Abstract

This study presents a novel approach to the development of self-compacting concrete (SCC) by partially replacing both cement and fine aggregate (sand) with waste marble sludge (WMS), a byproduct of the marble industry. The research aims to evaluate the feasibility of incorporating this industrial waste into SCC to enhance sustainability without compromising performance. To assess the fresh and hardened properties of the proposed mixtures, a comprehensive experimental program was conducted. Tests included slump flow, T50, and V-funnel for evaluating workability, as well as measurements of specific gravity, compressive strength, flexural strength, Brazilian tensile strength, and water absorption at 28 days of curing. The results demonstrated that the mix containing 5% cement replacement and 20% sand replacement with marble sludge exhibited the highest mechanical performance, achieving a compressive strength of 48.2 MPa, tensile strength of 3.9 MPa, and flexural strength of 4.4 MPa. Furthermore, increasing the percentage of cement replacement led to enhanced flowability, as evidenced by an increase in slump flow diameter and a reduction in V-funnel flow time, indicating improved workability. Overall, the findings suggest that controlled incorporation of WMS can produce SCC with desirable mechanical and rheological properties, offering a promising pathway for sustainable concrete production. In addition to the technical performance, a carbon footprint analysis was conducted to examine the environmental benefits of marble sludge utilization. The mixture with 10% cement and 20% sand replacement exhibited the lowest carbon footprint, while the 7.5% replacement level provided the best balance between strength and sustainability.

1. Introduction

The construction industry plays a pivotal role in global economic development, serving as a cornerstone for urbanization, infrastructure growth, and technological advancement [1,2,3,4,5,6,7]. Despite its economic importance, the sector remains one of the most resource-intensive and environmentally impactful domains worldwide [8,9]. Conventional construction materials, especially concrete—the most widely used construction material—are associated with substantial environmental costs [10,11,12,13,14]. The production of concrete involves the extraction of vast quantities of raw materials such as limestone, sand, and gravel, which contribute to habitat destruction, land degradation, and depletion of natural resources [15,16]. Additionally, the manufacturing of cement, a key component of concrete, is highly energy-consuming and responsible for approximately 8% of global carbon dioxide (CO2) emissions. This significant greenhouse gas output intensifies climate change and ecological imbalance, highlighting the urgent need for sustainable alternatives [17,18,19,20,21].

As urban populations continue to expand at unprecedented rates and infrastructure demands escalate, the pressure on the construction industry to adopt sustainable practices has become increasingly critical [22,23,24]. Innovations that reduce environmental impact without compromising structural integrity are vital for steering the sector toward a more sustainable future. In response, researchers and engineers have been exploring eco-efficient materials and construction methods that aim to diminish resource consumption, lower energy use, and minimize waste generation throughout the lifecycle of construction projects [25,26].

One promising development in this direction is Self-Compacting Concrete (SCC) [27,28,29]. Unlike traditional concrete, which requires vibration and compaction techniques to achieve proper setting and finish, SCC is engineered to be highly flowable and non-segregating. Its ability to effortlessly fill formwork and encapsulate reinforcement without external vibration offers numerous advantages, including improved surface finishes, enhanced durability, reduced labor and energy costs, and better control over the quality of the final product. These features make SCC particularly suitable for complex and densely reinforced structural elements, thereby increasing efficiency and safety in modern construction [19,30,31,32,33,34,35,36,37,38].

Concurrent with advancements in concrete technology, attention is increasingly being paid to the management and valorization of industrial waste. The marble industry, in particular, produces vast quantities of waste during quarrying, cutting, polishing, and finishing processes. This waste, commonly called marble sludge, primarily consists of fine particles rich in calcium carbonate. Typically disposed of in landfills or water bodies, marble sludge poses significant environmental challenges such as land pollution, water contamination, and health risks to nearby communities. Given its high calcium carbonate content and fine granulometry, marble sludge exhibits properties that could be harnessed beneficially in construction materials [39,40].

The integration of marble sludge into SCC offers a compelling opportunity to address these challenges. By substituting traditional materials like cement and fine aggregates with marble sludge, it is possible to reduce the extraction and consumption of virgin raw materials, thereby minimizing the carbon footprint of concrete production. Furthermore, this approach promotes waste reuse, aligns with circular economic principles, and contributes to the development of sustainable construction practices. Such utilization not only mitigates environmental impacts but also offers economic benefits through waste valorization and resource conservation.

This study aims to investigate the feasibility and performance of SCC mixtures incorporating waste marble sludge (WMS) as a partial replacement for cement and fine aggregates. The research encompasses a comprehensive evaluation of both the fresh and hardened properties of these mixes. Key parameters such as flowability and passing ability will be assessed alongside hardened characteristics including compressive strength and durability under environmental stressors. By systematically varying the proportions of marble sludge, the study seeks to identify optimal replacement levels and understand their implications for various structural applications.

In essence, this research contributes to the broader goal of promoting sustainable construction. It demonstrates how industrial by-products like marble sludges can be transformed into valuable resources within innovative, high-performance concrete. The findings are expected to provide valuable insights for engineers, policymakers, and industry stakeholders committed to environmental stewardship, resource efficiency, and technological innovation in the built environment. Ultimately, this work underscores the importance of developing sustainable materials that balance performance, environmental responsibility, and economic viability, paving the way for greener and more resilient infrastructure development.

2. Materials and Methods

2.1. Materials

The materials selected for this study were carefully chosen based on their widespread availability, compatibility with SCC requirements, and their alignment with sustainability objectives. Each material was characterized to ensure it met relevant standards and contributed effectively to the experimental investigation.

2.1.1. Cement

Ordinary Portland Cement (OPC) conforming to ASTM C150 Type I was utilized as the primary binding material. OPC is recognized globally for its reliable performance, consistent quality, and widespread use in concrete production. Its chemical composition, mainly calcium silicates, enables the formation of cementitious compounds that provide strength and durability.

In this study, OPC was partially replaced with WMS to explore the potential for sustainable material reuse. The replacement levels varied to assess the influence on fresh and hardened properties. The partial substitution aims to reduce cement consumption, decrease greenhouse gas emissions associated with cement manufacturing, and promote industrial waste valorization.

2.1.2. Fine Aggregates

Natural river sand with a fineness modulus of 2.6 was used as the fine aggregate. Its qualities include good grading, clean surface, and low organic content, making it suitable for SCC, which demands highly workable fine materials to facilitate flow and compaction.

