A Thermal Tactile Sensation Display with Controllable Thermal Conductivity

Abstract

1. Introduction

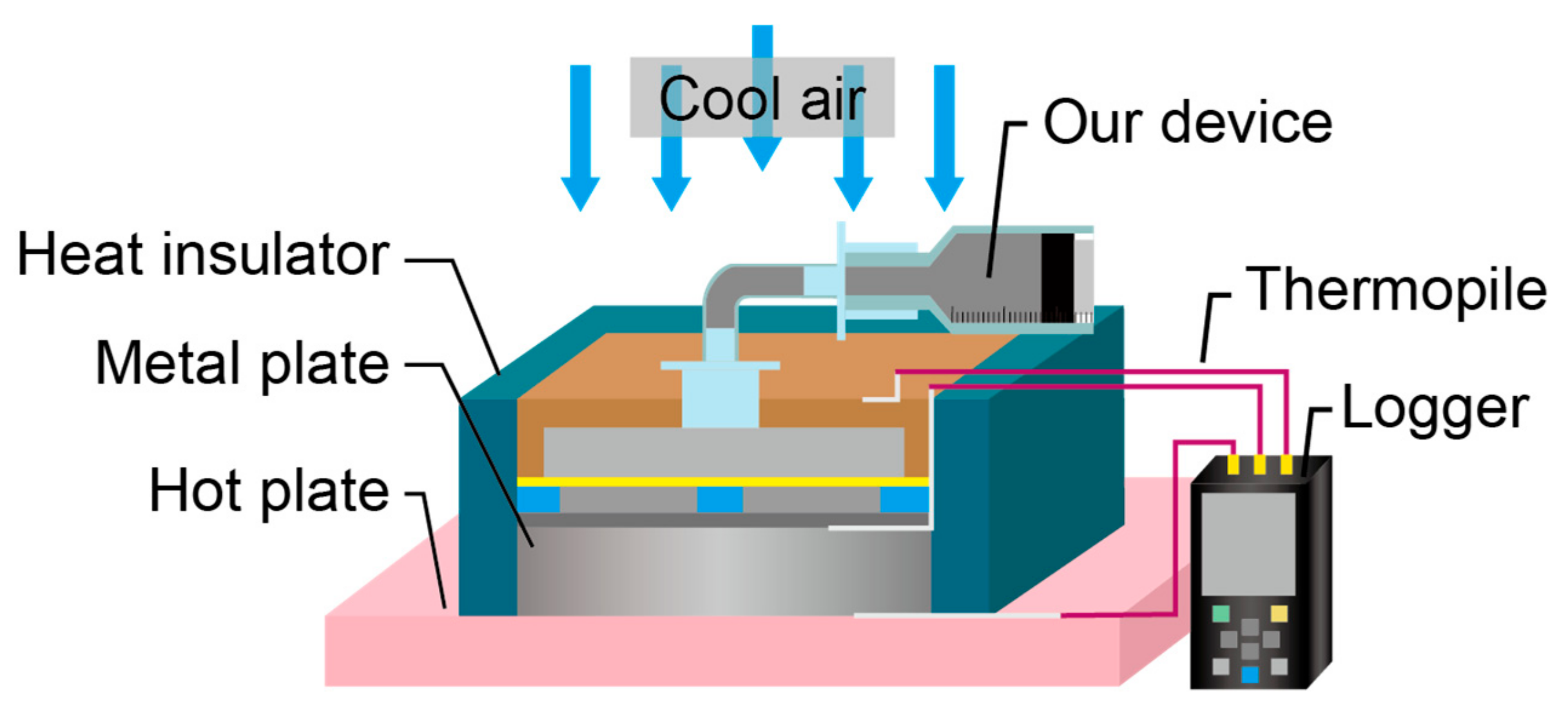

2. Principle and Fabrication Process

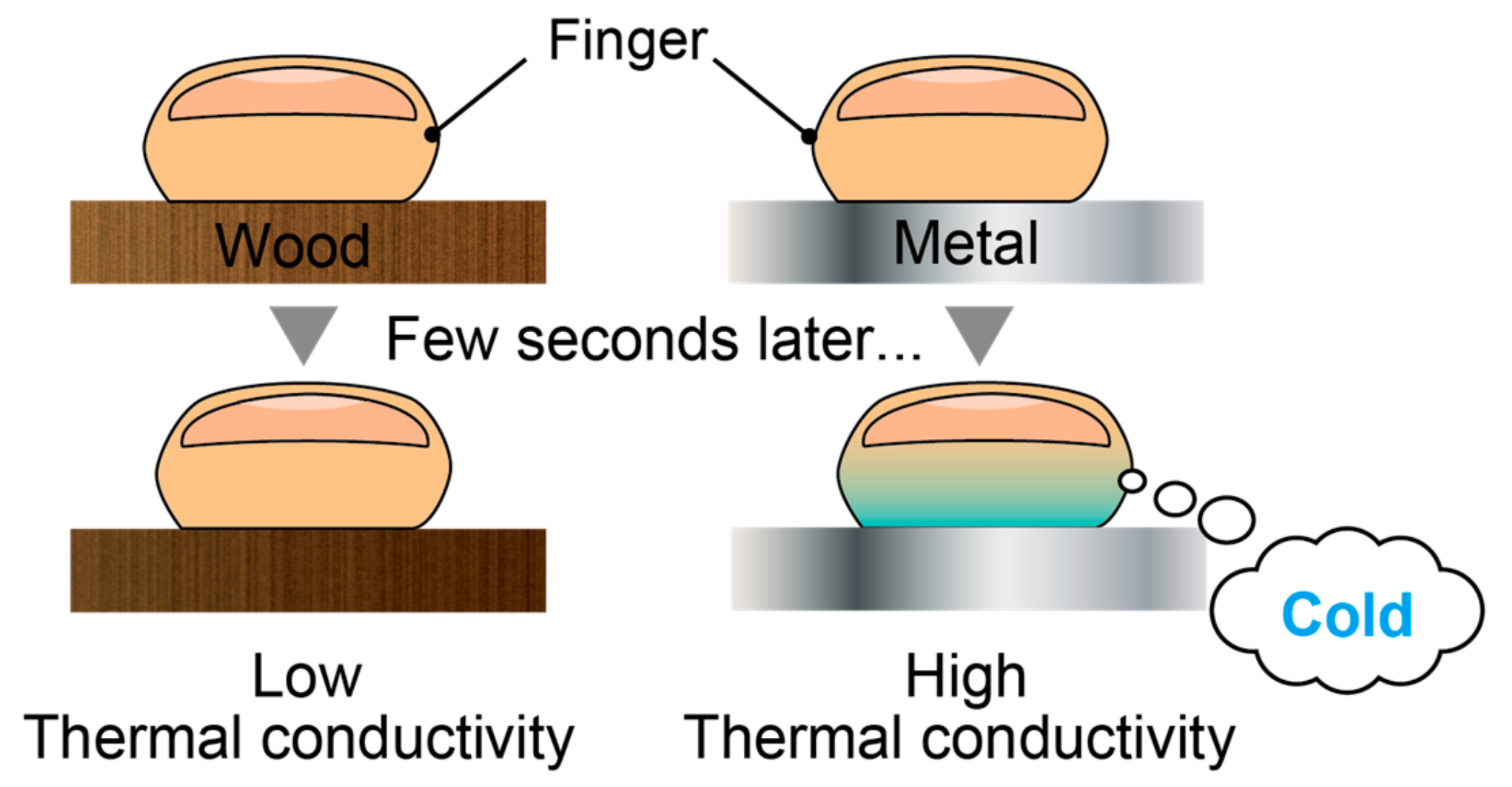

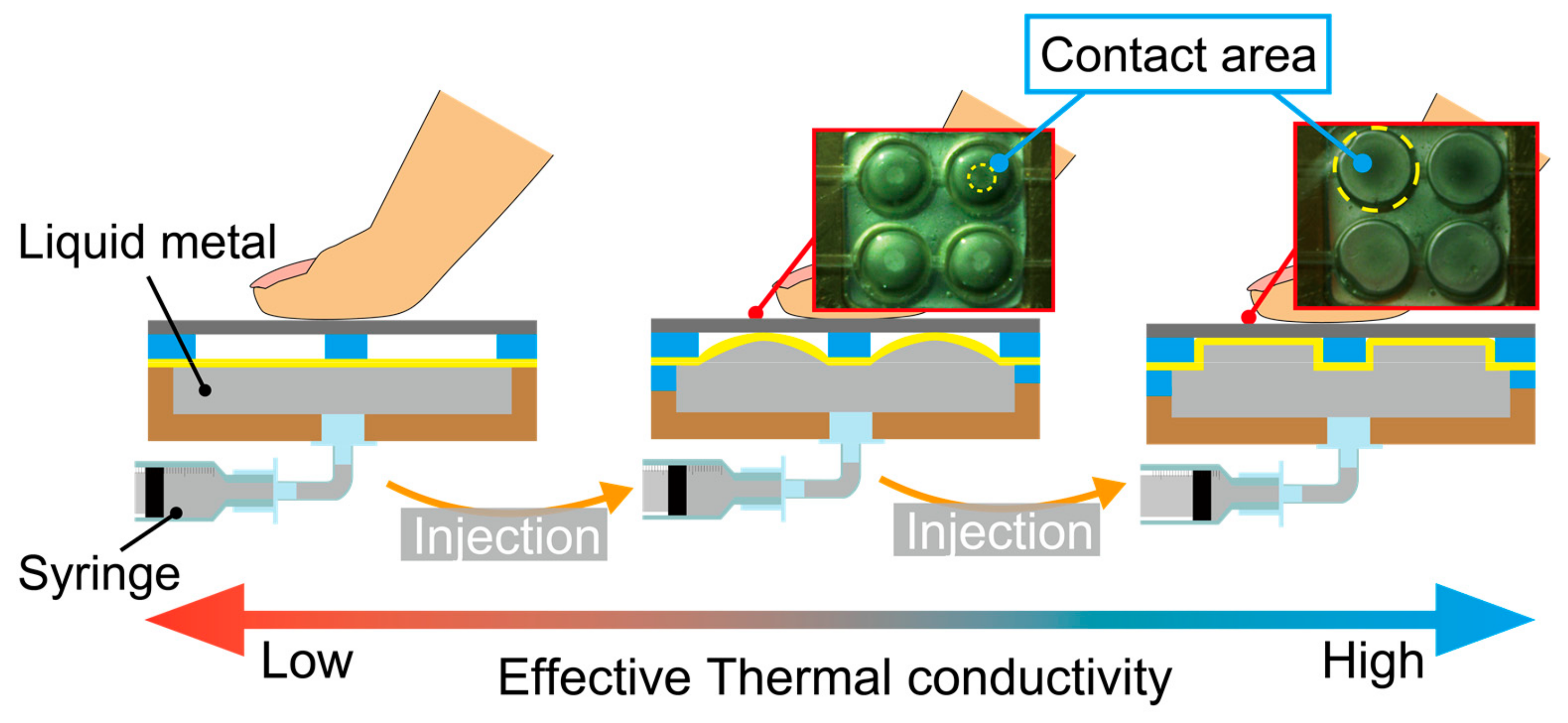

2.1. Principle

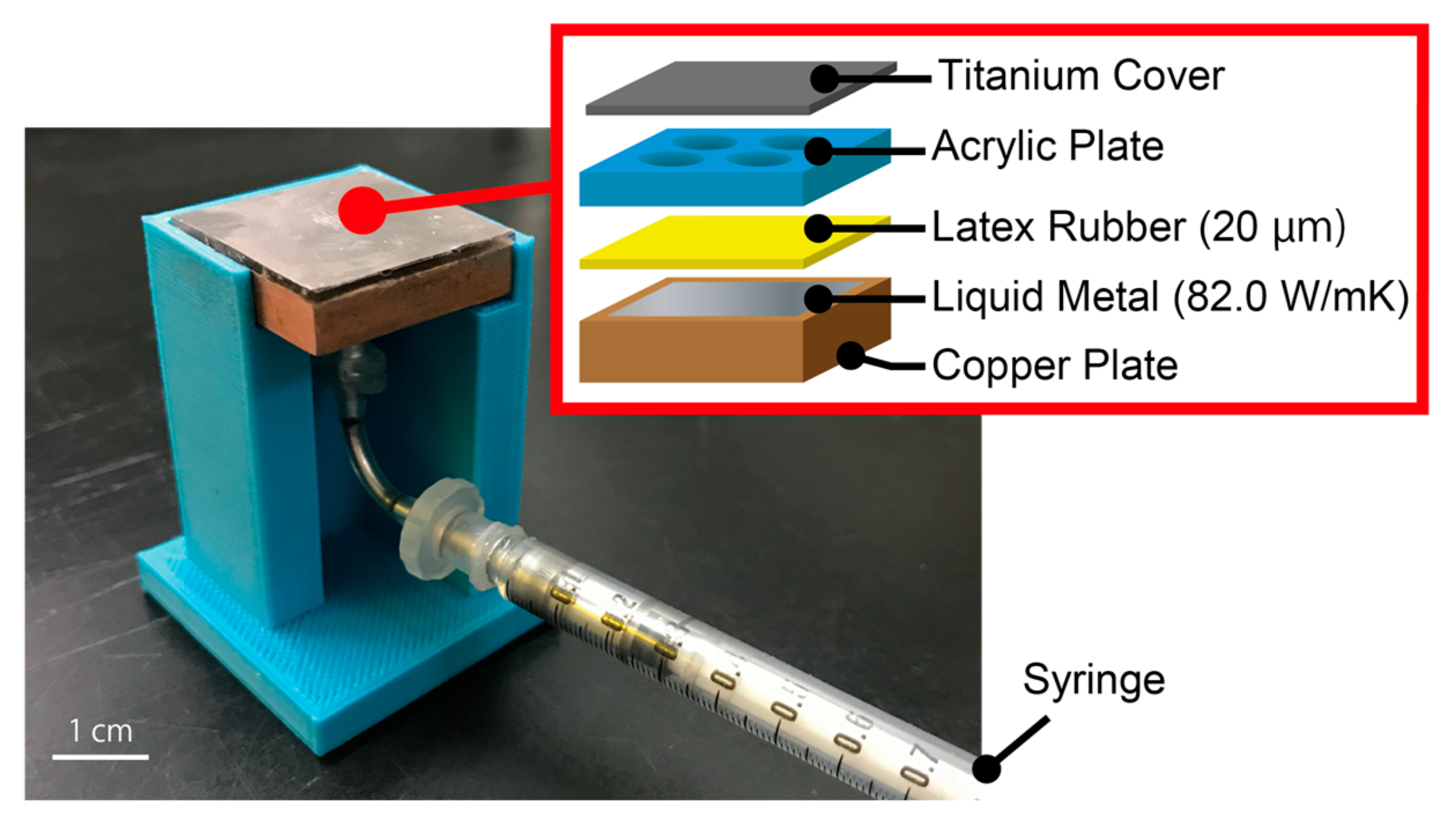

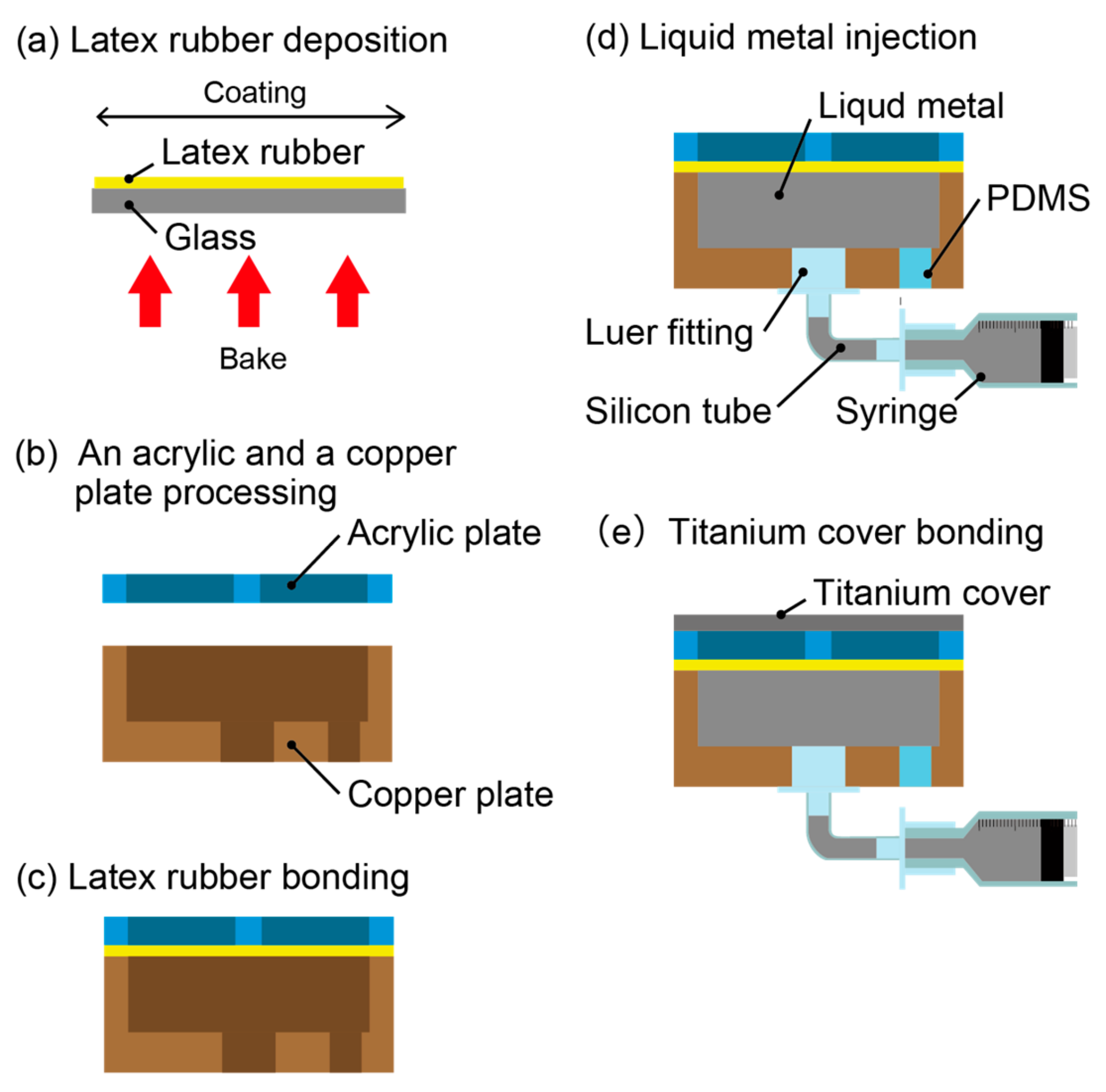

2.2. Fabrication Process

3. Experimental Procedure

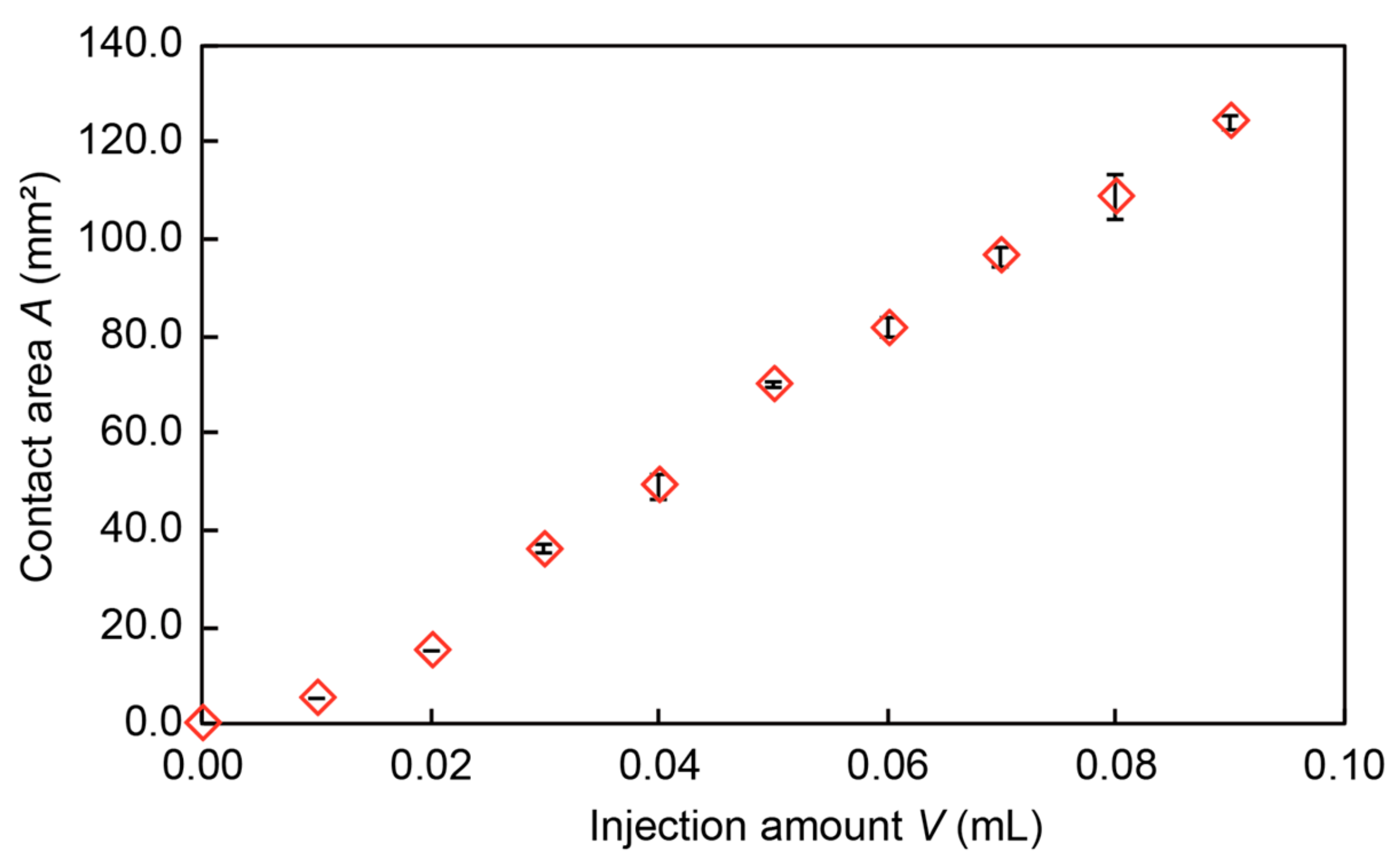

3.1. Measurement of the Contact Area

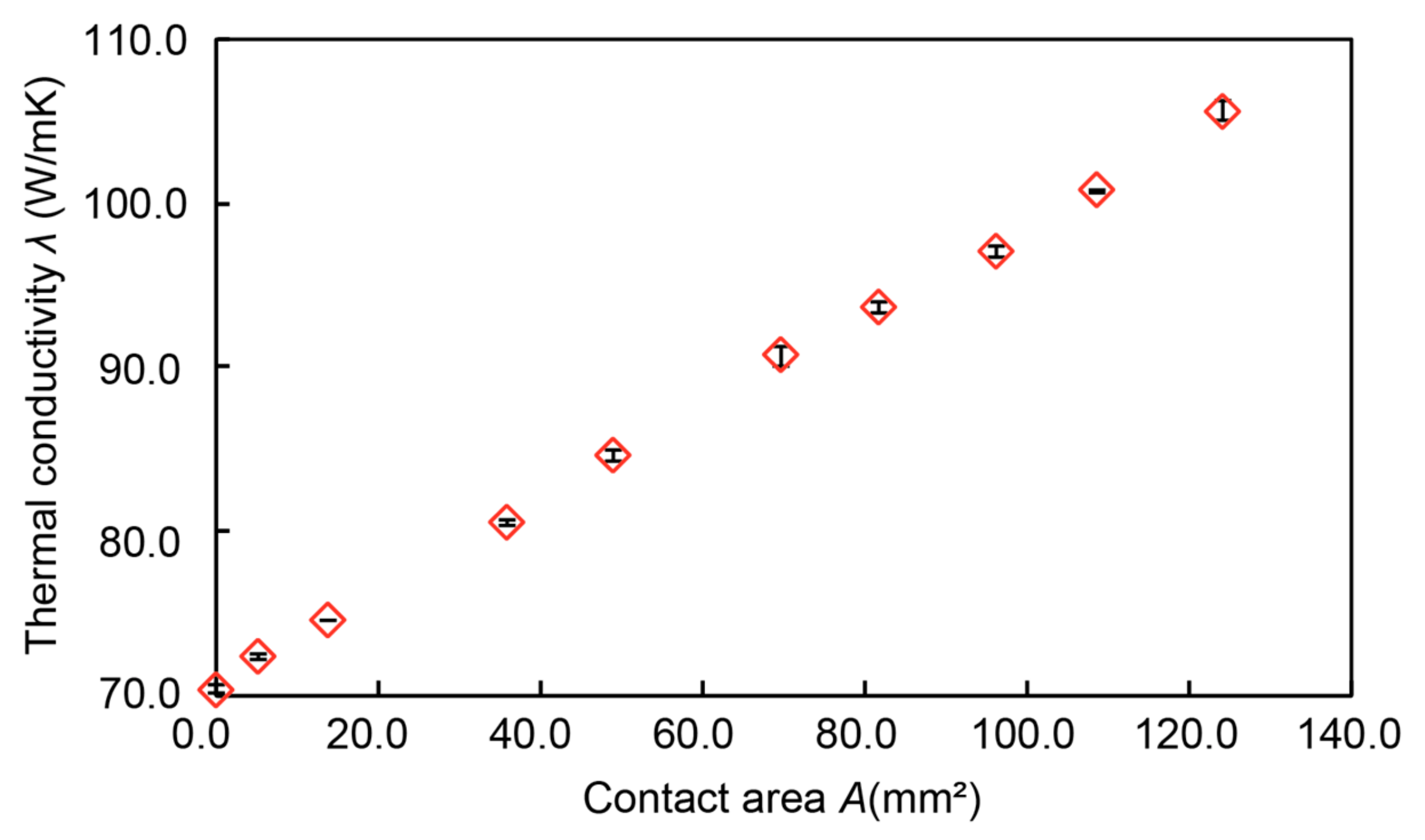

