Abstract

Today, sustainability represents a fundamental concept to be developed and implemented in any industrial context. Therefore, it is essential to be able to measure sustainability performance by proper indicators, along the entire lifecycle and the value chain, considering environmental, economic, and social impacts. Moreover, every manufacturing company should have a specific measuring framework to calculate all the specific parameters. In this direction, the modern digital transition and Industry 4.0 (I4.0) technologies are proposing to transform human–machine relations, with a significant impact on social and organizational aspects. At the same time, digitization can help companies to define and implement sustainability by correlating production with proper evaluation metrics. The aim of this research is to provide a complete overview of sustainability Key Performance Indicators (KPIs) based on the Triple Bottom Line concept, referring to the three sustainability areas. Such an overview can be used by companies to set their specific KPIs and metrics to measure their sustainability level, according to their needs.

1. Introduction

Sustainability is defined as “development that satisfies the needs of the present without compromising the ability of future generations to satisfy their own needs” [1]. Consequently, designing in a sustainable way means implementing a strategic plan to be increasingly competitive in the market. Presently, sustainability is a crucial concept that is considered very important when you want to design in an ecological, economic, and socially-respectful way. In this direction, the adoption of reliable systems to measure and quantify sustainability is fundamental for companies to understand their position according to modern sustainability goals, to strengthen their competitiveness, and to make sustainability a critical factor for their success [2].

In this context, three dimensions of sustainability have been defined in the literature [3]: environmental, economic, and social. In 1998, Elkington first defined the concept of the Triple Bottom Line (TBL) to treat all three dimensions of sustainability with equal importance [2]. The environmental dimension of the TBL concept is based on the relationship between the use and the renewal of natural resources. Referring to manufacturing industries, this dimension is manifested only in the use of renewable natural resources with zero emissions. This dimension is therefore linked to the concept of recycling and regeneration of resources. The social dimension refers to all those actions that make it possible to better preserve and develop the management of human resources. The third economic dimension refers to the ability to create value with a business strategy capable of balancing costs and revenues. It includes both the management of the economic and financial performance of the industry [4]. In this direction, the assessment of sustainability impact is a mandatory step forward in the achievement and improvement of company sustainability. Being able to manage the sustainable performance of a company means implementing a sustainable strategy. Despite this, being able to implement this plan still appears to be a significant gap in the literature. Having a set of sustainability performance indicators is a prerequisite for effective performance management [2]. The evaluation and management of corporate sustainability allow for the prevention and avoidance of problems. It is possible to eliminate and reduce risks, conform to standards and regulations, foresee threats, reduce costs, increase efficiency, strengthen competitive advantages, facilitate sustainability reporting and improve operational performance [5]. Every manufacturing company should have a measuring tool to be able to calculate all the specific parameters by proper Key Performance Indicators (KPIs). Lord Kelvin defined KPIs as “When you can measure what you are speaking about and measure it in numbers, you know something about it, when you cannot express it in numbers, your knowledge is of meager and unsatisfactory kind; it may be the beginning of knowledge, but you have scarcely, in your thoughts advanced to the stage of science” [6]. A KPI is a measurable value that demonstrates the effectiveness with which a company is achieving its main business objectives. A KPI is then transformed into a measurable number by proper evaluation metrics. In terms of sustainability, at the company level, a proper set of KPIs and related metrics need to be defined to quantify economic, environmental, and social performance.

Even though in recent years, companies have adopted different types of standards of the International Organization for Standardization (ISO) in their strategic plans, the results show that social and organizational aspects are still considered less important compared to environmental and economic ones. Therefore, implementing a social sustainability plan can be considered fundamental since neglecting fundamental social aspects can cause serious difficulties in showing itself to be a virtuous company [7]. Attention to workers, their working conditions, and gender equality appears to be increasingly important.

In recent years, the social aspects have been a source of studies for numerous researchers who have shown a strong interest in investigating and deepening the social dimension [8]. In 2015, the United Nations Agreement based on 17 Global Goals for Sustainable Development was established. In particular, all aspects not related to the economic sphere, but to the social and environmental one, were included. According to the arguments of the European Commission for sustainable development, the quality of human resources is a key competitive issue, which requires constant attention by management to different dimensions of economic, social, and environmental changes [9].

In addition to the concept of sustainability, the concept of I4.0 has been gaining ground among the main manufacturing companies in recent years. However, many companies are still opposed to turning their manufacturing actions into smart grid-connected processes. In fact, in order to have a smart factory according to the I4.0 concepts, high investments and knowledge are required, which not all companies have. The digital transition of factories and I4.0 technologies have not yet been fully exploited to correlate production and social metrics. As a result, there is a lack of adequate tools for monitoring social and organizational performance in the factory environment. The digitization of production processes not only enables the assessment of environmental and economic impact, but it can also play a key role in knowing the social performance of a manufacturing organization and identifying the social dimension in the circular economy scenario [10].

The combination of I4.0 technologies with the concept of sustainability would make each company a resilient and competitive firm in the market. Despite this, no studies have been found in the literature that define a methodology able to measure and quantify sustainability in a standardized way [7].

The aim of this study is to review the state of the art about sustainability indicators for manufacturing companies and to present a set of indicators that allow the measurement of sustainability according to its three areas, with particular attention to organizational and social impacts.

The rest of the article is divided as follows: chapter 2 illustrates the methodology used to select the articles and to carry out the paper review; chapter 3 investigates the resulting KPIs and their use in different manufacturing contexts, and finally selects a set of KPIs suitable for manufacturing contexts; chapter 4 discuss the results and finally chapter 5 presents the conclusions.

2. Materials and Methods

2.1. Research Questions

The aim of this research is to fill the gap found in the research by defining a set of sustainability performance indicators in an industrial context. This goal evokes three research questions, which are examined in this article:

- How can digitization help to have data in real time and constantly updated?

- How can one measure a generic set of sustainability KPIs in industrial contexts?

- How can one refer to the different areas of sustainability in the economic, social, and environmental fields?

2.2. Methodology

The research was carried out considering the state-of-the-art sustainability assessment indicators in the last 8 years on an international scientific scenario. We have considered different databases to provide an excellent view of the sustainability indicators used for industrial purposes, across countries and industrial sectors. The literature was identified through the following scientific paper databases: Scopus, Science Direct, Elsevier, IEEE, Google scholar, Taylor and Francis, and Springer.

