Abstract

An environmentally friendly catalyst and task-specific ionic liquid (IL), 1-(4-sulfonic acid) butyl-3-cetyl-2-methyl imidazolium hydrogen sulfate, was applied to the dehydration of xylose to furfural. Its structure was determined by FT-IR, 1H NMR technologies. The solubility of IL in water changed with the temperature, and had the advantages of homogeneous and heterogeneous catalysts. At the given conditions, xylose conversion of 95.3% and furfural yield of 67.5% were achieved over IL.

1. Introduction

The energy crisis and a concern about the environment have promoted the development of carbon-neutral renewable biomass for energy [1]. Biomass is a sustainable alternative for conventional fossil fuels, particularly when environmentally friendly technologies are applied. Biomass is the only sustainable carbon carrier among renewable sources and can be converted into energy by thermochemical conversion, biochemical conversion, and extraction. Among various conversion methods, hydrothermal conversion is the most promising, without special requirements for materials. Furfural and its derivatives derived from biomass have the potential to make jet and diesel fuel [2], and can be used to synthesize a variety of acids, aldehydes, and alcohols currently obtained from petroleum. Until now, the commercial furfural process has suffered from disadvantages such as furfural loss, equipment corrosion, and high-energy consumption [3]. Solid acid catalysts successfully solved some drawbacks of liquid catalysts, such as separation and recycling et al. [4,5,6]. Wang et al. applied sulfonated palygorskite solid acid catalyst (PAL-SO3H) prepared by a mechanochemical process to biomass-derived xylose into furfural, and 87% of furfural yield with 96% selectivity was achieved [7]. Mérida-Morales et al. evaluated zirconium-doped mesoporous silica catalysts in glucose dehydration to 5-hydroxymethylfurfural [8]. In order to minimize furfural degradation reactions, a biphasic system removing furfural from the reaction medium was applied to furfural production from xylose [9]. However, solid catalysts hold poor hydrothermal stability and mass transfer limits, and the cost increases for the application of extractant. How to synthesize a catalyst with advantages of both solid and liquid catalysts is a challenge. Until now, ionic liquids (ILs), which are salts composed of large organic cations and inorganic or organic anions [10], have been used widely in the process of treatment for biomass [11,12]. Some properties of ILs can be tailored by the manipulation of constituent ions, and ILs show excellent catalytic properties. Recently, ILs were applied widely in the conversion of carbohydrates into furfural as solvents [1,13,14,15,16]. In some cases, ionic liquids were used as catalysts for the conversion of biomass [17,18,19]. One of challenges is the separation of ILs in subsequent processes. A key to realize this aim is the structure of IL. Therefore, a form of imidazole-based IL with phase separation at low temperatures and water solubility at high temperatures has been designed and synthesized, which holds simultaneously the advantages of solid catalyst and liquid catalyst.

The aim of this work is to investigate the dehydration of xylose to furfural catalyzed over IL at low temperatures (393–453 K) and present an environmentally friendly technology for the catalytic dehydration of xylose to furfural. IL is highly acidic, as it contains a sulfonic acid and hydrogen sulfate. IL, in the process, holds performances such as free separation and extractant. The suitable conditions for maximum yield of furfural are presented. A kinetic model is proposed.

2. Results and Discussion

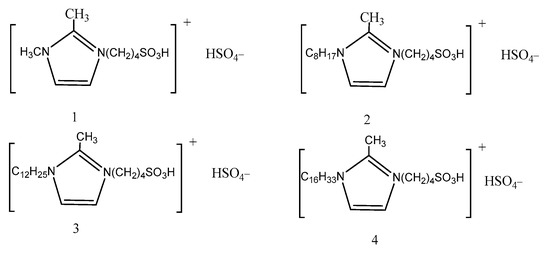

ILs were synthesized or purchased in order to determine an effect of the structure of ILs on its water solubility. The structures of ILs were shown in Scheme 1.

Scheme 1.

The structures of ILs.

ILs with different R (methyl, octyl, dodecyl, cetyl) were synthesized as following Scheme 2, and water solubility tests of ILs were carried out above 70 °C and below 40 °C, respectively. Entry 1 was liquid and water-soluble at room temperature. Entry 2 was semi-solid and fell short of our requirement at room temperature. Entries 3 and 4 were solid, and their properties had marked change. However, Entry 3 dissolved in water below 40 °C, which was outside our requirements. Entry 4 (1-(4-sulfonic acid) butyl-3-cetyl-2-methylimidazolium hydrogen sulfate) met the design requirements and was used in follow-up experiments.

