Abstract

The enzymatic synthesis of nucleotides offers several advantages over traditional multistep chemical methods, such as stereoselectivity, regioselectivity, enantioselectivity, simple downstream processing, and the use of mild reaction conditions. However, in order to scale up these bioprocesses, several drawbacks, such as the low enzyme stability and recycling, must be considered. Enzyme immobilization may overcome these cost-related problems by enhancing protein stability and facilitating the separation of products. In this regard, tetrameric hypoxanthine–guanine–xanthine phosphoribosyltransferase (HGXPRT) from Thermus thermophilus HB8 was covalently immobilized onto glutaraldehyde-activated MagReSyn®Amine magnetic iron oxide porous microparticles (MTtHGXPRT). In this context, two different strategies were followed: (a) an enzyme immobilization through its N-terminus residues at pH 8.5 (derivatives MTtHGXPRT1-3); and (b) a multipoint covalent immobilization through the surface lysine residues at pH 10 (derivatives MTtHGXPRT4-5). The immobilized derivatives of MTtHGXPRT3 (activity 1581 international units per gram of support, IU/g; retained activity 29%) and MTtHGXPRT5 (activity 1108 IU/g; retained activity 23%) displayed the best wet biocatalyst activity, and retained activity values in the enzymatic synthesis of inosine-5′-monophosphate (IMP). In addition, the dependence of the activities and stabilities of both derivatives on pH and temperature was tested, as well as their reusability potential. Taking these results into account, MTtHGXPRT3 was chosen as the best biocatalyst (negligible loss of activity at 60 °C during 24 h; reusable up to seven cycles). Finally, as proof of concept, the enzymatic production of dietary nucleotides from high concentrations of low soluble bases was achieved.

1. Introduction

Nucleoside-5′-monophosphates (NMPs) are often used as additives in food. For example, some dietary nucleotides, such as inosinic acid (inosine-5′-monophosphate, or IMP) or guanosinic acid (guanosine-5′-monophosphate, GMP), are common additives that are used as flavor enhancers in foods, since they induce an umami taste sensation [1]. In addition, the effect of some dietary nucleotide supplementation on growth and immune function in term infants has been extensively reported [2]. For this reason, nowadays, the demand for nucleotides in the food additives market is increasing, and the production of NMPs has been well studied.

These molecules have been traditionally synthesized by different chemical methods through multistep processes requiring the protection and de-protection of labile groups from precursor nucleosides, as well as the isolation of intermediates [3,4,5]. In addition, chemical strategies usually require the use of chemical reagents (phosphoryl chloride, POCl3, or phosphorus pentoxide, P2O5), acidic conditions, and organic solvents, which are expensive and environmentally harmful [6,7]. These synthetic routes usually provide poor or moderate global yields and low product purity, and are also associated with harsh reaction conditions and waste disposal issues. On the contrary, the enzymatic synthesis of NMPs shows many advantages, such as one-pot reactions under mild conditions, high stereoselectivity and regioselectivity, and an environmentally-friendly technology [1,8,9,10,11,12,13,14,15,16]. However, despite the advantages of the bioprocesses, their industrial application is often hampered by several factors, such as: (i) the high cost of the production of recombinant enzymes; (ii) a low stability of biocatalysts under the drastic conditions that are often needed in some industrial processes; (iii) the difficulty of separating the biocatalyst from the reaction medium; and (iv) the reuse of the biocatalyst.

Enzyme immobilization can circumvent these drawbacks by facilitating the separation of products and allowing biocatalyst reutilization in various reactor configurations. This enhances some enzyme features, such as protein stability, but also activity, selectivity, specificity, and resistance to inhibitors or chemical reagents, even purity [17,18,19,20,21]. Since the covalent immobilization of proteins is usually achieved via the nucleophilic attack of primary amino groups (especially the ε-NH2 of lysine residues) on electrophile groups from the support, covalent immobilization methodologies usually employ long reaction times (2−10 h) and alkaline conditions (pH 8−10) in order to avoid the protonation of amino groups. In this context, the activation of primary amino groups in the support by reaction with glutaraldehyde is one of the most versatile methods for support activation.

However, since different reactive species of glutaraldehyde (monomeric and polymeric forms) are found in equilibrium, the coupling mechanism between protein and glutaraldehyde is not well defined yet, and it seems that it is not limited to just one mechanism [22,23]. Moreover, it is proposed that glutaraldehyde suffers from intramolecular aldolic condensations, leading to an α,β-unsaturated aldehyde under alkaline conditions. These glutaraldehyde molecules can react with protein amino groups by means of two different mechanisms—Schiff base and Michael-type additions—but the formation of Schiff bases between internal aldehyde groups from the polymeric form of glutaraldehyde and primary amino groups from the protein leads to a more stable product.

During the last decade, the immobilization of enzymes onto magnetic supports has appeared as an alternative immobilization methodology that enables an easy recovery of the biocatalyst by applying a magnetic field [24,25]. Among various supports, porous magnetic materials have attracted much attention, due to their excellent magnetic responsibility, high specific surface area, good biocompatibility, chemically modifiable surface, and good reusability [26]. In this regard, glutaraldehyde-activated magnetic supports are suitable matrices for the development of bioprocesses catalyzed by immobilized enzymes.

