Abstract

This work investigated the effect of Fe/Mn ratio on the microstructure and mechanical properties of non-equimolar Fe80−xMnxCo10Cr10 (x = 30% and 50%) high-entropy alloys (HEAs) fabricated by laser powder bed fusion (LPBF) additive manufacturing. Process optimization was conducted to achieve fully dense Fe30Mn50Co10Cr10 and Fe50Mn30Co10Cr10 HEAs using a volumetric energy density of 105.82 J·mm−3. The LPBF-printed Fe30Mn50Co10Cr10 HEA exhibited a single face-centered cubic (FCC) phase, while the Fe50Mn30Co10Cr10 HEA featured a hexagonal close-packed (HCP) phase within the FCC matrix. Notably, the fraction of HCP phase in the Fe50Mn30Co10Cr10 HEAs increased from 0.94 to 28.10%, with the deformation strain ranging from 0 to 20%. The single-phase Fe30Mn50Co10Cr10 HEA demonstrated a remarkable combination of high yield strength (580.65 MPa) and elongation (32.5%), which surpassed those achieved in the FeMnCoCr HEA system. Comparatively, the dual-phase Fe50Mn30Co10Cr10 HEA exhibited inferior yield strength (487.60 MPa) and elongation (22.3%). However, it displayed superior ultimate tensile strength (744.90 MPa) compared to that in the Fe30Mn50Co10Cr10 HEA (687.70 MPa). The presence of FCC/HCP interfaces obtained in the Fe50Mn30Co10Cr10 HEA resulted in stress concentration and crack expansion, thereby leading to reduced ductility but enhanced resistance against grain slip deformation. Consequently, these interfaces facilitated an earlier attainment of yield limit point and contributed to increased ultimate tensile strength in the Fe50Mn30Co10Cr10 HEA. These findings provide valuable insights into the microstructure evolution and mechanical behavior of LPBF-printed metastable FeMnCoCr HEAs.

1. Introduction

Laser powder bed fusion (LPBF) is a disruptive additive manufacturing (AM) technology with the potential to revolutionize the fabrication of geometrically complex products from metal powders, overcoming the limitations of conventional processing methods [1,2]. Its ultra-high cooling rate of 103–108 K/s during non-equilibrium solidification effectively inhibits grain growth and the segregation of alloying elements within metal materials, which are challenging to achieve through conventional processing methods [3]. LPBF enables the production of metallic materials with microstructures characterized by highly heterogeneous grain geometries, sub-grain dislocation structures, and chemical segregation [4,5], thus resulting in exceptional mechanical properties.

High-entropy alloys (HEAs) have recently emerged as a novel paradigm for designing multi-principle-element alloys and attract significant attention from both academia and industry due to their distinctive microstructures and exceptional structural-functional properties [6]. According to phase types, HEAs can be generally categorized into single face-centered cubic (FCC) phase, such as the CoCrFeMnNi system (also known as Cantor alloys [7]); body-centered cubic (BCC) phase, such as the refractory NbMoTaW system; dual-phase such as FCC + BCC; or hexagonal close-packed (HCP) phase based on the structure of the phases [8]. Through optimizing the combination of constituent elements and modulating their proportions, HEAs can exhibit excellent mechanical properties. However, most of the reported studies have focused on conventional processes used for processing HEAs such as FeMnCoCrNi [9,10,11,12,13,14] and FeMnCoCr [15,16,17,18], resulting in inadequate yield strengths that limit practical engineering applications including jet aircraft turbine blades, nuclear fusion reactors, etc. Fortunately, LPBF offers rapid melting and solidification rates that promote the formation of refined grains [19], segregated phases [20], and high-density dislocation [21], which play a crucial role in strengthening the material by regulating dislocation motion during deformation.

The primary strengthening mechanisms of single-phase HEAs are solid-solution strengthening and dislocation strengthening, which enhance strength at the expense of plasticity. However, with the development of HEAs, design concepts based on equimolar ratios and single-phase microstructures have become limited. Therefore, the concept of “metastability-engineering” has been introduced in certain non-equimolar HEAs. Li et al. further expanded this concept by adjusting the Mn content in metastable FeMnCoCr HEAs to modulate the stacking fault energy of the matrix phase, thereby increasing the driving force (ΔG) for austenite-to-martensite (γ→ε) transformation within the matrix [16]. By promoting a dual-phase microstructure through composition design in FeMnCoCr HEAs, various mechanisms such as transformation-induced plasticity (TRIP), solid-solution lattice distortion, and dislocations can be utilized to strengthen their mechanical properties and overcome trade-offs between strength and ductility [22,23].

Engineering the martensitic transformation or TRIP effect has been validated as a viable and effective method of achieving superior strength–ductility synergy. Antolovich et al. reported that austenite-to-martensite at the crack of TRIP steels could assimilate additional energy [24]. Agrawal et al. demonstrated that the martensitic transformation delayed the crack initiation and prolonged crack extension life in the high cycle fatigue response of Fe40Mn20Co20Cr15Si5 HEA fabricated via LPBF [25]. Wang et al. discovered that the generation of compressive stress during martensitic transformation inhibited crack initiation [26]. However, some studies have shown that the transformation effect may degrade the ductility of alloys [27,28,29,30]. Unfortunately, the optimal combination of ductility and strength in HEAs remains poorly understood, due to potential deformation-induced transformation probably compromising their mechanical properties. Additionally, it has been observed that such transformation not only enhance plasticity but also induce local brittleness and nucleation damages [29]. Consequently, significant efforts were made to fabricate high-performance FeMnCoCr HEAs via LPBF while further exploring the mechanisms of martensitic transformation.

The FeMnCoCr high-entropy alloy system exhibits excellent mechanical properties overcoming the strength-ductility trade-off. Moreover, the Mn content plays an important role in the phase composition and phase stability of the alloy system. Specifically, the Mn content of 40 at% represents a critical point for the transition in deformation mechanisms, shifting from dislocation-dominated plasticity to twinning-induced plasticity and transformation-induced plasticity [16]. Therefore, Fe30Mn50Co10Cr10 (with a Mn content of 50 at%) and Fe50Mn30Co10Cr10 (with a Mn content of 30 at%) were selected for further investigation. However, at present, while a large amount of progress has been made towards LPBF-printed single-phase system HEAs, few studies have been carried out on single- and dual-phase FeMnCoCr systems. Furthermore, this is the first simultaneous study of the additive manufacturing of stable and metastable non-equimolar FeMnCoCr HEAs by tuning Mn elemental composition. This study investigated the processing optimization, microstructure, and mechanical properties of Fe80−xMnxCo10Cr10 HEAs fabricated by LPBF. Specifically, the effect of process parameters as well as Fe/Mn contents on the printability, microstructure, and mechanical properties of the LPBF-printed Fe80−xMnxCo10Cr10 HEAs were analyzed. A comparison of the microstructure and mechanical properties between Fe30Mn50Co10Cr10 and Fe50Mn30Co10Cr10 HEAs is discussed, while deformation-strengthening damage mechanisms are further elucidated. The underlying mechanisms behind TRIP effect and strengthening behavior during tensile deformation are revealed.

2. Materials and Experiments

2.1. Materials

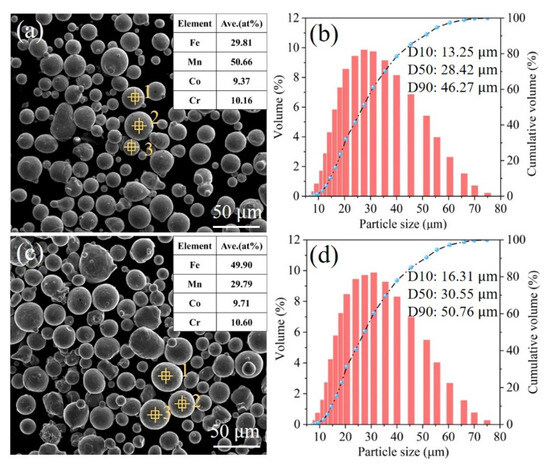

The pre-alloyed HEA powders used were Fe30Mn50Co10Cr10 (at%) and Fe50Mn30Co10Cr10 (at%) with a particle size distribution from 5 to 75 μm, which exhibited a stabilized single FCC phase and a metastable dual phase, respectively. The morphologies and element distributions of the powders were detected using a scanning electron microscope (SEM, FEI Quanta 250, Eindhoven, The Netherlands) with energy-dispersive spectroscopy (EDS) analysis. Both powder particles displayed near-spherical shapes (Figure 1a,c), as shown in the inserted images depicting the measured compositions of the powders, while three randomly selected powder particles were subjected to compositional analysis, indicating homogeneous elemental distribution. The average particle size D50 of the powders, measured using a laser particle size analyzer, increased from 28 to 30 μm upon decreasing the Mn content from 30 to 50 at% (Figure 1b,d).

