Study on Formation Mechanism of Pre-stressed Anchor Pressure Arch Based on Safe Co-Mining of Deep Coal and Gas

Abstract

1. Introduction

2. Structure and Mechanical Performance of Coal Rocks

2.1. Microstructure of Coal Rocks

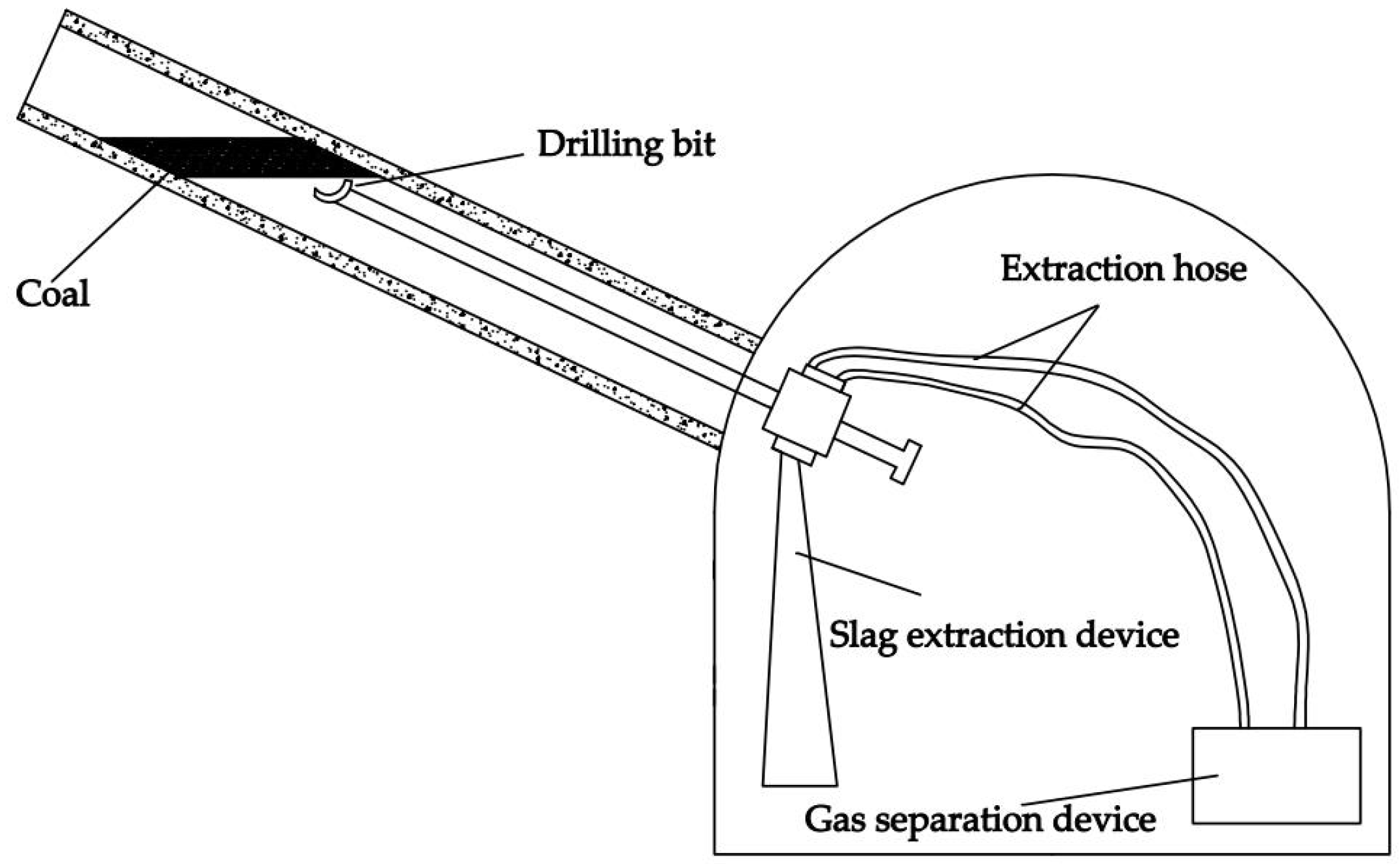

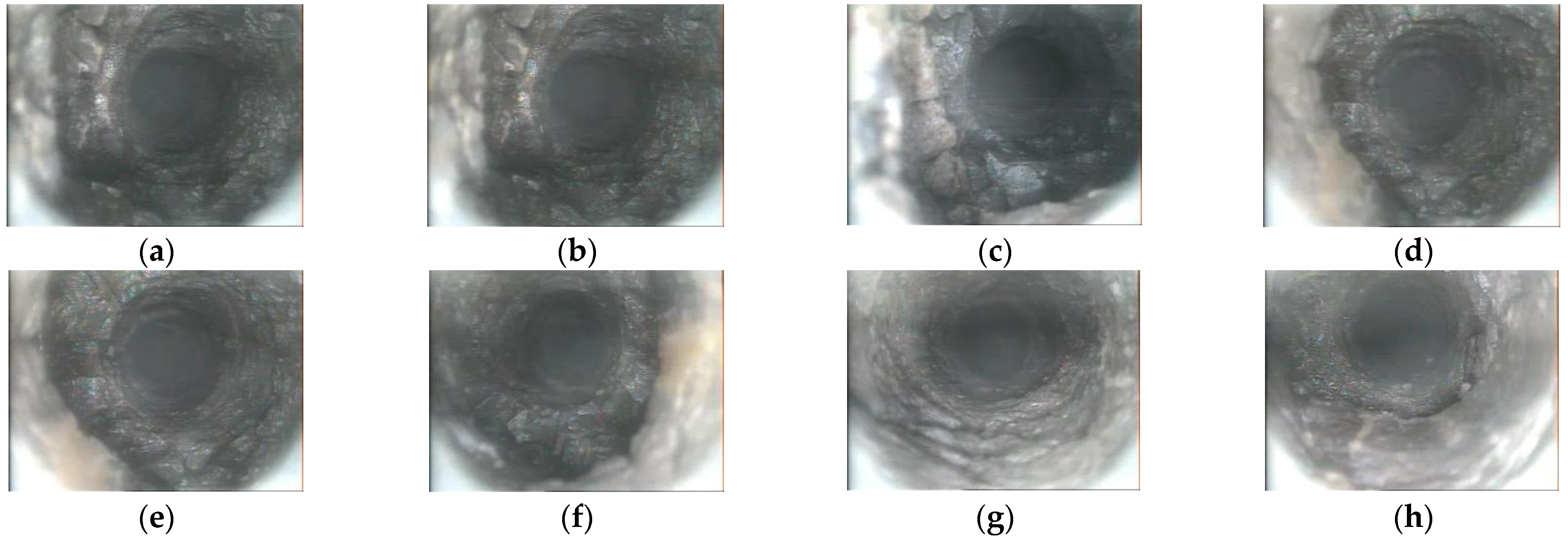

2.2. Boreholes of Coal Rock Structures

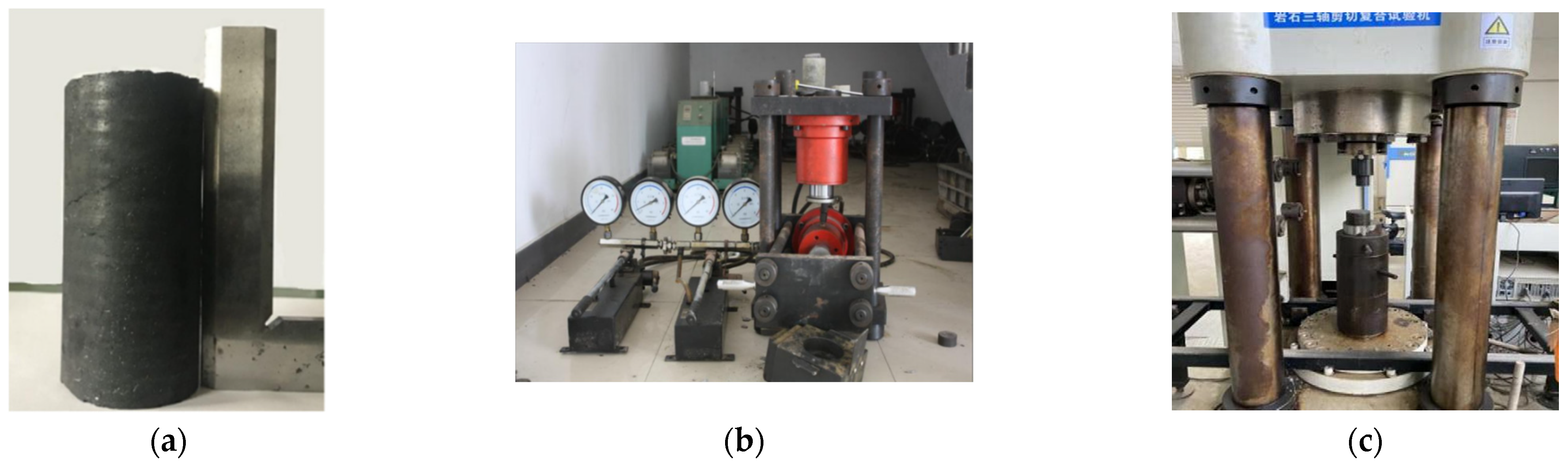

2.3. Measurement of Mechanical Parameters of the Coal Rock

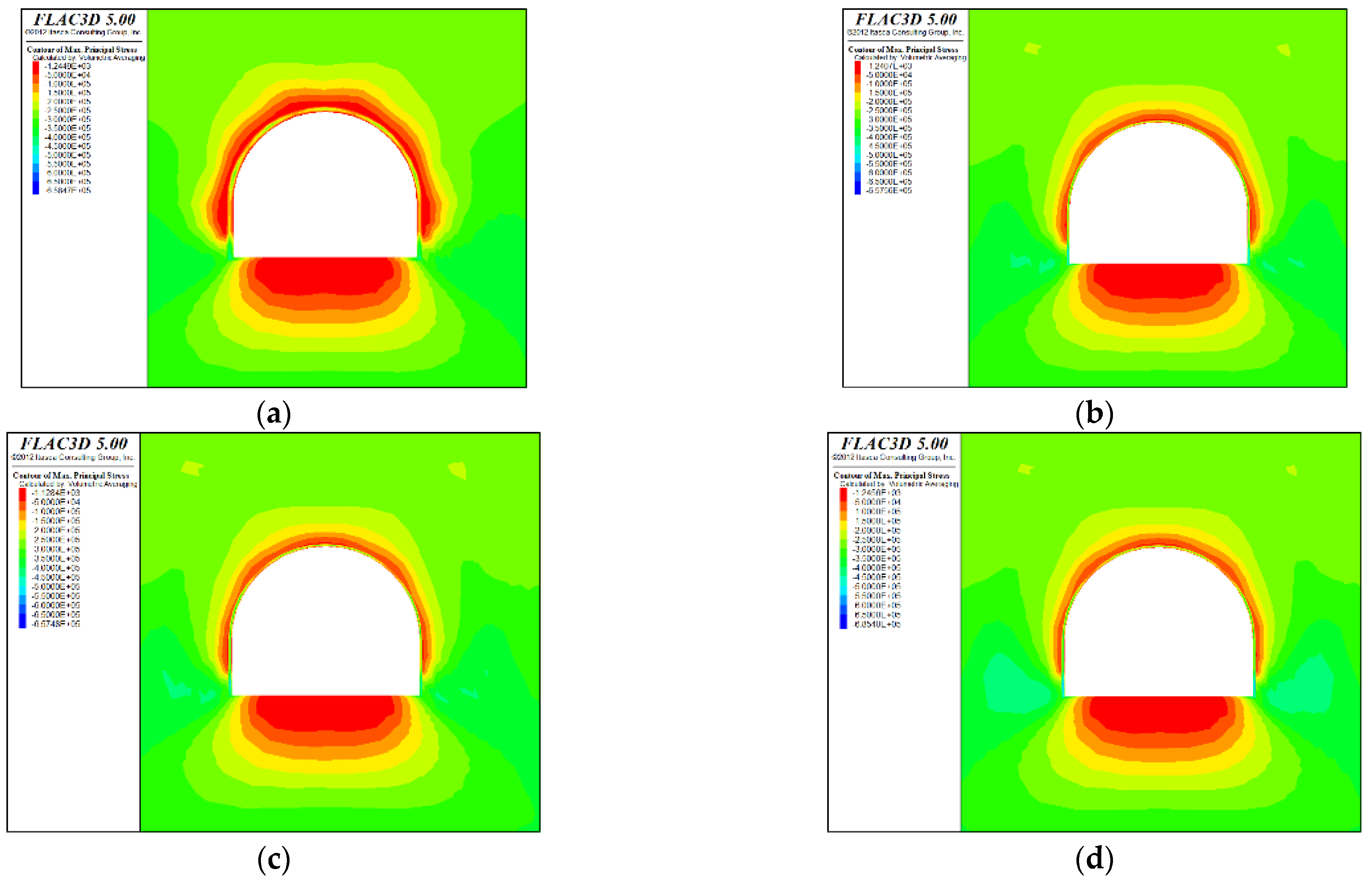

3. Numerical Model

4. Calculation Results by Numerical Model and Theoretical Analysis

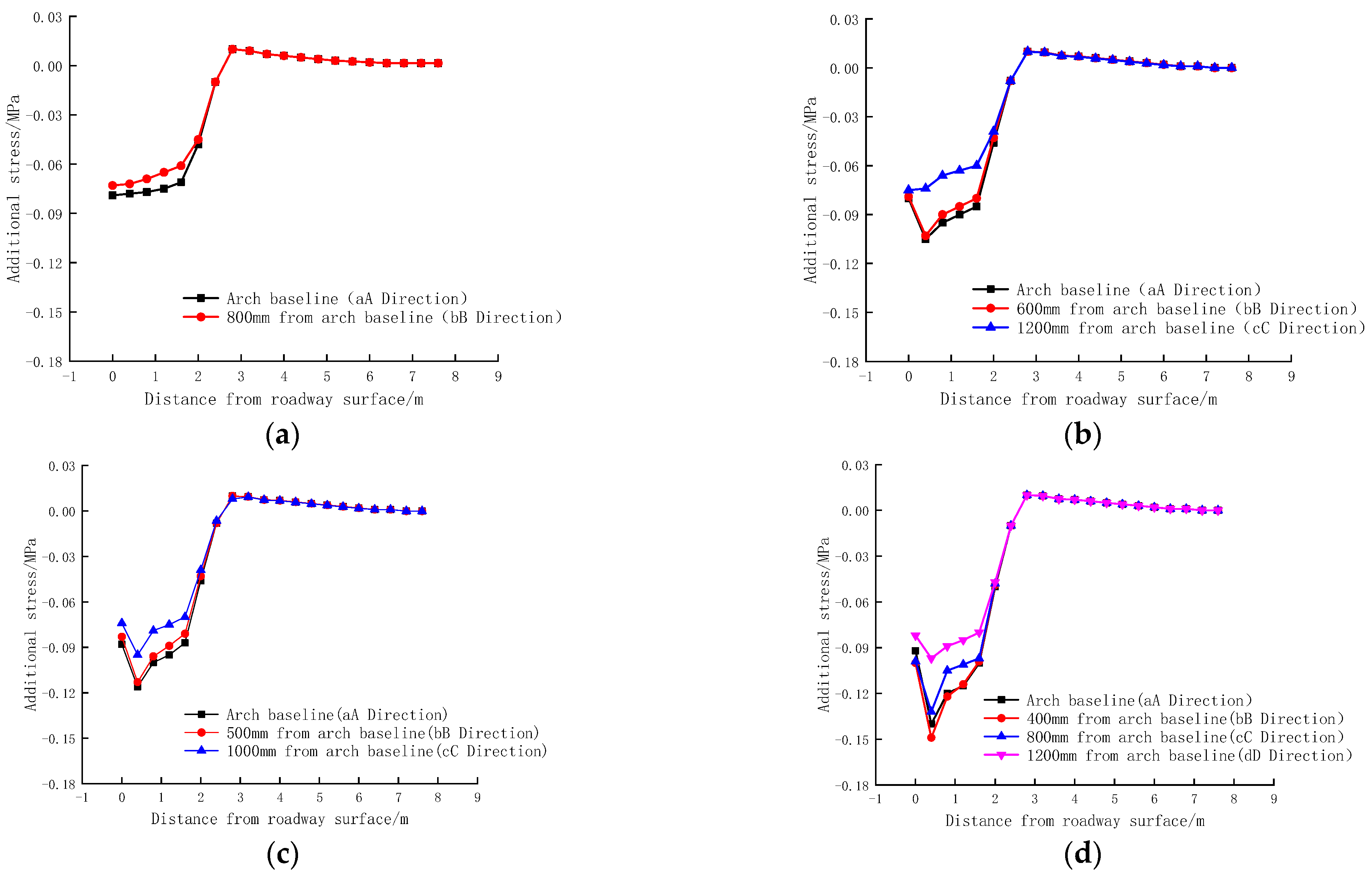