A portion of this sand was replaced with marble sludge to evaluate its effect on workability, surface finish, and mechanical strength. The replacement aimed to determine whether marble sludge could fulfill the particle size distribution and packing requirements crucial for self-compacting mixes while contributing to waste utilization.

2.1.3. Coarse Aggregates

Crushed granite aggregates with a nominal size of 10–20 mm were employed as coarse aggregates. These aggregates were selected for their hardness, durability, and angular shape, which improve the mechanical interlock within the concrete matrix.

Prior to mixing, the aggregates were thoroughly cleaned to remove dust, dirt, and loose particles, then dried to prevent excess moisture that could affect the water-cement ratio. Proper grading and cleanliness of coarse aggregates are essential for achieving the desired workability and strength in SCC.

2.1.4. WMS

WMS was collected from a local marble processing plant, where it is generated as a by-product during cutting, polishing, and finishing operations. The sludge was air-dried under shade to minimize moisture content and then sieved through a 75-micron sieve to obtain fine particles suitable for blending into the concrete mixes.

Chemical characterization using X-ray Fluorescence (XRF) analysis revealed that WMS is predominantly composed of calcium carbonate (CaCO3), along with minor amounts of silica, alumina, and other impurities. The high calcium carbonate content makes WMS an attractive candidate for partial replacement of cement and fine aggregates, as it has pozzolanic or filler properties that can influence the hydration process and microstructure of concrete (Table 1).

Table 1.

Chemical specifications of WMS.

2.1.5. Water

Potable water free from impurities, such as oils, organic materials, or chloride ions, was used for mixing and curing. The quality of water is critical in ensuring consistent hydration reactions and preventing potential durability issues related to sulfate attacks or corrosion.

2.1.6. Superplasticizer

A polycarboxylate ether-based high-range water reducer was employed to enhance the flowability of SCC. This admixture enables achieving the targeted slump flow and passing ability without increasing the water content, thus maintaining the desired water-to-binder ratio. The superplasticizer improves dispersion of particles, reduces internal friction, and minimizes segregation, all of which are essential for the stability and high performance of SCC.

2.2. Mix Design

The mix design followed the EFNARC guidelines for SCC, which specify procedures for achieving the required flowability, stability, and segregation resistance, as presentenced in Table 2. A control mix without marble sludge was prepared initially as a baseline.

Subsequently, several trial mixes were developed with varying proportions of WMS as partial replacements for cement and fine aggregates, as summarized below:

Table 2.

The mixture proportions in the present study (kg/m3).

Table 2.

The mixture proportions in the present study (kg/m3).

| Designation | Cement | Coarse Aggregates | Fine Aggregates | WMS | W/C | SP |

|---|---|---|---|---|---|---|

| NC | 400 | 600 | 1300 | - | 0.35 | 3.6 |

| SCC (5%C + 20%F) | 380 | 600 | 1040 | 280 | 0.35 | 3.6 |

| SCC (7.5%C + 20%F) | 370 | 600 | 1040 | 290 | 0.35 | 3.6 |

| SCC (10%C + 20%F) | 360 | 600 | 1040 | 300 | 0.35 | 3.6 |

| SCC (20%F) | 400 | 600 | 1040 | 260 | 0.35 | 3.6 |

2.3. Testing Procedures

To thoroughly evaluate the influence of WMS inclusion, both fresh and hardened properties of the SCC mixes were examined through standardized testing procedures (all experimental procedures were repeated three times to enhance reproducibility and minimize error):

2.3.1. Fresh Properties Tests

Slump Flow Test: Measures the initial spread of the concrete to assess workability and flowability.

V-Funnel Test: Determines viscosity and flow time, indicating how easily the concrete can pass through tight sections.

2.3.2. Hardened Properties Tests

Compressive Strength: Assessed at 28 days using 150 mm cube specimens following ASTM C39 [41], to determine the load-bearing capacity over time.

Split Tensile Strength: Measured on cylindrical specimens per ASTM C496 [42], providing insights into the concrete’s ability to resist tensile stresses.

Flexural Strength: Conducted on beam specimens according to ASTM C78 [43], indicating the material’s capacity to withstand bending forces, critical for structural elements.

Water Absorption Test Procedure: To evaluate the water absorption capacity of the concrete specimens, the test was conducted in accordance with ASTM C642—Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. This procedure provides a reliable measure of the porosity and permeability characteristics of concrete, which are critical indicators of durability. Concrete specimens were cast in cubic molds (150 mm × 150 mm × 150 mm) and cured under standard conditions for 28 days. Prior to testing, the samples were oven-dried at 105 ± 5 °C until a constant mass was achieved, ensuring complete removal of moisture.

The oven-dried specimens were cooled to room temperature and weighed to determine their dry mass. The specimens were then fully immersed in water at room temperature for 48 h. After immersion, the specimens were removed, surface water was wiped off, and the saturated surface-dry mass was recorded.

Water absorption was calculated using the following formula:

The specimen’s mass when oven-dried is WD and its mass when it has a dry surface but is still moist is WSSD.

This comprehensive testing regime aims to establish the viability of marble sludge as a sustainable additive or substitute in SCC, understanding its effects on the fresh and hardened states to inform practical implementation and optimize mix proportions.

2.4. Carbon Footprint Analysis

In addition to the evaluation of fresh and mechanical properties, the environmental implications of incorporating WMS in SCC were assessed through a simplified carbon footprint analysis. The purpose of this assessment was to quantify the potential reduction in greenhouse gas emissions when substituting cement and natural aggregates with marble sludge, thereby linking technical performance with sustainability outcomes [44,45,46,47].

For the analysis, the gate-to-gate system boundary was adopted, covering raw material production, processing, and transportation to the batching plant. The functional unit was defined as 1 m3 of SCC, consistent with common practice in life cycle assessment of concrete. Typical carbon emission factors from the literature and recognized LCA databases (IMPACT2002+) were used for the main constituents [48,49,50,51].

The LCA of the developed SCC mixtures confirmed a marked reduction in carbon footprint when waste marble powder (WMP) and waste marble aggregates (WMA) were incorporated. This observation is consistent with the detailed LCA study by Ahmadi et al. [45], who reported up to 20% lower Global Warming Potential (GWP) in SCC containing 20% WMP compared with control mixtures. Likewise, Sánchez et al. [44] demonstrated that partially replacing clinker and limestone with marble waste sludges in cement manufacture can reduce CO2 emissions by as much as 34%, together with significant reductions in water use and particulate emissions. These independent studies provide robust empirical evidence that the substitution of marble-derived materials for cementitious constituents effectively mitigates the environmental burden of concrete production.