A structured methodology was adopted to select the papers. We started with the insertion of macro-topics on the databases such as (“KPI” Or “Indicator” Or “Key Performance Indicator” Or “Metric” Or “LCA Indices”) And (“Sustainability” Or “TBL” Or “Triple Bottom Line” Or “Sustainable Development”) And (“Company” Or “Manufacturing Company” Or “Industry” Or “Firm” Or “Corporate” Or “Manufacturing” Or “Production” Or “Industrial Machines”) and, for each filter used, the number of articles was reduced. Terms relating to indicators, methods of selecting these indicators, the concept of sustainability, and the industrial context were used. After this analysis, the number of articles was 12,194.

The analysis was limited by the type of article, considering only the readable papers (selecting the “Open Access”, “Gold” and “Access allowed via university database or for a fee”), by year (from 2015 to 2022), by topic (“Environmental Science”, “Environmental” and “Energy”, “Business, Management and Accounting”, “Computer Science”, “Decision Sciences”, “Economics, Econometrics and Finance”, “Engineering”), by type of article (“Journal”, “Conference” or “Review”) and by language (“English”). Finally, we also searched for further articles by reading the references of the most important selected papers. The selection then led to the analysis of 63 articles.

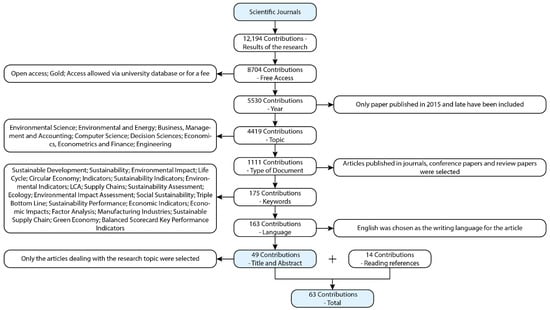

The bibliographic search generated 12,194 results starting from the selection of the concepts as mentioned above. The large number of articles written testifies to the importance of the topic and the need for a review article that summarizes the latest research and discoveries. The diagram shown in Figure 1 describes in detail the methodology for paper selection.

Figure 1.

Methodology for the review paper selection.

- Free access: we started with 12,194 articles, which were then reduced to 8704 after having selected those with free access (“open access”, “gold”, “access allowed via university database or for a fee”);

- Year: we reduced the articles to 5530 after the analysis of the year of publication—only papers published in 2015 and later were included. We selected articles starting from 2015 as it has been shown in previous articles that this year the peak of publications in this area was highlighted [11]. Nonetheless, additional articles (found in the bibliography of other articles) deemed relevant for the analysis were considered;

- Topic: 4419 articles were discarded after selecting the main topic of the articles analyzed (“Environmental Science”, “Environmental and “Energy”, “Business, Management and Accounting”, “Computer Science”, “Decision Sciences”, “Economics, Econometrics and Finance”, “Engineering”);

- Type of document: of the 1111 remaining articles, articles published in journals, conference papers and review papers were selected;

- Keywords: to further narrow the search, keywords that are most relevant to the topic were selected, resulting in 175 articles (“Sustainable Development”, “Sustainability”, “Environmental Impact”, “Life Cycle”, “Circular Economy”, “Indicators”, “Sustainability Indicators”, “Environmental Indicators”, “LCA”, “Supply Chains”, “Sustainability Assessment”, “Ecology”, “Environmental Impact Assessment”, “Social Sustainability”, “Triple Bottom Line”, “Sustainability Performance”, “Economic Indicators”, “Economic Impacts”, “Factor Analysis”, “Manufacturing Industries”, “Sustainable Supply Chain”, “Green Economy”, “Balanced Scorecard Key Performance Indicators”);

- Language: English was chosen as the writing language for the article, resulting in 163 articles;

- Title and abstract: of the 163 articles, the title and abstract were read, and only the articles dealing with the research topic were selected. The final selection of the articles read was 49.

- Reading references: of the 49 selected articles, the respective bibliographies were reviewed and further 14 articles deemed important for the research were selected (although they were published before 2015), due to their high relevance to the research topic.

2.3. Analysis of the Literature

The analysis of the selected articles allows for a complete overview of what are, to date, the KPIs used in industrial business contexts. To select the set of KPIs, we considered and analyzed the documents containing indicators of all three areas of sustainability. We created a series of KPIs by selecting them from the most recent articles, in order to have an updated state-of-the-art review starting from 2015 to 2022.

Table 1 sums up the main features of the 63 selected articles. For each article, the following was indicated: year of publication, definition of economic, environmental and/or social indicators, metrics for the calculation of KPIs, and the journal in which it was published.

Table 1.

Selected paper published in different journals and related classes of KPIs (Key Performance Indicators).

Table 1 highlights the large number of articles that list indicators in the three areas of sustainability, but, reading the articles, the authors noted that there is a lack of a single set of generic KPIs to measure sustainability in a manufacturing company. The existing literature does not seem to adequately cover all the pillars of economic, environmental, and social sustainability. Some authors have proposed indicators for measuring industrial performance in different contexts [14,34,48] and only a few have presented all three sustainability indicators [50,52,53,54]. Furthermore, only a few articles presented metrics capable of quantitatively measuring the reported indicator.

Reading the various articles, we also found the lack of a unique, standardized system to constantly monitor sustainability performance indicators. The purpose of controlling the sustainability parameters is crucial to obtain reliable data and exploit it to one’s advantage. Through specific metrics, performance indicators can be identified and measured. For every company, it is fundamental to predict the current sustainability level and to predict the future situation to drive sustainability parameter changes.

3. Results

The resulting list of KPIs that emerged from the literature review was reported considering the three areas of sustainability (environmental, economic, and social). Table 2 illustrates all the KPIs broken down by type of industrial sector. All the reported KPIs are with reference to the article in which they were selected. The table shows an exact correspondence of the indicators presented in the respective articles. For the meaning of each indicator, reference is made to the article in which it is mentioned.

Table 2.

KPI of the selected articles.

3.1. Selection of Sustainability KPIs

After the review, a subjective selection of indicators was carried out. Macro-categories were identified for each area. This selection made it possible to group together the main and generic KPIs that can be implemented in any company (regardless of company size and type of production). The selected KPIs are a generic set that must be adapted to every circumstance and type of company. Each KPI can therefore have different metrics with which to be measured depending on the business context.

The KPIs selected are shown below, divided into three categories: social indicators, environmental indicators, and economic indicators.

For each area of sustainability, the KPIs most used by manufacturing industries in recent years have been defined. A clear difference was found in the KPIs available for each sector (economic, environmental, and social). It was found that, only in recent years, the social sustainability indicators have been implemented and applied at an industrial level.

In particular, we focused on social and organizational sustainability indicators due to their importance in modern industrial scenarios but, at the same time, the lack of a standardized evaluation framework. A total amount of 117 indicators were obtained, respectively: 48 social indicators, 30 environmental indicators, and 39 economic indicators.

