Abstract

The primary objective of this research was to assess the efficacy of a novel solution under conditions closely resembling those of real-world scenarios. Biological beds, or filters, hold significant potential for widespread implementation in individual households, particularly in areas with dispersed housing. The system’s aim was to improve the quality of wastewater treated in on-site domestic biological treatment plants. A pivotal aspect of the project involved developing a prototype research installation for conducting comprehensive testing. Our installation system consisted of several components designed to create a laboratory-scale model for domestic wastewater treatment. The model comprised four biological reactors filled with ABS material and secured by a PUR frame. Additionally, the tested model included a controller for wastewater dosing control, a septic tank as a reservoir, and four tanks for collecting purified wastewater. Through regression analysis using the Generalized Linear Model (GLM), a correlation between CODCr and TSS was revealed. This study presents the research findings concerning the development of a prototype installation that incorporates an advanced reactor or filter. The data derived from this research have the potential to contribute to the creation of products that enhance the performance and efficiency of household wastewater treatment systems.

1. Introduction

Wastewater management is a pressing global concern, with increasing emphasis on sustainable and efficient methods of removal and treatment [1,2,3]. A pragmatic shift marked a transformation in waste material management and wastewater treatment technology, responding to the substantial global waste production and the demand for economical adsorbents to reduce wastewater treatment costs [4]. Today, a new approach encompasses the integration of waste materials into wastewater treatment and the creation of value-added products from previously used waste adsorbents, including electric material and cementitious materials, ultimately enhancing both waste management efficiency and commercial viability [5,6,7]. Wastewater is generated from various sources, including industrial processes, agricultural activities, and domestic usage [8,9]. The effective removal and treatment of wastewater are essential for environmental protection and human health [10]. Numerous theoretical and practical approaches have been developed to address this challenge, with an emphasis on different shredded materials and their role in these methods [11,12,13,14,15].

The assessment of product materials in the context of wastewater removal is of paramount importance in addressing the ever-growing concerns of environmental sustainability and public health [16]. Critical to achieving cleaner water is the careful selection of materials [17]. A comprehensive examination of the advantages and limitations of various materials provides invaluable insights for shaping the development of wastewater removal solutions that are both more efficient and environmentally friendly [18,19]. Efficient wastewater treatment hinges on low biological oxygen demand (BOD) and chemical oxygen demand (COD) levels, reflecting successful removal of pollutants for environmental health. The reduction in COD in wastewater is primarily associated with the removal of organic pollutants [20].

Various materials can be used to treat wastewater in small municipal systems. Ceramic aggregate is very popular as a filtering medium. Shao et al. [21] developed a non-sintered fly ash filter material with sludge as an additive and studied the impact of pH on the adsorption efficiency of ammonium nitrogen in wastewater. In other research, Lu et al. [22] demonstrated the use of another novel material—prepared using municipal solid waste incineration (MSWI) fly ash and the fuel ash from coal power plants, together with small amounts of silicon carbide foaming agent and magnesia flux as additives. These media have high efficiency in removing contaminants from wastewater, but their production requires thermal treatment, which results in high costs. Therefore, it seems advisable to look for other alternative filter materials produced from waste but without energy inputs.

ABS (Acrylonitrile Butadiene Styrene) is a water-resistant plastic known for its durability and resistance to water degradation, making it a popular choice for various applications in industries such as electronics, the automotive industry, and construction. Its hydrophobic nature prevents water from infiltrating the material, contributing to its long lifespan and reduced environmental impact [23]. ABS proves to be a valuable material in a wide range of applications. Nevertheless, its suitability or potential challenges can be contingent upon its application or the particular context in which it is utilized [24].

This paper presents a critical assessment of the role of various product materials in theoretical and practical approaches to wastewater removal. We focused on shredded materials in wastewater removal, considering both theory and practical applications.

The research’s primary objective was to evaluate the efficiency of a novel wastewater treatment process under conditions closely resembling those of real-world scenarios. This technical study focused on conducting scientific investigations into the effectiveness of innovative filters, specifically biological beds. At the laboratory research stage, a variant of the biological bed was developed and filled with finely crushed ABS. Our goal was to guide the development of sustainable solutions by emphasizing materials like ABS. The specific objectives were as follows:

- (a)

- To assess various shredded materials, reducing reliance on resources and minimizing the environmental impact of production processes;

- (b)

- To develop effective waste-material-based solutions for the removal of pollutants, as measured by CODCr and BOD5;

- (c)

- To support the principles of resource efficiency and the circular economy by exploring innovative methods for recycling and reusing electronic waste materials in a closed-loop system, thereby reducing waste generation and conserving natural resources;

- (d)

- To establish reliable total suspended sediment efficiency indicators for the evaluation of waste-material-based sediment treatments, ensuring their effectiveness in water purification.

