Abstract

The relationship between Lean Six Sigma, Industry 4.0 and sustainable manufacturing has been evaluated only to a limited extent within this domain of the published literature. A DMAIC-DMADV-based framework along with a phase-by-phase implementation path is proposed in this study to integrate Lean Six Sigma and Industry 4.0 technologies for achieving sustainable manufacturing. The paper also focused on identifying and prioritizing the critical success factors for the implementation of the proposed framework. The critical success factors identified through a literature review are ranked using the multi-decision criteria technique TOPSIS, with input from selected experts across various manufacturing companies. The results highlight that the most important enablers set clear sustainability goals, regularly monitor progress and have a skilled workforce. The findings provide actionable guidance for practitioners, and the study contributes to the existing body of knowledge by offering a comprehensive methodology to integrate Lean Six Sigma and Industry 4.0 for sustainable manufacturing. Further research must focus on the validation of the framework in diverse industrial settings and refining the sustainability assessment model to enhance its adaptability.

1. Introduction

Due to rising environmental concerns and regulatory pressures, sustainable manufacturing is considered a vital priority for industries worldwide [1]. Sustainable manufacturing based on the triple bottom line (TBL) balances economic performance, environmental protection and social equity [2]. This approach has encouraged manufacturers to adopt strategies that improve their process efficiency while reducing waste and minimizing environmental impacts. Through sustainable manufacturing, industries can achieve profitability, promote social well-being and significantly reduce their ecological footprint [3].

Lean Six Sigma is a widely applied methodology for process improvement that minimizes variability and reduces defects [4]. Lean principles ensure value creation and efficiency in the manufacturing process through the elimination of waste and streamlining of workflows [5]. Six Sigma applies statistical tools to identify and reduce variability, ensuring high-quality and consistent production output [6]. The combination of lean principles and Six Sigma tools can contribute to achieving sustainability goals through efficient energy utilization, process optimization, manufacturing high-quality products and reducing environmental impacts [7].

Industry 4.0 refers to the fourth Industrial Revolution that brought a technological revolution to the manufacturing sector through the introduction of advanced technologies such as artificial intelligence (AI), machine learning (ML), the Internet of Things (IoT), smart sensors, cyber–physical systems, big data analytics, etc., for facilitating interconnected intelligent systems [8]. Manufacturers can obtain real-time data using smart sensors and the Internet of Things to generate predictive insights with machine learning algorithms [9]. The available data can be shared between departments seamlessly to coordinate the production process efficiently with the support of cyber–physical systems and cloud computing technologies [10]. Big data analytics can further optimize operations to uncover the patterns and trends that hinder or support improvements to the process [11].

Integrating Lean Six Sigma and Industry 4.0 holds great potential to facilitate sustainable manufacturing practices [12]. Lean Six Sigma provides structured methodologies, such as DMAIC (define, measure, analyze, improve and control) and DMADV (define, measure, analyze, design and verify), which support systematic continuous process improvement by identifying the major inefficiencies and optimization of workflows [13]. Industry 4.0 introduces advanced real-time, data-driven technologies, including smart sensors, machine learning and the Internet of Things, to enable automation and predictive insights [14]. The integration of these paradigms creates a powerful approach, whereby Lean Six Sigma offers a systematic framework for continuous improvement, while Industry 4.0 accelerates the implementation of solutions with advanced analytics and real-time monitoring [15]. For example, the use of predictive maintenance tools supported by the IoT and big data analytics within a Lean Six Sigma framework reduces unplanned downtime and optimizes the utilization of resources [16]. Similarly, digital twin simulations combined with DMAIC’s improve phase enable the virtual testing of proposed changes, ensuring sustainable outcomes with minimal risks [17]. However, this approach is still a developing area of research, with limited studies exploring how these paradigms complement each other to achieve environmental, economic and social sustainability goals [18]. Further research is needed to address the gaps and validation of integrated frameworks through practical applications across diverse industrial contexts [19].

In this context, this study highlights the mapping and verification of the influence of Lean Six Sigma’s and Industry 4.0’s impacts on sustainable manufacturing. This study proposes an integrated Lean Six Sigma–Industry 4.0 framework for sustainable manufacturing, and the critical success factors for implementing the framework are identified through a comprehensive literature review. The critical success factors are ranked based on their significance using the multi-criteria decision-making technique, TOPSIS. This prioritization provides actionable insights to industry practitioners, supporting them to focus on the most important and impactful decisions for the effective implementation of the framework. The work is presented as follows: Section 2 provides a comprehensive literature review related to the influence of Lean Six Sigma and Industry 4.0 over sustainable manufacturing, followed by Section 3 which outlines the research methodology. The proposed framework is presented in Section 4 and the prioritization of critical success factors in the framework’s implementation is detailed in Section 5. Section 6 discusses the results, research implications and limitations. The study draws conclusions in Section 7, summarizing key findings and providing future research directions.

2. Literature Review

The literature review focused on studies related to the influence of Lean Six Sigma and Industry 4.0 on sustainability and identifying the scope of integration between them. Existing frameworks are also reviewed to highlight research gaps and areas for improvement.

The main aspect of Lean Six Sigma’s contribution towards sustainability is the minimization of the consumption of resources and energy [20]. This is achieved by removing non-value-adding activities from the manufacturing process. Applying the Lean Six Sigma strategy, not only to the production side but also to the supply chain and logistics, also leads to optimum resource utilization [21]. The defect and variability reduction from Six Sigma ensures fewer products are reworked, further conserving resources and energy. These benefits not only enhance operational efficiency but also lower expenses and carbon footprints. Using value stream mapping (VSM), industries can map the current state of processes to streamline workflows and identify bottlenecks for improved throughput, which contributes to sustainable efforts [22]. The main advantage of lean Six Sigma in sustainability is its profound impact on product quality and that it meets the needs of customers for a higher satisfaction level [23]. This will support process reliability improvements and a significant reduction in product recall. Case studies demonstrate its positive influence on sustainability in various industries and sectors [24,25,26].