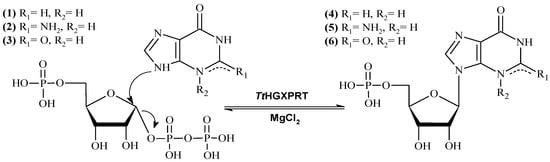

Hypoxanthine–guanine–xanthine phosphoribosyltransferase (HGXPRT, EC 2.4.2.8) catalyzes the reversible transfer of the 5-phosphoribosyl group from 5-phospho-α-d-ribosyl-1-pyrophosphate (PRPP) to N9 on the 6-oxopurine bases hypoxanthine (1), guanine (2), or xanthine (3) to form IMP (4), GMP (5), or xanthosine-5′-monophosphate (XMP) (6), respectively, in the presence of Mg2+ (Figure 1). In a previous work, our research group has shown the potential of HGXPRT from Thermus themophilus HB8, TtHGXPRT, as an industrial biocatalyst in the monoenzymatic and multienzymatic synthesis of dietary nucleotides [8,11,27]. However, this enzymatic approach has significant limitations to its practical application as an industrial biocatalyst, such as the high cost and instability of PRPP or the high cost of the production of the recombinant enzyme. In this context, the immobilization of the enzyme onto magnetic microbeads would offer several advantages, such as an easy recovery and the possibility of being successfully reused in batch reactions.

Figure 1.

Enzymatic synthesis of nucleoside-5′-monophosphates (NMPs) catalyzed by Thermus themophilus HB8 (TtHGXPRT).

Within this field, the present work describes—for the first time, to the best of our knowledge—the covalent immobilization of TtHGXPRT onto glutaraldehyde-activated magnetic iron oxide porous microspheres (MTtHGXPRT). The efficiency of these immobilization processes was tested at several pH values, temperatures, and protein loadings, leading to the selection of MTtHGXPRT3 as the best derivative (in terms of stability, activity, and reusability). Finally, MTtHGXPRT3 was employed in the enzymatic production of valuable nucleoside-5′-monophosphates (NMPs) that are commercially available as food additives (IMP or GMP).

The only precedent in the literature for the immobilization of a 6-oxopurine phosphoribosyltransferase was the development of a covalently linked enzyme aggregate (CLEA) multienzyme system, which contains an engineered 6-oxopurine phosphoribosyltransferase combined with several adenosine triphosphate (ATP) regeneration enzymes [28]. In this regard, the MTtHGXPRT3 derivative represents the first strict characterization and application of an immobilized pure purine phosphoribosyltransferase.

2. Results and Discussion

2.1. Covalent Immobilization of TtHGXPRT

According to results reported by the H++ protonation predictor program (Table S1, Supplemental Material), the N-terminus of His6-tagged TtHGXPRT is deprotonated at pH 8.5, and can perform a nucleophilic attack on aldehyde groups, leading to a covalent linkage. Accordingly, TtHGXPRT should be immobilized through its N-terminus at pH 8.5, and since TtHGXPRT has been reported as a homotetramer, four potential interaction sites are possible (one of each N-terminal group). Unfortunately, since the only available structure of TtHGXPRT deposited in the Protein Data Bank (PDB) shows monomers in the crystal lattice (PDB code 3ACD), we cannot confirm if all of the N-termini are located on the same plane. TtHGXPRT also contains seven lysine residues, all of which are fairly exposed and scattered around the protein surface. However, program H++ predicts that only five of them are deprotonated, with apparent pKa values lower than 10.0 (Lys18, Lys36, Lys37, Lys94, and Lys138) (Table S1). The calculated electrostatic potential surface of TtHGXPRT at pH values of 8.5 and 10 is shown in Figure S1. Lys94 and Lys138 are highlighted to show how the titration state changes with pH. These theoretical results suggest that TtHGXPRT could be immobilized through surface lysine residues when it is incubated at pH 10. However, due to the tetrameric nature of TtHGXPRT, the orientation of Lys residues on the monomer surface is unlikely to play a very important role. In addition, since the only available structure of TtHGXPRT deposited in the PDB is the monomer (PDB 3ACD), we cannot predict how the immobilization process will be conducted at pH 10.

The recombinant N-terminus His6-tagged TtHGXPRT was covalently immobilized onto glutaraldehyde-activated MagReSyn®Amine microspheres. In this regard, different immobilized biocatalysts were prepared by the immobilization of TtHGXPRT in 50 mM of potassium phosphate, pH 8.5 (MTtHGXPRT1–MTtHGXPRT3), and 50 mM of sodium borate, pH 10.0 (MTtHGXPRT4–MTtHGXPRT5). Magnetic biocatalysts were prepared by increasing the amount of enzyme in contact with the support in order to obtain a high load of the enzyme attached to the carrier (Table 1). In view of the experimental results, MTtHGXPRT3 and MTtHGXPRT5 were chosen as the best derivatives for further biochemical studies. MTtHGXPRT3 displayed an activity of 1581 IU/g of wet biocatalyst, and a retained activity of approximately 29% compared with the soluble enzyme. Similarly, the MTtHGXPRT5 derivative showed an activity of 1108 IU/g of wet biocatalyst, and an activity recovery of 23%.

Table 1.

Effect of enzyme/support mass ratio on the immobilization of TtHGXPRT on MagReSyn®aldehyde microspheres. MTtHGXPRT: MagReSyn®Amine magnetic iron oxide porous microparticles of hypoxanthine–guanine–xanthine phosphoribosyltransferase.

According to our previous work, TtHGXPRT works as a homotetramer [11], and its oligomeric state may not only contribute to the high thermal stability exhibited by this protein: it also plays an essential role in the catalysis and stabilization of the active conformation [11]. Since MTtHGXPRT derivatives displayed a significant loss of activity (only 25–30% of retained activity), we think that the immobilization process could affect the oligomeric assembly of the enzyme, leading to a lack of reactivity.

