Abstract

The use of CO2 as a CO surrogate for the carbonylation of olefin has attracted considerable attention due to its abundance, readily availability, nontoxicity, and recyclability. In this work, we describe the synthesis of methyl propionate (MPA), a key intermediate for methyl methacrylate in the commercial Lucite Alpha process, by the ruthenium-catalyzed methoxycarbonylation of ethylene with CO2 as a carbonyl source. An efficient approach to producing MPA has been developed by adding metal halide promoters and dehydrating agents. Control experiments suggest that the NHC-Ru-hydride may be the real active species formed in situ by the reaction of Ru3(CO)12 with ionic liquid (IL). NMR data demonstrate that inorganic salts favor the formation of active species, which is an important issue for their promotion effect. In terms of the strategy to overcome chemical equilibrium by the addition of dehydrating agents and IL participation in the formation of NHC-Ru-hydride active species, a tasked IL containing a siloxyl group was employed to Ru-catalyze the methoxycarbonylation of ethylene, which showed higher catalytic efficiency in comparison to IL without a siloxyl group.

1. Introduction

Catalytic alkene alkoxycarbonylation represents a significantly straightforward process to generate one carbon elongated esters with high synthetic versatility [1,2]. An excellent example is palladium-catalyzed formation of methyl propionate (MPA) by alkoxycarbonylation of ethylene with CO as a carbonyl source. The resulting MPA is an intermediate for methyl methacrylate in the commercial Lucite Alpha process [3]. Although CO is a cheap and ideal C1 source for large-scale carbonylation chemistry, it is difficult to handle and transport due to its highly toxic and flammable properties. Hence, considerable efforts have been devoted to developing CO-free carbonylation in the past few decades [4,5,6,7]. Among all of the CO substitutes, CO2 is considered as a very interesting CO surrogate due to its abundance, ready availability, nontoxicity, and recyclability [8,9]. Related to this work, Beller and co-workers [10] successfully developed a Ru-catalyzed alkoxycarbonylation of alkenes with CO2 and alcohols to give the corresponding carboxylic acid esters. The application of this novel alkoxycarbonylation reaction was further investigated by the Stouten and Wang group [11], who performed the methoxycarbonylation in continuous flow under supercritical conditions. These works demonstrated that the supercritical CO2 process was found to have a remarkably better environmental performance compared to the Lucite Alpha process. Further, investigation by Ji et al. [12] elucidated the role of ionic liquids (ILs) as a hydrogen donor medium to form real active species Ru-H in situ, which facilitates the reduction of CO2 to CO, promoting the Ru-catalyzed carbonylation of olefins. Recently, Xia and co-workers [13] proposed a [Ru(CO)3Cl2]2/Co2(CO)8 heterobimetallic binary catalytic system for the hydroesterification reaction of olefin with CO2, reducing the usage of noble metal and ILs additives. Nevertheless, the efficiency of this promising hydroesterification reaction process with CO2 is still far from satisfactory, especially for the value chemicals of MPA from ethylene methoxycarbonylations using CO2 as the feedstock.

The addition of inorganic salts into the metal-catalyzed carbonylation reaction, including the alkene alkoxycarbonylation, have been found to be an attractive strategy in improving reaction efficiency and selectivity [14,15,16]. However, to date, some published data on the order of promotion of salts are contradictory to each other. For example, Sasaki [8] reported that the order of promotion of lithium salts was Cl− > Br− > I− in the ruthenium complex-catalyzed hydroformylation of cyclohexene with CO2. On the contrary, an opposite sequence was observed in the Ru3(CO)12-initiated hydroesterification of alkenes with 2-pyridylmethyl formate as CO surrogate, where lithium iodide (LiI) showed the best activation effects, and the use of chloride salt resulted in a marginal improvement [17]. Furthermore, it has been observed that the inorganic salt additives play different roles in the Ru-catalyzed carbonylation reactions [12,14,15,16,17,18,19,20,21,22,23,24]. For instance, Tominaga et al. [18] supposed that LiCl could facilitate the deprotonation of ruthenium hydride (Ru-H) complexes to form active species for the activation of CO2 upon coordination in the hydroformylation of alkenes using carbon dioxide as a carbonyl source. At the same time, Chang and co-workers [17] argued that the effect of inorganic salts on the reaction is mainly attributed to the facile dissociation of the trirutheniumcarbonyl precursor into the presumed active metal species in the Ru-catalyzed hydroesterification of alkenes and alkynes using a 2-pyridylmethyl formate as CO surrogate. From another point of view, inorganic salts additives can also promote the reduction of CO2 to secondary CO, which may be realized because inorganic salts can promote the incorporation of CO2 into Ru-H to form Ru-COOH, thereby activating CO2 [12,14,19]. Therefore, the dependence of the type of inorganic salts on the promotion and essential role should be further clarified.