2. Materials and Methods

2.1. Construction of the Laboratory Model

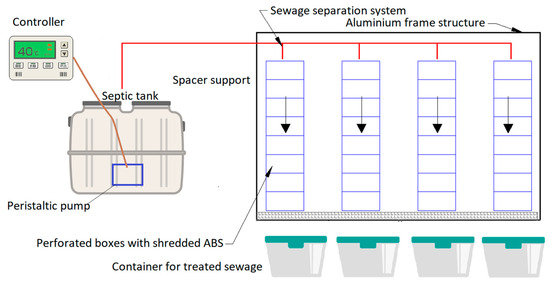

The model was established in a laboratory-prototype setting. The test system was a filter bed with a vertical flow (Figure 1). This setup contained several compartments divided by specialized partitions where targeted research investigations were carried out. These compartments were supplied with wastewater from a sewage settling tank (Figure 2).

Figure 1.

Schematic of experimental of biological reactor in a domestic wastewater treatment plant.

Figure 2.

Septic tank of pre-treated wastewater utilized for research.

The research setup essentially comprised the following components:

- (a)

- Supporting structure;

- (b)

- Plastic reactors;

- (c)

- System for dosing pre-treated wastewater into the reactors;

- (d)

- System for discharging treated wastewater;

- (e)

- Electrical power supply system.

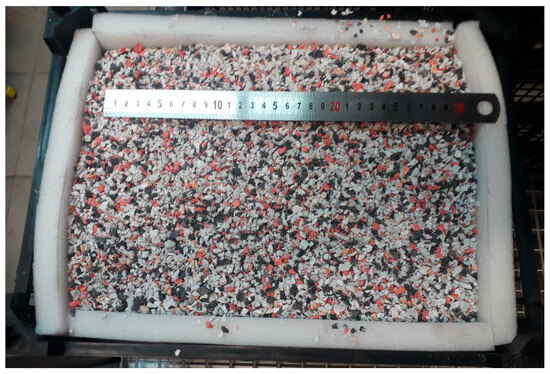

Two types of plastic materials were examined: one black, with particle sizes ranging from 0.2 to 1.0 cm, and the other light yellow, with particle sizes from 0.2 to 0.8 cm. Additionally, colored plastic derived from crushed PET (Polyethylene Terephthalate bottles) was utilized. The container was lined with a layer of PUR (polyurethane) foam and then filled with finely shredded e-waste material. The biological bed of the setup was filled with crushed ABS material from used waste of electrical and electronic equipment (WEEE) and used to fill containers measuring 30 × 40 cm with a height of 11 cm. Furthermore, three of the compartments incorporated a special layer made of shredded polyurethane foam (recycled plastic material). An example photo of the packing of the bed is shown in Figure 3. ABS with a density of 1.1 g/cm3 was used in the tests. The porosity of the ABS material was 45% (Figure 4). ABS (Acrylonitrile Butadiene Styrene) is a widely utilized plastic known for its robustness and longevity. Its environmental footprint is intricately tied to recycling practices, offering a sustainable approach by diminishing the demand for new materials and curbing waste. Appropriate recycling is pivotal for eco-friendly disposal since ABS has a slow biodegradation rate in landfills. Despite its petrochemical-based production, responsible disposal methods, especially recycling, can effectively temper its environmental impact. While ABS is inherently non-biodegradable, its overall influence on the environment hinges on disposal practices and the widespread adoption of recycling initiatives. Increased recycling of ABS contributes to resource conservation and eases the burden on waste management systems.

Figure 3.

System of vertical flow filter.

Figure 4.

The shredded ABS used in studies.

The studies were conducted with a hydraulic load on the filtration bed not exceeding 50 dm3/m2 daily, and a double recirculation of domestic wastewater was employed for the sprinkler system. The average wastewater quantity dosed into the reactors was approximately 20.8 mL per hour using peristaltic pumps. Additionally, the average total volume was at the level of 0.5 dm3 per day. The evaluation of the reactor/filter’s impact on wastewater (assessment of physicochemical properties of wastewater before and after reactor utilization) encompassed three primary wastewater pollution indicators: BOD5, CODCr, and total suspended solids. Moreover, the research involved observing whether the proposed technical solution was prone to clogging.

2.2. Determination of the Basic Parameters for the Treatment Efficiency

In the treated wastewater, the following parameters were measured using a multifunctional device: pH, dissolved oxygen, oxygen saturation, and wastewater temperature with the pH-dissolved oxygen meter CPO-401 (Elmetron Sp. j., Zabrze, Poland). BOD5 was determined using the respirometric BOD Measuring system WTW OxiTop-I IS 6 (Xylem Analytics Germany, Waldheim, Germany), and CODCr was measured using the WTW photoLAb 7200 VIS spectrophotometer (Xylem Analytics Germany). The TSS weight method was utilized to measure total suspended solids in wastewater. This method involved filtering a known volume of the sample through pre-weighed filter paper, drying it, and re-weighing it to calculate TSS concentration in mg/L. This approach ensured the precise quantification of suspended solid particles in water samples. Reductions in CODCr, BOD5, and total suspended solids (TSS) were calculated according to the formula in reference [25]:

where:

- a—treated wastewater concentration;

- b—wastewater concentration;

- y—reduction efficiency.