3.2. Measurement of Effective Thermal Conductivity

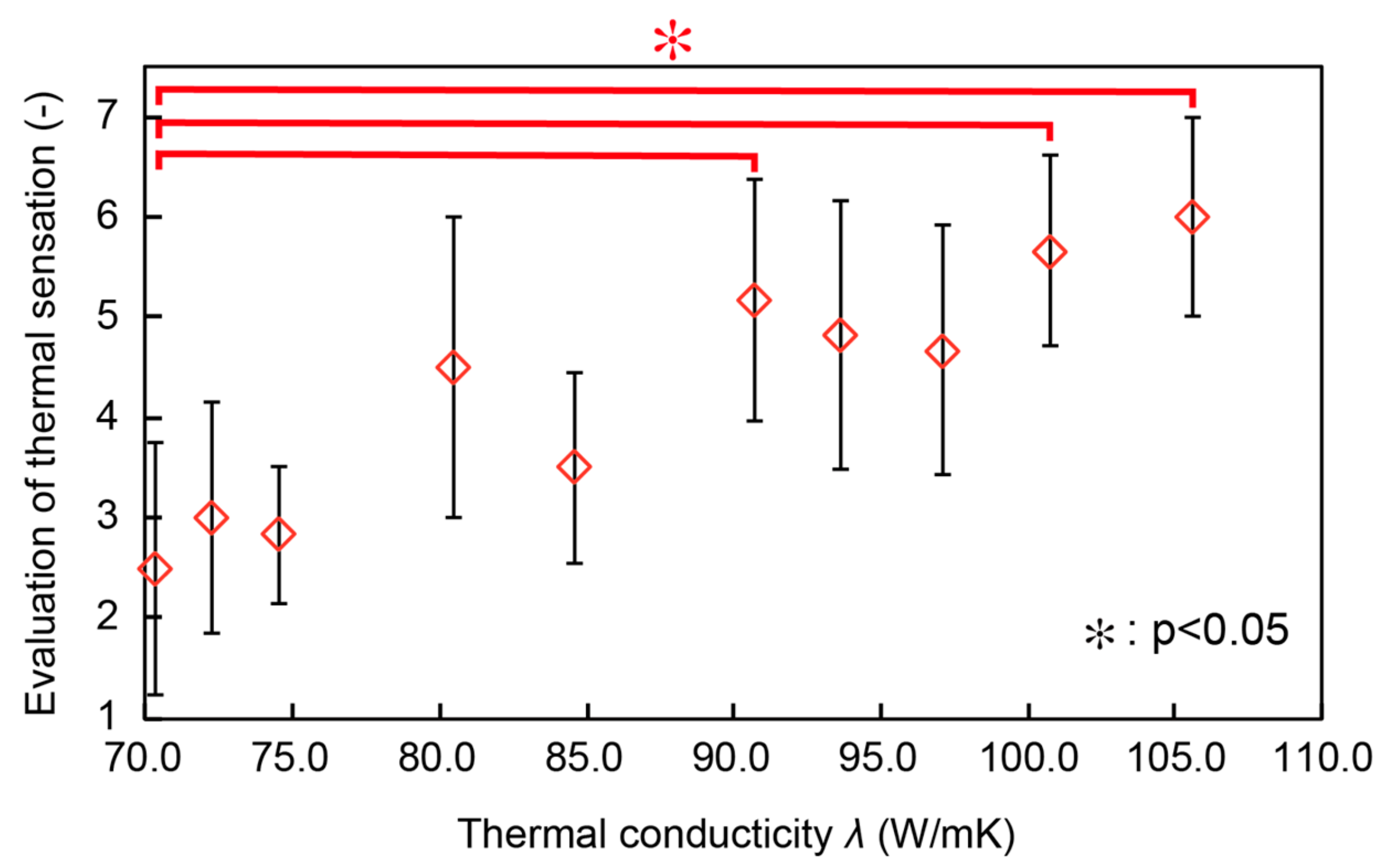

3.3. Evaluation of Thermal Sensation

3.4. Perceptual Threshold of Thermal Conductivity

4. Results and Discussion

4.1. Measurement of the Contact Area

4.2. Measurement of Thermal Conductivity

4.3. Evaluation of Thermal Sensation

4.4. Perceptual Thershold on Thermal Conductivity

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Storonks, C.H.; Parker, J.D.; Stacey, A.; Barnes, N. Psychophysical Evaluation of a Tactile Display Based on Coin Motors. Artif. Organs. 