Microstructure and Properties of Conventional Cast Versus Annular Laser-Clad Babbitt Alloy Layers for Sliding Bearings

Abstract

1. Introduction

2. Experiment Method and Devices

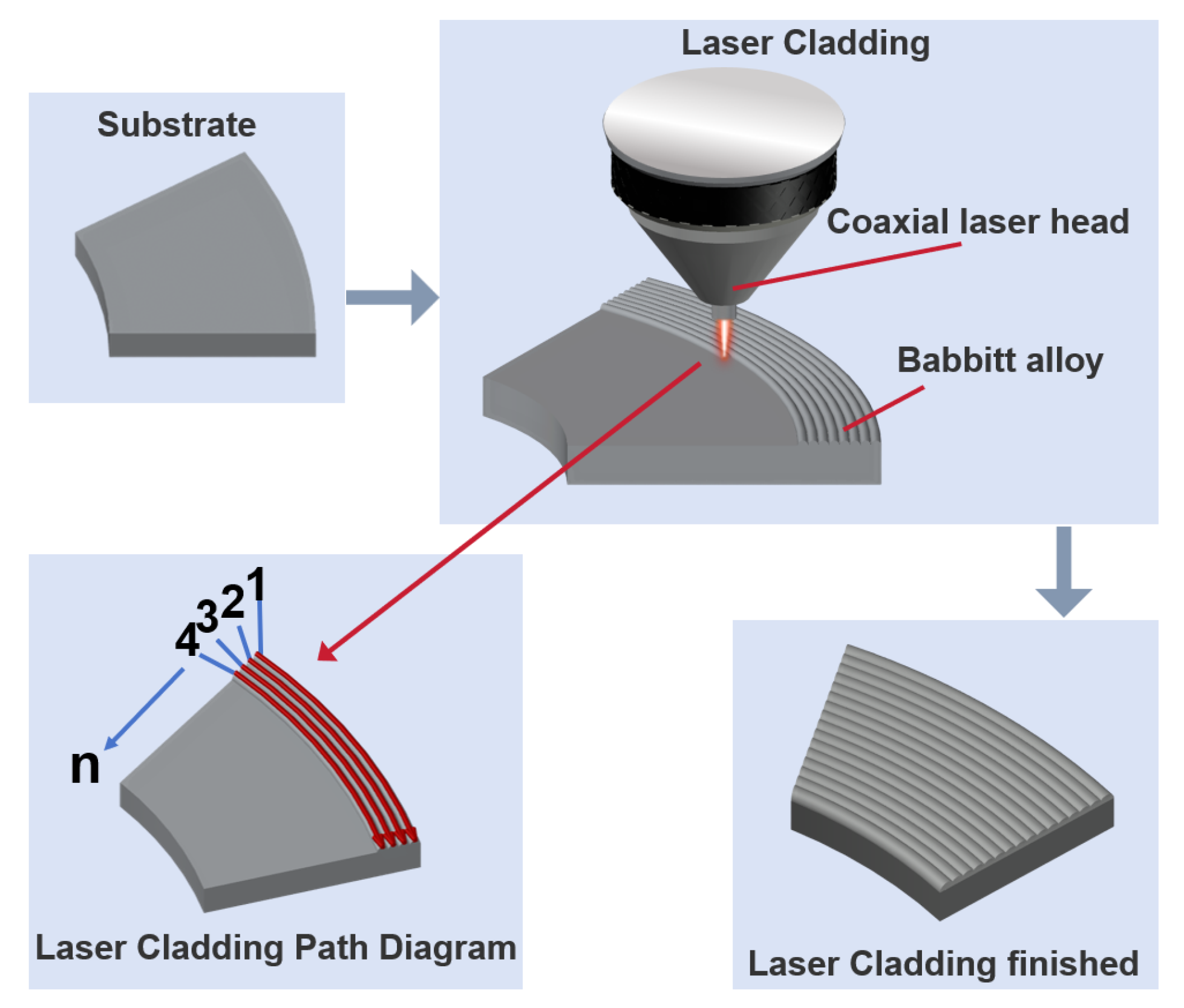

2.1. Laser Cladding of Babbitt Alloy Layer on Bearing Steel Substrate

2.2. Casting of Babbitt Alloy Layer on Bearing Steel Substrate

2.3. Structural and Performance Characterization

3. Results and Discussion

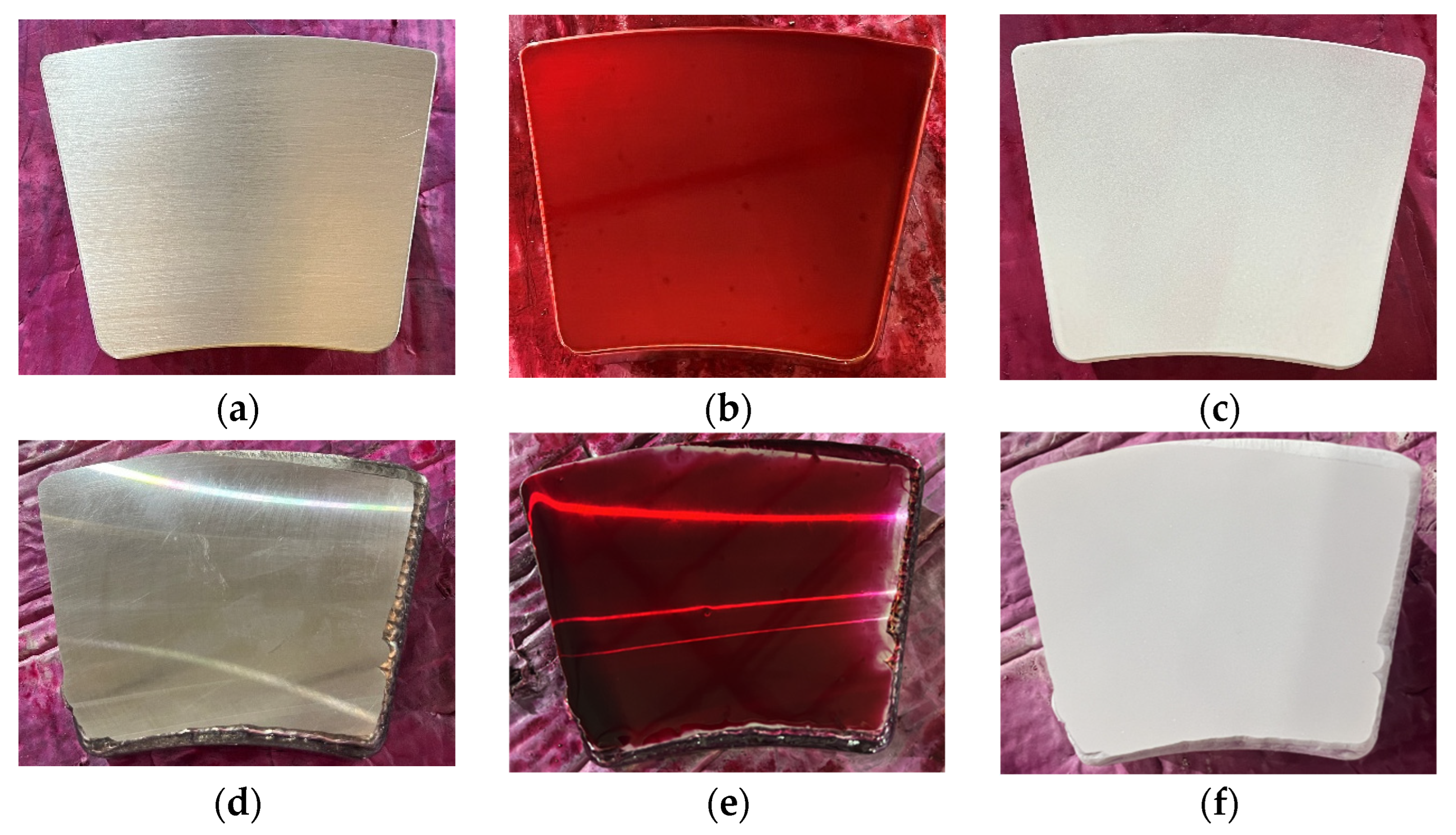

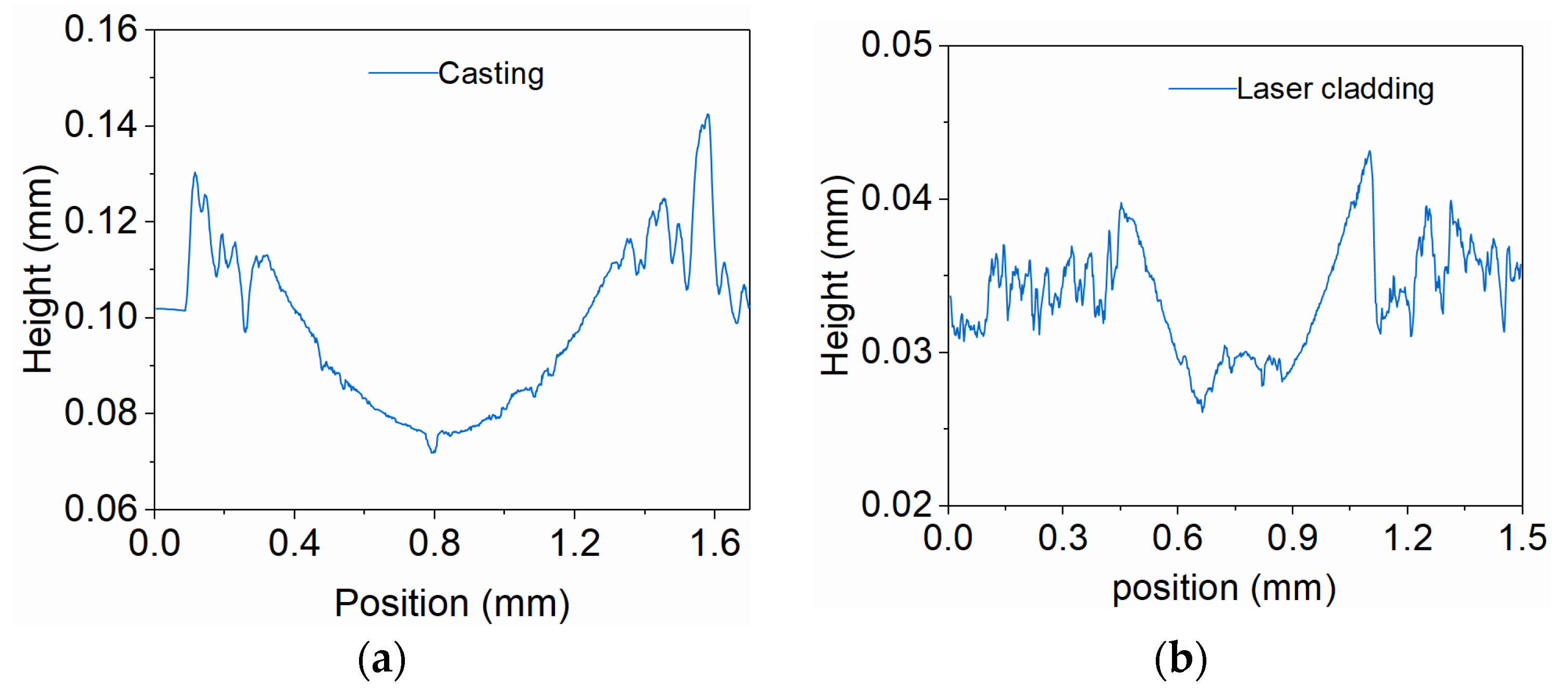

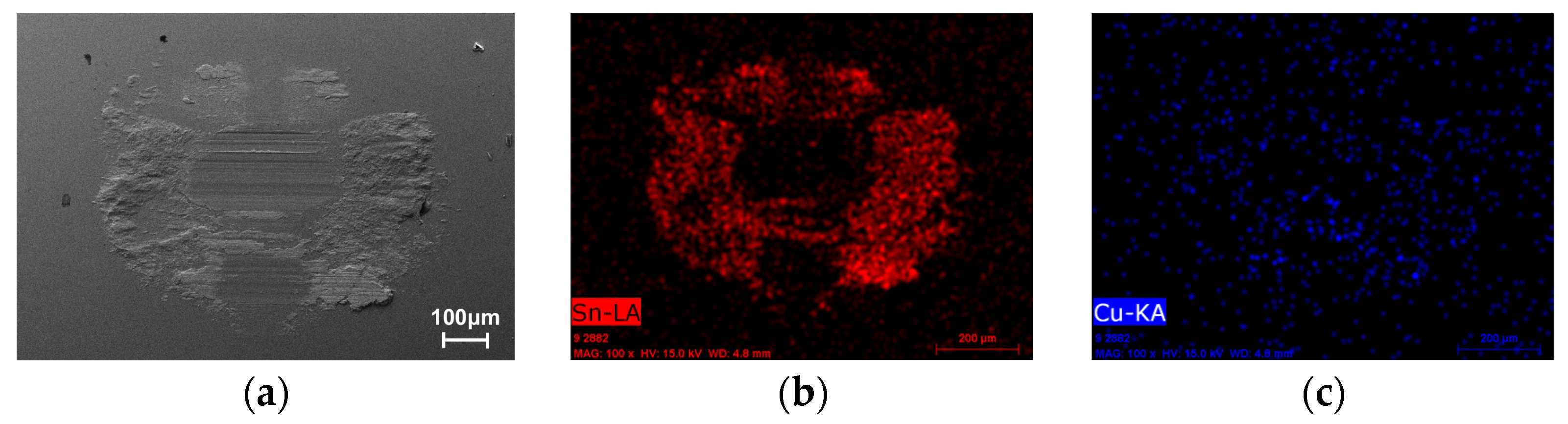

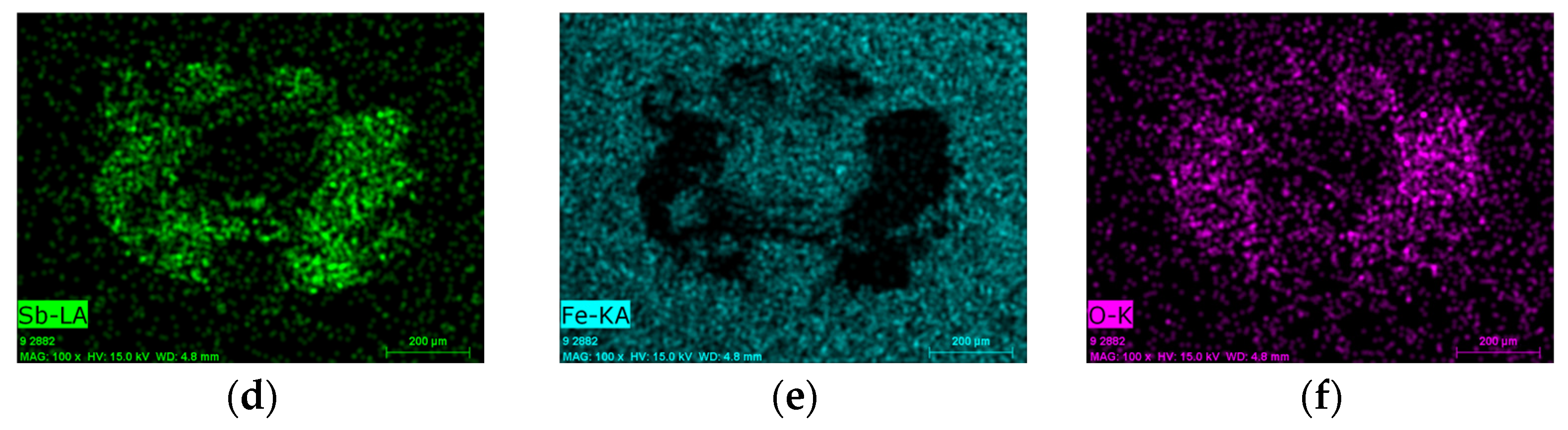

3.1. Surface Quality and Miacro-Structure of the Alloy Layer

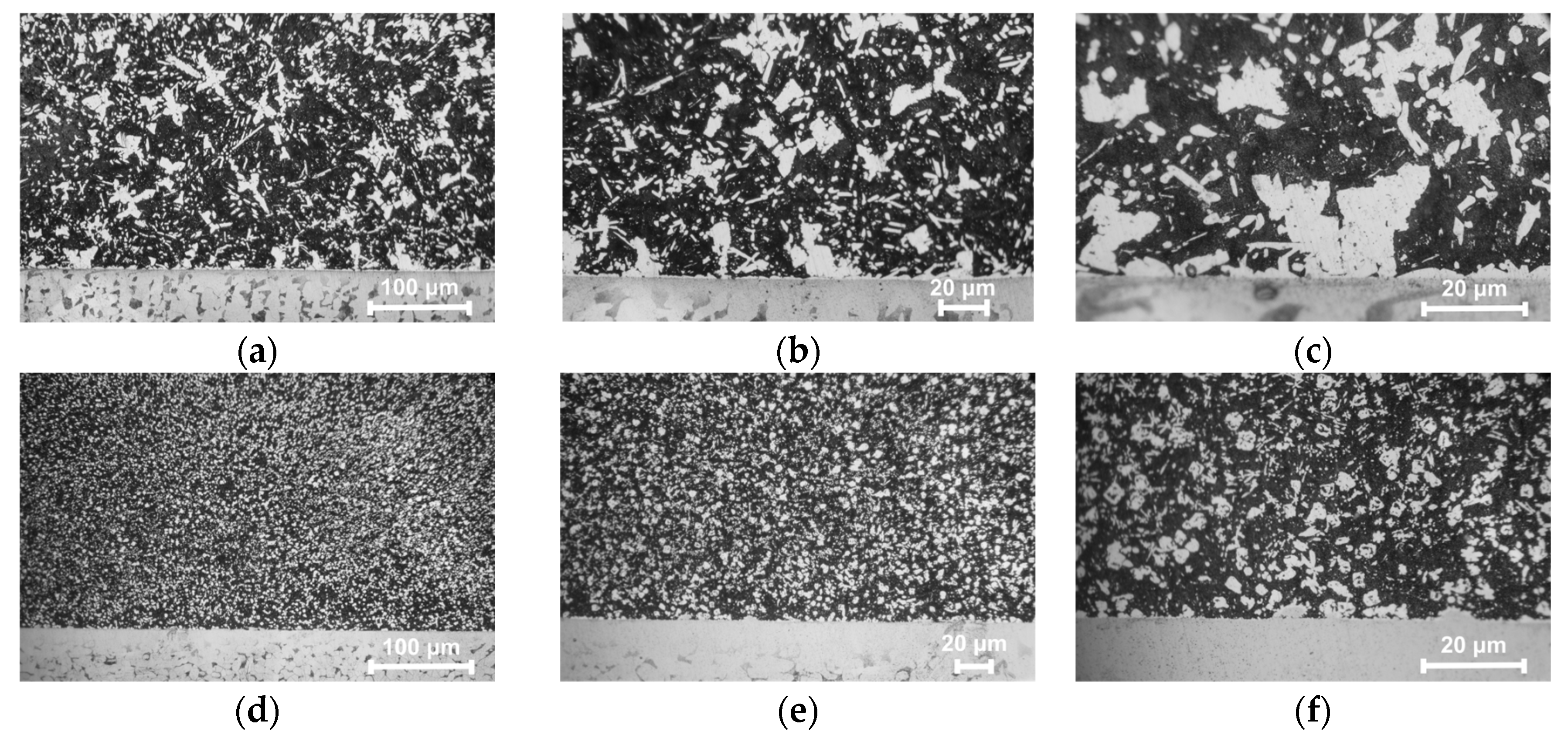

3.2. Microstructural Analysis by Metallographic Examination

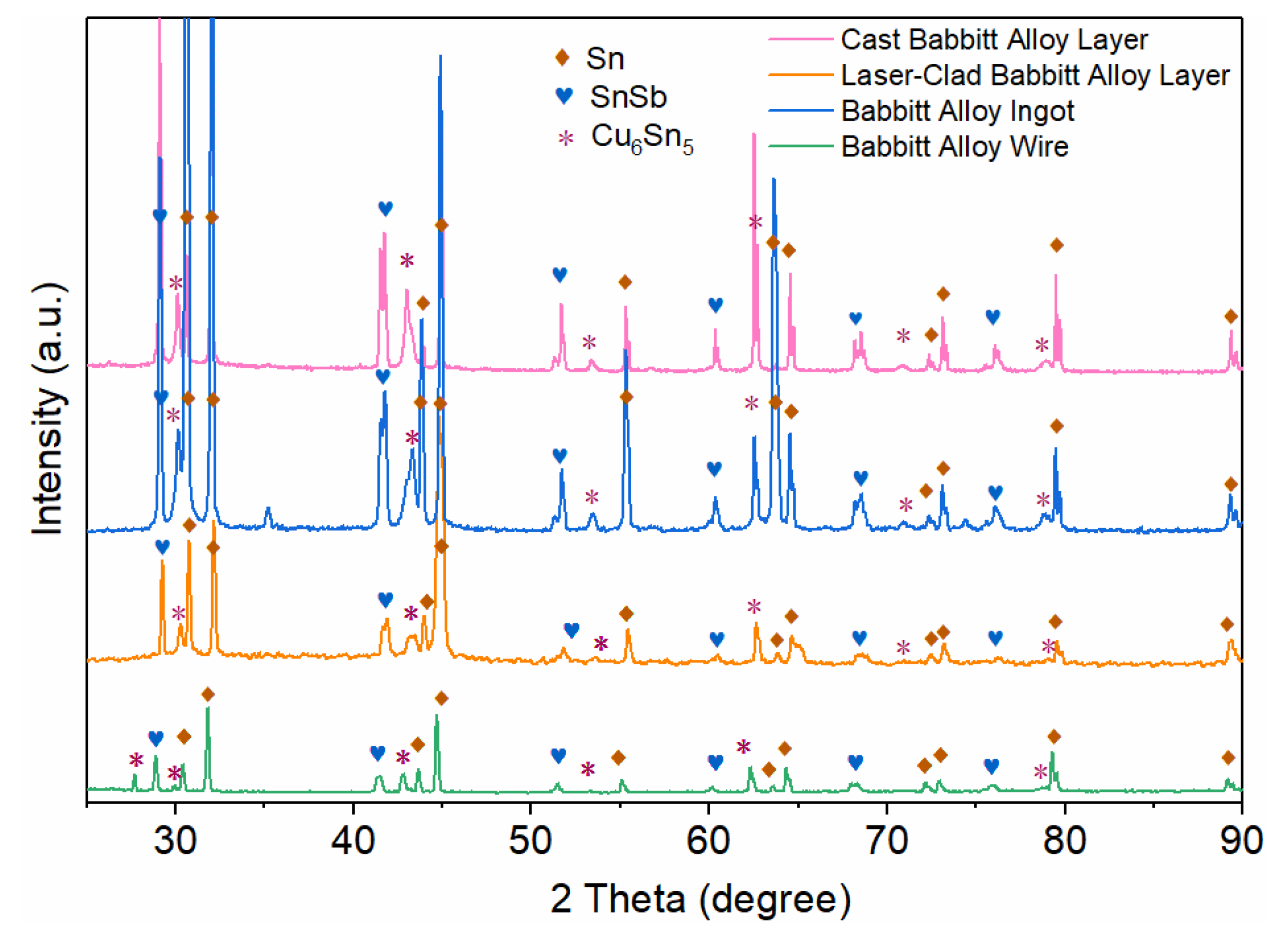

