Abstract

The annual increase in the world’s population significantly contributes to recent climate change and variability. Therefore, researchers, engineers, and professionals in all fields must integrate sustainability criteria into their decision-making. These criteria aim to minimize the environmental, social, economic, and energy impacts of human activities and industrial processes, helping mitigate climate change. This research focuses on developing scalable technology for the comprehensive use of avocados, adhering to sustainability principles. This work presents the modeling, simulation, and the WEP (Water-Energy-Product) technical evaluation of the process for obtaining bio-oil, chlorophyll, and biopesticide from the Creole-Antillean avocado. For this, the extractive-based biorefinery data related to water, energy, and products are taken from the material balance based on experimental results and process simulation. Then, eight process parameters are calculated, and eleven technical indicators are determined. Later, the extreme technical limitations for every indicator are demarcated, and an evaluation of the performance of the indicators is carried out. Results showed that the process has a high execution in aspects such as fractional water cost (TCF) and energy cost (TCE), as well as solvent reuse during extraction processes (SRI) and production yield, noting that the mentioned indicators are above 80%. In contrast, the metrics related to water management (FWC) and specific energy (ESI) showed the lowest performance. These discoveries support the use of optimization techniques like mass process integration. The energy-related indicators reveal that the process presents both benefits and drawbacks. One of the drawbacks is the energy source due to the high demand for electrical energy in the process, compared to natural gas. The specific energy intensity indicator (ESI) showed an intermediate performance (74%), indicating that the process consumes high energy. This indicator enables us to highlight that we can find energy aspects that require further study; for this reason, it is suitable to say that there is potential to enhance the energy efficiency of the process by applying energy integration methods.

1. Introduction

The increase in the world’s population each year is one of the main causes of the alterations and unexpected variability of the climate observed in recent years. Therefore, as researchers, engineers, and professionals in any area of study, it is essential to incorporate sustainability criteria into decision-making. Sustainability criteria are guidelines that minimize the environmental, social, economic, and energy impacts of human action and industrial production processes. These criteria help slow down the changes caused by climate change in which we are currently immersed. Through this research, we seek to develop a scalable technology for the comprehensive use of avocados under sustainability criteria.

In the department of Bolívar, avocado planting is concentrated in the “Montes de María” region, which is the main source of Creole-Antillean avocado (Laurus persea L.) in the country. Avocado consumption in Colombia reaches about 5.2 kg/person-year, ranking among the 10 most important consumer countries worldwide. However, a high percentage of the production of this fruit in the Montes de María deteriorates due to the vulnerability of the species to the effects of climate, limited production infrastructure that causes delays and deterioration of the fruit, and insufficient valorization alternatives. On the other hand, the consumption of its fruit generates about 30% of inedible by-products, corresponding to potentially usable peels and seeds, which are generally discarded as waste. Currently, there are no scalable technologies for the comprehensive use of the avocado fruit; for this reason, the present research aims to develop processing topologies for the sustainable use of the Creole-Antillean avocado grown in the Montes de María region through the valorization of its pulp, peel, and seed [1].

Given the complexity of engineering designs, technology has enabled simulation mechanisms that recreate reality to be able to analyze the behavior of certain phenomena under given conditions established by a computer, thus saving many resources in cases where the design is not available, and the behavior of the environment is unknown. Computer-aided process engineering (CAPE) refers to the management of the complications of systems that involve physical and chemical changes using computational tools and specialized software. The central competencies of CAPE are modeling, synthesis, design, control, problem-solving, and optimization, with their domains in products and manufacturing processes that involve molecular change, sustainability, business processes, biological systems, energy, and water. CAPE can be used at multiple scales, such as molecular, microscopic, pilot, and industrial scales, and it also serves to deal with the levels of uncertainty that arise during the development of emerging technologies. It is a multidisciplinary topic because, in addition to process engineering skills, it also requires knowledge of computer science, advanced mathematics, economics, and the environment, among others [2].

This article presents the modeling of the process for obtaining bio-oil, chlorophyll, and biopesticide from Creole-Antillean avocado under the concept of an extractive-based biorefinery, considering experimental data reported in the literature. Additionally, the simulation developed in the Aspen Plus® V14.0 software and the WEP (Water-Energy-Product) technical evaluation of the process in terms of water and energy consumption of the biorefinery for obtaining value-added products is presented. The reagents, water consumption, product flow, and raw materials (avocado seed, pulp, and peel) were obtained from the material balance. Later, eight process parameters are calculated from the process information related to energy, water, and products. With these parameters, eleven technical indicators are calculated that will allow the diagnosis of the process. Then, the upper and lower technical limits for each indicator are determined by the characteristics of the production development. Based on these limits, an evaluation of the indicators’ performance is carried out in percentage terms [3].

According to the above, the processes for obtaining bio-oil, chlorophyll, and biopesticide from the Creole-Antillean avocado are developed in an extractive-based biorefinery that presents three joint topologies, understanding biorefinery as a system that can integrate processes and equipment for biomass transformation for the production of fuels, energy, and chemical products [4]. In this sense, the first part of this extractive-based biorefinery is the topology for extracting avocado bio-oil, which is carried out from avocado pulp, using methanol as a solvent in the extraction stage [5]. Subsequently, the second topology consists of the process of obtaining chlorophyll from the avocado peel, using acetone as a solvent in the extraction section [6]. Finally, the third topology consists of the components of the avocado seed, using ethanol as an extractive solvent to obtain a biopesticide [7].

Based on the above, it is pertinent to discuss the novelty of the present work compared to the existing literature on avocado biorefineries. Table 1 presents a review of existing studies to establish the current state of knowledge, considering whether avocado biorefineries present a simulation with publicly available information and the development of a technical sustainability assessment relevant to this article, the latter being the research novelty that characterizes the present study. In fact, for the first time, simulation and WEP technical assessment are combined to determine the avocado biorefinery’s technical performance and detect improvement opportunities.

Table 1.

Comparison of studies based on process simulations performed for refining and petrochemical sector processes.

2. Materials and Methods

2.1. Processing Capacity

To determine the production capacity, it was considered that avocado production in the Montes de María area is 35,000 tons per year [11]. Based on this quantity, it was assumed that approximately 30% of this amount would be destined for the extractive-based biorefinery to be modeled. This 30% corresponds to the number of avocados that, for various reasons, would not reach their final use in the life cycle, which makes them suitable for use under the biorefinery concept (see Table 2).

Table 2.

Normalized composition of the Creole-Antillean avocado.

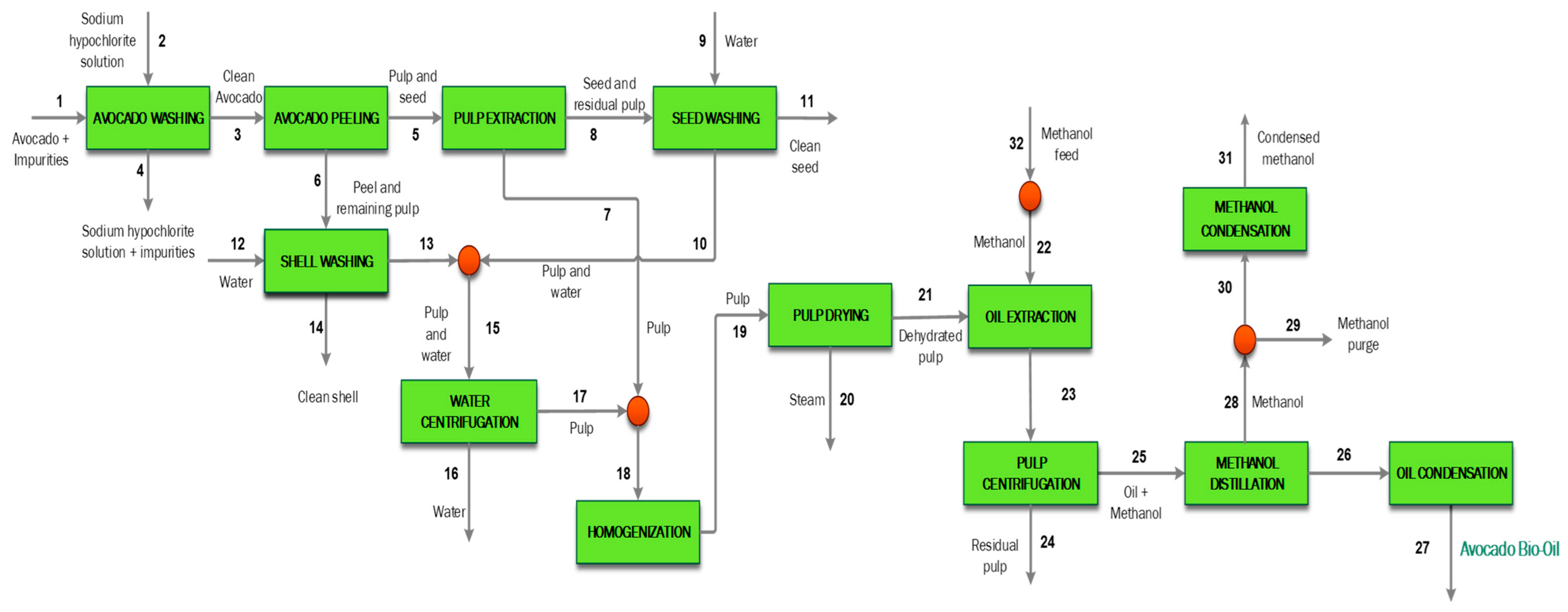

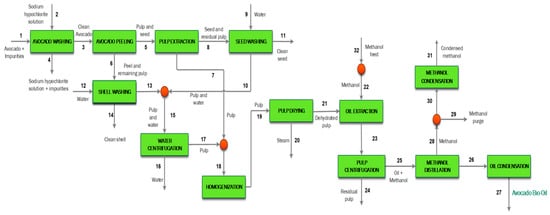

Figure 1 shows the process of obtaining bio-oil from Antillean avocado by solvent extraction. The process begins with washing the avocado (stream 1) with a sodium hypochlorite solution (stream 2) to eliminate contaminants present in the fruit. The peel is then separated (stream 6) and sent to a washing stage to remove the remaining pulp. In the pulping stage (pulp extraction), the pulp is separated from the seed, obtaining streams 7 and 8, respectively. Like the peel, the seed is sent to a washing stage to remove any pulp that may have remained on it. Washing the peel and seed produces a water-pulp mixture (streams 10 and 13), which is centrifuged to separate the pulp (stream 17) and the water (stream 16).