The primary contribution of Industry 4.0 towards sustainable manufacturing is its ability to enhance resource efficiency through real-time usage monitoring using the Internet of Things and smart sensors [27]. Energy consumption can be tracked using smart sensors and adjusted dynamically to reduce wastage. Studies show that Industry 4.0 technologies can facilitate automation and avoid human errors to reduce costs and enhance operational efficiency [28,29,30]. One of the key areas in which Industry 4.0 is applied is predictive maintenance, as the traditional approach relies on reactive methods that have higher costs, more downtime and wasted resources. The studies show that IoT, big data analytics, machine learning and artificial intelligence can predict failures in advance, allowing the industries to perform only necessary maintenance [31,32,33]. Industry 4.0 facilitates the circular economy through additive manufacturing, such as 3D printing and blockchains, which help to produce products that can be repaired, refurbished and recycled [34]. The product lifecycle can be optimized using digital twin simulations, ensuring the products are repaired, refurbished and recycled [35]. Not only in the production part, but also in the supply chain, artificial intelligence applications are used for route planning and optimization for facilitating sustainable supply chains [36].

Integrating Lean Six Sigma and Industry 4.0 can provide an integrated framework that carries the strengths of both paradigms: combining the structure of problem-solving methodologies with advanced real-time technologies [37,38]. Lean Six Sigma, through DMAIC and DMADV methodologies, offers robust statistical tools for continuous process improvement, while Industry 4.0 provides real-time data-driven technologies such as machine learning, IoT and big data analytics, which enhance the accuracy, speed and scalability of efforts for improvements [39]. For example, predictive maintenance that leverages IoT and machine learning can be integrated with Six Sigma’s defect-reduction goal, which can reduce variability and minimize downtime along with resource wastage [40]. The control phase in the Lean Six Sigma approach can be significantly enhanced by Industry 4.0 tools, enabling continuous feedback loops that ensure process efficiency over time [41]. The key performance indicators such as defect rates and energy consumption can be tracked continuously using smart sensors and can trigger corrective actions as needed based on big data analytics [42]. The integration also extends to the optimization of workflows, in which digital twin simulations can model the proposed processes identified in the improve phase of Lean Six Sigma. This will allow industry practitioners to test and refine solutions in a virtual environment before applying them in the real world to reduce the risk of process changes [43]. The outcomes of the integration between Lean Six Sigma and Industry 4.0 are illustrated in Table 1.

Table 1.

Integrated outcomes of Lean Six Sigma and Industry 4.0.

The limitation of Lean Six Sigma, specifically, its reliance on statistical analysis tools and manual data collection, can be overcome by adapting Industry 4.0 technologies [44]. Thus, both paradigms can complement each other to improve efficiency, customer satisfaction and sustainability. DMAIC (define, measure, analyze, improve and control) can provide a structured road map and framework for implementing Industry 4.0 technologies [45]. There are various studies in which researchers have attempted to create frameworks for combining Lean Six Sigma and Industry 4.0 [46,47,48,49,50,51]. Most frameworks remain conceptual as they are derived from literature reviews, and more studies are needed to validate them through real-world applications. DMAIC (define, measure, analyze, improve and control) and DMADV (define, measure, analyze, design and verify) phases are adapted for the framework structure and guidance to incorporate Industry 4.0 tools into each stage [52]. A significant research gap exists in developing a comprehensive framework combining Lean Six Sigma and Industry 4.0 for sustainable manufacturing. Also, limited studies for the combined application of paradigms address the social, economic and environmental aspects of sustainable manufacturing. Critical success factors must be identified and ranked for the effective implementation of such an integrated framework. Targeted studies and the application of multi-criteria decision-making (MCDM) tools can address the research gaps.

3. Research Methodology

The study’s main objective is to identify and prioritize the critical success factors of a Lean Six Sigma–Industry 4.0 integrated framework for sustainable manufacturing using TOPSIS. The methodology starts with framework conceptualization based on the insights from the literature review and the framework structure designed with DMAIC and DMADV principles. DMAIC (define, measure, analyze, improve and control) is a structured technique used in Lean Six Sigma that focuses on continuous improvement that starts with defining the problem, measuring the current performance, analyzing root causes, implementing the proposed solutions or improvements and ensuring the improvements are sustained over time [48]. At the same time, another Six Sigma methodology, DMADV (define, measure, analyze, design and verify), is applied during a new process or new product design stage. It involves defining the requirements, measuring key performance indicators, analyzing the alternatives, designing the process or product and verifying that the design meets the needs or requirements [53]. The main reason for selecting DMAIC and DMADV is that they provide a well-structured, systematic method of achieving continuous improvements that lead to the achievement of sustainability goals. The data-driven approach of DMAIC allows for target problem solving, and DMADV ensures that new designs or processes meet performance expectations and are optimized for sustainability from the beginning stage. The methodology continues to identify critical success factors of the proposed framework’s implementation using a literature review and it prioritizes the critical success factors using TOPSIS (Technique for Order Preference by Similarity to Ideal Solution) [54]. TOPSIS is a multi-criteria decision-making method that systematically ranks the critical success factors by measuring their closeness to the ideal point and distance from the negative ideal [55]. The highest priority factor will be the distance, which is the shortest from the positive ideal and the longest from the negative ideal. It has the advantage of representing the rationale of human choice in a logical way and demonstrates the scalar value that accounts for the best and worst alternatives [56]. In this study, a total of 25 experts were initially consulted, representing five different manufacturing companies. To streamline the data representation and maintain clarity, we aggregated the individual inputs from each company into a consolidated score (one per company) rather than displaying all 25 individual responses. This approach allowed us to reflect the group consensus with each organization, as the experts engaged in discussions and iteration reviews to arrive at a shared perspective. Although each company’s consolidated score appears as a single dataset in the decision matrix, it is underpinned by multiple expert inputs from diverse functional areas.

4. DMAIC–DMADV-Based Framework for Integration

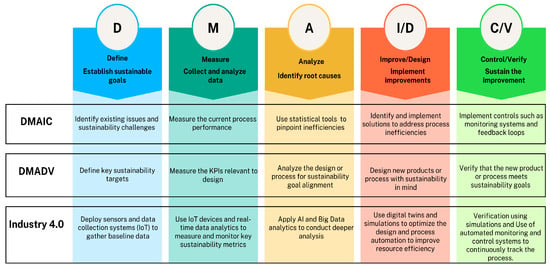

The proposed framework is conceptualized by incorporating the Lean Six Sigma methodologies DMAIC and DMADV, as well as Industry 4.0 technologies, as illustrated in Figure 1.

Figure 1.

Lean Six-Sigma Industry 4.0 framework for sustainable manufacturing.