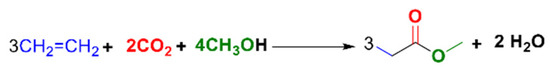

Screening the ethylene methoxycarbonylations with CO2 (Scheme 1), MPA is formed together with production of H2O [10]. It is well known that esters can be hydrolyzed in the presence of H2O at high temperature, which could result in low MPA yield. As a consequence, we conceive that it is desirable to achieve a higher yield by the removal of in situ water formation and overcoming the equilibrium limitation. Such a strategy has been applied in the synthesis of dimethyl carbonate (DMC) starting from CO2 and methanol [25,26,27,28,29]. The significance of fabricating an effective dehydrating agent for the removal of water from such a reaction is adopted for the enhancement of DMC yield. So far, various kinds of materials, including 2,2-dimethoxy propane [26], acetonitrile [27], 2-cyanopyridine (2-CP) [28], metal oxides [29], etc., have been employed as dehydrating agents to overcome this issue. Moreover, recyclable dehydrating agents are more preferable and practical in using this method to enhance yield.

Scheme 1.

Catalytic hydroesterification of ethylene with CO2.

Here, we report the Ru-catalyzed methoxycarbonylation of ethylene with CO2 as a CO surrogate assisted by inorganic halide additives and dehydrating agents. The roles of additives and dehydrating agents were preliminarily investigated. In light of the understanding of tetramethoxysilane (TMOS) and imidazolium ionic liquid to promote reaction, a siloxyl-functionalized ionic liquid, namely, 1-(3-trimethoxysilylpropyl)-3-methyl imidazolium chloride ([TmsPmim]Cl) was also used in this Ru-catalyzed methoxycarbonylation of ethylene with CO2.

2. Results and Discussion

2.1. Promoting Effect of Dehydrating Agent and Inorganic Salts

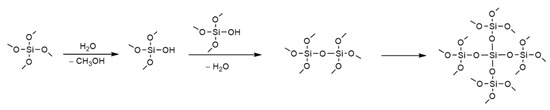

From the viewpoint of chemical reaction equilibrium, using dehydrating agents to remove by-product H2O from the reaction mixture should be an effective strategy to promote such transformation (Scheme 1). Therefore, the influence of several dehydrating agents on the Ru3(CO)12-catalyzed methoxycarbonylation of ethylene using CO2 as a C1 surrogate was examined with the aim of increasing the productivity of MPA. The results are summarized in Table 1. Notably, 2-CP, an efficient dehydrating agent in the synthesis of DMC directly from CO2 and CH3OH, deteriorated the synthesis of MPA, as evidenced by the lower yield than that without 2-CP (entry 4 vs. entry 1, Table 1). This most likely resulted from the fact that 2-CP can competitively coordinate with the Ru active center, limiting activation of the reactant by coordination interaction. To verify our hypothesis, we treated a solution of Ru3(CO)12 with 2-CP at the molar ratio of 2-CP: Ru3(CO)12 = 100:1 at 200 °C for 30 min and the solution was subjected to IR measurement. As shown in Figure S1, the original carbonyl peaks of Ru3(CO)12 shifted from 1960 and 2035 cm−1 to high wavenumber (2020 and 2060 cm−1) after Ru3(CO)12 treated by 2-CP. Furthermore, a shift of CN stretching vibration frequencies also occurred. These results confirmed that a coordination interaction probably takes place between Ru3(CO)12 and 2-CP.

Table 1.

Effects of dehydrating agents on hydroesterification reaction a.

To our delight, the productivity of MPA was enhanced by the addition of tetraalkoxysilanes such as TMOS (tetramethoxysilane) and TEOS (tetraethyloxysilane). When TMOS was used as the dehydrating reagent, the MPA yield was 18.6% higher than without TMOS, reaching 73.4% with the presence of 0.042 mmol Ru3(CO)12 and 5.6 mmol [Bmim]Cl (entry 1 vs. entry 2, Table 1). A slight decrease of MPA productivity was observed when TEOS was used as the dehydrating reagent (entry 3, Table 1). The difference in efficiency between TMOS and TEOS can probably be attributed to the fact that TMOS is prone to hydrolysis [30], and methanol, which is a reactant, is released. From the point of chemical equilibrium, such a case is beneficial to the reaction toward formation of the product side. Another promising prospect with TEOS as a dehydrating agent is that TMOS can be effectively synthesized through a base-catalyzed reaction of SiO2 and methanol in the presence of CO2 and acetal [31]. More interestingly, SiO2 can be obtained from rice hull ash, which is a natural and sustainable silica substrate [32].

