Abstract

Sliding bearing alloy layers must combine excellent tribological performance with reliable metallurgical bonding, but conventional fabrication methods often suffer from coarse grains, chemical segregation and poor interface adhesion. Annular coaxial laser wire-feed cladding, by providing more uniform heat input and rapid solidification, is expected to mitigate these deficiencies; however, systematic studies of this technique applied to tin-based Babbitt alloy layers remain limited. In this work, Babbitt layers produced by conventional casting and by annular coaxial laser wire-feed cladding were compared in terms of microstructure, phase constitution, hardness and tribological behavior. The results indicate that laser cladding can produce continuous, dense and well-bonded coatings and markedly refine the SnSb phase, reducing grain size from approximately 100 μm in the cast material to 10-20 μm. Hardness increased from 25.3 HB to 27.6 HB, while tribological performance improved substantially: the coefficient of friction decreased by about 38.19% and the wear volume was reduced by approximately 10.46%. These improvements are attributed mainly to the rapid solidification, low dilution and more uniform phase distribution associated with annular coaxial laser cladding, demonstrating the strong potential of this process for fabricating high-performance tin-based Babbitt bearing layers.

1. Introduction

Sliding bearings, as critical components of mechanical systems [1], exhibit exceptional multidirectional load-carrying capacity and dynamic stability [2]. These superior properties render them indispensable support elements for extreme-condition equipment such as nuclear reactor coolant pumps [3] and marine propulsion systems [4] while simultaneously serving pivotal roles in high-speed rotor systems including wind turbine generators [5,6], aerospace applications [7], high-speed rail transport [8] and mining machinery [9] under heavy impact loading conditions. The tribological properties of bearing lining materials directly determine the operational reliability and service life of machinery. Among these materials, tin-based Babbitt alloys have emerged as an ideal choice for sliding bearing alloy layers due to their superior anti-friction characteristics, seizure resistance, and wear durability [10]. Conventional Babbitt alloy fabrication techniques (e.g., casting, spraying, and brazing) often suffer from non-uniform cooling, coarse grains, compositional segregation, weak interfacial bonding, and low material utilization efficiency. In contrast, laser cladding technology, as an advanced additive manufacturing approach, enables precise control over the geometric parameters of alloy layers through accurate process regulation. This technique demonstrates remarkable advantages including refined microstructure, homogeneous composition, strong interfacial bonding, low dilution rate, and high material utilization efficiency [11,12,13,14,15], thereby providing an innovative solution for preparing high-performance bearing tin-based Babbitt alloy layers.

The single-beam Gaussian laser serves as the conventional heat source for laser cladding of Babbitt alloy layers. Kim et al. [16] systematically investigated laser-clad tin-based Babbitt alloys, confirming the viability of this technique as an effective alternative manufacturing approach. Li et al. [17] employed Gaussian laser cladding to produce Sn-Cu-Sb coatings metallurgically bonded to stainless steel, consisting of a Sn-matrix with dispersed Cu6Sn5 and SnSb intermetallic phases. Hao et al. [18] conducted a systematic study on the laser cladding process for tin-based Babbitt alloy coatings. The results revealed that the laser-clad alloy exhibited a uniform and fine-grained microstructure with metallurgical bonding to the substrate, demonstrating significantly higher interfacial strength than conventional cast alloys. In recent years, the novel luminous coaxial annular laser cladding technology has been introduced into the cladding field [19]. With its unique annular spot energy distribution, this innovative technique achieves more uniform heat input and more stable molten pool dynamics, effectively overcoming the inherent limitations of conventional Gaussian laser cladding such as edge heat accumulation and central overheating. Edvard et al. developed a novel powder cladding head based on annular laser beam technology, which enables axial powder feeding and adjustable laser beam intensity distribution (LBID) on workpiece surfaces. Through laser direct wire deposition on 304 stainless steel substrates, they successfully deposited Ni wires and observed that the dilution rate decreased with increasing workpiece illumination proportion (WIP) [20]. Subsequent research on 316L stainless steel powder cladding on 304 stainless steel substrates investigated the influence of LBID variation in axial powder feeding processes [21]. Alexander Kuznetsov [22] systematically investigated the cladding of AISI 316L powder onto SS 304 substrates, evaluating both process feasibility and the influence of processing parameters on powder catchment efficiency. Through systematic characterization of conventional parameters and WIP, Kotar [23] revealed their distinct impacts on process stability and clad geometry in coaxial wire-fed annular laser cladding of AISI 316L, with laser power demonstrating nonlinear dependence on workpiece irradiation proportion. Wang et al. [24] conducted simulation studies on the powder flow behavior in a novel internal-laser coaxial two-airflow powder feeding system. Subsequent annular laser direct metal deposition experiments demonstrated crack-free deposited layers without structural defects.

Although significant progress has been made in research on Gaussian laser cladding of Babbitt alloys, studies on the preparation of Babbitt alloy coatings using annular laser coaxial wire-feed cladding technology remain relatively limited. This study systematically compares the microstructural characteristics and mechanical properties of Babbitt alloys prepared by conventional casting and annular laser coaxial wire-feed cladding processes, aiming to elucidate the influence mechanisms of annular laser cladding on the microstructural evolution and mechanical properties of Babbitt alloys, thereby providing theoretical foundation and technical support for the development of novel high-performance bearing alloy layers.

