Feasibility Study of Selective Laser Melting for Metal Matrix Diamond Tools

Abstract

1. Introduction

2. Experimental Details

3. Results and Discussion

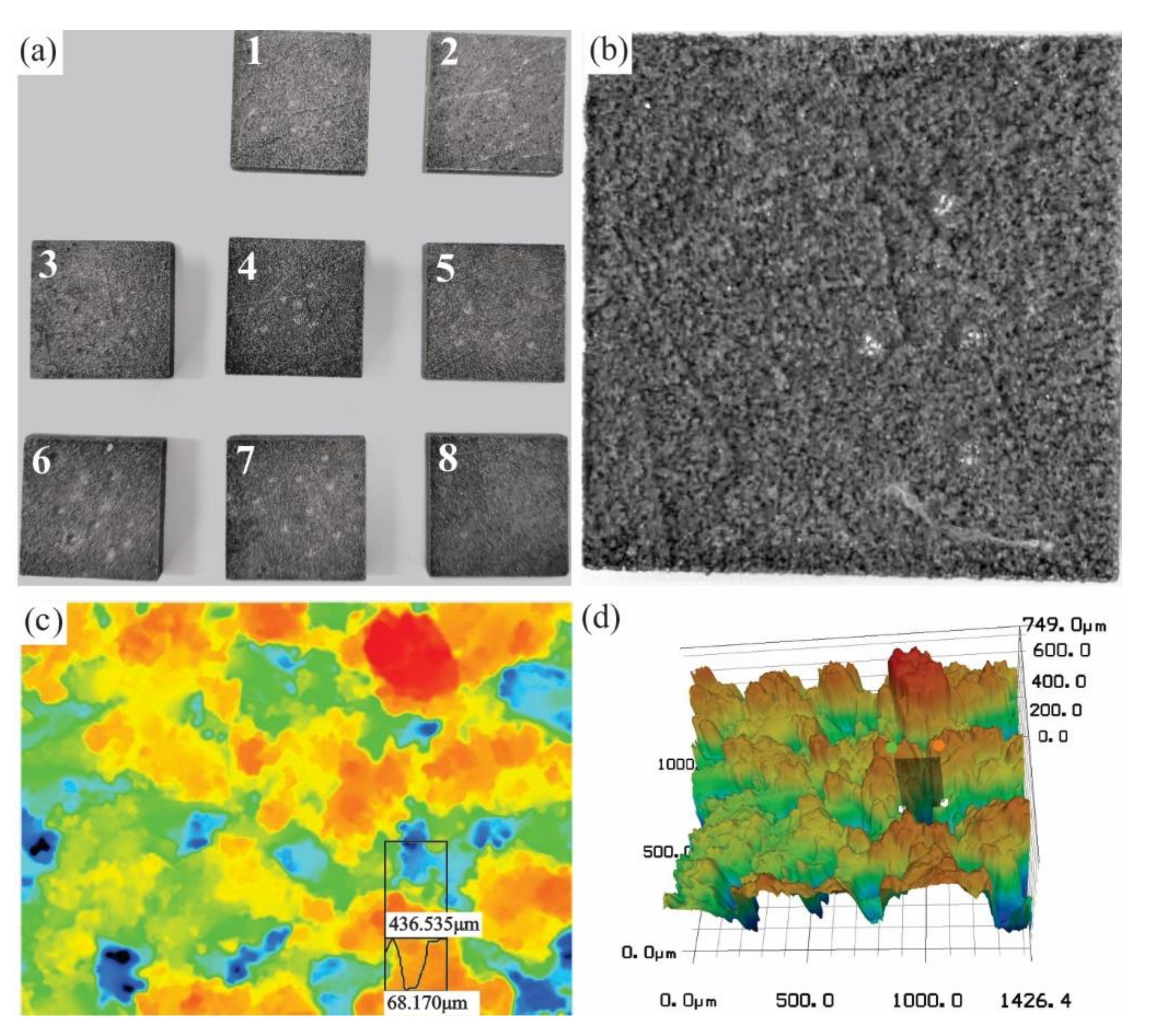

3.1. Surface Topographies and Hardness

3.2. Microstructure

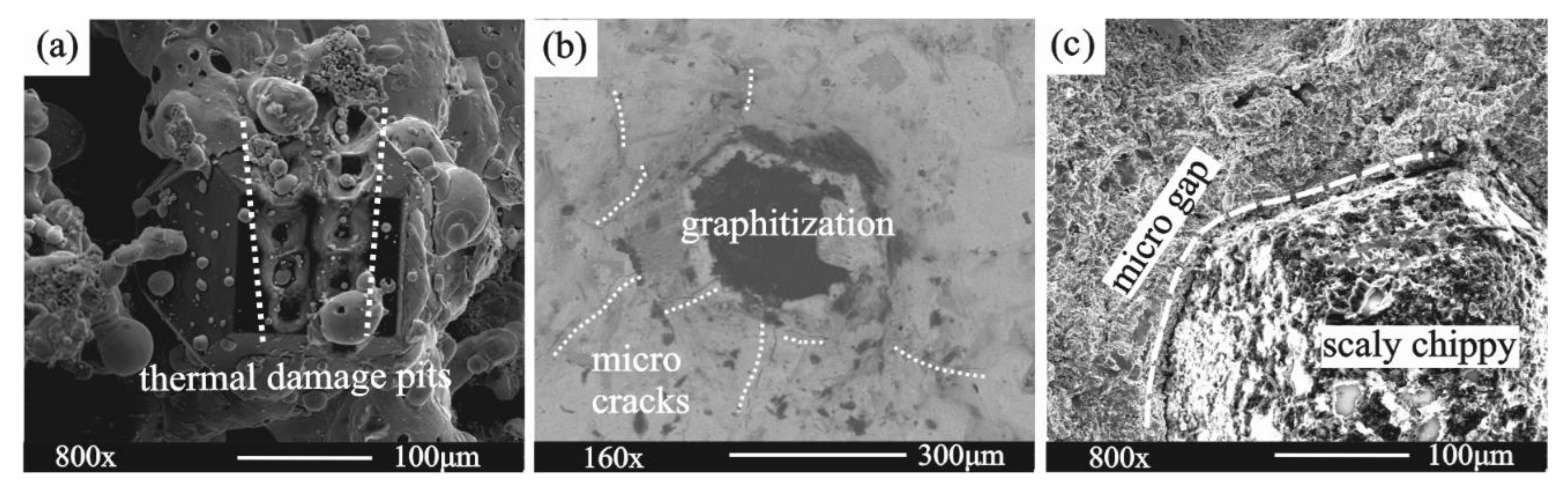

3.3. Thermal Damage to Diamond Particles

4. Conclusions

- (1)

- SLM has great prospects for application in the design and manufacturing of metal matrix diamond tools, although detailed fabricating technologies need to be further studied.

- (2)

- In this study, hardness of the MMDC samples manufactured by SLM was limited due to large layer thickness, with the highest value of 72 HRB.

- (3)

- Diamond particles in the SLM-formed composites are held more strongly by the metal matrix than the ones formed by vacuum brazing and hot-pressing sintering and suffer lower thermal damage.

- (4)

- Defects such as high porosity, micro-cracks, and thermal damage pits are the main challenges that need to be overcome for future applications of the technology.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Igharo, M.; Russell, J. Experimental study development of diamond impregnated cutting tools. Surf. Eng. 1994, 10, 52–55. [Google Scholar] [CrossRef]

- Konstanty, J. Production parameters and materials selection of powder metallurgy diamond tools. Powder Metall. 2006, 49, 299–306. [Google Scholar] [CrossRef]

- Palyanov, Y.N. The many facets of diamond crystals. Crystals 2018, 8, 72. [Google Scholar] [CrossRef]