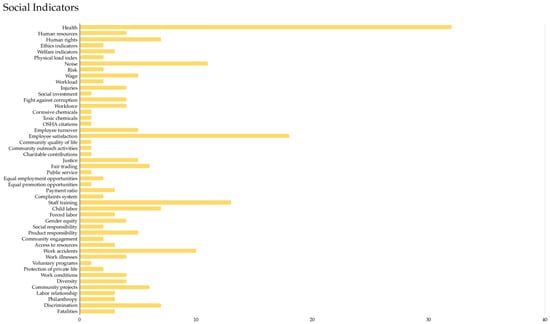

3.1.1. Social KPIs

A focus was placed on social and organizational sustainability indicators as, only recently, social, and organizational sustainability concepts have been implemented in corporate contexts. The monitoring of these aspects appears to be fundamental for a successful business strategy.

Figure 2 illustrates the selected 48 social KPIs and how many times each indicator appeared in the articles analyzed in the review. Results show higher attention to “health”, used by 32 papers. Below are: “employee satisfaction”, “staff training”, “noise”, and “work accidents”. These parameters are those that companies currently consider the highest priority. Table A1 in Appendix A lists the articles presenting each macro-category of selected social indicators.

Figure 2.

Social Indicators.

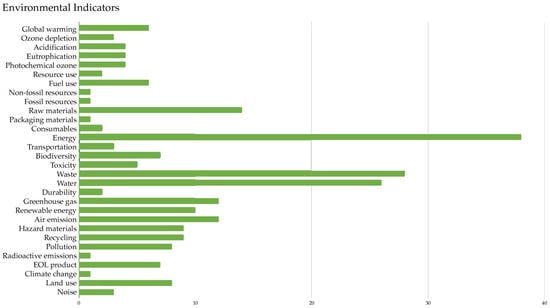

3.1.2. Environmental KPIs

The environmental indicators are those which, together with the economic indicators, are the most used in industrial contexts. Figure 3 illustrates the 30 selected environmental KPIs and how many times each indicator appeared in the articles analyzed. As shown in Figure 3, the most widely used environmental indicator is “energy”, cited by 38 papers, followed by: “waste”, “water”, and “raw materials”. Table A2 in Appendix A lists the articles presenting each macro-category of selected environmental indicators.

Figure 3.

Environmental Indicators.

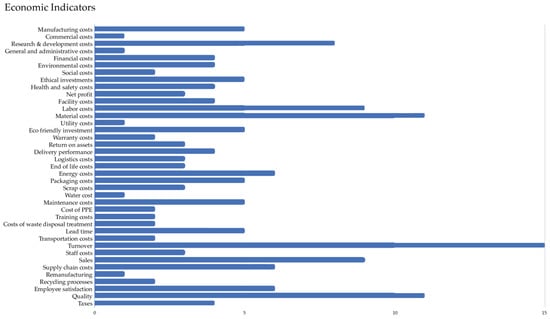

3.1.3. Economic KPIs

Economic indicators are indicators that have always been used in every business context. In fact, they are fundamental as they allow us to understand the company’s performance and to be able to implement initiatives to get more company revenue. Figure 4 illustrates the 39 selected economic KPIs and how many times each indicator appeared in the articles analyzed. Results show that the most important indicator is “turnover”, cited by 15 papers, followed by “material costs”, “quality”, “sales”, and “labor costs”. Table A3 in Appendix A lists the articles presenting each macro-category of selected economic indicators.

Figure 4.

Economic Indicators.

3.1.4. Set of KPIs Selected

After selecting and grouping the indicators into macro-categories, a comprehensive overview was defined. Table 3 shows the set of KPIs created, capable of monitoring sustainability in any industrial context. This set can be used by any manufacturing company that wants to design in a sustainable way or assess their processes according to the sustainability viewpoint.

Table 3.

Set of KPIs selected.

4. Discussion

The aim of the research was to classify all the KPIs currently cited by the recent scientific literature and used in industrial contexts, divided into the three areas of sustainability (environmental, economic, and social). As a result, it can be stated that the current literature can provide a “flat” set of KPIs without any specific guideline to implement them in companies, considering the different sectors, different sizes, and types of production.

As shown by the high number of KPIs present in the literature, every company wants to be able to measure its sustainability performance. Applying these performance indices, the company acquires value in terms of visibility and virtuosity of industrial activities. Being sustainable currently means being able to have a competitive business model integrated with a corporate strategic plan that incorporates the monitoring and management of sustainability parameters.

At the beginning of the article, the authors asked themselves a series of questions that this research tried to answer. These research questions are:

- How can digitization help to have data in real time and constantly updated?

- How can one measure a generic set of sustainability KPIs in industrial contexts?

- How can one refer to the different areas of sustainability in the economic, social, and environmental fields?

To answer the first question “How can digitization help to have data in real time and constantly updated?” we must take into consideration the new technologies of I4.0. Thanks to the complete digitalization of production, the integration of digital technologies into business processes, and good management of big data, environmental, economic, and social monitoring can be carried out dynamically and in real time. Eco-design, in a simulation environment, makes it possible to predict the environmental, social, and economic performance of alternative industrial solutions. IoT technologies make it possible to measure the effects in real time as they occur, providing the ability to intervene in processes to mitigate them. Today, I4.0 technologies are actively used to optimize production operations with related capabilities. Once active, digital tools allow manufacturers to optimize efficiency, translate data into actionable information, and produce more accurate demand forecasts and predictive maintenance programs. These data are provided by performance indicators that make it possible to receive the necessary data on which to make predictions and assessments.

The second question research was “How can one measure a generic set of sustainability KPIs in industrial contexts?”.

Thus, the review provides a set of indicators able to measure the overall company sustainability performance in different industrial contexts and with different production processes. We have developed a generic set of KPIs to assess sustainability performance in the industrial chain. This set of indicators will have to be flexible and adaptable to any industrial context in order to have a starting point for key indicators. Each company will then have the task of implementing specific KPIs according to their situation. In fact, for the generic set of KPIs selected, you can have numerous evaluation metrics depending on the business context. In this way, each company can be oriented towards the calculation of sustainability starting from a standardized methodology.

To answer the third question “How can one refer to the different areas of sustainability in the economic, social, and environmental fields?”, we have analyzed the state of the art in the literature, and we have presented all the indicators that are currently used in industrial contexts. These indicators have been divided into the three categories of the Triple Bottom Line. For each area (social, environmental, and economic), macro-categories of KPI have been identified in order to individuate general indicators that can be applied in any single company.