2. Experiment Method and Devices

2.1. Laser Cladding of Babbitt Alloy Layer on Bearing Steel Substrate

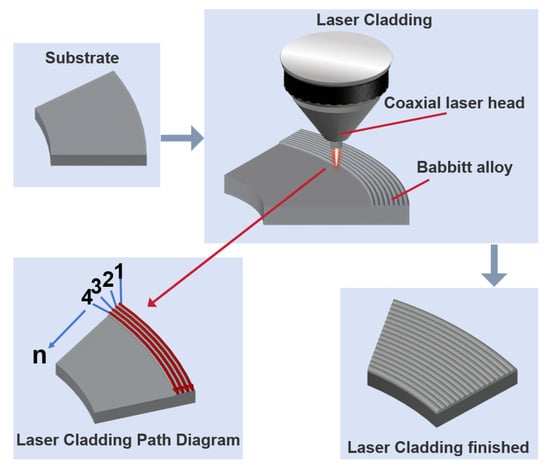

Grade 25 steel (GB/T 699-2015) [25] was selected as the substrate material, and tin-based Babbitt alloy ZSnSb11Cu6 wire with a diameter of 1.6 mm was employed as the cladding material. The laser cladding system primarily consisted of a Raycus Rfl-C3000S fiber laser and a Tolertek TL-WP-F100-F160-A-OTP coaxial wire-feeding laser head, both provided by Shanghai Tongli Laser Technology Co., Ltd. The experimental procedure comprised four main steps (Figure 1). (1) Steel surface pretreatment. The steel substrate surface was mechanically ground and subsequently subjected to ultrasonic cleaning in anhydrous ethanol, followed by surface drying. These procedures effectively eliminated surface impurities, corrosion products, and oxidation films, thereby ensuring interfacial cleanliness essential for the formation of superior metallurgical bonds. (2) Parameter setting and cladding path planning. Based on preliminary process optimization, the laser power was set to 2400 W, the wire feeding speed to 2.8 m min−1, the overlap offset to 1.7 mm, and the traverse speed to 25 mm s−1. The cladding path is designed using a unidirectional continuous scanning approach, beginning at one side of the substrate and ending at the other side, as illustrated in Figure 1. This strategy is implemented to avoid the temperature field asymmetry and molten pool turbulence phenomena commonly caused by bidirectional scanning. (3) Laser cladding process. Upon initiation of the laser cladding system, the wire material rapidly melts under the high-energy density laser (providing a linear energy input of 96 kJ/m and an energy density of approximately 43.6 J/mm2 over the annular spot), forming molten droplets that are continuously deposited. Concurrently, the laser energy partially melts the surface layer of the steel substrate, allowing the molten Babbitt alloy to thoroughly mix with the liquid steel substrate, thereby forming a metallurgical bonding interface. As the laser beam moves, the molten pool rapidly solidifies, resulting in a dense and uniform Babbitt alloy cladding layer. (4) Cooling and post-treatment. Following the completion of the cladding process, the deposited layer was naturally cooled to ambient temperature, which served to minimize residual stresses and mitigate crack initiation. Subsequently, upon complete cooling, post-treatment procedures comprising grinding and polishing were conducted to eliminate surplus alloy material and surface oxidation.

Figure 1.

Schematic Diagram of Annular Laser Cladding Process.

2.2. Casting of Babbitt Alloy Layer on Bearing Steel Substrate

The static casting process for depositing tin-based Babbitt alloy ZSnSb11Cu6 on 25# steel involves the following steps: First, the steel substrate is pre-treated using the same method as in laser cladding, and a solution of hydrochloric acid and ammonium chloride is applied to ensure the quality of the cast surface. Next, the cleaned mold is placed in a heating furnace and preheated to 150–200 °C to ensure uniform heating and prevent cracks due to temperature differences. The Babbitt alloy raw material is then heated in a furnace to 400–450 °C, with continuous stirring to ensure uniform composition and the removal of any surface dross. Once the alloy is fully melted and at the correct temperature, it is slowly poured into the preheated mold, maintaining a steady flow to avoid splashing and the formation of air bubbles. The casting is allowed to cool naturally to room temperature within the mold before demolding. Finally, the casting is cleaned and inspected, and any excess burrs and sprues are removed from the surface.

2.3. Structural and Performance Characterization

The surface morphology of the samples was examined using a JSM-6490LV scanning electron microscope (SEM, manufactured by JEOL Ltd., Tokyo, Japan). The SEM observations were conducted at an accelerating voltage of 15 kV. Phase composition was analyzed by X-ray diffraction (XRD, Bruker D8, Bruker Corp., Karlsruhe, Germany). The measurements were conducted using Cu Kα radiation (λ = 0.154 nm) over a 2θ range of 25–90° with a step size of 0.02°. Phase identification was carried out based on the PDF-2 2004 database without background subtraction. Metallographic observations were conducted with an OLYMPUS DSX1000 ultra-depth 3D digital microscope (manufactured by Olympus Corp., Tokyo, Japan). The polished samples were etched with a 4% nitric acid alcohol solution, thoroughly rinsed with deionized water, dried, and then examined under the microscope. The hardness of the Babbitt alloy layer was measured using a Laijin HBS-3000J digital Brinell hardness tester (manufactured by Laizhou Testing Machine & Diamond Tool Factory, Laizhou, China). A tungsten carbide (WC) spherical indenter with a diameter of 5 mm was employed. The tests were conducted under a load of 62.5 kgf with a dwell time of 60 s. Prior to hardness measurement, the test surfaces were prepared to a surface roughness of ≤1.6 µm (Ra) to minimize measurement deviations. Five individual measurements were taken at well-spaced locations on each sample to avoid any influence from adjacent indentations, and the average value was calculated as the reported hardness. The interfacial bond strength was determined by tensile testing in accordance with the Chinese National Standard GB GB/T 18329.2 [26] (equivalent to International Standard ISO 4386-2 [27]). The tests were performed using a WAW-300B microcomputer-controlled electro-hydraulic servo universal testing machine manufactured by Jinan Xinguang Testing Machine Manufacturing Co., Ltd. (Jinan, China). The geometry of the tensile specimen is shown in Figure S1 of the Supplementary Material, loading was applied at a constant displacement rate until failure occurred. Tribological properties were evaluated using an MFT-5000 multifunctional tribometer (Rtec Instruments, San Jose, CA, USA) in a reciprocating ball-on-disk configuration. A G10-grade precision steel ball with a diameter of 6.35 mm served as the counterpart. All tests were conducted at room temperature in ambient air under dry sliding conditions without lubrication. The specific test parameters were as follows: a normal load of 5 N, a reciprocating stroke of 5 mm, a frequency of 1 Hz, and a total test duration of 3600 s (corresponding to 3600 cycles). The coefficient of friction was recorded in real time by the instrument’s software. One test was performed per sample. The wear volume was quantified using three-dimensional profilometry, and the specific wear rate was subsequently calculated using the provided formula. The formula for specific wear rate (1) is:

where ∆V is the wear volume, Fn is the normal load, and L is the total sliding distance.

3. Results and Discussion

3.1. Surface Quality and Miacro-Structure of the Alloy Layer

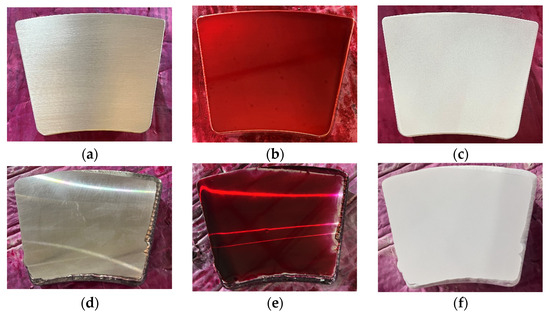

The surface defects of the materials were examined using dye penetrant inspection (DPI). As shown in Figure 2, microscopic porosity was observed on the cast alloy surface, whereas the laser-clad alloy layer exhibited a uniform and dense microstructure with no significant penetrant residue or defect indications. These results further confirm the stability and reliability of the laser cladding process, demonstrating that optimized process parameters—including laser power, scanning speed, and powder feed rate—effectively mitigate surface cracks and porosity caused by thermal stress concentration or excessive cooling rates during the cladding process. Additionally, the superior surface quality of the cladding layer indicates that the Babbitt alloy powder achieved complete melting and uniform distribution within the molten pool, thereby ensuring the structural integrity and continuity of the cladding layer.