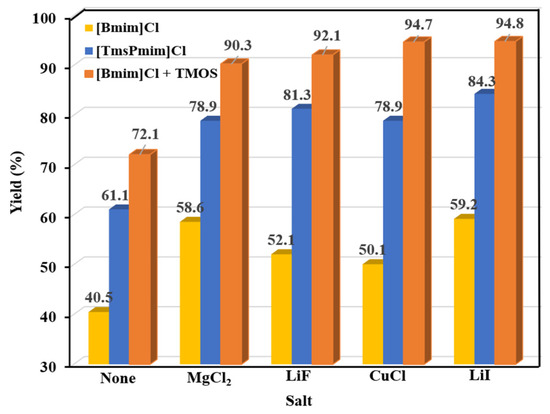

The addition of inorganic salts into the metal-catalyzed carbonylation reaction, including the alkene alkoxycarbonylation, has been found to be an attractive strategy in improving reaction efficiency and selectivity [14,15,16,17,18,19,20,21,22,23,24]. Accordingly, four kinds of inorganic salts of LiI, CuCl, LiF, and MgCl2 were selected for the preliminary evaluation of the effect of salts on the methoxycarbonylation of ethylene with CO2. Interestingly, the efficiency to selectively generate MPA was substantially improved for all additive salts tested, the extent of which varied depending on the type of salts. Here, LiI provided the highest promoting efficiency, improving by about 20% (Figure 1). This result is different from the previous report regarding the ruthenium-catalyzed one-pot hydroformylation of alkenes using CO2 as a reactant, where LiI showed the worst performance [18]. Considering the environmentally friendly nature and satisfactory acceleration of MgCl2 in the methoxycarbonylation of ethylene with CO2, unless otherwise specified, the subsequent reactions were conducted using MgCl2 as promoter.

Figure 1.

Effect of salt on the productivity of ethylene methoxycarbonylation with CO2 as CO surrogate. Reaction conditions: Ru3(CO)12 (0.010 mmol), Salt (0.126 mmol), Methanol 5.6 mL, Ethylene 0.2 MPa, CO2 4.0 MPa, 200 °C, 4 h. (  ) [Bmim]Cl (5.6 mmol); (

) [Bmim]Cl (5.6 mmol); (  ) [TmsPmim]Cl (5.6 mmol); (

) [TmsPmim]Cl (5.6 mmol); (  ) [Bmim]Cl (5.6 mmol) and TMOS (4.2 mmol).

) [Bmim]Cl (5.6 mmol) and TMOS (4.2 mmol).

) [Bmim]Cl (5.6 mmol); (

) [Bmim]Cl (5.6 mmol); (  ) [TmsPmim]Cl (5.6 mmol); (

) [TmsPmim]Cl (5.6 mmol); (  ) [Bmim]Cl (5.6 mmol) and TMOS (4.2 mmol).

) [Bmim]Cl (5.6 mmol) and TMOS (4.2 mmol).

2.2. Exploration of Reaction Mechanism

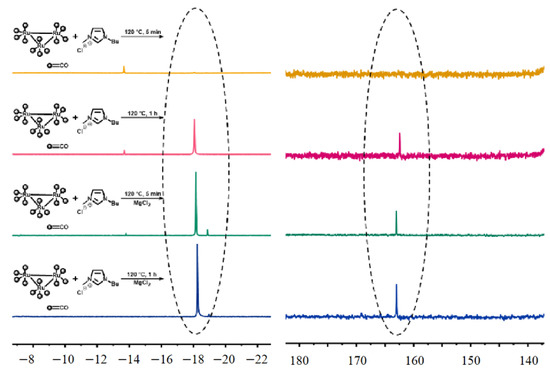

Ru-hydride-carbonyl-carbene complexes have been regarded as possible catalytic active species in the hydroformylation of alkenes using CO2 as the carbonyl source [15,33,34]. To explore the possible formation of such species, the reaction mixture of Ru3(CO)12 and [Bmim]Cl in the absence or presence of MgCl2 additive was investigated by NMR spectroscopy in light of reports (Figure 2) [15]. In the absence of MgCl2 additive, it was observed by 13C NMR spectra that the intensity of the signal at 163 ppm, assigned to N-heterocyclic carbene (NHC), enhanced gradually. Furthermore, the intensity peak at about −18 ppm, which is assignable to ruthenium hydride, showed a similar trend with prolonging reaction time. These results suggested the formation of Ru-hydride-carbonyl-carbene complex, face-capped trinuclear [Ru3(μ-H)2(μ3-MeImCH)(CO)9] (I) [15,33]. The isolated I displayed a slightly higher activity than pristine Ru3(CO)12 in the methoxycarbonylation of ethylene with CO2 under identical conditions (entry 1 vs. entry 2, Table 2). This observation supports I as a possible active species generated in situ from the combination of Ru3(CO)12 with the [Bmim]Cl catalytic system. The easier formation of active species I in the presence of MgCl2 is responsible for the promoting effect because metal halide salt can interact with Cl− anion of imidazolium ionic liquids. The C2-H bond can be weakened by the addition of inorganic salts and then 2-H is easy to disengage from the 1-alkyl-3-methylimidazolium-based IL [35,36]. This facilitates the formation of I carbene species. This speculation is further supported by the fact that the intensity of signals characteristic of Ru-NHC and Ru-H in the presence of MgCl2 at 5 min are comparable to those without MgCl2 for 60 min (Figure 2). The interactions varied with the kind of metal salt additive, which accounts for the observation of the dependence of yield (or activity) on the metal salt employed. It is the best evidence that the adduct of BmimMgCl3 derived from MgCl2 and [Bmim]Cl demonstrated a similar promoting effect to the binary MgCl2 and [Bmim]Cl in the Ru-catalyzed hydroesterification reaction (entry 6 vs. entry 7, Table 2).

Figure 2.

1H (400 MHz, CDCl3) NMR and 13C (100 MHz, CDCl3) NMR partial spectra of the species formed by reacting Ru3(CO)12 with [Bmim]Cl. Reaction condition: Ru3(CO)12 (0.2 mmol), [Bmim]Cl (3.2 mmol), 120 °C.