3. Results

3.1. Fresh Properties Results

The slump test results for the designed research mixtures are summarized in Table 3. The data obtained from these tests provide valuable insights into the workability and rheological behavior of the mixtures under different compositions (Figure 1a). Analyzing the results reveals a consistent trend: as the percentage of cement replaced with WMS increases, the slump values of the mixtures also tend to increase. This phenomenon can be attributed to the physical and chemical characteristics of the marble sludge, which seem to improve the flowability of the fresh concrete. Specifically, the increased workability may be due to the fine particles of marble sludge filling voids within the mixture, reducing internal friction and facilitating easier movement of the fresh concrete.

Table 3.

Slump results of SCC mixtures with different levels of WMS replacement.

Figure 1.

Fresh properties: (a) slump; (b) V-funnel.

Furthermore, the observed trend suggests that incorporating marble sludge not only helps with waste management but also enhances the fresh properties of concrete, potentially making it more suitable for application processes that require high workability. The increase in slump values with higher marble sludge content indicates that these mixtures require less effort during mixing and pouring, which can be advantageous in construction scenarios where ease of placement is critical.

Notably, the highest slump flow was recorded in the SCC mixture, designated as (10%C + 20%F). This particular mixture achieved a slump flow of 690 mm, a value that signifies excellent flowability. According to industry standards for SCC, a slump flow greater than 650 mm generally indicates that the mixture possesses superior self-compacting properties, allowing it to spread effortlessly under its own weight without the need for external compaction. The high slump flow of 690 mm suggests that the combination of 10% cement replacement and 20% fine aggregate replacement with marble sludge significantly improves the rheological properties of the mixture, facilitating ease of placement and ensuring a dense, well-compacted final product.

Overall, these findings demonstrate that WMS can be effectively used to modify the workability characteristics of concrete mixtures, with the potential to optimize both performance and sustainability in construction practices.

The T50 test results—which measure the time required for the concrete to spread to a diameter of 50 cm during the slump flow test—are presented in Table 4. These results provide valuable insight into the flow rate and viscosity of the SCC mixtures.

Table 4.

T50 results of SCC mixtures with different levels of WMS replacement.

According to the data, there is a noticeable trend: as the replacement percentage of cement with WMS increases, the T50 time decreases. This suggests that the mixtures become more fluid and exhibit faster flow behavior with higher levels of marble sludge substitution, likely due to the lubricating effect of the fine particles in the sludge.

The lowest T50 time was recorded in the SCC mixture labeled (10%C + 20%F), which reached the 50 cm spread in just 2 s. This rapid flow indicates excellent workability and low viscosity, aligning well with the performance expectations for SCC. Such behavior is advantageous in applications requiring high flowability without mechanical vibration.

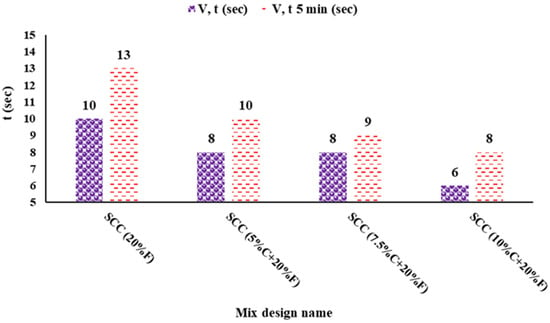

The V-funnel test results for the designed research mixtures are detailed in Figure 2, providing valuable insights into the flowability, viscosity, and overall rheological behavior of the SCC mixes (Figure 1b). The V-funnel test is a widely used method to evaluate the flow characteristics of SCC, as it measures the time required for a specific volume of fresh concrete to pass through a constricted funnel under gravity. This is a crucial parameter because it reflects the concrete’s ability to flow uniformly and fill formwork and around reinforcement without segregation or blockages, which are essential qualities for self-compacting applications.

Figure 2.

V-funnel flow times of SCC mixtures with different levels of WMS replacement.

Analyzing the data reveals a clear and consistent trend: as the percentage of cement replaced with WMS increases, the V-funnel flow time decreases. This inverse relationship suggests that higher marble sludge content enhances the flowability of the concrete mixture, resulting in shorter flow times. Such an improvement can be attributed to the nature of marble sludge, which typically consists of fine, smooth particles that act as natural lubricants within the paste. These characteristics reduce internal friction and allow the mixture to pass more easily through the narrow passage of the funnel. Additionally, the fine particles help in creating a more cohesive and well-graded mortar matrix, further facilitating smooth flow without stagnation.

The most remarkable result was observed in the SCC mixture designated as (10%C + 20%F), which achieved a V-funnel flow time of just 6 s. This extremely short flow time is indicative of excellent flowability and demonstrates that the mixture can rapidly and effortlessly navigate through restricted spaces without risk of segregation. Such a low flow time is well within the acceptable range for high-performance SCC, confirming that this particular formulation strikes an optimal balance between viscosity and cohesiveness—properties essential for ensuring uniform filling of complex formworks and dense reinforcement zones.

These findings highlight the potential of WMS not only as an environmentally sustainable aggregate replacement but also as a beneficial additive that enhances the rheological properties of SCC. The improved flowability observed in the mixture with 10% cement replacement and 20% fine aggregate substitution suggests it is particularly well-suited for demanding construction scenarios where high flowability, ease of placement, and minimal need for vibration are crucial. Ultimately, this combination offers practical benefits by enabling easier casting processes and potentially reducing construction time and costs.

3.2. Hardened Properties Results

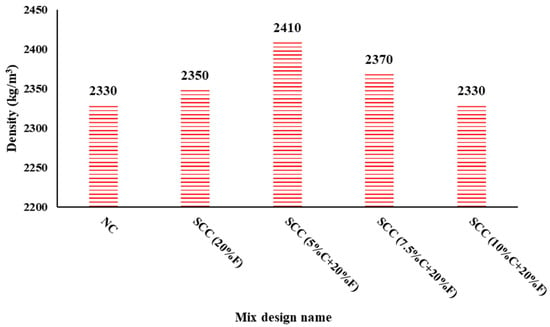

3.2.1. Density

The specific weight, or density, results of the various concrete mix designs are depicted in Figure 3. These values provide important insights into the mass-to-volume ratio of each mixture, reflecting the overall compactness and potential strength characteristics of the concrete. Density is a critical parameter in concrete technology, as higher density generally correlates with improved durability, strength, and reduced permeability, making it essential to optimize for structural performance and longevity.