We conducted a multivariate regression using CODCr, BOD5, or TSS as independent variables and temperature (Temp) and dissolved oxygen (DO) as predictors. The optimal model was determined using a GLM (Generalized Linear Model) approach. Regression was performed using PAST version 4.11. Reduction in selected wastewater pollution indicators was determined. They were compared with the limit values specified in the Regulation of the Minister of Maritime Affairs and Inland Navigation on substances particularly harmful to the aquatic environment and on conditions to be met when discharging wastewater into waters or onto the ground and when discharging rainwater or snowmelt into waters or into a water installation (Journal of Laws from 2019, item 1311). According to this law, a value below 2000 PE for WWTPs is equal to a concentration of 40 mg O2/dm3, 150 mg O2/dm3, and 50 mg/dm3 for BOD5, CODCr, and TSS, respectively. Basic descriptive statistics of the quality of pre-treated and treated wastewater such as the mean, minimum, maximum, standard deviation, range, median, and coefficient of variation were estimated.

3. Results and Discussion

The raw wastewater used in this study came from a septic tank connected to the university building (Agricultural University of Krakow, Poland). The wastewater was directed to the septic tank for preliminary treatment. In Table 1, the qualitative values of pre-treated wastewater in the septic tank are given. In the next stage, the wastewater was pumped to the surface of a vertical biological filter.

Table 1.

Parameters in wastewater after primary septic tank treatment.

In technical documentation, the term ‘closed-loop system’ typically refers to a system where the output influences the input, creating a loop of information or control. This closed-loop nature often involves feedback mechanisms or continuous monitoring and adjustments within the filtration system. However, for our examination purposes, we have excluded these elements as they are unnecessary (Figure 1). While backwashing the filter is possible, it was not considered necessary in our examples. Filter clogging may occur under specific conditions, including significant changes in the source or composition of wastewater (e.g., industrial wastewater) and the direct introduction of wastewater into the filtering system without utilizing a preliminary settling tank. It is recommended to use coarser particles at the top of the filtration bed and progressively finer material at the bottom; this enhances anti-clogging properties.

In this context, our material operates within a closed-loop system, meaning it is not disposed of in landfills but is instead reused within the system. Although this concept may not be explicitly depicted on the graph, the emphasis is on highlighting the sustainable reuse of materials within the system.

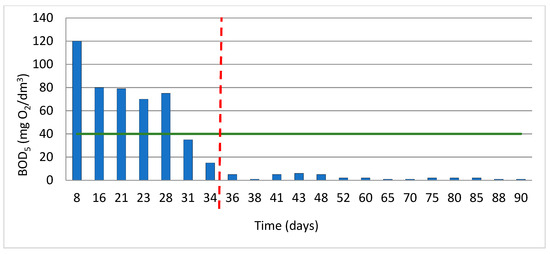

Optimal conditions, such as a 45 min treatment with an aluminum cathode and a current density of 75 A/m2, achieved over 90% removal of BOD5, CODCr, turbidity, chromium, iron, and nitrate. However, the electrocoagulated sludge contained problematic substances, including chromium (50%), Total Carbon (15%), and Sulfide (0.3%), posing disposal challenges. One piece of research highlighted electrocoagulation’s potential for tannery wastewater treatment while emphasizing the importance of addressing sludge disposal issues [26]. The wastewater, following the septic tank, exhibited the highest BOD5 concentration, peaking at 280 mg O2/dm3 (Table 1). Research findings indicated that BOD5 reduction to the required regulatory level occurred after 34 days (Figure 5). Similarly, the maximum CODCr concentration after the septic tank reached 475 mg O2/dm3,with a satisfactory reduction observed after 38 days.

Figure 5.

BOD5 values for the finer filter media, with the red dashed line indicating the moment of compliance. The green line represents the permissible value.

In the pre-treated wastewater, periodic anaerobic conditions were observed. The dissolved oxygen concentration reached a maximum of 0.26 mg O2/dm3, while the pH fluctuated within the range of 5.75 to 8.38 (Table 1).

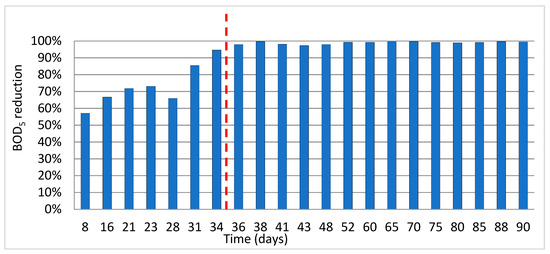

The results indicated that there was an enhancement in wastewater quality in each system within 30 days. For the first month, BOD5 values were high, reaching up to 120 mg O2/dm3 in the first week of reactor operation. Only after 30 days did a noticeable decrease occur, which was below the allowable level (Figure 5). During the initial phase of the filter bed’s operation, the reduction fell within the range of 51.7% to 85.4%. It was only after more than one month of continuous operation that the reduction achieved a substantial, consistent level exceeding 90% (Figure 6). In the studies [27] conducted by other researchers, it was observed that the BOD5 level in wastewater following a settling tank reached 774.7 mg O2/dm3. In contrast, our investigations indicated a BOD5 level not exceeding 120 mg O2/dm3. Furthermore, the maximum CODcr concentration in raw wastewater was reported at 1524 mg O2/dm3, whereas, in our study, it remained below 350 mg O2/dm3 (Figure 7).