Table 2.

Hydroesterification reaction performed under various catalytic species a.

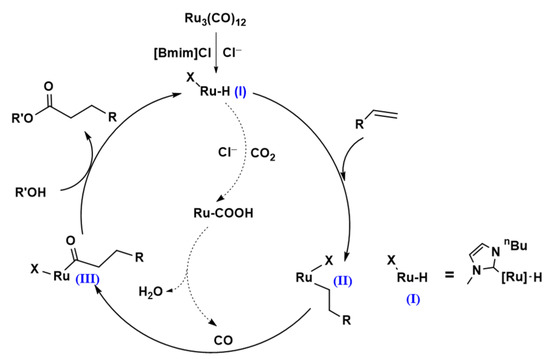

It should be pointed out that the promoting effect of the salt additive is also probably due to the facile reduction of CO2 by Ru-H to CO, as evidenced by Han and co-workers through a computational and experimental study. [12] Further indirect proof of results is from entry 3 in Table 2, where the yield of MPA was further improved by addition of MgCl2 into the Ru (I) catalytic system. Accordingly, a plausible mechanism is proposed as shown in Scheme 2. The whole reaction starts with the active species Ru (I) produced by the reaction of Ru3(CO)12 and [Bmim]Cl. The addition of inorganic salts can promote the formation of Ru-hydride-complexes. In this process, metal halides can promote the reduction of CO2 by forming Ru-COOH intermediates [12]. The conversion rate of CO2 to CO is positively correlated with the efficiency of hydroesterification. Further, in light of this assumption, the dehydrating agent plays a part by reacting with H2O produced during CO2 reduction, in favor of the formation of species III through the insertion of CO into the Ru-R bond of species II.

Scheme 2.

A probable mechanistic pathway for the Ru-catalyzed methoxycarbonylation of ethylene with CO2.

2.3. Optimization of Reaction Conditions

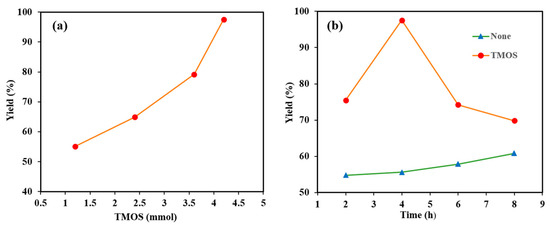

To further maximize formation of MPA, the influence of catalyst loading, reaction temperature, CO2 pressure, and reaction time was investigated in the presence of TMOS. As noted in Table 3, the higher temperature is favorable for the reaction. As the temperature varied from 160 °C to 200 °C, the yield increased from 27.1% to 97.5% (entries 1–3, Table 3). Furthermore, pressure plays a critical role in the catalytic activity. As indicated by entries 4 and 5 in Table 3, the yield increased significantly from 50.5% to 90.0% with increasing pressure from 2.0 MPa to 3.0 MPa. However, the productivity was promoted slightly as the CO2 pressure was further raised up to 4.0 MPa. One possible explanation for the increase of yield at higher pressure is due to the increased solubility of CO2 in the ILs [37,38], which leads to a higher CO2 concentration in the medium, which is beneficial to the methoxycarbonylation reaction. The limited solubility of CO2 in the ILs could account for the slight improvement in the reaction rate above a certain pressure (herein, 3.0 MPa). Although reducing catalyst loading from 0.042 mmol to 0.010 mmol decreases monomer conversion, the catalytic activity is still acceptable, with a yield of more than 70% in 4 h. Figure 3a shows the dependence of yields on the concentration of TMOS. The yield increases significantly with the increase of TMOS.

Table 3.

Yield of MPA under different conditions on hydroesterification reaction a.

Figure 3.

(a) Effect of the amount of TMOS on hydroesterification reaction of ethylene with CO2. Reaction conditions: Ru3(CO)12 (0.042 mmol), [Bmim]Cl (5.6 mmol), Methanol 5.6 mL, Ethylene 0.2 Mpa, CO2 4.0 Mpa, 200 °C, 4 h. (b) Effect of reaction time on hydroesterification reaction of ethylene with CO2. Reaction conditions: Ru3(CO)12 (0.042 mmol), [Bmim]Cl (5.6 mmol), TMOS (4.2 mmol), Methanol 5.6 mL, Ethylene 0.2 Mpa, CO2 4.0 Mpa, 200 °C.

Interestingly, with the extension of reaction time, the resulting MPA yield increased in the range of 2.0 to 4.0 h, rapidly decreased in the following two hours, and then dropped slightly. The highest yield (97.5%) was obtained when the reaction was performed at 4.0 h (Figure 3b). In the early reaction stage, the produced H2O was removed by reaction with the dehydrating agent (TMOS), and methanol and HO-Si-(OCH3)3 were formed. From the viewpoint of chemical equilibrium, this reaction is conducive to the reaction toward the generation of MPA. Meanwhile, the dimerization of HOSi(OMe)3 can form siloxane (MeO)3Si-O-Si(OMe)3 and H2O by hydroxyl condensation (Scheme 3). It is well known that esters can be hydrolyzed in the presence of H2O at high temperature, which may illustrate the observed decrease in the yield of MPA at longer reaction times. This assumption was verified by the finding of a peak at −85.7 ppm in the 29Si NMR spectrum for the resulting mixtures [30] (Figure S3).