For each KPI, a set of metrics need to be defined according to the specific context of application. For instance, “health” can be measured by some metrics such as: percentage of workers with work-related disease, percentage of employees receiving safety training, percentage of workstations with high voltage electricity, percentage of workstations with corrosive/toxic chemicals, physical load index, work-related injuries and illness, number of accidents per year. Diversely, “employee satisfaction” can be measured by: ratio between the number of sickness absence rate in an entity and the national average sickness absence rate. Metrics for “Staff training” can be: hours of training per year per employee. Metrics for “noise” can be: percentage of workstations with noise levels exceeding 85 db. Metrics for “work accidents” can be: percentage of entities with periodically verified risk assessment, work-related incident rate.

Despite the fact that the number of social KPIs is greater than the environmental and economic indicators, social indicators need more intensive work to define the related specific metrics, mainly due to the less experience of companies in this area. The selection identified includes all the parameters that every company should consider. During the analysis of the papers, a clear disparity in the use of environmental and economic performance indicators, rather than social indicators, was highlighted. Economic and environmental aspects were investigated in most of the articles analyzed. This did not happen for the social sphere, in fact, many companies, even today, have not implemented aspects related to the social sphere in their plan. For this reason, the emphasis was placed on social impact, identifying those parameters that every company should take into consideration in order to be defined as resilient and virtuous. After having enclosed the social indicators in macro-categories, 48 key indicators have been selected that will become part of the set of KPIs presented by the research.

There is a challenge that is emerging and involves all companies eager to become socially sustainable in industrial processes. These aspects are often misunderstood as the company focus is still focused on the economic and environmental aspects of I4.0.

5. Conclusions

The purpose of this paper was to define the state-of-the-art of how sustainability can be assessed and measured in different I4.0 industrial manufacturing contexts, considering its three areas (economic, environmental, and social). The paper presented an overview of sustainability KPIs based on the Triple Bottom Line concept, which refers to the three sustainability areas (social, economic, and environmental). Thanks to such KPIs (48 social indicators, 30 environmental indicators, and 39 economic indicators), companies could be able to measure corporate sustainability performance, providing data based on which strategic plans can be implemented. In this direction, the modern digital transition and I4.0 technologies can help companies to define and implement sustainability by correlating production and metrics. The article responds to this emerging gap by proposing a set of generic KPIs that can be used in any industrial context (regardless of company size and production). Particular attention was paid to social and organizational indicators as, to date, they are rarely implemented within manufacturing companies. To do this, it is necessary to integrate I4.0 technologies into various industrial contexts. In fact, they make it possible to obtain data in real time, exploit them and carry out actions to improve corporate sustainability. Eco-design makes it possible to predict environmental, social, and economic performance and allows strategic decisions to be made between possible industrial solutions. Though it has been highlighted that Industry 4.0 technologies are needed for data monitoring, the research highlighted the complete lack of such indicators. The authors have not found anything specific for this area (which takes into account the technologies of I4.0), so much so as to define this emerging gap as a starting point for future research. Although a detailed analysis of the state of the art of literature was performed, the selection of KPIs was limited starting from a specific year. Therefore, articles presenting other sustainability indicators may have been excluded from the analysis. Furthermore, the selection of the KPIs and the grouping into macro-categories were carried out personally by the authors, therefore a subjective evaluation was made. A final limitation of the research is that there are no case studies that demonstrate the effective validity of the set of KPIs in an industrial application and only for the social indicators have some metrics been defined in more detail to measure the KPIs.

Future research will concern a validation of the proposed set of KPIs by applying them in a specific business context, where a set of related metrics will be defined and implemented, and the three areas of sustainability will be correlated.

Author Contributions

Conceptualization, M.P.; methodology, M.P. and G.C.; validation, M.P.; data curation, G.C.; writing—original draft preparation, G.C.; writing—review and editing, M.P.; supervision, M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was co-funded by SACMI SC.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1, Table A2 and Table A3 list the articles presenting each macro-category of selected indicators (divided into social, environmental, and economic).

Table A1.

List of articles presenting the selected Social KPIs.

Table A1.

List of articles presenting the selected Social KPIs.