3.3. Crystal Structure and Phase Analysis of the Alloy Layer

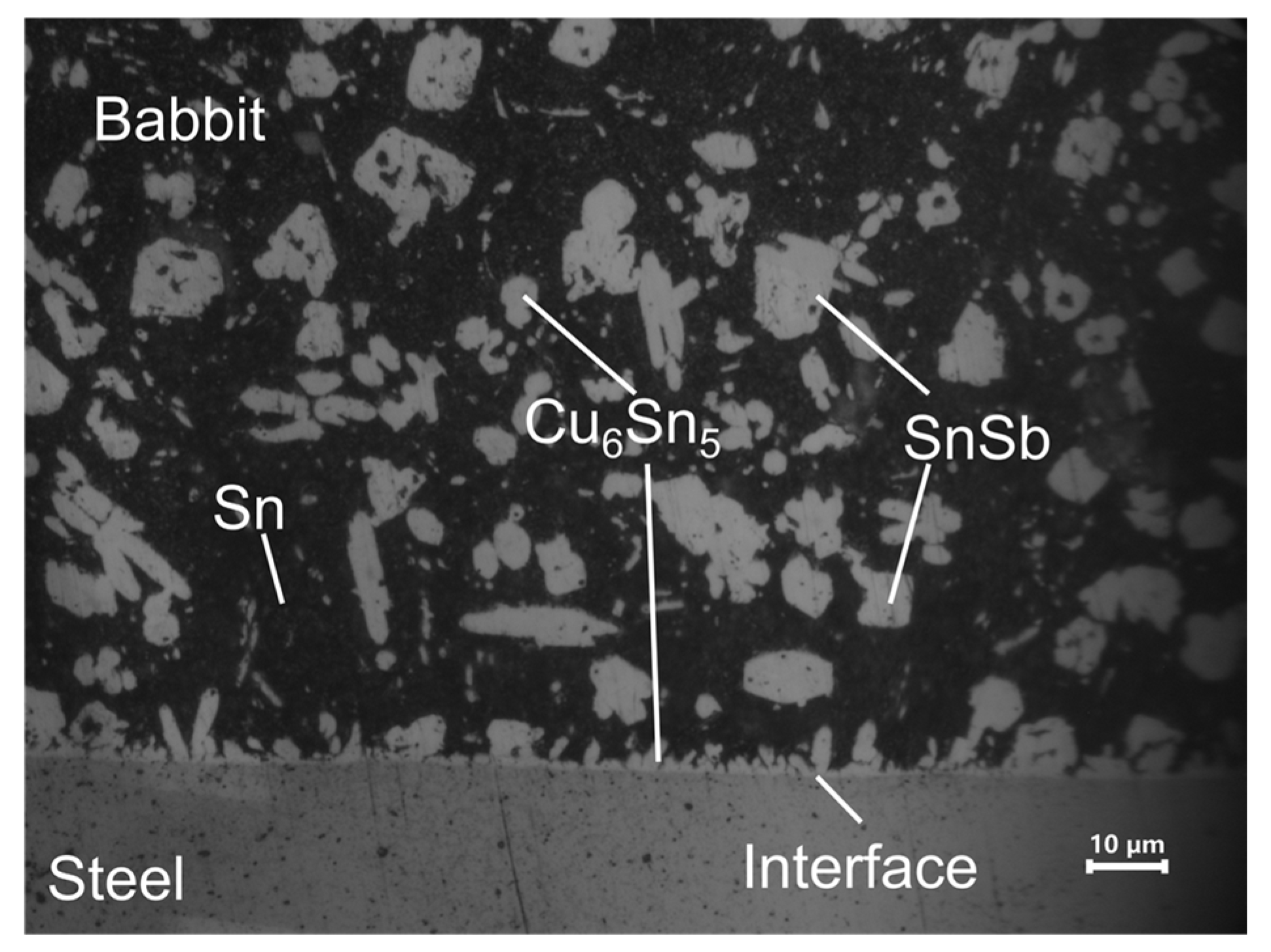

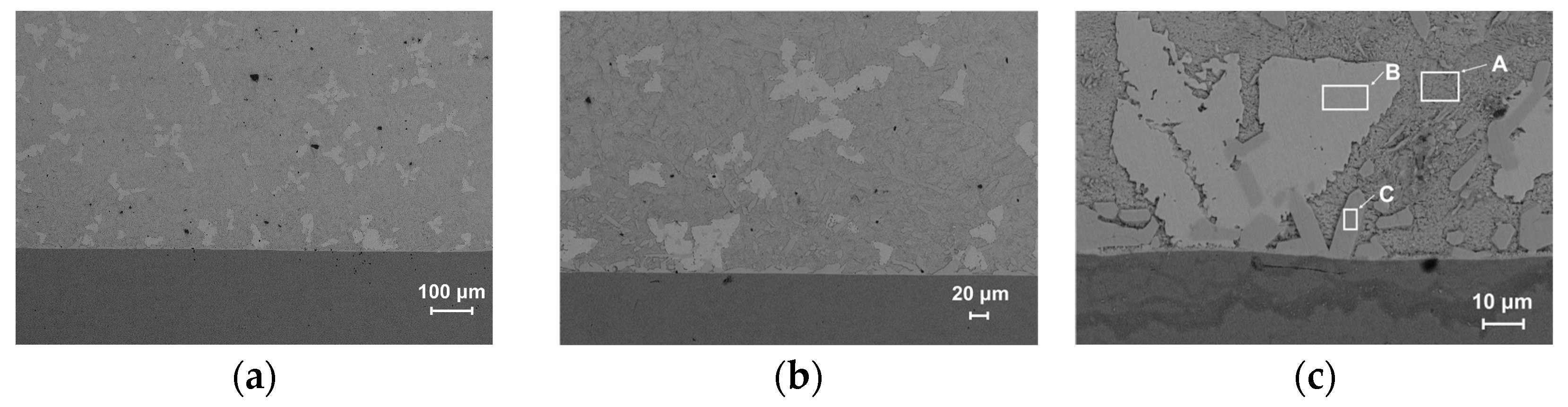

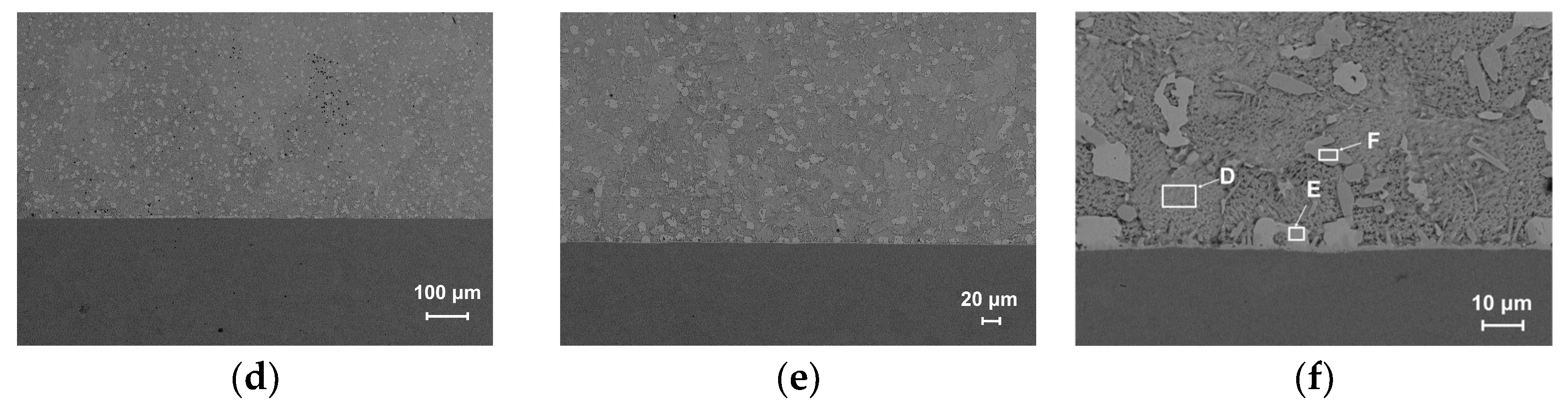

3.4. Microstructure Morphology Analysis of the Alloy Layers

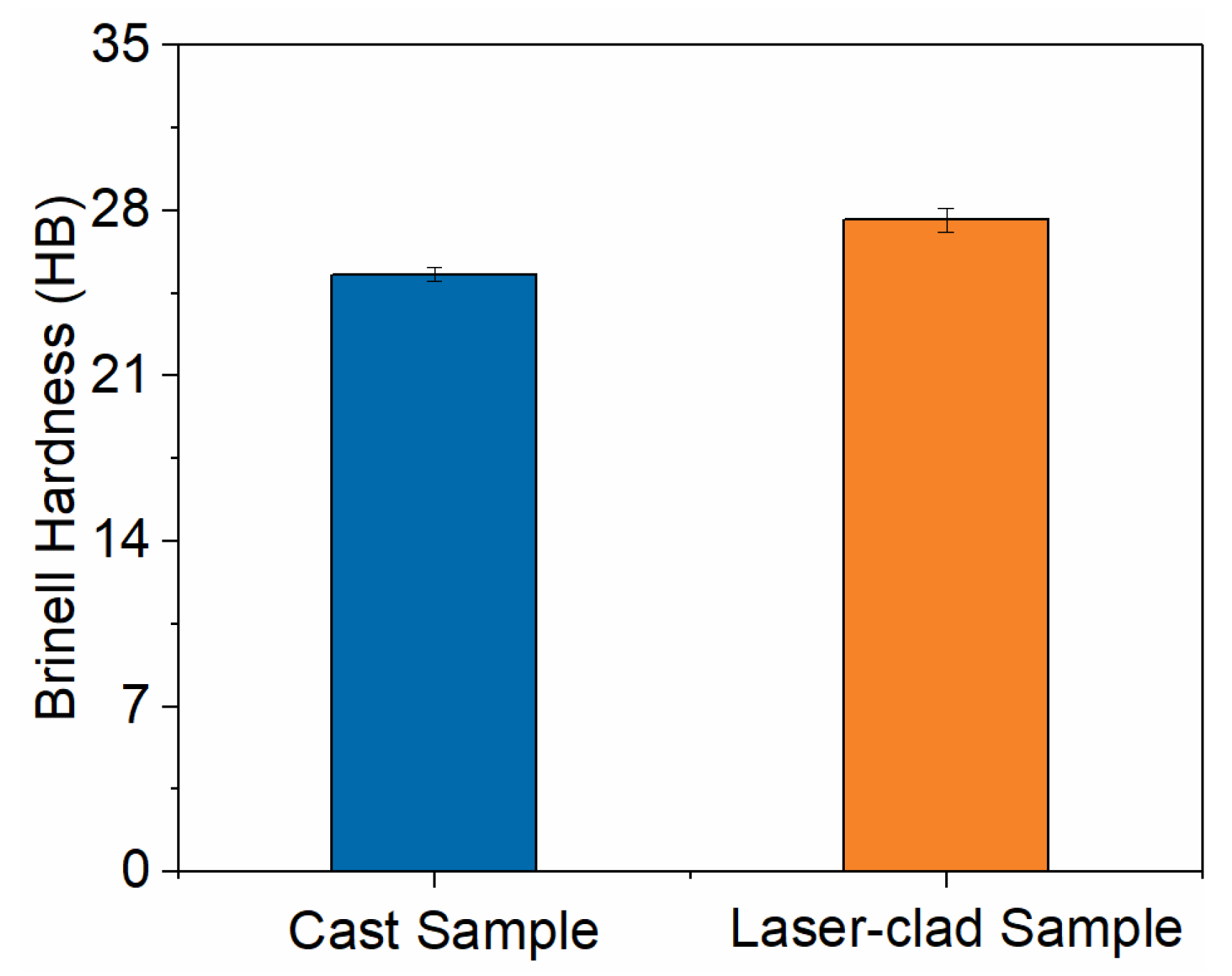

3.5. Hardness Measurement Results

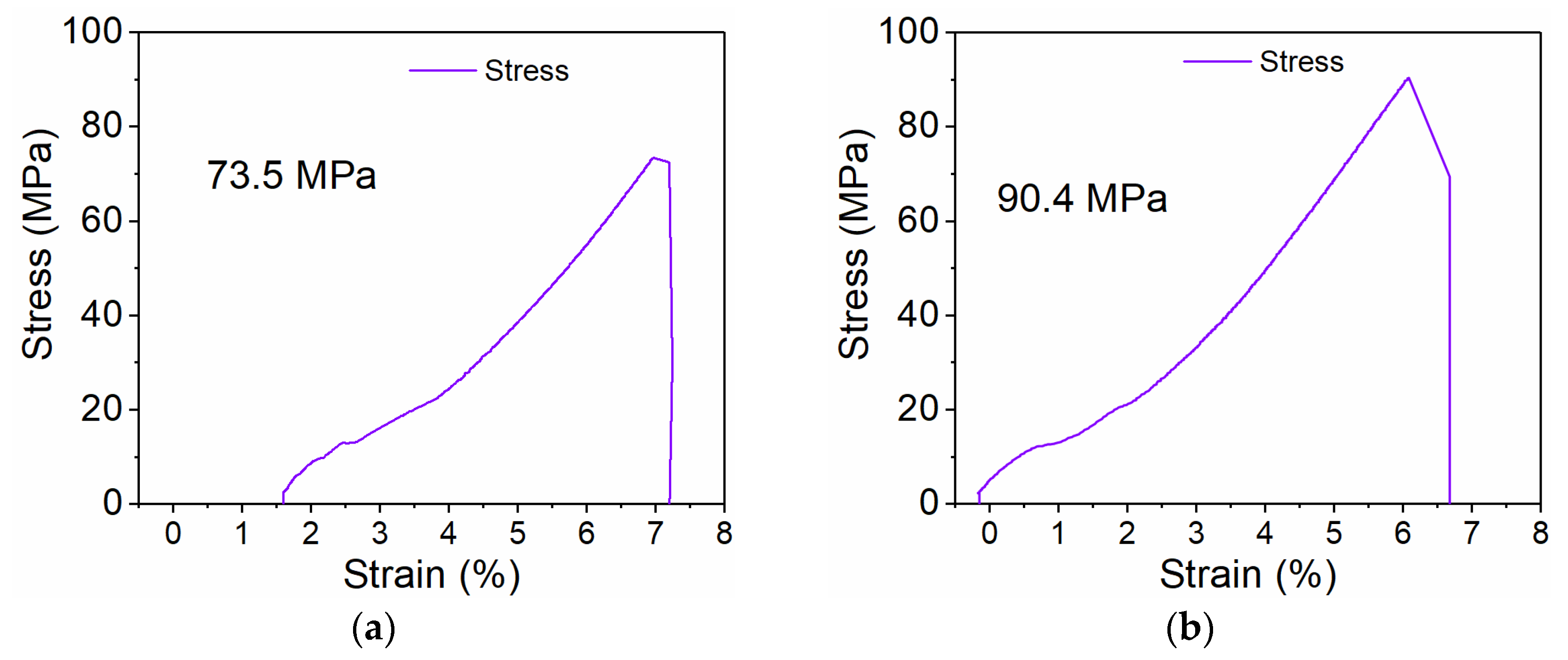

3.6. Analysis of the Bonding Performance Between the Alloy Layer and Substrate

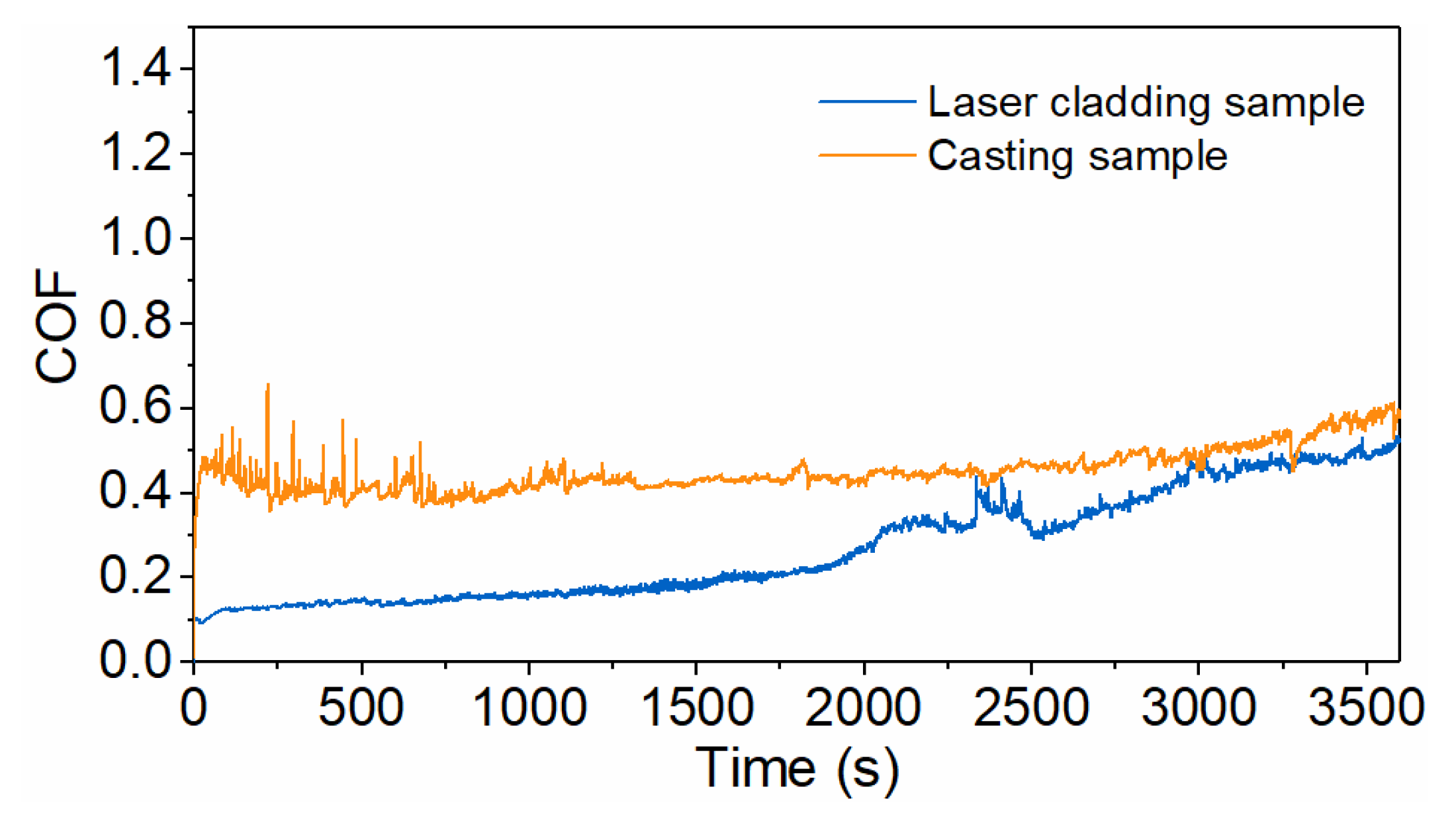

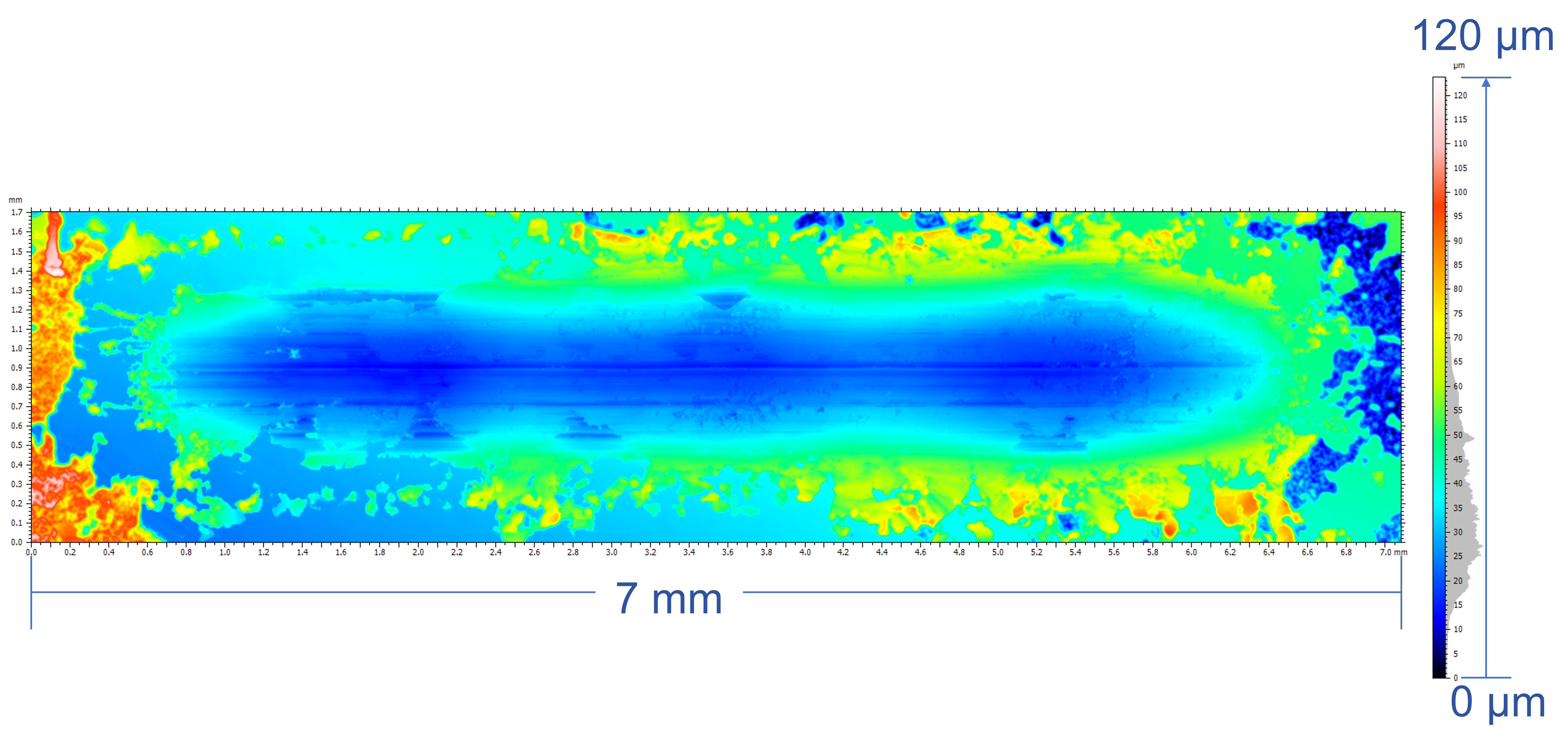

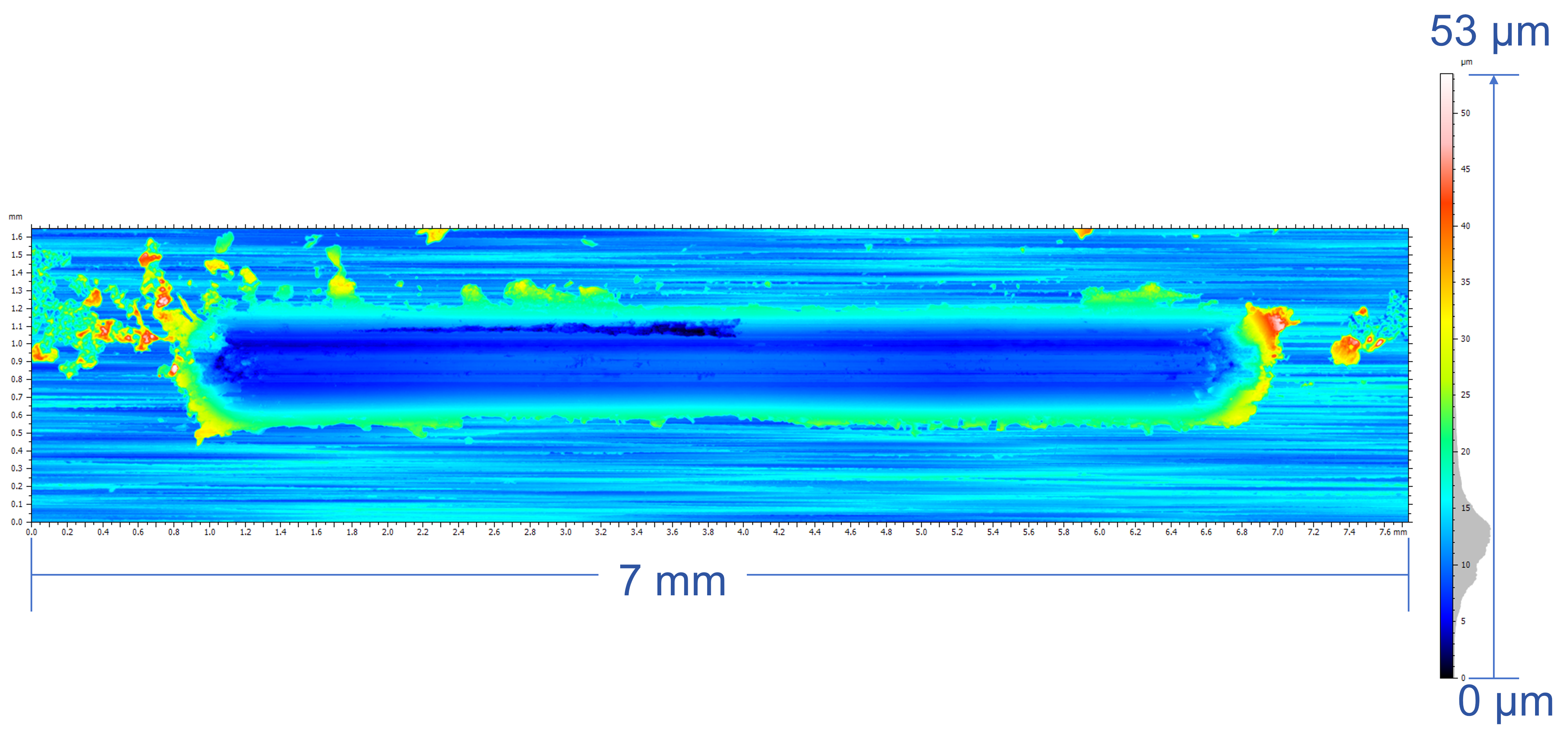

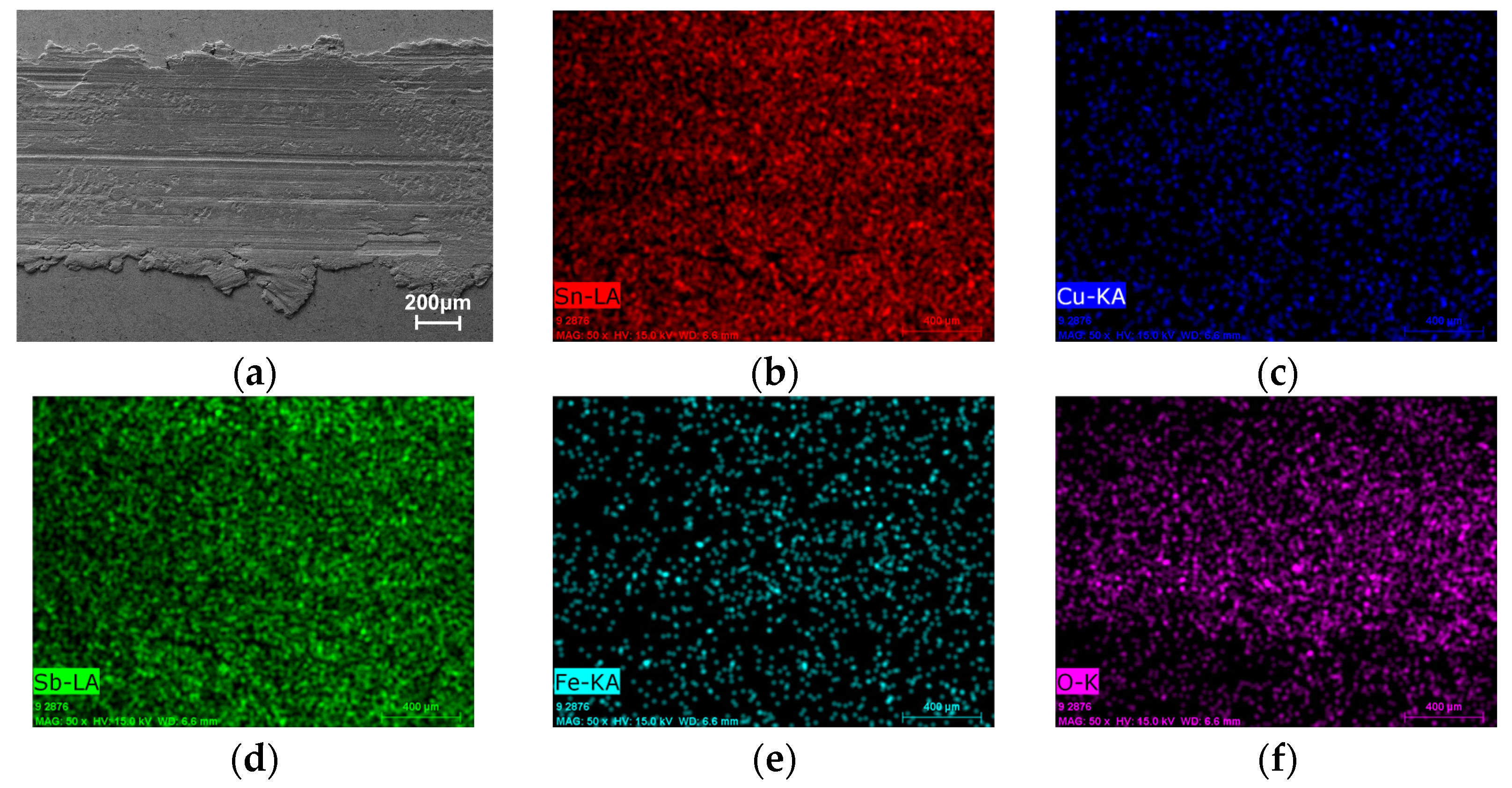

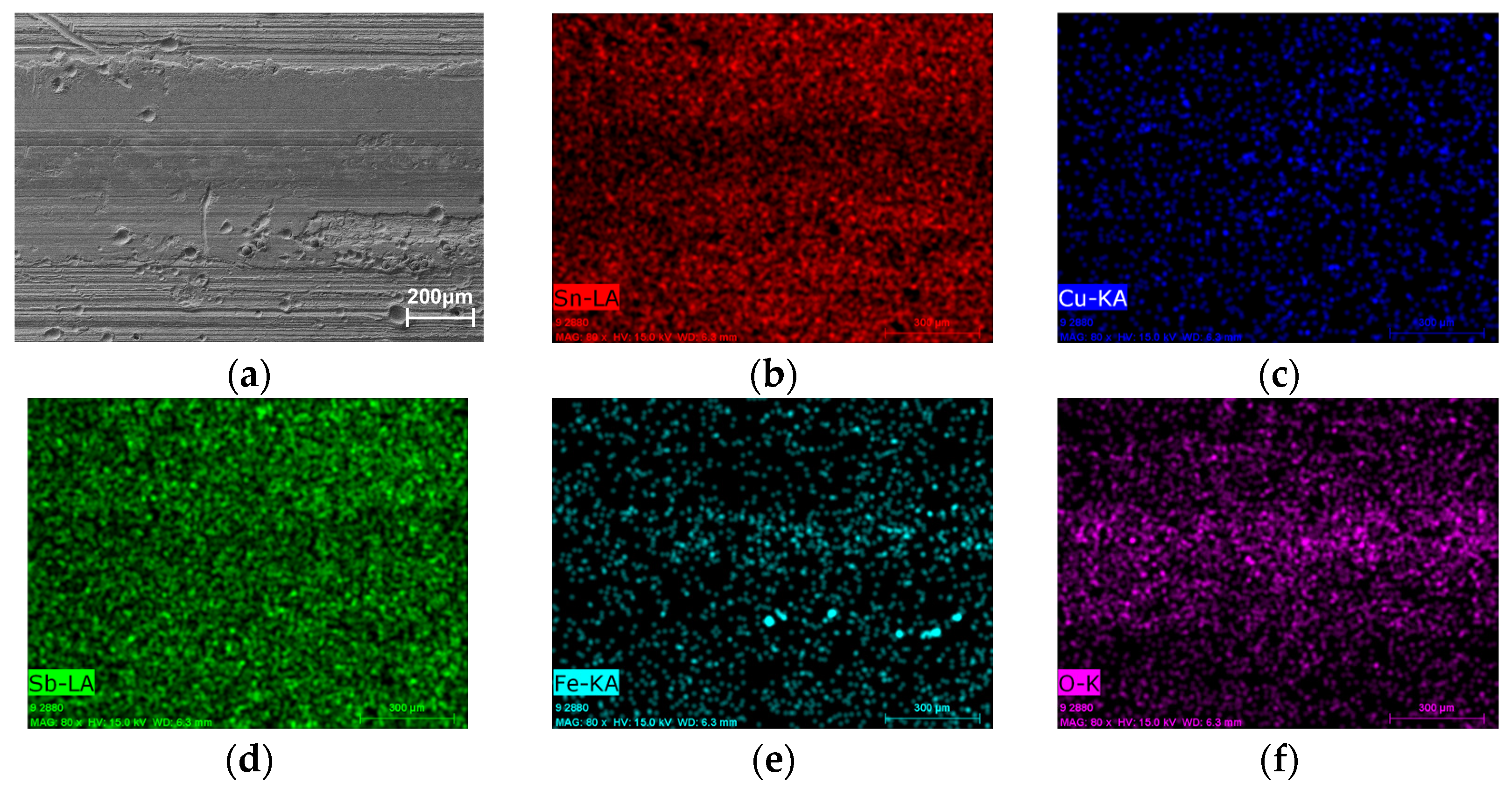

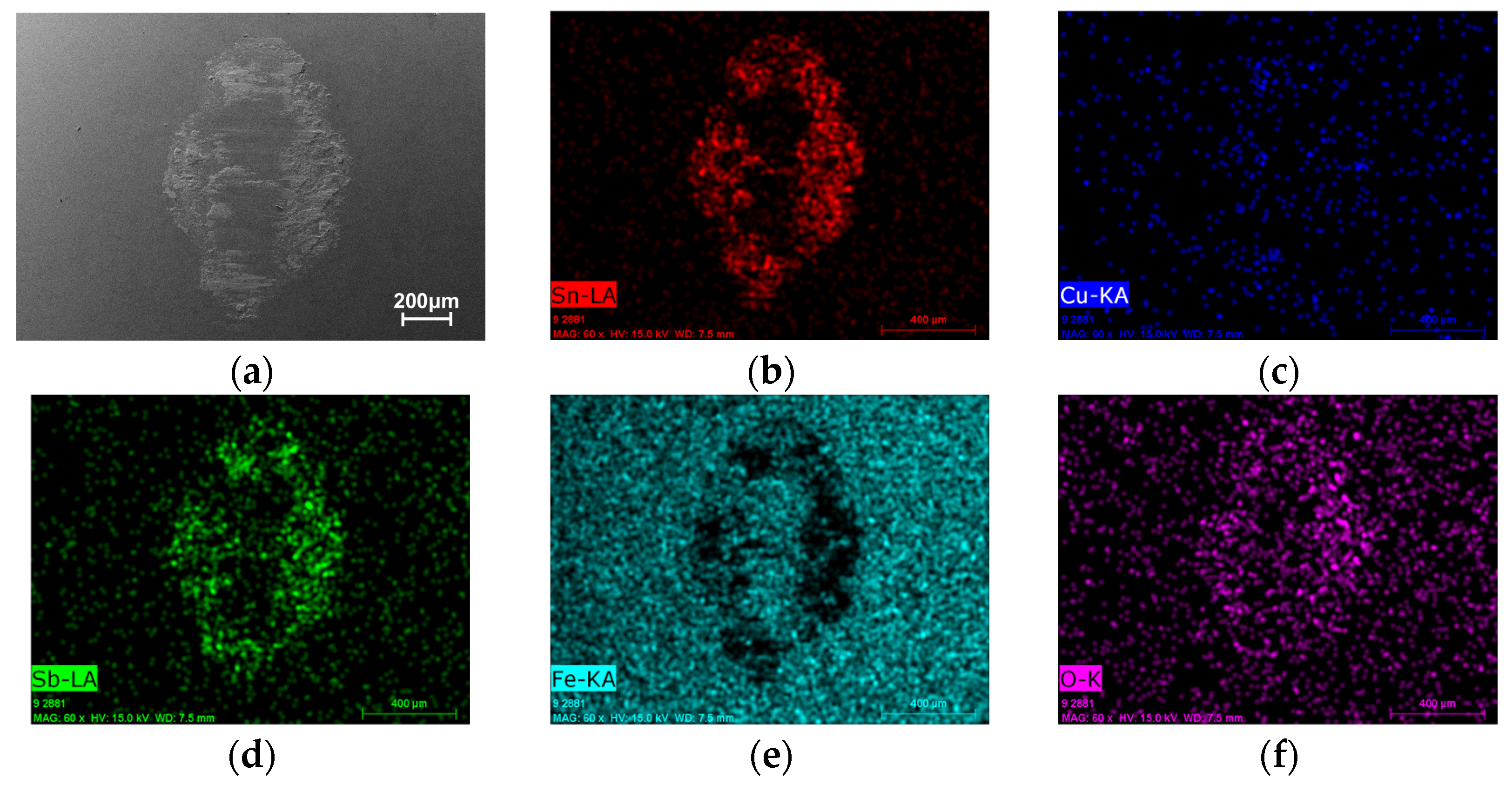

3.7. Tribological Performance of the Alloy Layer

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SEM | Scanning Electron Microscopy |

| EDS | Energy-Dispersive X-ray Spectroscopy |

