Fabrication and Characterization of Flexible Thermoelectric Generators Using Micromachining and Electroplating Techniques

Abstract

:1. Introduction

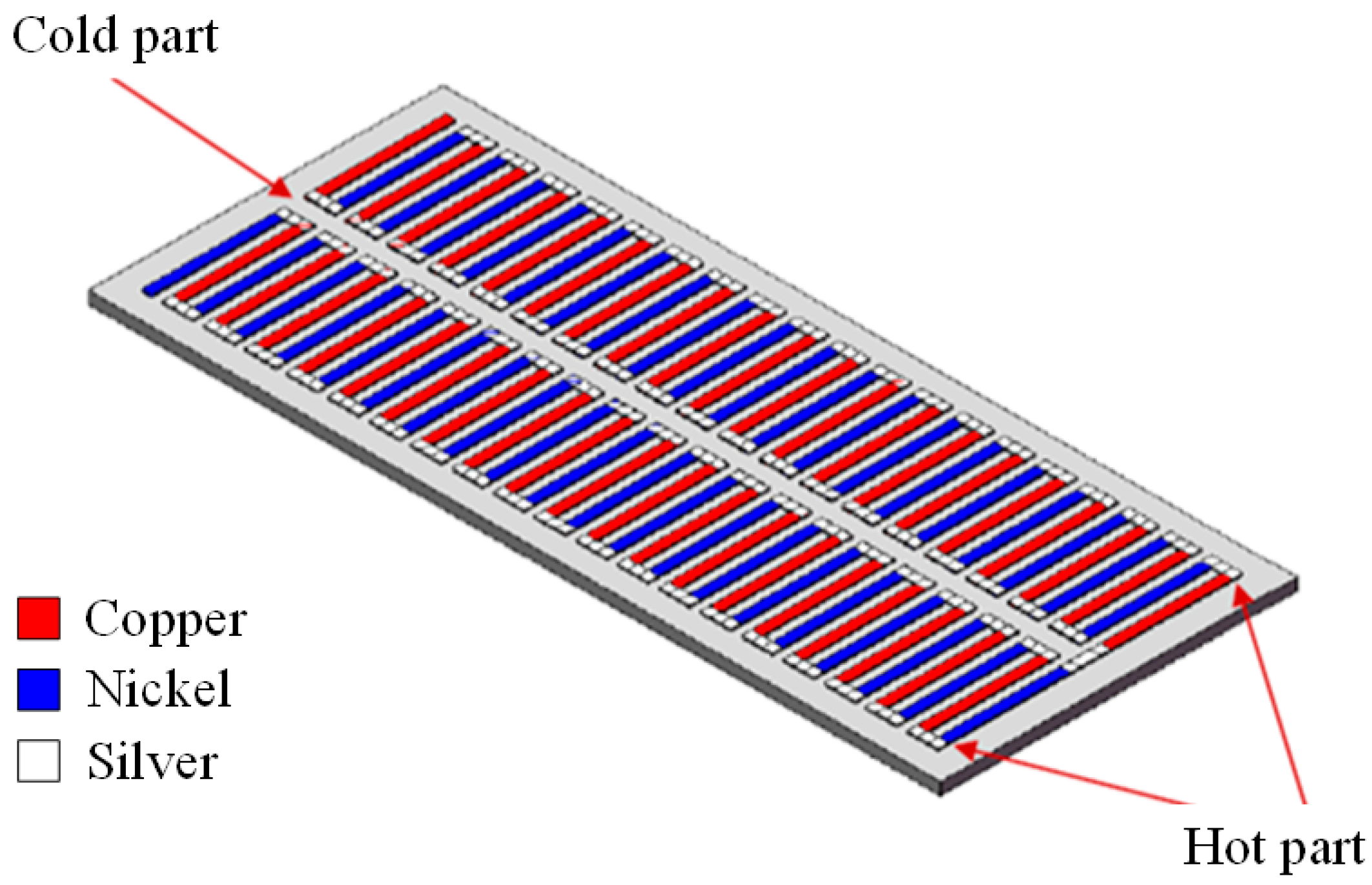

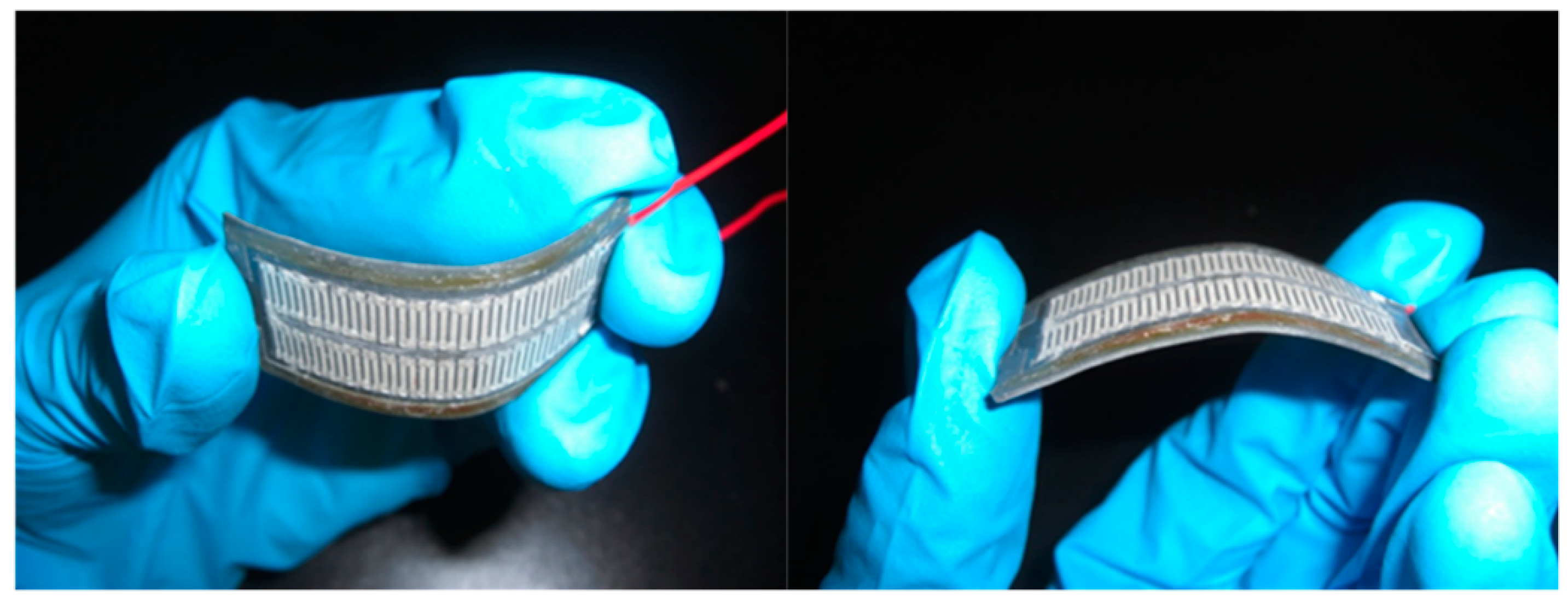

2. Design for the Thermoelectric Generator

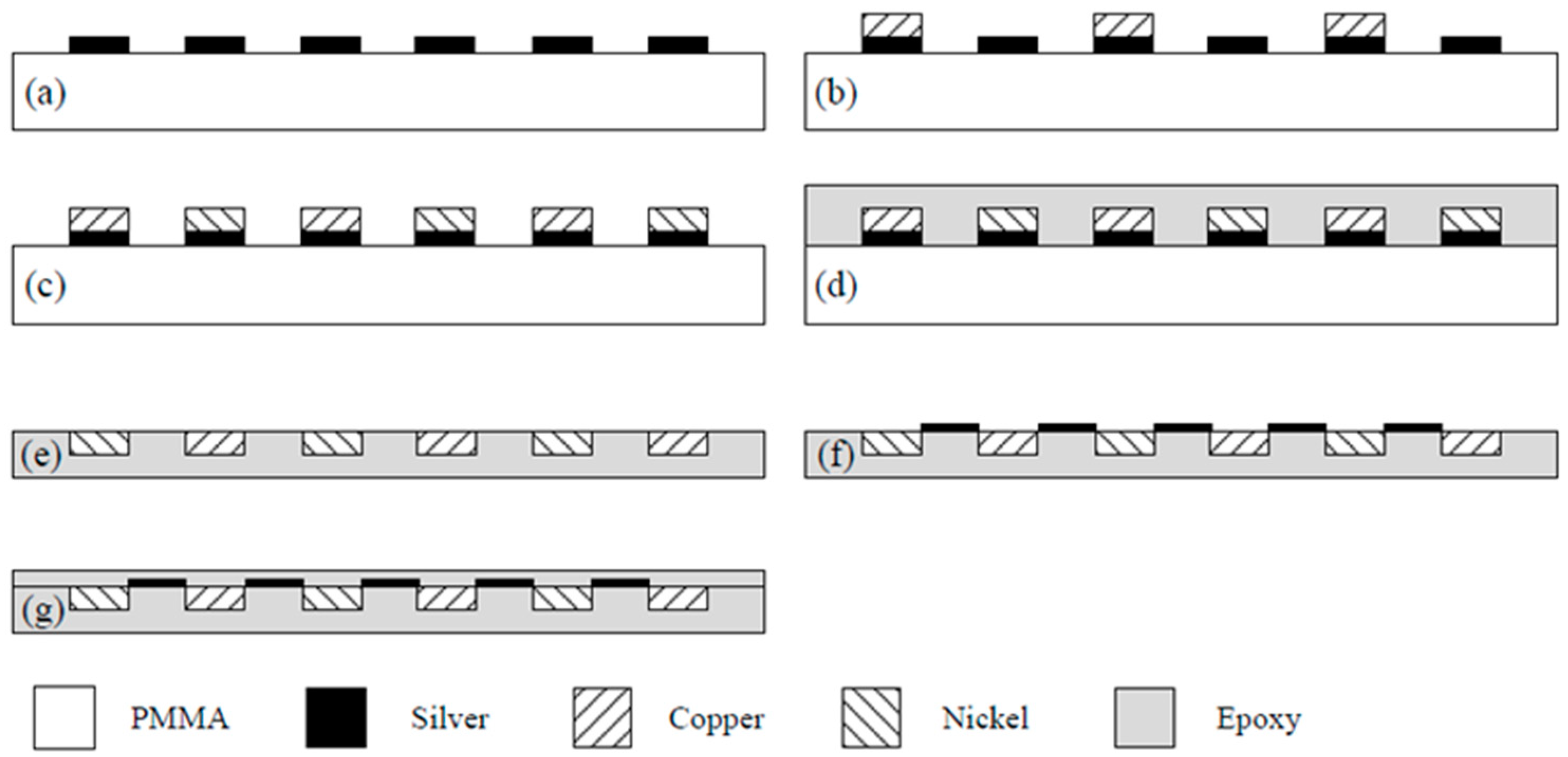

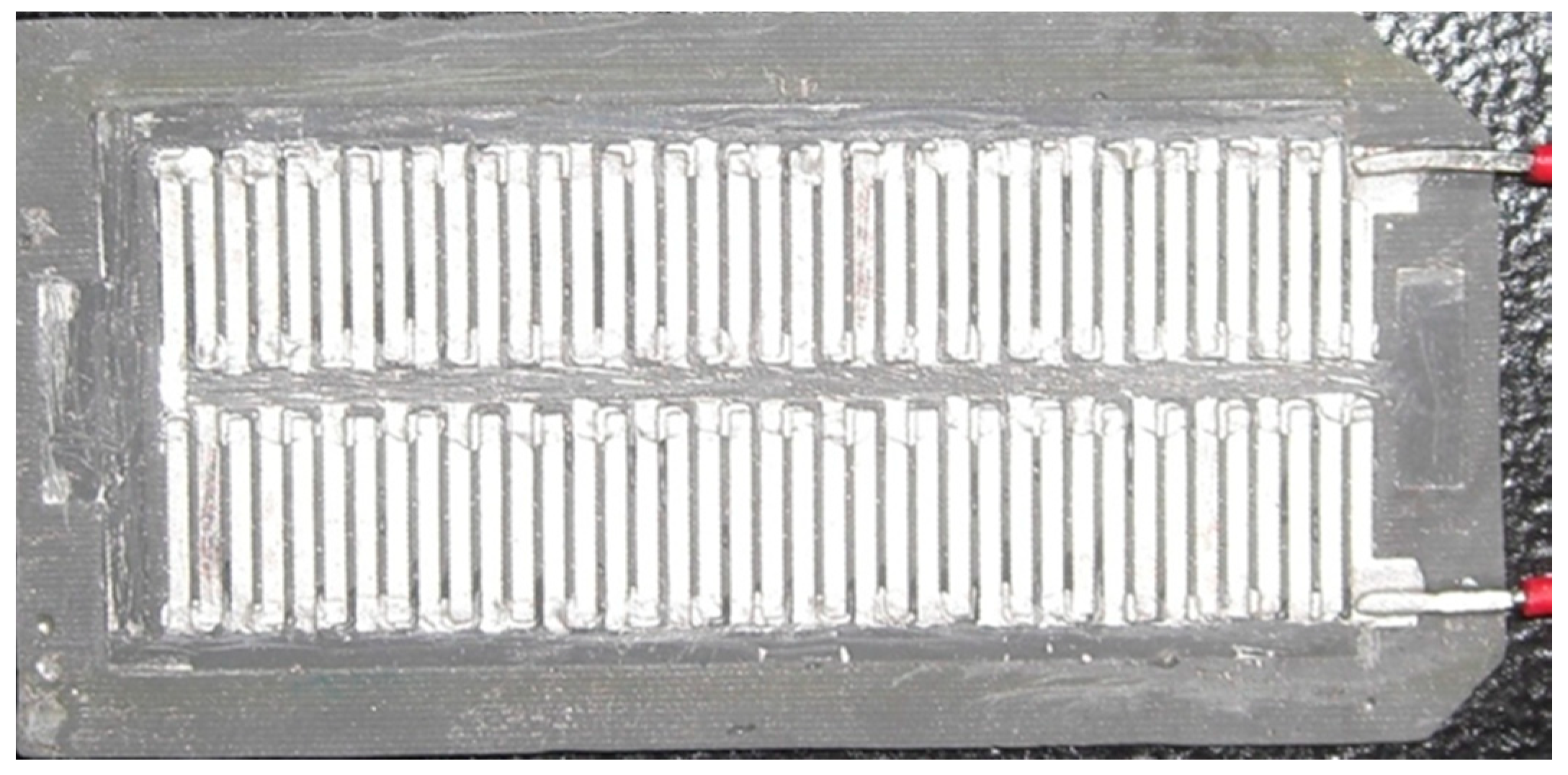

3. Fabrication of the Thermoelectric Generator

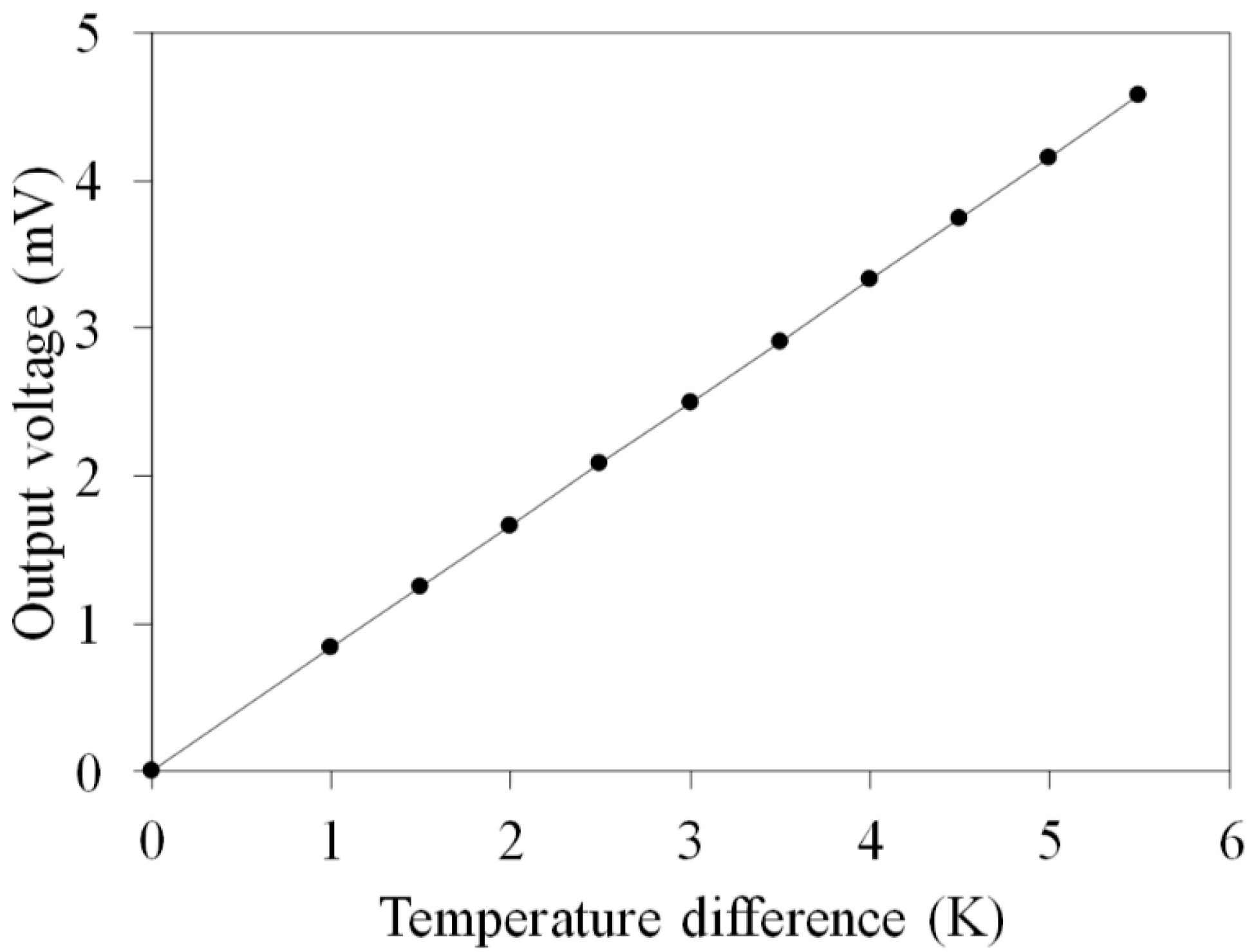