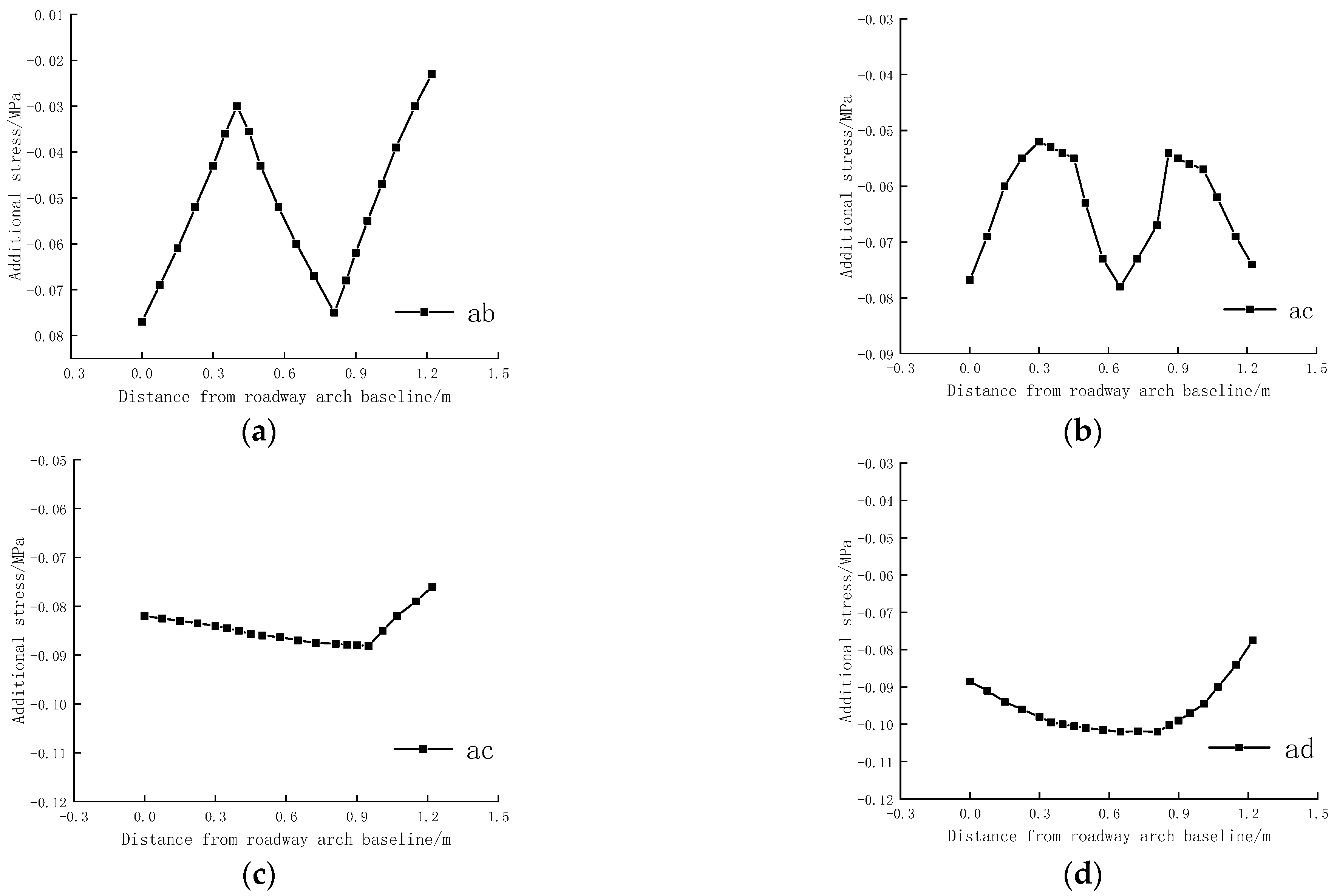

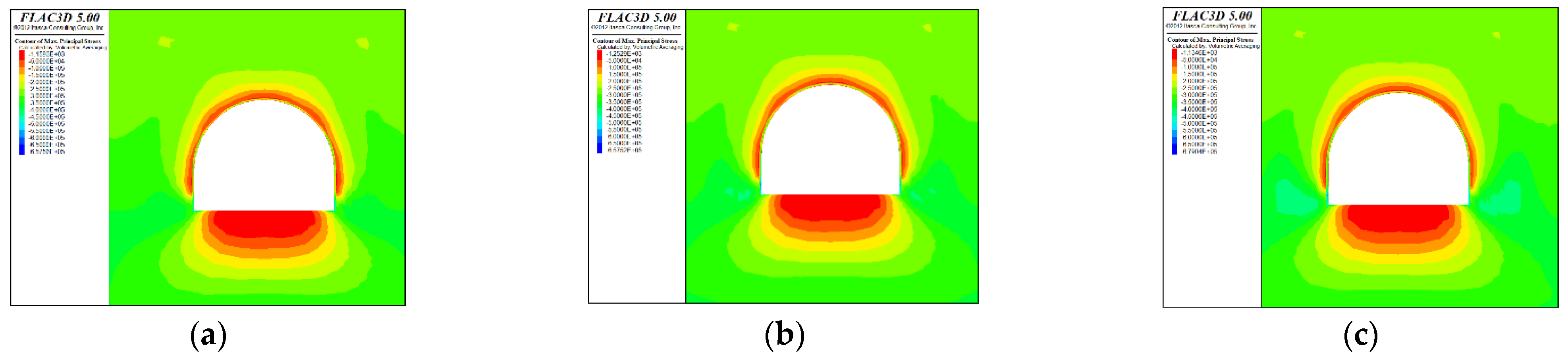

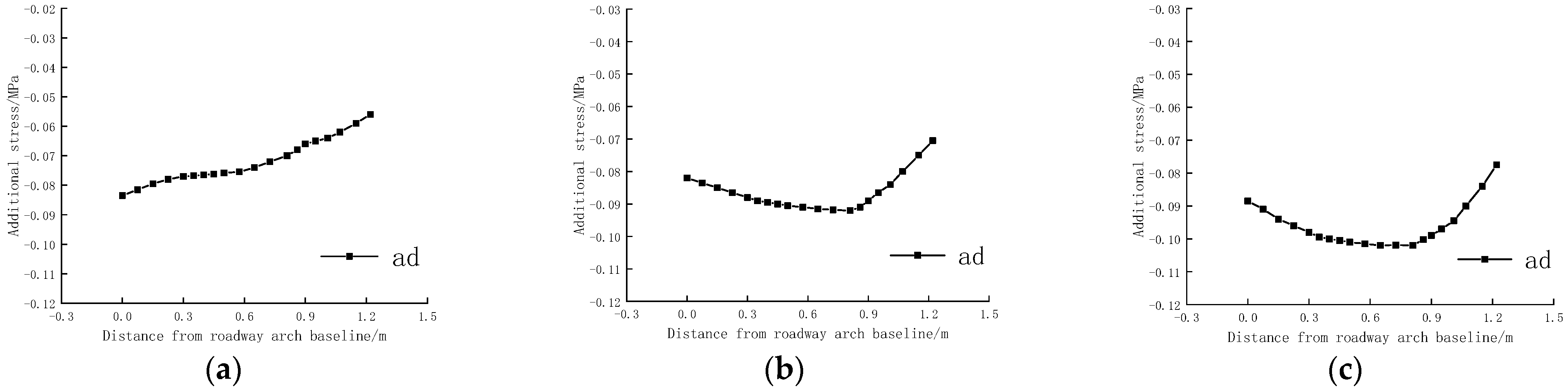

4.1. Magnitude and Distribution of Additional Stress in the Surrounding Rock under Different Bolt Spacing

- (1)

- Different bolt spacing; within a certain range from the surface of the roadway, the additional compressive stress along the direction of the bolt is first distributed in a small ‘fluctuation‘. With the increase of distance from the surface of the roadway, the additional compressive stress decreases at a faster rate.

- (2)

