Abstract

As the Framework Act on Sustainable Infrastructure Management has recently been enacted in Korea, it has become mandatory to establish a medium-and long-term plan for managing social infrastructure and evaluating the feasibility of maintenance projects. However, road agencies are experiencing problems due to a lack of deterioration models which are essential to conducting a life cycle cost analysis. Thus, this study developed deterioration models for bridge pavements as the first step to secure the power of execution of the Infrastructure Management Act. The deterioration model subdivided pavement materials into asphalt, conventional concrete, and latex-modified concrete. This study analyzed the data on diagnosis for the last 12 years in Korea by applying the Bayesian Markov Hazard Model. The average life expectancy by pavement type was analyzed as follows: 12.8 years for asphalt pavement; 23.4 years for concrete pavement; and 9.8 years for latex-modified concrete pavement. For the probabilistic life cycle cost analysis and risk management, probability distributions of life expectancy, effective range by confidence level, and Markov transition probability were presented. This study lays a foundation for deterministic and probabilistic life cycle cost analysis of bridge pavement. Future studies need to develop deterioration models standardized for all components of bridges and all types of social infrastructure.

1. Introduction

As social infrastructure that had been built in Korea (Republic of Korea; ROK) since the 1970s became superannuated [1] and failures (i.e., events) occurred therefrom, Korea enacted the Framework Act on Sustainable Infrastructure Management (hereinafter, the Infrastructure Management Act) in 2020. This Act focuses on reorganizing a system that manages the social infrastructure and requires the following: to re-establish criteria for maintenance; to set up a long- and short-term management plan; and to evaluate the feasibility of maintenance projects. This Act specifies, as one of its fundamental principles, to “minimize the life cycle cost incurred by deterioration” [2] and prescribes to apply a Life Cycle Cost Analysis (LCCA) as an evaluation of the economic feasibility of performance improvement projects [3].

The LCCA derives future budgetary demands necessary to anticipate a change in a state of assets retained by an organization and secure a targeted service level. To conduct the LCCA, a deterioration model with an asset register is essential for anticipating a future condition of the assets. Based on the “Special Act on the Safety Control and Maintenance of Establishments (hereinafter, the Infrastructure Safety Act)” enacted in 1990s [4], Korea has endeavored to develop data on the status, condition, and history of social infrastructure for the last 30 years. As a result, Korea has developed detailed data on major social infrastructure in a systematic way [5]. However, no deterioration model and LCCA techniques have been established so far for each type/member of social infrastructure, which are officially applicable. That is, even if it is forced to conduct an LCCA by enacting new legislation, it is not prepared to respond thereto in the real world.

Thus, this study aimed to develop a bridge pavement deterioration model for the LCCA as the first step to secure a power of execution of the Infrastructure Management Act. This study subdivided deterioration models by pavement materials (asphalt, concrete, and Latex-Modified Concrete (LMC)) to develop a direction for the development of deterioration models presented by ISO 55001 and International Infrastructure Management Manual (IIMM) which could respond to deterministic/probabilistic LCCA. To sufficiently secure empirical bases, data on inspection and diagnosis conducted for the last 12 years in Korea were applied. As analytical tools, the Bayesian Markov Hazard (BMH) model combining a Markov chain, a multi-state exponential hazard model, and a Markov Chain Monte-Carlo (MCMC) technique were introduced. As its findings, life expectancy by condition grade, deterioration curve, probability density and distribution of the life expectancy, confidence intervals of life expectancy at the 3-sigma rule, and Markov Transition Probability (MTP) as Probability of Failure (POF) were suggested.

This paper presents not only life expectancy for LCCA but also the factors necessary for asset management in a comprehensive manner. It is expected that the methodologies and procedures for deterioration modeling presented herein will become useful precedents that can be referred by other studies on infrastructure.

2. Literature Reviews

ISO 55001, an international standard for managing assets, states that it is essential to predict events likely to occur in the future [6]. It is a basis for sustainable organization management to define in advance the types of events and characteristics of risk which will obstruct an organization from achieving its objectives and establish strategies in preparation. The IIMM developed by applying ISO 55000 series and classifying types of deterioration models into deterministic models and probabilistic models [7]. Furthermore, ISO 55001 (Clause 10.2) requires the identification of a potential failure of assets and uses the same for preventive measures [1]. This means the application of Risk Centered Maintenance (RCM). It is required to investigate in advance the POF to realize the RCM, which would be able to be developed only through a probabilistic model. Thus, this study intended to develop a deterioration model which could support both functions to apply the requirements of ISO 55001.

Internationally, many studies are being conducted on social infrastructure deterioration modelling with a focus on pavement and bridges with various statistical techniques are applied thereto [8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41]. Do et al. [8] classified deterioration modelling techniques into six types and presented their advantages, disadvantages, and selection methods, respectively. Here, they are classified into the citation of useful life in accounting standards, simple calculation of elapse time between maintenances, multiple regression analysis, reliability analysis, traditional Markov chain, and advanced Markov chain application theory. It is presented that the appropriate methodology (or model) shall be selected based on the type, scale, and characteristics of obtained data and the information to be obtained through the deterioration model. Han and Lee [9] presented the conditions of deterioration model for asset management, as follows: (1) description of the transition of the deterioration speed, (2) derivation of information of uncertainty in the deterioration process, (3) derivation of influence of explanatory variables, (4) direct application of the Level of Service (LOS), and (5) resolution of lack of samples and presumption of model parameters. As a result, the BMH model was presented as a model optimized to meet these conditions.

