laser treatment [134].

The following electrochemical testing methods can be distinguished:

- Potentiodynamic polarization—to evaluate the corrosion resistance by measuring the material’s response to an applied potential. Determines parameters such as corrosion potential (Ecorr), corrosion current density (Icorr), and passivation behavior.

- Electrochemical Impedance Spectroscopy (EIS)—to assess the material’s impedance to electrochemical reactions, providing insights into corrosion mechanisms. Evaluates the integrity and protective nature of oxide layers and coatings.

- Cyclic voltammetry—to study the electrochemical behavior of materials, including redox reactions and passivation. Analyzes the formation and breakdown of passive films on the surface.

- Salt spray test—to simulate corrosive environments and evaluate the material’s resistance to corrosion. Assesses the long-term corrosion resistance and effectiveness of the hardened surface layer.

7. Challenges and Future Directions

While recent advances in modeling the laser surface hardening of metals have significantly improved the precision and efficiency of this process, several challenges remain. Future research and collaborative efforts will be crucial in overcoming these challenges and further advancing the field.

7.1. Current Limitations

Despite significant advancements in modeling the laser surface hardening of metals, several limitations still hinder its full potential and widespread application. One of the primary challenges is the complexity and computational intensity of the models. Although simplifications have been introduced, accurate simulations that consider all the relevant physical phenomena, such as heat transfer, phase transformations, and mechanical stresses, remain computationally demanding. This complexity can lead to long processing times and requires substantial computational resources, which may not be readily available in all industrial settings.

Another limitation is the difficulty in accurately predicting the effects of microstructural changes on the final properties of the hardened surface. The process involves numerous variables, including laser power, scanning speed, and material composition, each of which can significantly impact the outcome. Variations in these parameters can lead to inconsistencies in the hardness, depth of the hardened layer, and residual stresses, making it challenging to achieve uniform results across different parts and batches.

Additionally, the existing models often rely on assumptions and approximations that may not fully capture the real-world behavior of materials under laser treatment. For instance, the simplified models might neglect certain microstructural phenomena or the influence of external factors such as ambient temperature and cooling rates. These oversights can result in discrepancies between predicted and actual outcomes, necessitating further empirical adjustments and validations.

Moreover, there is a limitation in the adaptability of the models to new materials and alloys. As industries continuously develop new metal compositions to meet specific performance requirements, the existing models must be frequently updated and validated for these new materials. This ongoing need for adaptation and validation adds to the time and cost of implementing laser surface-hardening technologies in new applications.

Lastly, while robot-assisted laser systems have improved the precision of the hardening process, they also introduce challenges related to the integration and calibration of robotic components with laser equipment. Ensuring that the robotic movements are perfectly synchronized with the laser parameters is crucial for achieving the desired surface properties, and any misalignment or error in calibration can lead to suboptimal results.

Addressing these limitations will be essential for further improving the efficiency, accuracy, and applicability of laser surface-hardening technologies.

7.2. Future Research Areas

Advancing the field of laser surface hardening necessitates addressing current limitations and exploring new research areas to enhance the precision, efficiency, and applicability of this technology. Future research in this field can be directed toward several promising areas:

- ○

- Enhanced computational models—Developing more efficient computational models that can simulate laser surface hardening with higher accuracy and reduced computational resource requirements is a critical research area. This includes leveraging advanced algorithms, machine learning techniques, and high-performance computing to streamline simulations and make them more accessible for industrial applications.

- ○

- Real-time monitoring and control—Integrating real-time monitoring and adaptive control systems into laser-hardening processes can significantly improve outcomes. Research into advanced sensors and feedback mechanisms can enable dynamic adjustments of laser parameters based on real-time data, ensuring consistent hardness and microstructural properties across different parts and batches.

- ○

- Multiphysics and multiscale modeling—Developing models that incorporate multiphysics and multiscale phenomena can provide a more comprehensive understanding of the laser-hardening process. This includes accounting for the interactions between thermal, mechanical, and metallurgical processes at different scales, from the macroscopic level down to the grain structure level, to predict the final properties of the treated surface more accurately.

- ○

- Material-specific models—With the continuous development of new metal alloys tailored for specific applications, there is a need for material-specific models that can accurately predict the behavior of these materials under laser hardening. Research should focus on creating adaptable models that can be easily updated and validated for new materials, ensuring the technology keeps pace with advancements in material science.

- ○

- Integration with additive manufacturing—Combining laser surface hardening with additive manufacturing (3D printing) presents a novel research area. This integration can lead to the development of components with tailored surface properties directly during the manufacturing process, enhancing their performance and lifespan. Research should explore the synergies between these technologies and develop integrated process models.

- ○

- Sustainability and energy efficiency—Researching ways to make laser surface hardening more sustainable and energy-efficient is increasingly important. This includes optimizing process parameters to reduce energy consumption, developing eco-friendly materials and coatings, and investigating the recyclability of laser-hardened components.