In the define phase, the sustainable goals will be established by identifying existing problems, such as high amounts of waste, or sustainability challenges, such as energy inefficiencies. Also, the goals for new processes or product designs will align with these sustainability goals. To gather the baseline data and information on the needs of stakeholders, Industry 4.0 technologies such as big data analytics and IoT can be used. Data collection in the measure phase can be carried out with the support of Industry 4.0 tools such as IoT, smart sensors and cloud computing. The collected data contain the defect rate, energy consumption rate, baseline requirements, etc., which undergo a deep analysis during the analyze phase. Machine learning, simulation tools and advanced data analysis tools can be used to identify the root causes of inefficiencies and predict the behavior of new systems under development. The improve phase makes incremental improvements or changes to existing processes to remove the inefficiencies. Also, the product or process design needs to be finalized with sustainability in mind in the design phase, and Industry 4.0 technology like digital twins can be used to simulate and improve the process efficiency. The improvement needs to be maintained over time during the control stage through real-time feedback using Industry 4.0 technologies. Similarly, the designed product or process needs to be validated in the verify phase to ensure that it meets the sustainable targets or requirements. The findings from the control/verify phase feedback to earlier phases using feedback loops to adapt to changing market demands, regulatory requirements and technological advancements. The triple bottom line elements such as the environmental, economic and social impact of the framework’s adaptation can be assessed using the sustainability assessment model listed in Table 2.

Table 2.

Sustainability assessment model of Lean Six Sigma–Industry 4.0 framework.

4.1. Implementation Path for the Integrated Lean-Six Sigma–Industry 4.0 Framework

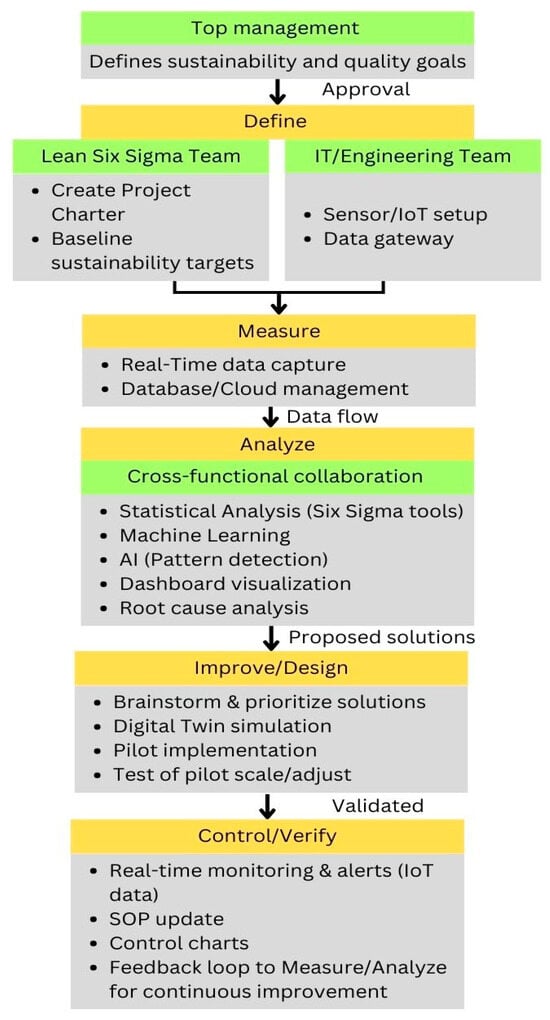

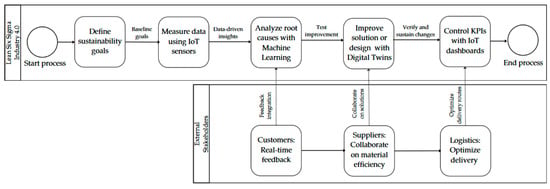

The proposed Lean Six Sigma–Industry 4.0 framework needs to be operationalized effectively through a structured, phase-by-phase implementation path. In the define phase, the main objective is to pinpoint key sustainability or operational challenges and establish the baseline performance metrics. This needs to be led by the Lean Six Sigma team collaborating with top management to set clear goals. The IT and Engineering teams facilitate the deployment of IoT sensors and data acquisition tools on targeted production lines, ensuring the collection of real-time data right from the outset. Cross-functional stakeholders, including those involved in production, the supply chain, quality control and IT, are engaged so that they are aligned in terms of the scope and anticipated outcome. There exists a shared understanding of the performance targets and long-term sustainability objectives. The framework then proceeds to the measure phase to measure the current state of operations to form a robust baseline. The deployed IoT sensors capture key parameters such as defect counts, process speeds and energy consumption at regular intervals and provide an accurate picture of the current performance. This forms a large dataset, and these datasets are then stored securely in cloud solutions, in which they can be easily accessed and analyzed by multiple stakeholders. To make sense of these data, Lean Six Sigma practitioners adopt tools such as SIPOC diagrams or value stream mapping, which are enriched with real-time insights that provide clear information regarding the key inefficiencies in cycle times, lead times or overall resource usage. Through this way of translating the raw sensor data into meaningful metrics, a clear and quantifiable picture of how each stage of the process is performing and where there are gaps can be obtained. The analyze phase uncovers the root cause of identified inefficiencies and validates potential improvement opportunities. In this stage, traditional Lean Six Sigma statistical methods such as Pareto analysis and control charts are integrated with advanced AI or machine learning algorithms to detect patterns within the data that point to recurring defects, unanticipated energy waste or any subtle correlations in the production environment. To further assist in visualizations of these insights, real-time dashboards will be implemented that enable the production and quality engineers to spot the abnormal trends immediately. Once the critical issues are well understood, the improve or design phase focuses on devising and implementing the solutions that address the identified root causes. A cross-functional team will work on the range of potential improvements such as alternative material choices, reconfigured workflows or machine settings. Digital twin simulations support this phase, which allows the data science and engineering teams to model the proposed solutions in a virtual environment, predicting outcomes without risking the current real-world production settings. A pilot test also validates the feasibility and effectiveness of the interventions. The process loops back to further refinements if there are discrepancies between the expected and actual outcomes, and it will be guided by additional analytics from machine learning models. After successful piloting and refinement, the control or verify phase ensures that the improvements are consistently delivering the intended benefits. The key performance indicators such as the defect rates and power consumption are constantly tracked using automated IoT-based monitoring systems and trigger the team with alerts whenever critical thresholds are crossed. To sustain the improvement, the organization formalizes new SOPs (standard operating procedures) to embed the improved process into routine operations. The data generated throughout this stage are then relayed back to previous phases for ongoing calibration, laying the groundwork for continuous improvement. Periodic technology updates and audits serve as checkpoints to monitor the performance of IoT sensors, the tuning of machine learning Models and adherence to SOPs. This will also ensure that all elements remain aligned with evolving production volumes, production mixes or sustainability goals. The entire implementation pathway is a cyclic process in which data-driven decisions, iterative enhancements and stakeholder collaboration converge to solidify the Lean Six Sigma–Industry 4.0 framework as a dynamic, organization-wide force for operational excellence and sustainability. Figure 2 illustrates the flow of activities, people and technologies involved in the framework’s implementation and Figure 3 shows the business process model of framework.