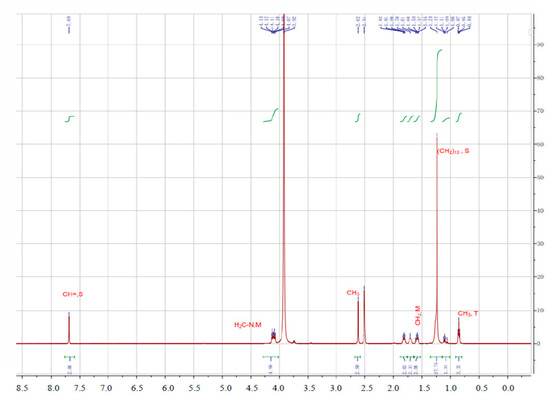

Scheme 2.

The synthesis routes of imidazolium-based ionic liquid.

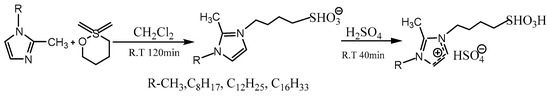

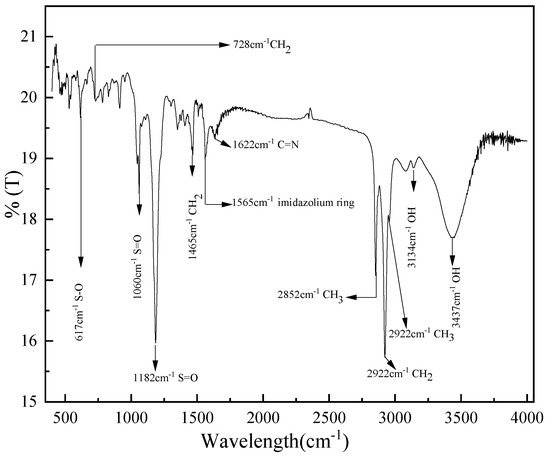

Figure 1 showed the FT-IR spectrum of 1-(4-sulfonic acid) butyl-3-cetyl-2-methyl imidazolium hydrogen sulfate. The peaks at 3134 and 3412 cm−1 were attributed to the stretching of the hydroxyl group (sulfonic acid group and hydrogen sulfate). The peak at about 2950 cm−1 was an asymmetric stretching vibration of the CH3 groups. A strong peak at 2922 cm−1 can be related to the (-CH-)n (n < 4) antisymmetric stretching vibration. The band at 2852 cm−1 was related to CH3. C=N vibrations at 1622 cm−1 were observed. The peak at 1565 cm−1 can be assigned to the imidazolium ring. A strong peak at 1465 cm−1 which was assigned the bending vibration of CH2 was found. The characteristic peaks of IL at around 1182 cm−1 and 1060 cm−1 could be clearly observed in Figure 1, which were ascribed to S=O asymmetric and symmetric stretching vibrations of the -SO3H group, respectively. In addition, S-O vibrations could be observed at 617 cm−1 [20]. A peak at around 728 was attributed to (-CH-)n (n > 4). These special IR peaks indicated that hydrogen sulfate was successfully assembled by 1-(4-sulfonic acid) butyl-3-cetyl-2-methyl imidazolium molecule as a cation for the corresponding ionic liquid (Entry 4). A detailed analysis of the 1H NMR spectrum of IL (Figure 2) is listed in Table 2.

Figure 1.

FT-IR spectra of 1-(4-sulfonic acid) butyl-3-cetyl-2-methylimidazolium hydrogen sulfate.

Figure 2.

1H NMR spectra of 1-(4-sulfonic acid) butyl-3-cetyl-2-methylimidazolium hydrogen sulfate (300 MHz, DMSO).

The acid-catalyzed dehydration of xylose to furfural usually proceeds via the consecutive protonation of hydroxyl groups (forming H2O+ groups) and cleavage of the C-O bonds, leading to the liberation of water molecules (three overall) and formation of trivalent carbocation intermediates which undergo deprotonation, resulting in C=C bond formation [4].

