Morphological and Surface Microtopographic Features of HPHT-Grown Diamond Crystals with Contact Twinning

Abstract

:1. Introduction

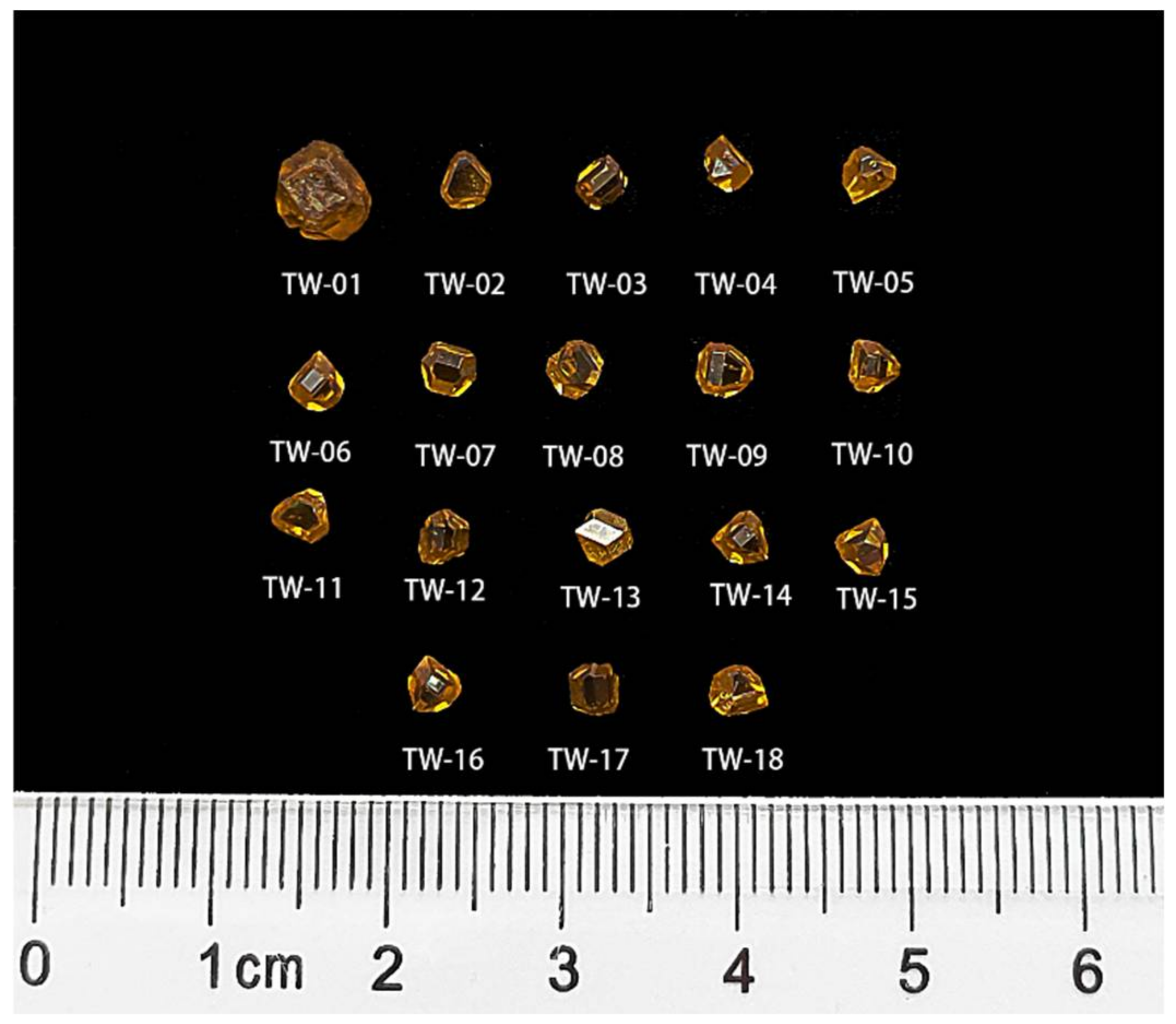

2. Materials and Methods

3. Results

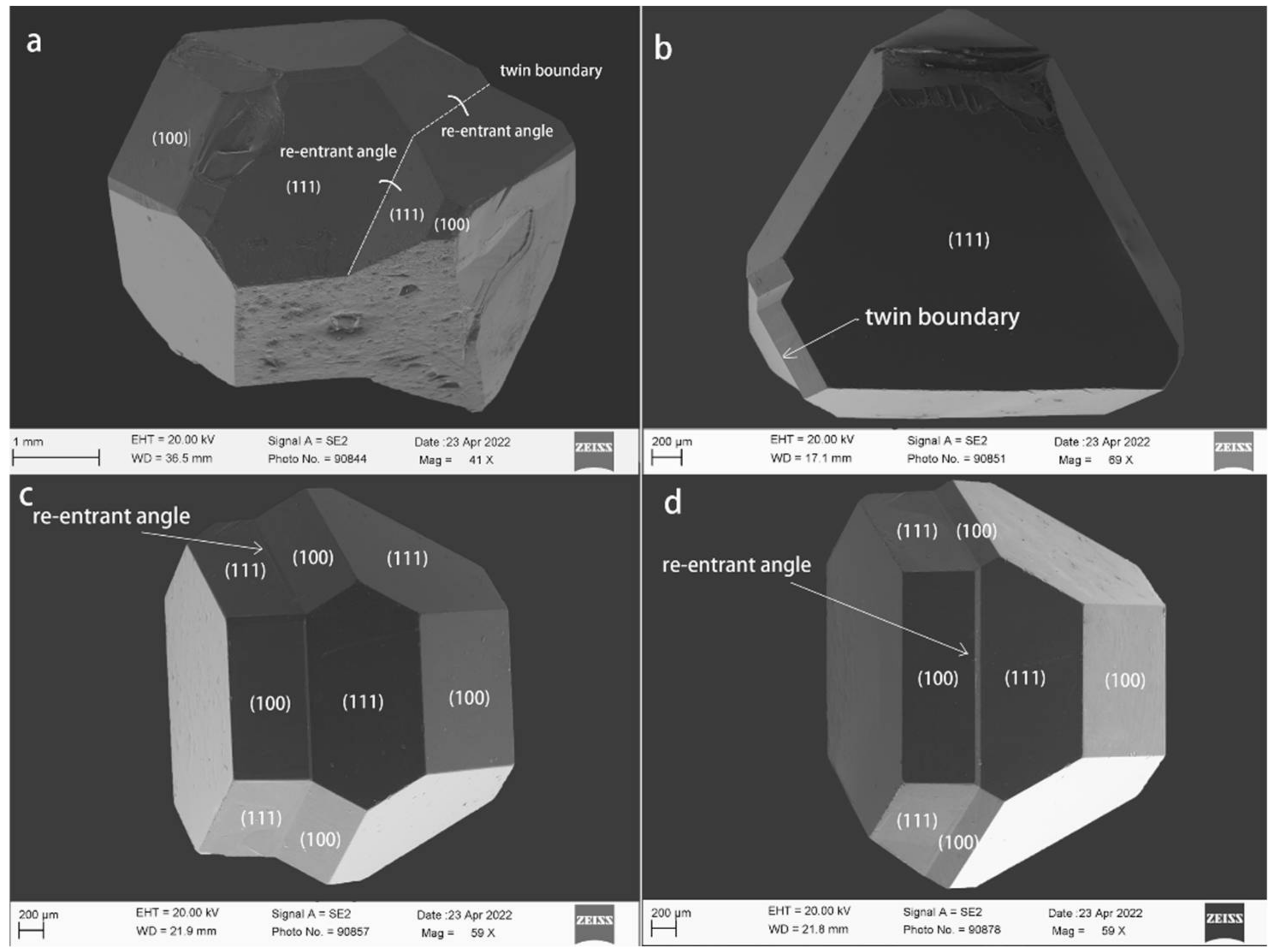

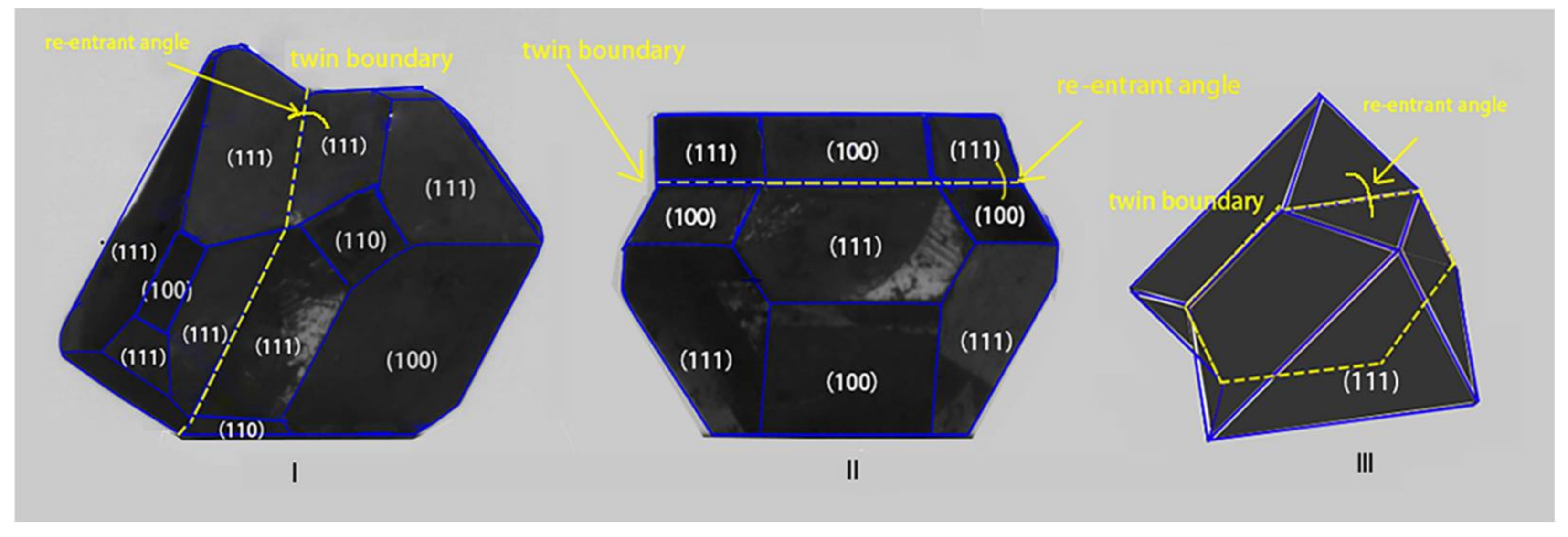

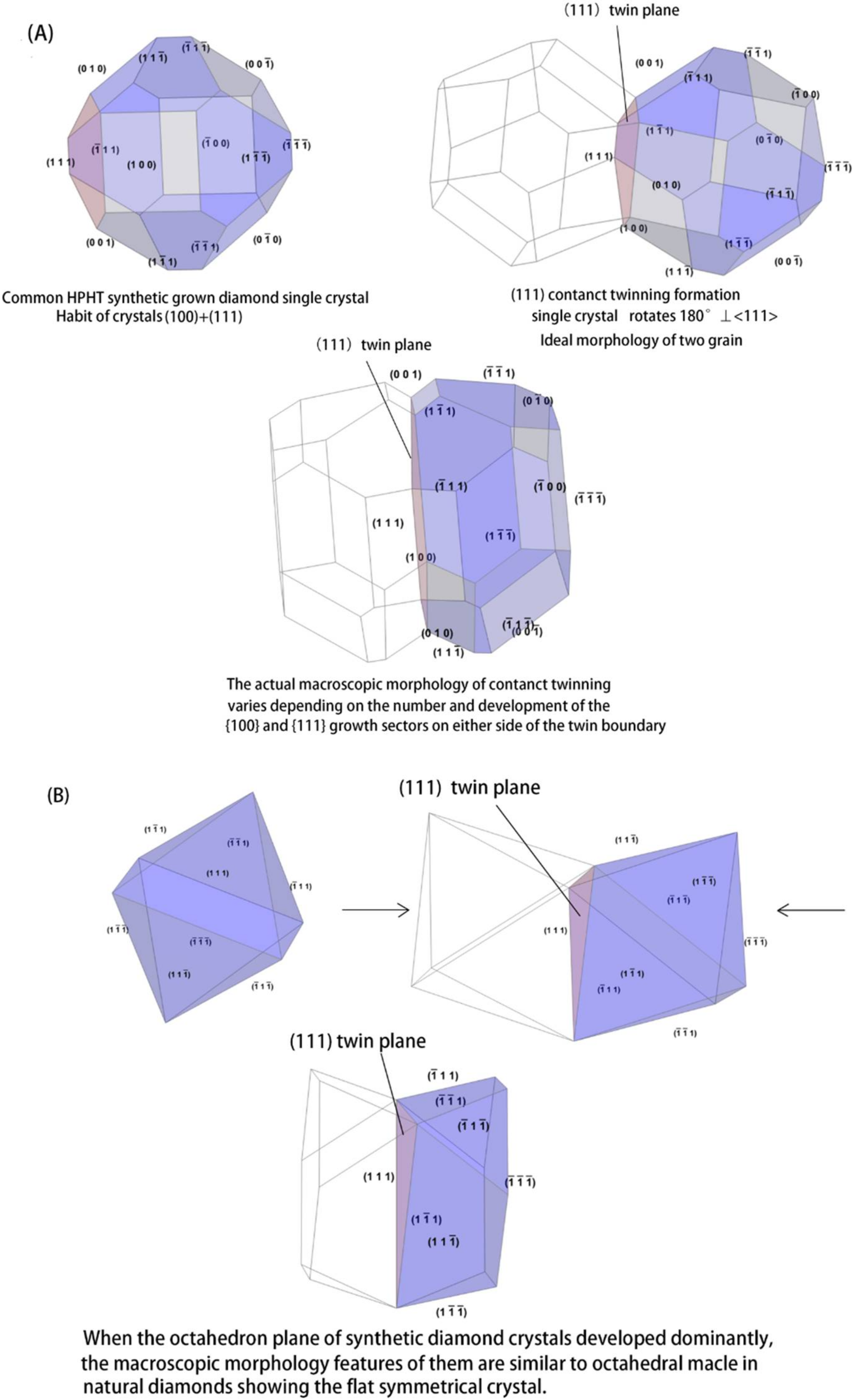

3.1. Macroscopic Morphology

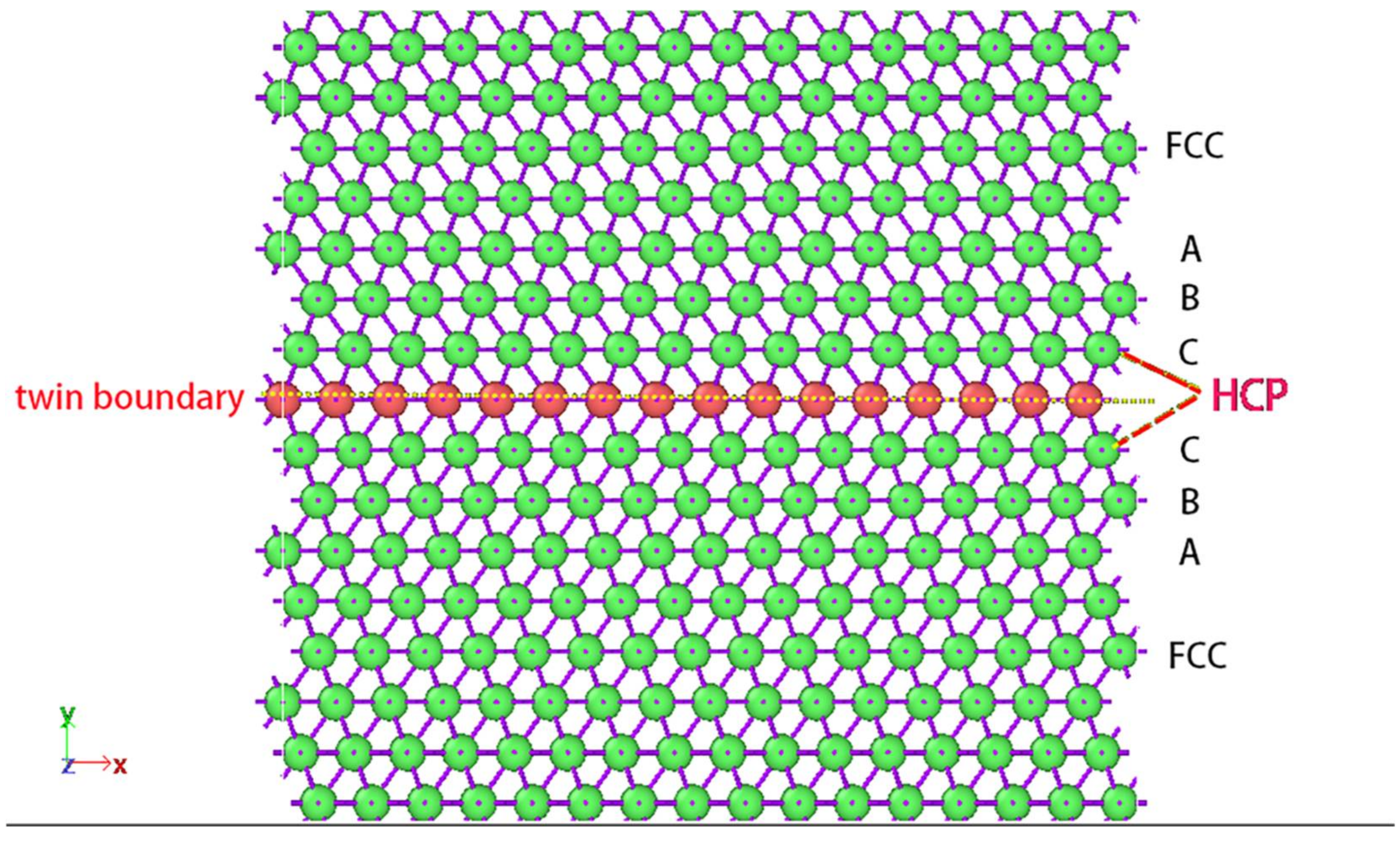

3.2. Twin Boundary

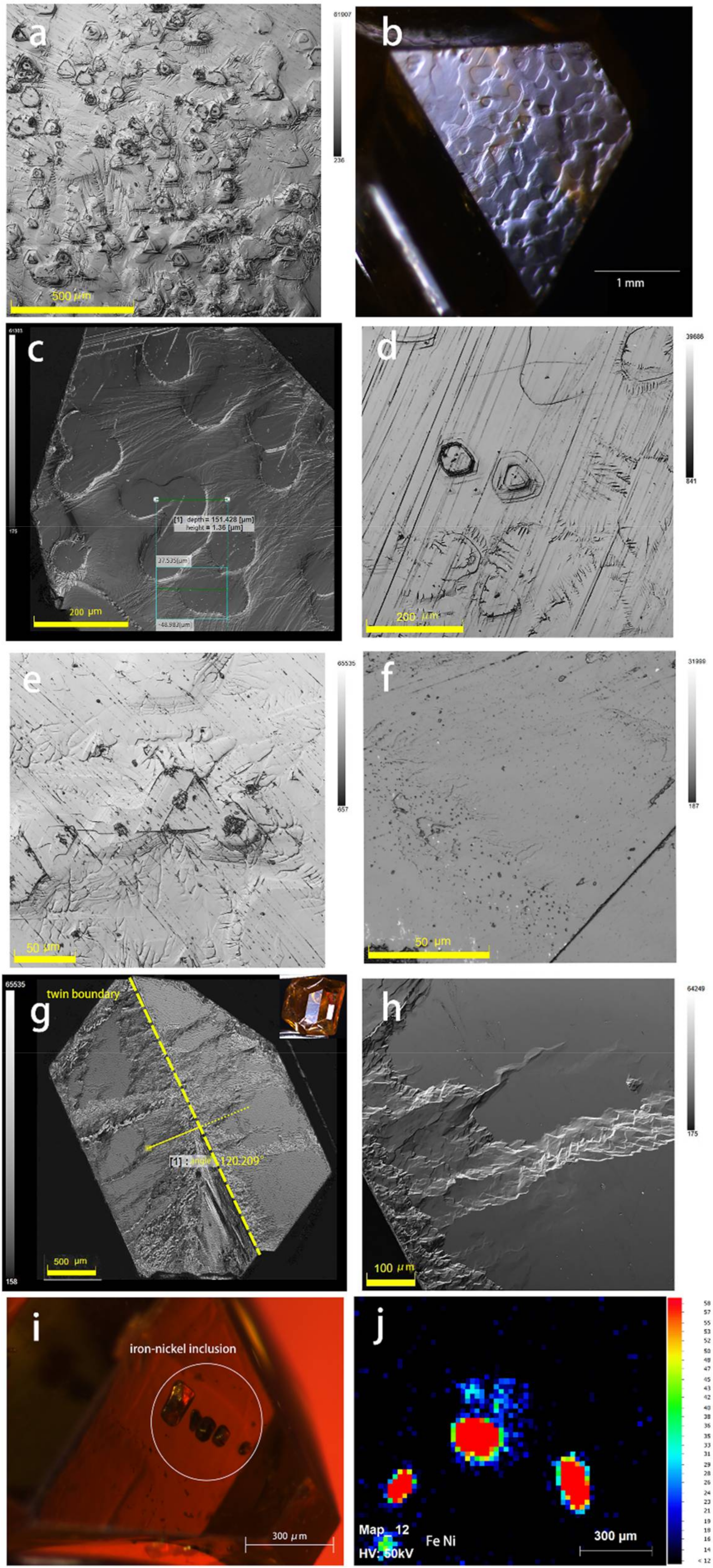