Figure 2.

Implementation path for the integrated Lean Six Sigma–Industry 4.0 framework.

Figure 3.

Business process model of framework.

4.2. Integration of Internal and External Stakeholders in the Framework

The proposed framework integrates external stakeholders, including customers, suppliers and logistic operators, ensuring alignment across the entire supply chain to extend its impact beyond the internal processes. This integration fosters collaboration, optimizes resource utilization and improves customer satisfaction. The development of IoT-enabled products and sensors embedded in smart products plays a critical role in capturing real-time feedback on product quality, enabling manufacturers to monitor customer satisfaction and address the areas of improvement proactively. This will also facilitate the early detection of defects, enabling proactive resolutions that enhance the loyalty of customers, reduce product returns and improve their reputation. The strengthening of collaborations with suppliers through real-time data sharing and predictive analysis ensures the availability of resources and minimizes waste. The inventory levels can be tracked using IoT systems and communicate replenishment needs in advance directly to suppliers. Meanwhile, predictive analysis forecasts the demand trends, allowing suppliers to optimize production schedules and their inventory. This avoids material shortages, reduces overproduction and improves the efficiency of the supply chain. Logistic operators also benefit from the framework with AI-based logistics systems that optimize the routes of delivery to reduce transportation costs and emissions. The traffic patterns and weather conditions can be analyzed using machine learning algorithms to determine the most efficient routes. The vehicles equipped with IOT devices provide real-time updates to logistic teams and this will reduce the transportation costs, delivery times and environmental impact. Thus, by leveraging Industry 4.0 technologies, manufacturers can seamlessly connect with stakeholders across the value chain, ensuring a smooth flow of information and collaboration. The integration of internal and external elements across DMAIC–DMADV phases is listed in Table 3.

Table 3.

Integration of internal and external elements across DMAIC–DMADV phases.

5. Prioritization of Critical Success Factors

The critical success factors for implementing the proposed Lean Six Sigma–Industry 4.0 framework for sustainable manufacturing are identified through a detailed literature review and listed in Table 4. The role of critical success factors in framework implementation is presented in Table 5. To prioritize the factors, the TOPSIS method is employed, which systematically ranks the critical success factors by their relative importance. This ranking helps industry practitioners to focus their efforts on the most important success factors, ensuring an efficient and effective approach to the implantation of the proposed framework. The TOPSIS methodology evaluates the distance of each factor from the ideal and non-ideal solutions, enabling objective decision making and actionable guidance.

Table 4.

Critical success factor for Lean Six Sigma–Industry 4.0 framework’s implementation.

Table 5.

Role of critical success factors in DMAIC and DMADV phases.

The identified critical success factors were further validated through expert consultations involving 25 industry experts in the field of Lean Six Sigma, Industry 4.0 and sustainable manufacturing across five manufacturing industries. The TOPSIS method was then applied to prioritize or rank the critical success factors based on their significance, using a ten-point scale, with one for the least important and ten for very important. The profiles of the companies and experts are given in Table 6. Experts with more than 3 years of experience in Industry 4.0, Lean Six Sigma and production are involved in the decision-making process.

Table 6.

Profile of responding companies and experts.

TOPSIS focused on the distance of each alternative from the positive ideal and the distance of each alternative from the negative ideal [67]. In other words, the best alternative should have the shortest distance from the positive ideal solution and the longest distance from the negative ideal solution. The decision matrix is shown in Table 7.

Table 7.

Decision matrix.

The steps for calculating TOPSIS [68] start with the normalization of the decision matrix using Equation (1), and the normalized matrix is shown in Table 8.

Table 8.

Normalized matrix.

According to Equation (2), the normalized matrix is multiplied by the weight of the criteria, and the weighted normalized decision matrix is shown in Table 9.

Table 9.

Weighted normalized decision matrix.

The degree of the distance of each alternative from the positive and negative ideals is determined according to Equations (3)–(6), and Table 10 shows both the positive and negative ideal values.

Table 10.

Positive and negative ideal values.

So that

where j1 and j2 denote the negative and positive criteria, respectively.

The distances between each alternative and the positive and negative ideal solutions are obtained using Equations (7) and (8), and the results listed in Table 11.

Table 11.

Distance to positive and negative ideal points.

The relative closeness degree (Ci) of each alternative to the ideal solution is obtained by Equation (9). The alternative has a shorter distance from the positive ideal solution and a longer distance from the negative ideal solution if the relative closeness degree has a value near one [69].

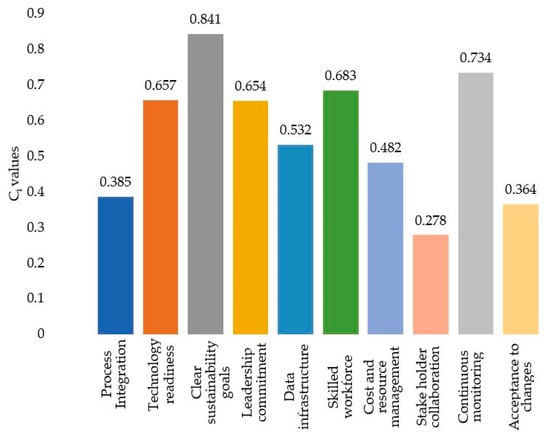

Table 12 shows the relative closeness degree of each alternative to the ideal solution and its ranking. Figure 4 shows Ci values indicating the priority rankings of the critical success factors.

Table 12.

Ci values and rankings.

Figure 4.

Relative closeness degree (Ci) indicating the priority rankings of the critical success factors.