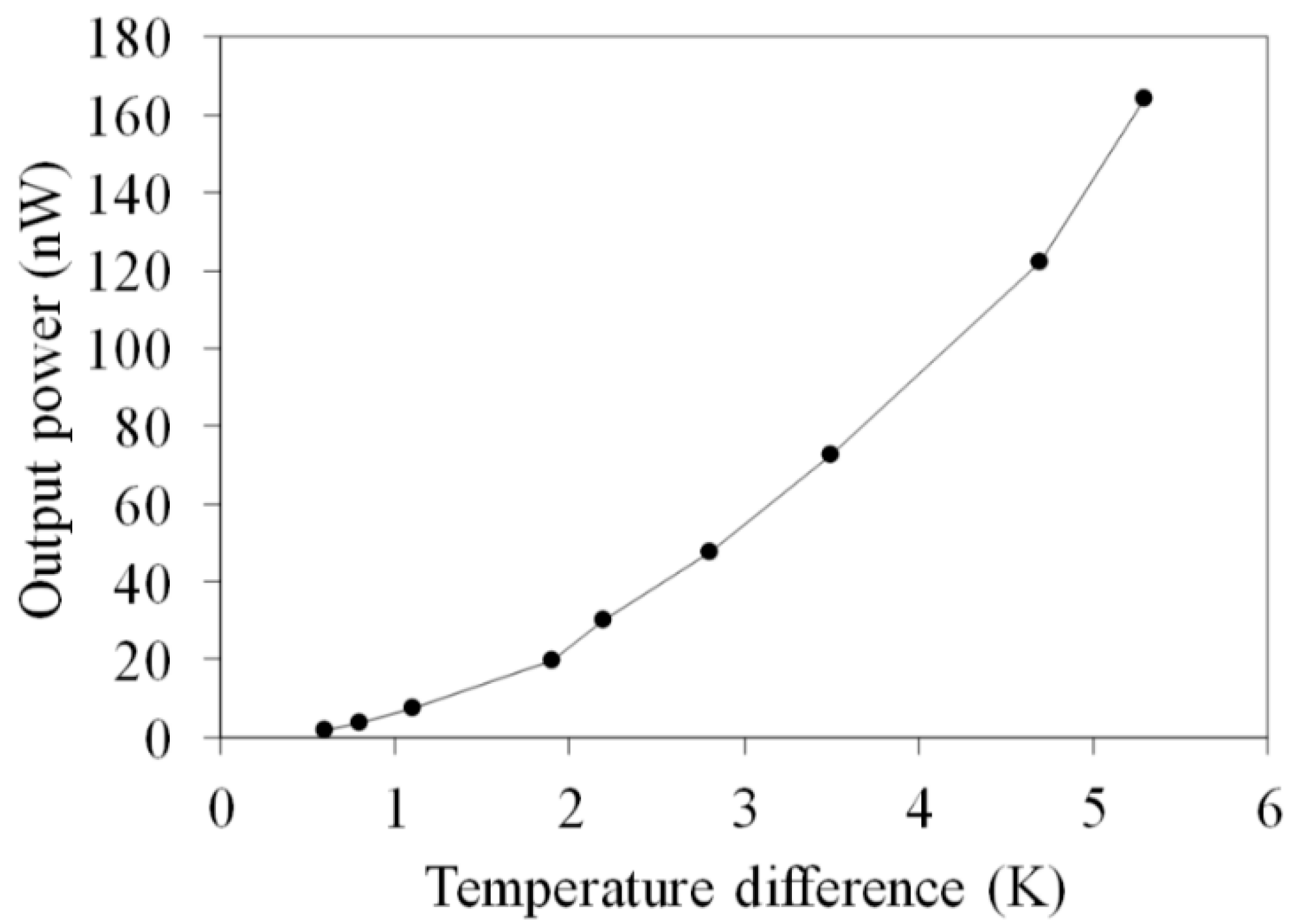

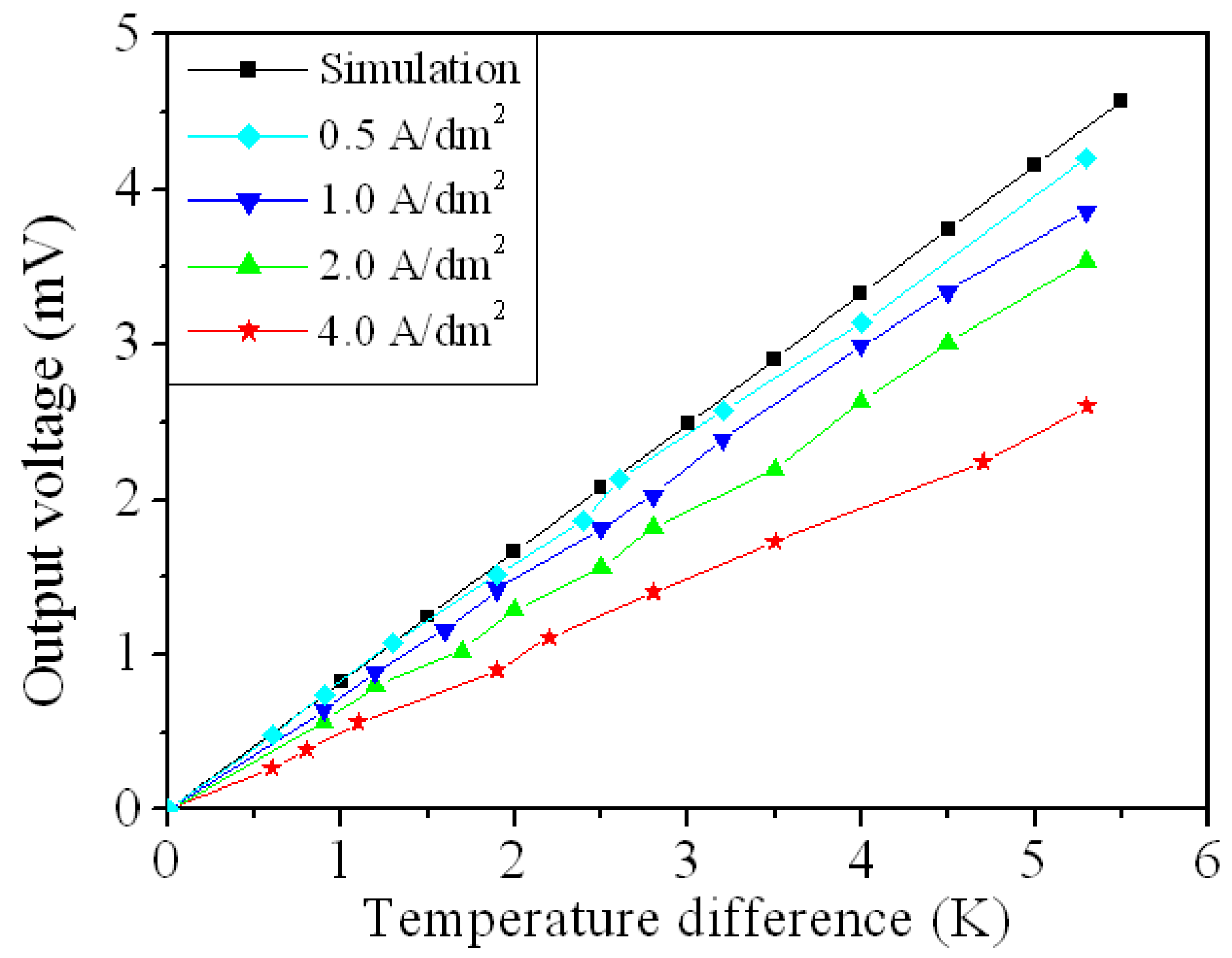

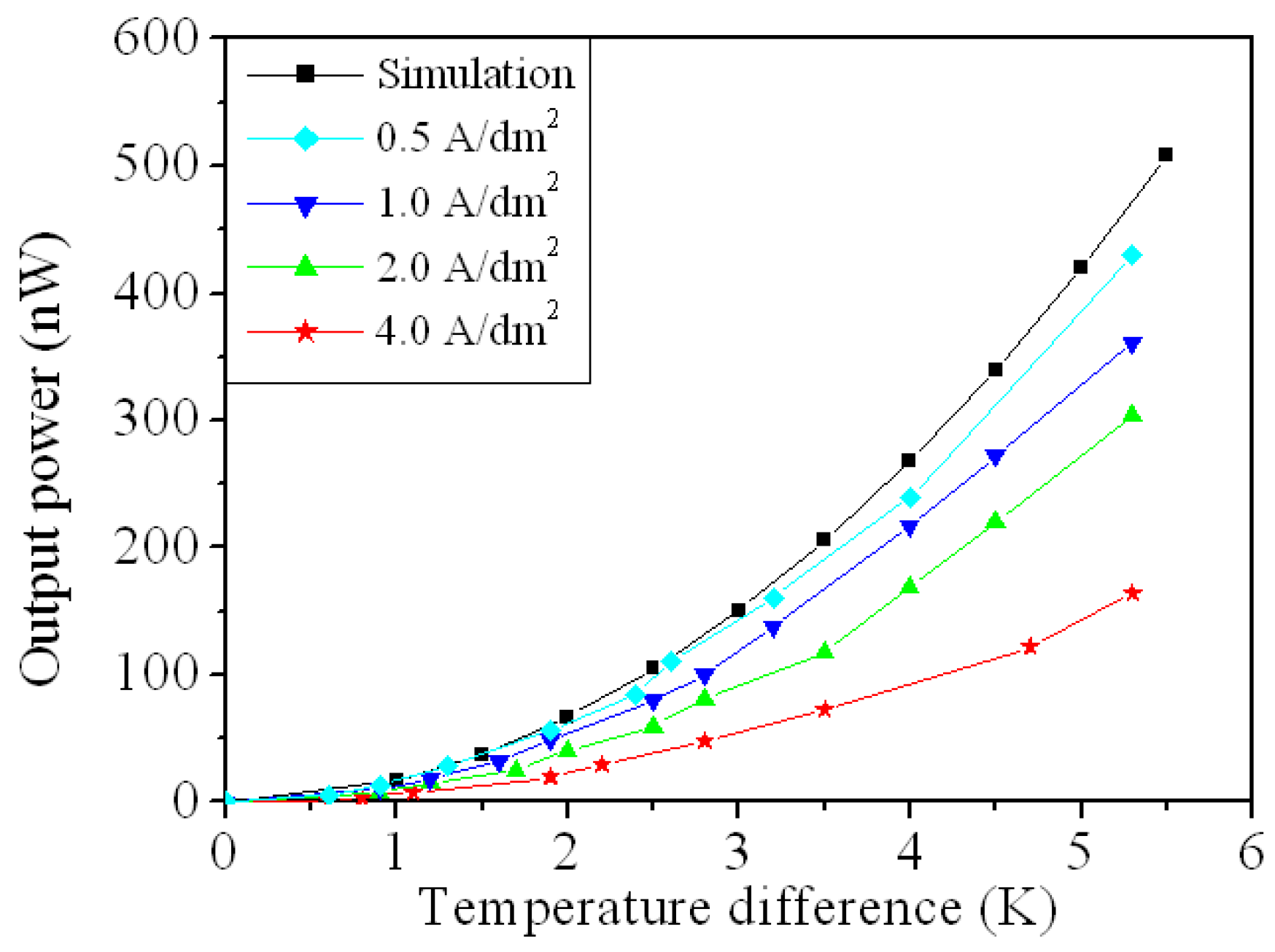

4. Results and Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Mirhosseini, M.; Rezania, A.; Rosendahl, L. Effect of heat loss on performance of thin film thermoelectric; a mathematical model. Mat. Res. Exp. 2019, 6, 096450. [Google Scholar] [CrossRef]