| XRD | X-ray Diffraction |

| HB | Brinell Hardness |

| COF | Coefficient of Friction |

| LBID | Laser Beam Intensity Distribution |

| WIP | Workpiece Illumination Proportion |

References

- Song, F.; Yang, X.; Dong, W.; Zhu, Y.; Wang, Z.; Wu, M. Research and prospect of textured sliding bearing. Int. J. Adv. Manuf. Technol. 2022, 121, 1–25. [Google Scholar] [CrossRef]

- Dai, J.; Tian, L.; Chang, H. An intelligent diagnostic method for wear depth of sliding bearings based on MGCNN. Machines 2024, 12, 266. [Google Scholar] [CrossRef]

- Wang, H.; Wu, S.S.; Yu, F.X.Z.; Bi, Y.C.; Xu, Z. Study on remaining useful life prediction of sliding bearings in nuclear power plant shielded pumps based on nearest similar distance particle filtering. Ann. Nucl. Energy 2025, 223, 111625. [Google Scholar] [CrossRef]

- Saleh, A.; Könekamp, M.; Jacobs, G.; Gilges, M.; Lehmann, B.; Lucassen, M. Evaluation of fatigue damage in stern tube sliding bearings of ship propulsion systems under ice impact. Forsch. Ingenieurwes. 2025, 89, 32. [Google Scholar] [CrossRef]

- Chen, J.; Min, J.H.; Li, L.J.; Liang, X.Y. Friction and wear performances of materials for wind turbine sliding bearing bushes. Appl. Sci. 2024, 14, 3962. [Google Scholar] [CrossRef]

- Ding, H.H.; Mermertas, U.; Hagemann, T.; Schwarze, H. Calculation and validation of planet gear sliding bearings for a three-stage wind turbine gearbox. Lubricants 2024, 12, 95. [Google Scholar] [CrossRef]

- Yin, Y.; Shi, P.F.; Zhang, S.H.; Qing, T.; Zhou, N.N.; Qian, L.M.; Chen, L. Lubrication failure mechanism of rolling-sliding steel ball against oil-impregnated porous polyimide and bearing steel in double friction pair. Eng. Fail. Anal. 2024, 164, 108622. [Google Scholar] [CrossRef]

