Abstract

This paper aims to facilitate in the reduction of issues related to agricultural wastes such as disposal and burning by incorporating two widely produced agricultural wastes in Pakistan, i.e., Rice Husk and Wheat Straw, in gypsum false ceiling plates to develop an eco-friendly construction product. There is an increased focus of research on the development of such eco-friendly gypsum products to make the use of gypsum sustainable. Composites containing agricultural residues with four different replacement levels of 2.5%, 5%, 7.5%, and 10% by weight are developed along with a control mix containing 100% gypsum. The physical, mechanical, and thermal properties of the developed composites are investigated. Also, the false ceiling plates are made using the developed composites and their flexural behavior is compared with that of the control specimen containing 100% gypsum. The results showed that density and shore C hardness reduced with increasing the amount of agricultural waste while the water absorption remained similar up to a dosage of 7.5%. Except for the 10% wheat straw dosage, flexural and compressive strength of developed composites showed a decrease with the increase of wheat straw and rice husk dosages but remained above the acceptable values of 1 MPa and 2 MPa, respectively, as per BS EN 14246. For the same replacement level, the composites containing wheat straw showed relatively inferior mechanical properties results as compared to those containing rice husk. The thermal conductivity test showed better thermal performance of the composite mixes as compared to the reference mix. The bending test on false ceiling plates showed that all the plates satisfied the minimum flexural strength criteria as per BS EN 14246 and the flexural strength of plates increased up to a replacement level of 5% for both the agricultural wastes.

1. Introduction

False ceilings are an important component of buildings for aesthetics, insulation, and hiding services [1]. They also provide soundproofing and reduce the area to be air-conditioned [2]. Gypsum is an ideal material for the development of false ceiling plates because it has a lighter weight, rapid setting time, better fire resistance, thermal and acoustic insulation properties, reasonable waterproofing ability, and a significantly lower cost as compared to the other possible materials such as wood, plastic, and fiber-reinforced polymers [3]. The possibility of making different shapes and customized designs of false ceiling plates made of gypsum is another advantage. In Pakistan, the annual gypsum extraction was 2.36 million metric tons in 2019 [4] and there is a growing trend in its extraction and consumption. This gypsum is mainly used for making plaster of Paris, plasterboard, gypsum powder for conditioning soil, and as a hardening retarder in the cement industry [4].

Pakistan, being an agriculture-based economy, produces large quantities of agricultural waste (crop residue) [5]. Sugarcane, wheat, and rice are the three major agricultural residue-producing crops in Pakistan [5,6]. While most of the sugarcane bagasse produced is utilized as a fuel by the sugar industry where it is generated [7], the residues of wheat and rice have multiple uses such as for cattle feed, particleboard, and as a fuel for biomass-based energy generation plants [5], but still, due to abundant production every year (about 13 million tons of wheat and rice residue [5]), most of it is either burnt in open fields or used as fuel for brick kilns, which results in the significant deterioration of the air quality and contributes to smog issues in Pakistan [8,9]. This necessitates discovering alternate uses for these residues in order to reduce the issues related to their burning and disposal.