The BMH model was proposed by Kaito and Kobayashi [10] and it overcomes the limitations of a model proposed by Tsuda [11] by applying the MCMC which is a non-parametric method. Thereafter, Bayesian Markov Mixed Hazard Model (hereinafter, the BMMH) that represents the heterogeneity of samples with a benchmark curve and heterogeneity factor was presented [12,13]. This study compared and examined the BMH Model and the BMMH Model to select the most appropriate deterioration modelling technique for this study. The BMMH Model satisfies the ideal conditions for the deterioration model proposed by Han and Lee [9], and is able to develop and compare deterioration models for various sample groups all at once [14,15]. However, the BMMH Model assumes that deterioration models have the similar shape of deterioration curve (i.e., a process in which a deterioration rate changes) due to their nature to utilize a benchmark approach. Such an assumption may not be significant in studies that simply compare the performance of design/material alternatives based on life expectancy. However, such an assumption may become fatal in studies on the LCCA where a process in which deterioration rate change acts as an optimization variable. Thus, this study determined that it would be appropriate to apply the BMH Model considering the possibility that a deterioration curve may vary depending on pavement materials.

Studies on pavement management conducted since the mid-1960s are being conducted more actively in the 21st century [16,17]. Significant results were derived even in Korea in relation to pavement deterioration characteristics from information accumulated through the operation of the Pavement Management System (PMS) [9,14,15,18,19,20,21]. However, it is impractical to apply the findings on general road pavement to the LCCA of bridge pavement. This is because it is difficult to assume that their deterioration characteristics are similar due to their different pavement design, materials, and understructure. Furthermore, a condition of pavement is internationally represented with cracking, rutting, and International Roughness Index (IRI). However, Korea regards bridge pavement as a bridge component and thus its condition is evaluated based on its grade in accordance with the Infrastructure Safety Act [22]. Naturally, the road pavement deterioration models cannot be applied to the LCCA of bridge pavement in Korea and it would be reasonable to derive models by historical performance data of bridge pavement.

A bridge is a complicated structure composed of many components. The American Society for Testing and Materials (ASTM) defines 48 detailed components (at Level 3: individual elements) [23]. Previous studies on bridges have focused on the structural defects in abutment, pier, deck, etc., or the safety of components having a direct effect on collapse [24,25,26,27,28,29,30,31]. Of course, as there are a variety of studies on the deterioration characteristics of bridge pavement [11,32,33,34,35,36], it is impractical to apply the findings of studies conducted in other countries to the LCCA in Korea without change. This is because the LCCA shall reflect thoroughly the deterioration characteristics of its own assets.

Next, the subdivision of the deterioration model is also of interest. It would be convenient to develop a network-based model which represents the whole bridge pavement. However, such a model would not be able to reflect a difference in life expectancy resulting from deviation of technology or materials of pavement. Even the IIMM stated that it would be able to secure the accuracy of prediction only considering the deviation of these assets in terms of technology and environment [7]. In general, asphalt and concrete are used as materials for bridge pavement. However, it takes too long to cure the concrete pavement (28 days or more) [42] and civil complaints are frequently raised due to work zones. To mitigate the problem, the LMC is used as the main material in Korea, which reduces the curing period significantly. The LMC pavement has physical characteristics different from those of conventional concrete and asphalt pavement and has high installation costs [32,33,34]. Thus, it is necessary to confirm its difference from conventional concrete pavement in terms of life expectancy.

The implications obtained through the literature review and plan for application thereof in this study are summarized as follows:

- (1)

- The deterministic and probabilistic approaches shall be applicable simultaneously to comply with international standards for asset management;

- (2)

- The BMH model is appropriate as a deterioration modeling technique to support a variety of asset management information;

- (3)

- The deterioration model for bridge pavement cannot cite a deterioration model for road pavement and shall be built with data native to Korea;

- (4)

- The deterioration model for bridge pavement shall be subdivided to correspond to reality in Korea. It is appropriate to divided it into asphalt, concrete, and LMC.

3. Methodology

3.1. Description of the BMH Model

3.1.1. A Basic Structure of the BMH Model

In this section, the study introduces the process, based on Kaito [10] and Tsuda [11], to disassemble the MTP using the multi-state exponential hazard functions which are the basic structure of the BMH model.

The Markov chain represents a condition with discrete grade . Here, a probability of condition change among grades can be represented with probability variable (see Equation (1)) and the MTP can be organized by collecting these probability elements (see Equation (2)). Naturally, under the axiom of probability, and . Since deterioration models do not include maintenance effects, the following shall be additional conditions: ; and .

In Equation (1), mean the time when a condition is investigated and means the elapsed time between them. These data could be obtained in a field by a road manager. However, what shall be assumed by the deterioration model is not how much the condition changes between but the time between and when the condition grade changes (i.e., life expectancy of grade ). It is impossible to figure out in an investigation system with a specific cycle. The BMH model regards it as a probability variable and seeks a solution to disassemble MTP based on the multi-state hazard model [11].

