Abstract

The green ecological property is increasingly recognized as a sustainable option in remanufacturing. In practice, despite the environmental concerns expressed by consumers, the growth of the remanufacturing industry falls short of expectations, largely due to the fact that, although remanufacturing conserves costs and is beneficial to our environment, it may not be a profitable option for OEMs, a major barrier in its appearance to green consumers. Many researchers have proposed that environmental groups and similar entities should provide necessary subsidies to encourage green consumerism and improve the profitability of the remanufacturing industry. In this paper, we intend to address how the subsidy policy on green consumerism impacts an OEM’s incentives in remanufacturing; more specifically, we develop two theoretical models: Model N, in which the OEM does not undertake remanufacturing, and Model R, in which the OEM does undertake remanufacturing under the subsidy policy for encouraging green consumerism. In addition to confirming the traditional wisdom that the subsidy policy encourages the remanufacturing industry, our analysis surprisingly reveals that, if a few consumers characterize green consumerism, the aggressive subsidy policy may potentially result in a cannibalization problem, in which remanufacturing hurts the OEM’s overall profits. Therefore, the government and environmental protection agencies need to fully consider the characteristics of the industry to avoid a “good intention, bad result” situation.

1. Introduction

Remanufacturing is an effective way to achieve resource-efficient recycling and reduce environmental burdens by recovering value from used materials and restoring them to like-new condition [1]. Taking the United Kingdom as an example, remanufacturing is estimated to reduce carbon dioxide emissions by almost 10 million tons annually, roughly equivalent to the emissions of 1% of automobiles in the UK [2]. Similarly, in the Chinese market, if all the engines of automobiles were remanufactured, they would reduce electricity usage by 6–9.4 billion kWh, equal to about 6.67–9.69 million tons of carbon dioxide emissions annually, on average [3]. As an advanced sustainability option, remanufacturing is receiving increasing attention due to its benefits for our environment and society [4,5].

However, it should be noted that the current developmental trends in the remanufacturing industry have not met expectations [6]; for example, in Europe, remanufacturing accounts for only 1.9% of new product manufacturing [7]. From a global perspective, efforts focused on remanufacturing have dropped from 9, to 8, to 7% between 2021 and 2023 [8]; this trend can also be observed in China, where, at the end of 2023, the output value of automotive remanufacturing, a leading sector in China’s remanufacturing industry, accounted for only 2–3% of total automotive sales [9].

Traditional wisdom suggests that one of the major reasons for current development not meeting expectations is that the consumer usually has a relatively lower willingness to pay for remanufactured products [10]; for instance, according to auctions conducted on eBay, consumers would prefer to pay about 15.3% less for a remanufactured product than they are willing to pay for a new one [11]. Obviously, a lower willingness from consumers to pay for remanufactured products is among the major barriers preventing OEMs from remanufacturing [12], as it not only leads to the OEMs’ perceived profits being lower than expected, but also causes conflict with others’ priorities [13].

Fortunately, with increasing responsibility for environmental social issues, green consumers, who make decisions based on a specific form of social awareness or social responsibility, have emerged [14]; for instance, according to the research of Tully and Winer [15], in certain advanced nations, such as the USA, EU countries, and Japan, over 60% of consumers are considered green consumers, many of whom are willing to pay up to 16.8% more for remanufactured products than traditional consumers. The emergence of green consumers not only brings forth an environmentally friendly outcome but also turns remanufacturing into a profitable business; however, when accomplishing sustainability goals, green consumers also incur a range of psychological and financial expenses, leading to a discrepancy between consumers’ stated intentions and their actual actions regarding sustainable practices [16]. According to a recent survey, almost 70 percent of respondents say they will purchase environmentally sustainable products, but only 5% actually follow through [17].

Given the barriers preventing consumers from accomplishing sustainable goals, more and more government organizations and environmental agencies have proposed the implementation of subsidy policies to encourage green consumer preferences [18]; for example, in 2023, the government of China initiated a policy to provide subsidies for remanufacturing, in which a subsidy of 10% of the price is provided for remanufactured products such as car engines and transmissions [19]. Similarly, the Welsh administration has declared an extra GBP 15 million in financial support for establishing the collection systems and infrastructure necessary for local firms to engage in plastic remanufacturing—through this subsidy plan, the Welsh government is set to collaborate with Welsh enterprises, public entities, non-profit organizations, and significant events in an effort to eliminate unnecessary single-use plastics in Wales [20].

On the one hand, although interest in remanufacturing has increased (see Zhou, Meng [1]; Örsdemir, Kemahlıoğlu-Ziya [21]; and Li, Zhang [22]), little focus has been shown to the implications of subsidy policies; on the other hand, many researchers (see, e.g., Chai, Sun [23]; Xu, Liu [24]; and Zhao, Liu [25]) have recently highlighted the implications of subsidy policy on optimal decisions around remanufacturing but ignored the emergence of green consumerism in the remanufacturing industry. Thus, we intend to fill the gap by considering the implications of government subsidies for green consumerism within the remanufacturing industry; more specifically, we constructed two theoretical models: Model N, in which the OEM only focuses on the production of new products and does not undertake remanufacturing at all; and Model R, in which the OEM participates in the operations of production and remanufacturing under a subsidy policy for encouraging remanufacturing consumerism among both traditional and green consumers. Using these two models, we plan to address the following research questions:

- (1)

- From the decision-making perspective, what are the implications of subsidy policy on the OEM’s optimal equilibrium?