2018, 8, 1224–1233. [Google Scholar] [CrossRef] [PubMed]

- Gibson, A.; Webb, A.; Stirling, L. Evaluation of a Visual-Tactile Multimodal Display for Surface Obstacle Avoidance During Walking. IEEE Trans. Human-Mach. Syst. 2018, 48, 604–613. [Google Scholar] [CrossRef]

- Hansen, V.K.; Eskildsen, S.M.; Larsen, V.O. Region-of-Interest based Finite Element Modelling of the Brain—An approach to Brain Surgery Simulation. Proc. Fourteenth Int. Conf. Pattern Recognit. 1998, 1, 292–296. [Google Scholar]

- Ogawa, K.; Ibrahim, Y.; Ohnishi, K. Development of Flexible Haptic Forceps Based on the Electro-Hydraulic Transmission System. IEEE Trans. Ind. Inform. 2018, 14, 5256–5267. [Google Scholar] [CrossRef]

- Liu, S.W.; Li, Y. The research for control strategies and methods of teleoperation system. World Autom. Congr. 2012, 1, 2–5. [Google Scholar]

- Hayashi, K.; Tamura, T. Teleoperation Performance using Excavator with Tactile Feedback. 2009 IEEE Int. Conf. Mechatron. Autom. ICMA 2009, 5, 2759–2764. [Google Scholar]