A multi-state hazard model could represent the condition of an object as plural discrete grades with a possibility of change and formulate routes changeable among these grades as a conditional probability. First, the life expectancy () of condition grade of pavement becomes a probability variable of the probability density function and the probability distribution function . The is a deterioration function and a survival function , which is equivalent thereto as follows:

The probability in which the condition changes to the condition during time interval [ is as follows:

Here, is a hazard function. The hazard function for life expectancy at condition is as follows:

Defining a probability of change among condition grades, the routes of deterioration possible within unit time are summarized as (1), (2), (3), (4) and may be induced to the multi-state exponential hazard model as follows [11]:

where

As shown in Equation (8) through (12), the Markov transition matrix becomes, after all, a function of . However, an influence from explanatory variables that interfere with deterioration process cannot be included in their forms. Thus, an estimation equation can be formulated as follows by adding to an estimation of unknown parameter vector corresponding to independent variable :

Here, the life expectancy of each condition grade is defined as a survival function of the exponential hazard function (see Equation (14)). The life expectancy up to condition is derived by accumulating the life expectancy of each condition grade

That is, the essence of the BMH model can be summarized as the process of to estimate and, to this end, the Metropolis-Hastings (M-H) technique is used, which is one of the most popular techniques among the MCMC.

3.1.2. Parameter Estimation by MCMC

Compared to conventional statistical techniques, such as the Maximum Likelihood Estimation (MLE), etc., the Bayesian statistical technique has the advantage of a lack of samples, an overflow caused by an increase in the dimensions in the matrix, the setting of an initial value of a parameter, and a local maximum [43]. These advantages are particularly effective in the deterioration modeling of social infrastructure, which requires substantial time and effort to secure samples sufficiently and has a variety of variables in elucidating the process of deterioration.

The basis of Bayesian statistics is to figure out or update the relation between prior distribution (or prior knowledge) and posterior distribution. The posterior distribution starts from the fact that it is proportional to the multiplication of prior distribution with a likelihood function [20] (see Equations (15) and (16)).

is a probability variable corresponding to prior distribution . , which is the posterior distribution of , is defined, in accordance with the Bayesian theorem, as follows:

In summary, the Bayesian computation can be defined as follows: (1) definition of prior distribution (also referred to as the initial value); (2) definition of likelihood function utilizing newly obtained; (3) adjustment of prior distribution and update of posterior distribution . However, it is still difficult or impossible to compute referred to as the “normalized constant” (see Equation (16)), i.e., the marginal probability of . This problem is resolved by the MCMC. To realize the MCMC, it is necessary to provide substantial explanation and formulas in relation to the following: definition of likelihood function satisfying Equation (8) through (12); realization of MCMC with M-H techniques; derivation of posterior distribution; examination of maximization using Geweke statistics, etc. This paper will explain in brief the definition of the likelihood function required to predict a model coefficient and the M-H technique.

First, represents data that can be collected in the field. Here, is a dummy variable to become 0 or 1 depending on a change of condition and is an interval between investigation times. In accordance with the Bayesian update rules, a likelihood function is defined, with , as follows:

As presented in Equation (13), is defined as a function of explanatory variable . The prior distribution is normalized as follows so that it is similar to the posterior distribution by assuming normal distribution with an M + 1 dimension.

and are average and covariance matrices of prior distribution, respectively. The MCMC is applied to compute , which is a normalized constant necessary to obtain posterior distribution.

This sampling technique is named “Markov” because an extracted sample is influenced only by the immediately preceding (current) condition and a sample is extracted under the Monte-Carlo sampling based on a probability distribution [43]. In brief, the M-H technique closes the distance with a target distribution (invariant distribution) by repeating the process to update prior distribution into posterior distribution with sampled jumping distribution [44]. Samples derived from the MCMC are classified into the following two groups: a burn-in sample group necessary to reach a convergence region; and an effective sample group used to organize distribution and assume parameters. Many statistical techniques have been developed to check whether the effective sample group converges. However, Geweke statistics are widely used [9,10,12,13,14,15,20,21,40,41]. For detailed information of the Geweke test, please refer to the references [44,45,46].

Lastly, in relation to the application of the BMH model, some important presumptions are enumerated, which shall be perceived by readers:

- (1)

- The state of infrastructure which changes in a continuous manner is represented as a discrete grade;

- (2)

- According to the basic nature of Markov chains, it is presumed that a change in object state is influenced only by its immediately previous state;

- (3)

- Deterioration characteristics (deterioration speed, uncertainty, influence of explanatory variables, etc.) vary depending on the grade and are mutually independent;

- (4)

- The life expectancy of each grade is presumed to be a stochastic variable depending on survival function (i.e., distribution function) and hazard function (i.e., probability density function);

- (5)

- It is presumed that the hazard function follows an exponential function which reflects the nature of event occurrence time depending on a degree of risk and the “memoryless” characteristic of Markov chains;

- (6)

- It is presumed that the conditions applied as an explanatory variable are maintained without change during the life expectancy;

- (7)

- It is presumed that the result of model parameters derived through MCMC is always the same.

3.2. Data Collection and Processing

Bridges on the national highway managed by the Ministry of Land, Infrastructure and Transport (MOLIT) were used to develop a deterioration model. The total length of the national highway in Korea is about 14,098 km. The national highway is widely distributed throughout the nation and has a total of 8850 bridges [47,48].

These bridges are managed in accordance with the Infrastructure Safety Act. The methods and cycles for diagnosis are applied as differentiated depending on the scale and condition grade of a bridge. The diagnosis is conducted in a unit of component and the findings thereof are collected and managed through the Bridge Management System (BMS). This study derived a deterioration model from data on inspection and diagnosis of all bridges collected for 12 years (2009~2020). A proportion by pavement material used in each bridge showed that asphalt, concrete, LMC, and other types were 88.3%, 5.5%, 5.9%, and 0.3%, respectively. In other words, it is possible to conduct the LCCA of all bridges (99.7%) except for some special cases (0.3%) based on the three pavement types.