Figure 2.

Dye penetrant inspection of the alloy layers. (a) Surface of the cast Babbitt alloy. (b) Surface coloring of cast alloy layer. (c) the cast Babbitt alloy coated with penetrant developer. (d) Surface of the laser-clad Babbitt alloy. (e) Surface coloring of the laser-clad Babbitt alloy. (f) The laser-clad Babbitt alloy coated with penetrant developer.

3.2. Microstructural Analysis by Metallographic Examination

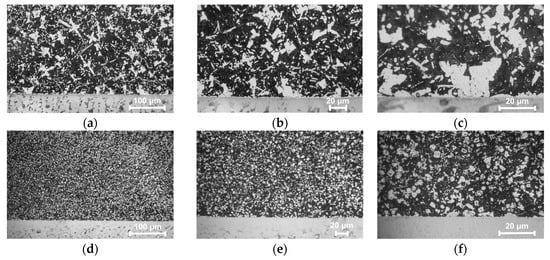

Microstructural characterization of the alloy layer was performed through metallographic analysis. According to the Sn-Sb-Cu ternary phase diagram [28], when the copper content (mass fraction) ranges from 0.5% to 8% and the antimony content exceeds 8%, the microstructure of the Babbitt alloy primarily consists of three phases: the Sn solid solution phase, the SnSb and the Cu6Sn5 intermetallic compound [29,30].

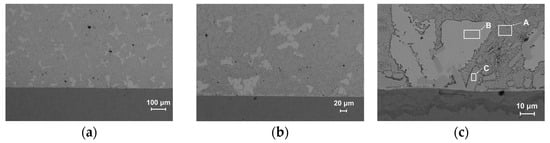

To characterize the interfacial microstructure, metallographic analysis was performed. As shown in Figure 3, micrographs of the interface for both samples are presented at magnifications of 100×, 200×, and 500×. In all micrographs, the Babbitt alloy is located above the substrate. In the as-cast samples (Figure 3a–c), the microstructure exhibits coarse SnSb phases with blocky and dendritic morphologies embedded in the soft black Sn matrix, along with finely dispersed Cu6Sn5 phases. The SnSb grains are notably large, reaching up to ~100 μm in size, and exhibit interconnected grain structures. In contrast, the laser-clad samples (Figure 3d–f) demonstrate a significantly refined microstructure, where the SnSb phase grain size is reduced to ~10–20 μm, and both the SnSb and Cu6Sn5 phases are uniformly distributed [31,32].

Figure 3.

Metallographic Image of the Alloy Interface. (a–c) Cast sample. (d–f) Laser clad sample.

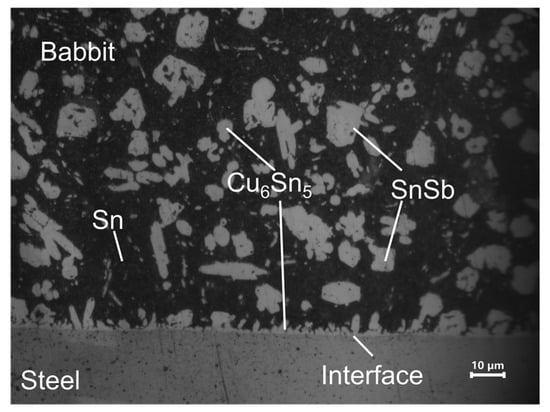

High-magnification metallographic observation (Figure 4) reveals that the Babbitt alloy grains in the laser-clad samples exhibit preferred growth along the interface, confirming a well-established metallurgical bond. Notably, the interfacial region is predominantly enriched with the Cu6Sn5 phase, which effectively impedes crack propagation and enhances interfacial bonding strength. Additionally, the fine and homogeneous distribution of the SnSb phase contributes to improved fatigue resistance [33]. These results demonstrate that, under the experimental conditions of this study, the laser cladding process can achieve satisfactory interfacial bonding without preheating the steel substrate, providing a basis for process simplification.

Figure 4.

Metallographic image of the laser-clad alloy interface under high magnification.

3.3. Crystal Structure and Phase Analysis of the Alloy Layer

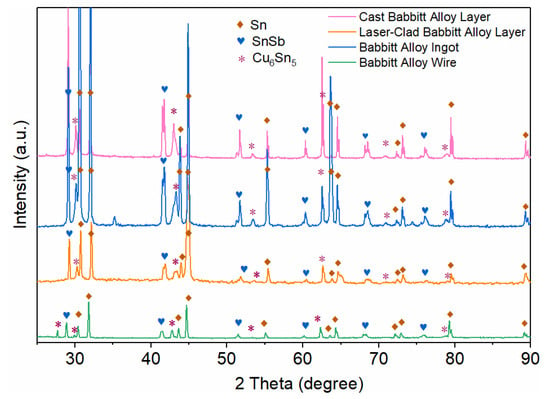

To investigate the influence of different preparation processes on the phase composition of babbitt alloy, X-ray diffraction (XRD) analysis was performed on four samples: the Babbitt alloy ingot, the cast alloy layer, the Babbitt alloy wire, and the laser-clad Babbitt alloy layer (Figure 5).

Figure 5.

XRD patterns of the Cast Babbitt alloy layer, laser-clad Babbit alloy layer, Babbit alloy ingot and the Babbit alloy wire.

The results reveal that all samples consist of the Sn matrix phase (PDF No. 04-0673) [34,35,36], the SnSb intermetallic compound phase (PDF No. 33-0118) [37], and the Cu6Sn5 intermetallic compound phase (PDF No. 45-1488) [38]. Quantitative analysis indicates that the mass fractions of the Sn phase in Babbitt alloy ingot, as-cast Babbitt alloy layer, Babbitt alloy wire and laser-clad Babbitt alloy layer are 69.45%, 58.36%, 40.51% and 55.61%, respectively; those of the SnSb phase are 14.49%, 21.57%, 13.96% and 14.75%; while the Cu6Sn5 phase, which serves as the main strengthening phase, accounts for 16.06%, 20.07%, 45.53% and 29.64% in the corresponding samples.

Notably, the strongest diffraction peak of the Sn phase in the laser-clad Babbitt alloy layer appears at 2θ = 44.9°, whereas the corresponding strong peak of the Sn phase in the cladding wire is located at 2θ ≈ 32.0°. This peak shift may originate from a preferred orientation or residual stress induced by the extremely high cooling rate during the laser-cladding process [39]. In contrast, the diffraction peak positions of the SnSb and Cu6Sn5 phases remain highly stable across all samples. Their strongest peaks are located at 2θ ≈ 29.0° (corresponding to the (002) plane) and 62.6°, respectively, consistent with the standard PDF cards, confirming the good stability of their crystal structures. The higher content of the hard Cu6Sn5 phase in the laser-cladded alloy layer contributes to the enhancement of its hardness, which is in good agreement with the hardness test results presented later in this work.