- Duan, L.; Pan, B.; Fang, X. Design and Manufacture of Diamond Tools; China University of Geosciences Press: Wuhan, China, 2013. [Google Scholar]

- Zhang, Y.; Pan, B. The effect of valine on the process of nickel electrocrystallization on glassy carbon electrode. J. Electroanal. Chem. 2017, 796, 43–48. [Google Scholar] [CrossRef]

- Li, M.; Sun, Y.; Meng, Q.; Wu, H.; Gao, K.; Liu, B. Fabrication of Fe-Based Diamond Composites by Pressureless Infiltration. Materials 2016, 9, 1006. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Tan, S.; Yang, K. Experimental research on metal-based diamond composites by 3D printing. Diam. Abras. Eng 2018, 1, 50–54. [Google Scholar]

- Zaitsev, A.A.; Sidorenko, D.A.; Levashov, E.A.; Kurbatkina, V.V.; Rupasov, S.I.; Andreev, V.A.; Sevast’yanov, P.V. Development and application of the Cu-Ni-Fe-Sn-based dispersion-hardened bond for cutting tools of superhard materials. J. Superhard Mater. 2012, 34, 270–280. [Google Scholar] [CrossRef]

- Pan, B.; Yang, Y.; Zhang, Y.; Zhang, Q. Effects of saccharin and tetramethylammonium bromide on the microstructure and microhardness of thick cobalt electrodeposits. Surf. Coat. Tech. 2017, 329, 49–54. [Google Scholar] [CrossRef]

- Chu, Z.Q.; Guo, X.Y.; Liu, D.H.; Tan, Y.X.; Li, D.; Tian, Q.H. Application of pre-alloyed powders for diamond tools by ultrahigh pressure water atomization. Trans. Nonferrous Met. Soc. China 2016, 26, 2665–2671. [Google Scholar] [CrossRef]

- Oliveira, F.A.C.; Anjinho, C.A.; Coelho, A.; Amaral, P.M.; Coelho, M. PM materials selection: The key for improved performance of diamond tools. Metal Powder Rep. 2017, 72, 339–344. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, S. A new diamond bit for extra-hard, compact and nonabrasive rock formation. J. Cent. South Univ. 2015, 22, 1456–1462. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, K.; Sun, Y.; Zhang, Z.; Zhang, S.; Liang, Y.; Li, X.; Ren, L. Effects of Bionic Units in Different Scales on the Wear Behavior of Bionic Impregnated Diamond Bits. J. Bionic Eng. 2016, 13, 659–668. [Google Scholar] [CrossRef]

- Sidorenko, D.; Mishnaevsky, L., Jr.; Levashov, E.; Loginov, P.; Petrzhik, M. Carbon nanotube reinforced metal binder for diamond cutting tools. Mater. Design. 2015, 83, 536–544. [Google Scholar] [CrossRef]

- Spierings, A.B.; Leinenbach, C.; Kenel, C.; Wegener, K. Processing of metal-diamond composites using selective laser melting. Rapid. Prototyp. J. 2015, 21, 130–136. [Google Scholar] [CrossRef]

- Kabir, M.R.; Richter, H. Modeling of processing-induced pore morphology in an additively-manufactured Ti-6Al-4V alloy. Materials 2017, 10, 145. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Zeng, X.; Yang, Z.; Wu, H. Effect of crystallographic textures on thermal anisotropy of selective laser melted Cu-2.4Ni-0.7Si alloy. J. Alloy Compd. 2018, 743, 258–261. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, J.; Song, C.; Wang, D.; Bai, Y. Current status and progress on technology of selective laser melting of metal parts. Laser Optoelectron. Prog. 2018, 55, 011401. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Tran, H.-C.; Lo, Y.-L.; Chang, Y.-C.; Lin, H.-Y.; Liang, S.Y. Analytical modeling of residual stress in laser powder bed fusion considering part’s boundary condition. Crystals 2020, 10, 337. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, S.; Zhao, H.; Guo, S.; Li, N.; Sun, B.; Chen, B. Research status and key technologies of 3D printing. J. Mater. Eng. 2016, 44, 122–128. [Google Scholar]