Since the BMH model uses condition grades as a unit of assumption, the criteria and meaning of determination on each condition grade are very significant. The criteria for determining the condition of bridge pavement under the Infrastructure Safety Act do not classify asphalt and concrete and determines four grades based on defect rate, effect on vehicle driving, and drainage condition. Here, since the defect rate is calculated as ‘damaged area/total area of bridge pavement’, it is possible to evaluate the grade objectively. However, the driving performance, drainage condition, and the final state grade are based on three indicators that are difficult to represent with numeric values determined depending on the inspector’s intuition [22]. For criteria in detail, please refer to Table 1 [22].

Table 1.

Definition of condition grades of bridge pavement in Korea [22].

The Annual Average Daily Traffic (AADT) was applied as an external explanatory variable having an effect on deterioration. Truck volume may be more significant in developing a deterioration model. However, there was no alternative, because the AADT represented the only data on all bridges in the BMS database. For reference, a correlation coefficient ‘R-value’ between AADTs and the truck volumes was derived to be 0.84, which may be determined as being regarded as a variable with which the AADT can replace the traffic volume of trucks. Due to limitations on purpose and secured data of this study, effects of the following shall be left for future studies: scale and form of bridges (rigid-frame bridge, PSCI bridge, cable bridge, etc.); climatic requirements (temperature, moisture, salt stress, etc.); and design deviation (thickness of pavement layer, etc.)

A time series data set is required to apply the BMH model. As presented in Equations (1) and (12), a data set is composed of the following: a condition grade at time A; a condition grade at time B; a time interval Z between two inspection times; and an explanatory variable m (i.e., AADT) that an analyst intends to apply. A total of 8935 data sets were developed as processing data on bridge pavement. Among them, the following were removed: (1) data with simple input errors (5 data sets); (2) data whose condition grade is upgraded with repair and reinforcement (330 data sets); and (3) data improper for developing a model due to short time periods that elapsed with an inspection interval of less than one year (2706 data sets). As a result, a total of 5894 data sets were classified as effective. By reorganizing the data sets by pavement materials, the following were secured: 5257 (89.2%) data sets with asphalt pavement; 288 (4.9%) data sets with concrete pavement; and 349 (5.9%) data sets with LMC pavement. It was determined that, even if the number of samples was relatively small in relation to concrete and LMC pavement, it would not be so impractical to develop a deterioration model empirically.

4. Results

4.1. Estimation of Hazard Functions, Life Expectancies, and Deterioration Curves

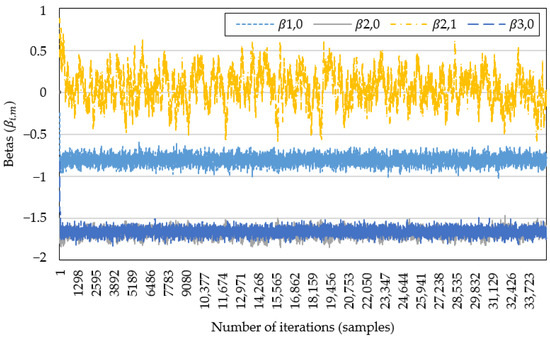

In this section, this study compares and analyzes the following: model parameters by bridge pavement type; hazard function; life expectancy; and results of derivation of deterioration curve. The MCMC was applied to a total of six model parameters (see Equation (13)). The number of times being sampled for each parameter was 35,000. The initial 5000 times were regarded as burn-in samples to enter a convergence region and 30,000 samples thereafter were used to assume parameters. The final model parameter values in Table 2 were easily obtained as expectation values of the distribution of the effective samples (i.e., Sample ID 5001~35,000), that is, the average of the effective samples. A stride of random walk was set to 0.001 to guarantee the stable movement of MCMC. Table 2 and Figure 1 present the process and result of assuming parameters with MCMC.

Table 2.

Parameters of the BMH model by the condition ratings.

Figure 1.

Trace-plots of the MCMC by parameters (case: asphalt pavement).

It is shown that the Geweke’s Z-score, based on which it was determined whether converged normally, was close to 0.00, which is an optimal value (tolerance interval [–2,2]). From the path of MCMC illustrated in Figure 1, it can be known that the sampling was conducted in a very stable manner. In particular, it can be verified that it entered into an effective region from about 1000 times of sampling and then repeated similar patterns thereafter. Table 3 shows the results of deriving hazard function and life expectancy by pavement type derived from the results in Table 2. For a deterioration curve derived by linking life expectancy by condition grade, please refer to Figure 2.

Table 3.

Hazard functions and life expectancy by condition grade.

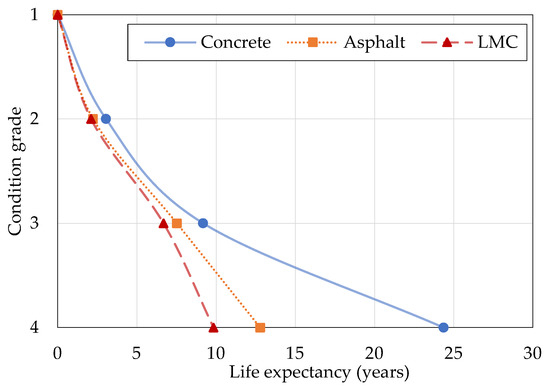

Figure 2.

Comparison of deterioration curves by bridge pavement materials.