| Social KPIs | No. Papers | Reference Papers |

|---|---|---|

| Health | 18 | [34] |

| [53] | ||

| [32] | ||

| [66] | ||

| [59] | ||

| [65] | ||

| [5] | ||

| [22] | ||

| [13] | ||

| [62] | ||

| [35] | ||

| [12] | ||

| [2] | ||

| [23] | ||

| [55] | ||

| [14] | ||

| [28] | ||

| [22] | ||

| Human resources | 4 | [34] |

| [48] | ||

| [35] | ||

| [23] | ||

| Human rights | 6 | [53] |

| [32] | ||

| [28] | ||

| [64] | ||

| [62] | ||

| [23] | ||

| Ethics indicators | 2 | [16] |

| [28] | ||

| Physical load index | 1 | [40] |

| Noise | 7 | [40] |

| [59] | ||

| [19] | ||

| [5] | ||

| [13] | ||

| [43] | ||

| [14] | ||

| Risk | 2 | [40] |

| [13] | ||

| Wage | 5 | [40] |

| [32] | ||

| [19] | ||

| [65] | ||

| [28] | ||

| Workload | 2 | [40] |

| [48] | ||

| Injuries | 3 | [40] |

| [32] | ||

| [19] | ||

| Social investment | 1 | [40] |

| Fight against corruption | 4 | [40] |

| [32] | ||

| [62] | ||

| [23] | ||

| Workforce | 1 | [40] |

| Corrosive chemicals | 1 | [40] |

| Toxic chemicals | 1 | [40] |

| OSHA citations | 1 | [40] |

| Employee turnover | 5 | [40] |

| [28] | ||

| [2] | ||

| [43] | ||

| [28] | ||

| Employee satisfaction | 12 | [16] |

| [40] | ||

| [53] | ||

| [48] | ||

| [66] | ||

| [19] | ||

| [28] | ||

| [22] | ||

| [12] | ||

| [55] | ||

| [43] | ||

| [28] | ||

| Community quality of life | 1 | [40] |

| Community outreach activities | 1 | [40] |

| Charitable | 1 | [40] |

| Contributions | ||

| Justice | 4 | [53] |

| [48] | ||

| [32] | ||

| [22] | ||

| Fair trading | 6 | [16] |

| [40] | ||

| [53] | ||

| [32] | ||

| [62] | ||

| [23] | ||

| Public service | 1 | [53] |

| Equal employment opportunities | 1 | [48] |

| [30] | ||

| Equal promotion opportunities | 1 | [48] |

| Payment ratio | 2 | [48] |

| [43] | ||

| Complaints system | 1 | [48] |

| Staff training | 10 | [40] |

| [65] | ||

| [28] | ||

| [18] | ||

| [12] | ||

| [2] | ||

| [30] | ||

| [63] | ||

| [14] | ||

| [28] | ||

| Child labor | 5 | [16] |

| [32] | ||

| [65] | ||

| [62] | ||

| [23] | ||

| Forced labor | 3 | [32] |

| [65] | ||

| [23] | ||

| Gender equity | 4 | [32] |

| [19] | ||

| [30] | ||

| [14] | ||

| Social responsibility | 2 | [32] |

| [23] | ||

| Product responsibility | 4 | [53] |

| [22] | ||

| [64] | ||

| [21] | ||

| Community engagement | 2 | [32] |

| [13] | ||

| Access to resources | 3 | [32] |

| [62] | ||

| [23] | ||

| Work accidents | 9 | [40] |

| [48] | ||

| [19] | ||

| [28] | ||

| [18] | ||

| [30] | ||

| [55] | ||

| [63] | ||

| [14] | ||

| Work illnesses | 4 | [40] |

| [18] | ||

| [12] | ||

| [43] | ||

| Voluntary programs | 1 | [13] |

| Protection of private life | 2 | [62] |

| [23] | ||

| Work conditions | 2 | [62] |

| [55] | ||

| Diversity | 2 | [40] |

| [12] | ||

| Community projects | 6 | [16] |

| [66] | ||

| [19] | ||

| [30] | ||

| [63] | ||

| [43] | ||

| Labor relationship | 3 | [28] |

| [13] | ||

| [12] | ||

| Philanthropy | 3 | [34] |

| [65] | ||

| [28] | ||

| Discrimination | 6 | [48] |

| [19] | ||

| [65] | ||

| [28] | ||

| [62] | ||

| [23] | ||

| Fatalities | 3 | [32] |

| [19] | ||

| [28] |

Table A2.

List of articles presenting the selected Environmental KPIs.

Table A2.

List of articles presenting the selected Environmental KPIs.

| Environmental KPIs | No. Paper | Reference Paper |

|---|---|---|

| Global warming | 6 | [34] |

| [16] | ||

| [32] | ||

| [65] | ||

| [13] | ||

| [35] | ||

| Ozone depletion | 3 | [34] |

| [16] | ||

| [22] | ||

| Acidification | 4 | [34] |

| [16] | ||

| [65] | ||

| [43] | ||

| Eutrophication | 4 | [34] |

| [16] | ||

| [65] | ||

| [43] | ||

| Photochemical ozone | 4 | [34] |

| [16] | ||

| [65] | ||

| [43] | ||

| Resource use | 1 | [16] |

| Fuel use | 3 | [28] |

| [61] | ||

| [14] | ||

| Non-fossil resources | 1 | [34] |

| Fossil resources | 1 | [34] |

| Raw materials | 11 | [34] |

| [40] | ||

| [59] | ||

| [19] | ||

| [28] | ||

| [22] | ||

| [35] | ||

| [2] | ||

| [61] | ||

| [43] | ||

| [14] | ||

| Packaging materials | 1 | [59] |

| Consumables | 1 | [34] |

| Energy | 16 | [16] |

| [40] | ||

| [53] | ||

| [32] | ||

| [59] | ||

| [19] | ||

| [22] | ||

| [13] | ||

| [64] | ||

| [18] | ||

| [12] | ||

| [2] | ||

| [61] | ||

| [63] | ||

| [43] | ||

| [14] | ||

| Transportation | 2 | [40] |

| [48] | ||

| Biodiversity | 3 | [34] |

| [62] | ||

| [22] | ||

| Toxicity | 4 | [16] |

| [32] | ||

| [66] | ||

| [65] | ||

| Waste | 13 | [16] |

| [40] | ||

| [53] | ||

| [48] | ||

| [66] | ||

| [59] | ||

| [13] | ||

| [64] | ||

| [30] | ||

| [63] | ||

| [43] | ||

| [28] | ||

| [22] | ||

| Water | 19 | [40] |

| [53] | ||

| [59] | ||

| [19] | ||

| [65] | ||

| [5] | ||

| [28] | ||

| [22] | ||

| [64] | ||

| [62] | ||

| [18] | ||

| [35] | ||

| [12] | ||

| [21] | ||

| [2] | ||

| [23] | ||

| [55] | ||

| [63] | ||

| [43] | ||

| Durability | 2 | [16] |

| [43] | ||

| Greenhouse gas | 8 | [40] |

| [53] | ||

| [59] | ||

| [28] | ||

| [22] | ||

| [64] | ||

| [12] | ||

| [43] | ||

| Renewable energy | 7 | [59] |

| [62] | ||

| [12] | ||

| [21] | ||

| [23] | ||

| [63] | ||

| [43] | ||

| Air emission | 10 | [53] |

| [66] | ||

| [19] | ||

| [65] | ||

| [5] | ||

| [22] | ||

| [13] | ||

| [55] | ||

| [61] | ||

| [14] | ||

| Hazard materials | 6 | [53] |

| [66] | ||

| [59] | ||

| [22] | ||

| [43] | ||

| [28] | ||

| Recycling | 8 | [59] |

| [13] | ||

| [62] | ||

| [12] | ||

| [21] | ||

| [30] | ||

| [23] | ||

| [28] | ||

| Pollution | 6 | [53] |

| [22] | ||

| [62] | ||

| [21] | ||

| [23] | ||

| [43] | ||

| Radioactive emissions | 1 | [59] |

| EOL product | 1 | [59] |

| Climate change | 1 | [65] |

| Land use | [53] | |

| [22] | ||

| [62] | ||

| [35] | ||

| [14] | ||

| [28] | ||

| Noise | 3 | [59] |

| [43] | ||

| [14] |

Table A3.

List of articles presenting the selected Economic KPIs.

Table A3.