Moreover, as reported in the literature, three different types of interactions between the support and the protein may take place when using a support that is highly activated with glutaraldehyde: covalent, hydrophobic, and anionic exchange interactions [29]. Even if all of the enzyme molecules are immediately incorporated into the support, it is not certain that the enzyme is covalently attached to the support. In fact, when a highly activated support is used, in most cases, an ionic exchange reaction among the enzyme and amino groups in the support takes place at the beginning [29,30,31,32,33,34,35]. In order to discard that the immobilization takes place through ionic exchange, the derivatives were washed four times with 1 M of NaCl solution to promote protein relase, but the presence of TtHGXPRT in the solution was not detected in the solution. Moreover, the sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE) analysis of MTtHGXPRT derivatives was performed to detect any non-covalently attached subunits. As shown in Figure S2, the presence of monomeric subunits of TtHGXPRT was observed after boiling the immobilized preparations in the presence of SDS and mercaptoethanol. These results suggest to us that not all of the subunits are covalently bonded, and this could be another reason for the significant loss of activity.

2.2. Biochemical Characterization of MTtHGXPRT Derivatives

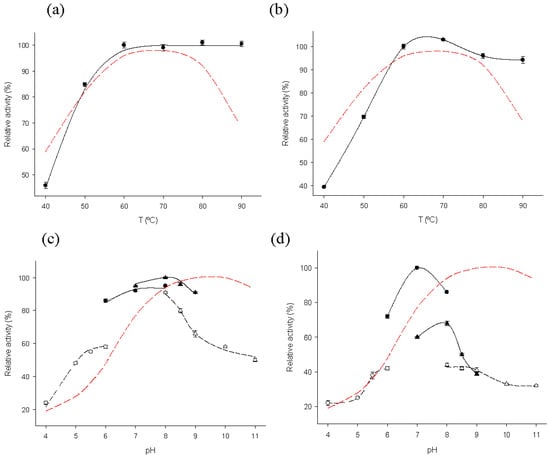

The dependence of the stability and activity of MTtHGXPRT3 and MTtHGXPRT5 on temperature and pH was studied to determine the optimal operating conditions of the enzyme (Figure 2).

Figure 2.

Temperature and pH dependence on the activity of MTtHGXPRT derivatives. (a) Effect of temperature on the activity of (●) MTtHGXPRT3 and (---) TtHGXPRT; (b) Effect of temperature on the activity of (●) MTtHGXPRT5 and (---) TtHGXPRT; (c) Effect of pH on MTtHGXPRT3 activity, (○) 50 mM sodium citrate (pH 4–6), (●) 50 mM sodium phosphate (pH 6–8), (▲) 50 mM Tris-HCl (pH 7–9), (∆) 50 mM sodium borate (pH 8–11), (---) effect of pH on TtHGXPRT activity; (d) Effect of pH on MTtHGXPRT5 activity, (○) 50 mM sodium citrate (pH 4–6), (●) 50 mM sodium phosphate (pH 6–8), (▲) 50 mM Tris-HCl (pH 7–9), (∆) 50 mM sodium borate (pH 8–11), (---) effect of pH on TtHGXPRT activity.

The temperature profile revealed that MTtHGXPRT3 displayed high activity (more than 80%) across a broad temperature range (from 50 °C to 90 °C), with a maximum of activity at 60–90 °C (Figure 2a). In a similar way, MTtHGXPRT5 displayed high activity in the 60–90 °C temperature range (more than 90%), with the maximum activity being observed at 60–70 °C (Figure 2b). In this regard, both derivatives, MTtHGXPRT3 and MTtHGXPRT5, displayed higher activity than soluble TtHGXPRT at high temperatures (relative activity <70% at 90 °C) (Figure 2a,b) [11].

Nonetheless, the pH profile revealed significant differences between both derivatives. MTtHGXPRT3 displayed high activity (relative activity >80%) in the pH 7–9 range, and there were no substantial differences depending on the nature of the buffer solution (similar activity at pH 7 in sodium phosphate buffer and Tris-HCl; similar activity at pH 8 in sodium phosphate buffer, Tris-HCl, and sodium borate). On the contrary, the relative activity of MTtHGXPRT5 was also high (>80%) in the pH 7–8 range, but was strongly affected by the nature of the solution and only displayed high activity values when it was incubated in 50 mM of sodium phosphate buffer. Since soluble TtHGXPRT has excellent activity (more than 80% of retained activity) in the pH 8–11 range, the results displayed in Figure 2 (Figure 2a,b) demonstrate that the pH dependence is affected by the immobilization process.

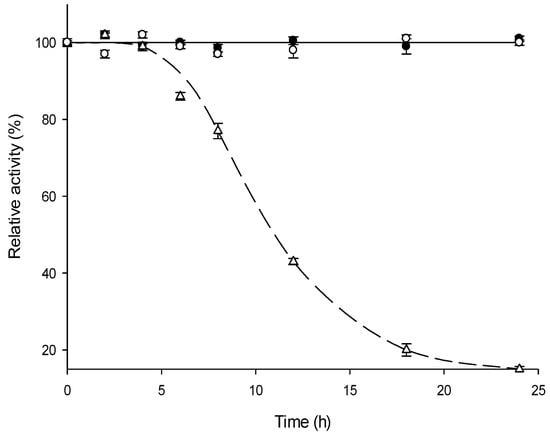

2.3. Thermal Stability of MTtHGXPRT Derivatives

The effect of the storage of MTtHGXPRT derivatives at 4 °C was analyzed in order to ensure biocatalyst stability, and both derivatives, MTtHGXPRT3 and MTtHGXPRT5, retained their activity for more than 100 days (85% relative activity) (data not shown). In addition, the effect of temperature on the stability of MTtHGXPRT derivatives was evaluated by incubating both derivatives for 24 h in 50 mM sodium phosphate pH 8, at 60 °C. Interestingly, there was a negligible loss of activity under any of these experimental conditions (Figure 3). On the contrary, we can observe that the stability of soluble TtHGXPRT is affected for storage periods longer than 4 h. Therefore, the immobilization process clearly increases the thermal stability of TtHGXPRT.