Time, temperature, and catalysts are the key factors for xylose dehydration reaction. In the study, all factors were conducted. The low furfural yield of the dehydration of xylose to furfural in water was reported for the prolonged reaction time due to the formation of byproducts, polymerization, resinification, and condensation reactions, etc. [21]. Thus, the influence of reaction time on xylose conversion and furfural yield was studied between 30–240 min at 160 °C. The results are shown in Figure 3a. It was found that the percentage of xylose conversion and furfural yield increased with the prolonged reaction time, and the maximum yield of furfural (67.5%) was obtained at 180 min with 95.3% conversion. Further, the furfural yield decreased with the increase in reaction time, even though xylose conversion was 95.3%. The reaction time was above 180 min, and furfural yield in fact decreased with high xylose conversion. A prolonged time promoted the formation of by products and the decomposition of furfural. Thus, higher xylose conversion and lower furfural yield at a longer reaction time were found due to the conversion of xylose into cyclic intermediates or the decomposition of xylose to other byproducts, such as the condensation of furfural [22,23], suggesting that side reactions were dominant. Therefore, the reaction time should not be longer than 180 min. Figure 3b showed the effect of temperature on xylose conversion and furfural yield. It was noted that the maximum conversion and yield were obtained at 160 °C, but the reaction temperature was above 160 °C and furfural yield decreased. The decrease in yield at 160 °C indicated that side reaction rates increased more than that of furfural formation [24]. Subsequently, temperature (160 °C) and time (120 min) were used as reaction conditions. By comparison, the performance of IL was higher than that of high-temperature water and comparable to that of others (Figure 3c). Xylose conversion and furfural yield were only ca. 25% and 15% by HTW (high-temperature water) as a catalyst, respectively. Xylose conversion of ca. 95.3% and furfural yield of ca. 67.5% were achieved over IL, which was comparable to that of liquid acid. The results showed that IL dissolved in water and formed acid solution at high temperature, which catalyzed the dehydration of xylose to furfural. IL showed potential for the dehydration of xylose to furfural. One reason was that IL can provide acidic conditions for the dehydration of xylose. Another possible reason was that IL could play a role as solvent for large bulk, and could also transfer the furfural product from the reaction mixture and prevent furfural dehydration. Recycling of the catalyst was important to develop the industrial catalyst. However, the IL catalyst was used for up to three consecutive recycle runs without regeneration. The results are shown in Figure 3d after three consecutive recycle runs. Results show that there is inconsistency in furfural yield and xylose conversion. The inconsistency in yield and conversion indicate that the IL was unstable. Furfural yield decreased from 65% to 42%, which was attributed to the loss of hydrion. The spent IL was regenerated by solution (4 wt.% H2SO4), and furfural yield of ca. 62% was achieved (in Figure 2d). The regenerated catalyst complied with the fresh catalyst, thus confirming that the IL catalyst has potential for industry.

Figure 3.

Catalytic performance of IL for dehydration of xylose to furfural. Reaction conditions (a): T = 160 °C, (b): t = 3 h, (c): t = 3 h T = 160 °C, (d): T = 160 °C t = 3 h, (C = 10 wt.% (0.67 mol/L), n (xylose):n (IL) = 5:1).

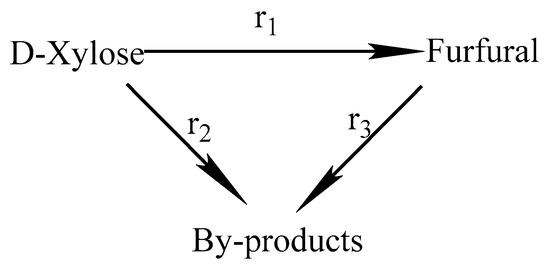

The kinetic studies in aqueous solution were carried out with IL as a catalyst. The reaction mechanism consisted of furfural formation, furfural loss reactions, and furfural degradation (Scheme 3). The three reactions were also assumed to be irreversible, and the first reaction (r1) shows the dehydration of D-xylose to furfural, which was assumed to be an irreversible first-order reaction [25,26].

where R is the reaction rate (mol/(L·s), [] is the xylose concentration (mol/L) and k is the reaction rate constant (s−1).

Scheme 3.

Kinetic mechanism for the conversion of xylose.

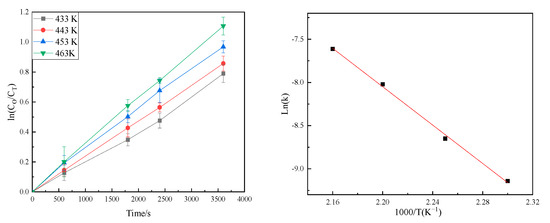

In order to evaluate the reproducibility of the data, experiments were repeated three times under the same conditions in Figure 4. The corresponding standard deviations ranged from 2.0% to 7.0%. Therefore, it was concluded that the accuracy of the data might be satisfactory. The research focused on the reactions (r1). The model with first-order kinetics (r1) fitted well with the experimental data. The Arrhenius expression gave a good fit to the rate constants obtained, as illustrated in Figure 3. The corresponding activation energy of 92.1 kJ/mol correlated well with the value obtained by [27]. In Table 1, the Arrhenius parameters are listed for the reaction.