Figure 6.

BOD5 reduction for the finer filter media, with the red dashed line indicating the moment of achieving the appropriate reduction.

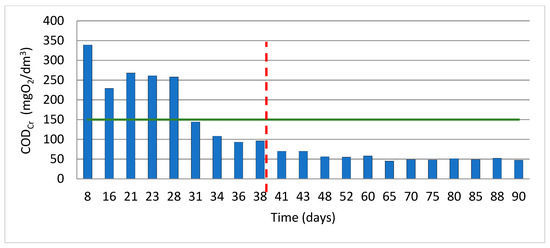

Figure 7.

CODCr values for the finer filter media, with the red dashed line indicating the moment of achieving the appropriate value. The green line represents the permissible value.

In our experiments, we observed variability in the BOD5 values. Beyond 28 days, higher values may arise due to the persistence of complex organic compounds and microbial adaptation during the adjustment process. Factors such as external sources of pollution introduced after day 23 and favorable environmental conditions supporting increased microbial activity could further contribute to this increase. These fluctuations in experimental conditions may influence the nature of organic matter and alterations in environmental parameters. As a result, additional data and analyses are essential for a precise identification of contributing factors (Figure 5).

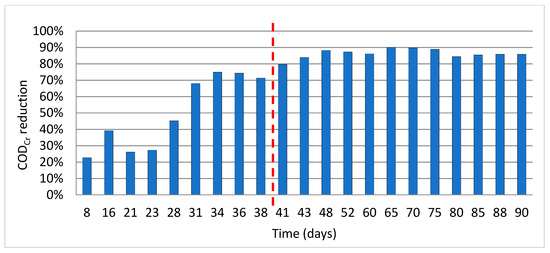

It took 38 days of operation in the biological reactor for the CODCr values to achieve a significant reduction to one fourth of their initial levels (Figure 7). During the initial weeks of the filter bed’s operation, CODCr reduction varied in the range of approximately 20–70%. It was only after 38 days of operation that a more stable reduction exceeding 80% was achieved (Figure 8). In another study involving shredded ABS, the most significant reduction in COD was noted with the sprayed loaded system. For BOD5 reduction, the highest efficacy was attained through the aeration system [25].

Figure 8.

CODCr reduction for the finer filter media, with the red dashed line marking the moment of achieving the desired reduction.

In the textile industry, water and chemicals are essential for raw material processing. Untreated wastewater poses environmental risks. Another study used chitosan extracted from prawn shells to treat textile wastewater, significantly reducing BOD5 and CODCr levels. Compared to microorganism treatment, prawn shell treatment proved more effective and cost efficient, offering a promising eco-friendly wastewater treatment method. Similarly, the maximum CODCr concentration after the septic tank reached 475 mg O2/dm3 (Table 1), with a satisfactory reduction observed after 38 days.