- (2)

- From an economic perspective, what are the implications of subsidy policy on the OEM’s profitability?

- (3)

- From a sustainability perspective, what are the implications of subsidy policy on environmental performance?

In our analysis, we first validate the conventional understanding that subsidy policies can promote the development of remanufacturing; more specifically, subsidies indeed enhance the ideal volumes of remanufactured products and the sustainability of our environment. However, we further find that, when the percentage of green consumers is significant, the subsidy policy may cause a potentially bad result by worsening the cannibalization problem between new and remanufactured products, which is not only detrimental to new production but also hurts the OEM’s overall profits. Therefore, the government and environmental protection agencies should endeavor to avoid the potential bad results caused by their good intentions.

This paper is organized as follows: we review the related literature and explain the detailed contributions in Section 2; we then formulate the theoretical models in Section 3; subsequently, we provide an analysis of our main results in Section 4; finally, we conclude with a discussion and outline potential paths for future research in Section 5.

2. Literature Review

This paper is mainly related to the three following topics that can be found in the literature: remanufacturing, subsidy policy, and green consumerism. Table 1 summarizes the contributions of this paper with regards to prior research.

There has been a large number of researchers highlighting remanufacturing. For example, Örsdemir, Kemahlıoğlu-Ziya [21] examined a situation, in which an original equipment manufacturer (OEM) was in competition with an independent remanufacturer (IR), and discovered that disregarding the competition or the OEM’s decisions regarding product quality results in an overestimation of the advantages of remanufacturing in terms of consumer and societal welfare. Li, Zhang [22] considered the application of intelligent manufacturing technology for improving the accuracy of remanufacturing and showed that intelligent remanufacturing does not always facilitate the process. Zhou, Meng [1] examined a supply chain that included an OEM and a contract manufacturer (CM), demonstrating that the CM employs distinct remanufacturing tactics under the two remanufacturing models, and opting out of remanufacturing could be the most favorable decision for the CM under the authorization model. Huang and Wang [26] investigated the effects of strategic consumer behavior and third-party costs on remanufacturing, revealing that, as consumers become more strategic, the demand for new products diminishes, while the demand for remanufactured products intensifies. Qin, Chen [27] established three remanufacturing models—integrated, outsourcing, and authorization remanufacturing—and showed that an OEM achieves the greatest profitability through integrated remanufacturing. Wu, Cao [5] explored and compared a durable goods producer’s decision making by establishing models of remanufacturing end-of-life and used products. Although the above researchers have analyzed remanufacturing operations, little focus has been shown to subsidy policies; thus, we intend to complement them by considering the implications of government subsidies on remanufacturing operations.

Table 1.

Contributions of this study with regards to prior research.

Table 1.

Contributions of this study with regards to prior research.

| Author(s) | Remanufacturing | Subsidy Policy | Green Consumerism |

|---|---|---|---|

| Zhou, Meng [1]; Wu, Cao [5]; Örsdemir, Kemahlıoğlu-Ziya [21]; Li, Zhang [22]; Huang and Wang [26]. | √ | ✗ | ✗ |

| Zheng, Zhao [28]; Liao [29]; Wang, Wang [30]; Shin and Kim [31]; Duan and Li [32]. | ✗ | √ | ✗ |

| Chai, Sun [23]; Xu, Liu [24]; Zhao, Liu [25]; Wu, Cheng [33]. | √ | √ | ✗ |

| This paper | √ | √ | √ |

On the other hand, subsidies have been recognized as supporting policies under various supply chain structures. For instance, Zheng, Zhao [28] provided insights into the product, innovation, and product–innovation subsidies and found that the product–innovation subsidy would be preferred for both the government and companies. Liao [29] used game theory to build a dual-channel green supply chain with the aim of comparing two government subsidy strategies and found that the strategies consistently encourage the manufacturer to enhance investment in green initiatives, thereby achieving a win–win–win outcome. Wang, Wang [30] considered the implications of subsidy policies under a three-stage Stackelberg model, consisting of the government, the manufacturer, and the retailer, and showed that the manufacturer’s and retailer’s inclinations towards various subsidy policies are influenced by the magnitudes of the subsidies. Shin and Kim [31] examined how government subsidy policies incentivize local companies to enhance product quality prior to exporting to foreign markets. Duan and Li [32] investigated the phenomenon of system collapse and highlighted it as another potential pattern for the evolution of platform ecosystems. The above research has highlighted the supporting impacts of subsidy policies under various supply chain structures; however, our research differs, as we mainly focus on the implications of government subsidy policy on operations management under remanufacturing.