Figure 4.

Arrhenius plot of k for the temperature range 433–463 K.

Table 1.

Kinetic parameter of xylose to furfural on IL.

3. Materials and Methods

3.1. Materials

1-(4-sulfonic acid) butyl-3-R(methyl, octyl, dodecyl, cetyl)-2-methylimidazolium hydrogen sulfate (95 wt.%) was from Shanghai Mooney Chemical Technology Co., Ltd. (Shanghai, China). All chemicals used were from Sigma-Aldrich (Shanghai, China), as follows: Xylose (≥99.0 wt.% purity), furfural (≥99.0 wt.% purity).

3.2. Instruments

The target IL was characterized by FT-IR, 1H NMR. The spectra ranging from 400 to 1300 cm−1 were collected on the Digilab FTS-3000 FT-IR spectrometer using KBr pellet technique. IL was determined by Avance III 300 MHz 1H-NMR spectroscopy (Bruker Company, Karlsruhe, Germany).

3.3. Synthesis of Catalysts

ILs were synthesized or purchased. Reaction of neutral nucleophile imidazole derivates (0.3 mol) with 1,4-butane sultone (0.3 mol) formed the requisite zwitterions. Subsequently, the synthesized solid was washed repeatedly with ether and was filtrated to remove non-ionic residues and dried under a vacuum. Then, sulfuric acid (98%, 16.4 mL) was added dropwise to a 200 mL three-port conical flask containing the solid at 0 °C. The mixture was stirred at 80 °C for 10 h. Product was washed with diethyl ether and dried in vacuo at 40 °C for 4 h to obtain the armed product. We synthesized various ionic liquids in order to verify the effect of branched chains on their water solubility, and screened ionic liquids that met the requirements (See Table 2).

Table 2.

1H NMR data and analysis.

3.4. Reactions

In the reaction, xylose (2.5 g), catalyst (0.5 g), and distilled water (25 mL) were poured into a reactor (autoclave); xylose concentration and the ratio of xylose to IL was 10 wt.% and 5, respectively. The reactor was heated to a temperature and kept for the set time. The composition of aqueous phase was determined on an LC-20AD (Shimadzu, Japan) equipped with a RID-10A refractive index detector and a Bio-rad Aminex HPX-87H column (300 × 7.8 mm). The conversion of xylose, selectivity of furfural, and yield of furfural were estimated by the following equations:

4. Conclusions

The dehydration of xylose to furfural in aqueous solution by acidic ionic liquid (1-(4-sulfonic acid) butyl-3-cetyl-2-methyl imidazolium hydrogen sulfate) catalyst was studied in a temperature range of 433–463 K. The results indicated that the catalyst holds the characteristics of easy separation and high-mass transfer, and exhibits a great potential for the replacement of conventional catalysts. The excellent catalytic performance of IL was attributed to the strong Bronsted acidity of IL (double position acids, sulfonic acid, and hydrogen sulfate). A first-order kinetic model with an activation energy of 92.4 kJ/mol was observed. A suitable temperature was found to be 433 K, where a balance between the rate of formation of furfural and the degradation of furfural was achieved. At this temperature, a SO3H-functionalized ionic liquid exhibited high catalytic activity for the synthesis of furfural from xylose (xylose conversion of 95.3% and furfural yield of 67.5%).

Author Contributions

Conceptualization, D.H., J.L. and H.D.; methodology, B.H.; software, Y.L.; validation, D.H. and B.H.; formal analysis, D.H. and J.L.; investigation, D.H.; resources, D.H.; data curation, H.D.; writing—original draft preparation, D.H. and H.D.; writing—review and editing, D.H.; visualization, B.H.; supervision, D.H.; project administration, D.H.; funding acquisition, D.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 21466001 and Open Foundation of Key Laboratory of Jiangxi University for Functional Materials Chemistry (FMC17301).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are available within the article.

Conflicts of Interest

All authors declare no conflict of interest.