There is a growing trend in research to make gypsum eco-friendly to ensure its sustainable use [10,11,12,13,14,15,16,17,18,19] and several researchers have investigated the effect of replacing gypsum with some waste material and a few have also tried to develop eco-friendly construction products using the developed composites. In one such study, gypsum mortars are analyzed by incorporating construction and demolition waste (CDW) [13]. Insulation waste (mineral wool and expanded polystyrene with graphite) and aggregates (natural, recycled from ceramic walls and recycled concrete) are incorporated in plaster mortar to measure their physical and mechanical properties. Conventional plaster matrix made with recycled aggregates showed lower mechanical resistance than plaster matrix made with recycled aggregates. Plaster mortars showed significant improvement in the flexure strength due to crushed mineral wool residues’ incorporation. Also, the developed composites showed reduced density and thermal conductivity and an improvement against water absorption due to the incorporation of expanded polystyrene residues. In a similar study, Villoria et al. [18] developed prefabricated elements for interior partitions from gypsum plaster to assess the feasibility of using demolition waste (concrete, ceramic, and expanded polystyrene waster) in a gypsum matrix. Gypsum specimens measuring 40 × 40 × 160 mm were prepared by incorporating 25%, 50%, and 75% waste (concrete, ceramic, and a mixture of both) based on the gypsum weight. Also, an optimum compound was used to prepare the gypsum block of 400 × 200 × 100 mm with a sandwich configuration. The results showed that the addition of concrete and ceramic waste improves the mechanical properties. The reduction in the capillary absorption and improvement in the thermal behavior was observed because of a decrease in the density due to the addition of expanded polystyrene waste in compounds containing concrete and ceramic waste. In another study, the effect of the replacement of gypsum with recycled wood residue for the development of eco-efficient composites was studied. It was concluded that the best thermal and acoustic properties were obtained at a waste replacement ratio of 20%, but mechanical properties showed a decreasing trend with the increase of wooden waste content [20]. In a similar study, density reduction of up to 38–40% of reference material was observed by incorporating 45% wood shavings. Gypsum composites showed improvement in thermal behavior as the proportion of wood wastes was increased. At 40% wood shavings, flexure strength and mechanical resistance to compression showed a reduction of 65% and 78%, respectively. This reduction in flexure and compression values is well under the standard limits [21]. In another study, the effect of antifoam agents in sawdust water extracts concluded that the addition of 20% sawdust in gypsum resulted in a composite of high mechanical performance which could meet the ASTM C 62 [22] requirement for building bricks. The low-density gypsum sawdust composites with higher performance than the commercial blocks at 30% sawdust insertion could be obtained. It was concluded that 20% to 30% of gypsum could be saved along with the physical and mechanical properties’ enhancement of composites [23].

Recycled discs resulting in polycarbonate (PC) waste were used as full reinforcement pieces, crushed aggregate and as a combination of both in a recent study to develop new gypsum coating products and materials. The thermal conductivity and mechanical behavior of the new pieces were assessed. It was found that the addition of PC waste in many cases improved the thermal and mechanical properties [24]. For building applications, the characterization of gypsum composites with cigarette butt waste was studied by Morales-Segura [25]. Cigarette butt waste with different percentages (0.5%, 1%, 1.5%, 2.0% and 2.5%) was incorporated in several gypsum specimens. Acoustic performance, bond strength, flexural strength, compressive strength, superficial hardness, and density of prepared gypsum composites were tested. The better mechanical performance of developed gypsum composites than the control gypsum showed the possibility of using cigarette butt waste in a gypsum matrix. In a recent study, bio-fibers (hemp fibers and sheep wool fibers) were incorporated in gypsum composites as a reinforcement [26]. The composition of gypsum composites and microstructure of the fibers were analyzed by X-ray diffraction and by scanning electron microscope with energy dispersive spectroscopy. The gypsum matrix with wool fibers showed superior mechanical performance than the gypsum matrix with hemp fibers. This is due to very good adhesion of the gypsum matrix with the wool fibers, which also helps in increasing fracture toughness. In another study, the plastic cable waste aggregates, without going through any treatment, were incorporated in gypsum boards to analyze the physical and mechanical properties [27]. The thermal comfort, thermal conductivity, flexure strength, shock-impact resistance and Young’s modulus of gypsum boards with different dimensions were measured. The plastic cable waste aggregates were considered as a suitable alternate to control gypsum boards.