- Piggott, A. Detailed transient multiphysics model for fast and accurate design, simulation and optimization of a thermoelectric generator (TEG) or thermal energy harvesting device. J. Electron. Mat. 2019, 48, 5442–5452. [Google Scholar] [CrossRef]

- Ahn, D.; Choi, K. Performance evaluation of thermoelectric energy harvesting system on operating rolling stock. Micromachines 2018, 9, 359. [Google Scholar] [CrossRef]

- Burton, M.R.; Mehraban, S.; Beynon, D.; McGettrick, J.; Watson, T.; Lavery, N.P.; Carnie, M.J. 3D printed SnSe thermoelectric generators with high figure of merit. Adv. Eng. Mat. 2019, 9, 1900201. [Google Scholar] [CrossRef]

- Jang, W.; Cho, H.A.; Choi, K.; Park, Y.T. Manipulation of p-/n-Type thermoelectric thin films through a layer-by-layer assembled carbonaceous multilayer structure. Micromachines 2018, 9, 628. [Google Scholar] [CrossRef] [PubMed]

- Zeng, W.; Tao, X.M.; Lin, S.P.; Lee, C.; Shi, D.L.; Lam, K.H.; Huang, B.L.; Wang, Q.M.; Zhao, Y. Defect-engineered reduced graphene oxide sheets with high electric conductivity and controlled thermal conductivity for soft and flexible wearable thermoelectric generators. Nano Eng. 2018, 54, 163–174. [Google Scholar] [CrossRef]

- Liu, H.C.; Zhang, J.K.; Shi, Q.F.; He, T.Y.Y.; Chen, T.; Sun, L.N.; Dziuban, J.A.; Lee, C. Development of a thermoelectric and electromagnetic hybrid energy harvester from water flow in an irrigation system. Micromachines 2018, 9, 395. [Google Scholar] [CrossRef]

- Fukuie, K.; Iwata, Y.; Iwase, E. Design of substrate stretchability using origami-like folding deformation for flexible thermoelectric generator. Micromachines 2018, 9, 315. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.B.; Yang, H.J.; We, J.H.; Kim, K.; Choi, K.C.; Cho, B.J. Thin-film thermoelectric module for power generator applications using a screen-printing method. J. Electron. Mat. 2011, 40, 615–619. [Google Scholar] [CrossRef]

- Phaga, P.; Vora-Ud, A.; Seetawan, T. Invention of low cost thermoelectric generators. Proced. Eng. 2012, 32, 1050–1053. [Google Scholar] [CrossRef]

- Big-Alabo, A. Performance evaluation of Ge/SiGe-based thermoelectric generator. Phys. E Low-Dimens. Syst. Nanostruct. 2019, 108, 202–205. [Google Scholar] [CrossRef]