Figure 1.

Characteristics of the Fe80−xMnxCo10Cr10 powders: (a,c) SEM images showing the morphology of the Fe30Mn50Co10Cr10 and Fe50Mn30Co10Cr10 powders, respectively, and inserted tables indicate the composition of the powders, (b,d) particle size distribution of the powders, respectively. Numbers 1, 2, and 3 represent EDS spectral point measurements.

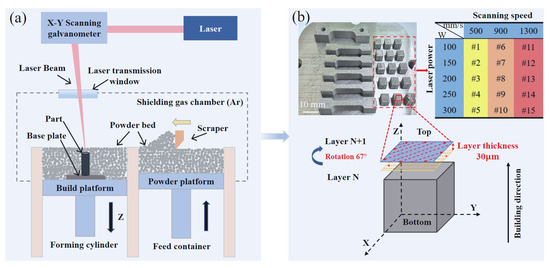

2.2. Sample Fabrication by LPBF

The LPBF process was conducted using a Dimetal-100 machine (Laseradd Technology, Guangzhou, China) with a 1064 nm Nd: YAG fiber laser and a two-axis scanner. A schematic illustration of the HEA samples produced by LPBF is shown in Figure 2a. The two types of Fe80−xMnxCo10Cr10 samples were printed on 316L stainless steel substrates and subsequently separated from the substrates by electrical discharge machining. The samples with sizes of 6 × 6 × 6 mm3 were printed using various combinations of process parameters as shown in Figure 2b, which included laser power (P) ranging from 100 W to 300 W, scanning speed (v) ranging from 500 mm/s to 1300 mm/s, hatch space (h) of 70 μm, a layer thickness (t) of 30 μm, and a scanning strategy involving rotating neighboring layers by 67° that can effectively mitigate residual stresses, thereby minimizing the risk of cracking in the fabricated samples. Volumetric energy densities (VEDs) were evaluated based on these parameters, i.e., VED = P/(vht). The same VEDs were used to print Fe30Mn50Co10Cr10 and Fe50Mn30Co10Cr10 HEAs for comparing their printability, microstructural evolution, and mechanical properties. The dog bone-shaped samples measuring 42 × 9 × 6 mm3 using different VEDs were fabricated and subsequently cut into tensile samples with dimensions of 42 × 9 × 1.5 mm3.

Figure 2.

(a) Schematic illustration of the LPBF process, and (b) printed HEA samples and process parameters used.

2.3. Characterizations

The relative density of the LPBF-printed HEAs depended on the ratio of the experimental density determined using Archimedes’ principle to the theoretical density, and each sample was tested three times to ensure that the results were reproducible. For microstructural characterizations, the samples were sequentially polished with 200-, 400-, 800-, 1200-, 2000-, and 3000-grit SiC sandpaper, and then polished using 2 μm sized diamond polishing particles until the surfaces were smooth without any scratches, and the polished sample surfaces were etched with aqua regia solution (HNO3:HCl = 1:3) for 30 s. The phase identification of the HEAs was performed via X-ray diffraction (XRD, Malvern Panalytical, Shanghai, China). The surface morphologies were characterized using an optical microscope (OM, Zeiss, Munich, Germany) and SEM, and composition characterization was conducted using an SEM equipped with an energy-dispersive spectrometer. The samples were polished by mechanical vibration on an electron-backscattered diffraction apparatus (EBSD, FEI Nova NanoSEM230, Hillsboro, OR, USA) for testing the microstructures of kernel average misorientation (KAM), inverse polar figure (IPF), and phase diagram used for analyzing the results with channel5 software.

2.4. Mechanical Testing

In microhardness testing, the indentation of the sample was performed on a digital microhardness tester (MVS-1000D1, Shanghai, China) with a Vickers indenter, applying a load of 0.2 kg for 15 s and ensuring the uniform distribution of five test points on the samples. The universal testing machine (SUST CMT5504, Zhuhai, China) was used to explore the tensile properties of the HEA samples, with a loading speed of 1 mm/min and a mechanical extensometer with a gauge length of 10 mm. Three samples were tested at room temperature for each printed HEA to verify the reproducibility of the mechanical properties, such as its yield strength (σy), ultimate tensile strength (σu), and elongation (δ). Intermittent tensile tests at strains of 10% and 20% were performed on the same samples, followed by cutting the fractured center region for an analysis of the deformed microstructure. The fracture morphology of the tensile samples was determined using a scanning electron microscope.

3. Results and Discussion

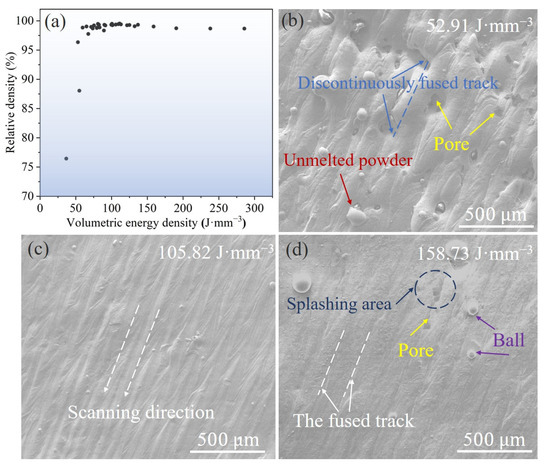

3.1. The Printability of LPBF-Printed Fe80−xMnxCo10Cr10 HEAs

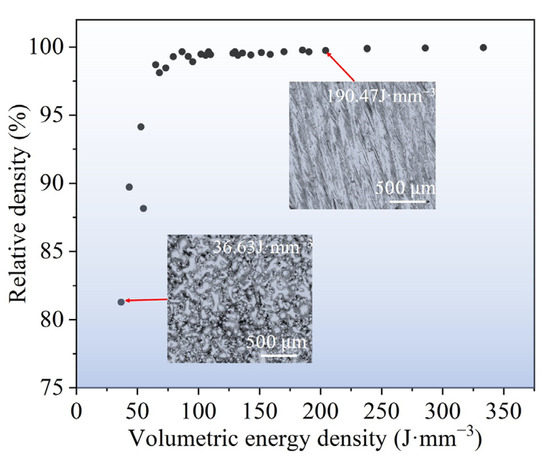

The relative density of the Fe30Mn50Co10Cr10 HEA samples exhibited an initial increase followed by a decrease as the VED increased from 36.63 to 285.71 J·mm−3 (Figure 3a). Notably, the relative density remained above 99% within a VED range of 75~150 J·mm−3. However, a slight decline in the relative density was observed with an increase in the VED, which can be attributed to the formation of pores in the samples under high-VED conditions. The augmentation of the Marangoni effect and elemental evaporation at elevated VEDs leads to increased porosity and a resultant reduction in relative density. Figure 3b–d illustrate the typical surface morphology of the printed samples. In the case of a VED of 52.91 J·mm−3, unmelted powder particles and pores were discernible on the sample surface along with discontinuities in melt track formation. With the VED increasing to 105.82 J·mm−3, a flat surface was achieved with continuous melt track formation, resulting in improved printing quality. However, at higher VEDs, overlapping melt tracks became evident along with pore formation on the sample surface and an increase in splashing phenomena [31].

Figure 3.

(a) Relative density of as-printed Fe30Mn50Co10Cr10 HEA samples with various volumetric energy densities. SEM images exhibiting the representative surface morphology of the as-printed samples under different VEDs: (b) 52.91 J·mm−3, (c) 105.82 J·mm−3, and (d) 158.73 J·mm−3.