Fortunately, there have been several studies recently that analyzed government subsidies in the remanufacturing industry. In particular, Chai, Sun [23] analyzed the effects of a government subsidy policy, along with the carbon cap and trade policies, on remanufacturing in a closed-loop supply chain and showed that both the subsidy policy and the carbon cap-and-trade policy are effective in encouraging remanufacturing. However, Xu, Liu [24] set out to devise strategies that can improve the quality of remanufactured products, thereby boosting consumer demand and promoting the expansion of the remanufacturing industry. Recently, Zhao, Liu [25] explored how varying subsidy levels and disparities affect the cost, quality, and market demand for remanufactured goods, in addition to the profitability of remanufacturing firms and vendors. Wu, Cheng [33] selected 391 Chinese SMEs through which to examine the relationships among green transformation, green innovation, government regulation, and green competitive advantages; their research demonstrated that tailoring subsidy levels and discrepancies according to product quality grades can effectively incentivize businesses and sellers to produce and market higher-quality remanufactured products. As previously mentioned, although the above studies have highlighted the implications of subsidy policy on optimal decisions around remanufacturing, they ignored the emergence of green consumerism in the remanufacturing industry. Therefore, we complement prior research in our study by considering the implications of government subsidies for green consumerism in the remanufacturing industry.

3. Model Formulation

3.1. Assumptions and Model Description

We consider the two following theoretical models: Model N, in which the OEM concentrates on the production of new products, but does not undertake remanufacturing at all; and Model R, in which the OEM participates in the operations of production and remanufacturing under a subsidy policy for encouraging remanufacturing consumerism, among both traditional and green consumers. In both models, the manufacturer’s decision-making parameters include the pricing of new and remanufactured products, while the government provides a quantitative subsidy for the manufacturer’s remanufactured products. Thus, we make the following necessary assumptions:

Assumption 1.

The unit variable cost of remanufacturing is lower than the unit variable cost of producing new products.

The manufacturer retrieves discarded products from consumers, which are then disassembled into their component parts [34]. We assume that the variable cost of producing new products is , and the cost of producing remanufactured products is . To reflect that remanufacturing is a relatively cost-saving business compared to producing, following Chai, Sun [23]; Yan, Xiong [35]; and He, Yan [36], we assume that the costs of the remanufacturing process, such as product assembly and testing, are lower than those of production; that is, . We further normalize and to zero and , respectively; although the value of reflects the cost-effectiveness of remanufacturing, in practice, this cost advantage does not necessarily lead to a competitive market advantage, due to the lower consumer acceptance of remanufactured products [21,36].

Assumption 2.

The consumer population in the market is not dynamically changed and is normalized to 1.

It should be noted that there are several benefits for normalizing the consumer population in the market to 1. First, since both of our models highlight the OEM’s optimal response under government subsidies for green consumerism, relaxing this assumption would not affect our results [36,37,38]. Second, keeping the market size of the consumer population unchanged helps us to simplify the analysis of the OEM’s operational decisions, but also enables us to focus on the implications of the government’s subsidy polices under green consumerism in the remanufacturing industry. Similar assumptions are widely adopted in the literature on remanufacturing (see, e.g., Zhang and He [6]; He, Yan [36]; and Zhang, Chen [39]).

Assumption 3.

The market conditions are similar during each period, and product demand and government subsidies remain stable. We study a single-period scenario.

We assume, as Zhang, Chen [39] and Wei, Chen [40] did, that all new products would turn into used cores when their end-of-life approaches; that is, we assume that the used cores are included in the second market and would be returned to the OEM for remanufacturing.

Assumption 4.

For new products, the willingness-to-pay is uniformly distributed within .

Note that, similar to Zhang and He [6]; He, Yan [36]; and Zhang, Chen [39], we have normalized the market size to 1; then, if a consumer purchases a new product, the valuation of the new product is , where is the market clear price for new products.

Assumption 5.

For remanufactured products, there are two different types of consumers, as follows: the green consumer, with a proportion of , whose valuation would equal to that of new products; and the strategic consumer, with a proportion of , whose valuation is lower than that of new products .

Notably, Guide and Li [11] pointed out that, based on auction results for commercial products, strategic consumers’ price sensitivity indicates a 9.7% lower willingness to pay for remanufactured products compared to new products. Accordingly, we assume that the utility that strategic consumers derive from remanufactured products is depreciated relative to the utility derived from new products, a distinction that not only highlights the price gap between remanufactured and new products, but also gives rise to the challenge of potential cannibalization, wherein the sale of one product may encroach on the sales of another; based on these conclusions, we can obtain that the willingness of strategic consumers to purchase remanufactured products is , where is the market clear price for the remanufactured product. However, since green consumers make decisions based on a specific form of social awareness or social responsibility and evaluate the remanufactured products in the same manner as they would new products, the utility for green consumers from purchasing remanufactured products is . The parameters and variables are detailed in Table 2.

Table 2.

Variable and parameter definitions.