The effect of tannery wastes such as wet blue chrome shavings and buffing dust incorporation in cement and gypsum-based materials to assess the mechanical and thermal properties has also been studied [28]. The results showed a decreasing trend in density, mechanical and thermal conductivity with the increase of tannery waste content. It was suggested to use tannery wastes as separation material in construction boards to avoid the reduction in mechanical strength. In another study [29], the potential of waste rubber’s different particle size proportions obtained from pipe foam insulation in gypsum matrix was investigated to make lightweight products. A maximum of 7.5% replacement of gypsum by weight was investigated. Density reduction achieved compared to reference material was 49% which represented the development of lightweight plaster rubber composites. The best-suited particle size obtained without compromising the mechanical strength of gypsum composites was 4–6 mm. In a similar study [30], three different particle size gradations of end-of-life tires were used in different fractions to assess the thermal, physical, and mechanical properties of plaster specimens. Compressive and bending strengths were reduced by the addition of rubber with the lowest values at 60%. Acoustic performance mainly depended on particle sizes rather than the percentage addition of rubber waste. It was concluded that compression layers or slabs can be made of plaster rubber boards. Another research study aimed to improve gypsum plaster’s elastic behavior by incorporating rubber waste from end-of-life tires, which resulted in reducing the modulus of elasticity compared to reference gypsum plaster without any additives. The rubber waste’s addition resulted in mechanical performance reduction, which was less effective due to its percentage than the size of rubber particles in the gypsum matrix [31]. In another study [32], the effect of end-of-life tire rubber in plasters on water absorption by immersion and capillarity and for open porosity was investigated. Furthermore, paste and rubber transition zones were observed through scanning electron microscope (SEM) techniques. Open porosity was increased due to the addition of the finest grading rubber compared to the reference gypsum matrix. In another research study [33], mechanical and thermal properties of various plasters were assessed by 100% replacement of natural sand and limestone filler with the polyethylene terephthalate (PET) and GFRP waste particles. Flexure and compressive strength were reduced with an increase in organic waste particles but the minimum values as per standard were achieved. In another study, the effect of recycled tile powder addition on the properties of gypsum mortars and gypsum pastes at ambient and high temperature was investigated [34]. The results showed an increase in water absorption and apparent porosity, but the strength of mixtures was found to decrease. High-temperature resistance, thermal conductivity, mass loss, and volume changes at high temperatures were improved with the addition of recycled tile powder. Recently, the life cycle assessment (LCA) of eco-gypsum ceiling tiles incorporating polyurethane foam waste was compared with standard gypsum ceiling tile. The findings showed that the traditional commercial gypsum tile has inferior environmental performance to the eco ceiling tile with polyurethane. Without compromising technical performance, it was observed that the water consumption, CO2 emissions, and energy consumption were reduced by 25%, 14%, and 14% compared to traditional gypsum tile [35].

Previous studies as presented above show that waste materials can be efficiently incorporated into gypsum composites. Hence, to mitigate the issues related to the burning and disposal of agricultural wastes and to conserve the limited natural resources of gypsum, the addition of agricultural residues in gypsum can be a good option for developing eco-friendly false ceiling material. There is also a paucity of research on proposing the use of gypsum-agricultural composites for developing a construction product. Hence, this study investigates the effect of the replacement of gypsum by agricultural residues (wheat straw and rice husk) on the physical, mechanical, and thermal insulation properties of the resulting gypsum composites. The possibility of using the developed composites to make an eco-friendly construction product is also investigated by studying the bending behavior of the false ceiling plates made from the developed gypsum composites.

The contents of this paper are as follows. Firstly, the details of the materials used in this study are presented. In the next section, the experimental methodology followed for this study is detailed along with the details of the mixes and test specimens, and lastly, the results of the experimental program are presented and discussed.

2. Materials

The experimental specimens consisted of gypsum as a base material and agricultural wastes (in the form of wheat straw and rice husk) as replacement materials to develop an eco-friendly construction product. Portable water was used in all the mixes. The details of the other materials used for developing different mixtures are mentioned in the next sections.

2.1. Gypsum

Gypsum (commercially available as plaster of Paris CaSO4.1/2H2O) was the major constituent for the prepared test specimens. The gypsum used for this study was acquired from a local supplier and it was in accordance with EN 13279-2:2014 [36]. The constituents present in gypsum as analyzed by the chemical characterization are shown in Table 1.

Table 1.

Characteristics of gypsum, wheat straw, and rice husk materials.

2.2. Wheat Straw

The wheat straw used for this study was collected from agricultural fields in the Punjab region of Pakistan where wheat is a major commercial crop and abundant quantities of wheat straw are produced every year. The fibrous wheat straw was produced by the thresher machine while separating the wheat grains from the wheat plant and, in this study, it was used as such without any artificial treatment and sorting as shown in Figure 1a. The maximum length and width of wheat straw fibers used for gypsum matrixes were 12 mm and 2.8 mm, respectively. The characteristics of wheat straw are shown in Table 1. The density of wheat straw is significantly lower than that of gypsum, a characteristic that will help in reducing the weight of the developed composites.

Figure 1.

Wheat straw and rice husk. (a) Wheat Straw; (b) Rice Husk.

2.3. Rice Husk

The rice husk used for this study was collected from a local rice processing plant where it is produced during the rice milling process. Results of chemical analysis and density of rice husk used are shown in Table 1. It was lighter in weight compared to wheat straw and more than 10 times lighter than gypsum. It was mainly comprised of particles with a maximum length dimension of 9 mm and a width of 2.40 mm, as shown in Figure 1b. A visual analysis of both the agricultural residues showed that the surface of the rice husk was rough while wheat straw particles had a smooth surface. Also, the rice husk particles were stiffer compared to the wheat straw. The same roughness was proven by the microstructure analysis of both wheat straw and rice husk by Wang et al. [37] and Chen et al. [38], respectively.