Figure 1.

Block diagram of the extraction process of Creole-Antillean avocado bio-oil produced in the Montes de María.

2.2. Modeling of the Bio-Oil Production Section from Creole-Antillean Avocado Pulp

Streams 7 and 17 are sent to the homogenization stage, forming a paste that is subsequently dried at 70 °C, removing the moisture present in it. Drying is carried out at this temperature to avoid degrading the biomass. The dehydrated pulp is put in contact with methanol in the extraction stage, which occurs at a temperature of 70 °C [5]. The stream resulting from the solvent extraction is made up of methanol, bio-oil, and pulp (stream 23). This is centrifuged to separate the solid from the liquid part, obtaining a defatted pulp (stream 24) and a bio-oil-solvent mixture (stream 25). Taking advantage of the difference in boiling points, methanol is distilled at 70 °C (stream 28) and subsequently condensed, in turn obtaining Antillean avocado bio-oil through stream 27. From the processing of 10,644 t/year of avocado, 1457.25 t/year of bio-oil is obtained by using Antillean avocado pulp and methanol as a solvent for extraction.

Table 3 and Table 4 show the modeling of the Creole-Antillean avocado bio-oil production process from the pulp of this fruit, where the mass balance is indicated with the pressure and temperature conditions of the mass streams and flows. Table 5 shows the energy consumption in MJ/h of the equipment used to obtain bio-oil from Antillean avocado.

Table 3.

Material balance of the bio-oil extraction process from Creole-Antillean avocado pulp.

Table 4.

Material balance of the bio-oil extraction process from Creole-Antillean avocado pulp (Continuation).

Table 5.

Energy requirements by stages for the bio-oil extraction process from Antillean avocado pulp.

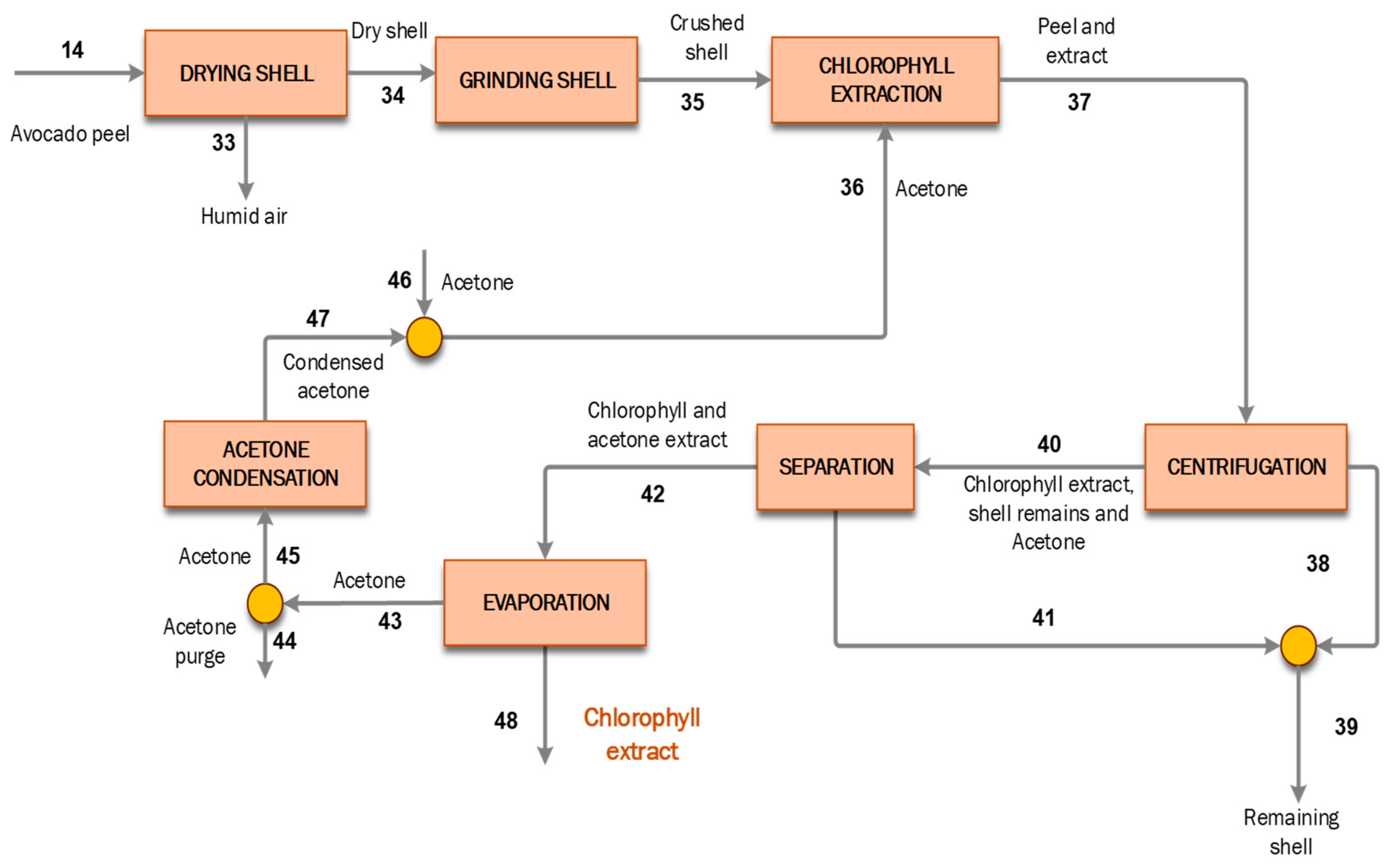

2.3. Modeling of the Chlorophyll Production Section from the Peel of the Creole-Antillean Avocado

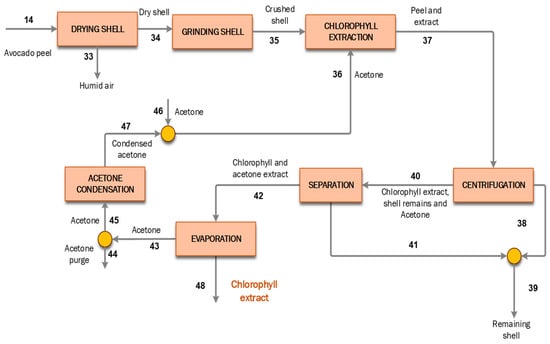

Figure 2 shows the process of obtaining chlorophyll from the peel of the Antillean avocado by solvent extraction. Initially, the excess moisture from the clean peel, coming from stream 14 (Figure 1), is removed by drying at 50 °C with an additional stream of air [6]. Subsequently, the dried peel (stream 34) is reduced in size by grinding and then placed in contact with the solvent (acetone), which is fed to the process in stream 46. Then, to separate the solids from the acetone extract, the mixture is centrifuged, where the remaining peel (stream 39) and a mixture of chlorophyll and solvent (stream 42) are obtained. The solvent and the chlorophyll extract are separated by evaporation at 40 °C, obtaining acetone (stream 43), which is recirculated to the process after purification, and stream 48, which contains a chlorophyll-rich extract.

Figure 2.

Block diagram of the chlorophyll extraction process from the peel of Creole-Antillean avocado produced in the Montes de María.

Table 6 and Table 7 show the modeling of the chlorophyll production process from the peel of Creole-Antillean avocado, where the mass balance with the pressure and temperature conditions of the streams and mass flows are indicated. Table 8 shows the energy consumption in MJ/h of the equipment used to obtain chlorophyll from the peel of the Creole-Antillean avocado.

Table 6.

Material balance of the chlorophyll extraction process from Creole-Antillean avocado peel.

Table 7.

Material balance of the chlorophyll extraction process from Creole-Antillean avocado peel (continued).

Table 8.

Energy requirements by stages for the process of extracting chlorophyll from the peel of the Creole-Antillean avocado.