3.4. Microstructure Morphology Analysis of the Alloy Layers

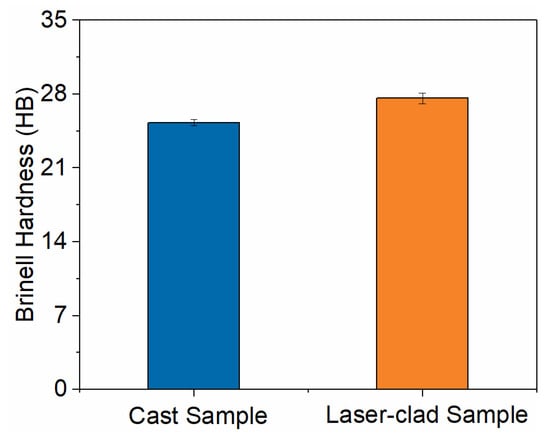

To comprehensively investigate the surface micro-morphology at the interface between cast and laser-clad Babbitt alloy layers, SEM images of the etched interface were captured at various magnifications. Figure 6a–c and d–f illustrate the cross-sectional micro-morphology of the cast and laser-clad alloy layers at magnifications of 100, 200, and 1000 times, respectively. Consistent with the metallographic images, a bright blocky SnSb phase is embedded in the gray Sn substrate, accompanied by acicular Cu6Sn5. The laser-clad layer exhibits finer grains and is free of pores and cracks, with a uniform distribution of constituents, indicating good densification of the alloy layer. Overall, the laser-clad alloy layer displays homogeneous physical and chemical properties, which can prevent performance fluctuations caused by localized defects.

Figure 6.

SEM of samples prepared by two methods. (a–c) Cast alloy layer microstructure at 100×, 200×, and 1000× magnification. (d–f) Laser clad alloy layer microstructure at 100×, 200×, and 1000× magnification. Regions A and D correspond to the Sn phase, regions B and E represent the SnSb phase, and regions C and F correspond to the Cu6Sn5 phase.

EDS compositional analysis of the phases in Figure 6c,f, summarized in Table 1, accurately quantified the chemical compositions of the phases in the as-cast (Figure 6c) and laser-clad (Figure 6d) samples, revealing three main phases: a Sn-rich matrix phase (β-Sn), a hard SnSb intermetallic, and a strengthening Cu6Sn5 intermetallic.

Table 1.

Results of the EDS analysis conducted on the Phases observed in Figure 6c,d.

Regions A and D correspond to the Sn-rich matrix (β-Sn). The notably higher Sn content (77.59 wt%) and lower Sb content in the laser-clad layer (Region D) indicate that rapid solidification suppressed the solid solution of Sb in β-Sn, resulting in a purer matrix. In theory, a purer and softer Sn matrix facilitates the formation of a continuous lubricating film during sliding, which is expected to improve friction compatibility. Regions B and E are identified as the hard SnSb phase. The composition of the SnSb phase in the laser-clad layer (Region E: Sn 56.02 wt%, Sb 43.48 wt%) is closer to its theoretical stoichiometry (SnSb), and metallographic observations show a significantly refined microstructure. Such a nearly stoichiometric, fine and uniformly dispersed hard phase can act as an effective wear-resistant skeleton, distributing the load more uniformly and thus potentially enhancing the macro-scale wear resistance of the material. Regions C and F are both confirmed as the Cu6Sn5 phase. Their highly consistent compositions demonstrate that this phase’s crystal structure is stable regardless of the fabrication process. In the laser-clad layer, Cu6Sn5 is enriched at the interface, which contributes to strong metallurgical bonding, while its uniform distribution throughout the clad layer also provides overall strengthening.

In summary, laser cladding, through rapid solidification, reconstructs the microstructure: it promotes the precipitation of Sb to form fine, dispersed SnSb hard particles, while simultaneously distributing Cu uniformly to create a Cu6Sn5 strengthening network that is homogeneous overall and locally enriched at the interface. This synergistic structure—characterized by matrix purification, fine and dispersed hard phases, and a strengthening phase with dual-mode distribution (bulk-uniform plus interface-enriched) forms the microstructural basis for the improved material performance.

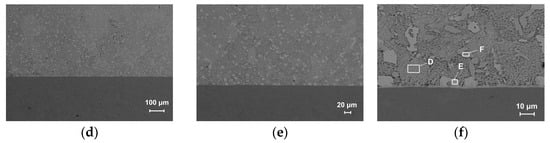

3.5. Hardness Measurement Results

To evaluate the hardness of the alloy layers, Brinell hardness tests were conducted using a digital hardness tester with a 5 mm diameter tungsten carbide indenter, under a test load of 62.5 kgf, and a dwell time of 60 s. Five indentations were measured, and the arithmetic mean was calculated. As shown in Figure 7, the average hardness of the cast Babbitt layer was 25.3 HB, while the average hardness of the laser-clad Babbitt layer was 27.6 HB, representing an increase of approximately 2.3 HB in the laser-clad layer compared to the cast layer. Metallographic and SEM analyses revealed significant grain refinement in the laser-clad layer, which can directly contribute to the hardness increase through the Hall–Petch effect.

Figure 7.

The Brinell hardness values of samples prepared by two methods.

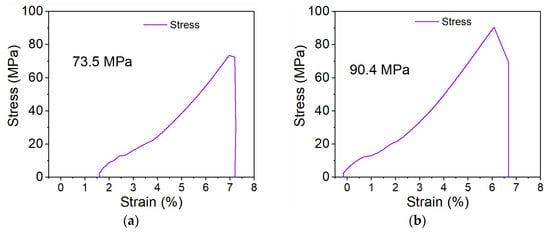

3.6. Analysis of the Bonding Performance Between the Alloy Layer and Substrate

The interfacial bond strength between the Babbitt alloy layer and the steel substrate was determined by tensile testing. Figure 8 presents representative Stress–Strain Curves for the cast alloy layer and laser-clad alloy layer samples. The calculated bond strength of the cast specimen was 73.5 MPa, whereas that of the laser-clad sample was 90.4 MPa, corresponding to an increase of approximately 23.0% under identical test conditions. This marked improvement indicates that the laser-cladding process enhances interfacial bonding quality and strength. Microstructural analysis shows that the laser-clad layer has finer, denser grains, is free of pores and cracks, and exhibits a uniform elemental/phase distribution, all of which favor the formation of a robust metallurgical bond, reduce the risk of interface-related failure, and contribute to more stable in-service performance.

Figure 8.

The Stress–Strain Curve Diagram. (a) The Stress–Strain Curve of cast sample. (b) The Stress–Strain Curve of laser-clad sample.