Figure 3.

Thermal inactivation at 60 °C and pH 8 of (∆) soluble TtHGXPRT, (●) MTtHGXPRT3, and (○) MTtHGXPRT5.

It is extensively reported that a multimeric state leads to a more functional and stable immobilized enzyme due to multipoint interactions [35,36]. In this regard, enzyme immobilization by surface lysine residues involves the largest surface of the protein, meaning that most of the subunits participate in the process. This fact may explain the good stabilization results achieved when immobilizing TtHGXPRT at pH 10 (MTtHGXPRT5) (no loss of activity when it is incubated at 60 °C during 24 h), but we have evidence that not all of the subunits are covalently attached to the support (Figure S2). Moreover, unexpectedly high thermal stability is also observed when immobilizing TtHGXPRT at pH 8.5 (immobilization through the N-terminus; MTtHGXPRT3). In this case, the oligomeric state of TtHGXPRT could lead to an immobilization process involving several N-terminal residues, thereby increasing the thermal stability of the protein. In addition, after the first immobilization, other lysine residues can react because of the proximity of the support.

Experimental results display a similar thermal stability in both derivatives. Since surface lysine residues reactivity is around 50% at pH 10 and not all of the subunits are covalently bonded, it seems that the protein would be preferably immobilized by N-terminal amino groups in both cases (pH 8.5 and pH 10). However, we cannot discard the possibility of an additional multipoint covalent immobilization at pH 10.

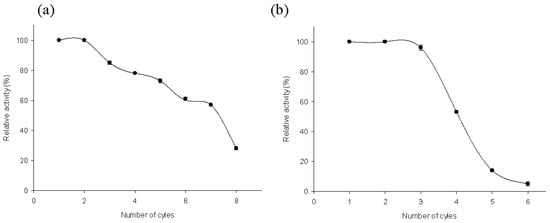

2.4. Recycling of MTtHGXPRT Derivatives

The recycling of enzymes is an essential requisite for their industrial application, so once the optimal operating conditions were established, the next step was to evaluate the reusability of the immobilized enzyme. To this end, MTtHGXPRT derivatives were employed in eight consecutive batch reactions (Figure 4).

Figure 4.

Recycling of MTtHGXPRT derivatives in the enzymatic production of inosine-5′-monophosphate (IMP). (a) MTtHGXPRT3; (b) MTtHGXPRT5.

As shown in Figure 4, MTtHGXPRT3 and MTtHGXPRT5 suffered a progressive loss of activity as the reuse number increased. MTtHGXPRT3 could be efficiently reused for at least seven cycles (>60% of retained activity) in the enzymatic synthesis of IMP, whereas MTtHGXPRT5 suffered a drastic activity decrease after three cycles (<60% of retained activity after four cycles). These results suggest that multipoint covalent immobilization could also be happening at pH 10, and it may lead to the rigidification of TtHGXPRT, thus altering the enzyme conformation and distorting its active site. Nevertheless, both derivatives display a similar trend.

Taking into account all of the experimental results (catalyst loading, retained activity, temperature and pH dependence on enzymatic activity, and thermal stability), MTtHGXPRT3 was chosen as the best derivative for synthetic applications.

2.5. Effect of Molar Ratio

To avoid the reverse reaction, different initial ratios of hypoxanthine (Hyp) and MgCl2 were analyzed. As shown in Table 2, an excess of Hyp leads to an increase of conversion (≈2-fold greater enzymatic activity). Thus, it seems that an excess of Hyp partially shifts the reaction equilibrium. In addition, an excess of MgCl2 is clearly harmful for the enzymatic process (Table 2). According to our experimental results, the ratio 2/1/1 (Hyp/PRPP/MgCl2) appears to be the optimal molar ratio.

Table 2.

Effect of substrate ratio in MTtHGXPRT3 activity.

Moreover, in order to know whether the presence of phosphate buffers affects the reaction (a high concentration of phosphate ions can chelate Mg2+ and decrease the concentration of such cations in the reaction medium), we tested the transferase reaction in the presence of phosphate buffer, Tris-HCl, and sodium borate buffer at pH 8. Our results show that 50 mM of sodium phosphate does not affect protein activity (Figure 3c,d).

2.6. Enzymatic Production of IMP and GMP

To explore the potential of MTtHGXPRT3 as an industrial biocatalyst, the enzymatic production of several dietary nucleotides (IMP and GMP) was carried out using high concentrations of low soluble nucleobases (guanine and hypoxanthine) (Table 3).

Table 3.

Enzymatic production of dietary nucleotides catalyzed by MTtHGXPRT3.

3. Materials and Methods

3.1. Chemicals

Cell culture medium reagents were purchased from Difco (St. Louis, MO, USA). Trimethyl ammonium acetate buffer was acquired from Sigma-Aldrich (Madrid, Spain). All of the other reagents and organic solvents were purchased from Scharlab (Barcelona, Spain) and Symta (Madrid, Spain). All of the nucleoside-5′-monophosphates and bases used in this work were provided by Carbosynth Ltd. (Compton, United Kingdom).