Scheme 3.

The hydrolysis and cross-linking of TMOS.

2.4. Applications of Siloxyl-Functionalized Ionic Liquid

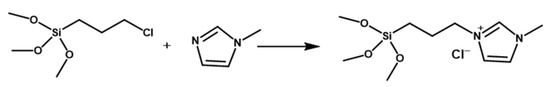

To simplify the catalytic system, a siloxyl-functionalized ionic liquid, namely, 1-(3-trimethoxysilylpropyl)-3-methyl imidazolium chloride ([TmsPmim]Cl) was used to replace the TMOS and [Bmim]Cl for the Ru-catalyzed methoxycarbonylation of CH2=CH2 with CO2 as carbonylation reagent. Happily, the MPA yield increased considerably from 40.5% to 61.1% under otherwise identical conditions (Table 1, entries 5 and 6). Such a phenomenon can be attributed to the fact that the siloxyl-functionalized [TmsPmim]Cl plays two roles, in participating in the formation of real active Ru species and in removing H2O via reaction with the Si-OCH3 group of [TmsPmim]Cl. It should be emphasized that the catalytic system with [TmsPmim]Cl showed slightly lower activity than that with binary [Bmim]Cl and TMOS system (Table 1, entries 6 and 7). In this tasked ionic liquid-based catalytic system, the metal halides also demonstrate a promotion activity as in the ternary catalytic system comprising Ru, [Bmim], and TMOS. Again, the addition of LiI resulted in the highest activity, producing 84.3% MPA (Figure 1).

3. Materials and Methods

3.1. Materials

Unless otherwise stated, all reagents and gases were purchased from commercial suppliers and used without further purification. All manipulations involving air- or water-sensitive compounds were performed using the standard Schlenk and vacuum line techniques under argon atmosphere. Ru3(CO)12 (triruthenium dodecacarbonyl), [Bmim]Cl (1-Butyl-3-methylimidazolium chloride), 2-CP (2-Cyanopyridine), TMOS (Tetramethyl orthosilicate), and TEOS (Tetraethyl orthosilicate) were purchased form Heowns Biochem Technologies LLC (Tianjin, China) and used directly. All salts were purchased from Tianjin Kemiou Chemical Reagent Co Ltd. (Tianjin, China), and dried under a vacuum at 80 °C overnight before use.

3.2. Characterization

All 1H, 13C, 29Si NMR spectra were recorded on a Bruker-400 spectrometer (Bruker, ZÜRICH, Switzerland) at room temperature with reference to tetramethylsilane (TMS) as internal standard in CDCl3. FT-IR spectra were measured on a Bruker Vector 22 spectrometer (Bruker, Ettlingen, Germany). The spectra of the compounds were acquired in 400–4500 cm−1 wavenumber range using a KBr pellet. ESI-MS experiments were carried out using a Bruker Q-TOF mass spectrometer (Bruker, Ettlingen, Germany). Samples were inserted into the electrospray interface at a flow rate of 2 mL/min and the source temperature was kept at 200 °C. UV-visible spectra were collected on a G6860A spectrophotometer (Agilent Technologies, Mulgrave, Australia). Products were identified with GC analysis on a SP-6890 instrument (Lunan Ruihong, Shandong, China).

3.3. Synthesis of 1-(3-Trimethoxysilylpropyl)-3-Methylimidazolium Chloride ([TmsPmim]Cl)

According to previous literature [39], the synthesis route of [TmsPmim]Cl is shown in Scheme 4. The mixture of N-methylimidazole (8.21 g, 0.1 mol) and 3-trimethoxysilylpropyl chloride (19.87 g, 0.1 mol) was stirred and heated to 343 K for 24 h under an argon atmosphere. After cooling down to room temperature, the mixture was washed with ethyl acetate five times. The solvent was removed on a rotary evaporator and the sample was dried in vacuum for 12 h to afford a yellow viscous liquid (92% yield). The 1H-NMR spectrum of compound is shown in Figure S4.

Scheme 4.

Preparation of [TmsPmim]Cl.

3.4. Synthesis of Metal-Based Ionic Liquids: BmimMgCl3

The BmimMgCl3 was prepared by mixing equal moles of [Bmim]Cl and MgCl2[40]. The compound [Bmim]Cl (3.49 g, 20 mmol) was dissolved in dry acetonitrile (10 mL) and MgCl2 (1.90 g, 20 mmol) was added. The mixture was stirred and refluxed for 24 h under argon atmosphere. The resulting hot solution was filtered immediately and treated by a rotary evaporator to remove acetonitrile, before being dried in a vacuum oven at 333 K overnight to yield the final product, BmimMgCl3 (95% yield). 1H-NMR and ESI-MS spectra of this complex are shown in Figures S5 and S6, respectively.