3. Experimental Program

In this study, test specimens were prepared from gypsum mixtures with 0, 2.5, 5, 7.5, and 10 percent by weight dosages of agricultural residues, i.e., wheat straw and rice husk. A summary of the mixes prepared is shown in Table 2. The water to gypsum ratio for the prepared mixes was optimized to achieve a workable mix by the procedures described in EN 13279-2:2014 [36]. For the control mix (0% agricultural residue) and mixes having rice husk and wheat straw dosages below 7.5%, the water gypsum ratio used was 0.55. However, for the mix with a 10% residue dosage, a 0.8 water gypsum ratio was used to obtain a workable mixture. Such an increase in W/G ratio for mixes with higher replacement ratios is also common in previous research [20,21] investigating the addition of similar low-density waste materials as investigated in the current study. For all the developed mixes, physical and mechanical characterization was done by performing the density, shore C hardness, thermal insulation, water absorption, flexure strength, and compression strength tests as per the relevant standards mentioned in Table 3. Further, the eco-friendly gypsum agricultural waste false ceiling plates were tested for flexure to ascertain their performance as per BS EN 14246 [39]. The details of the test specimens are presented in the next section.

Table 2.

The prepared mixes.

Table 3.

Details of test specimens.

Test Specimens and Methods

Different types of test specimens were prepared for each mix and their details are mentioned in Table 3. The density of the developed composites was determined using the prism samples of dimensions 160 mm × 40 mm × 40 mm made for flexural strength and hardness tests. After one day of casting, the specimens were unmolded and cured at room temperature for seven days. The samples were then placed in an oven at 40 °C for 24 h and taken out for cooling and the weights were recorded. This weight was used to determine the density of the composites by dividing it by the volume of the prism specimen. The shore C hardness was determined using the prism specimen (160 mm × 40 mm × 40 mm) in accordance with EN 102042 [40] using the test setup as shown in Figure 2. A total of 30 measurements were taken on three prepared specimens for each gypsum mix (10 readings for each specimen). The average of 30 values was taken as shore C hardness for each type of gypsum mixture.

Figure 2.

Brinell Hardness Testing Machine and scale.

Following the same procedure as used by Sumin Kim [41], the water absorption test was performed on samples with dimensions 100 mm × 100 mm × 15 mm. Three specimens of each residue proportion were prepared to determine the water absorption for the respective gypsum mix. First, the weights in the dry state were measured before immersing the samples in water. Then, the specimens were placed under 3 cm water for 24 h at 20 ± 1 °C as shown in Figure 3. After 24 h, the samples were taken out of the water and wiped with a towel to remove water from surfaces. For the 24 h immersion, no thickness swelling was observed in any gypsum composite. Finally, the increase in weight of each specimen was determined as the difference between the final and initial weight of the specimen and it was used for calculating water absorption. In addition, the thickness of the specimen at its center point was measured before and after the immersion to detect any thickness swelling over the 24 h immersion period.

Figure 3.

Water absorption samples immersed in 3 cm water for 24 h.

For the thermal conductivity test, gypsum plates measuring 300 mm × 300 mm × 15 mm were prepared for each mix. These plates were tested according to EN 12667:2001 [42] in guarded hot plate apparatus as shown in Figure 4, having a range of 0.015–2 W/m·K to determine the thermal conductivity coefficient. The thermal conductivity coefficient was calculated as follows:

where Q is sample heat flux (W/m2), d is sample thickness (m), and ∆T is average temperature difference between two sides of the sample (°C). The thickness of each plate specimen was measured before performing the thermal insulation test by Vernier caliper with an accuracy of 0.01 mm. Three samples were prepared and tested for each gypsum mix as mentioned in Table 3.

Figure 4.

Test setup for thermal conductivity test. (a) Guarded Hot Plate Apparatus; (b) Gypsum plate between hot and cold plates.