- Kumazawa, I.; Yano, S.; Suzuki, S.; Ono, S. A multi-modal interactive tablet with tactile feedback, rear and lateral operation for maximum front screen visibility. Proc. IEEE Virtual Real. 2016, 23, 211–212. [Google Scholar]

- Shinoda, H. Tactile Sensing for Dexterous Hand. J. Robot. Soc. 2000, 18, 767–771. [Google Scholar] [CrossRef]

- Tachi, S. Telexistence: Enabling Humans to Be Virtually Ubiquitous. IEEE Comput. Graph. Appl. 2016, 36, 8–14. [Google Scholar] [CrossRef]

- Kosemura, Y.; Hasagawa, S.; Miki, N. Surface properties that can be displayed by a microelectromechanical system-based mechanical tactile display. Micro Nano Lett. 2016, 11, 240–243. [Google Scholar] [CrossRef]

- Ishizuka, H.; Miki, N. MEMS-based tactile displays. Displays 2015, 37, 25–32. [Google Scholar] [CrossRef]

- Na, K.; Han, J.; Roh, D.; Chae, B.; Yoon, E.; Kang, Y.J.; Cho, I. Flexible latching-type tactile display system actuated by combination of electromagnetic and pneumatic forces. Proc. IEEE Int. Conf. Micro Electr. Mech. Syst. 2012, 2, 1149–1152. [Google Scholar]

- Ishizuka, H.; Miki, N. Development of a tactile display with 5 mm resolution using an array of magnetorheological fluid. Jpn. J. Appl. Phys. 2017, 56, 06GN19. [Google Scholar] [CrossRef]

- Ishizuka, H.; Miki, N. Fabrication of hemispherical liquid encapsulated structures based on droplet molding. J. Micromech. Microeng. 2015, 25, 125010. [Google Scholar] [CrossRef]

- Ishizuka, H.; Rorenzoni, N.; Miki, N. Tactile display for presenting stiffness distribution using magnetorheological fluid. Mech. Eng. J. 2014, 1, 1–10. [Google Scholar] [CrossRef][Green Version]