List of articles presenting the selected Economic KPIs.

| Economic KPIs | No. Paper | Reference Paper |

|---|---|---|

| Manufacturing costs | 5 | [34] |

| [40] | ||

| [53] | ||

| [48] | ||

| [62] | ||

| Commercial costs | 1 | [34] |

| Research and development costs | 8 | [34] |

| [59] | ||

| [19] | ||

| [28] | ||

| [62] | ||

| [18] | ||

| [2] | ||

| [28] | ||

| General and administrative costs | 1 | [34] |

| Financial costs | 4 | [34] |

| [16] | ||

| [32] | ||

| [23] | ||

| Environmental costs | 4 | [34] |

| [65] | ||

| [28] | ||

| [13] | ||

| Social costs | 2 | [34] |

| [21] | ||

| Ethical investments | 4 | [16] |

| [21] | ||

| [63] | ||

| [43] | ||

| Health and safety costs | 3 | [19] |

| [21] | ||

| [43] | ||

| Net profit | 3 | [40] |

| [65] | ||

| [18] | ||

| Facility costs | 4 | [40] |

| [32] | ||

| [19] | ||

| [65] | ||

| Labor costs | 7 | [40] |

| [48] | ||

| [59] | ||

| [19] | ||

| [65] | ||

| [61] | ||

| [14] | ||

| Material costs | 8 | [40] |

| [53] | ||

| [32] | ||

| [66] | ||

| [59] | ||

| [65] | ||

| [62] | ||

| [14] | ||

| Utility costs | 1 | [40] |

| Eco friendly investment | 4 | [19] |

| [65] | ||

| [13] | ||

| [2] | ||

| Warranty costs | 1 | [59] |

| Return on assets | 2 | [40] |

| [28] | ||

| Delivery performance | 3 | [40] |

| [48] | ||

| [14] | ||

| Logistics costs | 3 | [53] |

| [59] | ||

| [30] | ||

| End of life costs | 2 | [53] |

| [13] | ||

| Energy costs | 6 | [53] |

| [66] | ||

| [59] | ||

| [65] | ||

| [62] | ||

| [35] | ||

| Packaging costs | 4 | [53] |

| [59] | ||

| [19] | ||

| [43] | ||

| Scrap costs | 3 | [53] |

| [66] | ||

| [19] | ||

| Water costs | 1 | [53] |

| Maintenance costs | 5 | [53] |

| [48] | ||

| [19] | ||

| [65] | ||

| [62] | ||

| Cost of PPE | 2 | [53] |

| [19] | ||

| Training costs | 2 | [53] |

| [59] | ||

| Costs of waste disposal treatment | 2 | [53] |

| [66] | ||

| Lead time | 4 | [53] |

| [48] | ||

| [19] | ||

| [61] | ||

| Transportation costs | 1 | [59] |

| Turnover | 3 | [19] |

| [28] | ||

| [18] | ||

| Staff costs | 1 | [28] |

| Sales | 8 | [32] |

| [66] | ||

| [59] | ||

| [19] | ||

| [28] | ||

| [13] | ||

| [30] | ||

| [63] | ||

| Supply chain costs | 4 | [48] |

| [64] | ||

| [62] | ||

| [63] | ||

| Remanufacturing | 1 | [62] |

| Recycling processes | 2 | [62] |

| [12] | ||

| Employee satisfaction | 3 | [13] |

| [55] | ||

| [43] | ||

| Quality | 4 | [59] |

| [19] | ||

| [5] | ||

| [55] | ||

| Taxes | 4 | [32] |

| [19] | ||

| [30] | ||

| [63] |

References

- UN. Secretary-General; World Commission on Environment and Development. Report of the World Commission on Environment and Development. August 1987. Available online: https://digitallibrary.un.org/record/139811 (accessed on 26 July 2022).

- Wicher, P.; Zapletal, F.; Lenort, R. Sustainability performance assessment of industrial corporation using Fuzzy Analytic Network Process. J. Clean. Prod. 2019, 241, 118132. [Google Scholar] [CrossRef]

- Elkington, J. Partnerships fromcannibals with forks: The triple bottom line of 21st-century business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Braccini, A.M.; Margherita, E.G. Exploring Organizational Sustainability of Industry 4.0 under the Triple Bottom Line: The Case of a Manufacturing Company. Sustainability 2019, 11, 36. [Google Scholar] [CrossRef]

- Qorri, A.; Mujkić, Z.; Kraslawski, A. A conceptual framework for measuring sustainability performance of supply chains. J. Clean. Prod. 2018, 189, 570–584. [Google Scholar] [CrossRef]

- Fitz-Gibbon, C.T. Performance Indicators; Multilingual Matters: Clevedon, UK, 1990; Volume 2. [Google Scholar]

- Sundström, A.; Ahmadi, Z.; Mickelsson, K. Implementing Social Sustainability for Innovative Industrial Work Environments. Sustainability 2019, 11, 3402. [Google Scholar] [CrossRef]

- Khaled, R.; Ali, H.; Mohamed, E.K.A. The Sustainable Development Goals and corporate sustainability performance: Mapping, extent and determinants. J. Clean. Prod. 2021, 311, 127599. [Google Scholar] [CrossRef]

- European Commission. 2016. Available online: https://ec.europa.eu/growth/smes_it (accessed on 6 July 2022).

- García-Muiña, F.; Medina-Salgado, M.S.; González-Sánchez, R.; Huertas-Valdivia, I.; Ferrari, A.M.; Settembre-Blundo, D. Industry 4.0-based dynamic Social Organizational Life Cycle Assessment to target the social circular economy in manufacturing. J. Clean. Prod. 2021, 327, 129439. [Google Scholar] [CrossRef]

- García-Granero, E.M.; Piedra-Muñoz, L.; Galdeano-Gómez, E. Eco-innovation measurement: A review of firm performance indicators. J. Clean. Prod. 2018, 191, 304–317. [Google Scholar] [CrossRef]

- Abubakr, M.; Abbas, A.T.; Tomaz, I.; Soliman, M.S.; Luqman, M.; Hegab, H. Sustainable and Smart Manufacturing: An Integrated Approach. Sustainability 2020, 12, 2280. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. An analysis of metrics used to measure performance in green and sustainable supply chains. J. Clean. Prod. 2015, 86, 360–377. [Google Scholar] [CrossRef]

- Amrina, E.; Vilsi, A.L. Interpretive structural model of key performance indicators for sustainable manufacturing evaluation in cement industry. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Selangor, Malaysia, 9–12 December 2014; pp. 1111–1115. [Google Scholar] [CrossRef]

- Appolloni, A.; Jabbour, C.J.C.; D’Adamo, I.; Gastaldi, M.; Settembre-Blundo, D. Green recovery in the mature manufacturing industry: The role of the green-circular premium and sustainability certification in innovative efforts. Ecol. Econ. 2022, 193, 107311. [Google Scholar] [CrossRef]

- Azapagic, A.; Perdan, S. Indicators of Sustainable Development for Industry. Process Saf. Environ. Prot. 2000, 78, 243–261. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. Determining and applying sustainable supplier key performance indicators. Supply Chain Manag. Int. J. 2014, 19, 275–291. [Google Scholar] [CrossRef]

- Butnariu, A.; Avasilcai, S. The Assessment of The Companies’ Sustainable Development Performance. Procedia Econ. Financ. 2015, 23, 1233–1238. [Google Scholar] [CrossRef]