3.3. Etch Figures and Related Growth Features

3.3.1. Seed Crystals

3.3.2. Etch Figures

3.3.3. Growth Features

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Orlov, Y.L.; Huang, C.E. The Mineralogy of the Diamond; China Architecture & Building Press: Beijing, China, 1977. (In Russian) [Google Scholar]

- Tappert, M.C. Diamond in Nature; Springer: Berlin/Heidelberg, Germany, 2010; pp. 1–142. [Google Scholar]

- Sunagawa, I. The Morphology of the Diamond. J. Gemmol. Soc. Jpn. 2013, 30, 42–48. [Google Scholar]

- Cahn, R.W. Twinned crystals. Adv. Phys. 1954, 3, 363–445. [Google Scholar] [CrossRef]

- Yacoot, A.; Moore, M.; Machado, W.G. Twinning in Natural Diamond. I. Contact Twins. J. Appl. Crystallogr. 1998, 31, 767–776. [Google Scholar] [CrossRef]

- Kvasnytsya, V.M. Morphology of Diamond Crystals and Mechanism of Their Growth. J. Superhard Mater. 2021, 43, 75–84. [Google Scholar] [CrossRef]

- Yacoot, A.; Moor, M. An unusual octahedral diamond. Mineral. Mag. 1992, 56, 111–113. [Google Scholar] [CrossRef]

- Machado, W.G.; Moore, M.; Yacoot, A. Twinning in Natural Diamond. II. Interpenetrant Cubes. J. Appl. Crystallogr. 1998, 31, 777–782. [Google Scholar] [CrossRef]

- Lu, T.J.; Ke, J.; Qiu, Z.L. Surface dissolution features and contact twinning in natural diamonds. J. Mineral. Geochem. 2018, 195, 145–153. [Google Scholar] [CrossRef]