- The bolt spacing is a × b = 800 mm × 800 mm; the additional compressive stress on the surface of the straight wall along the roadway decreases first, then increases and then decreases with the increase of the arch baseline distance. The bolt spacing is a × b = 600 mm × 600 mm; the additional compressive stress on the surface of the straight wall along the roadway decreases first, then increases, then decreases, and then increases with the increase of the arch baseline distance. The bolt spacing is a × b = 500 mm × 500 mm and a × b = 400 mm × 400 mm; the additional compressive stress on the surface of the straight wall along the roadway increases first and then decreases with the increase of the arch baseline distance.

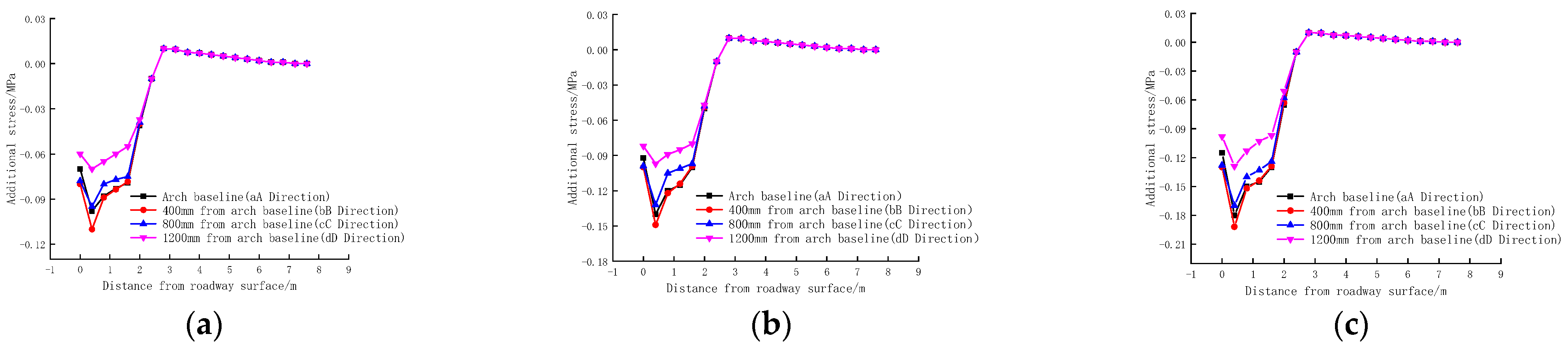

4.2. Magnitude and Distribution of Additional Stress in the Surrounding Rock at Different Bolt Pre-Tightening Force

- (1)

- Different bolt pre-tightening force; within a certain range from the surface of the roadway, the additional compressive stress along the direction of the bolt is first distributed in a small ‘fluctuation‘. With the increase of distance from the surface of the roadway, the additional compressive stress attenuates at a faster rate.