Figure 3.

Density results of SCC mixtures with partial cement and fine aggregate replacement by WMS.

From the data presented in the figure, the highest specific weight was recorded in the mix containing 5% cement replacement and 20% sand replacement with WMS, which achieved a density of approximately 2410 kg/m3. This suggests that a moderate level of marble sludge addition at these proportions can positively influence the microstructure by promoting denser particle packing. The likely mechanism behind this enhancement is the filler effect of the fine marble particles, which fill void spaces within the cement paste and between sand particles, reducing internal porosity and increasing overall compactness. This densification process not only improves the Immediate strength but may also enhance the durability of the concrete by limiting pathways for ingress of harmful agents.

Conversely, as the percentage of cement replaced with marble sludge increases beyond 5%, a gradual decline in specific weight is observed. This trend indicates that higher levels of marble sludge substitution may introduce increased porosity or reduce the binder content’s overall effectiveness. The decrease in density could be due to several factors: the lower specific gravity of marble sludge compared to Portland cement, the possibility of less cohesive binder matrix formation at higher replacement levels, or the formation of microvoids as a result of altered particle interactions. Such porosity compromises the microstructural integrity of the concrete, potentially leading to reductions in mechanical strength and durability.

These findings emphasize the importance of carefully selecting the optimal replacement ratio of marble sludge, balancing the benefits of sustainability and waste management with the structural requirements of the concrete. A moderate replacement level, such as 5% cement and 20% sand with marble sludge, appears to yield a denser, more compact mixture, likely translating into better mechanical and durability properties. Excessive replacement, on the other hand, may adversely affect the density and performance of the concrete, highlighting the need for a balanced approach in sustainable concrete design.

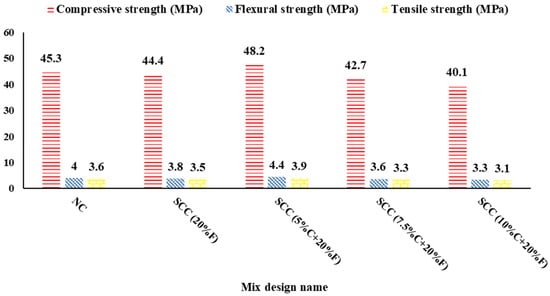

3.2.2. Compressive Strength

The compressive strength results for the various concrete mix designs are depicted in Figure 4, providing critical insights into the mechanical performance and structural capacity of mixtures incorporating WMS as partial replacements for both cement and fine aggregate. Compressive strength is a fundamental parameter in concrete technology, directly related to the ability of the material to withstand load-bearing conditions and is often considered a key indicator of concrete quality and durability.

Figure 4.

Mechanical properties of SCC mixtures incorporating WMS.

From the data, it is evident that the highest compressive strength was achieved by the mix containing 5% cement replacement and 20% sand replacement with marble sludge, which attained a peak value of approximately 48.2 MPa. This optimal mixture suggests that a modest level of marble sludge addition can positively influence the concrete’s mechanical properties. The enhancement in strength at this level is likely attributable to the filler effect of the fine marble particles, which improve the particle packing density within the matrix, thereby reducing micro-voids and enhancing the overall compactness of the structure. Moreover, the chemical composition of marble sludge, primarily calcium carbonate, may participate in secondary hydration reactions, potentially contributing to the formation of additional calcium silicate hydrate (C–S–H) gel—the primary binder responsible for concrete strength [52,53].

This supplementary pozzolanic activity can refine the microstructure, further improving the mixture’s resistance to compression.

Conversely, increasing the percentage of cement replacement beyond 5% results in a gradual decline in compressive strength. This trend can be attributed to the dilution effect, where the reduction in Portland cement content leads to decreased production of C–S–H gel, thus weakening the cementitious matrix [53].

Additionally, higher marble sludge content may introduce more porosity or reduce the bonding efficiency between particles, undermining the integrity of the concrete. As the replacement ratio exceeds the optimal point, these adverse effects become more pronounced, emphasizing the importance of balance in mix design.

The lowest recorded compressive strength was found in the SCC mixture labeled (10%C + 20%F), which showed a value of approximately 40.1 MPa. The decrease in strength despite improvements in workability and flowability illustrates the classic compromise in sustainable concrete formulations: enhancing one physical property often comes at the expense of another, particularly when incorporating waste materials at higher replacement levels.

Overall, these findings highlight the critical need for optimizing the replacement ratios of WMS in concrete to harness its environmental benefits while maintaining sufficient mechanical performance. An optimal balance ensures that the concrete remains structurally sound, durable, and sustainable, paving the way for more eco-friendly construction practices.

3.2.3. Flexural Strength

The flexural strength (or bending strength) results of the various concrete mix designs are presented in Figure 4, offering valuable insight into the ability of the mixtures to withstand tensile stresses and resist cracking when subjected to bending loads. Flexural strength is a key mechanical property, especially critical for structural elements such as beams, slabs, and pavements that experience bending forces during service.

According to the data shown in the figure, the highest flexural strength was achieved in the mix with 5% cement replacement and 20% sand replacement using WMS, reaching a peak value of approximately 4.4 MPa. This suggests that a limited amount of substitution with marble sludge can positively influence the tensile behavior of concrete. The improvement in flexural strength at this replacement level is likely due to the fine particles of marble sludge enhancing particle packing and promoting better interfacial bonding between the cement paste and aggregates. This improved particle interlock facilitates a more uniform distribution of stresses throughout the concrete matrix, thereby increasing its resistance to flexural failure and crack initiation. Additionally, the filler effect of marble sludge may contribute to the refinement of the microstructure, reducing microcracks and enhancing the concrete’s toughness.

However, as the percentage of cement replaced with marble sludge increases beyond 5%, a noticeable and progressive decline in flexural strength is observed. This decline is attributed to the reduction of cementitious material responsible for generating hydration products, such as calcium silicate hydrate (C–S–H), which are crucial for forming strong bonds within the matrix. The decreased cement content weakens the bond strength between the aggregates and paste, resulting in diminished tensile strength. Moreover, excessive marble sludge content may introduce microstructural discontinuities or increase porosity within the concrete, which act as stress concentration points and facilitate crack propagation under bending loads. These factors contribute to lowering the concrete’s flexural performance at higher substitution levels.