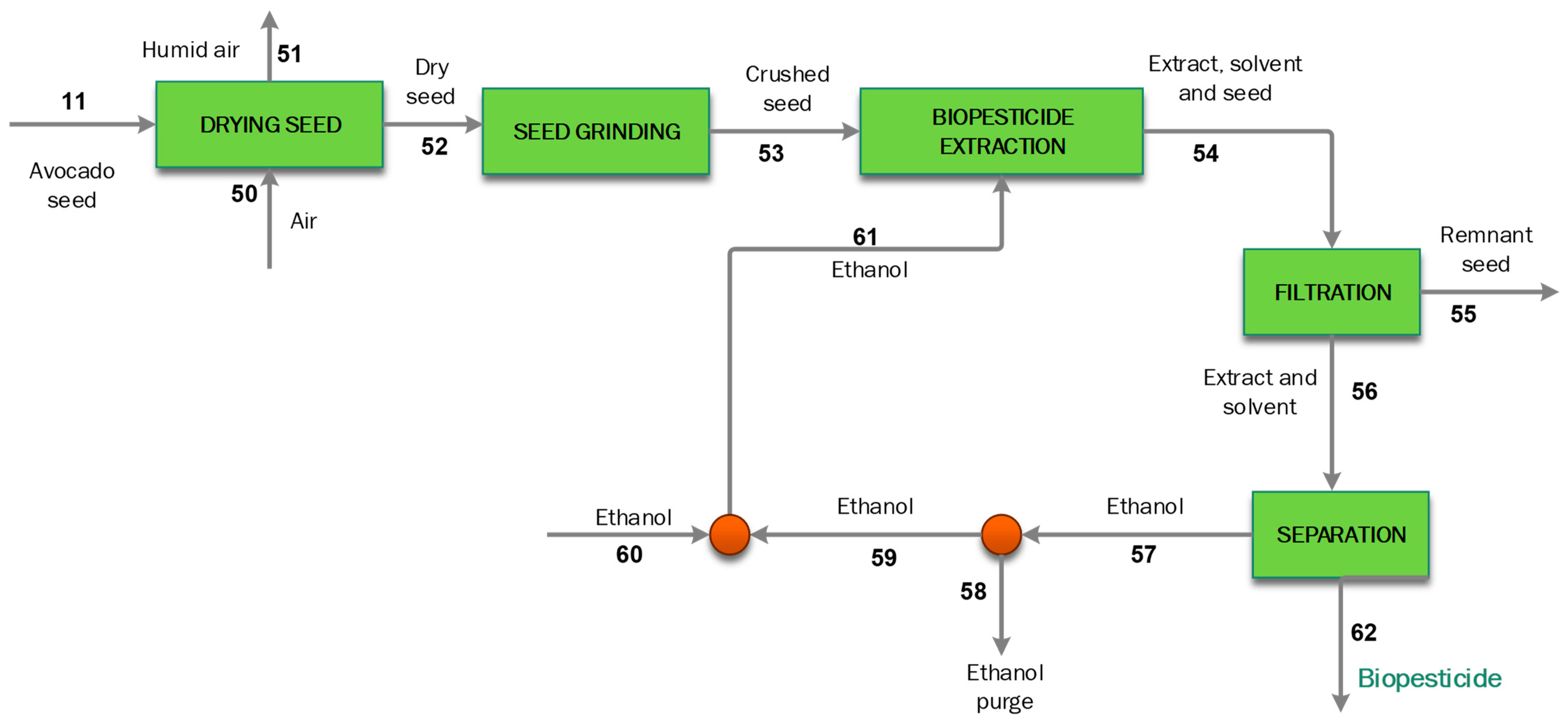

2.4. Modeling the Biopesticide Production Stage from the Creole-Antillean Avocado Seed

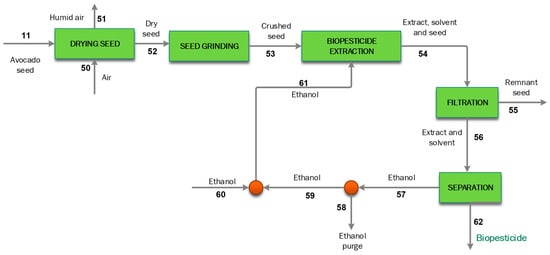

Figure 3 shows the block diagram of the biopesticide extraction from the Creole-Antillean avocado seed. The seed separated from the pulp and peel (stream 49) enters a dryer to reduce its moisture content with a stream of hot air at 70 °C. Size reduction is then performed to improve contact between the solvent and the material and facilitate extraction. Subsequently, the biopesticide is extracted from the crushed seed (stream 53) with a solvent (ethanol, 90% v) in a 1:2 seed: ethanol ratio [7] to separate the compounds with pest control properties. Then, a separation process is carried out to concentrate and purify the extract obtained at 81 °C and 1 atm, taking into account the difference in the boiling points of ethanol (78.4 °C) and water (100 °C). Finally, the extract is obtained on a dry basis with biopesticide potential (stream 62).

Figure 3.

Block diagram of the biopesticide extraction process from the Creole-Antillean avocado seed produced in Montes de María.

Table 9 shows the modeling of the Creole-Antillean avocado biopesticide production process from the seeds of this fruit, where the mass balance with the pressure and temperature conditions of the streams and mass flows are indicated.

Table 9.

Material balance of the biopesticide production process from Creole-Antillean avocado seeds.

Table 10 shows the energy consumption in MJ/h of the equipment used in the process of obtaining biopesticide from Creole-Antillean avocado seeds.

Table 10.

Energy requirements by stage for the biopesticide synthesis process from Creole-Antillean avocado seeds.

2.5. Computer-Aided Process Simulation (CAPE)

To model the process, information was provided to the Aspen Plus® simulator. Initially, a thermodynamic model was selected. For this process, NRTL-RK was established; that is, for the liquid phase, NRTL (Non-Random Two Liquid) was chosen, a local composition model useful in this case because of the presence of non-electrolytic polar substances, and for the vapor phase, the Redlich-Kwong equation of state. From this, the stages for the processing of pulp, peel, and seed were established, along with the operating conditions (T and P), and mass and energy balances.

The first step in modeling this process was to determine the production capacity. To determine the production capacity, it was assumed that the production capacity of the Creole-Antillean avocado in the Montes de María area is 35,000 tons per year [11]. Persea americana, commonly called the avocado tree or palto, is a tree of the Lauraceae family and cultivated in a large number of countries for its fruit, the Creole-Antillean avocado. This fruit is fleshy with a single seed consisting of an epicarp (peel), mesocarp (pulp), and endocarp (seed), the size, shape, and characteristics of which depend on the genotype. Taking the above into account, based on bibliographic information [12], the proportions of pulp, peel, and seed that would enter the process were established (Table 2).

Additionally, the raw materials (avocado pulp, seed, and peel) were declared in the Aspen Plus® simulator as solid mixtures of components from the software database, as shown in Table 11. The seed is simulated as a solid mixture containing leucine, glucose, calcium oxide, oleic acid, tannins, flavonoids, and phenols; the peel is simulated as a solid mixture composed of leucine, glucose, calcium oxide, and oleic acid; and the pulp is simulated as a solid mixture with a higher proportion of palmitic acid, oleic acid, and glucose [8].

Table 11.

Raw Material Declaration in Aspen Plus® Simulator.

2.6. Water-Energy-Product (WEP) Technical Evaluation of the Process

The first stage of the technical assessment of the process of obtaining value-added products from the use of the peel, seed, and pulp of the Creole-Antillean avocado is based on the material balance, preliminary economic data for water and energy, and the characteristics of the chemical species within the process. Eight process parameters are calculated from the information associated with water, energy, and also product, which constitute the second stage. The parameters related to the products are the product flow rate, waste flow rate, and residual raw material flow rate. The parameter related to water is the wastewater flow rate, and the parameters related to energy are energy flow, natural gas consumption, energy consumption, and electricity consumption.

In this context, using the eight parameters mentioned earlier, eleven technical indicators are computed during the third stage to assess the process. Of these, two are associated with the product (generation yield and unreacted material reuse rate), three pertain to water usage (fractional water use, total freshwater generation cost, and wastewater generation ratio), and six focus on energy (total energy cost, specific energy intensity, net energy ratio, energy utilization rate, natural gas consumption rate, and electrical energy usage rate). In the fourth stage, the maximum and minimum technical limits were set for every indicator according to the production process characteristics. According to these thresholds, the performance of each indicator was evaluated as a percentage.

The technical evaluation of the processes consisted of the quantification of indices for describing the performance of the processes in aspects such as the use of material, energy, energy, and water charges. These indices are calculated from the information provided by the simulation, such as the material and energy flows of the process. These indices also allow for the establishment of assessments that serve as references for more detailed process engineering studies (benchmarking purposes). [13]. Table 12 details the indicators used, the equations used for their calculation, and their descriptions [3].

Table 12.

Description of the technical indicators of the process.

2.7. Efficiency of the WEP Technical Assessment Indicators

The previously analyzed indicators are compared to provide an initial assessment of how the process aligns with the defined objectives, as shown by the values in Table 13. This analysis is conducted by normalizing the technical indicators against the reference parameters (best and worst-case scenarios).