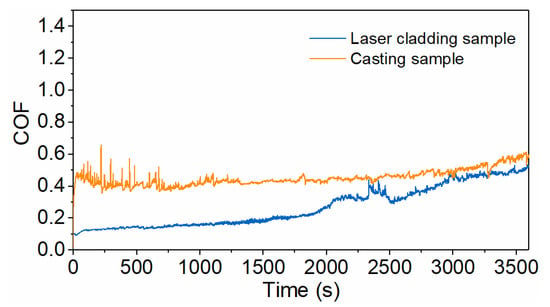

3.7. Tribological Performance of the Alloy Layer

Reciprocating ball-on-disk wear tests were performed to characterize the tribological behavior of the alloy layer. A G10-grade precision steel ball (diameter 6.35 mm) was used as the counterbody. Test conditions were set as follows: normal load 5 N, reciprocating stroke 5 mm, frequency 1 Hz, and test duration 3600 s. The coefficient of friction (COF) was recorded dynamically, and wear volumes was quantified by three-dimensional profilometry. Figure 9 presents the friction curves, where the blue line corresponds to the laser-clad sample and the yellow line to the cast sample. The average COF values were 0.4520 for the cast sample and 0.2794 for the laser-clad sample, i.e., the average COF of the laser-clad sample was reduced by approximately 38.19% relative to the cast sample.

Figure 9.

Friction coefficient curves of samples produced by laser cladding and casting processes.

The friction-coefficient-versus-time curves indicate that the as-cast sample exhibits large fluctuations in COF during the early stage of the test, and shows a gradual increase after approximately 3300 s. By contrast, the laser-cladded sample displays a lower overall COF, with an initial value of about 0.0926 that increases slowly at first, then the rate of increase accelerates after roughly 2000 s, and the COF approaches a steady state after approximately 3000 s.

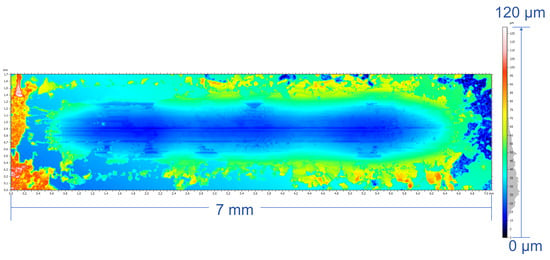

The pseudocolor wear maps and SEM morphology after the friction tests were presented in Figure 10 and Figure 11, revealing markedly different wear morphologies between the two samples. The wear scar of the as-cast alloy layer exhibits a characteristic three-lobed bulging morphology, with raised regions at both ends and a slightly narrower central bulge. This non-uniform wear pattern is consistent with a saddle-shaped contact stress distribution, in which the contact stress is highest at the ends and lower at the center. The observations indicate that the as-cast alloy layer exhibits a combined adhesive-abrasive wear mechanism, with localized fatigue spalling pits at coarse grain boundaries or porosity-induced defects, resulting in non-uniform wear width accompanied by significant material transfer and spalling [40,41].

Figure 10.

Friction and wear morphology of cast sample.

Figure 11.

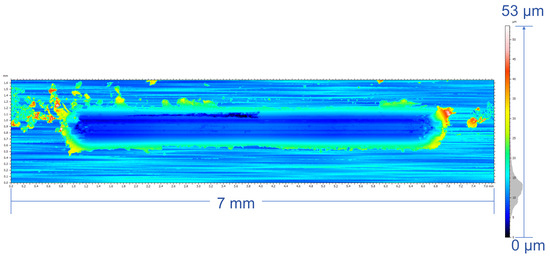

Friction and wear morphology of Laser-clad sample.

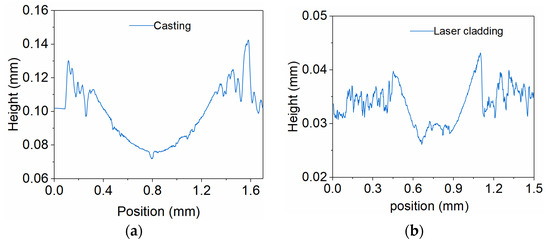

The 2D cross-sectional wear profile of the cast sample (Figure 12a) exhibits a wide groove, further corroborating this observation. In contrast, the laser-clad alloy layer showed predominantly mild abrasive wear, the surface exhibited regular, parallel frictional striations and no significant material transfer [42], features characteristic of abrasive wear under elastic contact conditions. These observations demonstrate that the laser-clad layer has higher hardness and a denser microstructure; grain refinement is beneficial for suppressing crack initiation, and fatigue spallation was not evident [36,43]. The cross-sectional wear profile of the laser-clad sample (Figure 12b) exhibits a pronounced, deep V-shaped groove, consistent with abrasive wear being the predominant mechanism. These results are consistent with the metallographic, SEM and microhardness test conclusions. The wear volume of the laser-clad alloy layer was 4.78 × 10−2 mm3 with a maximum depth of 2.98 × 10−2 mm, while the wear volume of the cast alloy layer was 5.28 × 10−2 mm3 with a maximum depth of 3.54 × 10−2 mm. Consistent with the friction measurements, higher friction coefficients are associated with increased material weight loss [40,44].

Figure 12.

The 2D wear morphology cross-sectional profile. (a) Cast sample. (b) Laser-clad sample.

The wear volume of the as-cast sample was approximately 10.46% greater than that of the laser-clad sample. The standardized volume wear rates of the laser-clad and as-cast alloy layers were 2.66 × 10−4 and 2.93 × 10−4 mm3·N−1·m−1, respectively. Overall, under identical test conditions, laser cladding markedly reduced the friction coefficient and improved wear resistance; this improvement is attributed to the finer, denser microstructure and higher hardness of the laser-clad layer, which act to suppress adhesive wear and fatigue spallation. These interpretations are supported by metallographic, SEM and microhardness analyses [45].

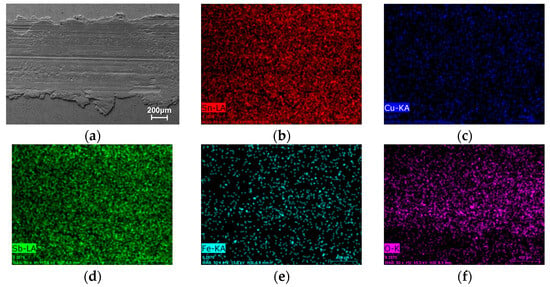

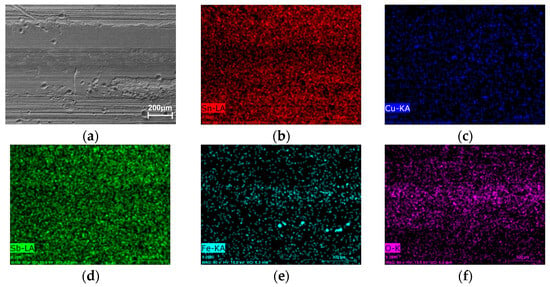

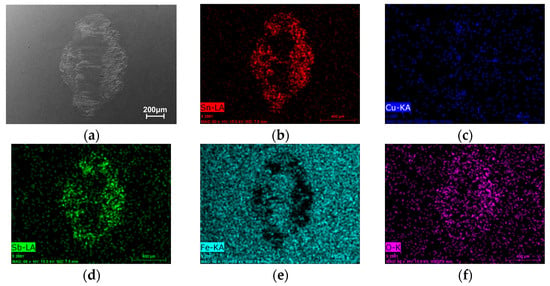

To further investigate the wear mechanisms, EDS elemental mapping was performed on the wear track surfaces (Figure 13, Figure 14, Figure 15 and Figure 16). Signals corresponding to Fe and O were detected in the wear tracks of both the as-cast and laser-clad alloy layers; however, their distribution patterns and relative intensities revealed fundamentally different dominant wear mechanisms.