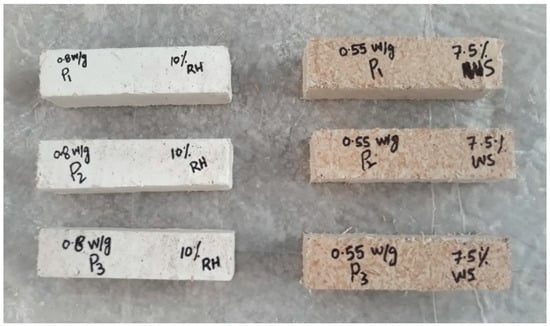

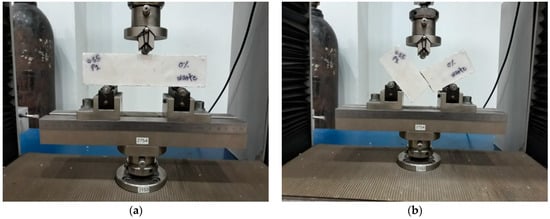

For the flexural and compressive strength tests, 160 mm × 40 mm × 40 mm prisms were prepared as shown in Figure 5 by following EN 13279-2:2014 [36]. Three prisms were prepared for each mix. After demolding, the samples were stored for seven days under 23 ± 2 °C temperature and relative humidity of 50 ± 5%. Then, the prisms were placed in an oven at 40 °C for 24 h and after that placed in air for cooling to room temperature. Three-point load tests were performed on these prisms for measuring flexure strength as per the procedure described in EN 13279-2:2014 [36] by using a TIRAtest 2810 universal testing machine with a load capacity of 10 kN (see Figure 6a). The test was conducted at a loading rate of 10 N/min. The pins used at supports had a 10 mm diameter as per standard to avoid local stressing of load at supports. The pins were placed at 100 mm center to center distance with the help of a graduated platform for supporting pins at exact locations. The data of the flexure test generated load-deflection curves for each test specimen. The corresponding flexure strength was calculated using Equation (2).

PF = 0.00234 × P

Figure 5.

Hardened gypsum prisms with 10% rice husk and 7.5% wheat straw.

Figure 6.

Strength test on control prism. (a) Before strength test on control prism; (b) After strength test on control prism.

PF is the flexure strength (MPa), and P is the average breaking load (N) of at least three obtained values.

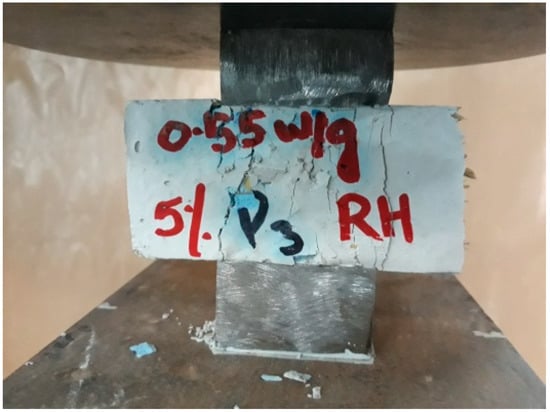

The 3 prisms of each dosage tested in the flexure test in turn yielded 6 broken pieces (Figure 6b) out of which 4 sound specimens were later tested in compression as recommended by EN 13279-2:2014 [36]. Steel strips measuring 40 mm × 40 mm were placed above and below the test specimen to ensure load application within a 40 mm strip of the specimen as shown in Figure 7.

Figure 7.

Compressive strength test setup.