3.5. Synthesis of N-Heterocyclic Carbene Complexes of Ruthenium

According to previous literature [33], a mixture of [Bmim]Cl (69.87 mg, 0.4 mmol) and KOtBu (44.9 mg, 0.4 mmol) was stirred in acetonitrile (5.0 mL) at room temperature for 20 min under argon atmosphere. Powdered Ru3(CO)12 (255.73 mg, 0.4 mmol) was then added, and immediate bubbling of the solution was observed. After 2 h, the solvent was filtered immediately to removed unreacted Ru3(CO)12 and treated by a rotary evaporator to remove acetonitrile. The resulting crude product was washed with hexane (50 mL) to leave a brick red powder (75% yield).

3.6. General Procedure for the Hydroesterification Reaction

All the hydroesterification experiments were carried out in a 20 mL autoclave equipped with a magnetic stirring bar. In a typical experiment, Ru3(CO)12 (6.7 mg, 0.01 mmol), co-catalyst [Bmim]Cl (0.98 g, 5.6 mmol), TMOS (0.64 g, 4.2 mmol), MgCl2 (0.012 g, 0.13 mmol), and methanol (5.6 mL) were charged into the reactor in an atmosphere of argon. The autoclave was then pressurized with ethylene (0.2 MPa) and carbon dioxide (4.0 MPa). The autoclave was heated at the required temperature for the specified time. After reaction, the autoclave was cooled. The excess gas was released, and the reaction mixture was passed through a short pad of silica gel before analysis by GC.

The yield of MPA is defined as follows:

where mA is the weight of MPA analyzed by GC after reaction; SA is the peak area of MPA; mB is the weight of internal standard (n-heptane); SB is the peak area of internal standard (n-heptane); F is the correction factor; MMPA is the molar mass of MPA.

4. Conclusions

In conclusion, we report an effective catalytic system Ru3(CO)12/[Bmim]Cl for the direct formation of MPA from ethylene, CO2, and methanol with high yields under optimized reaction conditions. The dramatic enhancement effects of certain inorganic salts and dehydrating agents for the hydroesterification reaction have been demonstrated in this work. Ru-hydride species formed in situ by the reaction of Ru3(CO)12 with [Bmim]Cl were demonstrated to be active species. The inorganic salts can promote the formation of Ru-hydride species. Based on the above conclusions, the possible reaction mechanism is described. All these findings offered a promising strategy to use inexpensive, easily available, and less toxic CO2 as a C1 building block for important industrial carbonylation processes.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/catal12080826/s1, Figure S1: IR spectra of a mixture of Ru3(CO)12 and 2-CP; Figure S2: 29Si NMR spectrum of the reaction mixture; Figure S3: 1H NMR spectrum of [TmsPmim]Cl; Figure S4: 1H NMR spectrum of BmimMgCl3; Figure S5: ESI-MS spectra of BmimMgCl3.

Author Contributions

B.L. conceived and designed the experimental work.; M.Q., T.D. and Y.K. performed the experiments; B.L., L.Z., Z.D. and M.Q. analyzed the data; M.Q. drafted the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by Hebei Natural Science Foundation (B2018202112 and B2022202015).

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sang, R.; Hu, Y.; Razzaq, R.; Jackstell, R.; Franke, R.; Beller, M. State-of-the-Art Palladium-Catalyzed Alkoxycarbonylations. Org. Chem. Front. 2021, 8, 799–811. [Google Scholar] [CrossRef]

- Brennführe, A.; Neumann, H.; Beller, M. Palladium-Catalyzed Carbonylation Reactions of Alkenes and Alkynes. ChemCatChem 2009, 1, 28–41. [Google Scholar] [CrossRef]

- Khokarale, S.G.; Mikkola, J.P. Efficient and Catalyst Free Synthesis of Acrylic Plastic Precursors: Methyl Propionate and Methyl Methacrylate Synthesis through Reversible CO2 Capture. Green Chem. 2019, 21, 2138–2147. [Google Scholar] [CrossRef]

- Morimoto, T.; Kakiuchi, K. Evolution of Carbonylation Catalysis: No Need for Carbon Monoxide. Angew. Chem. Int. Ed. 2004, 43, 5580–5588. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Liu, Q.; Jackstell, R.; Beller, M. Carbonylations of Alkenes with CO Surrogates. Angew. Chem. Int. Ed. 2014, 53, 2–13. [Google Scholar] [CrossRef] [PubMed]

- Hussain, N.; Chhalodia, A.K.; Ahmed, A.; Mukherjee, D. Recent Advances in Metal-Catalyzed Carbonylation Reactions by Using Formic Acid as CO Surrogate. ChemistrySelect 2020, 5, 11272–11290. [Google Scholar] [CrossRef]

- Konishi, H.; Manabe, K. Formic Acid Derivatives as Practical Carbon Monoxide Surrogates for Metal-Catalyzed Carbonylation Reactions. Synlett 2014, 25, 1971–1986. [Google Scholar] [CrossRef]

- Tominaga, K.; Sasaki, Y. Ruthenium Complex-Catalyzed Hydroformylation of Alkenes with Carbon Dioxide. Catal. Commun. 2000, 1, 1–3. [Google Scholar] [CrossRef]