3.2. Production TtHGXPRT

Recombinant His6-tagged TtHGXPRT was produced and purified as previously described [11]. In brief, TtHGXPRT was overexpressed by adding 0.5 mM isopropyl β-d-1-thiogalactopyranoside, and the cells were grown for a further 5 h. Cells were harvested using centrifugation (3500× g), and the resulting pellet was resuspended in Tris buffer (20 mM Tris-HCl, pH 8.0) containing 100 mM NaCl. Crude extracts were prepared by the ultrasonic cell disruption of whole cells. The lysate was centrifuged at 17,000× g for 35 min, and the cell pellet was removed. The lysate was then heated at 70 °C for 20 min. Insoluble material was removed by centrifugation (17,000× g, 15 min, 4 °C), and the supernatant was passed through a 0.22-μm filter (Merck Millipore, Madrid, Spain). Clear lysate was loaded onto a 5-mL HisTrap FF column (GE Healthcare, Madrid, Spain) that was pre-equilibrated in binding buffer (20 mM of Tris-HCl buffer, pH 8.0, with 100 mM NaCl and 10 mM imidazole). Bound proteins were eluted using a linear gradient of imidazole (from 10 mM to 500 mM). Fractions containing recombinant TtHGXPRT were identified by SDS-PAGE, pooled, and concentrated before being loaded onto a HiLoad 16/60 Superdex 200 prep grade column (GE Healthcare) pre-equilibrated in 20 mM Tris-HCl, pH 8.0. Fractions with the protein of interest identified by SDS-PAGE were pooled, and the protein was concentrated and stored at 4 °C until use. The standard activity assay for soluble enzyme was achieved by incubating 3 μg of pure enzyme with 10 mM PRPP, 10 mM Hyp, and 12 mM MgCl2 in 12 mM Tris pH 8 for a final volume of 40 μL. The reaction mixture was incubated at 40 °C for 10 min (300 rpm). The enzyme was inactivated by adding 40 μL of cold methanol in an ice bath and heating for 5 min at 100 °C. After centrifugation at 9000× g for 5 min, samples were half-diluted with water, and NMP production was analysed using HPLC to quantitatively measure the reaction products, as described below [11].

All of the determinations were carried out in triplicate, and the maximum error was less than 5%. Under such conditions, specific activity was defined as the amount of enzyme (mg) producing 1 µmol/min (IU) of IMP under the assay conditions.

3.3. Enzyme Immobilization

TtHGXPRT immobilization was carried out by covalent attachment of the enzyme to glutaraldehyde-activated MagReSyn®Amine porous microspheres (from ReSyn Biosciences, Pretoria, South Africa), according to the recommendations of the manufacturer. These iron-oxide containing porous microparticles consist of a loosely linked interpenetrating network of polymer, which is more fully described by Jordaan et al. in patent number WO2009057049 [37].

First, 25 µL of the bead suspension (20 mg mL−1) were washed and equilibrated in binding buffer (MTtHGXPRT 1–3 in 50 mM potassium phosphate buffer, pH 8.5; MTtHGXPRT 4–5 in 50 mM sodium borate buffer, pH 10) during 4 h at 25 °C. After the equilibration procedure, the beads were collected by a magnetic separator, and the supernatant was discarded. Activation of the support was accomplished by contacting MagReSyn®Amine microspheres with 200.0 µL of 50 mM sodium phosphate buffer pH 8.5 containing 5% (w/v) glutaraldehyde during 3 h at 25 °C, and then they were washed extensively with distilled water to remove the excess of the activating agent. Finally, activated microspheres were washed and equilibrated in binding buffer (50 mM potassium phosphate buffer, pH 8.5, or 50 mM sodium borate buffer, pH 10) shortly prior to use.

Subsequently, different amounts of enzyme (75–225 μg) were mixed with activated MagReSyn®Amine microspheres. The enzyme solution with the binding buffer was adjusted to 10× the volume of the initial beads suspension. The enzyme and bead suspensions were mixed thoroughly and incubated at room temperature under orbital shaking using a Sunflower 3D Mini–Shaker (BioSan, Latvia) for 4 h. After the binding procedure, the beads were collected by a magnetic separator and the supernatant was discarded. The beads were washed three times with washing buffer (50 mM of potassium phosphate buffer, pH 8.5, or 50 mM of sodium borate buffer, pH 10) to remove the non-covalently bound enzyme. After this, the beads were also treated with Glycine 3 N for 3 h at room temperature to quench any remaining amine reactive residues on the microparticles. The beads were washed with 50 mM of potassium phosphate buffer (pH 8.5) three times, and then stored at 4 °C.

3.4. Enzyme Activity Assay for Immobilized TtHGXPRT

As performed with the soluble enzyme, the enzymatic production of IMP from Hyp and PRPP was established as the standard reaction. The enzymatic activity of the immobilized enzyme was measured using 9–30 μg of different MTtHGXPRT derivatives (containing 6 μg of immobilized MTtHGXPRT), which was added to a 80-μL solution containing 10 mM 5-PRPP, 10 mM hypoxanthine, and 12 mM MgCl2 in 12 mM Tris-HCl pH 8.0 in a final volume of 80 μL. The reaction mixture was incubated at 60 °C for 10 min (300 rpm). The reaction was stopped by collecting the beads with a magnetic separator, and the supernatant was treated following the general procedure that was previously described [11]. NMP production was analysed using HPLC to quantitatively measure the reaction products, as described below. Biocatalyst activity was defined as the amount of derivative (g) producing 1 µmol/min (IU) of IMP under the assay conditions. All of the determinations were carried out in triplicate, and the maximum error was less than 5%.

3.5. Biochemical Characterization of Immobilized Biocatalysts

The pH profile of purified recombinant enzyme was initially determined using the standard assay described for immobilized TtHGXPRT with sodium citrate (pH 4–6), sodium phosphate (pH 6–8), Tris-HCl (pH 7–9), or sodium borate (pH 8–10) as reaction buffers (50 mM). The optimum temperature was determined using the standard assay across a 40–90 °C temperature range.

3.6. Thermal Stability and Reusability of MTtHGXPRT

MTtHGXPRT derivatives were stored at 4 °C in 50 mM sodium phosphate, pH 8.5, for 100 days. Samples were taken periodically, and enzymatic activity was evaluated. Storage stability was defined as the relative activity between the first and successive reactions. Moreover, the thermal stability of MTtHGXPRT3 and MTtHGXPRT5 was assessed by incubating 6 μg of derivative in 50 mM Tris-HCl buffer pH 8.0, at 60 °C for a period of 1–24 h. After this, the derivative was incubated during 15 min at 4 °C, and then, the activity was measured using the standard assay.