The lowest flexural strength was measured in the SCC mixture labeled (10%C + 20%F), with a value of approximately 3.3 MPa. Although this falls within acceptable limits for certain non-structural or lightly loaded applications, it clearly demonstrates the trade-off commonly encountered when incorporating larger proportions of waste materials: while workability and flowability may improve, mechanical properties related to tensile and bending forces can deteriorate. This balance between enhanced fresh properties and reduced mechanical durability must be carefully managed when designing sustainable concrete mixtures.

In summary, these findings highlight the critical importance of optimizing the replacement levels of WMS to ensure a balanced design that supports adequate mechanical strength, durability, and sustainability goals. By carefully selecting the substitution percentages, it is possible to achieve improvements in both environmental impact and concrete performance, facilitating broader adoption of eco-friendly construction materials.

3.2.4. Tensile Strength

The Brazilian tensile strength test results for the different concrete mixtures are shown in Figure 4, providing insight into the indirect tensile performance of SCC containing WMS as a partial replacement for cement and fine aggregates. This method, based on diametrical compression of cylindrical specimens, is widely accepted for assessing the splitting tensile strength of concrete, a key property for evaluating its resistance to cracking and overall structural integrity, particularly in applications such as pavements, slabs, and thin-shell structures.

The results indicate that the mixture with 5% cement and 20% fine aggregate replacement achieved the highest tensile strength of 3.9 MPa. This improvement can be attributed to multiple synergistic mechanisms. The fine WMS particles acted as micro-fillers, refining the pore structure and improving stress distribution within the concrete matrix. In addition, the calcium carbonate content of WMS may have contributed to secondary reactions, such as the formation of carboaluminate phases, which enhanced the interfacial transition zone (ITZ) between the paste and aggregates. The smooth, plate-like morphology of marble sludge particles also likely promoted better interlock and cohesion, further improving tensile resistance. These effects collectively explain the superior performance of the mixture at moderate replacement levels.

However, when the cement replacement exceeded 5%, a gradual decline in tensile strength was observed. This reduction can be explained by several factors. Higher WMS contents reduce the proportion of Portland cement available to form calcium silicate hydrate (C–S–H), the primary binding phase responsible for strength. Furthermore, excessive sludge can introduce microporosity or microstructural discontinuities, creating preferential paths for crack propagation under tensile loading. While the lubricating effect of WMS improves flowability, at higher contents it may also reduce internal friction between particles, compromising tensile capacity.

The SCC mixture with 10% cement and 20% fine aggregate replacement recorded the lowest tensile strength of 3.1 MPa, highlighting the trade-off between improved workability and reduced tensile performance. Although this value remains within acceptable limits for non-structural or lightly loaded applications, it demonstrates the limitations of excessive substitution.

In summary, these findings emphasize the importance of optimizing replacement levels in sustainable concrete design. A 5% cement and 20% fine aggregate replacement with WMS appears to provide the best balance, offering improved tensile performance while contributing to sustainability objectives, whereas higher substitution levels should be applied cautiously due to their potential to compromise mechanical behavior.

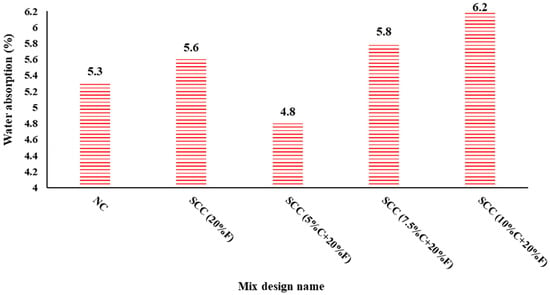

3.2.5. Water Absorption

The water absorption results for the different concrete mixtures are shown in Figure 5, offering important insights into the porosity, microstructural quality, and overall durability of SCC incorporating WMS as a partial replacement for cement and fine aggregates. Since water absorption directly reflects concrete permeability, it serves as a critical durability indicator, influencing resistance to freeze–thaw cycles, chemical ingress, and sulfate attack.

Figure 5.

Water absorption of SCC mixtures with partial cement and fine aggregate replacement using WMS.

The mixture containing 5% cement and 20% fine aggregate replacement exhibited the lowest water absorption (≈4.8%), indicating a denser and less permeable microstructure at this replacement level. This improvement can be explained by the filler effect of the fine WMS particles, which enhance particle packing, minimize capillary voids, and block pathways for water ingress. Such densification not only improves short-term durability but also suggests an extended service life under moisture exposure.

When cement replacement exceeded 5%, however, a progressive increase in water absorption was observed. Several factors contribute to this trend: the reduction in available Portland cement limits the formation of calcium silicate hydrate (C–S–H), weakening the binder matrix; excessive sludge interferes with hydration processes, leading to incomplete development of the cementitious structure; and higher WMS content may introduce micro-porosity, creating easier paths for water penetration. These combined effects explain the greater permeability in high-substitution mixes.

The highest absorption rate was recorded for the SCC with 10% cement and 20% fine aggregate replacement (≈6.2%), which, although still acceptable for certain non-structural or non-aggressive applications, suggests reduced durability in environments exposed to sustained moisture, chloride ingress, or freeze–thaw cycles.

In summary, the findings highlight the need to balance sustainability with durability. While incorporating WMS reduces environmental impact, its influence on porosity and permeability must be carefully managed. An optimized replacement level—such as 5% cement and 20% fine aggregates—minimizes water absorption and offers the most favorable trade-off between ecological benefits and long-term performance.

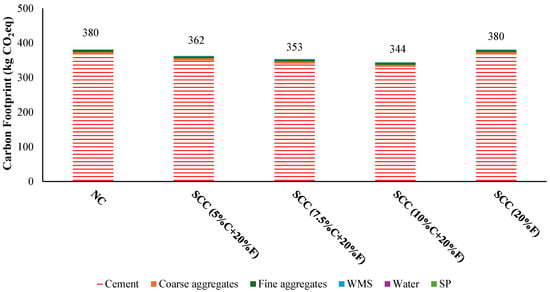

3.3. Carbon Footprint Results

Figure 6 presents the carbon footprint of the control mixture (NC) and SCC mixes incorporating WMS. The results demonstrate a clear variation in emissions across different replacement levels. The highest carbon footprint was recorded for the control concrete (NC) and the SCC mixture with only fine aggregate replacement (20%F), both at approximately 380.5 kg CO2-eq/m3. In contrast, the lowest footprint was observed for the SCC with 10% cement and 20% fine aggregate replacement, with a value of around 343.9 kg CO2-eq/m3. This reduction highlights the environmental benefit of substituting cement with WMS, since cement production is widely recognized as the most carbon-intensive component of concrete.