Table 13.

Reference values of the technical indicators.

Moreover, the energy utilization index (EUI) was introduced as a reference for evaluating the product’s energy capacity when used as fuel, considering its primary intended purpose.

3. Results and Discussion

3.1. Modeling and Computer-Aided Process Simulation (CAPE)

3.1.1. Simulation of the Bio-Oil Extraction Section from the Pulp of Creole-Antillean Avocado

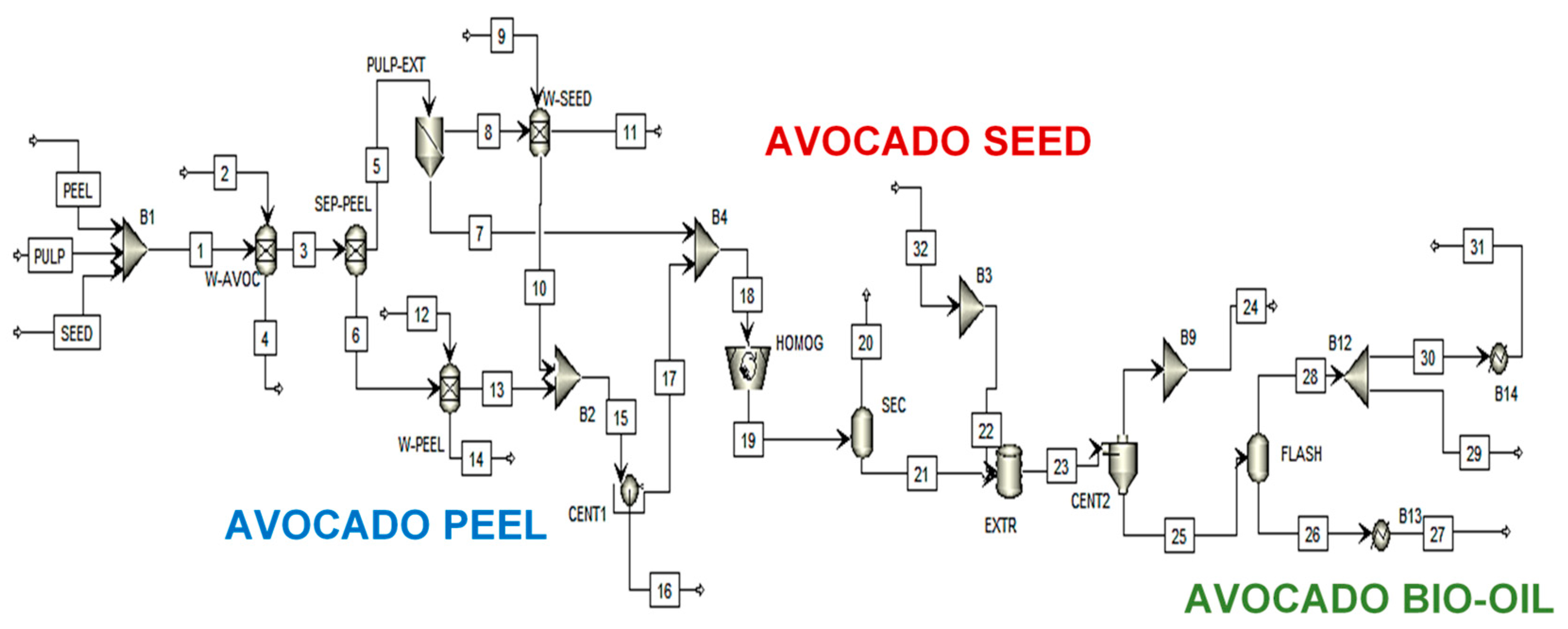

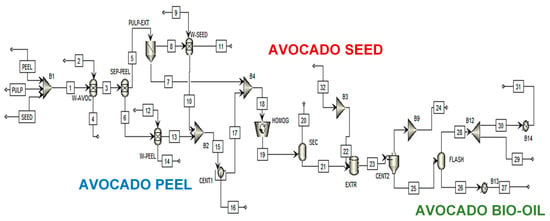

The modeled process is shown in Figure 4. Initially, 10,644 t/year of ripe Creole-Antillean avocados are fed, including pulp, peel, and seed (stream 1). The avocado enters the washing stage (W-AVOC) with sodium hypochlorite solution (stream 2). The first part of this extractive-based biorefinery is the avocado bio-oil extraction topology. The Creole-Antillean avocado bio-oil is extracted from its pulp. Therefore, the pulp conditioning stage is carried out, where the avocado peel is initially removed (SEP-PEEL), which exits through stream 6, and the pulping process is carried out to separate the pulp (stream 7) and the seed (stream 8).

Figure 4.

Simulation of the bio-oil production process from the pulp of Creole-Antillean avocado using Aspen Plus® software.

The peel and seed are washed again to recover part of the pulp that remained attached to them during the peeling and pulping processes, obtaining streams 13 and 10, respectively, as part of the recovered pulp and water. These mixed streams undergo a centrifugation process (CENT1) to remove excess water, and the resulting stream 17 joins stream 7, where the initially separated pulp enters. The bio-oil production process continues from stream 18. This stream containing the pulp is taken to a homogenization stage (HOMOG) to achieve a homogeneous consistency of the mass, characterized by a creamy texture. The mass formed is dried at 70 °C to eliminate the excess water present (stream 20) [5].

The next step is the bio-oil extraction stage. There are several oil extraction methods available. For this study, the extraction process was carried out based on the Soxhlet method, where the already dehydrated pulp is put in contact with an organic solvent (EXTR), in this case, methanol, due to its high solubility and easy recovery compared to other solvents, at a temperature of 70 °C. From this stage, a mixture of bio-oil, pulp, and solvent is obtained (stream 23). This stream goes to the centrifugation stage, from which a residual pulp is obtained that finally exits through stream 24, and a bio-oil-solvent mixture that exits through stream 25. This last stream containing the product of interest (bio-oil) is sent to a flash distillation process (FLASH) at 70 °C to separate the bio-oil from methanol. Finally, 910,387 t/year of Creole-Antillean avocado bio-oil is obtained and exited through stream 27.

The extraction yield obtained through the Soxhlet method using methanol as the solvent was 56.2% Creole-Antillean avocado oil on a dry basis. This value is compared with the conversion percentage reported by Reddy et al. (2012), in which a conversion yield of 64.76% of avocado oil on a dry basis was achieved by solvent extraction through the Soxhlet method at 69 °C and atmospheric pressure. This shows an approximation of 86.78% between the two values [14]. To validate the simulation, Table 14 shows a comparison of some properties of the bio-oil obtained, in addition to the yield, with the properties of similar processes previously modeled.

Table 14.

Validation of the properties of Creole-Antillean avocado bio-oil.

The higher calorific value, HHV, is an important property in oils since it indicates how much heat a gram of a certain compound releases when burned [16]. The HHV of Creole-Antillean avocado oil was calculated using equation 1, where d represents the density [17]. The higher calorific value of avocado oil has not been reported in the literature; for this reason, it was compared with castor oil, which is used in the cosmetics industry.