- Shi, G.Q.; Yu, X.D.; Meng, H.; Zhao, F.H.; Wang, J.F.; Jiao, J.H.; Jiang, H. Effect of surface modification on friction characteristics of sliding bearings: A review. Tribol. Int. 2023, 177, 107937. [Google Scholar] [CrossRef]

- Rahaman, M.L.; Bernal, E.; Spiryagin, M.; Cole, C.; Buckley, R.; Wu, Q. A review on frictional torque reduction approaches for energy efficient roller bearings. Adv. Mech. Eng. 2025, 17, 16878132251340233. [Google Scholar] [CrossRef]

- Abioye, T.E.; Zuhailawati, H.; Azlan, M.A.I.; Anasyida, A.S. Effects of sic additions on the microstructure, compressive strength and wear resistance of Sn-Sb-Cu bearing alloy formed via powder metallurgy. J. Mater. Res. Technol. 2020, 9, 13196–13205. [Google Scholar] [CrossRef]

- Heigel, J.C.; Gouge, M.F.; Michaleris, P.; Palmer, T.A. Selection of powder or wire feedstock material for the laser cladding of inconel® 625. J. Mater. Process. Technol. 2016, 231, 357–365. [Google Scholar] [CrossRef]

- Barroi, A.; Goncalves, D.A.; Hermsdorf, J.; Kaierle, S.; Overmeyer, L. Influence of laser power on the shape of single tracks in scanner based laser wire cladding. Physcs. Proc. 2016, 83, 667–673. [Google Scholar] [CrossRef]

- Siddiqui, A.A.; Dubey, A.K. Recent trends in laser cladding and surface alloying. Opt. Laser Technol. 2021, 134, 106619. [Google Scholar] [CrossRef]

- Li, Y.; Liu, J.; Hu, Z.Y.; Tan, N.; Zhang, G.L.; Li, Q. Microstructure and properties of laser cladding turning machining scrap. Opt. Laser Technol. 2022, 147, 107614. [Google Scholar] [CrossRef]

- Wang, W.H.; He, Q.L.; Shi, W.Q.; Wu, W.N. Research on modification technology of laser cladding stellite6/Cu composite coating on the surface of 316L stainless steel plow teeth. Micromachines 2025, 16, 827. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.K.; Choi, S.G.; Kim, J.H.; Jo, H.J.; Jo, Y.C.; Choi, S.P.; Cho, Y.T. Characterization of surface modification by laser cladding using low melting point metal. J. Ind. Eng. Chem. 2020, 87, 54–59. [Google Scholar] [CrossRef]

- Li, J. Microstructure and tensile fracture of laser cladding Sn-Cu-Sb coating on gas turbine steel surface. Mater. Prot. 2019, 52, 75–78. [Google Scholar]

- Hao, Y.B.; Wang, J.; Yang, P.; Wang, Y.L.; Liang, X.D.; Gao, J.L. Microstructures and properties of tin-based babbitt metal prepared by laser cladding deposition. Chin. J. Lasers 2020, 47, 0802009. [Google Scholar] [CrossRef]