- Machado, W.G.; Moore, M. Twinning in diamond: An X-ray topographic study. Acta Crystallogr. A 1981, 37, C248. [Google Scholar] [CrossRef]

- Xiao, J.; Wen, B.; Xu, B.; Zhang, X.; Wang, Y.; Tian, Y. Intersectional nanotwinned diamond-the hardest polycrystalline diamond by design. Npj Comput. Mater. 2020, 6, 119. [Google Scholar] [CrossRef]

- Huang, Q.; Yu, D.; Xu, B.; Hu, W.; Ma, Y.; Wang, Y.; Zhao, Z.; Wen, B.; He, J.; Liu, Z.; et al. Nanotwinned diamond with unprecedented hardness and stability. Nature 2014, 510, 250–253. [Google Scholar] [CrossRef]

- Solozhenko, V.L.; Kurakevych, O.O.; Yann-Le, G. Creation of Nanostuctures by Extreme Conditions: High-Pressure Synthesis of Ultrahard Nanocrystalline Cubic Boron Nitride. Adv. Mater. 2012, 24, 1540–1544. [Google Scholar] [CrossRef] [PubMed]

- Irifune, T.; Kurio, A.; Sakamoto, S.; Inoue, T.; Sumiya, H. Correction: Ultrahard polycrystalline diamond from graphite. Nature 2003, 421, 599–600. [Google Scholar] [CrossRef] [PubMed]