In addition, the reusability of MTtHGXPRT3 and MTtHGXPRT5 was evaluated by employing both derivatives in consecutive reactions. After each use, magnetic derivatives were recovered by an imposed magnetic field, and washed with 50 mM Tris-HCl buffer, pH 8.0. Then, the recovered derivatives were introduced into a fresh reaction medium and reused again.

3.7. Enzymatic Production of Dietary Nucleotides

The enzymatic production of IMP and GMP was carried out by incubating 12–30 μg of immobilized enzyme with 10–40 mM 5-PRPP, 20–80 mM purine base, and 12–48 mM MgCl2 in 12 mM Tris-HCl buffer pH 8.0, at 60 °C with 300 rpm orbital shaking at 10 min, in a final volume of 80 μL. Biocatalyst activity was evaluated as described in the Analytical methods section (see below).

3.8. Analytical Methods

The production of NMPs was followed and quantitatively measured with an ACE EXCEL 5 μm CN-ES column 250 mm × 4.6 mm (Advanced Chromatography Technologies) equilibrated with 100% trimethyl ammonium acetate at a flow rate of 0.8 mL/min. The NMP was eluted into the diode array detector for quantification at 254 nm.

Retention times for the bases and NMPs (hereafter abbreviated according to the recommendations of the IUPAC-IUB Commission on Biochemical Nomenclature) were as follows: guanine (Gua), 5.8 min; hypoxanthine (Hyp), 5.3 min; guanosine-5′-monophosphate (GMP), 3.1 min; inosine-5′-monophosphate (IMP), 3.4 min. The identification and quantification of most of the reaction substrates and products was performed in relation to the external standard calibration curve using the above, well-characterized commercial products (IMP or GMP).

3.9. Molecular Docking and Surface Analysis of TtHGXPRT

Recombinant N-terminus His6-tagged TtHGXPRT was modeled using the crystal structure of TtHGXPRT in complex with IMP (PDB code 3ACD) as a template [38]. This structure was improved by refining the loop conformations through assessing the compatibility of an amino acid sequence to known PDB structures, and the geometry of loop region was corrected as previously described [11]. PyMOL 2.1 [39] was used for building the TtHGXPRT structure, and for molecular illustration. The predicted titratable residues in the protein were studied at pH 8.5 and 10.0 using the H++ web server. (http://biophysics.cs.vt.edu/H++). The electrostatic potential on the surface of TtHGXPRT was computed using the APBS program [40].

4. Conclusions

Herein, we report for the first time the covalent immobilization of a purine phosphoribosyltransferase onto magnetic glutaraldehyde-activated microbeads, as well as its characterization and application in the enzymatic production of dietary nucleotides. Among all of the magnetic derivatives produced, MTtHGXPRT3 was selected as the optimum biocatalyst, displaying an activity of 1581 IU/g of wet biocatalyst and a retained activity of 29%. In addition, MTtHGXPRT3 outperformed soluble TtHGXPRT in thermal stability and could be reused for up to seven cycles.

Notwithstanding that several drawbacks still need to be overcome, such as the high price of PRPP and shifting the reaction equilibrium in a desired way, the reusability of this biocatalyst and the sustainability of this process are good reasons to further investigate this novel bioprocess.

Supplementary Materials

The following are available online at http://www.mdpi.com/2073-4344/8/5/184/s1, Table S1: Computed theoretical pKa values of the lysine residues in TtHGXPRT using the server H++ (http://biophysics.cs.vt.edu/H++), Figure S1: APBS-generated electrostatic surface of TtHGXPRT. (a) Titrable state of the protein at pH 8.5 ; (b) Titrable state of the protein at pH 10.5. Figure S2. SDS-PAGE analysis of soluble and immobilized TtHGXPRT, Lane 1. Prestained standard proteins from BioRad used as molecular weight markers. Lane 2. Supernatant obtained after boiling the soluble TtHGXPRT in the presence of SDS and mercaptoethanol. Lane 3. Supernatant obtained after boiling the MTtHGXPRT3 in the presence of SDS and mercaptoethanol. Lane 4. Supernatant obtained after boiling the MTtHGXPRT5 in the presence of SDS and mercaptoethanol.

Author Contributions

J.F.-L. and A.P., conceived and designed the experiments. J.d.A., S.M.-P., V.J.C.-S., O.J.C., D.H., A.P. and J.F.-L. contributed to the development and analysis of experimental data. J.J. provided magnetic MagReSyn®Amine magnetic iron oxide porous microparticles and advised on immobilization strategies.

Acknowledgments

This work was supported by grant SAN151610 from the Santander Foundation. Grant 2016/UEM08 from Universidad Europea de Madrid is also acknowledged.

Conflicts of Interest

Justin Jordaan has an interest in ReSyn Biosciences. For the purpose of this study he advised on immobilization strategy but did not directly participate in the experimentation and did not generate any data.