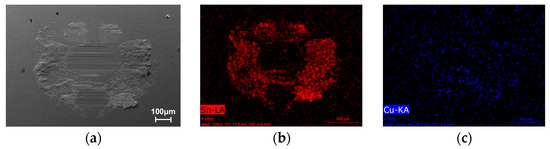

Figure 13.

SEM image and corresponding EDS elemental maps of the wear track on the as-cast alloy layer. (a) SEM of the wear track. (b–f) Distribution maps of Sn, Cu, Sb, and O, respectively.

Figure 14.

SEM image and corresponding EDS elemental maps of the wear track on the laser-clad alloy layer. (a) SEM of the wear track. (b–f) Distribution maps of Sn, Cu, Sb, and O, respectively.

Figure 15.

SEM image and corresponding EDS elemental maps of the wear track wear scar on the G10 steel ball counterpart after sliding against the as-cast Babbitt alloy layer. (a) SEM of the wear track. (b–f) Distribution maps of Sn, Cu, Sb, and O, respectively.

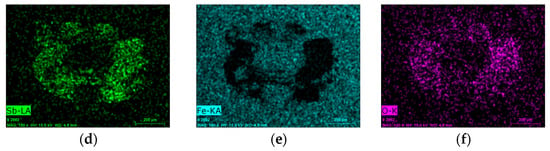

Figure 16.

SEM image and corresponding EDS elemental maps of the wear track wear scar on the G10 steel ball counterpart after sliding against the laser-clad Babbitt alloy layer. (a) SEM of the wear track. (b–f) Distribution maps of Sn, Cu, Sb, and O, respectively.

In the cast alloy wear track (Figure 13), the Fe signal within the wear track was strong and uniformly distributed. Combined with the SEM observation of severe material extrusion and smearing, this indicates that extensive, large-scale adhesive transfer occurred at an early stage of sliding. Material from the counterpart steel ball was continuously smeared onto the relatively soft as-cast surface. This is further corroborated by the distinct chemical signature on the counterpart ball itself, where its wear scar (Figure 15) shows a clear enrichment of Sn, Cu, and Sb elements transferred from the Babbitt alloy. The concurrent uniform distribution of O suggests that oxidation accompanied this process. The resulting composite structure—a soft matrix overlaid with a hard transferred layer- is prone to instability and spallation under cyclic stressing, generating third-body abrasives that intensify three-body abrasion, ultimately leading to a progressively increasing and highly fluctuating coefficient of friction.

In contrast, for the laser-clad alloy wear track (Figure 14), the overall Fe signal in the wear track was significantly weaker and exhibited pronounced local reduction. Meanwhile, clear enrichment of Sn, Cu, and Sb elements was detected at the periphery of the wear scar on the counterpart steel ball (Figure 16). This evidence demonstrates that a limited and controlled material exchange took place at the clad surface. Due to the higher hardness of the clad layer, adhesive effects were initially suppressed. As sliding progressed, trace amounts of surface material (Sn, Sb, Cu) underwent mild transfer to the steel ball under frictional heating and pressure, forming an ultrathin, sacrificial transfer film. This film, in turn, protected the underlying clad layer, thereby preventing extensive reverse transfer of Fe from the steel ball. The distribution of O within the wear track indicates that slight oxidation accompanied this process.

These mechanistic interpretations align perfectly with the macro-scale performance: the as-cast alloy, unable to resist severe adhesive transfer, entered a detrimental cycle of “material loss–oxidation–spallation,” manifesting as a high, fluctuating friction coefficient and large wear volume. In contrast, the laser-clad layer, owing to its higher hardness and refined microstructure, regulated the wear process into a stable regime dominated by mild abrasive wear, supplemented by controlled minor material exchange and oxidation. This resulted in a shallow, regular V-shaped wear track, a stable and low friction coefficient, and a significantly reduced wear volume. Consequently, the superiority of the laser-cladding process lies not only in enhancing the intrinsic material properties but also in actively guiding and stabilizing the dynamic behavior of the entire tribo-system.

4. Conclusions

Based on a systematic comparison of microstructure, mechanical properties, and tribological performance, annular laser coaxial wire-feed cladding demonstrates clear advantages over conventional casting for preparing Babbitt alloy layers. The laser-clad layer exhibits a uniform, defect-free surface and a significantly refined microstructure, with the SnSb phase grain size reduced from ∼100 μm (as-cast) to ∼10–20 μm. A sound metallurgical bond characterized by interfacial enrichment of the Cu6Sn5 strengthening phase is formed at the interface. The tensile bond strength reaches 90.4 MPa for the laser-clad layer—approximately 23.0% higher than that of the as-cast layer (73.5 MPa). The macro-hardness of the laser-clad layer is 27.6 HB, about 9% greater than that of the as-cast counterpart (25.3 HB). In tribological tests, the average coefficient of friction of the laser-clad layer is reduced to 0.2794 (∼38% lower than the 0.4520 of the as-cast layer), and its wear volume is decreased by about 10.5% (4.78 × 10−2 mm3 vs. 5.28 × 10−2 mm3). These findings collectively confirm that annular laser cladding effectively refines the microstructure, strengthens interfacial bonding, and enhances both mechanical and wear-resistant properties, offering a promising technical route for fabricating high-performance bearing surfaces. This study primarily focused on comparing the macroscopic properties of the alloy layers. Due to the scope of the work, a quantitative characterization of the gradient in micromechanical properties (e.g., nano-hardness) across the steel/alloy interfacial transition zone was not performed. Future research will employ advanced characterization techniques such as nanoindentation grid mapping and micropillar compression to establish quantitative relationships between the interfacial microstructure and local mechanical properties.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/mi17010134/s1. Figure S1. Schematic diagram of the tensile specimen geometry; Figure S2. Schematic illustration of the ball-on-disk reciprocating wear test setup.