Based on Assumptions 4 and 5, we derive the inverse demand functions for both new and remanufactured products as follows:

3.2. Model N

We first develop a benchmark, in which the OEM only concentrates on new product production and does not engage in remanufacturing (Model N); then, we are able to calculate the OEM’s situation as follows:

Since the OEM would not offer remanufactured products under Model N, then the inverse demand function can be written as . Substituting into Equation (2) and maximizing it provides the optimal outcomes for Table 3 (Detailed derivation can be found in Appendix A).

Table 3.

Optimal outcomes for both models.

3.3. Model R

In Model R, the OEM provides both products, a scenario which can be summarized as follows:

The term represents the profits of selling new products, while indicates those of remanufacturing. Note that the parameter refers to the level of the subsidy provided per unit of remanufactured product; then, when substituting Equation (1) into (3), maximizing it provides the optimal outcomes for Table 3 (Detailed derivation can be found in Appendix A).

To ensure that the outcomes of both models are positive, we need to balance and ; that is, if and , new products compete, so a heavy cannibalization problem results from remanufacturing, such that the OEM would not engage in new product production. Obviously, this extreme case is meaningless, as no used cores can be collected.

Based on the optimal outcomes of Model R, we now can address how green consumerism impacts the OEM’s optimal equilibrium, as follows (The proof can be found in Appendix B):

Proposition 1.

Both products’ prices increase with the proportion of green consumers, i.e., , .

Proposition 1 indicates that, as the proportion of green consumers increases, both products’ prices increase, which can be interpreted as follows: Since green consumers make decisions based on a specific form of social awareness or social responsibility, they are prepared to spend extra for products with environmental features that traditional products lack. Observing the positive responses to their remanufactured products, rational OEMs would like to set relatively higher prices. On the other hand, as the percentage of green consumers rises, the potential market for new products tends to shrink. Thus, as the prices of remanufactured products increase, the OEM would also set relatively higher prices for new products, in order to offset the decrease in the potential market for new products; that is, the prices of both types of products will increase as the proportion of green consumers rises (The proof can be found in Appendix C).

Proposition 2.

The quantities of new (remanufactured) products decrease (increase) with the parameter , i.e., ().

Although Proposition 1 found that the prices of remanufactured products increase with the proportion of green consumers, Proposition 2 reveals that the optimal quantities of remanufactured products also increase with the proportion of green consumers. In fact, Proposition 2 confirms the traditional wisdom that, as the proportion of green consumers, , increases, the potential market for remanufactured products increases. Consequently, although the prices of remanufactured products increase, the optimal quantities of remanufactured products also increase; that is, larger numbers of green consumers not only enhance the marginal revenue of the remanufactured products, i.e., , but also promote the remanufactured products’ sales, .

However, Proposition 2 also indicates the concern around cannibalization problems, in that, the higher the volume of remanufactured units sold in the market, the heavier the cannibalization problems caused by new product sales; that is, . Obviously, this argument is consistent with the results of the prior literature, such as Guide and Li [11]; Tan, Cao [14]; Gu, Chhajed [41]; etc., such that the emergence of remanufacturing creates the potential for cannibalization of new products sales (The proof can be found in Appendix D).

4. Impacts of Government Subsidies

In this section, we provide an analysis of our main results regarding the implications of government subsidies for green consumerism on the remanufacturing industry.

We first compare with to highlight the following question (The proof can be found in Appendix D): from the decision-making perspective, what are the implications of subsidy policy on the OEM’s optimal equilibrium?

Proposition 3.

The quantities of are lower than those of ; furthermore, .

Recall that, as Proposition 2 shows, the emergence of green consumers enables the OEM to provide more remanufactured products, cannibalizing new product sales. By comparing the optimal quantities of with those of , we conclude that the optimal quantities of new products in Model R are indeed lower than those in Model N, i.e., . However, according to , we can further conclude that, if the government adopts a subsidy policy for remanufacturing, such cannibalization problems become severe; that is, with higher subsidy levels, the difference between increases.

Proposition 3 is partially aligned with the findings of Tan, Cao [14], who concluded that, as the proportion of green consumers increases, the more units will be remanufactured, and the fiercer the cannibalization problems become. However, notably, we further show that, while the increasing percentage of green consumers indeed enhances the optimal number of remanufactured products, the subsidy policy to the remanufacturing industry would worsen such a cannibalization problem. Thus, we complement previous conclusions by addressing government subsidies for green consumerism in the remanufacturing industry.

Thus far, we have highlighted the implications of subsidy policies on the OEM’s optimal equilibrium and found that, if the government adopts a subsidy policy for remanufacturing, the cannibalization problem becomes severe. Now, we address the implications of subsidy policies on the OEM’s profitability; more specifically, we first compare the OEM’s profitability from new product sales in Model R to that in Model N, as follows (The proof can be found in Appendix E):

Proposition 4.

Subsidy policies always hurt new products’ profitability, i.e., ; furthermore, .