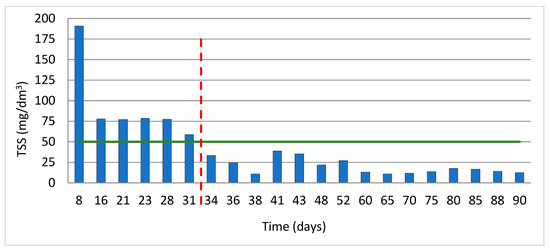

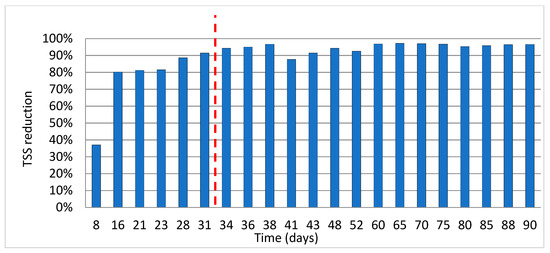

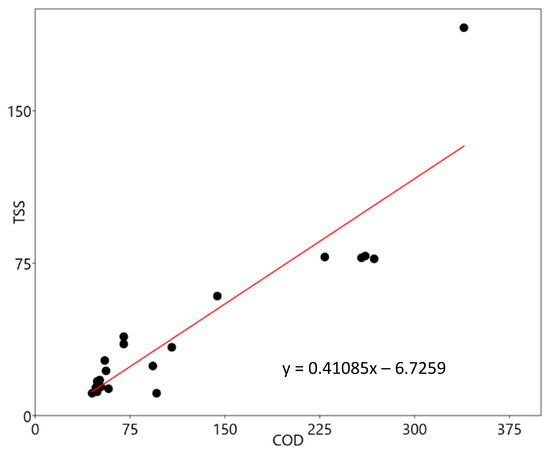

In the initial week, TSS levels were notably elevated, and it took over a month to achieve a satisfactory value which fell below 50 mg/dm3, complying with the established regulatory standard (Figure 9). Substantial TSS reduction was attained beginning in the second week of filter operation, with the required reduction, in line with regulatory standards, documented after 31 days (Figure 10). Based on the GLM and multivariate regression, the relationship between TSS and CODCr has been established (Figure 11). Substantial TSS reduction was attained beginning in the second week of filter operation, with the required reduction, in line with regulatory standards, documented after 31 days.

Figure 9.

TSS values for the finer filter media, with the red dashed line indicating the point of achieving the desired value. The green line represents the permissible limit.

Figure 10.

TSS reduction for the finer filter media, with the red dashed line.

Figure 11.

A Generalized Linear Model (GLM) for TSS (mg/dm3) and COD (mg O2/dm3).

The CODCr:BOD5 ratio suggested effective removal of nitrogen compounds through advanced biological treatment of the wastewater [28]. During the four-month study, a filter filled with 0.5 V of polyurethane foam sponge waste proved highly stable and effective, achieving reductions averaging 87.8% for CODCr, 91.0% for BOD5, 80.0% for suspended solids. Additionally, poly(ethylene terephthalate) flakes exhibited comparable performance, with average CODCr and suspended solids reductions of 87.1% and 84.0%, respectively [29]. The CODCr/BOD5 ratio of 1.31 indicated that the incoming wastewater was highly biodegradable and relatively easy to treat. In simple terms, this means that the influent wastewater’s composition can be readily broken down through biological processes, making it a desirable characteristic for wastewater treatment [30]. The CODCr-to-BOD5 ratio helps gauge the balance between pollutants that can be chemically or biologically treated. A high ratio means more chemical treatment potential, while a low ratio indicates effective biological pollutant degradation. Wastewater facilities use this ratio to tailor treatment methods to the pollutants present in the water [31]. The TSS level in untreated municipal (raw) wastewater did not surpass 340 mg/dm3. TSS levels in the effluent after the septic tank reached a maximum of 689 mg/dm3 (Table 1), and reduction to the required norm took place between the 31st and 34th day of operation (Figure 10).

This study has shown that the average reduction level for BOD5 was 98.9%, while, for CODCr, it was 84.4%, and, for TSS, it was 95% (Table 2). Throughout the four-month research period, the 60 cm foam filter consistently achieved substantial reductions of 60–80% in pollutants, including organic compounds and bacteria, demonstrating its superior performance. The evaluation of materials used in wastewater removal is crucial for addressing concerns related to process efficiency [27], environmental sustainability [32,33,34], and public health [35]. Preventing the formation of stagnant zones within the filtration bed is essential for effective wastewater management systems [36], especially in the context of a circular economy [36], particularly within urban wastewater management systems [37]. This section emphasizes key points in wastewater management, stressing the importance of exclusive domestic wastewater that avoids reacting with recycled ABS material. COD statistically correlated with TSS, suggesting that the chemical degradation of organic compounds was influenced by the level of suspended solid (Table 3). Furthermore, in the studies conducted on PUR sponge, a substantial reduction in COD of 87.1% and in TSS of 84.0% was observed [29]

Table 2.

Basic descriptive statistics and the mean percentage reduction for BOD5, CODCr, and TSS in the investigated filter bed after treatment.

Table 3.

Multivariate regression analysis for the examined indicators following the filtration bed purification process. BOD was used as dependent value.

The elevated p-value associated with temperature in Table 3 indicates, upon analyzing the data, that temperature may not exert a statistically significant influence on the measured outcome. Possible explanations for this observation include temperature having no significant effect on the outcome, restricted variability in temperature within the sample, a small sample size, or the statistical model not effectively capturing the relationship. A thorough consideration of these factors, along with the study context, is crucial for a precise interpretation of the results. After the filtration process, there is often sludge to manage. We can handle it in various ways. We might let it settle in tanks, remove the water, or use processes like composting or anaerobic digestion to reduce its volume. Some sludge can be applied to land as a soil conditioner, while other sludge might be incinerated or sent to landfills. The choice depends on the type of sludge and environmental regulations. Combining different methods helps manage sludge effectively in the filtration system.

Based on research evaluating the efficiency of a biological reactor in a domestic wastewater treatment plant, selecting key process parameters is imperative for optimizing the intermittently dosed biological filter bed solution. ABS, among the studied polymers, exhibits the highest microplastic release, posing a potential threat [38]. When contemplating the incorporation of plastic materials, particularly ABS, in biological treatment processes, environmental considerations take precedence. ABS, akin to numerous plastics, holds the potential to release microplastics into treated wastewater during its degradation process. This raises ecological concerns. In the realm of biological treatment, where organic filtration materials are frequently efficacious, the utilization of plastics prompts inquiries about sustainability and environmental impact. Whenever possible, giving preference to organic filtration materials over plastics is recommended due to their lower environmental risk.