- Kobayashi, T.; Fukumori, M. Proposal of a Design Tool for Tactile Graphics with Thermal Sensation. In Proceedings of the 2012 18th International Conference on Virtual Systems and Multimedia, Milan, Italy, 2–5 September 2012; pp. 537–540. [Google Scholar]

- Yamamoto, A.; Cros, B.; Hashimoto, H.; Higuchi, T. Control of Thermal Tactile Display Based on Prediction of Contact Temperature. Int. Conf. Robot. Autom. 2014, 2, 1536–1541. [Google Scholar]

- Yang, G.; Kyung, K.; Srinivasan, A.M.; Kwon, D. Quantitative Tactile Display Device with Pin-Array Type Tactile Feedback and Thermal Feedback. Proc. IEEE Int. Conf. Robot. Autom. 2006, 1, 3917–3922. [Google Scholar]

- Mao, Z.; Wu, J.; Li, J.; Zhou, L.; Li, X.; Yang, Y. A Thermal Tactile Display Device with Multiple Heat Sources. Proc. 2012 Int. Conf. Ind. Control Electron. Eng. ICICEE 2012 2012, 1, 192–195. [Google Scholar]

- Ino, S.; Shimizu, S.; Odagawa, T.; Sato, M.; Takahashi, M.; Izumi, T.; Ifukube, T. A Tactile Display for Presenting Quality of Materials by Changing the Temperature of Skin Surface. Work. Robot Hum. Commun. 1993, 1, 220–224. [Google Scholar]

- Yang, G.; Kyung, K.; Srinivasan, A.M.; Kwon, D. Development of Quantitative Tactile Display Device to Provide Both Pin- Array-Type Tactile Feedback and Thermal Feedback. In Proceedings of the Second Joint EuroHaptics Conference and Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems (WHC’07), Tsukaba, Japan, 22–24 March 2007; pp. 578–579. [Google Scholar]

- Yang, T.; Yang, G.; Kwon, D.; Kang, S. Implementing Compact Tactile Display for Fingertips with Multiple Vibrotactile Actuator and Thermoelectric Module. Proc. IEEE Int. Conf. Robot. Autom. 2007, 1, 7–8. [Google Scholar]

- Ishizuka, H.; Hatada, R.; Cortes, C.; Miki, N. Development of a fully flexible sheet-type tactile display based on electrovibration stimulus. Micromachines 2018, 9, 230. [Google Scholar] [CrossRef]

- Saga, S. Thermal-Radiation-Based Haptic Interface. Haptic Interact. 2015, 277, 105–107. [Google Scholar]

- Shen, H.; Jiang, S.; Sukigara, S. Dependence of Thermal Contact Properties on Compression Pressure. J. Fiber Sci. Technol. 2017, 73, 177–181. [Google Scholar] [CrossRef]

- Zhao, D.; Qian, X.; Gu, X.; Jajja, A.S.; Yang, R. Measurement Techniques for Thermal Conductivity and Interfacial Thermal Conductance of Bulk and Thin Film Materials. J. Electron. Packag. 2016, 138, 1–19. [Google Scholar] [CrossRef]

- Tong, J.; Mao, O.; Goldreich, D. Two-point orientation discrimination versus the traditional two-point test for tactile spatial acuity assessment. Front. Human Neurosci. 2013, 7, 1–11. [Google Scholar] [CrossRef] [PubMed]

| Thermal Conductivity (W/mK) | Value Difference (W/mK) | Significant Difference |

|---|---|---|

| 75 vs. 80 | 5 | NS |

| 75 vs. 85 | 10 | NS |

| 75 vs. 90 | 15 | NS |

| 75 vs. 95 | 20 | * |

| 75 vs. 100 | 25 | * |

| 75 vs. 105 | 30 | *** |

| Thermal Conductivity (W/mK) | Value Difference (W/mK) | Significant Difference |

|---|---|---|

| 75 vs. 91 | 16 | NS |

| 75 vs. 92 | 17 | NS |

| 75 vs. 93 | 18 | * |

| 75 vs. 94 | 19 | * |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hirai, S.; Miki, N. A Thermal Tactile Sensation Display with Controllable Thermal Conductivity. Micromachines 2019, 10, 359. https://doi.org/10.3390/mi10060359

Hirai S, Miki N. A Thermal Tactile Sensation Display with Controllable Thermal Conductivity. Micromachines. 2019; 10(6):359. https://doi.org/10.3390/mi10060359

Chicago/Turabian StyleHirai, Seiya, and Norihisa Miki. 2019. "A Thermal Tactile Sensation Display with Controllable Thermal Conductivity" Micromachines 10, no. 6: 359. https://doi.org/10.3390/mi10060359

APA StyleHirai, S., & Miki, N. (2019). A Thermal Tactile Sensation Display with Controllable Thermal Conductivity. Micromachines, 10(6), 359. https://doi.org/10.3390/mi10060359