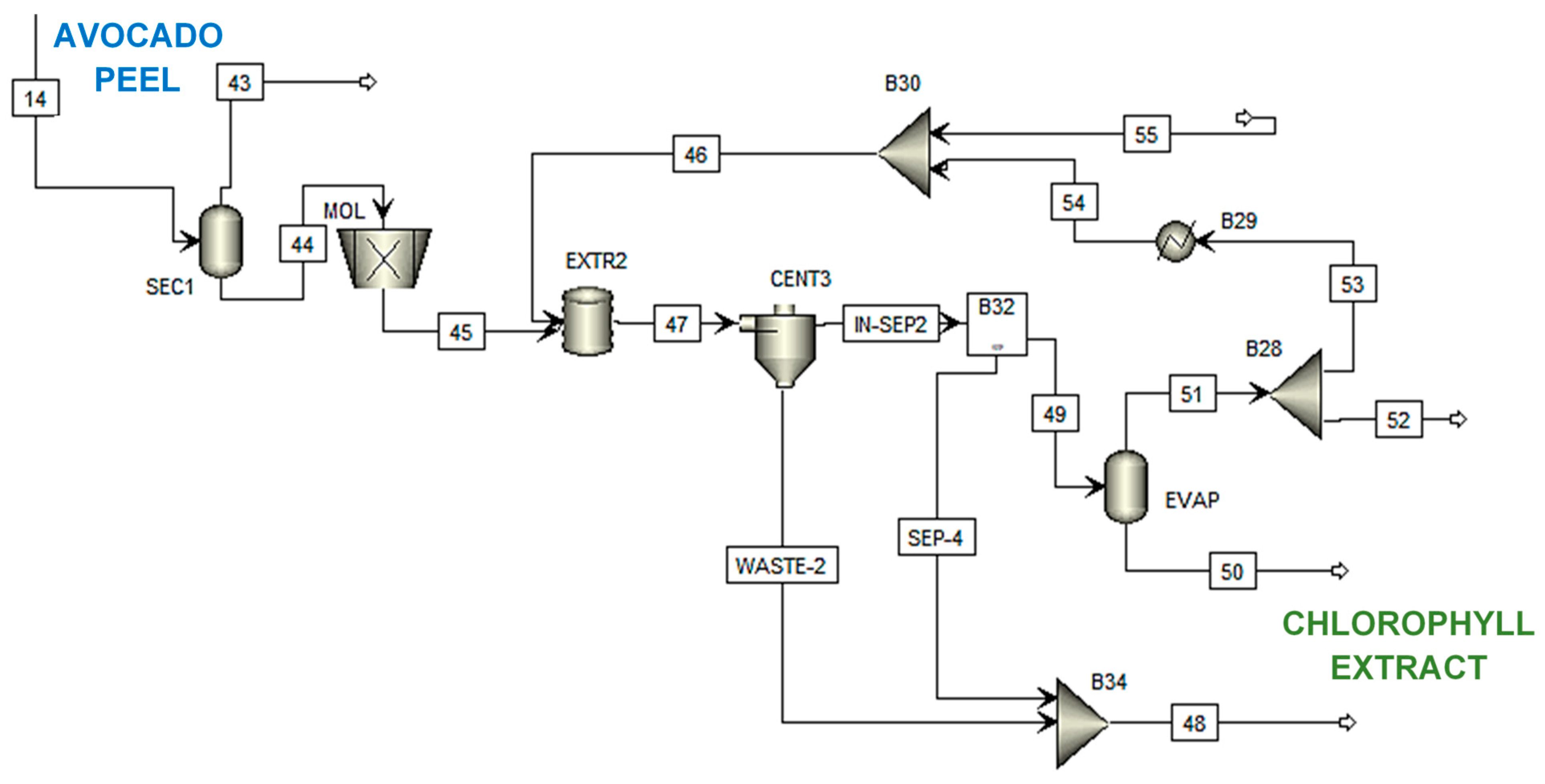

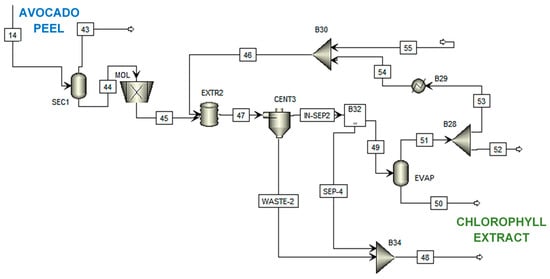

3.1.2. Simulation of the Section for Obtaining Chlorophyll from the Peel of the Creole-Antillean Avocado

Based on the previous model, avocado waste continues to be used. Initially, the assembly process for obtaining an extract rich in chlorophyll from the peel of the Creole-Antillean avocado is carried out (see Figure 5). Chlorophyll is responsible for the green color of most plants. Owing to its particular characteristics, chlorophyll is of interest in some industries, for example, in the cosmetics industry as a pigment, in the pharmaceutical industry for its medicinal properties, or even in the food industry for its antibacterial and energizing properties.

Figure 5.

Simulation of the section for obtaining chlorophyll from Creole-Antillean avocado peel in the Aspen Plus® software.

Initially, the washed peel that enters through stream 14 is dried at 60 °C with an additional stream of air [6] to reduce the moisture content, and subsequently, it goes to a grinding stage (MOL) to reduce its size and facilitate the extraction process. To obtain the chlorophyll extract, the crushed shell (stream 45) is placed in contact with the solvent (EXTR2), which in this case is acetone (stream 46). This mixture enters a centrifugation stage from which two streams are obtained: on the one hand, the remaining shell, which can be used for different purposes, for example, as fertilizer (stream 48) and, on the other hand, a mixture of chlorophyll extract and solvent (stream 49). The separation of the chlorophyll extract and the solvent is carried out through evaporation (EVAP). From this stage, two streams are obtained: stream 51, with a solvent that goes to a recovery stage to be purged, condensed, and recirculated to the process, and stream 50, where 30.81 t/year of a chlorophyll-rich extract is obtained.

Simulation of the section for obtaining chlorophyll from the peel of the Creole-Antillean avocado to validate the topology of obtaining this extract. The article by García et al. is used as a reference, where chlorophyll is obtained from aloe vera peel . The yield of chlorophyll obtained from the Antillean avocado peel was 2.54% with ethanol, while that obtained by García et al. (2021) was 2.90% with hexane. An approximate percentage of 87.58% was obtained [18].

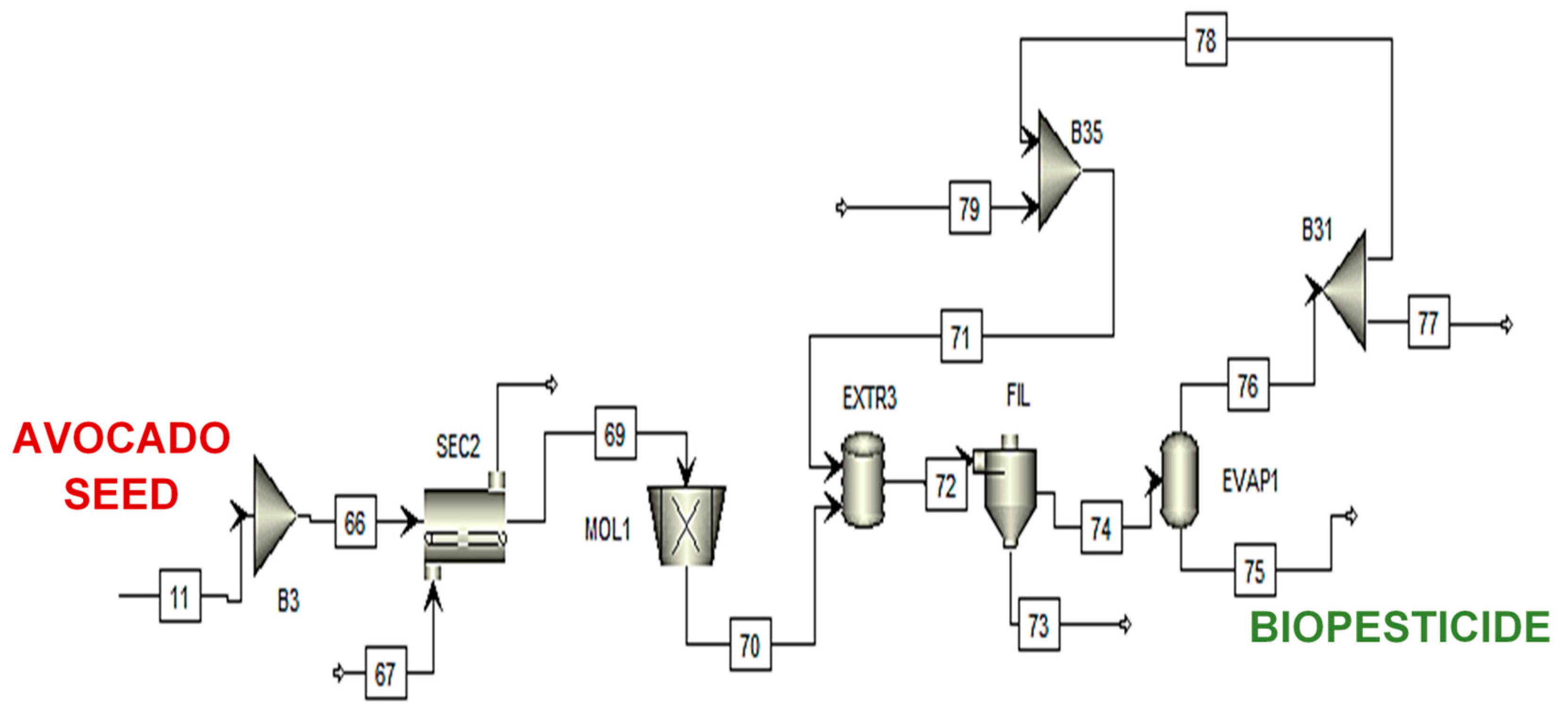

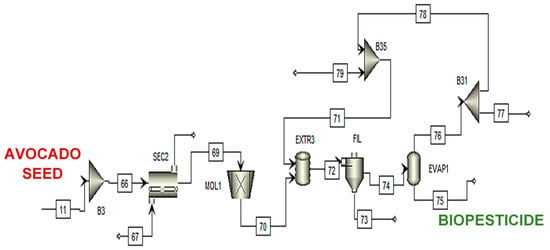

3.1.3. Simulation of the Biopesticide Extraction Section from the Creole-Antillean Avocado Seed

The main components of the Creole-Antillean avocado seeds are proteins, sugar, starch, fat, and water (see Table 15). The bioactive compounds found in avocados include phenolics, flavonoids, carotenoids, vitamin E, and vitamin C [7]. Avocado seeds contain high amounts of tannins [19]. Tannins are not a particular type of compound; they are a whole family of phenolic biomolecules that are naturally produced by plants as a defense mechanism against insects that feed on them [20]. The presence of phenolic compounds in the avocado seed, which are mainly responsible for the inhibition of fungi and bacteria [21], makes it attractive for its high potential when developing new products that take advantage of this insecticidal property and at the same time are more friendly to the environment and human health, taking into account that conventional pesticides are related to many causes of diseases in humans today [22].

Table 15.