4. Conclusions

The laboratory-tested biological filter bed technology presents several notable advantages. Its design is straightforward, requiring no specialized solutions. The absence of movement within the biological bed minimizes friction between bed elements, preventing the loss of plastic particles (ABS). Moreover, the optimal oxygen conditions within the bed create an ideal environment for the biological processes essential for wastewater pollutant removal. However, certain challenges accompany this laboratory-tested filter bed technology. During the preparatory stage, it is crucial to thoroughly rinse the bed to eliminate impurities such as plastic dust and residues from printer toner, especially black ABS, potentially originating from laser printers. Ensuring the even distribution of wastewater across the filtration bed’s surface to prevent hydraulic breakthroughs or the formation of preferential filtration pathways is another challenge. Periodic dosing of the bed is necessary, with a recommended minimum frequency of once per hour based on the assumed hydraulic load. The bed’s height is a minimum of 150 cm and divided into independent segments, numbering between 10 and 14. Each segment’s height is recommended to be no less than 11 cm and ought not exceed 20 cm. The hydraulic load should not exceed 50 dm3/m2 daily. The PUR foam must not react with the wastewater and must stay within typical wastewater values. Ensuring a uniform distribution of the wastewater load across the bed is crucial for optimal performance. We suggest implementing wastewater recirculation to improve treatment efficiency and protect the bed from exposure to low temperatures. The bed’s design, aimed at facilitating oxygen access from the air, is another essential consideration. The findings suggested considering placing the filter bed within a reinforced concrete tank buried in the ground for enhanced functionality. The research has demonstrated the importance of implementing robust safeguards to prevent the entry of hazardous gases into the bed tank, such as incorporating a siphon at the sedimentation tank inlet. In summary, the research has led to the selection of a recirculating dosed-bed technology that can also function as a biological filter, primarily due to the relatively small grain sizes of the filter media. It is worth emphasizing the significant reduction achieved in wastewater pollutant indicators such as BOD5, CODCr, and total suspended solids. Assessing the recyclability of plastics, including ABS, and exploring eco-friendly alternatives in biological treatment processes are crucial. A thorough evaluation of the environmental impact and risks tied to microplastic release informs responsible material choices for sustainable wastewater treatment practice.

Author Contributions

Conceptualization, K.C.; methodology, W.H.; software, D.B.; validation, Ł.B., M.K., M.S., T.P., I.B.P. and J.S.; formal analysis, A.M. and T.S.; investigation, D.B.; resources, T.S.; data curation, W.H.; writing—original draft preparation, W.H.; writing—review and editing, W.H. and D.B.; visualization, K.C.; supervision, Ł.B., M.K., M.S., T.P., I.B.P. and J.S.; project administration, K.C.; funding acquisition, K.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available on request due to restrictions.

Conflicts of Interest

Author Tomasz Sionkowski was employed by the company Grundfos Pompy Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The company Grundfos Pompy Ltd. in affiliation and funding] had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Qadir, M.; Drechsel, P.; Jiménez Cisneros, B.; Kim, Y.; Pramanik, A.; Mehta, P.; Olaniyan, O. Global and regional potential of wastewater as a water, nutrient and energy source. In Natural Resources Forum; Blackwell Publishing Ltd.: Oxford, UK, 2010; Volume 1, pp. 40–51. [Google Scholar]

- Mateo-Sagasta, J.; Raschid-Sally, L.; Thebo, A. Global Wastewater and Sludge Production, Treatment and Use. In Wastewater; Drechsel, P., Qadir, M., Wichelns, D., Eds.; Springer: Dordrecht, The Netherlands, 2015; pp. 15–38. [Google Scholar] [CrossRef]

- Adhikari, S.; Halden, R.U. Opportunities and limits of wastewater-based epidemiology for tracking global health and attainment of UN sustainable development goals. Environ. Int. 2022, 163, 107217. [Google Scholar] [CrossRef] [PubMed]

- Ighalo, J.O.; Omoarukhe, F.O.; Ojukwu, V.E.; Iwuozor, K.O.; Igwegbe, C.A. Cost of adsorbent preparation and usage in wastewater treatment: A review. Clean. Chem. Eng. 2022, 3, 100042. [Google Scholar] [CrossRef]

- Ghosh, S.; Malloum, A.; Igwegbe, C.A.; Ighalo, J.O.; Ahmadi, S.; Dehghani, M.H.; Othmani, A.; Gökkus, Ö.; Mubarak, N.M. New generation adsorbents for the removal of fluoride from water and wastewater: A review. J. Mol. Liq. 2022, 46, 118257. [Google Scholar] [CrossRef]