References

- Behrens, M.; Meyerhof, W.; Hellfritsch, C.; Hofmann, T. Sweet and umami taste: Natural products, their chemosensory targets, and beyond. Angew. Chem. Int. Ed. 2011, 50, 2220–2242. [Google Scholar] [CrossRef] [PubMed]

- Hawkes, J.S.; Gibson, R.A.; Roberton, D.; Makrides, M. Effect of dietary nucleotide supplementation on growth and immune function in term infants: A randomized controlled trial. Eur. J. Clin. Nutr. 2006, 60, 254–264. [Google Scholar] [CrossRef] [PubMed]

- Lapponi, M.J.; Rivero, C.W.; Zinni, M.A.; Britos, C.N.; Trelles, J.A. New developments in nucleoside analogues biosynthesis: A review. J. Mol. Catal. B Enzym. 2016, 133, 218–233. [Google Scholar] [CrossRef]

- Mikhailopulo, I.A. Biotechnology of nucleic acid constituents—State of the art and perspectives. Curr. Org. Chem. 2007, 11, 317–333. [Google Scholar] [CrossRef]

- Fresco-Taboada, A.; de la Mata, I.; Arroyo, M.; Fernández-Lucas, J. New insights on nucleoside 2’-deoxyribosyltransferases: A versatile biocatalyst for one-pot one-step synthesis of nucleoside analogs. Appl. Microbiol. Biotechnol. 2013, 97, 3773–3785. [Google Scholar] [CrossRef] [PubMed]

- Yoshikawa, M.; Kato, T.; Takenishi, T. A novel method for phosphorylation of nucleosides to 5′-nucleotides. Tetrahedron Lett. 1967, 8, 5065–5068. [Google Scholar] [CrossRef]

- Yoshikawa, M.; Kato, T.; Takenishi, T. Studies of phosphorylation. III. Selective phosphorylation of unprotected nucleosides. Bull. Chem. Soc. Jpn. 1969, 42, 3505–3508. [Google Scholar] [CrossRef]

- Del Arco, J.; Fernández-Lucas, J. Purine and Pyrimidine Phosphoribosytransferases: A versatile tool for enzymatic synthesis of nucleoside-5’-monophosphates. Curr. Pharm. Des. 2015, 23, 6898–6912. [Google Scholar] [CrossRef] [PubMed]

- Del Arco, J.; Acosta, J.; Pereira, H.M.; Perona, A.; Lokanath, N.K.; Kunishima, N.; Fernández-Lucas, J. Enzymatic production of non-natural nucleoside-5’-monophosphates by a novel thermostable uracil phosphoribosyltransferase. ChemCatChem 2018, 10, 439–448. [Google Scholar] [CrossRef]

- Del Arco, J.; Martinez, M.; Donday, M.; Clemente-Suarez, V.J.; Fernández-Lucas, J. Cloning, expression and biochemical characterization of xanthine and adenine phosphoribosyltransferases from Thermus thermophilus HB8. Biocatal. Biotransform. 2017, 1–8. [Google Scholar] [CrossRef]

- Del Arco, J.; Cejudo-Sanches, J.; Esteban, I.; Clemente-Suarez, V.J.; Hormigo-Cisneros, D.; Perona, A.; Fernández-Lucas, J. Enzymatic production of dietary nucleotides from low-soluble purine bases by an efficient, thermostable and alkali-tolerant biocatalyst. Food Chem. 2017, 237, 605–611. [Google Scholar] [CrossRef] [PubMed]

- Serra, I.; Conti, S.; Piškur, J.; Clausen, A.R.; Munch-Petersen, B.; Terreni, M.; Ubiali, D. Immobilized Drosophila melanogaster deoxyribonucleoside kinase (DmdNK) as a high performing biocatalyst for the synthesis of purine arabinonucleotides. Adv. Synth. Catal. 2014, 356, 563–570. [Google Scholar] [CrossRef]

- Fernández-Lucas, J. Multienzymatic synthesis of nucleic acid derivatives: A general perspective. Appl. Microbiol. Biotechnol. 2015, 99, 4615–4627. [Google Scholar] [CrossRef] [PubMed]

- Zou, Z.; Ding, Q.; Ou, L.; Yan, B. Efficient production of deoxynucleoside-5′-monophosphates using deoxynucleoside kinase coupled with a GTP-regeneration system. Appl. Microbiol. Biotechnol. 2013, 97, 9389–9395. [Google Scholar] [CrossRef] [PubMed]

- Mori, H.; Iida, A.; Fujio, T.; Teshiba, S. A novel process of inosine 5′-monophosphate production using overexpressed guanosine/inosine kinase. Appl. Microbiol. Biotechnol. 1997, 48, 693–698. [Google Scholar] [CrossRef] [PubMed]

- Gudiño, E.D.; Santillán, J.Y.; Iglesias, L.E.; Iribarren, A.M. An enzymatic alternative for the synthesis of nucleoside 5′-monophosphates. Enzyme Microb. Technol. 2018, 111, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Mateo, C.; Palomo, J.M.; Fernandez-Lorente, G.; Guisan, J.M.; Fernandez-Lafuente, R. Improvement of enzyme activity, stability and selectivity via immobilization techniques. Enzyme Microb. Technol. 2007, 40, 1451–1463. [Google Scholar] [CrossRef]

- Sheldon, R.A.; van Pelt, S. Enzyme immobilisation in biocatalysis: Why, what and how. Chem. Soc. Rev. 2013, 42, 6223–6235. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, R.C.; Ortiz, C.; Berenguer-Murcia, A.; Torres, R.; Fernández-Lafuente, R. Modifying enzyme activity and selectivity by immobilization. Chem. Soc. Rev. 2013, 42, 6290–6307. [Google Scholar] [CrossRef] [PubMed]

- Secundo, F. Conformational changes of enzymes upon immobilization. Chem. Soc. Rev. 2013, 42, 6250–6261. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, O.; Ortiz, C.; Berenguer-Murcia, Á.; Torres, R.; Rodrigues, R.C.; Fernandez-Lafuente, R. Strategies for the one-step immobilization-purification of enzymes as industrial biocatalysts. Biotechnol. Adv. 2015, 33, 435–456. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, O.; Ortiz, C.; Berenguer-Murcia, Á.; Torres, R.; Rodrigues, R.C.; Fernandez-Lafuente, R. Glutaraldehyde in bio-catalysts design: A useful crosslinker and a versatile tool in enzyme immobilization. RSC Adv. 2014, 4, 1583–1600. [Google Scholar] [CrossRef]