Author Contributions

Conceptualization, G.W. and J.J.; methodology, J.J., G.X. and Y.X.; investigation, J.J. and J.Y.; resources, J.J., G.W. and G.X.; data curation, J.J., J.Y., H.X., Y.X., Z.G. and Z.Z.; Validation, J.J. and J.Y., writing—original draft preparation, J.J.; writing—review and editing, J.J. and G.X.; funding acquisition, J.J. and G.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Domestic Visiting Engineer Program for Universities “Industry-Academia Collaboration Project” (Grant No. FG2024055, Department of Education of Zhejiang Province); 2024 Zhejiang Zhuji City “Call for Proposals” Research Projects (Grant No. 2024330101004608); Zhejiang Provincial Natural Science Foundation of China (Grant No. ZCLQN25A0406), the Science and Technology Bureau of Jiaxing City (Grant No. 2024AY10044); Special Project for High-Level Talent Recruitment of Zhejiang Institute of Communications (Grant No. 2025rcxm21).

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

The original contributions presented in this study are included in the article/Supplementary Material. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

Authors Yongli Xu, Zhongwai Guo and Zhenghong Zhou are employees of Zhejiang Shenfa Bearing Co., Ltd. The other authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| SEM | Scanning Electron Microscopy |

| EDS | Energy-Dispersive X-ray Spectroscopy |

| XRD | X-ray Diffraction |

| HB | Brinell Hardness |

| COF | Coefficient of Friction |

| LBID | Laser Beam Intensity Distribution |

| WIP | Workpiece Illumination Proportion |

References

- Song, F.; Yang, X.; Dong, W.; Zhu, Y.; Wang, Z.; Wu, M. Research and prospect of textured sliding bearing. Int. J. Adv. Manuf. Technol. 2022, 121, 1–25. [Google Scholar] [CrossRef]

- Dai, J.; Tian, L.; Chang, H. An intelligent diagnostic method for wear depth of sliding bearings based on MGCNN. Machines 2024, 12, 266. [Google Scholar] [CrossRef]

- Wang, H.; Wu, S.S.; Yu, F.X.Z.; Bi, Y.C.; Xu, Z. Study on remaining useful life prediction of sliding bearings in nuclear power plant shielded pumps based on nearest similar distance particle filtering. Ann. Nucl. Energy 2025, 223, 111625. [Google Scholar] [CrossRef]

- Saleh, A.; Könekamp, M.; Jacobs, G.; Gilges, M.; Lehmann, B.; Lucassen, M. Evaluation of fatigue damage in stern tube sliding bearings of ship propulsion systems under ice impact. Forsch. Ingenieurwes. 2025, 89, 32. [Google Scholar] [CrossRef]

- Chen, J.; Min, J.H.; Li, L.J.; Liang, X.Y. Friction and wear performances of materials for wind turbine sliding bearing bushes. Appl. Sci. 2024, 14, 3962. [Google Scholar] [CrossRef]

- Ding, H.H.; Mermertas, U.; Hagemann, T.; Schwarze, H. Calculation and validation of planet gear sliding bearings for a three-stage wind turbine gearbox. Lubricants 2024, 12, 95. [Google Scholar] [CrossRef]

- Yin, Y.; Shi, P.F.; Zhang, S.H.; Qing, T.; Zhou, N.N.; Qian, L.M.; Chen, L. Lubrication failure mechanism of rolling-sliding steel ball against oil-impregnated porous polyimide and bearing steel in double friction pair. Eng. Fail. Anal. 2024, 164, 108622. [Google Scholar] [CrossRef]

- Shi, G.Q.; Yu, X.D.; Meng, H.; Zhao, F.H.; Wang, J.F.; Jiao, J.H.; Jiang, H. Effect of surface modification on friction characteristics of sliding bearings: A review. Tribol. Int. 2023, 177, 107937. [Google Scholar] [CrossRef]

- Rahaman, M.L.; Bernal, E.; Spiryagin, M.; Cole, C.; Buckley, R.; Wu, Q. A review on frictional torque reduction approaches for energy efficient roller bearings. Adv. Mech. Eng. 2025, 17, 16878132251340233. [Google Scholar] [CrossRef]

- Abioye, T.E.; Zuhailawati, H.; Azlan, M.A.I.; Anasyida, A.S. Effects of sic additions on the microstructure, compressive strength and wear resistance of Sn-Sb-Cu bearing alloy formed via powder metallurgy. J. Mater. Res. Technol. 2020, 9, 13196–13205. [Google Scholar] [CrossRef]

- Heigel, J.C.; Gouge, M.F.; Michaleris, P.; Palmer, T.A. Selection of powder or wire feedstock material for the laser cladding of inconel® 625. J. Mater. Process. Technol. 2016, 231, 357–365. [Google Scholar] [CrossRef]

- Barroi, A.; Goncalves, D.A.; Hermsdorf, J.; Kaierle, S.; Overmeyer, L. Influence of laser power on the shape of single tracks in scanner based laser wire cladding. Physcs. Proc. 2016, 83, 667–673. [Google Scholar] [CrossRef]

- Siddiqui, A.A.; Dubey, A.K. Recent trends in laser cladding and surface alloying. Opt. Laser Technol. 2021, 134, 106619. [Google Scholar] [CrossRef]

- Li, Y.; Liu, J.; Hu, Z.Y.; Tan, N.; Zhang, G.L.; Li, Q. Microstructure and properties of laser cladding turning machining scrap. Opt. Laser Technol. 2022, 147, 107614. [Google Scholar] [CrossRef]

- Wang, W.H.; He, Q.L.; Shi, W.Q.; Wu, W.N. Research on modification technology of laser cladding stellite6/Cu composite coating on the surface of 316L stainless steel plow teeth. Micromachines 2025, 16, 827. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.K.; Choi, S.G.; Kim, J.H.; Jo, H.J.; Jo, Y.C.; Choi, S.P.; Cho, Y.T. Characterization of surface modification by laser cladding using low melting point metal. J. Ind. Eng. Chem. 2020, 87, 54–59. [Google Scholar] [CrossRef]

- Li, J. Microstructure and tensile fracture of laser cladding Sn-Cu-Sb coating on gas turbine steel surface. Mater. Prot. 2019, 52, 75–78. [Google Scholar]

- Hao, Y.B.; Wang, J.; Yang, P.; Wang, Y.L.; Liang, X.D.; Gao, J.L. Microstructures and properties of tin-based babbitt metal prepared by laser cladding deposition. Chin. J. Lasers 2020, 47, 0802009. [Google Scholar] [CrossRef]

- Zhu, G.X.; Li, G.Q.; Wang, L.F.; Shi, S.H. Contrastive analysis of temperature and stress field distribution in cladding layer by the gaussian and hollow-ring laser modes. Int. J. Adv. Manuf. Technol. 2023, 127, 5599–5609. [Google Scholar] [CrossRef]

- Govekar, E.; Jeromen, A.; Kuznetsov, A.; Levy, G.; Fujishima, M. Study of an annular laser beam based axially-fed powder cladding process. Cirp. Ann.-Manuf. Technol. 2018, 67, 241–244. [Google Scholar] [CrossRef]