- Guven, H.; Ersahin, M.E.; Ozgun, H.; Ozturk, I.; Koyuncu, I. Energy and material refineries of future: Wastewater treatment plants. J. Environ. Manag. 2023, 329, 117130. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Sun, Y.; Shi, Y.; Wang, Z.; Okeke, S.; Yang, L.; Zhang, W.; Xiao, L. Structure evolution of air cathodes and their application in electrochemical sensor development and wastewater treatment. Sci. Total Environ. 2023, 869, 161689. [Google Scholar] [CrossRef] [PubMed]

- Rosemarin, A.S.; Macura, B.; Carolus, J.F.; Barquet, K.; Ek, F.; Järnberg, L.; Lorick, D.; Johannesdottir, S.; Pedersen, S.M.; Koskiaho, J.; et al. Circular nutrient solutions for agriculture and wastewater–a review of technologies and practices. Curr. Opin. Environ. Sustain. 2020, 45, 78–91. [Google Scholar] [CrossRef]

- Karić, N.; Maia, A.S.; Teodorović, A.; Atanasova, N.; Langergraber, G.; Crini, G.; Ribeiro, A.R.L.; Đolić, M. Bio-waste valorisation: Agricultural wastes as biosorbents for removal of (in) organic pollutants in wastewater treatment. Chem. Eng. J. Adv. 2022, 9, 100239. [Google Scholar] [CrossRef]

- Molinos-Senante, M.; Hernández-Sancho, F.; Sala-Garrido, R. Economic feasibility study for wastewater treatment: A cost–benefit analysis. Sci. Total Environ. 2010, 408, 4396–4402. [Google Scholar] [CrossRef]

- Soffian, M.S.; Halim, F.Z.A.; Aziz, F.; Rahman, M.A.; Amin, M.A.M.; Chee, D.N.A. Carbon-based material derived from biomass waste for wastewater treatment. Environ. Adv. 2022, 9, 100259. [Google Scholar] [CrossRef]

- García-Pérez, A.; Harrison, M.; Chivers, C.; Grant, B. Recycled shredded-tire chips used as support material in a constructed wetland treating high-strength wastewater from a bakery: Case study. Recycling 2015, 1, 3–13. [Google Scholar] [CrossRef]

- Santucci, V.; Fiore, S. Recovery of waste polyurethane from E-waste. Part II. Investigation of the adsorption potential for wastewater treatment. Materials 2021, 14, 7587. [Google Scholar] [CrossRef] [PubMed]

- Dorji, U.; Dorji, P.; Shon, H.; Badeti, U.; Dorji, C.; Wangmo, C.; Tijing, L.; Kandasamy, J.; Vigneswaran, S.; Chanan, A.; et al. On-site domestic wastewater treatment system using shredded waste plastic bottles as biofilter media: Pilot-scale study on effluent standards in Bhutan. Chemosphere 2022, 286, 131729. [Google Scholar] [CrossRef]

- Weltens, R.; Vanermen, G.; Tirez, K.; Robbens, J.; Deprez, K.; Michiels, L. Screening tests for hazard classification of complex waste materials–Selection of methods. Waste Manag. 2012, 32, 2208–2217. [Google Scholar] [CrossRef] [PubMed]

- O’Brien, J.W.; Grant, S.; Banks, A.P.; Bruno, R.; Carter, S.; Choi, P.M.; Covaci, A.; Crosbie, N.D.; Gartner, C.; Hall, W.; et al. A National Wastewater Monitoring Program for a better understanding of public health: A case study using the Australian Census. Environ. Int. 2019, 122, 400–411. [Google Scholar] [CrossRef]

- Dvořák, L.; Gómez, M.; Dolina, J.; Černín, A. Anaerobic membrane bioreactors—A mini review with emphasis on industrial wastewater treatment: Applications, limitations and perspectives. Desalination Water Treat. 2016, 57, 19062–19076. [Google Scholar] [CrossRef]

- Gedda, G.; Balakrishnan, K.; Devi, R.U.; Shah, K.J. Introduction to conventional wastewater treatment technologies: Limitations and recent advances. Mater. Res. Found 2021, 91, 1–36. [Google Scholar]

- Nasr, F.A.; Doma, H.S.; Abdel-Halim, H.S.; El-Shafai, S.A. Chemical industry wastewater treatment. Environmentalist 2007, 27, 275–286. [Google Scholar] [CrossRef]

- Oladipo, A.A.; Adeleye, O.J.; Oladipo, A.S.; Aleshinloye, A.O. Bio-derived MgO nanopowders for BOD and COD reduction from tannery wastewater. J. Water Process Eng. 2017, 16, 142–148. [Google Scholar] [CrossRef]

- Shao, Q.; Lu, M.; Zhou, J.; Zhu, Z.; Song, Y. Preparation of non-sintered fly ash filter (NSFF) for ammonia nitrogen adsorption. Environ. Technol. 2019, 40, 1988–1999. [Google Scholar] [CrossRef]

- Lu, N.; Chen, H.; Chen, J.; Cao, Y.-F. Ceramic Aggregate Material Formulated with MSWI Fly Ash and Fuel Ash for Use as Filter Media. Minerals 2023, 13, 845. [Google Scholar] [CrossRef]