- Yu, D.; Teong, S.P.; Zhang, Y. Transition Metal Complex Catalyzed Carboxylation Reactions with CO2. Coord. Chem. Rev. 2015, 293, 279–291. [Google Scholar] [CrossRef]

- Wu, L.; Liu, Q.; Fleischer, I.; Jackstell, R.; Beller, M. Ruthenium-catalysed alkoxycarbonylation of alkenes with carbon dioxide. Nat. Commun. 2014, 5, 3091. [Google Scholar] [CrossRef] [PubMed]

- Stouten, S.C.; Anastasopoulou, A.; Hessel, V.; Wang, Q. Life Cycle Assessment of Novel Supercritical Methyl Propionate Process with Carbon Dioxide Feedstock. React. Chem. Eng. 2017, 2, 688–695. [Google Scholar] [CrossRef]

- Bi, K.L.; Xu, B.H.; Ding, W.L.; Han, L.J.; Ji, L. Mechanism of CO2 Reduction in Carbonylation Reaction Promoted by Ionic Liquid Additives: A Computational and Experimental Study. Green Energy Environ. 2021. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, C.; Xia, C.; Tian, X.; He, L. Alkoxycarbonylation of Olefins with Carbon Dioxide by Reusable. Green Chem. 2018, 20, 5533–5539. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, L.; Fleischer, I.; Selent, D.; Franke, R.; Jackstell, R.; Beller, M. Development of a Ruthenium/Phosphite Catalyst System for Domino Hydroformylation–Reduction of Olefins with Carbon Dioxide. Chem. Eur. J. 2014, 20, 6888–6894. [Google Scholar] [CrossRef]

- Ali, M.; Gual, A.; Ebeling, G.; Dupont, J. Ruthenium-Catalyzed Hydroformylation of Alkenes by using Carbon Dioxide as the Carbon Monoxide Source in the Presence of Ionic Liquids. ChemCatChem 2014, 6, 2224–2228. [Google Scholar] [CrossRef]

- Jääskeläinen, S.; Haukka, M. The Use of Carbon Dioxide in Ruthenium Carbonyl Catalyzed 1-Hexene Hydroformylation Promoted by Alkali Metal and Alkaline Earth Salts. Appl. Catal. A-Gen. 2003, 247, 95–100. [Google Scholar] [CrossRef]

- Park, E.J.; Lee, J.M.; Han, H.; Chang, S. Halide Ions as a Highly Efficient Promoter in the Ru-Catalyzed Hydroesterification of Alkenes and Alkynes. Org. Lett. 2006, 8, 4355–4358. [Google Scholar] [CrossRef] [PubMed]

- Tominaga, K.; Sasaki, Y. Ruthenium-Catalyzed One-Pot Hydroformylation of Alkenes Using Carbon Dioxide as a Reactant. J. Mol. Catal. A-Chem. 2004, 220, 159–165. [Google Scholar] [CrossRef]

- Tominaga, K.; Sasaki, Y.; Hagihara, K.; Watanabe, T.; Saito, M. Reverse Water-Gas Shift Reaction Catalyzed by Ruthenium Cluster Anions. Chem. Lett. 1994, 23, 1391–1394. [Google Scholar] [CrossRef]

- Ostapowicz, T.G.; Schmitz, M.; Krystof, M.; Klankermayer, J.; Leitner, W. Carbon Dioxide as a C1 Building Block for the Formation of Carboxylic Acids by Formal Catalytic Hydrocarboxylation. Angew. Chem. 2013, 125, 12341–12345. [Google Scholar] [CrossRef]

- Evans, J.; Gao, J.X.; Leach, H.; Street, A.C. EXAFS Infrared and Kinetic Studies on a Ruthenium Carbonyl Hydrof Ormylation System. J. Organomet. Chem. 1989, 372, 61–66. [Google Scholar] [CrossRef]

- Lavigne, G.; Lugan, N.; Kalck, P.; Soulie, J.M.; Lerouge, O.; Sailladrd, J.Y.; Halet, J.F. New Polymetallic Ruthenium Carbonyl Halide Complexes: Exotic Combinations of Electron Defictent Skeletons with Electron Rich Anions. Their Potential Interest in Ethylene Hydroesterification. J. Am. Chem. Soc. 1992, 114, 10669–10670. [Google Scholar] [CrossRef]

- Dombek, B.D. Hydrogenation of Carbon Monoxide by Ruthenium Complexes with Iodide Promoters: Catalytic and Mechanistic Investigations. J. Organomet. Chem. 1983, 250, 467–483. [Google Scholar] [CrossRef]

- Hidai, M.; Koyasu, Y.; Chikanari, K.; Uchida, Y. Synthesis of Ketones and Esters from Olefins, Carbon Monoxide and Alcohols by Using Ruthenium-Iodide Catalysts. J. Mol. Catal. 1987, 40, 243–254. [Google Scholar] [CrossRef]

- Tamboli, A.H.; Chaugule, A.A.; Kim, H. Catalytic Developments in the Direct Dimethyl Carbonate Synthesis from Carbon Dioxide and Methanol. Chem. Eng. J. 2017, 323, 530–544. [Google Scholar] [CrossRef]