- Zhu, G.X.; Li, G.Q.; Wang, L.F.; Shi, S.H. Contrastive analysis of temperature and stress field distribution in cladding layer by the gaussian and hollow-ring laser modes. Int. J. Adv. Manuf. Technol. 2023, 127, 5599–5609. [Google Scholar] [CrossRef]

- Govekar, E.; Jeromen, A.; Kuznetsov, A.; Levy, G.; Fujishima, M. Study of an annular laser beam based axially-fed powder cladding process. Cirp. Ann.-Manuf. Technol. 2018, 67, 241–244. [Google Scholar] [CrossRef]

- Govekar, E.; Jeromen, A.; Kuznetsov, A.; Kotar, M.; Kondo, M. Annular laser beam based direct metal deposition. Proc. Cirp 2018, 74, 222–227. [Google Scholar] [CrossRef]

- Kuznetsov, A.; Jeromen, A.; Levy, G.; Fujishima, M.; Govekar, E. Annular laser beam cladding process feasibility study. Phys. Procedia 2016, 83, 647–656. [Google Scholar] [CrossRef]

- Kotar, M.; Fujishima, M.; Levy, G.N.; Govekar, E. Advances in the understanding of the annular laser beam wire cladding process. J. Mater. Process. Technol. 2021, 294, 117105. [Google Scholar] [CrossRef]

- Wang, K.X.; Tong, Y.G.; Chen, Y.X.; Kong, L.C.; Lu, K.J.; Wang, J.; Liang, X.B. Powder stream performance of a novel annular laser direct metal deposition with inside-laser coaxial powder feeding nozzle: Simulation and experimental perspectives. Opt. Laser Technol. 2024, 175, 110723. [Google Scholar] [CrossRef]

- GB/T 699-2015; Quality Carbon Structural Steels. Standardization Administration of China: Beijing, China, 2015.

- GB/T 18329.2-2023; Plain Bearings—Metallic Multilayer Plain Bearings—Part 2: Destructive Testing of Bond for Bearing Metal Layer Thicknesses c or Equal to 2 mm. State Administration for Market Regulation (Standardization Administration of China): Beijing, China, 2023.

- ISO 4386-2:2019; Plain Bearings—Metallic Multilayer Plain Bearings—Part 2: Destructive Testing of Bond for Bearing Metal layer. International Organization for Standardization: Geneva, Switzerland, 2019.

- Yi, H.T.; Dong, B.W.; Wu, Z.P.; Ke, C.; Jie, J.C.; Li, T.J. Calphad-guided optimization of the microstructure of Sn-Sb-Cu bearing alloys. Mater. Chem. Phys. 2022, 290, 126627. [Google Scholar] [CrossRef]

- Goudarzi, M.M.; Jahromi, S.A.J.; Nazarboland, A. Investigation of characteristics of tin-based white metals as a bearing material. Mater. Des. 2009, 30, 2283–2288. [Google Scholar] [CrossRef]

- Barykin, N.P.; Fazlyakhmetov, R.F.; Valeeva, A.K. Effect of the structure of babbit B83 on the intensity of wear of tribocouplings. Met. Sci. Heat Treat. 2006, 48, 88–91. [Google Scholar] [CrossRef]

- Wang, X.B.; Yin, Z.W.; Chen, Y.H. Study on fatigue strength of SnSb11Cu6 babbitt-steel bimetal sliding bearing material prepared by mig brazing. Mech. Ind. 2020, 21, 106. [Google Scholar] [CrossRef]

- Dong, Q.; Yin, Z.W.; Li, H.L.; Zhang, X.Y.; Jiang, D.; Zhong, N. Effects of Ag micro-addition on structure and mechanical properties of Sn-11Sb-6Cu babbitt. Mater. Sci. Eng. A 2018, 722, 225–230. [Google Scholar] [CrossRef]

- Wei, M.Z.; Sun, K.; Zhang, X.L.; Zhang, C.; Chen, Z.H.; Zhou, J.; Xue, F. Microstructure and bonding strength of tin-based babbitt alloy on astm 1045 steel by mig arc brazing. J. Adhes. Sci. Technol. 2018, 32, 2150–2161. [Google Scholar] [CrossRef]

- Sadykov, F.A.; Barykin, N.P.; Valeev, I.S.; Danilenko, V.N. Influence of the structural state on mechanical behavior of tin babbit. J. Mater. Eng. Perform. 2003, 12, 29–36. [Google Scholar] [CrossRef]

- Alcover, P.R.C.; Pukasiewicz, A.G.M. Evaluation of microstructure, mechanical and tribological properties of a babbitt alloy deposited by arc and flame spray processes. Tribol. Int. 2019, 131, 148–157. [Google Scholar] [CrossRef]

- Xu, T.; Zhang, S.; Wang, Z.Y.; Zhang, C.; Zhang, D.; Wang, M.; Wu, C. Wear behavior of graphite self-lubricating babbitt alloy composite coating on 20 steel prepared by laser cladding. Eng. Fail. Anal. 2022, 141, 106698. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Zhao, F.F.; Li, Y.; Li, P.Y.; Zeng, Q.F.; Dong, G.N. Study on tribological properties of multi-layer surface texture on babbitt alloys surface. Appl. Surf. Sci. 2016, 390, 540–549. [Google Scholar] [CrossRef]

- Singh, G.V.P.B.; Subramanian, K.V.L. Quantitative XRD study of amorphous phase in alkali activated low calcium siliceous fly ash. Constr. Build. Mater. 2016, 124, 139–147. [Google Scholar] [CrossRef]

- Huang, F.L.; Zhang, T.; Yu, Z.H.; Pan, T.Y.; Zhang, T.Y.; Xue, H. MXene cracked-layer composite sodium alginate/CNC-based hydrogel for robust sensing with high-sensitivity dynamic motion perception. Int. J. Biol. Macromol. 2025, 332, 148654. [Google Scholar] [CrossRef]

- He, X.W.; Li, G.; Song, S.A.; Hua, J.L. Effect of deposition current on microstructure and tribological properties of tin-based babbitt alloy on magnesium alloy deposited by tig process. Surf. Coat. Technol. 2025, 496, 131702. [Google Scholar] [CrossRef]

- Zhu, Y.X.; Zhou, H.M.; Chen, Z.X.; Wang, Z.D.; He, F.J.; Xu, C.X. Study on microstructure and properties of Ni60A/WC composite coating by alternating-magnetic-field-assisted laser cladding. Micromachines 2022, 13, 653. [Google Scholar] [CrossRef] [PubMed]

- Li, H.C.; Hu, Y.B.; Di, R.F.; Yuan, R.W.; Shi, C.; Lei, J.B. Effects of WC particles on microstructure and mechanical properties of 316L steel obtained by laser melting deposition. Ceram. Int. 2022, 48, 20388–20399. [Google Scholar] [CrossRef]

- Ren, X.Y.; Chen, H.M.; Chang, Y.; Chen, N.N.; Shi, Z.H.; Zhang, Y.G.; Guo, Z.M.; Hu, J.Z. Effect of Zn on microstructure and wear resistance of Sn-based babbitt alloy. Crystals 2024, 14, 907. [Google Scholar] [CrossRef]

- Xia, P.C.; Yin, T.H.; Xie, K.; Cao, M.Q.; Tan, Y.L. The influence of cladding current on the microstructure and wear properties of nial composite coatings. J. Therm. Spray Technol. 2023, 32, 948–958. [Google Scholar] [CrossRef]

- Khruschov, M.M. Principles of abrasive wear. Wear 1974, 28, 69–88. [Google Scholar] [CrossRef]

| EDS Scanned Region | Possible Phases | Compositional Elements (wt.%) | ||

|---|---|---|---|---|

| Sn | Sb | Cu | ||

| A | Sn | 69.32 | 28.01 | 2.66 |

| B | SnSb | 57 | 43 | 0.00 |

| C | Cu6Sn5 | 58.89 | 4.06 | 37.05 |

| D | Sn | 77.59 | 22.41 | 0.00 |

| E | SnSb | 56.02 | 43.48 | 0.51 |

| F | Cu6Sn5 | 58.60 | 5.24 | 36.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Jin, J.; Ye, J.; Xue, H.; Xu, Y.; Guo, Z.; Zhou, Z.; Xu, G.; Wang, G. Microstructure and Properties of Conventional Cast Versus Annular Laser-Clad Babbitt Alloy Layers for Sliding Bearings. Micromachines 2026, 17, 134. https://doi.org/10.3390/mi17010134

Jin J, Ye J, Xue H, Xu Y, Guo Z, Zhou Z, Xu G, Wang G. Microstructure and Properties of Conventional Cast Versus Annular Laser-Clad Babbitt Alloy Layers for Sliding Bearings. Micromachines. 2026; 17(1):134. https://doi.org/10.3390/mi17010134

Chicago/Turabian StyleJin, Jing, Jun Ye, Hao Xue, Yongli Xu, Zhongwai Guo, Zhenghong Zhou, Gaohuan Xu, and Guobiao Wang. 2026. "Microstructure and Properties of Conventional Cast Versus Annular Laser-Clad Babbitt Alloy Layers for Sliding Bearings" Micromachines 17, no. 1: 134. https://doi.org/10.3390/mi17010134

APA StyleJin, J., Ye, J., Xue, H., Xu, Y., Guo, Z., Zhou, Z., Xu, G., & Wang, G. (2026). Microstructure and Properties of Conventional Cast Versus Annular Laser-Clad Babbitt Alloy Layers for Sliding Bearings. Micromachines, 17(1), 134. https://doi.org/10.3390/mi17010134