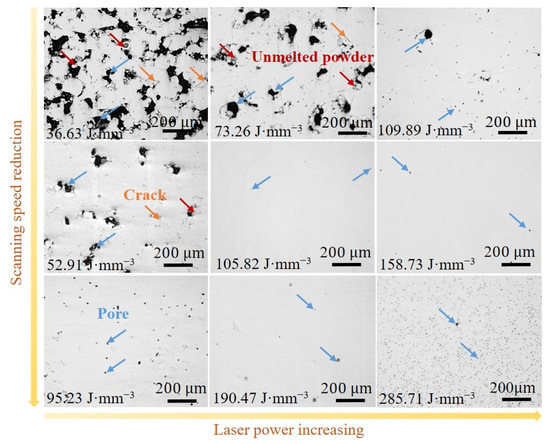

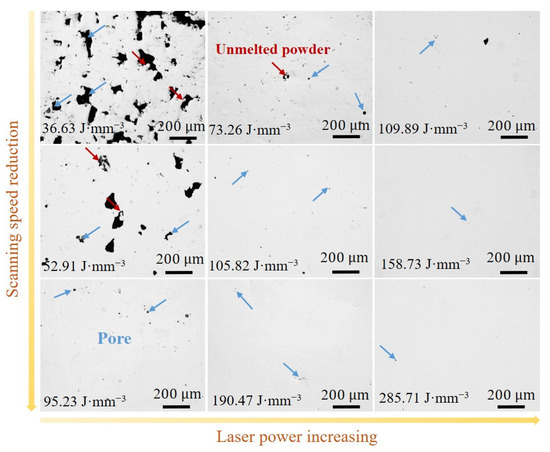

Figure 4 presents optical microscope images of the LPBF-printed Fe30Mn50Co10Cr10 samples with the combination of laser power and scan speed. The surface morphology of the printed samples exhibits defects such as unmelted powder particles, cracks, and pores. Initially, an increase in VED led to a decrease in the number of defects before eventually increasing, which is consistent with the trend observed for relative density. At high VEDs (above 190 J·mm−3), numerous small circular pores appeared on the sample surface due to the low boiling point of Mn (2324 °C) and the smallest heat of vaporization (220.7 kJ/mol), making it susceptible to vaporization under higher laser energy densities. Consequently, this results in intensified recoil pressure within the melt pool, promoting the formation of pores that are prone to axial fluctuations and radial perturbations governed by energy and pressure balances [32]. Moreover, this phenomenon induces instability and poses a risk of pore collapse, which can lead to gas bubble formation within the melt pool that may become trapped by a solidification front [33]. These small pores act as sources for stress concentration while also serving as locations for crack initiation and propagation that can degrade mechanical properties.

Figure 4.

Optical microscopic images of the LPBF-printed Fe30Mn50Co10Cr10 HEAs with different VEDs. The red, blue and orange arrows represent unmelt powder, pore and crack, respectively.

The volumetric energy density increased from 36.63 to 333.33 J·mm−3 (Figure 5), with an increase in the relative density of the LPBF-printed Fe50Mn30Co10Cr10 HEAs. Particularly, relative densities exceeding 99% were achieved at VEDs above 85 J·mm−3. Figure 5 demonstrates that at a VED of 36.63 J·mm−3, numerous unmelted powder particles and pores are observed on the sample surface, while discontinuous melt tracks are formed. However, when the VED reaches 190.47 J·mm−3, a flat surface morphology with visible melt tracks devoid of significant defects is attained.

Figure 5.

Relative density of as-printed Fe50Mn30Co10Cr10 HEA samples, and inserted image presents representative surface morphology of as-printed samples under different VEDs.

The surface morphology of LPBF-printed Fe50Mn30Co10Cr10 HEA samples with various laser powers and scanning speeds is depicted in Figure 6. The results reveal that the printed samples primarily exhibited defects including unmelted powder particles and pores. An inverse relationship between defects and VED is observable, which aligns to the trend in the relative density of the HEA samples. In comparison to Fe30Mn50Co10Cr10, the Fe50Mn30Co10Cr10 samples printed at high VEDs (above 190 J·mm−3) displayed fewer round pores on their surfaces. This can be attributed to the higher content of Fe, which possesses a high melting and boiling point compared to Mn, thereby promoting homogeneity in heat conduction at the two-phase interface during powder melting and the uniform distribution of elements within the melt pool. These factors contribute to reducing temperature gradients and solute solubility differences across different regions of the melt pool, inhibiting Marangoni effect formation [34]. Consequently, there were minimal defects on the surface of the Fe50Mn30Co10Cr10 samples under high-VED conditions.

Figure 6.

Optical microscopic images of the LPBF-printed Fe50Mn30Co10Cr10 HEA samples processed with different VEDs. The red and blue arrows represent unmelt powder and pore, respectively.

3.2. The Microstructure of LPBF-Printed Fe80−xMnxCo10Cr10 HEAs

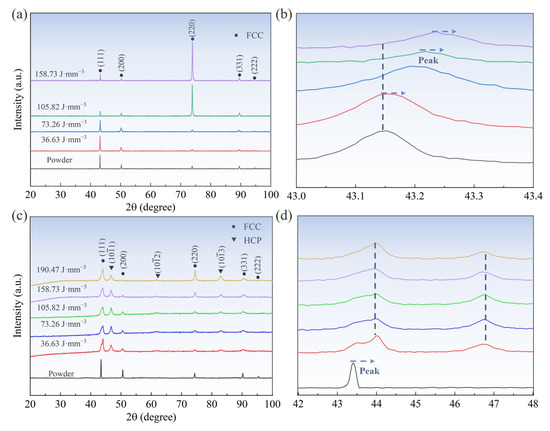

The Fe30Mn50Co10Cr10 HEA powders and their LPBF-printed samples exhibit a single-phase austenitic crystal structure (Figure 7a). The shift towards higher diffraction angles for peak (111), which changed from 43.15° to 43.25°, indicates a decrease in lattice parameters within the HEA as the VED increases (Figure 7b). This occurrence of a shifted diffraction angle can be attributed to the significant evaporation of Mn, with a lower boiling point compared to other elements in the FeMnCoCr HEA system, leading to a significantly lower elemental concentration at different volumetric energy densities. Additionally, due to its larger atomic diameter compared to Fe, Co, and Cr, the volatilization of Mn results in decreased lattice parameters within this HEA [21]. The diffraction pattern in Figure 7c exclusively demonstrates characteristic peaks corresponding to the austenitic crystal structure of Fe50Mn30Co10Cr10 powders, and the samples fabricated with different VEDs reveal the presence of martensite and austenite phase. Figure 7d demonstrates that the diffraction angles for peak (111) did not change as the VED increased except for the powder, and compared to the Fe30Mn50Co10Cr10 sample, its diffraction peak angle shows a more stabilized state at different VEDs. In summary, decreasing the Mn content from 50 to 30 at% transformed the lattice structure of the Fe80−xMnxCo10Cr10 HEA from FCC single-phase to FCC/HCP dual-phase. Gradual heat accumulation during the LPBF process results in a reduced temperature gradient and cooling rate in the melt pool, thereby promoting a thermotropic martensite phase transition. Notably, an increased intensity in the diffraction peak (220) was observed for the LPBF-printed Fe30Mn50Co10Cr10 and Fe50Mn30Co10Cr10 HEA samples when increasing the VED, indicating a preferential grain orientation within these samples.

Figure 7.

XRD patterns of the Fe80−xMnxCo10Cr10 powders and their LPBF-printed samples: (a) different VEDs of Fe30Mn50Co10Cr10, (b) enlarged drawing of peak (111) in (a), (c) different VEDs of Fe50Mn30Co10Cr10, (d) enlarged drawing of peak (111) in (c).