References

- Xiao, S.; Liu, B.; Wang, Y.; Fang, Z.; Zhang, Z. Efficient conversion of cellulose into biofuel precursor 5-hydroxymethylfurfural in dimethyl sulfoxide–ionic liquid mixtures. Bioresour. Technol. 2014, 151, 361–366. [Google Scholar] [CrossRef]

- O’Neill, R.E.; Vanoye, L.; De Bellefon, C.; Aiouache, F. Aldol-condensation of furfural by activated dolomite catalyst. Appl. Catal. B Environ. 2014, 144, 46–56. [Google Scholar] [CrossRef]

- Gómez Millán, G.; Hellsten, S.; Llorca, J.; Luque, R.; Sixta, H.; Balu, A.M. Recent Advances in the Catalytic Production of Platform Chemicals from Holocellulosic Biomass. ChemCatChem 2019, 11, 2022–2042. [Google Scholar] [CrossRef]

- Hua, D.; Li, P.; Wu, Y.; Chen, Y.; Yang, M.; Dang, J.; Xie, Q.; Liu, J.; Sun, X.-Y. Preparation of solid acid catalyst packing AAO/SBA-15-SO3H and application for dehydration of xylose to furfural. J. Ind. Eng. Chem. 2013, 19, 1395–1399. [Google Scholar] [CrossRef]

- Li, Q.; Hu, Y.; Tao, Y.-Y.; Zhang, P.-Q.; Ma, C.-L.; Zhou, Y.-J.; He, Y.-C. Improving Biocatalytic Synthesis of Furfuryl Alcohol by Effective Conversion of D-Xylose into Furfural with Tin-Loaded Sulfonated Carbon Nanotube in Cyclopentylmethyl Ether-Water Media. Catal. Lett. 2021, 151, 3189–3196. [Google Scholar] [CrossRef]

- De Lima, L.F.; Lima, J.L.M.; Jorqueira, D.S.S.; Landers, R.; Moya, S.F.; Suppino, R.S. Use of amorphous Nb2O5 and Nb2O5/Al2O3 as acid catalysts for the dehydration of xylose to furfural. React. Kinet. Mech. Catal. 2021, 132, 73–92. [Google Scholar] [CrossRef]

- Wang, R.; Liang, X.; Shen, F.; Qiu, M.; Yang, J.; Qi, X. Mechanochemical Synthesis of Sulfonated Palygorskite Solid Acid Catalysts for Selective Catalytic Conversion of Xylose to Furfural. ACS Sustain. Chem. Eng. 2020, 8, 1163–1170. [Google Scholar] [CrossRef]

- Mérida-Morales, S.; García-Sancho, C.; Oregui-Bengoechea, M.; Ginés-Molina, M.J.; Cecilia, J.A.; Arias, P.L.; Moreno-Tost, R.; Maireles-Torres, P. Influence of morphology of zirconium-doped mesoporous silicas on 5-hydroxymethylfurfural production from mono-, di- and polysaccharides. Catal. Today 2021, 367, 297–309. [Google Scholar] [CrossRef]

- Gómez Millán, G.; Bangalore Ashok, R.P.; Oinas, P.; Llorca, J.; Sixta, H. Furfural production from xylose and birch hydrolysate liquor in a biphasic system and techno-economic analysis. Biomass Convers. Biorefinery 2021, 11, 2095–2106. [Google Scholar] [CrossRef] [Green Version]

- Clough, M.T.; Geyer, K.; Hunt, P.A.; Son, S.; Vagt, U.; Welton, T. Ionic liquids: Not always innocent solvents forcellulose. Green Chem. 2015, 17, 231–243. [Google Scholar] [CrossRef] [Green Version]

- Kotadia, D.A.; Soni, S.S. Symmetrical and unsymmetrical Bronsted acidic ionic liquids for the effective conversion of fructose to 5-hydroxymethyl furfural. Catal. Sci. Technol. 2013, 3, 469–474. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q.; Liu, X.; Chang, F.; Hu, D.; Zhang, Y.; Xue, W.; Yang, S. InCl3-ionic liquid catalytic system for efficient and selective conversion of cellulose into 5-hydroxymethylfurfural. RSC Adv. 2013, 3, 3648–3654. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, H.; Wang, P. Solid acids as catalysts for the conversion of d-xylose, xylan and lignocellulosics into furfural in ionic liquid. Bioresour. Technol. 2013, 136, 515–521. [Google Scholar] [CrossRef] [PubMed]