6. Discussion and Implications

The results from the TOPSIS analysis revealed that setting and following clear sustainability goals emerged as the highest-priority critical success factor. Without a clear direction, efforts towards sustainability are not practical. This aligns with the existing studies, as it underscores the importance of goal setting to focus on resource utilization, progress monitoring and the adjustment of strategies. The second-highest-ranked success factor for the framework’s effective implementation is the continuous monitoring of sustainability metrics and process efficiencies. Proactive decision making can be achieved through continuous monitoring and ensures sustainability practices are optimized over time. The critical role of a skilled workforce is listed as the third priority, followed by technology readiness and leadership commitment. While technology plays a critical role, a skilled and trained workforce is essential for data interpretation, the management of advancement systems and the application of relevant technology to develop innovative solutions to sustainability challenges. Continuous professional development of the workforce in emerging Industry 4.0 technologies and Lean Six Sigma methodologies are also crucial for maintaining workforce competency. The readiness of the organization to implement Industry 4.0 technologies and Lean Six Sigma strategies significantly influences its ability to achieve sustainability goals. At the same time, leadership is crucial for fostering a culture of innovation and sustainability, as well as driving change across the organization. The lower-priority factors, such as process integration, cost–resource management, the acceptance of changes and stakeholder collaboration, also need to be considered while setting plans for the framework’s implementation.

The findings provide a roadmap for the industries that implement sustainable manufacturing practices. The manufacturing industries need to prioritize establishing clear sustainability goals during the strategic planning stage. The goals should align with quality and global sustainability standards to ensure relevance and effectiveness. Adopting relevant Industry 4.0 technologies to facilitate continuous monitoring, real-time tracking and process optimization stays a prime focus. These efforts will not be effective unless their workforce is trained to handle the complexities of Industry 4.0 advanced technologies. Industries should evaluate their readiness in terms of technology and resources and address the gaps to ensure the smooth transition to sustainable and process improvement practices. Leadership teams must commit to generating policies, allocating budgets and fostering a culture that prioritizes long-term environmental and social benefits over short-term financial gains. In addition to the enablers, organizations may face practical challenges in framework implementation such as the need for high levels of investment, resistance to change and data management complexity.

The results also establish a strong link to existing studies and address the gaps identified in the prior research. The combination of Lean Six Sigma process capabilities with Industry 4.0 technologies is supported by various studies [70,71], and the insights from this work state that such integration accelerates process improvement and sustainability outcomes. Also, the inclusion of data infrastructure as a critical success factor is aligned with recent studies [72] which highlight the need for robust data systems to handle the data complexity in the process. While the final TOPSIS rankings are based on these five aggregated datasets, they effectively capture the viewpoints of 25 experts. Each company’s rating is the product of multiple expert deliberations, thereby reflecting a collective judgement rather than a single individual’s opinion.

Despite its insights and contributions, this study possesses some limitations. A key limitation of our study is the relatively small sample size of experts, which may not achieve broad statistical power in a classical sense. Although the consensus-based approach helps in capturing the diverse perspectives of each organization, the findings are not necessarily generalizable to all manufacturing contexts. Further studies should consider enlarging the participant pool across a wide range of industries, potentially employing advanced statistical methods such as confirmatory factor analysis or structural equational modelling to strengthen the robustness of the results. The study focused on critical success factors without exploring their interdependence, and the study does not account for variability across geographical contexts. Another limitation is that the framework’s practical implementation challenges are underexplored, leaving room for further research in this area.

7. Conclusions

This study proposed the Lean Six Sigma–Industry 4.0 framework for facilitating sustainable manufacturing and prioritizing the key success factors that influence the framework’s implementation.

- The proposed framework integrates the structured problem-solving approach with advanced technologies to align operational efficiency with environmental and economic sustainability.

- Using TOPSIS, setting clear sustainability goals is identified as the most significant success factor for the framework’s effective implementation. Continuous monitoring and having a skilled workforce ranked as the second and the third critical success factors, highlighting their central role in sustainable manufacturing;

- Ranking critical success factors can provide practical guidance and a road map for manufacturing industries to deploy sustainable manufacturing practices;

- Future research studies can focus on studying the interrelationships among critical success factors and incorporating advanced decision-making models that can improve the robustness and reliability of prioritization results;

- The validation of the framework and sustainability assessment model using real case studies in manufacturing industries should also be considered in the future scope of research;

- The proposed framework outlines key components and implementation steps for integrating Lean Six Sigma and Industry 4.0, providing a structured approach for manufacturers to enhance sustainability and operational efficiency. By detailing the critical success factors and their prioritization using TOPSIS, this study offers practical guidance for decision makers to focus on key enablers during the implementation process;

- This work contributes to the ongoing efforts in sustainable manufacturing by presenting actionable insights and laying the groundwork for further research and validation in diverse industrial contexts;

- This study establishes guidance for integrating Lean Six Sigma and Industry 4.0 to achieve sustainable manufacturing and a holistic approach that ensures the manufacturing process evolves toward sustainability while maintaining competitiveness in a rapidly changing industrial landscape.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su17031331/s1, Expert Questionnaire for prioritizing critical success factors for Lean Six Sigma-Industry 4.0 integrated Framework Implementation.

Author Contributions

Conceptualization, A.I. and G.K.; methodology, A.I. and G.K.; software, A.I.; validation, A.I. and G.K.; formal analysis, A.I. and G.K.; investigation, A.I. and G.K.; resources, A.I. and G.K.; data curation, A.I. and G.K.; writing—original draft preparation, A.I. and G.K.; writing—review and editing, G.K.; visualization, A.I. and G.K.; supervision, G.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article/Supplementary Materials. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yang, X.; Xu, Y.; Razzaq, A.; Wu, D.; Cao, J.; Ran, Q. Roadmap to Achieving Sustainable Development: Does Digital Economy Matter in Industrial Green Transformation? Sustain. Dev. 2024, 32, 2583–2599. [Google Scholar] [CrossRef]

- Yip, W.S.; Zhou, H.; To, S. A Critical Analysis on the Triple Bottom Line of Sustainable Manufacturing: Key Findings and Implications. Environ. Sci. Pollut. Res. 2023, 30, 41388–41404. [Google Scholar] [CrossRef] [PubMed]

- Hermawan, A.N.; Masudin, I.; Zulfikarijah, F.; Restuputri, D.P.; Shariff, S.S.R. The Effect of Sustainable Manufacturing on Environmental Performance through Government Regulation and Eco-Innovation. Int. J. Ind. Eng. Oper. Manag. 2024, 6, 299–325. [Google Scholar] [CrossRef]