- Govekar, E.; Jeromen, A.; Kuznetsov, A.; Kotar, M.; Kondo, M. Annular laser beam based direct metal deposition. Proc. Cirp 2018, 74, 222–227. [Google Scholar] [CrossRef]

- Kuznetsov, A.; Jeromen, A.; Levy, G.; Fujishima, M.; Govekar, E. Annular laser beam cladding process feasibility study. Phys. Procedia 2016, 83, 647–656. [Google Scholar] [CrossRef]

- Kotar, M.; Fujishima, M.; Levy, G.N.; Govekar, E. Advances in the understanding of the annular laser beam wire cladding process. J. Mater. Process. Technol. 2021, 294, 117105. [Google Scholar] [CrossRef]

- Wang, K.X.; Tong, Y.G.; Chen, Y.X.; Kong, L.C.; Lu, K.J.; Wang, J.; Liang, X.B. Powder stream performance of a novel annular laser direct metal deposition with inside-laser coaxial powder feeding nozzle: Simulation and experimental perspectives. Opt. Laser Technol. 2024, 175, 110723. [Google Scholar] [CrossRef]

- GB/T 699-2015; Quality Carbon Structural Steels. Standardization Administration of China: Beijing, China, 2015.

- GB/T 18329.2-2023; Plain Bearings—Metallic Multilayer Plain Bearings—Part 2: Destructive Testing of Bond for Bearing Metal Layer Thicknesses c or Equal to 2 mm. State Administration for Market Regulation (Standardization Administration of China): Beijing, China, 2023.

- ISO 4386-2:2019; Plain Bearings—Metallic Multilayer Plain Bearings—Part 2: Destructive Testing of Bond for Bearing Metal layer. International Organization for Standardization: Geneva, Switzerland, 2019.

- Yi, H.T.; Dong, B.W.; Wu, Z.P.; Ke, C.; Jie, J.C.; Li, T.J. Calphad-guided optimization of the microstructure of Sn-Sb-Cu bearing alloys. Mater. Chem. Phys. 2022, 290, 126627. [Google Scholar] [CrossRef]

- Goudarzi, M.M.; Jahromi, S.A.J.; Nazarboland, A. Investigation of characteristics of tin-based white metals as a bearing material. Mater. Des. 2009, 30, 2283–2288. [Google Scholar] [CrossRef]

- Barykin, N.P.; Fazlyakhmetov, R.F.; Valeeva, A.K. Effect of the structure of babbit B83 on the intensity of wear of tribocouplings. Met. Sci. Heat Treat. 2006, 48, 88–91. [Google Scholar] [CrossRef]

- Wang, X.B.; Yin, Z.W.; Chen, Y.H. Study on fatigue strength of SnSb11Cu6 babbitt-steel bimetal sliding bearing material prepared by mig brazing. Mech. Ind. 2020, 21, 106. [Google Scholar] [CrossRef]

- Dong, Q.; Yin, Z.W.; Li, H.L.; Zhang, X.Y.; Jiang, D.; Zhong, N. Effects of Ag micro-addition on structure and mechanical properties of Sn-11Sb-6Cu babbitt. Mater. Sci. Eng. A 2018, 722, 225–230. [Google Scholar] [CrossRef]

- Wei, M.Z.; Sun, K.; Zhang, X.L.; Zhang, C.; Chen, Z.H.; Zhou, J.; Xue, F. Microstructure and bonding strength of tin-based babbitt alloy on astm 1045 steel by mig arc brazing. J. Adhes. Sci. Technol. 2018, 32, 2150–2161. [Google Scholar] [CrossRef]

- Sadykov, F.A.; Barykin, N.P.; Valeev, I.S.; Danilenko, V.N. Influence of the structural state on mechanical behavior of tin babbit. J. Mater. Eng. Perform. 2003, 12, 29–36. [Google Scholar] [CrossRef]

- Alcover, P.R.C.; Pukasiewicz, A.G.M. Evaluation of microstructure, mechanical and tribological properties of a babbitt alloy deposited by arc and flame spray processes. Tribol. Int. 2019, 131, 148–157. [Google Scholar] [CrossRef]

- Xu, T.; Zhang, S.; Wang, Z.Y.; Zhang, C.; Zhang, D.; Wang, M.; Wu, C. Wear behavior of graphite self-lubricating babbitt alloy composite coating on 20 steel prepared by laser cladding. Eng. Fail. Anal. 2022, 141, 106698. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Zhao, F.F.; Li, Y.; Li, P.Y.; Zeng, Q.F.; Dong, G.N. Study on tribological properties of multi-layer surface texture on babbitt alloys surface. Appl. Surf. Sci. 2016, 390, 540–549. [Google Scholar] [CrossRef]

- Singh, G.V.P.B.; Subramanian, K.V.L. Quantitative XRD study of amorphous phase in alkali activated low calcium siliceous fly ash. Constr. Build. Mater. 2016, 124, 139–147. [Google Scholar] [CrossRef]

- Huang, F.L.; Zhang, T.; Yu, Z.H.; Pan, T.Y.; Zhang, T.Y.; Xue, H. MXene cracked-layer composite sodium alginate/CNC-based hydrogel for robust sensing with high-sensitivity dynamic motion perception. Int. J. Biol. Macromol. 2025, 332, 148654. [Google Scholar] [CrossRef]

- He, X.W.; Li, G.; Song, S.A.; Hua, J.L. Effect of deposition current on microstructure and tribological properties of tin-based babbitt alloy on magnesium alloy deposited by tig process. Surf. Coat. Technol. 2025, 496, 131702. [Google Scholar] [CrossRef]

- Zhu, Y.X.; Zhou, H.M.; Chen, Z.X.; Wang, Z.D.; He, F.J.; Xu, C.X. Study on microstructure and properties of Ni60A/WC composite coating by alternating-magnetic-field-assisted laser cladding. Micromachines 2022, 13, 653. [Google Scholar] [CrossRef] [PubMed]

- Li, H.C.; Hu, Y.B.; Di, R.F.; Yuan, R.W.; Shi, C.; Lei, J.B. Effects of WC particles on microstructure and mechanical properties of 316L steel obtained by laser melting deposition. Ceram. Int. 2022, 48, 20388–20399. [Google Scholar] [CrossRef]

- Ren, X.Y.; Chen, H.M.; Chang, Y.; Chen, N.N.; Shi, Z.H.; Zhang, Y.G.; Guo, Z.M.; Hu, J.Z. Effect of Zn on microstructure and wear resistance of Sn-based babbitt alloy. Crystals 2024, 14, 907. [Google Scholar] [CrossRef]

- Xia, P.C.; Yin, T.H.; Xie, K.; Cao, M.Q.; Tan, Y.L. The influence of cladding current on the microstructure and wear properties of nial composite coatings. J. Therm. Spray Technol. 2023, 32, 948–958. [Google Scholar] [CrossRef]

- Khruschov, M.M. Principles of abrasive wear. Wear 1974, 28, 69–88. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.