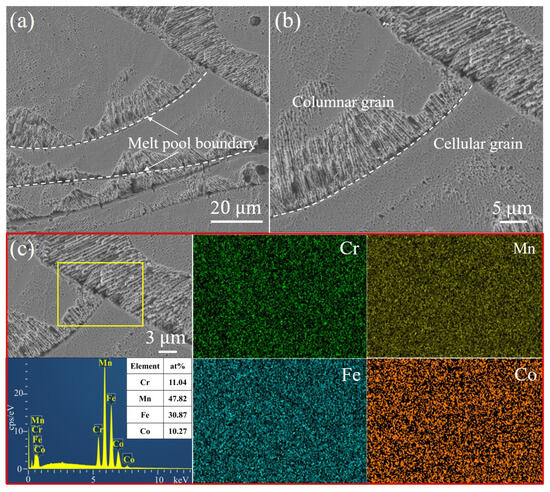

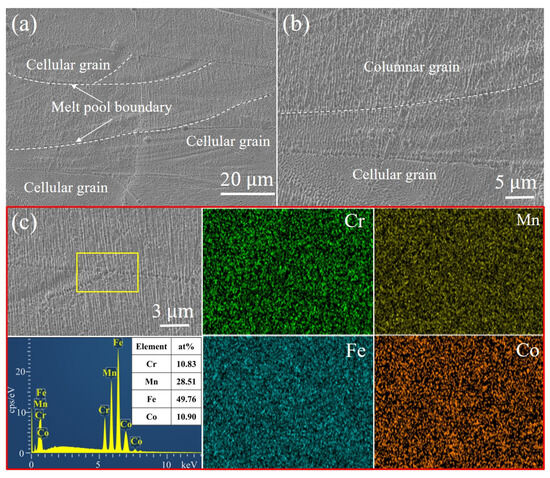

The microstructure of the Fe30Mn50Co10Cr10 HEA sample printed using a volumetric energy density of 105.82 J·mm−3 reveals the presence of corrosion pits at the melt pool boundary, as depicted in Figure 8a,b. The accelerated corrosion rate observed at this boundary can be attributed to the existence of significant thermal stresses. Within the melt pool, columnar crystal structures grew along the heat flow direction at both the bottom boundary and inner area, while a cellular crystal structure was observed at the top region. Additionally, limited spherical pores were detected within the melt pool, which may have resulted from the volatilization of low-melting-point elements such as Mn during the LPBF process. Elemental mapping analysis depicted in Figure 8c demonstrates the uniform distribution of Fe, Mn, Co, and Cr elements within the Fe30Mn50Co10Cr10 HEA corresponding to locations where corrosion pits occurred at the melt pool boundary (highlighted by the yellow box), without any significant elemental segregation.

Figure 8.

Microstructure and element distribution of the LPBF-printed Fe30Mn50Co10Cr10 HEA sample using a VED of 105.82 J·mm−3: (a) SEM image, (b) high-magnification image of (a), and (c) EDS mapping of element distributions.

The microstructure of the LPBF-printed Fe50Mn30Co10Cr10 HEA using an identical VED to Fe30Mn50Co10Cr10 is presented in Figure 9, showing primarily columnar and cellular grains with a distinct melt pool boundary. The morphology of the melt pool exhibited a semi-elliptical shape due to the Gaussian beam profile of the laser. Additionally, a significant heat accumulation led to large temperature gradients between solidified layers, facilitating the growth of columnar grains perpendicular or at an angle to the melt pool boundary. Numerous columnar grains extended across multiple solidified layers, while some gradually transformed into cellular grains as they propagated from perpendicular to the melt pool boundary to the direction of the heat flow. Figure 9c demonstrates a homogeneous distribution of HEA elements throughout the cross-section of the printed sample without any noticeable element segregation, except for minimal volatilization observed for Mn.

Figure 9.

Microstructure and element distribution of the LPBF-printed Fe50Mn30Co10Cr10 HEA sample using a VED of 105.82 J·mm−3: (a) SEM image, (b) high-magnification image of (a), and (c) EDS mapping of element distribution.

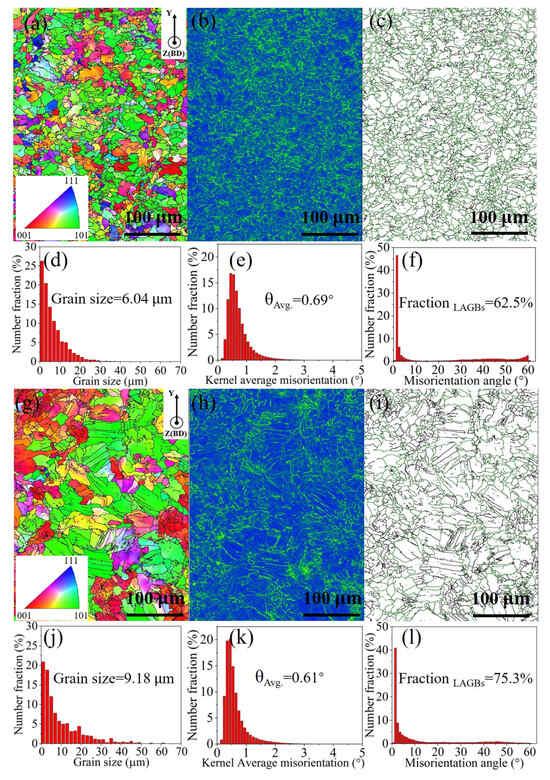

To further investigate the microstructure of the LPBF-printed Fe80−xMnxCo10Cr10 HEAs with different compositions in terms of grain size, crystal orientation, and grain texture, representative samples printed with the same VED (105.82 J·mm−3) were selected for microstructure analysis using EBSD (Figure 10). The Fe30Mn50Co10Cr10 HEA sample exhibits a smaller grain size compared to the Fe50Mn30Co10Cr10 sample (Figure 10a,g), with average grain sizes of 6.04 μm and 9.18 μm, respectively (Figure 10d,j). According to the Hall–Petch theory [35], increasing grain size is generally detrimental to the mechanical properties of metallic materials. A comparison between the KAM color map and KAM distributions reveals that the Fe30Mn50Co10Cr10 sample has a higher KAM value (0.69°) than the Fe50Mn30Co10Cr10 sample (0.61°) (Figure 10b,e,h,k), exhibiting a higher value of geometrically necessary dislocations (GNDs) in the Fe30Mn50Co10Cr10 HEA. Figure 10c,f,i,l demonstrate that the content of low-angle grain boundaries (LAGBs), ranging from 2° to 15° in orientation angles, is lower in the Fe30Mn50Co10Cr10 sample (62.5%) compared to that in the Fe50Mn30Co10Cr10 sample (75.3%). The reduction in the LAGBs contributes to improvements in mechanical properties due to their significant advantage as nucleation sites during creep and fatigue processes [36].

Figure 10.

EBSD analyses of the Fe80−xMnxCo10Cr10 HEA samples: (a–c) IPF, KAM color map, and misorientation map of the Fe30Mn50Co10Cr10 sample, respectively; (d–f) its grain size distribution, KAM distribution, and misorientation angle distribution, respectively. (g–i) IPF, KAM color map, and misorientation map of the Fe50Mn30Co10Cr10 sample, respectively, and (j–l) its grain size distribution, KAM distribution, and misorientation angle distribution, respectively.

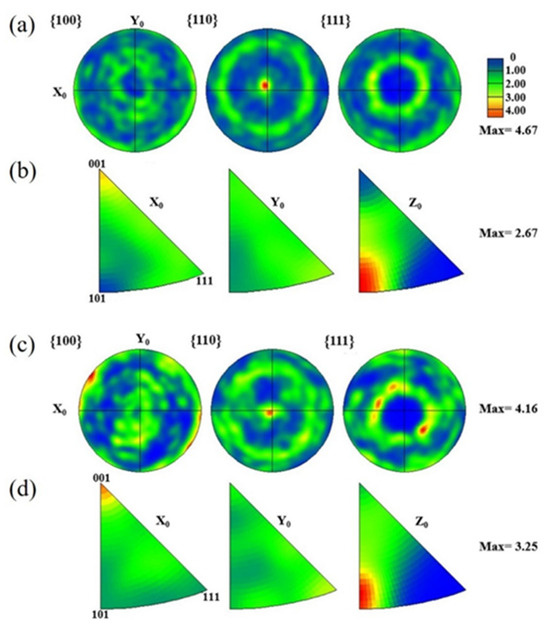

The Fe50Mn30Co10Cr10 sample exhibits a more disordered grain orientation, as depicted in Figure 11a,c, while both HEAs demonstrate the preferential growth of grains with an orientation parallel to <110>. This is evidenced by the prominent peak of intensity that was observed at the central region of the (110) polar figure, which corresponds well with the strong (220) diffraction peaks observed in the XRD pattern (Figure 7). In Figure 11b,d, both HEAs exhibit a strong texture with a <101> orientation along the build direction, thus highlighting the influence of direction of heat flow on the resulting texture characteristics. Typically, austenitic crystal structures tend to grow with a prioritized texture with <001> oriented along the build direction [37]. However, this preferred orientation and microstructure can be altered by adjusting the rotating angle of successive solidified layers.

Figure 11.

Grain orientation of LPBF-printed Fe80−xMnxCo10Cr10 HEAs: (a,b) polar figure and IPF of the Fe30Mn50Co10Cr10 alloy along the X-Y plane, respectively, and (c,d) polar figure and IPF of the Fe50Mn30Co10Cr10 alloy along the X-Y plane.