Average life expectancy by pavement material type was analyzed as 12.8 years, 24.4 years and 9.8 years for asphalt, concrete and LMC, respectively. The presented contents were a deterministic deterioration model and can be used as a condition update function when applying the LCCA. The life of concrete was almost twice that of asphalt. On the contrary, the LMC pavement belonging to concrete showed a life shorter than asphalt pavement. In terms of the shape of the deterioration curve, the deterioration curve of asphalt and LMC was close to linear, and the deterioration curve of concrete was close to logarithmic, wherein the deterioration rate gradually became slow. In particular, all three types of pavement showed similar deterioration characteristics up to C grade. However, the life expectancy was relatively long in C → D grade in concrete pavement.

It is necessary to examine whether the results of this study are consistent with the physical properties of pavement materials. The Structural Number of Pavement (SNP) is an index that can compare the structural strength of pavements equally. American Association of State Highway Officials (AASHO) road test, the fourth Highway Development and Management (HDM-4) model of the World Bank, and the conversion factor of the surface layer proposed/applied by the American Concrete Pavement Association (ACPA), the value of 0.30 to 0.44 for asphalt and 0.50 for concrete are specified [49,50,51]. That is, concrete has a high contribution of up to 1.7 times. The difference in life expectancy between concrete and asphalt presented in this study was about 1.9 times, confirming a similar trend.

In light of the preceding research on the presumption of life expectancy by pavement material, the life expectancy of asphalt, concrete, and LMC is presumed to be about 10~15 years, 25~30 years, and 15 years, respectively [32,33,34,35]. They also presented the difference in pavement strength and durability as a cause for such deviation. It seems that the life expectancy of asphalt and concrete is similar to the findings of this research. However, the life expectancy of LMC was substantially different from that in the preceding research. It is presumed that the “Rapid Setting-LMC (RS-LMC)” which is widely used in Korea is disadvantageous to securing strength, compared to traditional LMC [52,53].

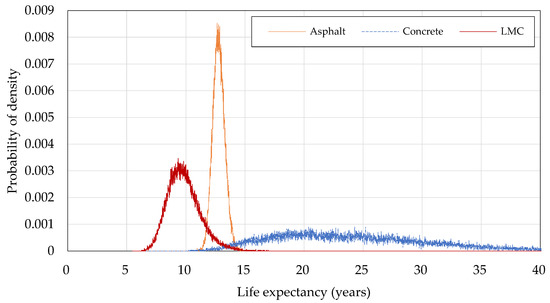

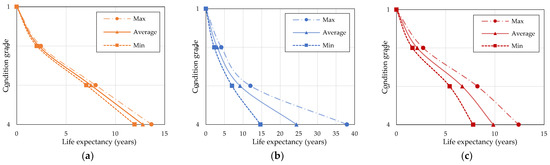

4.2. Uncertainty of Life Expectancy and Confidence Intervals by 3-Sigma Rule

The life expectancies presented in Figure 2 were represented as single values in terms of average. However, since they include uncertainty, they could be significantly different from average life expectancy depending on the conditions of each bridge. Thus, this study presented the probability distribution of life expectancy using parameter samples derived through the MCMC process (see Figure 3) and derived a confidence interval of life expectancy by applying 3-sigma rules [54] (see Table 4). Statistical ranges of life expectancy based on a confidence level of 95% (2-sigma) are illustrated in Figure 4.

Figure 3.

Probability density of life expectancy by bridge pavement materials.

Table 4.

Statistical confidence intervals of life expectancy at the 3-sigma rule.

Figure 4.

Deterioration curves at confidence interval 95% (2-sigma) (a) Asphalt pavement; (b) Concrete pavement; (c) LMC pavement.

In Figure 3, asphalt and LMC had a relatively small dispersion of life expectancy. Furthermore, the form of distribution is also clear. On the contrary, in the case of concrete, the probability density was distributed in a wide area and its peak was not clear, either. If additional data were secured, the form of distribution might change. However, in light of the fact that the number of the data was about 350, it is not very likely that the peak position of probability density would move significantly (i.e., probability that the value of life expectancy would change significantly). However, in case of concrete C grade → D grade with the largest dispersion, it was necessary to verify the reliability of results by collecting more data and updating the model in a continuous manner.

The probability distribution of life expectancy illustrated in Figure 3 can be used as a probability density of Monte Carlo sampling. That is, the probability distribution of future budgetary demand can be prepared through a repetitive LCCA simulation. The scope of required budget can be derived based on the confidence level. This means that the probabilistic LCCA would become feasible.

4.3. Calculation of POF Presneted by Markov Transition Probability Matrix

The estimation of POF is essential to manage organizational risks, to apply the RCM. Here, if a failure is defined as a transition between condition grades, the POF can be organized in an MTP format and used as a probabilistic condition update function. One of the biggest advantages of the BMH model is that the MTP standardized in a unit time can be combined through multi-state hazard functions (see Equations (8)–(12)). Table 5 shows the results of MTP calculation by pavement material type.

Table 5.

Average Markov transition probability matrix by pavement material.

The MTP in Table 5 is an average condition change probability by pavement material. If the AADT of bridge is applied as an explanatory variable of hazard function (see Equation (13)), the probabilistic LCCA becomes feasible at every individual bridge. This is because the MTP and hazard function unique to each bridge are secured. Meanwhile, the life expectancy of concrete pavement with C grade was relatively long (see Figure 2). Compared to 3→4 grade transition probability, concrete pavement (0.068) was lower than asphalt pavement (0.173) by more than 2.5 times and LMC (0.275) by more than 4 times, respectively.