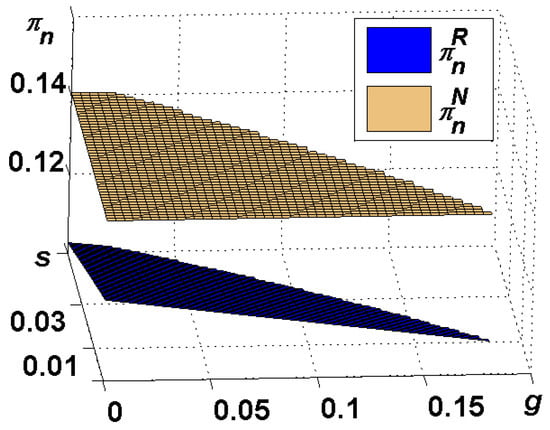

Recall that, as Proposition 3 shows, always holds true due to the cannibalization problems, which naturally hurts the profitability of new products; that is, Proposition 4 confirms the argument of Proposition 3 from the profitability perspective. On the other hand, following , detailed in Proposition 3, Proposition 4 also confirms that, if the government adopts a subsidy policy for remanufacturing, such cannibalization problems become severe and result in a greater difference between and . In Figure 1, we can observe that the profitability of is always lower than that of ; moreover, as subsidy levels increase, the profitability of decreases, thus enhancing the difference of .

Figure 1.

Impacts of on and .

Having confirmed that, whether from the quantity or the profitability perspective, a subsidy policy to the remanufacturing industry would worsen the cannibalization problem, we now take one step further to address the implications of subsidy policy on the OEM’s profitability; in other words, comparing with , the analysis yields the following result (The proof can be found in Appendix F).

Proposition 5.

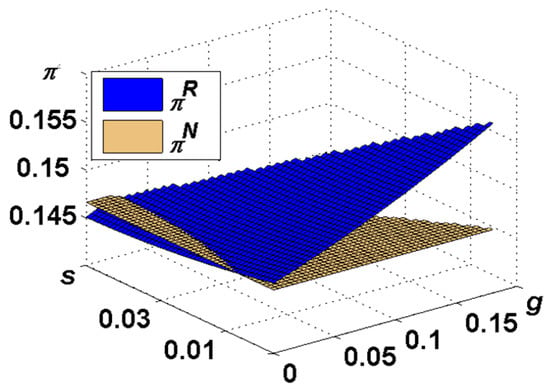

holds for ; otherwise, the opposite is true.

As depicted in Figure 2, the OEM’s profit decreases with higher government subsidies, but the impact varies with different proportions of ; more specifically, when is limited, stimulating remanufacturing through subsidies is not profitable for the OEM. The intuition behind this can be understood as follows: Recall that both products’ prices, and , are positively correlated with the proportion of green consumers, i.e., , meaning that, the more strategic consumers, the lower the prices of both new and remanufactured products. Moreover, when the number of green consumers is low, almost all remanufactured products are purchased by strategic consumers; under this condition, additional subsidies lead to a natural decrease in the prices of both remanufactured and new products. As a result, from the total profitability perspective, stimulating remanufacturing through subsidies is not a profitable business for the OEM.

Figure 2.

Impacts of on and .

As previously mentioned, remanufacturing is an effective method through which to achieve resource-efficient recycling and reduce environmental burdens by recovering value from used products and restoring products to like-new condition [1]. As demonstrated by Zhang, Chen [39] and Zhou, Xiong [38], the environmental impacts of remanufacturing can be calculated as the reduction in environmental burdens through source-saving. Let denote the environmental impact of per used cores; then, we can finally focus on the following question (The proof can be found in Appendix G): from a sustainability perspective, what are the implications of subsidy policy on our environmental performance?

Proposition 6.

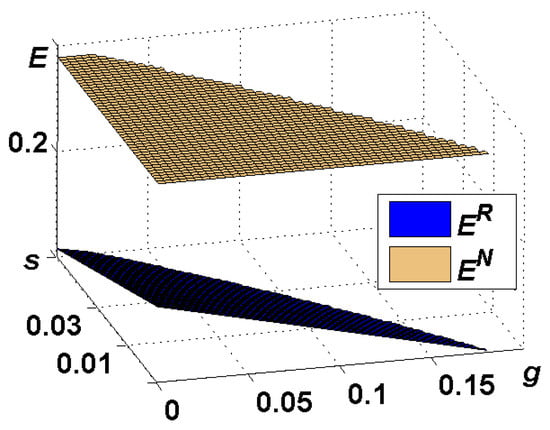

Model R is a better choice for the environment than Model N, i.e., ; furthermore, .

Recall that, as Proposition 3 shows, , meaning that the amounts of disposed used products in Model R are lower than those in Model N; furthermore, in Model R, the OEM engages in remanufacturing under a subsidy policy, further reducing the availability of used cores. Drawing from the data presented in Figure 3, it becomes evident that, since holds true, we can then conclude that Model R is a better choice for the environment than Model N; moreover, Figure 3 illustrates that, as subsidy levels, , increase, the environmental burdens in Model N remain unchanged; however, the environmental burdens in Model R decrease. Thus, subsidy policies for remanufacturing enhance the difference between and .