3.3. Mechanical Properties

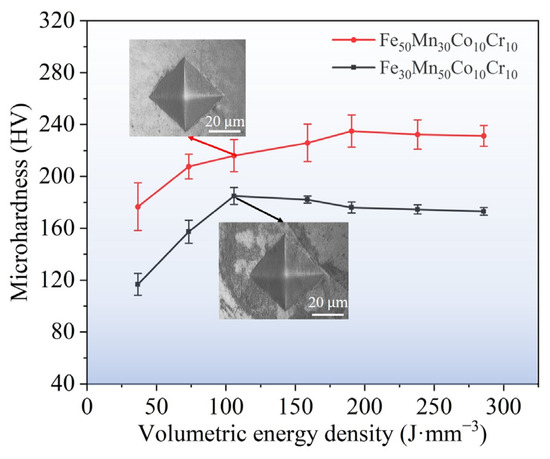

Figure 12 depicts the microhardness of as-printed Fe80−xMnxCo10Cr10 HEAs with various VEDs. It is evident that with increasing VED, the microhardness of the Fe50Mn30Co10Cr10 samples and the Fe30Mn50Co10Cr10 samples tend to initially increase and then decrease. Moreover, the microhardness of Fe50Mn30Co10Cr10 remains consistently higher than that of Fe30Mn50Co10Cr10. In the case of a VED of 36.63 J·mm−3, the minimum microhardness values for the Fe50Mn30Co10Cr10 and Fe30Mn50Co10Cr10 samples are 176.66 HV and 116.74 HV, respectively. Furthermore, with the VED increasing to 105.82 J·mm−3, there is an increase in maximum microhardness in the Fe30Mn50Co10Cr10 sample, reaching up to 184.98 HV; however, this increase in microhardness is accompanied by a significant presence of microporous defects in samples at higher VEDs, leading to an overall decrease in microhardness. In the case of a VED of 190.47 J·mm−3, the maximum microhardness on the Fe50Mn30Co10Cr10 sample reaches 234.96 HV, due to martensitic ε-phase formation resulting in higher microhardness.

Figure 12.

Microhardness of LPBF-printed Fe80−xMnxCo10Cr10 HEA samples under different VEDs.

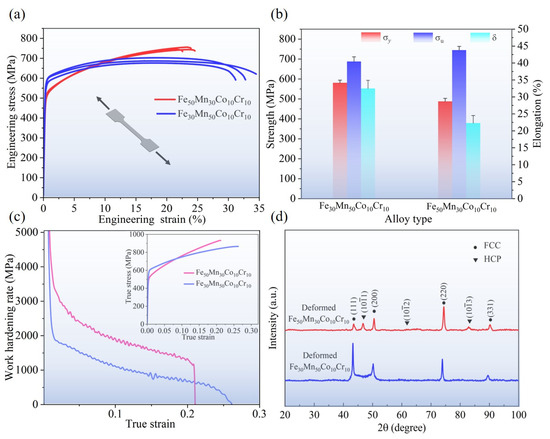

Representative stress–strain curves of Fe30Mn50Co10Cr10 and Fe50Mn30Co10Cr10 HEAs fabricated by LPBF at identical VED are illustrated in Figure 13a. The yield strength and ultimate tensile strength of the Fe50Mn30Co10Cr10 samples are 487.60 MPa and 744.90 MPa, respectively. In contrast, the Fe30Mn50Co10Cr10 samples exhibit an σy value of 580.65 MPa and an σu value of 687.70 MPa. In addition, it is noteworthy that the elongation of the Fe50Mn30Co10Cr10 sample (22.3%) is lower than that observed for the Fe30Mn50Co10Cr10 sample (32.5%), as presented in Table 1. Interestingly, despite possessing a slightly higher σy value due to its smaller grain size, grain-refined single-phase FCC-structured Fe30Mn50Co10Cr10 samples exhibit significantly lower σu values compared to dual-phase Fe50Mn30Co10Cr10 samples with various grain sizes. The discrepancy can be attributed to an increase in martensitic phase fraction and higher residual stresses within the austenitic phase matrix during the tensile deformation process [38], causing an earlier attainment of yield limit point for the Fe50Mn30Co10Cr10 HEA.

Figure 13.

Tensile properties of LPBF-printed Fe30Mn50Co10Cr10 and Fe50Mn30Co10Cr10 HEAs under an identical VED of 105.82 J·mm−3: (a) stress–strain curves, (b) histogram of yield strength, ultimate tensile strength, and elongation, (c) responses between work hardening rate and true strain, and inserted image presents true stress–strain curves, and (d) XRD patterns of the deformed samples printed by VED of the two HEAs.

Table 1.

Tensile properties of Fe80−xMnxCo10Cr10 alloy (at%).

The Fe50Mn30Co10Cr10 sample displays a higher work hardening rate compared to the Fe30Mn50Co10Cr10 sample (Figure 13c, attributed to the occurrence of a martensitic phase transition in the high dislocation region of austenite. This phase transition impedes dislocation slip and results in a sustained higher work hardening rate. Conversely, the fracture behavior of the Fe50Mn30Co10Cr10 sample is characterized by an abrupt decline in work hardening rate, indicating a “hard and brittle” effect during late strain stages. Although the martensitic phase transformation improves the ultimate tensile strength of the Fe50Mn30Co10Cr10 sample, it adversely affects its ductility. The deformed Fe50Mn30Co10Cr10 HEA samples in Figure 13d exhibit the presence of both martensite and austenite phases, while the deformed Fe30Mn50Co10Cr10 HEA samples consist of a sole austenite single phase. In conclusion, this study highlights the excellent mechanical properties achieved through LPBF printing for both Fe30Mn50Co10Cr10 and Fe50Mn30Co10Cr10 HEAs.

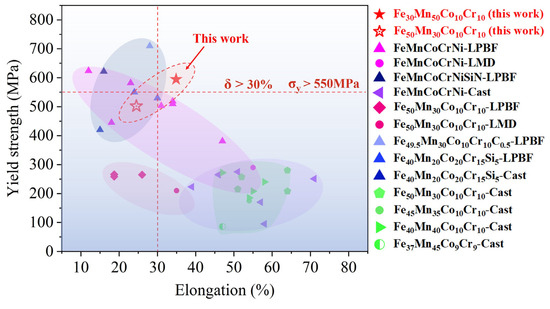

As shown in Figure 14, the LPBF-printed FeMnCoCr HEA systems exhibit an an exceptional combination of ductility and strength compared with previously reported additively manufactured FeMnCoCr HEAs [4,21,39,40,41,42,43,44,45,46,47,48,49,50] and cast FeMnCoCr-based HEAs [9,10,11,12,13,14,15,16,17,18,29,50,51,52,53,54,55]. This study shows that the elongation is over ~30% and the yield strength is over ~550 MPa. Meanwhile, the yield strength is significantly higher than the cast counterparts, and its ductility is comparable to pure and elementally added alloys.

Figure 14.

Comparison chart of the mechanical properties of the typical Fe30Mn50Co10Cr10, Fe50Mn30Co10Cr10 HEAs, and FeMnCoCr-based HEAs fabricated by AM [4,21,39,40,41,42,43,44,45,46,47,48,49,50] and traditional manufacturing process [9,10,11,12,13,14,15,16,17,18,29,50,51,52,53,54,55].

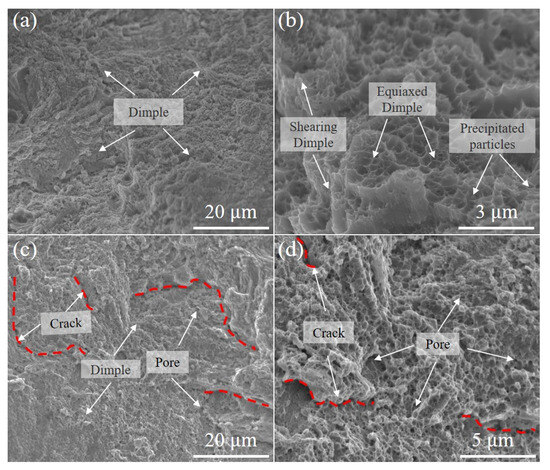

The fracture surface of the Fe30Mn50Co10Cr10 sample exhibits a multitude of equiaxial and shear dimples, indicating typical ductile fracture behavior (Figure 15a,b). Additionally, sporadic precipitated particles are observed at the center of these dimples, contributing to stress concentration and promoting micro-void expansion during tensile deformation, thereby influencing the mechanical properties of the HEAs. Figure 15c,d demonstrate that the Fe50Mn30Co10Cr10 sample displays a characteristic ductile fracture with numerous dimples containing pore and crack defects. This can be attributed to the presence of heterogeneous interfacial stresses between austenite and newly formed martensite, which induce the initiation and propagation of microcracks and pores within the dual-phase structure, consequently resulting in reduced ductility.