- Yadav, G.; Desai, T.N. Lean Six Sigma: A Categorized Review of the Literature. Int. J. Lean Six Sigma 2016, 7, 2–24. [Google Scholar] [CrossRef]

- Palange, A.; Dhatrak, P. Lean Manufacturing a Vital Tool to Enhance Productivity in Manufacturing. Mater. Today Proc. 2021, 46, 729–736. [Google Scholar] [CrossRef]

- Bañuelas, R.; Antony, J.; Brace, M. An Application of Six Sigma to Reduce Waste. Qual. Reliab. Eng. Int. 2005, 21, 553–570. [Google Scholar] [CrossRef]

- Ben Ruben, R.; Vinodh, S.; Asokan, P. Lean Six Sigma with Environmental Focus: Review and Framework. Int. J. Adv. Manuf. Technol. 2018, 94, 4023–4037. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Internet of Things for Smart Factories in Industry 4.0, a Review. Internet Things Cyber-Phys. Syst. 2023, 3, 192–204. [Google Scholar] [CrossRef]

- Yue, X.; Cai, H.; Yan, H.; Zou, C.; Zhou, K. Cloud-Assisted Industrial Cyber-Physical Systems: An Insight. Microprocess. Microsystems 2015, 39, 1262–1270. [Google Scholar] [CrossRef]

- Chong, D.; Shi, H. Big Data Analytics: A Literature Review. J. Manag. Anal. 2015, 2, 175–201. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and Lean Manufacturing Practices for Sustainable Organisational Performance in Indian Manufacturing Companies. Int. J. Prod. Res. 2020, 58, 1319–1337. [Google Scholar] [CrossRef]

- Hanoosh, J.A.A.; Kowang, T.O. The Fundamental Concept of Integrates Lean Six Sigma and DMADV Methodologies. Int. J. Acad. Res. Bus. Soc. Sci. 2023, 13, 1171–1183. [Google Scholar] [CrossRef]

- Tsaramirsis, G.; Kantaros, A.; Al-Darraji, I.; Piromalis, D.; Apostolopoulos, C.; Pavlopoulou, A.; Alrammal, M.; Ismail, Z.; Buhari, S.M.; Stojmenovic, M.; et al. A Modern Approach towards an Industry 4.0 Model: From Driving Technologies to Management. J. Sens. 2022, 2022, 5023011. [Google Scholar] [CrossRef]

- Ojha, R. Lean in Industry 4.0 Is Accelerating Manufacturing Excellence—A DEMATEL Analysis. TQM J. 2023, 35, 597–614. [Google Scholar] [CrossRef]

- Rahardjo, B.; Wang, F.-K.; Lo, S.-C.; Chu, T.-H. A Sustainable Innovation Framework Based on Lean Six Sigma and Industry 5.0. Arab. J. Sci. Eng. 2024, 49, 7625–7642. [Google Scholar] [CrossRef]

- Maheshwari, P.; Devi, Y. Investigating the Relationship between Lean Six Sigma Performance Strategy with Digital Twin Modeling: Practices and Factors. J. Clean. Prod. 2024, 436, 140449. [Google Scholar] [CrossRef]

- Ciccullo, F.; Pero, M.; Caridi, M.; Gosling, J.; Purvis, L. Integrating the Environmental and Social Sustainability Pillars into the Lean and Agile Supply Chain Management Paradigms: A Literature Review and Future Research Directions. J. Clean. Prod. 2018, 172, 2336–2350. [Google Scholar] [CrossRef]

- Kumar, P.; Bhadu, J.; Singh, D.; Bhamu, J. Integration between Lean, Six Sigma and Industry 4.0 Technologies. Int. J. Six Sigma Compet. Advant. 2021, 13, 19. [Google Scholar] [CrossRef]

- Erdil, N.O.; Aktas, C.B.; Arani, O.M. Embedding Sustainability in Lean Six Sigma Efforts. J. Clean. Prod. 2018, 198, 520–529. [Google Scholar] [CrossRef]

- Ramakrishnan, V.; Ramasamy, N.; Anand, M.D.; Santhi, N. Supply Chain Management Efficiency Improvement in the Automobile Industry Using Lean Six Sigma and Artificial Neural Network. IEEE Trans. Eng. Manag. 2024, 71, 3278–3294. [Google Scholar] [CrossRef]

- Tabanli, R.M.; Ertay, T. Value Stream Mapping and Benefit–Cost Analysis Application for Value Visibility of a Pilot Project on RFID Investment Integrated to a Manual Production Control System—A Case Study. Int. J. Adv. Manuf. Technol. 2013, 66, 987–1002. [Google Scholar] [CrossRef]

- de Freitas, J.G.; Costa, H.G.; Ferraz, F.T. Impacts of Lean Six Sigma over Organizational Sustainability: A Survey Study. J. Clean. Prod. 2017, 156, 262–275. [Google Scholar] [CrossRef]

- Powell, D.; Lundeby, S.; Chabada, L.; Dreyer, H. Lean Six Sigma and Environmental Sustainability: The Case of a Norwegian Dairy Producer. Int. J. Lean Six Sigma 2017, 8, 53–64. [Google Scholar] [CrossRef]

- Zhu, Q.; Johnson, S.; Sarkis, J. Lean Six Sigma and Environmental Sustainability: A Hospital Perspective. Supply Chain Forum Int. J. 2018, 19, 25–41. [Google Scholar] [CrossRef]

- Gandhi, J.D.; Thanki, S. Sustainability Index Development by Integrating Lean Green and Six Sigma Tools: A Case Study of the Indian Manufacturing Industry. Int. J. Prod. Perform. Manag. 2024; ahead of print. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Giallanza, A. Industry 4.0 Technologies for Manufacturing Sustainability: A Systematic Review and Future Research Directions. Appl. Sci. 2021, 11, 5725. [Google Scholar] [CrossRef]

- Voinea, G.-D.; Gîrbacia, F.; Duguleană, M.; Boboc, R.G.; Gheorghe, C. Mapping the Emergent Trends in Industrial Augmented Reality. Electronics 2023, 12, 1719. [Google Scholar] [CrossRef]