- Cagno, E.; Neri, A.; Howard, M.; Brenna, G.; Trianni, A. Industrial sustainability performance measurement systems: A novel framework. J. Clean. Prod. 2019, 230, 1354–1375. [Google Scholar] [CrossRef]

- Cayzer, S.; Griffiths, P.; Beghetto, V. Design of indicators for measuring product performance in the circular economy. Int. J. Sustain. Eng. 2017, 10, 289–298. [Google Scholar] [CrossRef]

- Cazeri, G.T.; Anholon, R.; Ordoñez, R.E.C.; Novaski, O. Performance Measurement of Green Supply Chain Management: A Literature Review and Gaps for Further Research. Braz. J. Oper. Prod. Manag. 2017, 14, 60–72. [Google Scholar] [CrossRef]

- Chaim, O.; Muschard, B.; Cazarini, E.; Rozenfeld, H. Insertion of sustainability performance indicators in an industry 4.0 virtual learning environment. Procedia Manuf. 2018, 21, 446–453. [Google Scholar] [CrossRef]

- Chardine-Baumann, E.; Botta-Genoulaz, V. A framework for sustainable performance assessment of supply chain management practices. Comput. Ind. Eng. 2014, 76, 138–147. [Google Scholar] [CrossRef]

- Chavan, M.A.S.; Road, P.-S. Prioritization of green supply chain indicators with analytic hierarchy process (AHP) model. Int. J. Mech. Eng. Technol. 2018, 9, 1444–1460. [Google Scholar]

- Ching, N.T.; Ghobakhloo, M.; Iranmanesh, M.; Maroufkhani, P.; Asadi, S. Industry 4.0 applications for sustainable manufacturing: A systematic literature review and a roadmap to sustainable development. J. Clean. Prod. 2022, 334, 130133. [Google Scholar] [CrossRef]

- Cuthbertson, R.; Cetinkaya, B.; Ewer, G.; Klaas-Wissing, T.; Piotrowicz, W.; Tyssen, C. Sustainable Supply Chain Management; Springe: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- de Oliveira, A.C.; Sokulski, C.C.; Batista, A.A.d.; de Francisco, A.C. Competencies for sustainability: A proposed method for the analysis of their interrelationships. Sustain. Prod. Consum. 2018, 14, 82–94. [Google Scholar] [CrossRef]

- Dočekalová, M.P.; Kocmanová, A. Composite indicator for measuring corporate sustainability. Ecol. Indic. 2016, 61, 612–623. [Google Scholar] [CrossRef]

- Dorn, C.; Bethrend, R.; Giannopoulos, D.; Napolano, L.; James, V.; Herrmann, A.; Uhlig, V.; Krause, H.; Founti, M.; Trimis, D. A Systematic LCA-enhanced KPI Evaluation towards Sustainable Manufacturing in Industrial Decision-making Processes. A Case Study in Glass and Ceramic Frits Production. Procedia CIRP 2016, 48, 158–163. [Google Scholar] [CrossRef]

- Erol, I.; Sencer, S.; Sari, R. A new fuzzy multi-criteria framework for measuring sustainability performance of a supply chain. Ecol. Econ. 2011, 70, 1088–1100. [Google Scholar] [CrossRef]

- Favara, P.; Raymond, D.; Ambrusch, M.; Libera, A.; Wolf, G.; Simon, J.A.; Maco, B.; Collins, E.R.; Harclerode, M.A.; McNally, A.D.; et al. Ten years later: The progress and future of integrating sustainable principles, practices, and metrics into remediation projects. Remediat. J. 2019, 29, 5–30. [Google Scholar] [CrossRef]

- Ferrari, A.M.; Volpi, L.; Pini, M.; Siligardi, C.; García-Muiña, F.E.; Settembre-Blundo, D. Building a Sustainability Benchmarking Framework of Ceramic Tiles Based on Life Cycle Sustainability Assessment (LCSA). Resources 2019, 8, 11. [Google Scholar] [CrossRef]

- Ferrari, A.M.; Volpi, L.; Settembre-Blundo, D.; García-Muiña, F.E. Dynamic life cycle assessment (LCA) integrating life cycle inventory (LCI) and Enterprise resource planning (ERP) in an industry 4.0 environment. J. Clean. Prod. 2021, 286, 125314. [Google Scholar] [CrossRef]

- Garcia-Muiña, F.; González-Sánchez, R.; Ferrari, A.; Settembre-Blundo, D. The Paradigms of Industry 4.0 and Circular Economy as Enabling Drivers for the Competitiveness of Businesses and Territories: The Case of an Italian Ceramic Tiles Manufacturing Company. Soc. Sci. 2018, 7, 255. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Muiña, E.; González-Sánchez, R.; Ferrari, A.M.; Volpi, L.; Pini, M.; Settembre-Blundo, D. Identifying the Equilibrium Point between Sustainability Goals and Circular Economy Practices in an Industry 4.0 Manufacturing Context Using Eco-Design. Soc. Sci. 2019, 8, 241. [Google Scholar] [CrossRef]

- Govindan, K.; Aditi, J.; Dhingra, D.; Kaul, A.; Jha, P. Structural model for analysis of key performance indicators for sustainable manufacturer–supplier collaboration: A grey-decision-making trial and evaluation laboratory-based approach. Bus. Strategy Environ. 2021, 30, 1702–1722. [Google Scholar] [CrossRef]

- Hagen, J.; Büth, L.; Haupt, J.; Cerdas, F.; Herrmann, C. Live LCA in learning factories: Real time assessment of product life cycles environmental impacts. Procedia Manuf. 2020, 45, 128–133. [Google Scholar] [CrossRef]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance measurement for green supply chain management. Benchmarking Int. J. 2005, 12, 330–353. [Google Scholar] [CrossRef]

- Huang, A. A Framework and Metrics for Sustainable Manufacturing Performance Evaluation at the Production Line, Plant and Enterprise Levels. Ph.D. Thesis, University of Kentucky Libraries, Lexington, KY, USA, 2017. [Google Scholar] [CrossRef]

- Huang, A.; Badurdeen, F. Metrics-based approach to evaluate sustainable manufacturing performance at the production line and plant levels. J. Clean. Prod. 2018, 192, 462–476. [Google Scholar] [CrossRef]

- Hutchins, M.J.; Sutherland, J.W. An exploration of measures of social sustainability and their application to supply chain decisions. J. Clean. Prod. 2008, 16, 1688–1698. [Google Scholar] [CrossRef]

- Khalid, A.M.; Sharma, S.; Dubey, A.K. Developing an indicator set for measuring sustainable development in India: Ahmad Mohd Khalid, Seema Sharma and Amlendu Kumar Dubey/Natural Resources Forum. Nat. Resour. Forum 2018, 42, 185–200. [Google Scholar] [CrossRef]