- Tomishige, K.; Kunimori, K. Catalytic and Direct Synthesis of Dimethyl Carbonate Starting from Carbon Dioxide Using CeO2-ZrO2 Solid Solution Heterogeneous Catalyst: Effect of H2O Removal from the Reaction System. Appl. Catal. A-Gen. 2002, 237, 103–109. [Google Scholar] [CrossRef]

- Honda, M.; Kuno, S.; Begum, N.; Fujimoto, K.; Suzuki, K.; Nakagawa, Y.; Tomishige, K. Catalytic synthesis of dialkyl carbonate from low pressure CO2 and alcohols combined with acetonitrile hydration catalyzed by CeO2. Appl. Catal. A-Gen. 2010, 384, 165–170. [Google Scholar] [CrossRef]

- Honda, M.; Tamura, M.; Nakagawa, Y.; Sonehara, S.; Suzuki, K.; Fujimoto, K.; Tomishige, K. Ceria-Catalyzed Conversion of Carbon Dioxide into Dimethyl Carbonate with 2-Cyanopyridine. ChemSusChem 2013, 6, 1341–1344. [Google Scholar] [CrossRef]

- Choi, J.C.; He, L.N.; Yasuda, H.; Sakakura, T. Selective and High Yield Synthesis of Dimethyl Carbonate Directly from Carbon Dioxide and Methanol. Green Chem. 2002, 4, 230–234. [Google Scholar] [CrossRef]

- Zhang, Q.; Yuan, H.Y.; Fukaya, N.; Yasuda, H.; Choi, J.C. A Simple Zinc Catalyst for Carbamate Synthesis Directly from CO2. ChemSusChem 2017, 10, 1501–1508. [Google Scholar] [CrossRef]

- Fukaya, N.; Choi, S.J.; Horikoshi, T.; Kumai, H.; Hasegawa, M.; Yasuda, H.; Sato, K.; Choi, J.C. Synthesis of Tetramethoxysilane from Silica and Methanol Using Carbon Dioxide and an Organic Dehydrating Reagent. Chem. Lett. 2016, 45, 828–830. [Google Scholar] [CrossRef]

- Laine, R.M.; Furgal, J.C.; Doan, P.; Pan, D.; Popova, V.; Zhang, X. Avoiding Carbothermal Reduction: Distillation of Alkoxysilanes from Biogenic, Green, and Sustainable Sources. Angew. Chem. Int. Ed. 2016, 55, 1065–1069. [Google Scholar] [CrossRef] [PubMed]

- Cabeza, J.A.; Rio, I.; Miguel, D.; Sánchez-Vega, M.G. Easy activation of two C-H bonds of an N-heterocyclic carbene N-methyl group. Chem. Commun. 2005, 31, 3956–3958. [Google Scholar] [CrossRef] [PubMed]

- Bruce, M.I.; Cole, M.L.; Fung, R.S.C.; Forsyth, C.M.; Hilder, M.; Junk, P.C.; Konstas, K. The reactivity of N-heterocyclic carbenes and their precursors with [Ru3(CO)12]. Dalton Trans. 2008, 31, 4118–4128. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Zhao, S.; Wang, R. Mechanism of Alkylation of Benzene with Ethylene Catalyzed by [bmim]Cl/FeCl3 Ionic Liquid. Chin. J. Catal. 2004, 25, 247–251. [Google Scholar]

- Ko, N.H.; Lee, J.S.; Huh, E.S.; Lee, H.; Jung, K.D.; Kim, H.S.; Cheong, M. Extractive Desulfurization Using Fe-Containing Ionic Liquids. Energy Fuels 2008, 22, 1687–1690. [Google Scholar] [CrossRef]

- Lim, B.H.; Choe, W.H.; Shim, J.J.; Ra, C.S.; Tuma, D.; Lee, H.; Lee, C.S. High-Pressure Solubility of Carbon Dioxide in Imidazolium-Based Ionic Liquids with Anions [PF6] and [BF4]. Korean J. Chem. Eng. 2009, 26, 1130–1136. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, Y.; Ren, R.X.F.; Zhang, Y.; Zhang, J.; Zhang, X. Solubility of CO2 in Sulfonate Ionic Liquids at High Pressure. J. Chem. Eng. Data 2005, 50, 230–233. [Google Scholar] [CrossRef]

- Raut, A.B.; Shende, V.S.; Sasaki, T.; Bhanage, B.M. Reductive Amination of Levulinic Acid to N-Substituted Pyrrolidones over RuCl3 Metal Ion Anchored in Ionic Liquid Immobilized on Graphene Oxide. J. Catal. 2020, 383, 206–214. [Google Scholar] [CrossRef]

- Li, Z.; Cai, Z.; Zeng, Q.; Zhang, T.; France, L.J.; Song, C.; Zhang, Y.; He, H.; Jiang, L.; Long, J.; et al. Selective Catalytic Tailoring of the H Unit in Herbaceous Lignin for Methyl p-Hydroxycinnamate Production over Metal-Based Ionic Liquids. Green Chem. 2018, 20, 3743–3752. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).