It is presumed that these findings resulted from the physical characteristics of the material itself and behavioral characteristics with bridge deck. In general, concrete has a relatively high strength and loses almost no durability even with long-term use. Furthermore, since the same material as the bridge deck is used, it can be well-attached to the bridge deck and is structurally stable in terms of shrinkage, expansion, and vibration. In addition to this, it is presumed that the RS-LMC is disadvantageous to secure structural stability and strength, because latex is included therein.

5. Conclusions

As the first step to secure an execution power of the Infrastructure Management Act, this study developed a deterioration model for bridge pavement in Korea. This study subdivided deterioration models by pavement material by accepting a direction of developing deterioration models as presented in ISO 55001 and IIMM and developed a deterioration model which could respond to deterministic/probabilistic LCCA altogether. In sum, the findings of this study are as follows:

- 1.

- The average life expectancy by pavement material was analyzed to be 12.8 years, 23.4 years and 9.8 years for asphalt, conventional concrete, and LMC, respectively. Thus, a basis of the deterministic LCCA was established;

- 2.

- This study presented the probabilistic distribution of life expectancy and the POF (i.e., MTP matrix) by pavement material by applying the BMH model. Thus, a basis of the probabilistic LCCA was established;

- 3.

- The effective range of life expectancy at a confidence level of 95% was 12.0~13.7 years, 14.7~37.9 years, and 7.8~12.4 years for asphalt, concrete, and LMC, respectively. This result may be referred even to define the service life and effective range necessary to evaluate asset values;

- 4.

- The life expectancy of the LMC pavement most expensive in terms of price was shorter than that of conventional asphalt. It is necessary to figure out causes therefore and review in terms of technology and economic feasibility whether to continue to apply LMC pavement.

The limitation of this study and future research tasks may be classified into the following three groups: First, as the purpose of the study was restricted to the development of a deterioration model for LCCA, we did not approach in depth the influence on various internal/external explanatory variables. It is necessary for future research to sophisticate deterioration models considering bridge understructure, deviation in pavement design, environmental factors, etc. Second, it is necessary to verify how much the research findings correspond to reality. Even if this study asked experts of BMS and PMS about the accuracy of life expectancy of three types of pavement, even experts with broad experiences could not give a definite answer. As the best alternative solution, it is necessary to apply various deterioration modeling techniques and compare the results thereof in a relative manner. Lastly, bridge pavement is only one of numerous components. The securement of execution power of the Infrastructure Management Act presented as the fundamental purpose of this study is achievable only after enabling the LCCA for all components of bridges and all social infrastructure. Future research shall develop deterioration models standardized for various types of social infrastructure by applying a method to develop a deterioration model as presented in this study.

Author Contributions

Conceptualization, D.H.; methodology, D.H.; software, D.H.; validation, D.H.; formal analysis, J.-H.L. and D.H.; investigation, J.-H.L.; resources, J.-H.L.; data curation, J.-H.L.; writing—original draft preparation, D.H.; writing—review and editing, J.-H.L. and K.-T.P.; visualization, J.-H.L.; supervision, K.-T.P.; project administration, K.-T.P.; funding acquisition, K.-T.P. All authors have read and agreed to the published version of the manuscript.

Funding

Research for this paper was carried out under the KICT Research Program (project no. 20220217-001, Development of DNA-based smart maintenance platform and application technologies for aging bridges) funded by the Ministry of Science and ICT.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors appreciate the technical support of the asset metrics research team of Kyoto University and Osaka University. Also, we conducted this study with research support from the Ministry of Science and ICT and the project “Development of DNA-based smart maintenance platform and application technologies for aging bridges”. We express our gratitude to everyone involved.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Lee, Y. Megatrend—Inquire into the Future of Construction Vol. 4: Sustainable Infrastructure Management; Korea Research Institute for Construction Policy: Seoul, Korea, 2021; p. 119. (In Korean) [Google Scholar]

- MOLIT (Ministry of Land, Infrastructure and Transport). Framework Act on Sustainable Infrastructure Management; National Act-17237; MOLIT: Sejong City, Korea, 2020; p. 1. (In Korean)

- MOLIT (Ministry of Land, Infrastructure and Transport). Evaluation Standard for Performance Improvement Project of Road Facilities; Government Notice–2021/213; MOLIT: Sejong City, Korea, 2021; p. 4. (In Korean)

- MOLIT (Ministry of Land, Infrastructure and Transport). Special Act on the Safety and Management of Facilities; National Act-17237; MOLIT: Sejong City, Korea, 2021; pp. 12–15. (In Korean)

- Facility Management System. Available online: https://www.fms.or.kr/com/mainFrame.do (accessed on 30 May 2022).

- ISO 55001. 2014 Asset Management-Management Systems-Requirements; ISO (International Organization for Standardization): Geneva, Switzerland, 2014; p. 1. [Google Scholar]

- IPWEA (Institute of Public Works Engineering Australasia). International Infrastructure Management Manual (International Edition 2015), 5th ed.; IPWEA: North Sydney, Australia, 2015; pp. 2–90. [Google Scholar]

- Do, M.; Park, S.; Han, D.; Lee, S.; Shin, H.; Kim, S. Infrastructure Asset Management with ISO 55000; CIR Publication: Seoul, Korea, 2018; pp. 55–60. [Google Scholar]

- Han, D.; Lee, S. Stochastic forecasting of life expectancies considering multi-maintenance criteria and localized uncertainty in the pavement-deterioration process. J. Test. Eval. 2016, 44, 128–140. [Google Scholar] [CrossRef]

- Kaito, K.; Kobayashi, K. Bayesian estimation of markov deterioration hazard model. J. Jpn. Soc. Civ. Eng. Part A 2007, 63, 336–355. [Google Scholar] [CrossRef][Green Version]