- Butler, J.E.; Oleynik, I. A mechanism for crystal twinning in the growth of diamond by chemical vapour deposition. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2008, 366, 295–311. [Google Scholar] [CrossRef] [PubMed]

- Wild, C.; Kohl, R.; Herres, N.; Muller-Sebert, W.; Koidl, P. Oriented CVD diamond films: Twin formation, structure and morphology. Diam. Relat. Mater. 1994, 3, 373–381. [Google Scholar] [CrossRef]

- Pipkin, N.J. The Growth of Twins and Twin Lamellae in Synthetic Diamond Crystals. In Specialty Steels and Hard Materials, Proceedings of the International Conference on Recent Developments in Specialty Steels and Hard Materials (Materials Development ‘82), Pretoria, South Africa, 8–12 November 1982; Elsevier: Amsterdam, The Netherlands; pp. 439–444.

- Abduriyim, A.; Kitamura, M. Growth morphology and change in growth conditions of a spinel-twinned natural diamond. J. Cryst. Growth 2002, 237–239, 1286–1290. [Google Scholar] [CrossRef]

- Orlov, Y.L.; Wiley, I. The mineralogy of the diamond. Phys. Earth Planet. Inter. 1979, 19, 364. [Google Scholar]

- Sutton, J.R. A contribution to the study of the diamond macle. Trans. R. Soc. S. Afr. 1919, 8, 153–167. [Google Scholar] [CrossRef]

- Churchman, A.T.; Geach, G.A.; Winton, J. Deformation Twinning in Materials of the A4 (Diamond) Crystal Structure. Proc. R. Soc. A 1956, 238, 194–203. [Google Scholar]

- Guo, Q.Z.; Yu, W.L.; Bi, Y.J. Study of crystal defects in natural diamond. Diam. Relat. Mater. 1993, 2, 1239–1242. [Google Scholar]

- Kanda, H.; Obsawa, T. Growth hillocks on the {111} surface of high pressure synthetic diamond. Diam. Relat. Mater. 1996, 5, 8–12. [Google Scholar] [CrossRef]

- Wu, X.X.; Lu, T.J.; Tang, S. Observation of etched surface micro-features on HPHT synthetic diamonds using laser confocal microscopy. Gems Gemmol. 2018, 54, 246–248. [Google Scholar]

- Wu, X.X.; Lu, T.J.; Yang, C.Y.; Zhang, J.; Tang, S.; Cheng, H.; Zhang, Y.; Ke, J.; He, M.Y. Observation of Surface Microstructure of HPHT Synthetic Diamond Crystals and Genesis Discussion. Rock Miner. Anal. 2019, 38, 411–417. [Google Scholar]

- Tolansky, S.; Sunagawa, I. Spiral and Other Growth Forms of Synthetic Diamonds: A Distinction Between Natural and Synthetic Diamond. Nature 1959, 184, 1526–1527. [Google Scholar] [CrossRef]

- Fedortchouk, Y. A new approach to understanding diamond surface features based on a review of experimental and natural diamond studies. Earth-Sci. Rev. 2019, 193, 45–65. [Google Scholar] [CrossRef]

- Li, C.R.; Du, Z.M.; Xu, J.; Li, J.B.; Su, X.P.; Zhang, W.J. Thermodynamic Analysis on the Synthetic Process of Diamond under High Temperature and High Pressure: Phase Equilibria and Their Application. J. Synth. Cryst. 2015, 44, 2658–2663. [Google Scholar]

- Yin, L.W.; Li, M.S.; Sun, D.S.; Hao, Z.Y.; Chang, K.J. Microscopic Observation of Synthetic Diamond Growth Produced in Fe-Ni-C System. J. Synth. Cryst. 2000, 4, 386–389. [Google Scholar]

- De Theije, F.K.; Van Veenendaal, E.; Van Enckevort, W.J.P.; Vlieg, E. Oxidative etching of cleaved synthetic diamond {111} surfaces. Surf. Sci. 2001, 492, 91–105. [Google Scholar] [CrossRef]

- Khokhryakov, A.F.; Palyanov, Y.N. Effect of crystal defects on diamond morphology during dissolution in the mantle. Am. Mineral. 2015, 100, 1528–1532. [Google Scholar] [CrossRef]