- Serrano-Ruiz, J.C.; Campelo, J.M.; Francavilla, M.; Romero, A.A.; Luque, R.; Menendez-Vazquez, C.; Garcia, A.B.; Garcia-Suarez, E.J. Efficient microwave-assisted production of furfural from C5 sugars in aqueous media catalysed by Bronsted acidic ionic liquids. Catal. Sci. Technol. 2012, 2, 1828–1832. [Google Scholar] [CrossRef]

- Qi, X.; Watanabe, M.; Aida, T.M.; Smith, R.L. Synergistic conversion of glucose into 5-hydroxymethylfurfural in ionic liquid-water mixtures. Bioresour. Technol. 2012, 109, 224–228. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Liu, H.; Song, C.; Gu, X.; Li, H.; Zhu, W.; Yin, S.; Han, C. The dehydration of fructose to 5-hydroxymethylfurfural efficiently catalyzed by acidic ion-exchange resin in ionic liquid. Bioresour. Technol. 2013, 133, 347–353. [Google Scholar] [CrossRef]

- Zhou, L.; Liang, R.; Ma, Z.; Wu, T.; Wu, Y. Conversion of cellulose to HMF in ionic liquid catalyzed by bifunctional ionic liquids. Bioresour. Technol. 2013, 129, 450–455. [Google Scholar] [CrossRef]

- Shi, J.; Yang, Y.; Wang, N.; Song, Z.; Gao, H.; Xia, Y.; Li, W.; Wang, H. Catalytic conversion of fructose and sucrose to 5-hydroxymethylfurfural using simple ionic liquid/DMF binary reaction media. Catal. Commun. 2013, 42, 89–92. [Google Scholar] [CrossRef]

- Shi, J.; Gao, H.; Xia, Y.; Li, W.; Wang, H.; Zheng, C. Efficient process for the direct transformation of cellulose and carbohydrates to 5-(hydroxymenthyl)furfural with dual-core sulfonic acid ionic liquids and co-catalysts. RSC Adv. 2013, 3, 7782–7790. [Google Scholar] [CrossRef]

- Koukabi, N.; Kolvari, E.; Zolfigol, M.A.; Khazaei, A.; Shaghasemi, B.S.; Fasahati, B. A Magnetic Particle-Supported Sulfonic Acid Catalyst: Tuning Catalytic Activity between Homogeneous and Heterogeneous Catalysis. Adv. Synth. Catal. 2012, 354, 2001–2008. [Google Scholar] [CrossRef]

- Pawar, H.S. Sulfonic Acid Anchored Heterogeneous Acid-Catalyst DICAT-3 for Conversion of Xylose into Furfural in Biphasic Solvent System. ChemistrySelect 2020, 5, 916–923. [Google Scholar] [CrossRef]

- Rong, C.; Ding, X.; Zhu, Y.; Li, Y.; Wang, L.; Qu, Y.; Ma, X.; Wang, Z. Production of furfural from xylose at atmospheric pressure by dilute sulfuric acid and inorganic salts. Carbohydr. Res. 2012, 350, 77–80. [Google Scholar] [CrossRef] [PubMed]

- Cai, D.; Chen, H.; Zhang, C.; Teng, X.; Li, X.; Si, Z.; Li, G.; Yang, S.; Wang, G.; Qin, P. Carbonized core-shell diatomite for efficient catalytic furfural production from corn cob. J. Clean. Prod. 2021, 283, 125410. [Google Scholar] [CrossRef]

- Qi, Z.; Wang, Q.; Liang, C.; Yue, J.; Liu, S.; Ma, S.; Wang, X.; Wang, Z.; Li, Z.; Qi, W. Highly Efficient Conversion of Xylose to Furfural in a Water–MIBK System Catalyzed by Magnetic Carbon-Based Solid Acid. Ind. Eng. Chem. Res. 2020, 59, 17046–17056. [Google Scholar] [CrossRef]

- Weingarten, R.; Cho, J.; Conner, J.W.C.; Huber, G.W. Kinetics of furfural production by dehydration of xylose in a biphasic reactor with microwave heating. Green Chem. 2010, 12, 1423. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.B.; Lee, M.R.; Park, E.D.; Lee, S.M.; Lee, H.; Park, K.H.; Park, M.-J. Kinetic study of the dehydration of d-xylose in high temperature water. React. Kinet. Mech. Catal. 2011, 103, 267–277. [Google Scholar] [CrossRef]

- Root, D.F.; Saeman, J.F.; Harris, J.F.; Neill, W.K. Kinetics of the acid-catalyzed conversion of xylose to furfural. For. Prod. J. 1959, 9, 158–165. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).