- Kaber, D.B.; Onal, E.; Endsley, M.R. Design of Automation for Telerobots and the Effect on Performance, Operator Situation Awareness, and Subjective Workload. Hum. Factors Ergon. Manuf. 2000, 10, 409–430. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Cinar, Z.M.; Abdussalam Nuhu, A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine Learning in Predictive Maintenance towards Sustainable Smart Manufacturing in Industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Ayvaz, S.; Alpay, K. Predictive Maintenance System for Production Lines in Manufacturing: A Machine Learning Approach Using IoT Data in Real-Time. Expert Syst. Appl. 2021, 173, 114598. [Google Scholar] [CrossRef]

- Yan, J.; Meng, Y.; Lu, L.; Li, L. Industrial Big Data in an Industry 4.0 Environment: Challenges, Schemes, and Applications for Predictive Maintenance. IEEE Access 2017, 5, 23484–23491. [Google Scholar] [CrossRef]

- Psarommatis, F.; Azamfierei, V.; Lindström, J.D. Circular Product Design for Allowing Re-Using and Re-Purposing of Products And Components: A Conceptual Framework for Circularity. IFAC-PapersOnLine 2024, 58, 306–311. [Google Scholar] [CrossRef]

- Wang, X.V.; Wang, L. Digital Twin-Based WEEE Recycling, Recovery and Remanufacturing in the Background of Industry 4.0. Int. J. Prod. Res. 2019, 57, 3892–3902. [Google Scholar] [CrossRef]

- Sharma, R.; Shishodia, A.; Gunasekaran, A.; Min, H.; Munim, Z.H. The Role of Artificial Intelligence in Supply Chain Management: Mapping the Territory. Int. J. Prod. Res. 2022, 60, 7527–7550. [Google Scholar] [CrossRef]

- Tissir, S.; Cherrafi, A.; Chiarini, A.; Elfezazi, S.; Bag, S. Lean Six Sigma and Industry 4.0 Combination: Scoping Review and Perspectives. Total. Qual. Manag. Bus. Excel. 2023, 34, 261–290. [Google Scholar] [CrossRef]

- Shrivastava, A.; Mishra, R.P. The Synergy of Industry 4.0 and Lean Six Sigma: A Framework for Improvement in Circular Economy Generation in the Automotive Landscape. Nanotechnol. Percept. 2024, 20, 1524–1543. [Google Scholar] [CrossRef]

- Sordan, J.E.; Oprime, P.C.; Pimenta, M.L.; da Silva, S.L.; González, M.O.A. Contact Points between Lean Six Sigma and Industry 4.0: A Systematic Review and Conceptual Framework. Int. J. Qual. Reliab. Manag. 2022, 39, 2155–2183. [Google Scholar] [CrossRef]

- Christou, I.T.; Kefalakis, N.; Zalonis, A.; Soldatos, J. Predictive and Explainable Machine Learning for Industrial Internet of Things Applications. In Proceedings of the 2020 16th International Conference on Distributed Computing in Sensor Systems (DCOSS), Marina del Rey, CA, USA, 25–27 May 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 213–218. [Google Scholar] [CrossRef]

- Duc, M.L.; Hlavaty, L.; Bilik, P.; Martinek, R. Design and Implement Low-Cost Industry 4.0 System Using Hybrid Six Sigma Methodology for CNC Manufacturing Process. IEEE Access 2023, 11, 127176–127201. [Google Scholar] [CrossRef]

- Lee, J.; Ni, J.; Singh, J.; Jiang, B.; Azamfar, M.; Feng, J. Intelligent Maintenance Systems and Predictive Manufacturing. J. Manuf. Sci. Eng. 2020, 142, 110805. [Google Scholar] [CrossRef]

- Tran, T.-a.; Ruppert, T.; Eigner, G.; Abonyi, J. Real-Time Locating System and Digital Twin in Lean 4.0. In Proceedings of the 2021 IEEE 15th International Symposium on Applied Computational Intelligence and Informatics (SACI), Timisoara, Romania, 19–21 May 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 369–374. [Google Scholar] [CrossRef]

- Singh, A.B.; Gaurav, G.; Sarkar, P.; Dangayach, G.S.; Meena, M.L. Present, Past, and Future of Lean Six Sigma Applications: From Evolution to the Era of Artificial Intelligence. Recent Patents Eng. 2024, 18, e110523216792. [Google Scholar] [CrossRef]

- Chiarini, A.; Kumar, M. Lean Six Sigma and Industry 4.0 Integration for Operational Excellence: Evidence from Italian Manufacturing Companies. Prod. Plan. Control. 2021, 32, 1084–1101. [Google Scholar] [CrossRef]

- Citybabu, G.; Yamini, S. Lean Six Sigma and Industry 4.0—A Bibliometric Analysis and Conceptual Framework Development for Future Research Agenda. Int. J. Prod. Perform. Manag. 2024, 73, 1502–15344. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R.; Antony, J.; Cross, J.; Garza-Reyes, J.A.; Singh, M.; Singh, I.P.; Sony, M. Integrated Green Lean Six Sigma-Industry 4.0 Approach to Combat COVID-19: From Literature Review to Framework Development. Int. J. Lean Six Sigma 2024, 15, 50–79. [Google Scholar] [CrossRef]

- Citybabu, G.; Yamini, S. Lean Six Sigma 4.0—A Framework and Review for Lean Six Sigma Practices in the Digital Era. Benchmarking Int. J. 2024, 31, 3288–3326. [Google Scholar] [CrossRef]

- Skalli, D.; Cherrafi, A.; Charkaoui, A.; Chiarini, A.; Shokri, A.; Antony, J.; Garza-Reyes, J.A.; Foster, M. Integrating Lean Six Sigma and Industry 4.0: Developing a Design Science Research-Based LSS4.0 Framework for Operational Excellence. Prod. Plan. Control. 2024, 1–27. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R.; Cross, J.; Garza-Reyes, J.A.; Antony, J.; Yadav, V. Integrating Green Lean Six Sigma and Industry 4.0: A Conceptual Framework. J. Manuf. Technol. Manag. 2023, 34, 87–121. [Google Scholar] [CrossRef]

- Skalli, D.; Charkaoui, A.; Cherrafi, A.; Garza-Reyes, J.A.; Antony, J.; Shokri, A. Industry 4.0 and Lean Six Sigma Integration in Manufacturing: A Literature Review, an Integrated Framework and Proposed Research Perspectives. Qual. Manag. J. 2023, 30, 16–40. [Google Scholar] [CrossRef]