- (2)

- The bolt pre-tightening force F = 50 kN, F = 70 kN, and F = 90 kN; the additional compressive stress along the surface of the straight wall of the roadway increases first and then decreases with the increase of the arch baseline distance.

4.3. Magnitude and Distribution of Additional Stress in the Surrounding Rock under Different Bolt Lengths

- (1)

- Different bolt length; within a certain range from the surface of the roadway, the additional compressive stress along the direction of the bolt is first distributed in a small ‘fluctuation‘. With the increase of distance from the surface of the roadway, the additional compressive stress attenuates at a faster rate.

- (2)

- The bolt length L = 1500 mm; the additional compressive stress along the straight wall surface of the roadway decreases with the increase of the arch baseline distance. The bolt length L = 2000 mm and L = 2400 mm; the additional compressive stress on the surface of the straight wall along the roadway increases first and then decreases with the increase of the arch baseline distance.

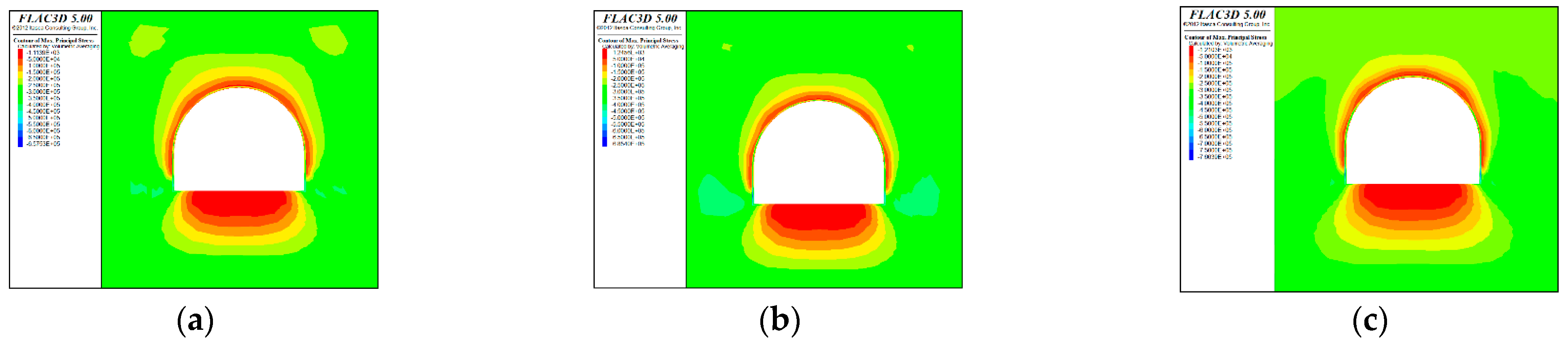

5. Formation and Bearing Mechanism the Pre-Stressed Bolt Compression Arch in a Deep Soft Rock Roadway

5.1. Formation of the Pre-Stressed Bolt Compression Arch in a Deep Soft Rock Roadway

5.2. Bearing Mechanism of the Pre-Stressed Bolt Compression Arch in the Deep Soft Rock Roadway

5.2.1. Thickness of the Compression Arch

5.2.2. Strength of the Compression Arch

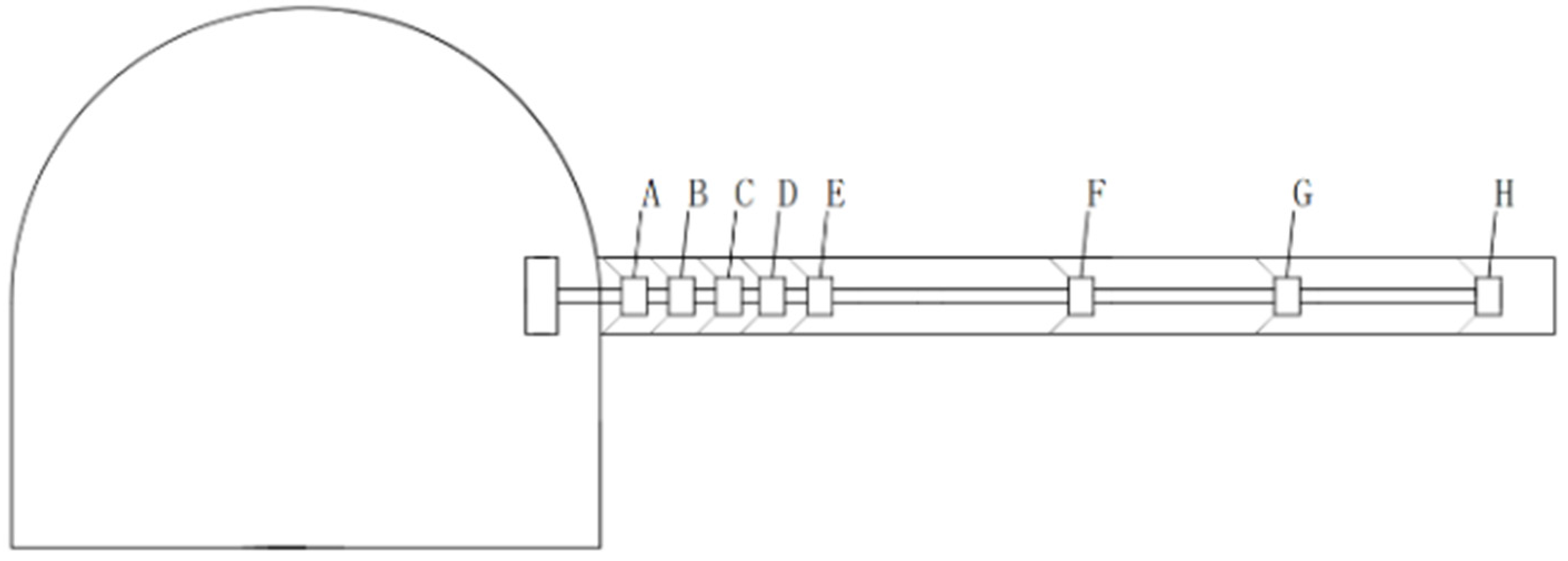

5.3. Engineering Verification and Application

6. Conclusions

- (1)

- A single pre-stressed force bolt forms a triangular area with a certain range of uniform additional compressive stress distribution in the surrounding rock of a deep soft rock roadway. The interaction of multiple pre-stressed force bolts makes the additional compressive stress that is evenly distributed in the triangular area effectively superimposed to form a certain thickness and strength compression arch. The thickness and strength of the compressed arch are determined by the range and size of the uniformly distributed additional compressive stress.