- Tolansky, S. Synthetic Diamonds: Growth and Etch Phenomena. Proc. R. Soc. A 1962, 270, 443–451. [Google Scholar]

- Klepikov, I.V.; Vasilev, E.A.; Antonov, A.V. Growth Nature of Negative Relief Forms of Diamonds from Ural Placer Deposits. Crystallogr. Rep. 2020, 65, 300–306. [Google Scholar] [CrossRef]

- Tolansky, S. Comparative optical and interferometric studies on synthetic diamonds. Proc. R. Soc. A Math. Phys. Sci. 1976, 3, 31–38. [Google Scholar]

- Tolansky, S. Some observations on the morphology and physical characteristics of synthetic diamond. Proc. R. Soc. A Math. Phys. Sci. 1976, 3, 67–68. [Google Scholar]

- Reed, T.B. The art and science of growing crystals (Gilman, J.J., ed.). J. Chem. Educ. 1964, 41, A392. [Google Scholar] [CrossRef]

- Kanda, H.; Akaishi, M.; Setaka, N.; Yamaoka, S.; Fukunaga, O. Surface structures of synthetic diamonds. J. Mater. Sci. 1980, 15, 2743–2748. [Google Scholar] [CrossRef]

- Ming, M.G.; Shang, S.L.; Mei, H.H.; Tai, C.S.; Jun, Z.W.; Guang, J.G.; Yue, Y.; Yuan, N. Growth characteristics of type IIa large single crystal diamond with Ti/Cu as nitrogen getter in FeNi-C system. Chin. Phys. B 2020, 29, 457–462. [Google Scholar]

- Yin, L.W.; Li, M.S.; Yuan, Q.; Xu, B.; Hao, Z.Y. Characterization of Growth Hillocks on the Surface of High-Pressure Synthetic Diamond. Chin. Phys. Lett. 2002, 19, 1707–1710. [Google Scholar]

- Zang, C.Y.; Huang, G.F.; Ma, H.A.; Jia, X.P. Surface Structure of Large Synthetic Diamonds by High Temperature and High Pressure. Chin. Phys. Lett. 2007, 24, 2991–2993. [Google Scholar]

- Nai, B.M.; Tsukamoto, K.; Sunagawa, I.; Chernov, A.A. Stacking faults as self-perpetuating step sources. J. Cryst. Growth 1988, 91, 11–19. [Google Scholar]

- Yin, L.W.; Yuan, Q.; Li, M.S.; Liu, Y.X.; Xu, B.; Hao, Z.Y. Twin diamond Crystals Grown at High Temperature and High Pressure from the Fe-Ni-C System. Chin. Phys. Lett. 2002, 19, 1371–1373. [Google Scholar]

- Singh, J.B.; Sundararaman, M.; Krishnan, M. The nature of pseudo-twinning modes on the basis of a twin classification scheme. Scr. Mater. 2011, 64, 371–373. [Google Scholar] [CrossRef]

- Travis J, V.; Gupta, Y.M. Elastic moduli of hexagonal diamond and cubic diamond formed under shock compression. Phys. Rev. B 2021, 103, L100101. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, K.; Lu, T.; He, M.; Song, Z.; Zhang, J.; Ke, J. Morphological and Surface Microtopographic Features of HPHT-Grown Diamond Crystals with Contact Twinning. Crystals 2022, 12, 1264. https://doi.org/10.3390/cryst12091264

Sun K, Lu T, He M, Song Z, Zhang J, Ke J. Morphological and Surface Microtopographic Features of HPHT-Grown Diamond Crystals with Contact Twinning. Crystals. 2022; 12(9):1264. https://doi.org/10.3390/cryst12091264

Chicago/Turabian StyleSun, Kaiyue, Taijin Lu, Mingyue He, Zhonghua Song, Jian Zhang, and Jie Ke. 2022. "Morphological and Surface Microtopographic Features of HPHT-Grown Diamond Crystals with Contact Twinning" Crystals 12, no. 9: 1264. https://doi.org/10.3390/cryst12091264

APA StyleSun, K., Lu, T., He, M., Song, Z., Zhang, J., & Ke, J. (2022). Morphological and Surface Microtopographic Features of HPHT-Grown Diamond Crystals with Contact Twinning. Crystals, 12(9), 1264. https://doi.org/10.3390/cryst12091264