- Tsuda, Y.; Kaito, K.; Aoki, K.; Kobayashi, K. Estimating markovian transition probabilities for bridge deterioration forecasting. J. Struct. Eng. Earthq. Eng. 2006, 23, 241s–256s. [Google Scholar] [CrossRef]

- Obama, K.; Okada, K.; Kaito, K.; Kobayashi, K. Disaggregated hazard rates evaluation and bench-marking. J. Jpn. Soc. Civ. Eng. 2008, 64, 857–874. [Google Scholar] [CrossRef][Green Version]

- Kaito, K.; Kobayashi, K.; Aoki, K.; Matsuoka, K. Hierarchical bayesian estimation of mixed hazard models. J. Jpn. Soc. Civ. Eng. 2012, 68, 255–271. [Google Scholar]

- Han, D.; Kaito, K.; Kobayashi, K.; Aoki, K. Performance evaluation of advanced pavement materials by bayesian markov mixture hazard model. KSCE J. Civ. Eng. 2017, 20, 729–737. [Google Scholar] [CrossRef]

- Han, D.; Kaito, K.; Kobayashi, K. Application of bayesian estimation method with markov hazard model to improve deterioration forecasts for infrastructure asset management. KSCE J. Civ. Eng. 2014, 18, 2107–2119. [Google Scholar] [CrossRef]

- Hass, R.; Hudson, W.R.; Falls, L.C. Pavement Asset Management; Scrivener Publishing: Beverly, MA, USA, 2015; pp. 5–8. [Google Scholar]

- Heriberto, P.A.; Alaitz, L.U.; Ricardo, A.; Eduardo, R. Research trends in pavement management during the first years of the 21st century: A bibliometric analysis during the 2000–2013 period. Appl. Sci. 2018, 8, 1041. [Google Scholar] [CrossRef]

- Han, D. Empirical evaluation of utility of anti-frost layer in pavement structure considering regional climate characteristics. Int. J. Pavement Eng. 2022, 8, 2821–2828. [Google Scholar] [CrossRef]

- Kobayashi, K.; Do, M.; Han, D. Estimation of markov transition probabilities for pavement deterioration forecasting. KSCE J. Civ. Eng. 2010, 14, 343–351. [Google Scholar] [CrossRef]

- Han, D.; Do, M.; Kim, B. Internal property and stochastic deterioration modeling of total pavement condition index for transportation asset management. Int. J. Highw. Eng. 2017, 19, 1–11. [Google Scholar] [CrossRef]

- Han, D.; Kaito, K.; Kobayashi, K.; Aoki, K. Management scheme of road pavements considering heterogeneous multiple life cycles changed by repeated maintenance work. KSCE J. Civ. Eng. 2017, 21, 1747–1756. [Google Scholar] [CrossRef]

- MOLIT (Ministry of Land, Infrastructure and Transport). Detailed Guidelines for the Safety and Maintenance of Facilities; Ministry of Land, Infrastructure and Transport: Sejong-Si, Korea, 2021; pp. 1–38. (In Korean)

- ASTM (American Society for Testing and Material). Standard Classification for Bridge Elements—Uniformat II (E2103/E2103M-19); ASTM International: West Conshohocken, PA, USA, 2019; p. 4. [Google Scholar]

- Huang, Y.H. Artificial neural network model of bridge deterioration. J. Perform. Constr. Facil. 2010, 24, 597–602. [Google Scholar] [CrossRef]

- Akiyama, M.; Frangopol, D.M. Long-term seismic performance of RC structures in an aggressive environment: Emphasis on bridge piers. Struct. Infrastruct. Eng. 2014, 10, 865–879. [Google Scholar] [CrossRef]

- Biondini, F.; Frangopol, D.M. Time-variant redundancy and failure times of deteriorating concrete structures considering multiple limit states. Struct. Infrastruct. Eng. 2016, 13, 94–106. [Google Scholar] [CrossRef]

- Yanweerasak, T.; Pansuk, W.; Akiyama, M.; Frangopol, D.M. Life-cycle reliability assessment of reinforced concrete bridges under multiple hazards. Struct. Infrastruct. Eng. 2018, 14, 1011–1024. [Google Scholar] [CrossRef]

- Lee, J.H.; Choi, Y.; Ann, H.; Jin, S.Y.; Lee, S.J.; Kong, J.S. Maintenance cost estimation in PSCI girder bridges using updating probabilistic deterioration model. Sustainability 2019, 11, 6593. [Google Scholar] [CrossRef]

- Saeed, T.U.; Qiao, Y.; Chen, S.; Gkritza, K.; Labi, S. Methodology for probabilistic modeling of highway bridge infrastructure condition: Accounting for improvement effectiveness and incorporating random effects. J. Infrastruct. Syst. 2017, 23, 04017030. [Google Scholar] [CrossRef]

- Saeed, T.U.; Moomen, M.; Ahmed, A.; Murillo-Hoyos, J.; Volovski, M.; Labi, S. Performance evaluation and life prediction of highway concrete bridge superstructure across design types. J. Perform. Constr. Facil. 2017, 31, 04017052. [Google Scholar] [CrossRef]

- Sinha, K.C.; Labi, S.A.; McCullouch, B.G.; Bhargava, A.; Bai, Q. Updating and Enhancing the Indiana Bridge Management System (IBMS), Volume 1 (Technical Manual); Publication FHWA/IN/JTRP-2008/30; Indiana Department of Transportation and Purdue University: West Lafayette, IN, USA, 2009; pp. 97–107. [Google Scholar]