- (2)

- The bolt spacing and bolt length significantly affect the thickness of the compression arch, and the bolt spacing, bolt length, and pre-tightening force of bolts significantly affect the strength of the compression arch. The bolt pre-tightening force F = 70 kN, the length L = 2400 mm, and the additional compressive stress begin to be effectively superimposed when the bolt spacing is reduced to a × b = 600 mm × 600 mm. When reducing the bolt spacing between the bolts to a × b = 500 mm × 500 mm, 400 mm × 400 mm, the thickness of the compression arch is changed from 0 mm to 266.67 mm, 533.33 mm, and the strength of the compression arch is increased from 0 MPa to −1.489 MPa, −1.533 MPa. The pre-tightening force of the bolt is changed to F = 50 kN and 90 kN, the thickness of the compression arch is unchanged, and the strength is changed from−1.533 MPa to−1.482 MPa and−1.589 MPa; when the length of the bolt is changed to L = 2000 mm and 1500 mm, the thickness of the compression arch is changed to 400 mm and 266.67 mm, and the strength of the compression arch is changed from−1.533 MPa to−1.494 MPa and−1.48 MPa.

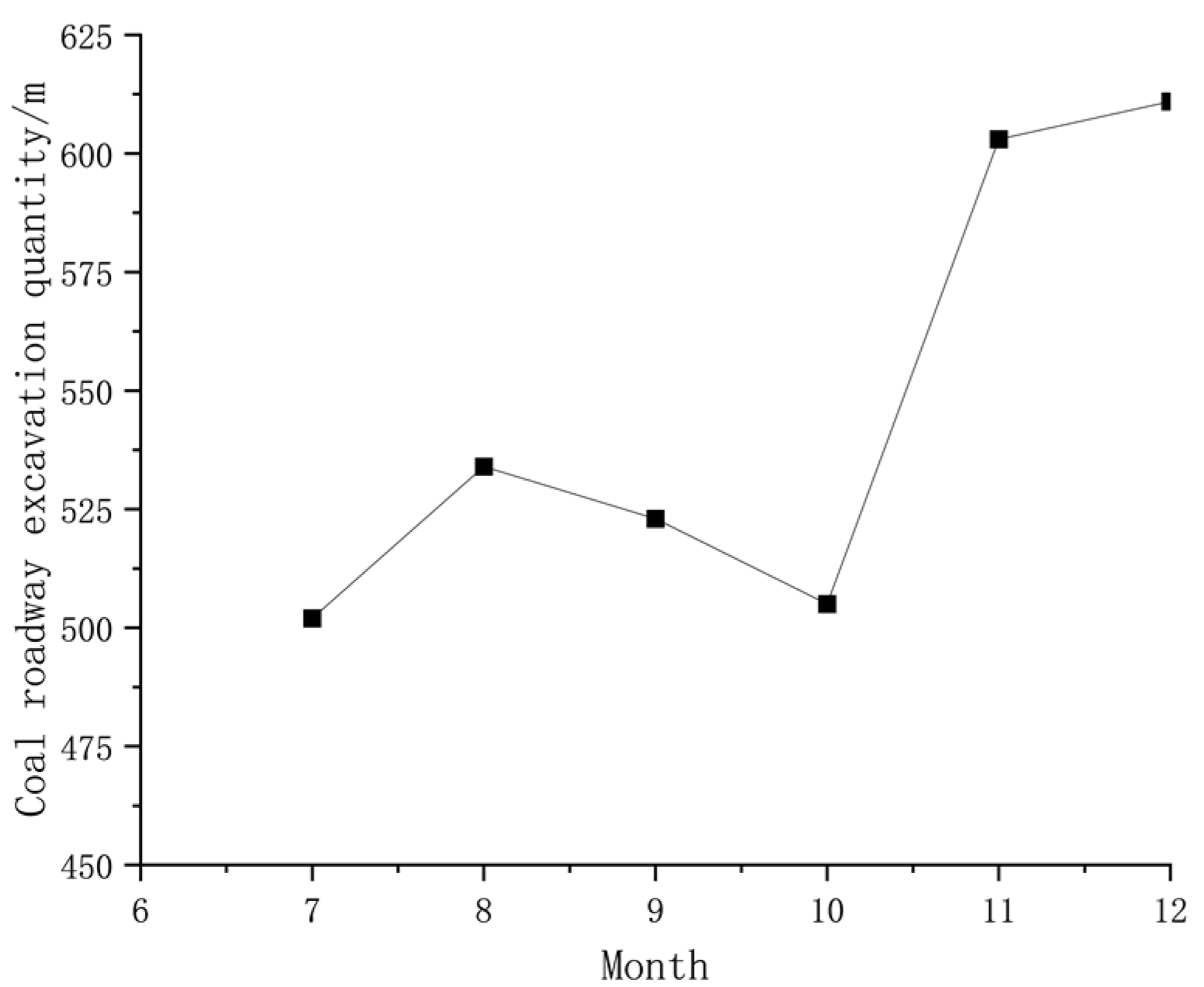

- (3)