- Lai, B.; Zhou, Y.; Yang, P. Treatment of wastewater from acrylonitrile–butadiene–styrene (ABS) resin manufacturing by Fe0/GAC–ABFB. Chem. Eng. J. 2012, 200, 10–17. [Google Scholar] [CrossRef]

- Kumar, A.; Prasad, B.; Sandhwar, V.K.; Garg, K.K. Mechanistic insight into heterogeneous Fenton-like catalysis with M-Al2O3/SiO2 (M = Fe, Co and Ni) for acrylonitrile mineralization from real ABS resin wastewater: Optimization and toxicity assessment. J. Environ. Chem. Eng. 2021, 9, 105177. [Google Scholar] [CrossRef]

- Chmielowski, K.; Halecki, W.; Bedla, D.; Dacewicz, E. Use of waste poly(acrylonitrile-co-butadiene-co-styrene) for wastewater treatment in a biological filter reactor. Przemysł Chem. 2022, 101, 109–111. (In Polish) [Google Scholar]

- Benhadji, A.; Ahmed, M.T.; Maachi, R. Electrocoagulation and effect of cathode materials on the removal of pollutants from tannery wastewater of Rouïba. Desalination 2011, 277, 128–134. [Google Scholar] [CrossRef]

- Młyński, D.; Młyńska, A.; Chmielowski, K.; Pawełek, J. Investigation of the Wastewater Treatment, Plant Processes Efficiency Using Statistical Tools. Sustainability 2020, 12, 10522. [Google Scholar] [CrossRef]

- Wei, G.; Wei, T.; Li, Z.; Wei, C.; Kong, Q.; Guan, X.; Qiu, G.; Hu, Y.; Wei, C.; Zhu, S.; et al. BOD/COD ratio as a probing index in the O/H/O process for coking wastewater treatment. Chem. Eng. J. 2023, 466, 143257. [Google Scholar] [CrossRef]

- Dacewicz, E.; Chmielowski, K. Application of multidimensional clustering for an assessment of pollutants removal from domestic wastewater using a filter with a plastic waste filling. J. Water Process Eng. 2019, 29, 100794. [Google Scholar] [CrossRef]

- Khelifi, E.; Gannoun, H.; Touhami, Y.; Bouallagui, H.; Hamdi, M. Aerobic decolourization of the indigo dye-containing textile wastewater using continuous combined bioreactors. J. Hazard. Mater. 2008, 152, 683–689. [Google Scholar] [CrossRef]

- Li, X.; Huang, Y.; Guo, Y.; Li, W.; Li, Y. Full-scale application and performance of a new multi-self-reflow decentralized Wastewater treatment device: Impact of hydraulic and pollutant loads. J. Environ. Sci. 2023, 131, 37–47. [Google Scholar] [CrossRef]

- Yu, W.-J.; Sun, J.; Zhang, W.-J.; Chen, Y.; Yang, J.-L.; Li, S.-P.; Zhu, G.-C.; Lu, Y.-Z. The Influence of Atmospheric Pressure and Organic Loading on the Sustainability of Simultaneous Nitrification and Denitrification. Sustainability 2023, 15, 15689. [Google Scholar] [CrossRef]

- Dereszewska, A.; Cytawa, S. Circular Economy in Wastewater Treatment Plants—Potential Opportunities for Biogenic Elements Recovery. Water 2023, 15, 3857. [Google Scholar] [CrossRef]

- Vilela, P.; Nam, K.; Yoo, C. Wastewater Treatment System Optimization for Sustainable Operation of the SHARON–Anammox Process under Varying Carbon/Nitrogen Loadings. Water 2023, 15, 4015. [Google Scholar] [CrossRef]

- Guerra-Rodríguez, S.; Oulego, P.; Rodríguez, E.; Singh, D.N.; Rodríguez-Chueca, J. Towards the Implementation of Circular Economy in the Wastewater Sector: Challenges and Opportunities. Water 2020, 12, 1431. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Islam, N.; Tasannum, N.; Mehjabin, A.; Momtahin, A.; Chowdhury, A.A.; Almomani, F.; Mofijur, M. Microplastic removal and management strategies for wastewater treatment plants. Chemosphere 2024, 347, 140648. [Google Scholar] [CrossRef] [PubMed]

- Hirbod, F.; Karimi, T.; Mohammadnazari, Z.; Rabbani, M.; Aghsami, A. Municipal solid waste management using multiple disposal location-arc routing and waste segregation approach: A real-life case study in England. J. Ind. Prod. Eng. 2024, 41, 81–100. [Google Scholar] [CrossRef]

- Liu, Z.; Nowack, B. Probabilistic material flow analysis and emissions modeling for five commodity plastics (PUR, ABS, PA, PC, and PMMA) as macroplastics and microplastics. Resour. Conserv. Recycl. 2022, 179, 106071. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).