Figure 3.

Impacts of on and .

5. Conclusions

Remanufacturing is an effective method through which to achieve resource-efficient recycling and reduce environmental burdens by recovering value from used products and restoring products to like-new condition. However, the current developmental trend in the remanufacturing industry has not met expectations because of the reduced consumer readiness to pay higher prices for remanufactured items [10]. According to auctions conducted on eBay, consumers are 15.3% less inclined to pay the same price for a remanufactured product as they would pay for a new product [11]. On the other hand, green consumers, who make decisions based on a specific form of social awareness or social responsibility, have emerged [14]; thus, many consumers now experience a range of psychological and financial burdens, causing a discrepancy between their stated intentions and their actual actions regarding environmentally friendly practices [16].

To overcome the obstacles caused by behaviors hindering consumers from achieving sustainability objectives, more and more government organizations and environmental agencies have proposed the implementation of subsidy policies to encourage green consumer preferences. In practice, more and more governments, e.g., China, Wales, Japan, and the European Union, have launched various remanufacturing subsidy policies to encourage green consumerism for remanufactured products, such as car engines and transmissions.

Although many researchers (see, e.g., Chai, Sun [23]; Xu, Liu [24]; and Zhao, Liu [25]) have highlighted the implications of subsidy policy on optimal decisions around remanufacturing, they ignored the emergence of green consumerism in the remanufacturing industry. Thus, we complement them with our research by considering the implications of government subsidies for green consumerism in the remanufacturing industry. In order to understand the implications of the government subsidies for green consumerism in remanufacturing industry, we formulated the two following models: Model N, in which the OEM only focuses on the production of new products and does not undertake remanufacturing at all; and Model R, in which the OEM engages in the operations of production and remanufacturing under a subsidy policy for encouraging remanufacturing consumerism, including both traditional and green consumers.

Our analysis confirms that the emergence of green consumers enables the OEM to provide more remanufactured products, which cannibalizes new product sales. Furthermore, if the government adopts a subsidy policy for remanufacturing, such cannibalization problems become severe and naturally hurt the profitability of new products; moreover, by comparing the OEM’s total profitability in Models R and N, we find that, when the number of green consumers is limited, stimulating remanufacturing through subsidies may lead to a potentially bad result, wherein the cannibalization problem caused by remanufacturing hurts the OEM’s overall profits.

This study provides the following directions for future research: First, we only considered the OEM’s optimal pricing problems within a single period; however, in anticipation that there might be a subsidy policy for remanufacturing, consumers, especially strategic consumers, may delay purchases. Therefore, future researchers could highlight the OEMs’ dynamic pricing issues under subsidy policies. Second, all remanufactured products were provided by the OEM in our model; however, in practice, almost all products are distributed by retailers, especially dominant retailers such as Walmart, Tesco, Amazon, etc. As such, future researchers could highlight the implications of distribution structures on remanufacturing options under subsidy policies. Third, in order to highlight our research aims, we did not address issues such as information asymmetry, quality uncertainty, and sales efforts. Future research could further delve into these aspects.

Author Contributions

W.X. wrote the manuscript; J.W. contributed to the methodology and software; J.Z. conducted the review and edited the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

The authors thank the Humanities and Social Sciences Foundation for Young Scholars of China’s Ministry of Education (15YJC630154) for funding this research.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A. Equilibrium Outcome Derivation

- (1)

- Derivation of equilibrium outcomes for Model N

Substituting into (2), after simplification, provides .

Maximizing the above function provides . Substituting Equation (2) into (3) provides , ;

- (2)

- Derivation of equilibrium outcomes for Model N

Substituting (1) into (2), after simplification, provides

Maximizing the above function provides , .

Substituting them in into (3) provides the following equilibrium outcomes:

To ensure that the outcomes of both models are positive, we need to balance and .

Appendix B. Proof of Proposition 1

According to the outcomes in Table 2, we find that

We can easily find that, for any , the statements and always hold true.

That is, as Proposition 1 shows, both products’ optimal prices increase with the proportion of green consumers.

Appendix C. Proof of Proposition 2

According to the outcomes in Table 2, we find that

We can easily find that, for any and , the statements and always hold true.

That is, as Proposition 2 shows, the optimal quantities of () decrease (increase) with the proportion of green consumers.

Appendix D. Proof of Proposition 3

According to the outcomes in Table 2, we find that

We can easily find that, for any and , the statement always holds true.

Moreover, based on the outcomes, we can obtain . We can easily find that, for any and , always holds true.

That is, as Proposition 3 shows, ; furthermore, subsidy policy leads the cannibalization problem to become more severe.

Appendix E. Proof of Proposition 4

We solve as follows:

Accordingly, we find that, for any , , and , the statement always holds true.

Furthermore, based on the above equation, we can obtain

We find that, for any , , and , the statement always holds true.

That is, as Proposition 4 shows, subsidy policies always hurt new products’ profitability; moreover, as subsidy levels increase, the profitability of decreases, thus enhancing the difference of .