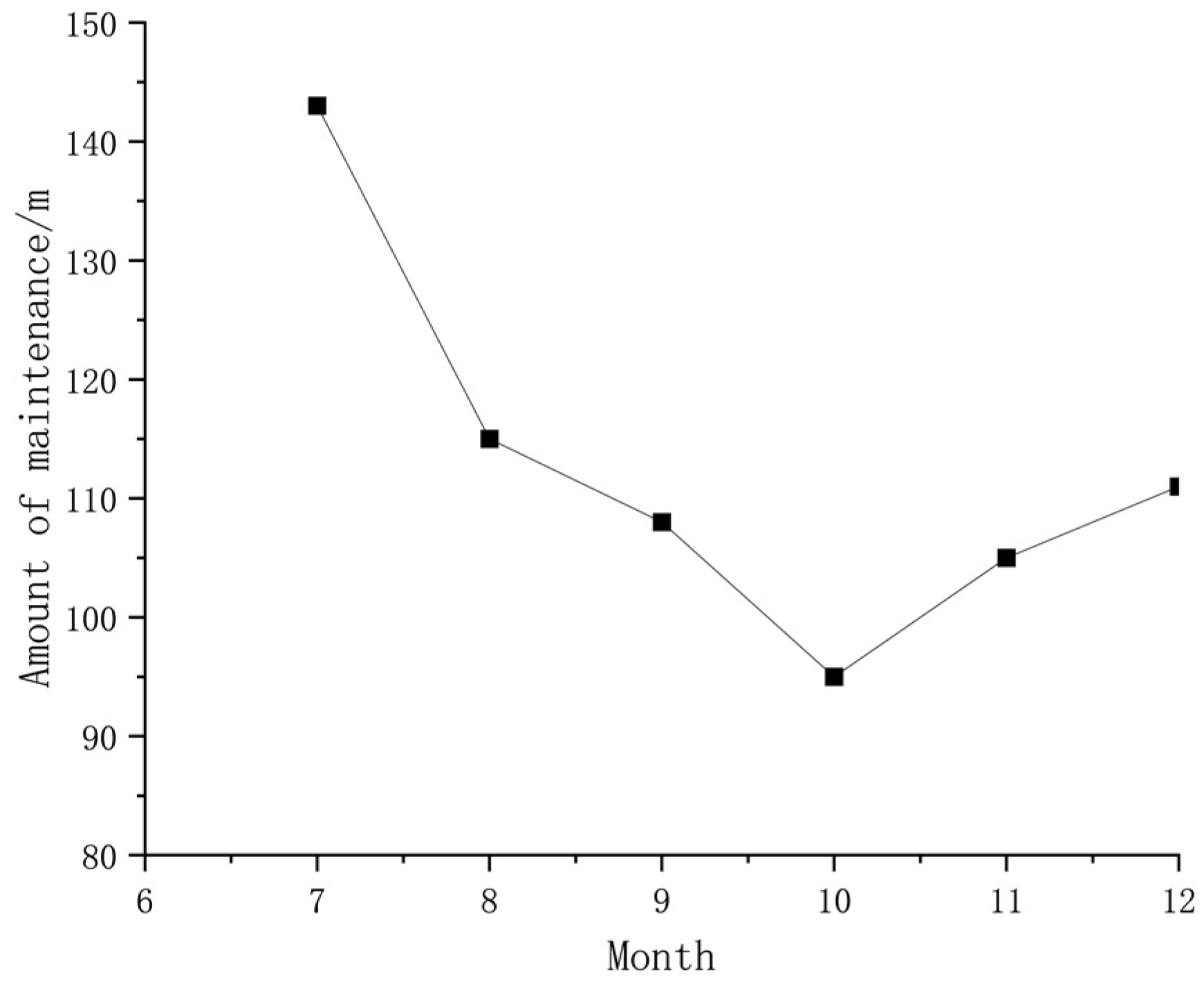

- The new support scheme is applied to the engineering practice of the straight wall semi-circular arch roadway in the deep fracture zone of the west wing return air roadway in Yuandian No.2 Mine. The multi-point displacement meter measures the pre-stressed anchor compression arch’s displacement distribution, and the measured results are mostly consistent with the findings of the study. After the formulation of the new support scheme, the amount of coal roadway excavation increased by 71.33 m/month on average, the maintenance amount of extraction roadway decreased by 112 m/month on average, and the extraction rate increased by 41%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, W.; Zhang, K.; Tang, X.; Zhao, Z.; Wan, H. Coking Coals Potential Resources Prediction in Deep Coal Beds in Northern China. Energy Explor. Exploit. 2010, 28, 313–325. [Google Scholar] [CrossRef]

- Li, D.; Cheng, Y. Evaluation of Gas Control Ability of a Coal and Gas Outburst Mine. Energy Sources Part A Recovery Util. Environ. Eff. 2014, 36, 2401–2409. [Google Scholar] [CrossRef]

- Lu, S.; Li, L.; Cheng, Y.; Sa, Z.; Zhang, Y.; Yang, N. Mechanical failure mechanisms and forms of normal and deformed coal combination containing gas: Model development and analysis. Eng. Fail. Anal. 2017, 80, 241–252. [Google Scholar] [CrossRef]

- Xinfeng, W.; Yiying, Z.; Qiao, Z.; Youyu, W.; Wengang, L.; Tian, J. Space-Time Evolution Characteristics of Deformation and Failure of Surrounding Rock in Deep Soft Rock Roadway. Sustainability 2022, 14, 12587. [Google Scholar] [CrossRef]

- Hao, T.; Xiang, J.; Hongyi, Z.; Tianbin, L. Numerical simulation of large compression deformation disaster and supporting behavior of deep buried coal rock tunnel with high in situ stress based on CDEM. Adv. Civ. Eng. 2022, 2022, 5985165. [Google Scholar]

- Zhang, J.; Liu, L.; Liu, C.; Li, Y. Mechanism and application of new prestressed yield bolt for controlling deep high-stress rock mass. Tunn. Undergr. Space Technol. 2022, 119, 104254. [Google Scholar]

- Bo, W.; Wei, Y.; Ziquan, C. Effect of bolt plate on the mechanical behavior of prestressed rock bolt used in squeezing large deformation tunnel. Acta Geotech. 2022, 17, 3591–3611. [Google Scholar]

- Xiaowei, G.; Xigui, Z.; Peng, L.; Rui, L.; Cancan, L.; Muhammad, S.N.; Cong, W.; Boyang, L.; Wenjie, X.; Guowei, L. Full-stress bolting technology and application of bolts in the coal roadway. Energies 2021, 14, 7475. [Google Scholar]

- Xiaowei, F.; Nong, Z.; Fengzhen, H.; Sen, Y.; Xigui, Z. Implementation of a pretensioned, fully bonded bolting system and its failure mechanism based on acoustic emission: A laboratorial and field study. Geotech. Test. J. 2017, 40, 978–999. [Google Scholar]

- Kai, W.; Baogui, Y.; Zhongkui, W.; Xiaolong, W. Analytical solution for the deformation and support parameters of coal roadway in layered roof strata. Geofluids 2021, 2021, 6669234. [Google Scholar]

- Zhang, Q.; Jiang, B.; Wang, S.; Ge, X.; Zhang, H. Elasto-plastic analysis of a circular opening in strain-softening rock mass. Int. J. Rock Mech. Min. Sci. 2012, 50, 38–46. [Google Scholar] [CrossRef]

- Minggao, Q.; Pingwu, S.; Jialin, X. Mine Pressure and Rock Strata Control; China University of Mining and Technology Press: Xuzhou, China, 2010; pp. 25–26. [Google Scholar]

- Mohammadi, M.; Hossaini, M.F.; Bagloo, H. Rock bolt supporting factor: Rock bolting capability of rock mass. Bull. Eng. Geol. Environ. 2017, 76, 231–239. [Google Scholar] [CrossRef]

- Li, S.-c.; Wang, H.-t.; Wang, Q.; Jiang, B.; Wang, F.-q.; Guo, N.-b.; Liu, W.-j.; Ren, Y.-x. Failure mechanism of bolting support and high-strength bolt-grouting technology for deep and soft surrounding rock with high stress. J. Cent. South Univ. 2016, 23, 440–448. [Google Scholar] [CrossRef]

- Zhang, Q.-H.; Liu, Q.-B.; Wang, S.-H.; Liu, H.-L.; Shi, G.-H. Progressive failure of blocky rock system: Geometrical-mechanical identification and rock-bolt support. Rock Mech. Rock Eng. 2022, 55, 1649–1662. [Google Scholar] [CrossRef]