- Dai, C.L.; Chiou, J.H.; Lu, M.S.C. A maskless post-CMOS bulk micromachining process and its application. J. Micromech. Microeng. 2005, 15, 2366–2371. [Google Scholar] [CrossRef]

- Itoigawa, K.; Ueno, H.; Shiozaki, M.; Toriyama, T.; Sugiyama, S. Fabrication of fexible thermopile generator. J. Micromech. Microeng. 2005, 15, 233–238. [Google Scholar] [CrossRef]

- Lu, Y.; Qiu, Y.; Jiang, Q.L.; Cai, K.F.; Du, Y.; Song, H.J.; Gao, M.Y.; Huang, C.J.; He, J.Q.; Hu, D.H. Preparation and characterization of Te/Poly(3,4-ethylenedioxythiophene): poly(styrenesulfonate)/Cu7Te4 ternary composite films for flexible thermoelectric power generator. ACS Appl. Mater. Interfac. 2018, 10, 42310–42319. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.F.; Qiu, Y.; Cai, K.F.; Yao, Q.; Chen, S.; Chen, L.D.; He, J.Q. High performance n-type Ag2Se film on nylon membrane for flexible thermoelectric power generator. Nat. Commun. 2019, 10, 841. [Google Scholar] [CrossRef] [PubMed]

- Selvan, K.V.; Rehman, T.; Saleh, T.; Ali, M.S.M. Copper-cobalt thermoelectric generators: Power improvement through optimized thickness and sandwiched planar structure. IEEE Trans. Electron Dev. 2019, 66, 3459–3465. [Google Scholar] [CrossRef]

- Jo, S.E.; Kim, M.K.; Kim, M.S.; Kim, Y.J. Flexible thermoelectric generator for uuman body heat energy harvesting. Electron. Lett. 2012, 48, 1015–1016. [Google Scholar] [CrossRef]

- Oh, J.Y.; Lee, J.H.; Han, S.W.; Chae, S.S.; Bae, E.J.; Kang, Y.H.; Choi, W.J.; Cho, S.Y.; Lee, J.O.; Baik, H.K.; et al. Chemically exfoliated transition metal dichalcogenide nanosheet-based wearable thermoelectric generators. Energ. Environ. Sci. 2016, 9, 1696–1705. [Google Scholar] [CrossRef]

- Kim, J.Y.; Oh, J.Y.; Lee, T.I. Multi-dimensional nanocomposites for stretchable thermoelectric applications. Appl. Phys. Lett. 2019, 114, 043902. [Google Scholar] [CrossRef]

- Chen, Y.W.; Wu, C.C.; Hsu, C.C.; Dai, C.L. Fabrication and testing of thermoelectric CMOS-MEMS microgenerators with CNCs film. Appl. Sci. 2018, 8, 1047. [Google Scholar] [CrossRef]

- Peng, S.W.; Shih, P.J.; Dai, C.L. Manufacturing and characterization of a thermoelectric energy harvester using the CMOS-MEMS technology. Micromachines 2015, 6, 1560–1568. [Google Scholar] [CrossRef]

- Haynes, W.M. CRC Handbook of Chemistry and Physics, 95th ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Yang, M.Z.; Wu, C.C.; Dai, C.L.; Tsai, W.J. Energy harvesting thermoelectric generators manufactured using the complementary metal oxide semiconductor process. Sensors 2013, 13, 2359–2367. [Google Scholar] [CrossRef] [PubMed]

- Kao, P.H.; Shih, P.J.; Dai, C.L.; Liu, M.C. Fabrication and characterization of CMOS-MEMS thermoelectric micro generators. Sensors 2010, 10, 1315–1325. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, W.-L.; Shih, P.-J.; Hsu, C.-C.; Dai, C.-L. Fabrication and Characterization of Flexible Thermoelectric Generators Using Micromachining and Electroplating Techniques. Micromachines 2019, 10, 660. https://doi.org/10.3390/mi10100660

Lee W-L, Shih P-J, Hsu C-C, Dai C-L. Fabrication and Characterization of Flexible Thermoelectric Generators Using Micromachining and Electroplating Techniques. Micromachines. 2019; 10(10):660. https://doi.org/10.3390/mi10100660

Chicago/Turabian StyleLee, Wnag-Lin, Po-Jen Shih, Cheng-Chih Hsu, and Ching-Liang Dai. 2019. "Fabrication and Characterization of Flexible Thermoelectric Generators Using Micromachining and Electroplating Techniques" Micromachines 10, no. 10: 660. https://doi.org/10.3390/mi10100660

APA StyleLee, W.-L., Shih, P.-J., Hsu, C.-C., & Dai, C.-L. (2019). Fabrication and Characterization of Flexible Thermoelectric Generators Using Micromachining and Electroplating Techniques. Micromachines, 10(10), 660. https://doi.org/10.3390/mi10100660