Figure 6.

Carbon footprint of SCC mixtures incorporating WMS.

Across all mixtures, the dominant role of cement in driving emissions is evident. Even with aggregate and admixture contributions included, cement consistently accounted for the majority of the carbon footprint. The inclusion of WMS, treated as a by-product with negligible upstream burden, further lowered the embodied carbon by offsetting part of the cement demand. These results confirm that strategies aimed at reducing clinker content provide the greatest potential for emission reduction in SCC.

The carbon footprint values obtained in this study are in close agreement with the results reported by Huang et al. [46] for sludge-derived low-carbon concrete, who observed an approximate 9% reduction in overall emissions at only 10% cement replacement and up to 83% reduction at full substitution scenarios. When normalized to 1 m3 of SCC, our best-performing mixtures achieve comparable or better performance than these benchmarks, confirming that incorporating marble waste is an equally effective decarbonisation strategy. This alignment with prior LCA-based investigations reinforces the credibility of our findings and supports the broader application of marble waste as a sustainable binder or aggregate replacement in structural concretes.

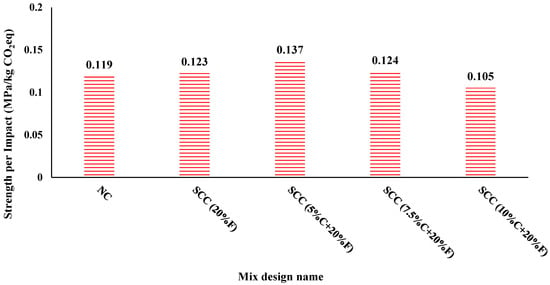

In Figure 7, the compressive strength and carbon footprint results are combined to evaluate the strength-per-impact indicator (MPa kg−1 CO2-eq), which quantifies the mechanical performance obtained per unit of embodied carbon. The SCC with 7.5% cement and 20% fine aggregate replacement achieved the highest efficiency, indicating the best balance between structural performance and reduced emissions. Conversely, the 20%F mixture showed the lowest efficiency, as its carbon footprint remained high while strength improvements were limited.

Figure 7.

Strength-to-carbon efficiency of SCC mixtures incorporating WMS.

Taken together, these findings emphasize that cement is the principal contributor to the carbon footprint of SCC, and even partial substitution has a direct and measurable impact on lowering emissions. At the same time, the results highlight that there is an optimal replacement level where environmental benefits are achieved without undermining structural integrity. Moderate substitution of cement with WMS emerges as the most effective strategy, enabling meaningful reductions in embodied carbon while maintaining or even enhancing the mechanical performance of SCC. This balance underscores the potential of WMS to contribute to more sustainable construction practices, providing both ecological and technical advantages in the pursuit of greener infrastructure.

4. Conclusions

This study introduces a dual replacement strategy in self-compacting concrete (SCC), simultaneously substituting cement and fine aggregate with waste marble sludge (WMS)—a novel approach not widely explored in prior literature.

- The research demonstrates that controlled incorporation of WMS (specifically 5% cement and 20% sand replacement) can significantly enhance mechanical performance, achieving compressive strength of 48.2 MPa, flexural strength of 4.4 MPa, and tensile strength of 3.9 MPa at 28 days.

- The optimized mix also exhibited reduced water absorption (~4.8%), indicating a denser microstructure and improved durability—highlighting WMS’s role in refining pore structure.

- Fresh property evaluation revealed that a mix with 10% cement and 20% sand replacement achieved superior flowability, with a slump flow of 610 mm and V-funnel time of 8 s—validating WMS’s positive impact on SCC rheology.

- A carbon footprint analysis confirmed the environmental benefit of WMS integration, with the 10% cement replacement mix reducing emissions to 343.9 kg CO2-eq/m3, compared to 380.5 kg CO2-eq/m3 for the control.

- The mix with 7.5% cement replacement offered the best strength-to-carbon efficiency, establishing a practical balance between mechanical performance and sustainability.

Overall, the study provides experimental validation for the use of WMS as a sustainable and performance-enhancing component in SCC, contributing to eco-efficient concrete design and circular economy practices in the construction industry.

5. Future Research Directions

Building upon the promising results of this study, several avenues for future research can be pursued to further explore and optimize the use of waste marble sludge (WMS) in self-compacting concrete (SCC):

- Long-Term Durability Assessment: While the current study focused on mechanical and rheological properties at 28 days, future investigations should assess long-term durability aspects such as resistance to chloride penetration, sulfate attack, carbonation depth, and freeze–thaw cycles. These evaluations are essential for validating the suitability of WMS-based SCC in aggressive environmental conditions.

- Microstructural and Mineralogical Analysis: Advanced characterization techniques such as X-ray diffraction (XRD), thermogravimetric analysis (TGA), and nanoindentation can be employed to understand the hydration mechanisms and interfacial transition zones (ITZ) influenced by WMS particles. This would provide deeper insight into the role of WMS in modifying the cementitious matrix.

- Optimization through Statistical Design: Future studies may adopt response surface methodology (RSM) or factorial design approaches to identify optimal replacement levels of cement and sand with WMS, considering multiple performance criteria including strength, workability, and environmental impact.

- Integration with Other Industrial Wastes: The synergistic use of WMS with other supplementary cementitious materials (SCMs) such as fly ash, silica fume, or slag could be explored to enhance composite performance and broaden the scope of sustainable mix designs.

- Field Application and Scale-Up Studies: Pilot-scale trials and real-world applications of WMS-based SCC in structural elements (e.g., slabs, beams, precast units) would help validate laboratory findings and assess practical challenges related to mixing, placement, and curing.

- Life Cycle Assessment (LCA) and Cost Analysis: A comprehensive life cycle assessment comparing conventional SCC and WMS-modified SCC in terms of energy consumption, emissions, and economic feasibility would support broader adoption in green construction practices.

- Standardization and Guidelines Development: Based on accumulated data, future work could contribute to the formulation of technical guidelines or amendments to existing standards for the use of marble sludge in concrete production.

By addressing these directions, future research can strengthen the scientific foundation and practical viability of WMS as a sustainable component in SCC, contributing to circular economy goals and reducing the environmental footprint of the construction industry.