- Arpad, H.; Chris, H. Comparison of Environmental Implications of Asphalt and Steel-Reinforced Concrete Pavements. Transp. Res. Rec. 1998, 1626, 105–113. [Google Scholar] [CrossRef]

- Kuhlmann, L.A. Performance History of Latex-Modified Concrete Overlays. ACI J. 1981, 69, 123–144. [Google Scholar]

- Lee, S.J.; Park, S.I.; Park, S.H. Latex concrete bridge pavement application. Int. J. Highw. Eng. 2000, 2, 55–63. [Google Scholar]

- Saeed, T.U.; Qiao, Y.; Chen, S.; Alqadhi, S.; Zhang, Z.; Labi, S.; Sinha, K.C. Effects of Bridge Surface and Pavement Maintenance Activities on Asset Rating; Publication FHWA/IN/JTRP-2017/19; Indiana Department of Transportation and Purdue University: West Lafayette, IN, USA, 2017; pp. 7–52. [Google Scholar] [CrossRef]

- Jin, S.Y.; Lee, J.H.; Choi, Y.R.; Lim, J.; Kong, J.S. Optimal Bridge Maintenance Cost Calculation Algorithms Considering Components Correlation using Genetic Algorithms; Workshop on Life Cycle Management: Rotterdam, The Netherlands, 2019. [Google Scholar]

- Srikanth, I.; Arockiasamy, M. Deterioration models for prediction of remaining useful life of timber and concrete bridges: A review. J. Traffic Transp. Eng. 2020, 7, 152–173. [Google Scholar] [CrossRef]

- Estes, A.C.; Frangopol, D.M. Repair optimization of highway bridges using system reliability approach. J. Struct. Eng. 1999, 125, 766–775. [Google Scholar] [CrossRef]

- Lavrenz, S.M.; Saeed, T.U.; Murillo-Hoyos, J.; Volovski, M.; Labi, S. Can interdependency considerations enhance forecasts of bridge infrastructure condition? Evidence using a multivariate regression approach. Struct. Infrastruct. Eng. 2020, 16, 1177–1185. [Google Scholar] [CrossRef]

- Kobayashi, K.; Kaito, K.; Nam, L. A statistical deterioration forecasting method using hidden markov model for infrastructure management. Transp. Res. Part B 2012, 46, 544–561. [Google Scholar] [CrossRef]

- Han, D. Heterogeneous deterioration process and risk of deficiencies of aging bridges for transportation asset management. Sustainability 2021, 13, 7094. [Google Scholar] [CrossRef]

- KCS-14 20 10: 2022. Standard Specification for Concrete Construction; KCS (Korean Construction Specification); Ministry of Land, Infrastructure and Transport: Sejong-Si, Korea, 2022; p. 19. (In Korean) [Google Scholar]

- Train, K.E. Discrete Choice Methods with Simulation, 2nd ed.; Cambridge University Press: New York, NY, USA, 2009; pp. 185–214. [Google Scholar]

- Koop, G.; Poirier, D.J.; Tobias, J.L. Bayesian Econometric Methods; Cambridge University Press: New York, NY, USA, 2007; pp. 128–157. [Google Scholar]

- Geweke, J. Evaluating the accuracy of sampling-based approaches to the calculation of posterior moments. In Bayesian Statistics, 4th ed.; Bernardo, J.M., Berger, J.M., Dawid, A.P., Smith, A.F.M., Eds.; Oxford University Press: Oxford, UK, 1992; pp. 169–193. [Google Scholar]

- Chan, N.H.; Wong, H.Y. Simulation Techniques in Financial Risk Management; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2006; pp. 167–185. [Google Scholar]

- MOLIT (Ministry of Land, Infrastructure and Transport). Yearbook of Road Statistics 2020; MOLIT: Sejong-Si, Korea, 2021; p. 8. (In Korean)

- MOLIT (Ministry of Land, Infrastructure and Transport). Yearbook of Road Bridge and Tunnel Statistics 2021; MOLIT: Sejong-Si, Korea, 2021; p. 3. (In Korean)

- Rohde, G.T.; Hartman, A. Comparison of procedures to determine structural number from FWD deflections. In Proceedings of the 18th ARRB Transport Research Conference and Transit New Zealand Land Transport Symposium, Melbourne, Australia, 2–6 September 1999. [Google Scholar]

- Morosiuk, G.; Riley, M.J.; Odoki, J.B. Modelling Road Deterioration and Works Effects (Version 2)—Highway Development & Management Series (HDM-4); Transport Research Laboratory: Crowthorne, UK, 2004; Volume 6, pp. B2–B4. [Google Scholar]

- ACPA (American Concrete Pavement Association), Equivalency Chart: For Concrete and Asphalt Pavements. ACPA org. Available online: https://www.scribd.com/document/355669917/ACPAPavementEquivalencyChart-1 (accessed on 1 September 2022).

- Michael, M.S. Very-Early-Strength Latex-Modified Concrete Overlay. Transp. Res. Rec. 1999, 1, 18–23. [Google Scholar] [CrossRef]

- Jeong, W.-K.; Kim, Y.-G.; Kim, K.-H.; Yun, K.-K. Rehabilitation of Concrete Pavement with VES-LMC overlay. J. Ind. Technol. 2005, 25, 3–10. (In Korean) [Google Scholar]

- Pukelsheim, F. The three sigma rule. Am. Stat. 1994, 48, 88–91. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).