- Krajnc, D.; Glavic, P. Indicators of sustainable production. Clean Technol. Environ. Policy 2003, 5, 279–288. [Google Scholar] [CrossRef]

- Lenort, R.; Staš, D.; Wicher, P.; Holman, D.; Ignatowicz, K. Comparative Study of Sustainable Key Performance Indicators in Metallurgical Industry. Rocz. Ochr. Śr. 2017, 19, 36–51. [Google Scholar]

- Lopes, F.P.; Santos, A.d.L.; Filho, M.L.S. Indicators to assess social sustainability aspects—Research in industries of the electrical and electronic sector in Brazil. In Proceedings of the 2015 IEEE Conference on Control Applications (CCA), Sydney, Australia, 21–23 September 2015; pp. 583–588. [Google Scholar] [CrossRef]

- Melkonyan, A.; Gottschalk, D.; Vasanth Kamath, V.P. Sustainability assessments and their implementation possibilities within the business models of companies. Sustain. Prod. Consum. 2017, 12, 1–15. [Google Scholar] [CrossRef]

- Nagarajan, H.P.N.; Raman, A.S.; Haapala, K.R. A Sustainability Assessment Framework for Dynamic Cloud-based Distributed Manufacturing. Procedia CIRP 2018, 69, 136–141. [Google Scholar] [CrossRef]

- Narimissa, O.; Kangarani-Farahani, A.; Molla-Alizadeh-Zavardehi, S. Evaluation of sustainable supply chain management performance: Indicators. Sustain. Dev. 2020, 28, 118–131. [Google Scholar] [CrossRef]

- Neri, A.; Cagno, E.; Lepri, M.; Trianni, A. A triple bottom line balanced set of key performance indicators to measure the sustainability performance of industrial supply chains. Sustain. Prod. Consum. 2021, 26, 648–691. [Google Scholar] [CrossRef]

- Papetti, A.; Pandolfi, M.; Peruzzini, M.; Germani, M. A framework to promote social sustainability in industry 4.0. Int. J. Agil. Syst. Manag. 2020, 13, 233–257. [Google Scholar] [CrossRef]

- Dočekalová, M.P.; Kocmanová, A.; Šimberová, I.; Koleňák, J. Modelling of Social Key Performance Indicators of Corporate Sustainability Performance. Acta Univ. Agric. Silvic. Mendel. Brun. 2018, 66, 303–312. [Google Scholar] [CrossRef]

- Peruzzini, M.; Gregori, F.; Luzi, A.; Mengarelli, M.; Germani, M. A social life cycle assessment methodology for smart manufacturing: The case of study of a kitchen sink. J. Ind. Inf. Integr. 2017, 7, 24–32. [Google Scholar] [CrossRef]

- Peruzzini, M.; Pellicciari, M. Application of Early Sustainability Assessment to Support the Design of Industrial Systems. Ind. Eng. Manag. Syst. 2018, 17, 209–225. [Google Scholar] [CrossRef]

- Peruzzini, M.; Pellicciari, M. User experience evaluation model for sustainable manufacturing. Int. J. Comput. Integr. Manuf. 2018, 31, 494–512. [Google Scholar] [CrossRef]

- Piotrowicz, W.; Cuthbertson, R. Performance measurement and metrics in supply chains: An exploratory study. Int. J. Product. Perform. Manag. 2015, 64, 1068–1091. [Google Scholar] [CrossRef]

- Popovic, T.; Barbosa-Póvoa, A.; Kraslawski, A.; Carvalho, A. Quantitative indicators for social sustainability assessment of supply chains. J. Clean. Prod. 2018, 180, 748–768. [Google Scholar] [CrossRef]

- Rahdari, A.H.; Rostamy, A.A.A. Designing a general set of sustainability indicators at the corporate level. J. Clean. Prod. 2015, 108, 757–771. [Google Scholar] [CrossRef]

- Resat, H.G.; Unsal, B. A novel multi-objective optimization approach for sustainable supply chain: A case study in packaging industry. Sustain. Prod. Consum. 2019, 20, 29–39. [Google Scholar] [CrossRef]

- Shuaib, M.; Seevers, D.; Zhang, X.; Badurdeen, F.; Rouch, K.E.; Jawahir, I.S. Product Sustainability Index ( ProdSI ): A Metrics-based Framework to Evaluate the Total Life Cycle Sustainability of Manufactured Products. J. Ind. Ecol. 2014, 18, 491–507. [Google Scholar] [CrossRef]

- Strezov, V.; Evans, A.; Evans, T.J. Assessment of the Economic, Social and Environmental Dimensions of the Indicators for Sustainable Development: Economic, social and environmental dimensions of sustainability. Sustain. Dev. 2017, 25, 242–253. [Google Scholar] [CrossRef]

- Tajbakhsh, A.; Hassini, E. Performance measurement of sustainable supply chains: A review and research questions. Int. J. Product. Perform. Manag. 2015, 64, 744–783. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Neri, A.; Howard, M. Measuring industrial sustainability performance: Empirical evidence from Italian and German manufacturing small and medium enterprises. J. Clean. Prod. 2019, 229, 1355–1376. [Google Scholar] [CrossRef]

- Uysal, F. An Integrated Model for Sustainable Performance Measurement in Supply Chain. Procedia Soc. Behav. Sci. 2012, 62, 689–694. [Google Scholar] [CrossRef]

- Varsei, M.; Soosay, C.; Fahimnia, B.; Sarkis, J. Framing sustainability performance of supply chains with multidimensional indicators. Supply Chain Manag. Int. J. 2014, 19, 242–257. [Google Scholar] [CrossRef]

- Visentin, C.; Trentin, A.W.d.; Braun, A.B.; Thomé, A. Life cycle sustainability assessment: A systematic literature review through the application perspective, indicators, and methodologies. J. Clean. Prod. 2020, 270, 122509. [Google Scholar] [CrossRef]

- Çankaya, S.Y.; Sezen, B. Effects of green supply chain management practices on sustainability performance. J. Manuf. Technol. Manag. 2019, 30, 98–121. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, C.; Cheng, Y.; Chen, H.; Wang, W. Research on the Mechanism of the Sustainable Development Model of Enterprises Based on Big Data Analysis Model. Mob. Inf. Syst. 2021, 2021, 4469255. [Google Scholar] [CrossRef]

- Zharfpeykan, R.; Akroyd, C. Factors influencing the integration of sustainability indicators into a company’s performance management system. J. Clean. Prod. 2022, 331, 129988. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).