Figure 15.

SEM images of fractured morphology of LPBF-fabricated Fe80−xMnxCo10Cr10 samples after tensile deformation: (a) Fe30Mn50Co10Cr10 sample, (b) high-magnification image of (a), (c) Fe50Mn30Co10Cr10 sample, and (d) high-magnification image of (c). The red dotted lines represent crack.

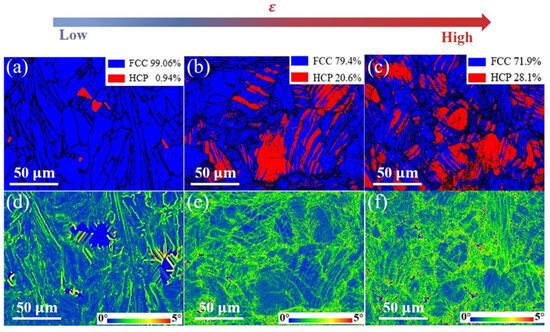

In summary, the two HEAs have extraordinary tensile properties, especially the characteristics (brittleness) of the Fe50Mn30Co10Cr10 HEA during tensile deformation. Moreover, the Fe30Mn50Co10Cr10 HEA has better ductility and does not present transition behavior during deformation (Figure 13d). Therefore, it is valuable to further explore the microstructural evolution of Fe50Mn30Co10Cr10 HEAs under different strains. The microstructure deformation in the LPBF-printed Fe50Mn30Co10Cr10 sample was investigated using EBSD at various regions of its fracture with different strain levels. The melt pools experienced significant temperature gradients and cooling rates during LPBF. The appearance of a minimal presence of HCP phase in the LPBF-fabricated Fe50Mn30Co10Cr10 HEA can be attributed to a non-equilibrium solidification of the melt pools significantly promoting a thermal martensitic transformation in this HEA (Figure 16a). With an increase in local strain from 0 to 20%, the average proportion of the HCP phase obtained from EBSD increases accordingly, ranging from 0.94% to 28.1% (Figure 16b,c). At the initial stage of deformation, regions with or neighboring to the FCC phase present significantly larger KAM values (Figure 16e), while regions with the HCP phase exhibit less noticeable KAM values. The KAM values indicate the density of GNDs to be within a specified area [56]; thus, larger KAM values in the FCC phase regions indicate a higher density of GNDs and pronounced plastic strains within these areas. These results illustrate that it is predominantly the FCC phase that accommodates plastic strain at this stage. Regarding strain partitioning behavior during the intermediate and late stages of deformation, the FCC phase regions still obtain larger KAM values, while most of the HCP phase regions exhibit even larger KAM values in comparison to those observed in the initial stage (Figure 16f). Generally, the HCP phase is known to be more rigid and less susceptible to deformation compared to FCC phase observed in most industrial alloys. Moreover, the GND at the FCC/HCP interface that contributes to the tendency of microporous generation is significantly higher compared with the other regions. This is an explanation for why it is more challenging for GND arrays to form within internal regions of the HCP-phase grains; instead, dislocations and stacking faults occur as slip bands within the HCP phase [57].

Figure 16.

EBSD results illustrating the microstructural evolution in the Fe50Mn30Co10Cr10 HEA sample under increasing tensile strains: (a–c) phase distributions at strains of 0%, 10%, and 20%, respectively, and (d–f) KAM maps at strains of 0%, 10%, and 20%, respectively.

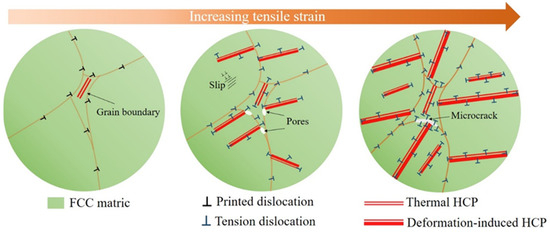

The phase transformations in the Fe50Mn30Co10Cr10 HEA play a dual influence mechanism on its mechanical properties, as illustrated in Figure 17. During early deformation, the phase transformation enhances the strain hardening rate and the mechanical strength of the HEA. However, during late deformation stages, the dual-phase deformation of martensite and austenite causes a local high degree of incompatibility, leading to blocked dislocation movement and increased dislocation density near the interphase, generating stress concentration [29]. This promotes the nucleation of pores and the expansion of cracks. The formation of a martensite phase transition is more brittle, making it susceptible to induced crack expansion and damaging the HEA’s ductility. The Fe50Mn30Co10Cr10 HEA has lower stacking fault energy than the Fe30Mn50Co10Cr10 HEA [16], allowing for the easy bundling of incomplete dislocations to ensure cross slip as the stacking fault energy decreases. The synergistic deformation of these two phases generates a beneficial dynamic strain–stress partitioning effect [58]. During the deformation process, the GNDs accumulated at the interface of the dual-phase region generate heterogeneous deformation-induced stresses [59], which further lead to the plastic instability of the alloy. Therefore, the martensitic transformation plays a dual role in strength and ductility; i.e., one is useful for tensile strength and initial ductile elongation, while the other is harmful for ductility fracture. This contradicts the general view that the martensite phase transition is beneficial for ductility [60].

Figure 17.

Schematic diagram of microstructural evolution of the Fe50Mn30Co10Cr10 HEA at increased strains.

4. Conclusions

In this study, gas-atomized non-equimolar Fe30Mn50Co10Cr10 and Fe50Mn30Co10Cr10 powders were used for laser powder bed fusion. The microstructural evolution and mechanical properties of non-equimolar Fe80−xMnxCo10Cr10 (x = 30%, 50%) HEAs fabricated by LPBF were comprehensively characterized. The findings are presented as follows.

The increased volumetric energy density led to a higher relative density for the LPBF-printed Fe80−xMnxCo10Cr10 sample. At a VED of 75 and 85 J·mm−3, the Fe30Mn50Co10Cr10 and Fe50Mn30Co10Cr10 samples achieved a relative density of 99%, respectively. Surface morphological observations revealed the formation of circular pores in the Fe30Mn50Co10Cr10 sample when Mn element evaporation occurred above a VED of 190 J·mm−3, resulting in a decrease in relative density.

The LPBF-printed and deformed Fe30Mn50Co10Cr10 samples exhibited single-phase FCC structures, but the Fe50Mn30Co10Cr10 samples exhibited dual-phase FCC-HCP structures under different VEDs. The diffraction peak intensities of both HEAs shifted with the increase in VED. The grain orientation of both HEAs demonstrated preferential growth of grains with an orientation parallel to <110>, which corresponds to the strong (220) diffraction peaks observed in the XRD pattern. The microstructure of both HEAs consisted of columnar and cellular grains. Moreover, with an increase in the strain of the Fe50Mn30Co10Cr10 sample from 0 to 20%, there was a corresponding rise in the average fraction of the martensitic phase range from 0.94% to 28.1%.

At a VED of 105.82 and 190.47 J·mm−3, the maximum microhardness of the Fe30Mn50Co10Cr10 and Fe50Mn30Co10Cr10 samples reached 184.98 HV and 234.96 HV, respectively. The yield strength, ultimate tensile strength, and elongation of the Fe50Mn30Co10Cr10 samples were 487.60 MPa, 744.90 MPa, and 22.3%, respectively. In contrast, the Fe30Mn50Co10Cr10 samples exhibited an σy value of 580.65 MPa, an σu value of 687.70 MPa, and an δ value of 32.5%. Despite the fact that the Fe50Mn30Co10Cr10 HEA possessed larger grains, lower dislocation density, and fewer LAGBs compared to the Fe30Mn50Co10Cr10 HEA in the horizontal plane, the ultimate tensile strength of the former was superior to that of the latter. Such an abnormal phenomenon can be attributed to the HCP phase formed during tensile deformation in the Fe50Mn30Co10Cr10 HEA, enhancing its mechanical strength. Moreover, the elongation of the Fe50Mn30Co10Cr10 HEA was lower compared with the Fe30Mn50Co10Cr10 HEA.