Approximate composition of the Creole-Antillean avocado seed [23].

The third section of the extractive-based biorefinery (see Figure 6) of this work consists of the use of the components of the Creole-Antillean avocado seed (usually considered an agro-industrial waste) to obtain a natural pesticide. The process begins in stream 66, where the seed, which is already separated from the peel and pulp, enters a drying stage (SEC2) to reduce its moisture content. Subsequently, the seed is crushed to facilitate extraction. The already crushed seed (stream 70) enters the extraction stage (EXTR3), where the solvent extraction method is implemented to separate the bioactive compounds of interest from the avocado seed. This process is carried out using 90% ethanol as the extraction solvent in a 1:2 solid-to-solvent ratio [7].

Figure 6.

Simulation of the biopesticide production section from Creole-Antillean avocado seed in the Aspen Plus® software.

The extract is filtered and concentrated through a fractional distillation process at 81 °C, taking advantage of the difference in the boiling points of ethanol (78.4 °C) and water (100 °C) at atmospheric pressure. At approximately 80 °C, this alcohol evaporates, and it is possible to obtain, as a result, even a mixture of 95% ethanol and 5% water, representing the purest form of distillation after the distillation process, which are values accepted as standard in the industry. Finally, approximately 1229.303 t/year of the extract on a dry basis with biopesticidal potential are obtained by stream 75, obtaining an approximate yield of 61.63%.

It is worth clarifying that there is very little bibliographic information that could be found on the use of the Creole-Antillean avocado seed focused on obtaining an extract with insecticidal properties. However, pesticides currently used for pest control in crops are related to problems in human health [24] and damage to the environment due to the persistence of many pesticide compounds [25]. Therefore, it is necessary to explore green alternatives that reduce the risks to human health and the environment; among these, the use of avocado seed in the development of biopesticides has been proposed owing to its composition and characteristics [19]. Regarding its composition, avocado seed constitutes some bioactive compounds that have biocidal activity against bacteria, fungi, and some insects, which has allowed the potential of avocado seed extracts to be considered as a biopesticide. Most compounds with biocidal activity are found in lipid fractions, which has led to the belief that the compounds responsible for these properties are of a moderately polar or apolar nature [26].

To validate this topology, an analysis of some articles with certain similarities was carried out. For example, in a study carried out by Gidigbi et al. (2019), they obtained an extract with oil properties from avocado seeds, obtaining a bio-oil conversion yield of 18% [27]. In a study called “Qualitative and Quantitative Analysis of the Chemical Content of Hexane, Acetone, Ethanol and Aqueous Extract of Avocado Seeds” [28], it was experimentally confirmed that ethanolic extracts of avocado seeds contain phenols, tannins, flavonoids, and alkaloids, unlike the hexane extract of avocado seeds, which is richer in fatty acids. This supports the use of ethanol as an extractive solvent for seeds in this project. Finally, in the present project, 1.82%, 0.142%, and 0.687% of the total tannin, flavonoid, and phenol contents were obtained, respectively. Meanwhile, Rivai et al. obtained 0.2044%, 0.1084%, and 0.0309% using the same solvent (ethanol) [28].

3.2. WEP Technical Evaluation of the Process

3.2.1. WEP Technical Evaluation Parameters

Table 16 shows the Water-Energy-Products (WEP) criteria employed in the technical analysis of the process. This involves considering the input streams of raw materials, such as avocado, and other substances used throughout the different stages of the process, including water, ethanol, air, or water used in the extraction and separation operations of the desired products. These streams impact just how the process can manage fundamental resources. Additionally, the quantity of generated material helps determine the efficiency of the process in utilizing energy or raw materials for production. In this analysis, Creole-Antillean avocado was regarded as the sole raw material since it is the sole component that experiences a chemical transformation, in contrast to water, which serves merely as a mass and heat conveyor.

Table 16.

Process parameters related to the use of WEP in the Creole-Antillean avocado extractive-based biorefinery.

According to Table 16, the main raw material of the process is avocado, including the seed, peel, and pulp, and 1101.56 kg/h is required to reach a production of 176,764 kg/h, including bio-oil, chlorophyll, and biopesticide. Regarding the management of industrial resources, such as water, the biorefinery is supplied with 105,865 m3/h of water, of which 3128 m3/h ends up as wastewater generated in the process. Finally, concerning energy consumption, this process operates with electricity and natural gas, reaching a total energy consumption of 2539.108 MJ/h, including cooling and heating sections.

3.2.2. WEP Technical Evaluation Indicators

Table 17 shows a summary of the WEP technical indicators obtained for the Creole-Antillean avocado extractive-based biorefinery to obtain bio-oil, chlorophyll, and biopesticide. The utilization of raw materials was described by evaluating the process yield and the recycled material index.

Table 17.

Results of the technical evaluation of the Creole-Antillean avocado extractive-based biorefinery.

The production yield obtained is 21.15%, which is mainly due to the high yield in the use of the pretreated peel and pulp. This yield is higher than that reported by Dávila et al. (2017) of 14.01% for an avocado biorefinery to obtain bio-oil, sugars, microencapsulated phenolic extracts, xylitol, and ethanol, with cogeneration of energy [29]. Similar yields for a large-scale biorefinery of Creole-Antillean avocado obtained a yield of approximately 10% for avocado oil [30].

The global energy balance of the extractive-based biorefinery was carried out to calculate the net energy profit of the system. The caloric content of the biomass and oils was considered in the calculation of energy inputs. The public services were estimated by simulating the process. Energy production includes all three products considered in the process. The Lower Heating Value (HHV) of the biopesticide and chlorophyll was provided by Aspen Plus®, and the HHV of the bio-oil was measured experimentally. The net energy ratio (NER) was calculated as the ratio of the net energy output to net energy input. An NER value > 1 indicates that the fuel system has a net energy gain, i.e., the energy provided to the process is lower than the energy obtained from the products [31]. The energy utilization index (EUI) was approximately 2.6, which indicates that the products can potentially be used as fuel due to their high energy content. This can be attributed to the energy value of the biomass and its potential to produce fuels, as well as the high HHV value obtained for the oil.

The total energy cost was estimated by summing the energy requirements of each stage (see Table 5, Table 8 and Table 10), obtaining a total of 57,803.177 MBTU/day, and multiplying that amount by 10 USD/MBTU. To determine the natural gas consumption rate, it was initially established how many cubic meters (m3) of natural gas could be consumed by the equipment that runs on this fuel in the process (distillers in bio-oil production and the biopesticide and evaporator in chlorophyll extraction), taking into account the transferred heat required for their operation. Taking the above into account, a calorific value for natural gas of 38 MJ/m3 was considered, and the quantity of natural gas was determined using Equation (2).

The specific energy intensity in biorefineries refers to the amount of energy required to transform biomass into value-added products. The specific energy intensity (ESI) index was 9287.515 MJ per ton, indicating that the process has a high energy demand for the production of the biopesticide, bio-oil, and chlorophyll extraction, but it is much lower than the process reported by Paraskevopoulou et al. (2022) in their study of a biorefinery for the production of oil and energy from peach seeds with a processing capacity of 10,000 tons per year, where they reported a value of 22,000 MJ per ton. This difference can be explained by the fact that energy recovery from peach seeds is achieved by biomass combustion, which represents a considerably high contribution to the total energy used during the process [32]. Ortiz-Sanchez et al. (2023) reported an ESI of 131 and 412 kJ/t in two biorefinery topologies from organic kitchen waste, finding that the high energy consumption in the second case is attributed to the extensive number of operations required to produce the desired product, including lactic acid production, lactic acid recovery, lactide production, PLA production, and recovery. Additionally, the PLA production process demands significant energy due to several vacuum operations. In contrast, the first process exhibited lower specific energy consumption as it involved fewer unit operations compared to the second biorefinery [33].

The indicators are measured based on the consumption of natural gas and electricity per ton of product, reflecting the amount of each energy source utilized in the process. Specifically, the process consumes 53.62 m³ of natural gas and 5605 kWh of electricity per ton of product, which means that the process uses higher amounts of energy from the electrical grid compared to gas since it is mainly used in equipment such as dryers and condensers. Because of this, the indicator of electrical energy consumption is much higher than that of gas. The TFC was USD 10,731.74 per year, considering the freshwater used as a compound during the stages of the process.

Additionally, the upper and lower limits of some technical indicators of the WEP assessment for the Creole-Antillean avocado biorefinery were obtained from standards or benchmarks of existing industrial processes, such as the optimistic cases of the FWC (0.5 m3 of water per ton of product) and TCE (10 USD per MMBTU of natural gas) indicators, which were determined taking as a reference the PVC production process by suspension, due to both processes being on an industrial scale [3]. However, other indicators, such as TCF and ESI, cannot be compared with the standards or benchmarks of existing industrial processes because the simulated process is emerging.