- Zhang, C.; Ren, Y.; Chen, X. The development situation of selective laser melting metal powder based on 3D printing. Appl. Mech. Mater. 2014, 518, 12–18. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y. Research status and technical prospect of rapid manufacturing of metallic part by selective laser melting. Aeronaut. Manuf. Tech. 2012, 404, 32–37. [Google Scholar]

- Sharma, V.; Pandey, P.M. Recent advances in turning with textured cutting tools: A review. J. Clean. Prod. 2016, 137, 701–735. [Google Scholar] [CrossRef]

- Artini, C.; Muolo, M.L.; Passerone, A. Diamond-metal interfaces in cutting tools: A review. J. Mater. Sci. 2012, 47, 3252–3264. [Google Scholar] [CrossRef]

- Zhao, X.; Duan, L. A review of the diamond retention capacity of metal bond matrices. Metals 2018, 8, 307. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Mercelis, P.; Van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef]

- West, C.; Wang, X. Modeling of selective laser sintering/selective laser melting. In Proceedings of the Laser 3D Manufacturing IV. P SPIE. 2, San Francisco, CA, USA, 8 January–2 February 2017; Volume 10095, p. 1009506. [Google Scholar] [CrossRef]

- Reis, L.; Amaral, P.M.; Li, B.; de Freitas, M.; Guerra Rosa, L. Evaluation of the residual stresses due to the sintering process of diamond-metal matrix hot-pressed tools. Theor. Appl. Fract. Mec. 2008, 49, 226–231. [Google Scholar] [CrossRef]

- Liu, F.; Yang, Y.; Pan, B. Influence of tungsten coating on microstructure and thermal damage of brazed diamonds. Surf. Eng. 2019, 35, 29–36. [Google Scholar] [CrossRef]

- Liu, W.; Pan, F.; Yang, H.; Yu, G.; Chen, Z.; Tan, S. Influence of magnetic treatment parameters on mechanical properties of hot-pressing sintering iron-based diamond bit matrix. Geol. Sci. Technol. Inf. 2018, 37, 269–274. [Google Scholar] [CrossRef]

| Sample Number | Laser Power (W) | Scanning Speed (mm·s−1) | Volume Energy Density (J·mm−3) |

|---|---|---|---|

| 1 | 180 | 700 | 12.24 |

| 2 | 200 | 700 | 13.61 |

| 3 | 160 | 800 | 9.52 |

| 4 | 180 | 800 | 10.71 |

| 5 | 200 | 800 | 11.90 |

| 6 | 160 | 900 | 8.47 |

| 7 | 180 | 900 | 9.52 |

| 8 | 200 | 900 | 10.58 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, X.; Yang, Z.; Tan, S.; Duan, L. Feasibility Study of Selective Laser Melting for Metal Matrix Diamond Tools. Crystals 2020, 10, 596. https://doi.org/10.3390/cryst10070596

Fang X, Yang Z, Tan S, Duan L. Feasibility Study of Selective Laser Melting for Metal Matrix Diamond Tools. Crystals. 2020; 10(7):596. https://doi.org/10.3390/cryst10070596

Chicago/Turabian StyleFang, Xiaohong, Zhan Yang, Songcheng Tan, and Longchen Duan. 2020. "Feasibility Study of Selective Laser Melting for Metal Matrix Diamond Tools" Crystals 10, no. 7: 596. https://doi.org/10.3390/cryst10070596

APA StyleFang, X., Yang, Z., Tan, S., & Duan, L. (2020). Feasibility Study of Selective Laser Melting for Metal Matrix Diamond Tools. Crystals, 10(7), 596. https://doi.org/10.3390/cryst10070596