Appendix F. Proof of Proposition 5

We now solve as follows:

Based on the above function, solving provides

where

Comparing with , we find that, for , is true.

Thus, for any , is true.

Appendix G. Proof of Proposition 6

Let denote the environmental impact per used core. Thus,

We can then solve as follows:

We find that, for any and , the statement always holds true.

Furthermore,

We also find that, for any and , the statement always holds true.

References

- Zhou, Q.; Meng, C.; Sheu, J.-B.; Yuen, K.F. Remanufacturing mode and strategic decision: A game-theoretic approach. Int. J. Prod. Econ. 2023, 260, 108841. [Google Scholar] [CrossRef]

- Luo, R.; Zhou, L.; Song, Y.; Fan, T. Evaluating the impact of carbon tax policy on manufacturing and remanufacturing decisions in a closed-loop supply chain. Int. J. Prod. Econ. 2022, 245, 108408. [Google Scholar] [CrossRef]

- Yuan, X.; Liu, M.; Yuan, Q.; Fan, X.; Teng, Y.; Fu, J.; Ma, Q.; Wang, Q.; Zuo, J. Transitioning China to a circular economy through remanufacturing: A comprehensive review of the management institutions and policy system. Resour. Conserv. Recycl. 2020, 161, 104920. [Google Scholar] [CrossRef]

- Xu, J. and Y. Duan, Pricing and greenness investment for green products with government subsidies: When to apply blockchain technology? Electron. Commer. Res. Appl. 2022, 51, 101108. [Google Scholar] [CrossRef]

- Wu, S.; Cao, J.; Shao, Q. How to select remanufacturing mode: End-of-life or used product? Environ. Dev. Sustain. 2024, 12, 1–21. [Google Scholar] [CrossRef]

- Zhang, W.; He, Y. Optimal policies for new and green remanufactured short-life-cycle products considering consumer behavior. J. Clean. Prod. 2019, 214, 483–505. [Google Scholar] [CrossRef]

- Sakao, T.; Bocken, N.; Nasr, N.; Umeda, Y. Implementing circular economy activities in manufacturing for environmental sustainability. CIRP Ann. 2024, 73, 457–481. [Google Scholar] [CrossRef]

- Fraser, M.; Haigh, L.; Soria, A.C. The Circularity Gap Report 2023. 2022. Available online: https://assets.website-files.com/5e185aa4d27bcf348400ed82/63d4468c9a1c6ea04138f206_Global%20CGR%202023%20-Methodology%20Document.pdf (accessed on 1 November 2024).

- Shangpu Group. Market Size and Development Trends of the Automotive Remanufacturing Industry in 2023. 2023. Available online: https://baijiahao.baidu.com/s?id=1780278351289217297&wfr=spider&for=pc (accessed on 10 October 2024).

- Zolfagharinia, H.; Zangiabadi, M.; Hafezi, M. How much is enough? Government subsidies in supporting green product development. Eur. J. Oper. Res. 2023, 309, 1316–1333. [Google Scholar]

- Guide, V.D.R., Jr.; Li, J. The Potential for Cannibalization of New Products Sales by Remanufactured Products. Decis. Sci. 2010, 41, 547–572. [Google Scholar] [CrossRef]

- Gleim, M.R.; Smith, J.S.; Andrews, D.; Cronin, J.J., Jr. Against the Green: A Multi-method Examination of the Barriers to Green Consumption. J. Retail. 2013, 89, 44–61. [Google Scholar] [CrossRef]

- ElHaffar, G.; Durif, F.; Soman, D.; Dubé, L. Green … but at what cost? A typology and scale development of perceived green costs. J. Clean. Prod. 2023, 428, 139402. [Google Scholar] [CrossRef]

- Tan, H.; Cao, G.; He, Y.; Lu, Y. Channel Structure Choice for Remanufacturing under Green Consumerism. Processes 2021, 9, 1985. [Google Scholar] [CrossRef]

- Tully, S.M.; Winer, R.S. The Role of the Beneficiary in Willingness to Pay for Socially Responsible Products: A Meta-analysis. J. Retail. 2014, 90, 255–274. [Google Scholar] [CrossRef]

- ElHaffar, G.; Durif, F.; Dubé, L. Towards closing the attitude-intention-behavior gap in green consumption: A narrative review of the literature and an overview of future research directions. J. Clean. Prod. 2020, 275, 122556. [Google Scholar] [CrossRef]

- Feifer, J. 70% of Consumers Say They’ll Buy ’Green’ Products, but Only 5% Actually Do. 2023. Available online: https://www.entrepreneur.com/green-entrepreneur/70-of-consumers-say-theyll-buy-green-products-but-only/458397 (accessed on 10 December 2024).

- Meng, Q.; Li, M.; Li, Z.; Zhu, J. How Different Government Subsidy Objects Impact on Green Supply Chain Decision considering Consumer Group Complexity. Math. Probl. Eng. 2020, 1, 5387867. [Google Scholar] [CrossRef]

- www.GOV.cn. Trade-in for Remanufactured Parts to Receive a 10% Subsidy. 2014. Available online: https://www.gov.cn/gzdt/2013-08/29/content_2477063.htm (accessed on 19 October 2024).