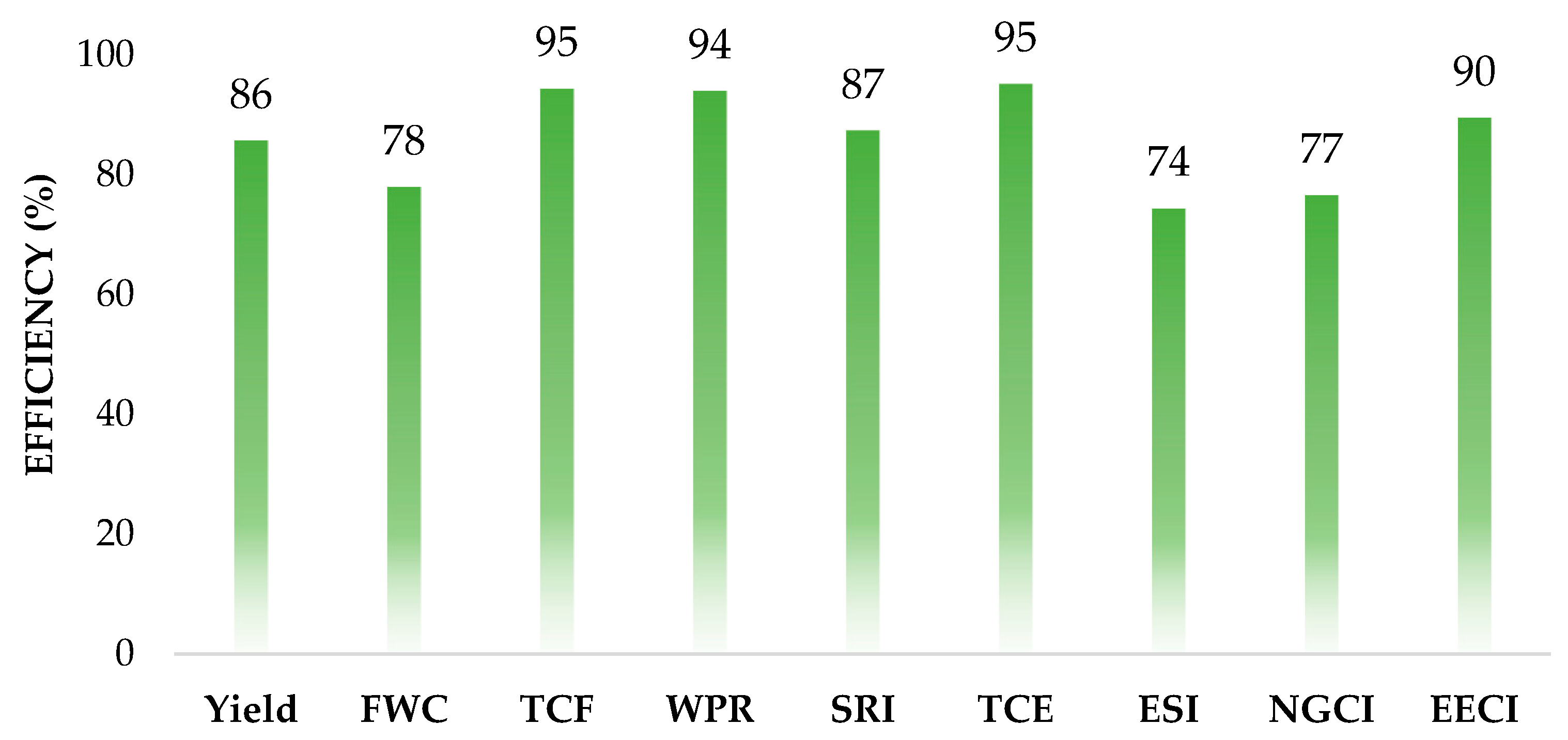

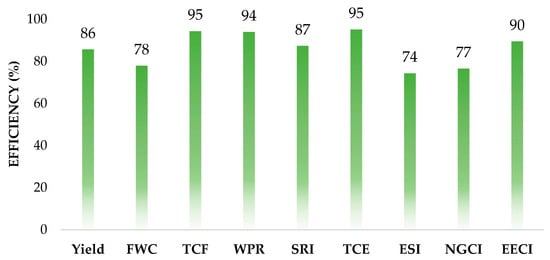

3.2.3. Performance of the WEP Technical Assessment Indicators

Figure 7 demonstrates the efficiency of the nine metrics assessed for the production process of bio-oil, biopesticides, and chlorophyll from the Creole-Antillean avocado under varying conditions; the NER and EUI metrics were excluded from the analysis. This is because, given their nature and calculation methods, they do not offer varying values that can be normalized into percentages. Thus, they did not contribute to the evaluation. The remaining data allow for an assessment of the process’s efficiency regarding energy, mass, and output. Furthermore, it is possible to identify areas that could benefit from process optimization techniques.

Figure 7.

Performance of nine of the indicators evaluated for the production process of bio-oil, biopesticide, and chlorophyll from avocado.

According to the above, the process has high execution in certain aspects, including fractional water and energy costs, as well as solvent reuse during the extraction processes, highlighting that the previous indicators are over 75%. This indicates that the process does not need substantial developments in raw material management. However, the indicators associated with water management and specific energy showed the lowest performance. These discoveries support the application of optimization techniques or methodologies, for example, mass integration of processes, to improve the characteristics of the process, recognizing the significance of water resource demands that these processes be utilized wisely and sustainably.

The indicators related to energy show that the process has both benefits and drawbacks. One of the disadvantages is the energy source, due to the high demand for electrical energy in the process, compared to natural gas. The specific energy intensity indicator (ESI) showed an intermediate performance (74%), indicating that the process consumes high energy, which can lead to additional issues related to environmental criteria because of pollutant emissions and safety concerns from high processing temperatures. Furthermore, there could be energy losses that have not been accounted for, impacting the efficient use of energy resources. This indicator highlights the need to study the energy aspects more closely. It is essential to assess not only the quantity but also the quality of the energy flows at each stage, potentially using exergy analysis. Additionally, there is potential to enhance the energy performance of the process through integration techniques and by exploring the possibility of altering the energy source for the selected equipment.

4. Conclusions

Technical evaluation of the process of obtaining value-added products from the peel, seed, and pulp of the Creole-Antillean avocado is a fundamental step in the optimization and understanding of the process. It is based on material balance, preliminary economic facts for water and energy, and the chemical properties of the species involved. This process involves calculating various parameters related to the products, water, and energy, which provides a detailed view of their performance and efficiency. From these parameters, eleven technical indicators are calculated that allow the process to be diagnosed, including aspects such as production performance, water and energy consumption, and associated costs.

A high content of extracts was obtained from the peel and pulp of the avocado, presenting a higher yield and productivity than the avocado seed. As a result, the pulp and peel of Creole-Antillean avocado have a yield and productivity of 0.19 and 0.004 kg of extract per kg of material per hour, respectively. These results are comparable to those presented by Restrepo-Serna et al. (2022), who reported a 34.38% yield in the ethanolic extraction of compounds from the avocado peel [34]. Dávila et al. (2017) reported an efficiency of 14.2% in obtaining oil from avocado pulp, producing 142 kg of oil per ton of raw material [29].

On the other hand, the residual water indicator was 22.69%, which means that of the 3.48 m3/h of water consumed, 2.69 m3/h ends up as residual water. This is because water enters the process to adapt the raw material to the sodium hypochlorite solution (stream 2, see Figure 1) and as steam for drying when necessary.

Finally, an important aspect of this assessment is the process simulation, which provides detailed information on material and energy flows. This allows quantifying indices to describe performance in key aspects, such as resource use and associated costs. Specifically, in an extractive-based Avocado Biorefinery, process simulation makes it possible to assess how basic resources, such as water and energy, are managed and to determine the efficiency of the process in producing value-added products.

Author Contributions

Conceptualization, Á.D.G.-D.; methodology, S.G.-M. and T.C.H.-R.; software, S.G.-M. and T.C.H.-R.; validation, T.C.H.-R. and Á.D.G.-D.; formal analysis, T.C.H.-R.; investigation, T.C.H.-R.; resources, Á.D.G.-D.; data curation, T.C.H.-R.; writing—original draft preparation, S.G.-M. and T.C.H.-R.; writing—review and editing, Á.D.G.-D.; visualization, Á.D.G.-D.; supervision, Á.D.G.-D.; project administration, Á.D.G.-D.; funding acquisition, Á.D.G.-D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Colombian Ministry of Science, Technology and Innovation MINCIENCIAS and Sistema General de Regalías (SGR) through the project “Sustainable Use of Avocado (Laurus Persea L.) Produced in the Montes de María to obtain Value Added Products under the Biorefinery Concept in the Department of Bolívar”, Code BPIN 2020000100325.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author, Á.D.G.-D., upon reasonable request.