Author Contributions

Conceptualization, methodology, validation, writing—original draft preparation, K.L.; supervision, writing—review and editing, funding acquisition, V.T. and C.H.; data curation, G.H. and Z.D.; visualization, Y.Z. and Z.W.; formal analysis, F.Y.; investigation, writing—review and editing, Z.F.; project administration, Y.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Fundamental Research Funds for the Central Universities (Grant No. 2023ZYGXZR061), Science and Technology Program of Guangzhou (Grant No.202201010362), Guangdong Basic and Applied Basic Research Foundation (Grant No. 2022A1515010304).

Data Availability Statement

The data presented in this paper are available on request from the corresponding author. The data are not publicly available due to privacy restrictions.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shi, W.; Li, J.; Liu, Y.; Liu, S.; Lin, Y.; Han, Y. Experimental study on mechanism of influence of laser energy density on surface quality of Ti-6Al-4V alloy in selective laser melting. J. Cent. South Univ. 2022, 29, 3447–3462. [Google Scholar] [CrossRef]

- Ren, J.; Zhang, Y.; Zhao, D.; Chen, Y.; Guan, S.; Liu, Y.; Liu, L.; Peng, S.; Kong, F.; Poplawsky, J.D.; et al. Strong yet ductile nanolamellar high-entropy alloys by additive manufacturing. Nature 2022, 608, 62–68. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.D.; De, A.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Li, R.; Niu, P.; Yuan, T.; Li, Z. Displacive transformation as pathway to prevent micro-cracks induced by thermal stress in additively manufactured strong and ductile high-entropy alloys. Trans. Nonferrous Met. Soc. China 2021, 31, 1059–1073. [Google Scholar] [CrossRef]

- Kartikeya Sarma, I.; Selvaraj, N.; Kumar, A. Parametric investigation and characterization of 17-4 PH stainless steel parts fabricated by selective laser melting. J. Cent. South Univ. 2023, 30, 855–870. [Google Scholar] [CrossRef]

- Han, C.; Fang, Q.; Shi, Y.; Tor, S.B.; Chua, C.K.; Zhou, K. Recent advances on high-entropy alloys for 3D printing. Adv. Mater. 2020, 32, 1903855. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Ritchie, R.O.; Meyers, M.A. Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog. Mater. Sci. 2019, 102, 296–345. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Gali, A.; George, E.P. Tensile properties of high- and medium-entropy alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef]

- Salishchev, G.A.; Tikhonovsky, M.A.; Shaysultanov, D.G.; Stepanov, N.D.; Kuznetsov, A.V.; Kolodiy, I.V.; Tortika, A.S.; Senkov, O.N. Effect of Mn and V on structure and mechanical properties of high-entropy alloys based on CoCrFeNi system. J. Alloys Compd. 2014, 591, 11–21. [Google Scholar] [CrossRef]

- Chen, J.; Yao, Z.; Wang, X.; Lu, Y.; Wang, X.; Liu, Y.; Fan, X. Effect of C content on microstructure and tensile properties of as-cast CoCrFeMnNi high entropy alloy. Mater. Chem. Phys. 2018, 210, 136–145. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Horst, O.M.; Eggeler, G.; George, E.P. Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2016, 118, 152–163. [Google Scholar] [CrossRef]

- Yao, M.J.; Pradeep, K.G.; Tasan, C.C.; Raabe, D. A novel, single phase, non-equiatomic FeMnNiCoCr high-entropy alloy with exceptional phase stability and tensile ductility. Scr. Mater. 2014, 72, 5–8. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J. Grain size-dependent phase-specific deformation mechanisms of the Fe50Mn30Co10Cr10 high entropy alloy. Mater. Sci. Eng. A 2022, 854, 143867. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef]

- He, Z.F.; Jia, N.; Wang, H.W.; Liu, Y.; Li, D.Y.; Shen, Y.F. The effect of strain rate on mechanical properties and microstructure of a metastable FeMnCoCr high entropy alloy. Mater. Sci. Eng. A 2020, 776, 138982. [Google Scholar] [CrossRef]

- Wang, H.; He, Z.; Jia, N. Microstructure and mechanical properties of a FeMnCoCr high-entropy alloy with heterogeneous structure. Acta Met. Sin. 2020, 57, 632–640. [Google Scholar]

- Guan, S.; Wan, D.; Solberg, K.; Berto, F.; Welo, T.; Yue, T.M.; Chan, K.C. Additive manufacturing of fine-grained and dislocation-populated CrMnFeCoNi high entropy alloy by laser engineered net shaping. Mater. Sci. Eng. A 2019, 761, 138056. [Google Scholar] [CrossRef]

- Guo, C.; Wei, S.; Wu, Z.; Wang, P.; Zhang, B.; Ramamurty, U.; Qu, X. Effect of dual phase structure induced by chemical segregation on hot tearing reduction in additive manufacturing. Mater. Des. 2023, 228, 111847. [Google Scholar] [CrossRef]

- Li, R.; Niu, P.; Yuan, T.; Cao, P.; Chen, C.; Zhou, K. Selective laser melting of an equiatomic CoCrFeMnNi high-entropy alloy: Processability, non-equilibrium microstructure and mechanical property. J. Alloys Compd. 2018, 746, 125–134. [Google Scholar] [CrossRef]

- Huang, H.; Wu, Y.; He, J.; Wang, H.; Liu, X.; An, K.; Wu, W.; Lu, Z. Phase-transformation ductilization of brittle high-entropy alloys via metastability engineering. Adv. Mater. 2017, 29, 1701678. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; De Vecchis, R.R.; Li, C.; Zhang, H.; Hu, X.; Sridar, S.; Wang, Y.; Chen, W.; Xiong, W. Design metastability in high-entropy alloys by tailoring unstable fault energies. Sci. Adv. 2022, 8, o7333. [Google Scholar] [CrossRef] [PubMed]

- Antolovich, S.D.; Singh, B. On the toughness increment associated with the austenite to martensite phase transformation in TRIP steels. Metall. Mater. Trans. B 1971, 2, 2135–2141. [Google Scholar] [CrossRef]

- Agrawal, P.; Haridas, R.S.; Thapliyal, S.; Yadav, S.; Mishra, R.S.; McWilliams, B.A.; Cho, K.C. Metastable high entropy alloys: An excellent defect tolerant material for additive manufacturing. Mater. Sci. Eng. A 2021, 826, 142005. [Google Scholar] [CrossRef]

- Wang, X.; Liu, C.; Sun, B.; Ponge, D.; Jiang, C.; Raabe, D. The dual role of martensitic transformation in fatigue crack growth. Proc. Natl. Acad. Sci. USA 2022, 119, e2110139119. [Google Scholar] [CrossRef] [PubMed]

- Jacques, P.; Furnemont, Q.; Pardoen, T.; Delannay, F. On the role of martensitic transformation on damage and cracking resistance in TRIP-assisted multiphase steels. Acta Mater. 2001, 49, 139–152. [Google Scholar] [CrossRef]

- Lacroix, G.; Pardoen, T.; Jacques, P.J. The fracture toughness of TRIP-assisted multiphase steels. Acta Mater. 2008, 56, 3900–3913. [Google Scholar] [CrossRef]

- Wei, S.; Kim, J.; Tasan, C.C. Boundary micro-cracking in metastable Fe45Mn35Co10Cr10 high-entropy alloys. Acta Mater. 2019, 168, 76–86. [Google Scholar] [CrossRef]

- Hu, C.; Huang, C.P.; Liu, Y.X.; Perlade, A.; Zhu, K.Y.; Huang, M.X. The dual role of TRIP effect on ductility and toughness of a medium Mn steel. Acta Mater. 2023, 245, 118629. [Google Scholar] [CrossRef]

- Li, Z.; Li, H.; Yin, J.; Li, Y.; Nie, Z.; Li, X.; You, D.; Guan, K.; Duan, W.; Cao, L.; et al. A review of spatter in laser powder bed fusion additive manufacturing: In situ detection, generation, effects, and countermeasures. Micromachines 2022, 13, 1366. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.; Liu, H.; Wang, H.; Wei, Q.; Xiao, Y.; Tang, Z.; Wu, Y.; Wang, H. Identifying the keyhole stability and pore formation mechanisms in laser powder bed fusion additive manufacturing. J. Mater. Process. Technol. 2023, 321, 118153. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Chia, H.Y.; Yan, W. Mechanism of keyhole pore formation in metal additive manufacturing. NPJ Comput. Mater. 2022, 8, 22. [Google Scholar] [CrossRef]