Author Contributions

Conceptualization, H.M. and H.B.; methodology, H.M. and H.B.; formal analysis, H.M. and H.B.; investigation, H.M. and H.B.; resources, H.M. and H.B.; data curation, R.M.M. and H.B.; writing—original draft preparation, H.M. and H.B.; writing—review and editing, H.M., S.M.K. and H.B.; visualization, H.M. and H.B.; supervision, H.M. and H.B.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study is available on request from the corresponding author. The data is not publicly available due to confidentiality issues.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| ITZ | Interfacial transition zone |

| OPC | Ordinary Portland cement |

| SCC | Self-compacting concrete |

| WMS | Waste marble sludge |

References

- Lopes, J. Construction in the economy and its role in socio-economic development. In New Perspectives on Construction in Developing Countries; Routledge: Oxford, UK, 2012; pp. 40–71. [Google Scholar]

- Yu, H.; Wen, B.; Zahidi, I.; Fai, C.M.; Madsen, D.Ø. Constructing the future: Policy-driven digital fabrication in China’s urban development. Results Eng. 2024, 22, 102096. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostafaei, H. Impact of Fibers on the Mechanical and Environmental Properties of High-Performance Concrete Incorporating Zeolite. J. Compos. Sci. 2025, 9, 222. [Google Scholar] [CrossRef]

- Mostafaei, H.; Bahmani, H. Sustainable high-performance concrete using zeolite powder: Mechanical and carbon footprint analyses. Buildings 2024, 14, 3660. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Aghamohammadi, O.; Bahmani, H.; Ebrahimi, S. Improving thermal characteristics and energy absorption of concrete by recycled rubber and silica fume. Dev. Built Environ. 2023, 16, 100221. [Google Scholar] [CrossRef]

- Aziz, M.A.; Zubair, M.; Saleem, M. Development and testing of cellulose nanocrystal-based concrete. Case Stud. Constr. Mater. 2021, 15, e00761. [Google Scholar] [CrossRef]

- Saffari, R.; Nikooee, E.; Habibagahi, G.; Van Genuchten, M.T. Effects of biological stabilization on the water retention properties of unsaturated soils. J. Geotech. Geoenviron. Eng. 2019, 145, 04019028. [Google Scholar] [CrossRef]

- Shabani, K.; Maysam, B.; Fatehi, H.; Chang, I. Improvement of the geotechnical engineering properties of dune sand using a plant-based biopolymer named serish. Geomech. Eng. 2022, 29, 535–548. [Google Scholar]

- Saffari, R.; Habibagahi, G.; Nikooee, E.; Niazi, A. Biological stabilization of a swelling fine-grained soil: The role of microstructural changes in the shear behavior. Iran. J. Sci. Technol. Trans. Civ. Eng. 2017, 41, 405–414. [Google Scholar] [CrossRef]

- Turk, J.; Cotič, Z.; Mladenovič, A.; Šajna, A. Environmental evaluation of green concretes versus conventional concrete by means of LCA. Waste Manag. 2015, 45, 194–205. [Google Scholar] [CrossRef] [PubMed]

- Sobuz, H.R.; Visintin, P.; Ali, M.S.M.; Singh, M.; Griffith, M.C.; Sheikh, A.H. Manufacturing ultra-high performance concrete utilising conventional materials and production methods. Constr. Build. Mater. 2016, 111, 251–261. [Google Scholar] [CrossRef]

- Van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ‘green’ concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Tavares, V.; Soares, N.; Raposo, N.; Marques, P.; Freire, F. Prefabricated versus conventional construction: Comparing life-cycle impacts of alternative structural materials. J. Build. Eng. 2021, 41, 102705. [Google Scholar] [CrossRef]

- Rostampour, M.A.; Davood, M.; Hadi, B.; Hasan, M. Crack Assessment Using Acoustic Emission in Cement-Free High-Performance Concrete Under Mechanical Stress. J. Compos. Sci. 2025, 9, 380. [Google Scholar] [CrossRef]

- Grădinaru, C.M.; Muntean, R.; Șerbănoiu, A.A.; Ciocan, V.; Burlacu, A. Sustainable development of human society in terms of natural depleting resources preservation using natural renewable raw materials in a novel ecological material production. Sustainability 2020, 12, 2651. [Google Scholar] [CrossRef]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2022, 48, 741–746. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Soomro, M.; Tam, V.W.Y.; Evangelista, A.C.J. Production of cement and its environmental impact. In Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2023; pp. 11–46. [Google Scholar]

- Mostazid, M.I.; Sakai, Y. Low-carbon footprint approach to produce recycled compacted concrete. Ceram. Int. 2023, 49, 22219–22231. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostofinejad, D.; Eftekhar, M.R. A novel eco-friendly thermal-insulating high-performance geopolymer concrete containing calcium oxide-activated materials with waste tire and waste polyethylene terephthalate. Dev. Built Environ. 2024, 18, 100473. [Google Scholar] [CrossRef]

- Shurrab, J.; Hussain, M.; Khan, M. Green and sustainable practices in the construction industry: A confirmatory factor analysis approach. Eng. Constr. Archit. Manag. 2019, 26, 1063–1086. [Google Scholar] [CrossRef]

- Maqbool, R.; Saiba, M.R.; Altuwaim, A.; Rashid, Y.; Ashfaq, S. The influence of industrial attitudes and behaviours in adopting sustainable construction practices. Sustain. Dev. 2023, 31, 893–907. [Google Scholar] [CrossRef]

- Zubair, M.; Mu’azu, N.D.; Nasir, M.; Manzar, M.S.; Aziz, M.A.; Saleem, M.; Al-Harthi, M.A. Cellulose nanocrystals from office paper waste for green mortar: Process optimization modeling, characterization, and mechanical properties. Arab. J. Sci. Eng. 2022, 47, 5377–5393. [Google Scholar] [CrossRef]

- Aghdam, K.A.; Rad, A.F.; Shakeri, H.; Sardroud, J.M. Approaching green buildings using eco-efficient construction materials: A review of the state-of-the-art. J. Constr. Eng. Proj. Manag. 2018, 8, 1–23. [Google Scholar]