Acknowledgments

The authors thank the Universidad de Cartagena for their technical support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yabrudy Vega, J. El aguacate en Colombia: Estudio de caso de los Montes de María, en el Caribe Colombiano; Banco de la República de Colombia: Bogotá, Colombia, 2012. [Google Scholar]

- Puigjaner, L.; Heyen, G. (Eds.) Computer Aided Process and Product Engineering (CAPE); John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Aguilar-Vásquez, E.; Ramos-Olmos, M.; González-Delgado, Á.D. A Joint Computer-Aided Simulation and Water-Energy-Product (WEP) Approach for Technical Evaluation of PVC Production. Sustainability 2023, 15, 8096. [Google Scholar] [CrossRef]

- Cherubini, F.; Jungmeier, G.; Wellisch, M.; Willke, T.; Skiadas, I.; Van Ree, R.; de Jong, E. Toward a common classification approach for biorefinery systems. Biofuels Bioprod. Biorefining 2009, 3, 534–546. [Google Scholar] [CrossRef]

- Alberto, J.; Ortega, A.; Valdez, L.; Huerta, C.; Elena, M.; Cassellis, R.; Zavala, M. Efecto de diferentes métodos de extracción sobre el perfil de ácidos grasos en el aceite de aguacate (Persea americana Mill. var. Hass). Rev. Venez. Cienc. Tecnol. Aliment. 2011, 2, 263–276. [Google Scholar]

- Weemaes, C.; Ooms, V.; Indrawati Ludikhuyze, L.; Van den Broeck, I.; Van Loey, A.; Hendrickx, M. Pressure-temperature degradation of green color in broccoli juice. J. Food Sci. 1999, 64, 504–508. [Google Scholar] [CrossRef]

- Setyawan, H.Y.; Sukardi, S.; Puriwangi, C.A. Phytochemicals properties of avocado seed: A review. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 733, No. 1; p. 012090. [Google Scholar]

- Herrera-Rodríguez, T.; Parejo-Palacio, V.; González-Delgado, Á. Computer-aided simulation of avocado oil production in North Colombia. Chem. Eng. Trans. 2022, 92, 415–420. [Google Scholar]

- Sousa, D.; Rodrigues, D.; Castro, P.M.; Matos, H.A. Equation-Oriented Modeling and Optimization of a Biorefinery Based on Avocado Waste. Processes 2023, 12, 91. [Google Scholar] [CrossRef]

- Poveda-Giraldo, J.A.; Piedrahita-Rodríguez, S.; Cardona-Alzate, C.A. Life Cycle Analysis of Biotechnological Processes based on the Composition of the Raw Material. Eucalyptus, Avocado, and Plantain cases in a Biorefinery System. CET J.-Chem. Eng. Trans. 2021, 83, 397–402. [Google Scholar]

- Mallarino-Miranda, L.; Tejeda-Benitez, L.; Jimenéz-Escalante, M.; Gonzalez-Delgado, Á.; Tejeda-Benitez, L.P. Aprovechamiento sostenible del aguacate (Laurus persea) para la obtención de productos de valor agregado en los Montes de María en el Departamento de Bolívar-Colombia. RIADS Rev. Investig. Agropecu. Desarro. Sosten. 2020, 5, 32–38. [Google Scholar]

- Robayo Medina, A.T. Caracterización Fisicoquímica de Diferentes Variedades de Aguacate, Persea americana Mill.(Lauraceae) e Implementación de un Método de Extracción del Aceite de Aguacate Como Alternativa de Industrialización. Ph.D. Dissertation, Universidad Nacional de Colombia, Bogota, Colombia, 2016. [Google Scholar]

- González-Delgado, Á.D.; Moreno-Sader, K.A.; Martínez-Consuegra, J.D. Biorrefinación Sostenible del Camarón: Desarrollos Desde la Ingeniería de Procesos Asistida Por Computador; Corporación Universitaria Minuto de Dios-UNIMINUTO: Bogotá, Colombia, 2022. [Google Scholar]

- Reddy, M.; Moodley, R.; Jonnalagadda, S.B. Fatty acid profile and elemental content of avocado (Persea americana Mill.) oil–effect of extraction methods. J. Environ. Sci. Health Part B 2012, 47, 529–537. [Google Scholar] [CrossRef] [PubMed]

- Macías Fuyo, D.A.; Rodríguez Parra, D.F. Sustitución de grasa por aceite de aguacate en la elaboración de salchicha tipo Frankfurt. 2021. [Google Scholar]

- Fassinou, W.F.; Van de Steene, L.; Toure, S.; Martin, E. What correlation is appropriate to evaluate biodiesels and vegetable oils higher heating value (HHV)? Fuel 2011, 90, 3398–3403. [Google Scholar] [CrossRef]

- Demirbaş, A. A direct route to the calculation of heating values of liquid fuels by using their density and viscosity measurements. Energy Convers. Manag. 2000, 41, 1609–1614. [Google Scholar] [CrossRef]

- Garcia Pacheco, Y.E.; Morales, N.; Meriño, L.; Palacio Montañez, J.M.; Angarita Santana, A.; Vargas-Barrios, D. Obtención de clorofila a partir de cáscaras de sábila (Aloe barbadensis) por medio de solventes. Inge Cuc 2021, 17, 133–142. [Google Scholar] [CrossRef]

- Bahru, T.B.; Tadele, Z.H.; Ajebe, E.G. A review on avocado seed: Functionality, composition, antioxidant and antimicrobial properties. Chem. Sci. Int. J. 2019, 27, 1–10. [Google Scholar] [CrossRef]

- Fuller-Thomson, E.G. Tannins as a Pesticide: The impact of tannic acid on the growth rates of Myzus persicae and Arabidopsis thaliana. IScientist 2019, 4, 26–35. [Google Scholar]

- Deuschle VC, K.N.; Cruz, R.; Flores, V.; Denardi, L.; Deuschle, R.; Rossi, G.G.; Viana, C. Persea americana: Phenolic profile, antioxidant potential, antimicrobial activity and in silico prediction of pharmacokinetic and toxicological properties. Indian J. Pharm. Sci. 2019, 81, 766–775. [Google Scholar]

- Paternina-Ricardo, S.; Garcia-Espiñeira, M.C.; Arroyo-Salgado, B. Evaluation of herbicidal and insecticidal properties of avocado seed extract for application as a biopesticide. Chem. Eng. Trans. 2022, 92, 733–738. [Google Scholar]

- Ejiofor, N.C.; Ezeagu, I.E.; Ayoola, M.; Umera, E.A. Determination of the chemical composition of avocado (Persea americana) seed. Adv. Food Technol. Nutr. Sci. Open J. 2018, 2, 51–55. [Google Scholar] [CrossRef]

- Barros, M.; De Siqueira, D.; Carvalho, D. Association between exposure to pesticides and allergic diseases in children and adolescents: A systematic review with meta-analysis. J. Pediatr. 2022, 98, 551–564. [Google Scholar] [CrossRef]

- Knapke, E.T.; Magalhaes DD, P.; Aqiel, M.; Mandrioli, D.; Perry, M.J. Environmental and occupational pesticide exposure and human sperm parameters: A Navigation Guide review. Toxicology 2022, 465, 153017. [Google Scholar] [CrossRef]

- Soledad CP, T.; Paola, H.C.; Carlos Enrique, O.V.; Israel RL, I.; Guadalupe Virginia, N.M.; Raúl, Á.S. Avocado seeds (Persea americana cv. Criollo sp.): Lipophilic compounds profile and biological activities. Saudi J. Biol. Sci. 2021, 28, 3384–3390. [Google Scholar] [CrossRef]

- Gidigbi, J.A.; Ngoshe, A.; Martins, A. Industrial viability study of the avocado seed oil. Int. J. Recent. Innov. Acad. Res. 2019, 3, 48–57. [Google Scholar]

- Rivai, H.; Putri, Y.T.; Rusdi, R. Qualitative and quantitative analysis of the chemical content of hexane, acetone, ethanol and water extract from avocado seeds (Persea americana Mill.). Sch. Int. J. Tradit. Complement. Med. 2019, 2, 25–31. [Google Scholar]

- Dávila, J.A.; Rosenberg, M.; Castro, E.; Cardona, C.A. A model biorefinery for avocado (Persea americana mill.) processing. Bioresour. Technol. 2017, 243, 17–29. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; Ortiz-Sanchez, M.; Restrepo-Serna, D.L.; Piñeres, P.P.; Cordero, A.P.; Alzate CA, C. Influence of products portfolio and process contextualization on the economic performance of small-and large-scale avocado biorefineries. Bioresour. Technol. 2021, 342, 126060. [Google Scholar] [CrossRef] [PubMed]

- Niño-Villalobos, A.; Puello-Yarce, J.; González-Delgado, Á.D.; Ojeda, K.A.; Sánchez-Tuirán, E. Biodiesel and hydrogen production in a combined palm and jatropha biomass biorefinery: Simulation, techno-economic, and environmental evaluation. ACS Omega 2020, 5, 7074–7084. [Google Scholar] [CrossRef]

- Ortiz-Sanchez, M.; Solarte-Toro, J.C.; Alzate, C.A.C. Food waste valorization applying the biorefinery concept in the Colombian context: Pre-feasibility analysis of the organic kitchen food waste processing. Biochem. Eng. J. 2023, 194, 108864. [Google Scholar] [CrossRef]

- Paraskevopoulou, C.; Vlachos, D.; Bechtsis, D.; Tsolakis, N. An assessment of circular economy interventions in the peach canning industry. Int. J. Prod. Econ. 2022, 249, 108533. [Google Scholar] [CrossRef]

- Restrepo-Serna, D.L.; Solarte-Toro, J.C.; Cardona-Alzate, C.A. A biorefinery approach for an integral valorisation of avocado peel and seeds through supercritical fluids. Waste Biomass Valorization 2022, 13, 3973–3988. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).