- Michi, R.A.; Plotkowski, A.; Shyam, A.; Dehoff, R.R.; Babu, S.S. Towards high-temperature applications of aluminium alloys enabled by additive manufacturing. Int. Mater. Rev. 2022, 67, 298–345. [Google Scholar] [CrossRef]

- Hall, E.O. The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Society. Sect. B 1951, 64, 747. [Google Scholar] [CrossRef]

- Tan, L.; Sridharan, K.; Allen, T.R. Effect of thermomechanical processing on grain boundary character distribution of a Ni-based superalloy. J. Nucl. Mater. 2007, 371, 171–175. [Google Scholar] [CrossRef]

- Zhou, K.; Han, C. Laser Powder Bed Fusion. Met. Powder-Based Addit. Manuf. 2023, 75–159. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Zhu, Z.G.; Nguyen, Q.B.; Ng, F.L.; An, X.H.; Liao, X.Z.; Liaw, P.K.; Nai, S.; Wei, J. Hierarchical microstructure and strengthening mechanisms of a CoCrFeNiMn high entropy alloy additively manufactured by selective laser melting. Scr. Mater. 2018, 154, 20–24. [Google Scholar] [CrossRef]

- Wang, B.; Sun, M.; Li, B.; Zhang, L.; Lu, B. Anisotropic response of CoCrFeMnNi high-entropy alloy fabricated by selective laser melting. Materials 2020, 13, 5687. [Google Scholar] [CrossRef]

- Chen, P.; Yang, C.; Li, S.; Attallah, M.M.; Yan, M. In-situ alloyed, oxide-dispersion-strengthened CoCrFeMnNi high entropy alloy fabricated via laser powder bed fusion. Mater. Des. 2020, 194, 108966. [Google Scholar] [CrossRef]

- Haase, C.; Tang, F.; Wilms, M.B.; Weisheit, A.; Hallstedt, B. Combining thermodynamic modeling and 3D printing of elemental powder blends for high-throughput investigation of high-entropy alloys–Towards rapid alloy screening and design. Mater. Sci. Eng. A 2017, 688, 180–189. [Google Scholar] [CrossRef]

- Xiang, S.; Luan, H.; Wu, J.; Yao, K.; Li, J.; Liu, X.; Tian, Y.; Mao, W.; Bai, H.; Le, G.; et al. Microstructures and mechanical properties of CrMnFeCoNi high entropy alloys fabricated using laser metal deposition technique. J. Alloys Compd. 2019, 773, 387–392. [Google Scholar] [CrossRef]

- Guo, L.; Gu, J.; Gan, B.; Ni, S.; Bi, Z.; Wang, Z.; Song, M. Effects of elemental segregation and scanning strategy on the mechanical properties and hot cracking of a selective laser melted FeCoCrNiMn-(N, Si) high entropy alloy. J. Alloys Compd. 2021, 865, 158892. [Google Scholar] [CrossRef]

- Hou, Y.; Liu, T.; He, D.; Li, Z.; Chen, L.; Su, H.; Fu, P.; Dai, P.; Huang, W. Sustaining strength-ductility synergy of SLM Fe50Mn30Co10Cr10 metastable high-entropy alloy by Si addition. Intermetallics 2022, 145, 107565. [Google Scholar] [CrossRef]

- Hou, Y.; Li, Z.; Chen, L.; Xiang, Z.; Dai, P.; Chen, J. SLM Fe50Mn30Co10Cr10 metastable high entropy alloy with Al-Ti addition: Synergizing strength and ductility. J. Alloys Compd. 2023, 941, 168830. [Google Scholar] [CrossRef]

- Niu, P.; Li, R.; Fan, Z.; Yuan, T.; Zhang, Z. Additive manufacturing of TRIP-assisted dual-phases Fe50Mn30Co10Cr10 high-entropy alloy: Microstructure evolution, mechanical properties and deformation mechanisms. Mater. Sci. Eng. A 2021, 814, 141264. [Google Scholar] [CrossRef]

- Zhu, Z.G.; An, X.H.; Lu, W.J.; Li, Z.M.; Ng, F.L.; Liao, X.Z.; Ramamurty, U.; Nai, S.M.L.; Wei, J. Selective laser melting enabling the hierarchically heterogeneous microstructure and excellent mechanical properties in an interstitial solute strengthened high entropy alloy. Mater. Res. Lett. 2019, 7, 453–459. [Google Scholar] [CrossRef]

- Thapliyal, S.; Agrawal, P.; Agrawal, P.; Nene, S.S.; Mishra, R.S.; McWilliams, B.A.; Cho, K.C. Segregation engineering of grain boundaries of a metastable Fe-Mn-Co-Cr-Si high entropy alloy with laser-powder bed fusion additive manufacturing. Acta Mater. 2021, 219, 117271. [Google Scholar] [CrossRef]

- Agrawal, P.; Thapliyal, S.; Nene, S.S.; Mishra, R.S.; McWilliams, B.A.; Cho, K.C. Excellent strength-ductility synergy in metastable high entropy alloy by laser powder bed additive manufacturing. Addit. Manuf. 2020, 32, 101098. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.H.; Park, H.; Kim, J.; Yang, G.; Kim, R.; Song, T.; Suh, D.; Kim, J. Temperature-dependent universal dislocation structures and transition of plasticity enhancing mechanisms of the Fe40Mn40Co10Cr10 high entropy alloy. Int. J. Plast. 2022, 148, 103148. [Google Scholar] [CrossRef]

- He, Z.F.; Jia, N.; Ma, D.; Yan, H.; Li, Z.M.; Raabe, D. Joint contribution of transformation and twinning to the high strength-ductility combination of a FeMnCoCr high entropy alloy at cryogenic temperatures. Mater. Sci. Eng. A 2019, 759, 437–447. [Google Scholar] [CrossRef]

- You, D.; Yang, G.; Choa, Y.; Kim, J. Crack-resistant σ/FCC interfaces in the Fe40Mn40Co10Cr10 high entropy alloy with the dispersed σ-phase. Mater. Sci. Eng. A 2022, 831, 142039. [Google Scholar] [CrossRef]

- Deng, Y.; Tasan, C.C.; Pradeep, K.G.; Springer, H.; Kostka, A.; Raabe, D. Design of a twinning-induced plasticity high entropy alloy. Acta Mater. 2015, 94, 124–133. [Google Scholar] [CrossRef]

- Tasan, C.C.; Deng, Y.; Pradeep, K.G.; Yao, M.J.; Springer, H.; Raabe, D. Composition dependence of phase stability, deformation mechanisms, and mechanical properties of the CoCrFeMnNi high-entropy alloy system. Jom 2014, 66, 1993–2001. [Google Scholar] [CrossRef]

- Gao, H.; Huang, Y.; Nix, W.D.; Hutchinson, J.W. Mechanism-based strain gradient plasticity—I. Theory. J. Mech. Phys. Solids 1999, 47, 1239–1263. [Google Scholar] [CrossRef]

- Fang, Q.; Chen, Y.; Li, J.; Jiang, C.; Liu, B.; Liu, Y.; Liaw, P.K. Probing the phase transformation and dislocation evolution in dual-phase high-entropy alloys. Int. J. Plast. 2019, 114, 161–173. [Google Scholar] [CrossRef]

- Yang, K.; Li, Y.; Hong, Z.; Du, S.; Ma, T.; Liu, S.; Jin, X. The dominating role of austenite stability and martensite transformation mechanism on the toughness and ductile-to-brittle-transition temperature of a quenched and partitioned steel. Mater. Sci. Eng. A 2021, 820, 141517. [Google Scholar] [CrossRef]

- Li, A.X.; Liu, X.S.; Li, R.; Yu, S.B.; Jiang, M.H.; Zhang, J.S.; Che, C.N.; Huang, D.; Yu, P.F.; Li, G. Double heterogeneous structures induced excellent strength-ductility synergy in Ni40Co30Cr20Al5Ti5 medium-entropy alloy. J. Mater. Sci. Technol. 2023, 181, 176–188. [Google Scholar] [CrossRef]

- Tian, C.; Ouyang, D.; Wang, P.; Zhang, L.; Cai, C.; Zhou, K.; Shi, Y. Strength-ductility synergy of an additively manufactured metastable high-entropy alloy achieved by transformation-induced plasticity strengthening. Int. J. Plast. 2024, 172, 103823. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).