- Kun, Z.; Jinpeng, S.; Zengkai, L.; Hongyue, C.; Qiang, Z.; Shaoan, S. Sensitivity analysis and experimental verification of bolt support parameters based on orthogonal experiment. Shock Vib. 2020, 2020, 8844282. [Google Scholar]

- Li, N.; Wang, F.; Song, G. Monitoring of bolt looseness using piezoelectric transducers: Three-dimensional numerical modeling with experimental verification. J. Intell. Mater. Syst. Struct. 2020, 31, 911–918. [Google Scholar] [CrossRef]

- Wang, Z.; Fei, C.-W.; Wang, J.-J. Equivalent simulation of mechanical characteristics for parametric modeling of bolted joint structures. Adv. Mech. Eng. 2017, 9, 1687814017704360. [Google Scholar] [CrossRef]

- Wang, X.-Y.; Zhu, S.-F.; Wang, X.; Zhang, X.-C. Stress and thickness calculation of a bolted flat cover with double metal sealing rings. Nucl. Sci. Tech. 2018, 29, 120. [Google Scholar] [CrossRef]

- Chen, Y.; Wen, G.; Hu, J. Analysis of Deformation Characteristics of Fully Grouted Rock Bolts Under Pull-and-Shear Loading. Rock Mech. Rock Eng. 2020, 53, 2981–2993. [Google Scholar] [CrossRef]

| Cohesion c (MPa) | Internal Friction Angle | Poisson’s Ratio γ | Elastic Modulus E (MPa) | Shear Modulus G (MPa) |

|---|---|---|---|---|

| 0.5 | 16 | 0.36 | 952 | 350 |

| Bolt Spacing a × b (mm) | Uniform Distribution Range (mm) | Distribution Interval (Mpa) | Distribution Interval (Mpa) | |||

|---|---|---|---|---|---|---|

| aA Direction | bB Direction | cC Direction | dD Direction | |||

| 800 × 800 | 1600 | −0.071~−0.078 | −0.061~−0.073 | - | - | −0.021~−0.076 |

| 600 × 600 | 1600 | −0.08~−0.105 | −0.079~−0.103 | −0.06~−0.075 | - | −0.052~−0.078 |

| 500 × 500 | 1600 | −0.087~−0.116 | −0.081~−0.113 | −0.07~−0.095 | - | −0.078~−0.089 |

| 400 × 400 | 1600 | −0.092~−0.115 | −0.099~−0.149 | −0.097~−0.132 | −0.08~−0.097 | −0.078~−0.102 |

| Bolt Pre-Tightening Force F (kN) | Uniform Distribution Range (mm) | Distribution Interval (Mpa) | Distribution Interval (Mpa) | |||

|---|---|---|---|---|---|---|

| aA Direction | bB Direction | cC Direction | dD Direction | |||

| 50 | 1600 | −0.07~−0.098 | −0.079~−0.11 | −0.075~−0.095 | −0.055~−0.07 | −0.057~−0.076 |

| 70 | 1600 | −0.092~−0.115 | −0.099~−0.149 | −0.097~−0.132 | −0.08~−0.097 | −0.078~−0.102 |

| 90 | 1600 | −0.115~−0.18 | −0.129~−0.192 | −0.124~−0.17 | −0.097~−0.098 | −0.097~−0.128 |

| Bolt Length L (mm) | Uniform Distribution Range (mm) | Distribution Interval (Mpa) | Distribution Interval (Mpa) | |||

|---|---|---|---|---|---|---|

| aA Direction | bB Direction | cC Direction | dD Direction | |||

| 1500 | 800 | −0.085~−0.11 | −0.078~−0.095 | −0.068~−0.078 | −0.048~−0.058 | −0.056~−0.084 |

| 2000 | 1200 | −0.083~−0.101 | −0.088~−0.104 | −0.081~−0.091 | −0.062~−0.076 | −0.071~−0.092 |

| 2400 | 1600 | −0.092~−0.115 | −0.099~−0.149 | −0.097~−0.132 | −0.08~−0.097 | −0.078~−0.102 |

| Support Parameters of the Bolt | Thickness of Pre-Stressed Bolt Compression Arch (mm) |

|---|---|

| 70 kN, a × b = 800 mm × 800 mm, L = 2400 mm | No arch is formed |

| 70 kN, a × b = 600 mm × 600 mm, L = 2400 mm | 0 |

| 70 kN, a × b = 500 mm × 500 mm, L = 2400 mm | 266.67 |

| 70 kN, a × b = 400 mm × 400 mm, L = 2400 mm | 533.33 |

| 70 kN, a × b = 400 mm × 400 mm, L = 1500 mm | 266.67 |

| 70 kN, a × b = 400 mm × 400 mm, L = 2000 mm | 400 |

| Support Parameters of Bolt | (MPa) | (MPa) | (MPa) |

|---|---|---|---|

| 70 kN, a × b = 800 mm × 800 mm, L = 2400 mm | - | - | - |

| 70 kN, a × b = 600 mm × 600 mm, L = 2400 mm | - | - | - |

| 70 kN, a × b = 500 mm × 500 mm, L = 2400 mm | −0.092 | −1.489 | 0.551 |

| 70 kN, a × b = 400 mm × 400 mm, L = 2400 mm | −0.117 | −1.533 | 0.567 |

| 50 kN, a × b = 400 mm × 400 mm, L = 2400 mm | −0.088 | −1.482 | 0.548 |

| 90 kN, a × b = 400 mm × 400 mm, L = 2400 mm | −0.149 | −1.589 | 0.588 |

| 70 kN, a × b = 400 mm × 400 mm, L = 1500 mm | 0.087 | −1.48 | 0.547 |

| 70 kN, a × b = 400 mm × 400 mm, L = 2000 mm | −0.095 | −1.494 | 0.553 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Li, N.; Hu, M.; Liu, H. Study on Formation Mechanism of Pre-stressed Anchor Pressure Arch Based on Safe Co-Mining of Deep Coal and Gas. Sustainability 2023, 15, 3004. https://doi.org/10.3390/su15043004

Wu D, Li N, Hu M, Liu H. Study on Formation Mechanism of Pre-stressed Anchor Pressure Arch Based on Safe Co-Mining of Deep Coal and Gas. Sustainability. 2023; 15(4):3004. https://doi.org/10.3390/su15043004

Chicago/Turabian StyleWu, Deyi, Nanyu Li, Menghan Hu, and Hanghang Liu. 2023. "Study on Formation Mechanism of Pre-stressed Anchor Pressure Arch Based on Safe Co-Mining of Deep Coal and Gas" Sustainability 15, no. 4: 3004. https://doi.org/10.3390/su15043004

APA StyleWu, D., Li, N., Hu, M., & Liu, H. (2023). Study on Formation Mechanism of Pre-stressed Anchor Pressure Arch Based on Safe Co-Mining of Deep Coal and Gas. Sustainability, 15(4), 3004. https://doi.org/10.3390/su15043004