- Vijayan, D.S.; Devarajan, P.; Sivasuriyan, A.; Stefańska, A.; Koda, E.; Jakimiuk, A.; Vaverková, M.D.; Winkler, J.; Duarte, C.C.; Corticos, N.D. A state of review on instigating resources and technological sustainable approaches in green construction. Sustainability 2023, 15, 6751. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Ou, J. Self-compacting concrete. In Smart and Multifunctional Concrete Toward Sustainable Infrastructures; Springer: Berlin/Heidelberg, Germany, 2017; pp. 11–36. [Google Scholar]

- Daczko, J. Self-Consolidating Concrete: Applying What We Know; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Mostafaei, H.; Bahmani, H.; Mostofinejad, D. Damping Behavior of Fiber-Reinforced Concrete: A Comprehensive Review of Mechanisms, Materials, and Dynamic Effects. J. Compos. Sci. 2025, 9, 254. [Google Scholar] [CrossRef]

- Umar, M.; Qian, H.; Khan, M.N.A.; Siddique, M.S.; Almujibah, H.A.; Elshekh, A.E.; Bashir, M.O.; Vatin, N.I. Strength and durability of concrete with bentonite clay and quarry dust. Front. Mater. 2025, 11, 1458836. [Google Scholar] [CrossRef]

- Althoey, F.; Ansari, W.S.; Sufian, M.; Deifalla, A.F. Advancements in low-carbon concrete as a construction material for the sustainable built environment. Dev. Built Environ. 2023, 16, 100284. [Google Scholar] [CrossRef]

- da Silva Rego, J.H.; Sanjuán, M.Á.; Mora, P.; Zaragoza, A.; Visedo, G. Carbon dioxide uptake by brazilian cement-based materials. Appl. Sci. 2023, 13, 10386. [Google Scholar] [CrossRef]

- Alyhya, W.S. Self-Compacting Concrete: Mix Proportioning, Properties and Its Flow Simulation in the V-Funnel. Ph.D. Thesis, Cardiff University, Cardiff, UK, 2016. [Google Scholar]

- Long, G.; Gao, Y.; Xie, Y. Designing more sustainable and greener self-compacting concrete. Constr. Build. Mater. 2015, 84, 301–306. [Google Scholar] [CrossRef]

- Tripathi, D.; Kumar, R.; Mehta, P.K. Development of an environmental-friendly durable self-compacting concrete. Environ. Sci. Pollut. Res. 2022, 29, 54167–54180. [Google Scholar] [CrossRef]

- Witkowski, H. Sustainability of self-compacting concrete. Archit. Civ. Eng. Environ. 2015, 8, 83–88. [Google Scholar]

- Li, J.; Zhang, J.; Ni, S.; Liu, L.; Walubita, L.F. Mechanical performance and environmental impacts of self-compacting concrete with recycled demolished concrete blocks. J. Clean. Prod. 2021, 293, 126129. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostafaei, H.; Mostofinejad, D. Review of Energy Dissipation Mechanisms in Concrete: Role of Advanced Materials, Mix Design, and Curing Conditions. Sustainability 2025, 17, 6723. [Google Scholar] [CrossRef]

- Mostafaei, H.; Chamasemani, N.F.; Mashayekhi, M.; Hamzehkolaei, N.S.; Santos, P. Sustainability Enhancement and Evaluation of a Concrete Dam Using Recycling. Appl. Sci. 2025, 15, 2479. [Google Scholar] [CrossRef]

- Nemerow, N.L.; Agardy, F.J.; Sullivan, P.J.; Salvato, J.A. Environmental Engineering: Environmental Health and Safety for Municipal Infrastructure, Land Use and Planning, and Industry; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- ASTM C39-12; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2004.

- ASTM C78; Standard Test Method for Flexural Strength of Concrete. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2016.

- Sánchez, A.R.; Ramos, V.C.; Polo, M.S.; Ramón, M.V.L.; Utrilla, J.R. Life cycle assessment of cement production with marble waste sludges. Int. J. Environ. Res. Public Health 2021, 18, 10968. [Google Scholar] [CrossRef]

- Ahmadi, M.; Abdollahzadeh, E.; Kashfi, M.; Khataei, B.; Razavi, M. Life Cycle Assessment and Performance Evaluation of Self-Compacting Concrete Incorporating Waste Marble Powder and Aggregates. Materials 2025, 18, 2982. [Google Scholar] [CrossRef]

- Huang, B.; Zhuge, Y.; Rameezdeen, R.; Xing, K.; Huang, G.; Liu, Y. Integrated carbon assessment for sludge-derived concrete: Modelling and a comparative study. J. Clean. Prod. 2024, 435, 140304. [Google Scholar] [CrossRef]

- Mostafaei, H.; Ashoori Barmchi, M.; Bahmani, H. Seismic Resilience and Sustainability: A Comparative Analysis of Steel and Reinforced Structures. Buildings 2025, 15, 1613. [Google Scholar] [CrossRef]

- Silva, L.S.; Amario, M.; Stolz, C.M.; Figueiredo, K.V.; Haddad, A.N. A comprehensive review of stone dust in concrete: Mechanical behavior, durability, and environmental performance. Buildings 2023, 13, 1856. [Google Scholar] [CrossRef]

- Akbar, M.; Hussain, Z.; Imran, M.; Bhatti, S.; Anees, M. Concrete matrix based on marble powder, waste glass sludge, and crumb rubber: Pathways towards sustainable concrete. Front. Mater. 2024, 10, 1329386. [Google Scholar] [CrossRef]

- Mostafaei, H.; Kelishadi, M.; Bahmani, H.; Wu, C.; Ghiassi, B. Development of sustainable HPC using rubber powder and waste wire: Carbon footprint analysis, mechanical and microstructural properties. Eur. J. Environ. Civ. Eng. 2025, 29, 399–420. [Google Scholar] [CrossRef]

- Mostafaei, H.; Rostampour, M.A.; Chamasemani, N.F.; Wu, C. An In-Depth Exploration of Carbon Footprint Analysis in the Construction Sector with Emphasis on the Dam Industry. In Carbon Footprint Assessments: Case Studies & Best Practices; Springer: Berlin/Heidelberg, Germany, 2024; pp. 45–80. [Google Scholar]

- Bahmani, H.; Mostafaei, H. Eco-Friendly Self-Compacting Concrete Incorporating Waste Marble Sludge as Fine and Coarse Aggregate Substitute. Buildings 2025, 15, 3218. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.; Deifalla, A.F. Self-compacting concrete with partially substitution of waste marble: A review. Int. J. Concr. Struct. Mater. 2023, 17, 25. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).