- Zucca, P.; Sanjust, E. Inorganic materials as supports for covalent enzyme immobilization: Methods and mechanisms. Molecules 2014, 19, 14139–14194. [Google Scholar] [CrossRef] [PubMed]

- Fernández-Lucas, J.; Harris, R.; Mata-Casar, I.; Heras, A.; de la Mata, I.; Arroyo, M. Magnetic chitosan beads for covalent immobilization of nucleoside 2′-deoxyribosyltransferase: Application in nucleoside analogues synthesis. J. Ind. Microbiol. Biotechnol. 2013, 40, 955–966. [Google Scholar] [CrossRef] [PubMed]

- Bayramoglu, G.; Yilmaz, M.; Arica, M.Y. Preparation and characterization of epoxy-functionalized magnetic chitosan beads: Laccase immobilized for degradation of reactive dyes. Bioprocess Biosyst. Eng. 2010, 33, 439–448. [Google Scholar] [CrossRef] [PubMed]

- Sheng, W.; Xi, Y.; Zhang, L.; Ye, T.; Zhao, X. Enhanced activity and stability of papain by covalent immobilization on porous magnetic nanoparticles. Int. J. Biol. Macromol. 2018, 114, 143–148. [Google Scholar] [CrossRef] [PubMed]

- Acosta, J.; Arco, J.D.; Martinez-Pascual, S.; Clemente-Suárez, V.J.; Fernández-Lucas, J. One-Pot Multi-Enzymatic Production of Purine Derivatives with Application in Pharmaceutical and Food Industry. Catalysts 2018, 8, 9. [Google Scholar] [CrossRef]

- Scism, R.A.; Bachmann, B.O. Five-component cascade synthesis of nucleotide analogues in an engineered self-immobilized enzyme aggregate. ChemBioChem 2010, 11, 67–70. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, O.; Torres, R.; Ortiz, C.; Fernandez-Lafuente, R. Modulation of the properties of immobilized CALB by chemical modification with 2, 3, 4-trinitrobenzenesulfonate or ethylendiamine. Advantages of using adsorbed lipases on hydrophobic supports. Process. Biochem. 2012, 47, 1220–1227. [Google Scholar] [CrossRef]

- Hernandez, K.; Fernandez-Lafuente, R. Control of protein immobilization: coupling immobilization and site-directed mutagenesis to improve biocatalyst or biosensor performance. Enzyme Microb. Technol. 2011, 48, 107–122. [Google Scholar] [CrossRef] [PubMed]

- Betancor, L.; López-Gallego, F.; Hidalgo, A.; Alonso-Morales, N.; Dellamora-Ortiz, G.; Mateo, C.; Fernández-Lafuente, R.; Guisán, J.M. Different mechanisms of protein immobilization on glutaraldehyde activated supports: Effect of support activation and immobilization conditions. Enzyme Microb. Technol. 2006, 39, 877–882. [Google Scholar] [CrossRef]

- Adriano, W.S.; Filho, E.H.C.; Silva, J.A.; Giordano, R.L.C.; Gonçalves, L.R.B. Stabilization of penicillin G acylase by immobilization on glutaraldehyde-activated chitosan. Braz. J. Chem. Eng. 2005, 22, 529–538. [Google Scholar] [CrossRef]

- Adriano, W.S.; Filho, E.H.C.; Silva, J.A.; Gonçalves, L.R.B. Optimization of penicillin G acylase multipoint immobilization on to glutaraldehyde–chitosan beads. Biotechnol. Appl. Biochem. 2005, 41, 201–207. [Google Scholar] [CrossRef] [PubMed]

- Adriano, W.S.; Mendonça, D.B.; Rodrigues, D.S.; Mammarella, E.J.; Giordano, R.L.C. Improving the properties of chitosan as support for the covalent multipoint immobilization of chymotrypsin. Biomacromolecules 2008, 9, 2170–2179. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, O.; Torres, R.; Ortiz, C.; Berenguer-Murcia, Á.; Rodrigues, R.C.; Fernandez-Lafuente, R. Heterofunctional supports in enzyme immobilization: From traditional immobilization protocols to opportunities in tuning enzyme properties. Biomacromolecules 2013, 14, 2433–2462. [Google Scholar] [CrossRef] [PubMed]

- Fernandez-Lafuente, R. Stabilization of multimeric enzymes: Strategies to prevent subunit dissociation. Enzyme Microb. Technol. 2009, 45, 405–418. [Google Scholar] [CrossRef]

- Jordaan, J.; Simpson, C.; Brady, D.; Gardiner, N.S.; Gerber, I.B. Emulsion-derived particles. U.S. Patent No. 9,574,054, 2017. [Google Scholar]

- Kanagawa, M.; Baba, S.; Ebihara, A.; Shinkai, A.; Hirotsu, K.; Mega, R.; Kim, K.; Kuramitsu, S.; Sampei, G.; Kawai, G. Structures of hypoxanthine-guanine phosphoribosyltransferase (TTHA0220) from Thermus thermophilus HB8. Acta Crystallogr. Sect. F Struct. Biol. Cryst. Commun. 2010, 66, 893–898. [Google Scholar] [CrossRef] [PubMed]

- DeLano, W.L. The PyMOL molecular graphics system. 2002. Available online: http://www.pymol.org (accessed on 20 April 2018).

- Baker, N.A.; Sept, D.; Joseph, S.; Holst, M.J.; McCammon, J.A. Electrostatics of nanosystems: Application to microtubules and the ribosome. Proc. Natl. Acad. Sci. USA 2001, 98, 10037–10041. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).