- ○

- Robotic and automation advances—As robotic systems become more sophisticated, research should focus on improving the integration of laser hardening with advanced robotic automation. This involves developing more precise and adaptive robotic controls, enhancing the synchronization between laser systems and robotic movements, and exploring the use of artificial intelligence to automate and optimize the process further.The importance of this area can be seen in the recently emerging solutions.Process planning is crucial for efficient laser surface hardening. Simulation tools, such as FANUC ROBOGUIDE, are used to model and optimize the hardening processes, ensuring high accuracy and repeatability [135].Robotic arms equipped with advanced scanning systems enhance the precision and efficiency of the hardening process. These systems allow for detailed inspections and adjustments during the manufacturing process, ensuring consistent quality [136].Lesyk et al. explored the use of a robot-based laser 3D system for hardening the AISI 1066 steel shafts of gear mechanisms, achieving a 2.5 times increase in surface hardness and establishing optimal laser heat treatment parameters [137].Fakir et al. used a robotic arm to precisely control the movements of a Nd-YAG 3.0-kW laser source during the laser-hardening process of a cylindrical AISI-4340 steel specimen. This robotic control ensures accurate manipulation of the laser in space and time, creating the necessary temperature gradient for microstructural transformation and achieving consistent hardness across the material [9].Pawłowicz emphasizes the advantages of fully automated laser-hardening processes, including reduced thermal deformation and the ability to selectively harden parts that were previously untreatable, which is facilitated by CAD/CAM system integration [138].Gu and Shulkin discuss the integration of automatic tool path generation and precise processing temperature control through feedback systems in laser beam hardening [139].

- ○

- Industry 4.0 and IoT integration—Incorporating Industry 4.0 principles and the Internet of Things (IoT) into laser surface hardening can lead to smarter and more connected manufacturing processes. Research in this area should explore how to utilize data analytics, cloud computing, and IoT-enabled devices to monitor, control, and optimize laser-hardening operations remotely and in real time.

- ○

- Collaborative research and standardization—Collaborative efforts among academia, industry, and government bodies are essential to drive innovation in laser surface hardening. Establishing industry standards and best practices can streamline the adoption of new technologies and ensure consistent quality across different applications.

These areas have the potential to significantly advance technology, making it more efficient, precise, and widely applicable in various industrial sectors.

8. Conclusions

The field of laser surface hardening has witnessed significant advancements in recent years, which were primarily driven by improvements in modeling techniques. These advancements have enhanced the process’s precision, efficiency, and applicability, making it a more viable option for various industrial applications. Key developments include the refinement of numerical simulations, which have become more sophisticated and less time-consuming, allowing for more accurate predictions of the hardening process outcomes. Additionally, the integration of statistical models with finite element methods has enabled a better optimization of process parameters, resulting in uniform and high-quality hardened layers.

Robot-assisted 3D laser systems have also emerged as a significant innovation, offering precise control over the laser-hardening process, which is crucial for treating complex geometries and achieving consistent surface properties. The application of fractal geometry and genetic programming has further enhanced the ability to model and predict the microstructural changes during laser hardening, ensuring that the desired hardness and surface characteristics are consistently achieved.

These modeling advancements have not only improved the efficiency and effectiveness of the laser surface hardening process but also expanded its applicability to more complex and varied industrial scenarios. By optimizing parameters and eliminating undesirable effects such as tempering in overlapped regions, these techniques ensure that the treated metal components exhibit superior performance and longevity. As a result, industries ranging from automotive to aerospace and manufacturing are increasingly adopting laser surface-hardening techniques to enhance the durability and functionality of their products.

The recent advances in modeling techniques for laser surface hardening have transformed the process into a more precise, efficient, and widely applicable technology. These improvements promise continued innovation and broader adoption in various industrial sectors, leading to enhanced performance and an extended lifespan of metal components.

Funding

This work was supported by the Ministry of Science and Higher Education, Poland, Grant AGH University of Krakow no. 16.16.110.663.

Data Availability Statement

Not applicable.

Conflicts of Interest

The author declare no conflicts of interest.

References

- Ion, J.C. Laser Processing of Engineering Materials: Principles, Procedure and Industrial Application; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Laser Materials Processing, 1st ed.; Bass, M., Ed.; Elsevier Science: Amsterdam, The Netherlands, 1983; Volume 3, ISBN 9780444601322. [Google Scholar]

- Guarino, S.; Barletta, M.; Afilal, A. High Power Diode Laser (HPDL) surface hardening of low carbon steel: Fatigue life improvement analysis. J. Manuf. Process. 2017, 28, 266–271. [Google Scholar] [CrossRef]

- Nemova, G. Brief Review of Recent Developments in Fiber Lasers. Appl. Sci. 2024, 14, 2323. [Google Scholar] [CrossRef]

- Steen, W.M. Laser Material Processing, 3rd ed.; Springer: London, UK, 2003; ISBN 9781852336981. [Google Scholar]

- Bailey, N.S. Numerical Modeling and Experimental Analysis of Residual Stresses and Microstructural Development During Laser-Based Manufacturing Processes; Purdue University Graduate School: West Lafayette, IN, USA, 2020. [Google Scholar]

- Ashby, M.F.; Easterling, K.E. The transformation hardening of steel surfaces by laser beams—I. Hypo-eutectoid steels. Acta Metall. 1984, 32, 1935–1948. [Google Scholar] [CrossRef]

- Yares’ko, S.I. Finite-Element Modeling in the Technology of Hardening Laser Processing of a Metal-Cutting Tool. J. Eng. Phys. Thermophys. 2019, 92, 314–325. [Google Scholar] [CrossRef]