- Hashim, R.M.; Muhammad, N.A.; Shammari, A.Z.M.; Muhammad, N. Performance Improvement for Additive Manufacturing of Spur Gear via the Define-Measure-Analyze-Improve-Control (DMAIC) Method. Int. J. Adv. Manuf. Technol. 2024, 135, 2929–2938. [Google Scholar] [CrossRef]

- Huang, C.-T.; Chen, K.; Chang, T.-C. An Application of DMADV Methodology for Increasing the Yield Rate of Surveillance Cameras. Microelectron. Reliab. 2010, 50, 266–272. [Google Scholar] [CrossRef]

- Lai, Y.-J.; Liu, T.-Y.; Hwang, C.-L. TOPSIS for MODM. Eur. J. Oper. Res. 1994, 76, 486–500. [Google Scholar] [CrossRef]

- Shukla, A.; Agarwal, P.; Rana, R.S.; Purohit, R. Applications of TOPSIS Algorithm on Various Manufacturing Processes: A Review. Mater. Today Proc. 2017, 4, 5320–5329. [Google Scholar] [CrossRef]

- Qureshi, K.M.; Mewada, B.G.; Buniya, M.K.; Qureshi, M.R.N.M. Analyzing Critical Success Factors of Lean 4.0 Implementation in Small and Medium Enterprises for Sustainable Manufacturing Supply Chain for Industry 4.0 Using PLS-SEM. Sustainability 2023, 15, 5528. [Google Scholar] [CrossRef]

- Zulfiqar, M.; Sony, M.; Bhat, S.; Antony, J.; Salentijn, W.; McDermott, O. Unlocking the Potential: Empirical Analysis of Enablers, Barriers, Benefits and Technologies for Integrating Industry 4.0 and Lean Six Sigma in Manufacturing Organisations. TQM J. 2024, 36, 2360–2382. [Google Scholar] [CrossRef]

- Letchumanan, L.T.; Gholami, H.; Yusof, N.M.; Bin Ngadiman, N.H.A.; Salameh, A.A.; Štreimikienė, D.; Cavallaro, F. Analyzing the Factors Enabling Green Lean Six Sigma Implementation in the Industry 4.0 Era. Sustainability 2022, 14, 3450. [Google Scholar] [CrossRef]

- Khanzode, A.G.; Sarma, P.R.S.; Goswami, M. Modelling Interactions of Select Enablers of Lean Six-Sigma Considering Sustainability Implications: An Integrated Circular Economy and Industry 4.0 Perspective. Prod. Plan. Control. 2023, 34, 1020–1036. [Google Scholar] [CrossRef]

- Pozzi, R.; Rossi, T.; Secchi, R. Industry 4.0 Technologies: Critical Success Factors for Implementation and Improvements in Manufacturing Companies. Prod. Plan. Control. 2021, 34, 139–158. [Google Scholar] [CrossRef]

- Hines, P.; Tortorella, G.L. Barriers and Enablers of Lean Industry 4.0. In Challenging the Future with Lean; Van Kollenburg, T., Kokkinou, A., McDermott, O., Eds.; IFIP Advances in Information and Communication Technology; Springer Nature: Cham, Switzerland, 2024; Volume 681, pp. 37–51. [Google Scholar] [CrossRef]

- Kashyap, A.; Yadav, A.K.; Vatsa, O.N.; Chandaka, T.N.; Shukla, O.J. Investigation of the Critical Success Factors in the Implementation of the Lean Industry 4.0 in Manufacturing Supply Chain: An ISM Approach. Manag. Environ. Qual. Int. J. 2023, 34, 981–996. [Google Scholar] [CrossRef]

- Wankhede, V.A.; Vinodh, S.; Antony, J. Empirical Analysis of Key Operational Characteristics of Lean Six Sigma and Industry 4.0 Integration. TQM J. 2024, 37, 611–634. [Google Scholar] [CrossRef]

- Birajdar, D.; Vasudevan, H. A Model for Integrating Industry 4.0 and Lean Tools Using Critical Success Factors in Indian Manufacturing Industries. In Proceedings of the International Conference on Intelligent Manufacturing and Automation; Vasudevan, H., Kottur, V.K.N., Raina, A.A., Eds.; Lecture Notes in Mechanical Engineering. Springer Nature: Singapore, 2023; pp. 215–222. [Google Scholar] [CrossRef]

- Khourshed, N.F. Investigating the Critical Success Factors for Integrating Lean Six Sigma and Industry 4.0. Qual. Manag. J. 2023, 30, 259–278. [Google Scholar] [CrossRef]

- Papathanasiou, J.; Ploskas, N. “TOPSIS” In Multiple Criteria Decision Aid; Springer Optimization and Its Applications; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–30. [Google Scholar] [CrossRef]

- Sarkar, A. A TOPSIS Method to Evaluate the Technologies. Int. J. Qual. Reliab. Manag. 2014, 31, 2–13. [Google Scholar] [CrossRef]

- Yadav, N.; Shankar, R.; Singh, S.P. Impact of Industry4.0/ICTs, Lean Six Sigma and Quality Management Systems on Organisational Performance. TQM J. 2020, 32, 815–835. [Google Scholar] [CrossRef]

- Huang, Y.-S.; Li, W.-H. A Study on Aggregation of TOPSIS Ideal Solutions for Group Decision-Making. Group Decis. Negot. 2012, 21, 461–473. [Google Scholar] [CrossRef]

- Vimal, K.E.K.; Rashmi, D.; Sivakumar, K.; Kandasmay, J.; Paranitharan, K.P.; Venkataraman, B. Developing a Delphi Assisted Total Interpretive Structural Model (D-TISM) for Adopting the Industry 4.0 Technologies within Lean Six Sigma Framework. Prod. Plan. Control. 2023, 36, 20–44. [Google Scholar] [CrossRef]

- Hines, P.; Tortorella, G.L.; Antony, J.; Romero, D. Lean Industry 4.0: Past, Present, and Future. Qual. Manag. J. 2023, 30, 64–88. [Google Scholar] [CrossRef]

- Autenrieth, P.; Lorcher, C.; Pfeiffer, C.; Winkens, T.; Martin, L. Current Significance of IT-Infrastructure Enabling Industry 4.0 in Large Companies. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Stuttgart, Germany, 17–20 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–8. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).