- Doherty, J. £15m Recycling Fund for Welsh Local Authorities. 2018. Available online: https://www.letsrecycle.com/news/15-million-recycling-welsh-local-authorities/ (accessed on 26 October 2024).

- Örsdemir, A.; Kemahlıoğlu-Ziya, E.; Parlakturk, A.K. Competitive Quality Choice and Remanufacturing. Prod. Oper. Manag. 2014, 23, 48–64. [Google Scholar] [CrossRef]

- Li, K.; Zhang, L.; Fu, H.; Liu, B. The effect of intelligent manufacturing on remanufacturing decisions. Comput. Ind. Eng. 2023, 178, 109114. [Google Scholar] [CrossRef]

- Chai, Q.; Sun, M.; Lai, K.-H.; Xiao, Z. The effects of government subsidies and environmental regulation on remanufacturing. Comput. Ind. Eng. 2023, 178, 109126. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, C.; Wei, F.; Zhao, S.; Mao, H. The influence of government subsidies on remanufacturers’ production decisions, considering product quality, customer purchase intention, and carbon emissions. J. Clean. Prod. 2024, 443, 141130. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, C.; Wei, F.; Xu, Y.; Li, W. Impact of subsidizing remanufactured products based on their quality rating. Environ. Dev. Sustain. 2024, 21, 1–25. [Google Scholar] [CrossRef]

- Huang, Y.T.; Wang, Z.J. Pricing and production decisions in a closed-loop supply chain considering strategic consumers and technology licensing. Int. J. Prod. Res. 2019, 57, 2847–2866. [Google Scholar] [CrossRef]

- Qin, L.; Chen, W.; Zhang, Y.; Ding, J. Cooperation or competition? The remanufacturing strategy with quality uncertainty in construction machinery industry. Comput. Ind. Eng. 2023, 178, 109106. [Google Scholar] [CrossRef]

- Zheng, J.; Zhao, H.; Fu, J. Diverse government subsidy modes in a supply chain considering different innovation dimensions. Soft Comput. 2024, 28, 3973–3986. [Google Scholar] [CrossRef]

- Liao, C.H. Analysis of government subsidy strategies for blockchain-enabled green supply chains under competition. Rairo-Oper. Res. 2024, 58, 4119–4143. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Li, B.; Cheng, Y. The choice of subsidy policy for incentivizing product design for environment. Comput. Ind. Eng. 2023, 175, 108883. [Google Scholar] [CrossRef]

- Shin, I.; Kim, H. The effect of subsidy policies on the product quality improvement. Econ. Model. 2010, 27, 687–696. [Google Scholar] [CrossRef]

- Duan, W.; Li, C. Be alert to dangers: Collapse and avoidance strategies of platform ecosystems. J. Bus. Res. 2023, 162, 113869. [Google Scholar] [CrossRef]

- Cheng, P.; Yang, F. Study on the impact of digital transformation on green competitive advantage: The role of green innovation and government regulation. PLoS ONE 2024, 19, e0306603. [Google Scholar]

- Wei, X. Effects of double subsidies and consumers’ acceptability of remanufactured products on a closed-loop supply chain with trade-in programs. J. Clean. Prod. 2024, 447, 141565. [Google Scholar] [CrossRef]

- Yan, W.; Xiong, Y.; Xiong, Z.; Guo, N. Bricks vs. clicks: Which is better for marketing remanufactured products? Eur. J. Oper. Res. 2015, 242, 434–444. [Google Scholar] [CrossRef]

- He, J.; Yan, W.; Li, Y.; Lu, D. Recycling and/or reusing: When product innovation meets the recast of WEEE direct. Int. J. Prod. Res. 2024, 62, 7018–7029. [Google Scholar] [CrossRef]

- Cohen, M.C.; Lobel, R.; Perakis, G. The Impact of Demand Uncertainty on Consumer Subsidies for Green Technology Adoption. Manag. Sci. 2016, 62, 1235–1258. [Google Scholar] [CrossRef]

- Zhou, Y.; Xiong, Y.; Jin, M. Less is more: Consumer education in a closed-loop supply chain with remanufacturing. Omega 2021, 101, 102259. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, H.; Xiong, Y.; Yan, W.; Liu, M. Managing collecting or remarketing channels: Different choice for cannibalisation in remanufacturing outsourcing. Int. J. Prod. Res. 2021, 59, 5944–5959. [Google Scholar] [CrossRef]

- Wei, J.; Chen, W.; Liu, G. How manufacturer’s integration strategies affect closed-loop supply chain performance. Int. J. Prod. Res. 2021, 59, 4287–4305. [Google Scholar] [CrossRef]

- Gu, W.; Chhajed, D.; Petruzzi, N.C.; Yalabik, B. Quality design and environmental implications of green consumerism in remanufacturing. Int. J. Prod. Econ. 2015, 162, 55–69. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).