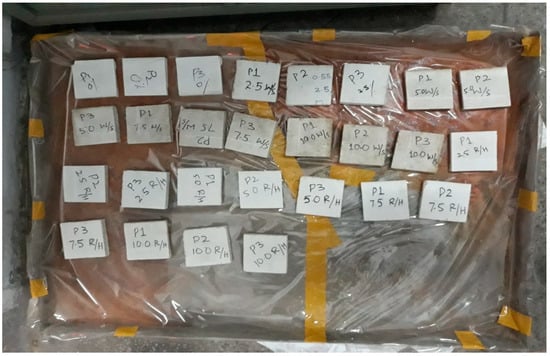

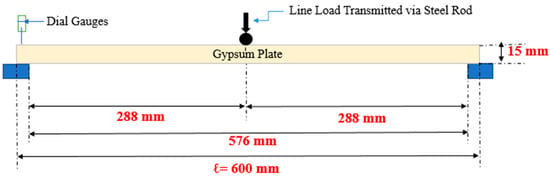

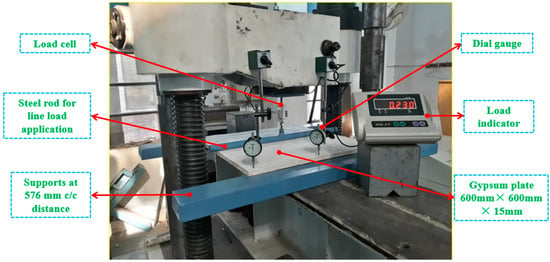

As a potential eco-friendly construction product for the developed gypsum composites, the gypsum false ceiling plates with dimensions 600 mm × 600 mm × 15 mm were prepared for each mix as per the EN 14246:2006 [39] standard, which establishes the minimum requirements for the design of gypsum false ceiling plates in discontinuous false ceilings as mentioned in Table 4. The most common dimensions of discontinuous false ceiling plates used in the local construction industry are 600 mm × 600 mm × 15 mm. The plates were prepared by using the same method of casting as used by local plate manufacturers, which involves pouring the wet mix into molds with the bottom surface made of glass and leveling the top surface with a sharp edge without applying any pressure during casting. The casting setup used for this study and a freshly cast and finished gypsum plate are shown in Figure 8. For each gypsum composite, three plates were prepared. The bending test was carried out on developed plates to calculate breaking loads and to check the post-peak behavior of false ceiling plates, which was expected to improve due to incorporating wheat straw and rice husk in the mixes. As a passing criterion as per EN 14246:2006, a line load of 6 kg was applied to each plate at its center for 30 min and the development of any permanent cracks on the bottom side of the plate was observed. All the plates made in this study passed this check. Then, a constantly increasing line load at a rate of 0.1 mm/min was applied on the plate until it broke. Along with the load measurements, the midspan deflection of the plate was also measured to plot the load-deflection curve to confirm the post-peak behavior and to calculate the energy dissipation capacity of the developed gypsum composites. The schematic diagram of the test setup used is shown in Figure 9 whereas the actual test setup is shown in Figure 10.

Table 4.

Minimum requirements for gypsum plates according to EN 14246:2006.

Figure 8.

Wet mix of gypsum–waste composite (Left) and finished gypsum false ceiling plate (Right).

Figure 9.

Schematic diagram of bending test setup.

Figure 10.

Test setup for false ceiling plates.

4. Results and Discussion

4.1. Tests on Gypsum Composites

The results of the various tests conducted on the developed gypsum composites are presented and compared with the results of the reference mixture as well as with the limiting values of the relevant standards [36,39].

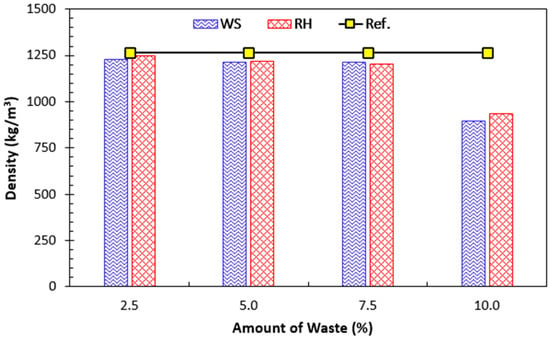

4.1.1. Density

Figure 11 presents the density comparison of each gypsum mixture with the control gypsum mix. An increase in the percentage of both agricultural residues (wheat straw and rice husk) caused a reduction in density values compared to the reference gypsum mix. A reduction of 29% and 26% in density values is observed compared to the control gypsum matrix with a 10% dosage of wheat straw and rice husk, respectively. The reduction in density is observed because both agricultural by-products have a significantly lower density than gypsum. Further, a higher value of the W/G ratio is responsible for the increased reduction in density values for the case of composites with 10% agricultural residues. The coefficient of variation (CoV) for the density test on gypsum composite specimens is below 5%.

Figure 11.

Density variations with the amount of waste replaced with gypsum.

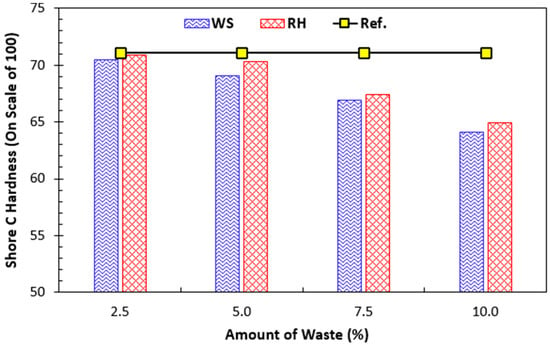

4.1.2. Shore C Hardness

The results of shore C hardness tests are presented in Figure 12. It is evident that the replacement of gypsum with agricultural wastes caused a decrease in shore C hardness of gypsum composites. The shore C hardness values showed a decreasing trend with the increase in residues’ dosage. However, the difference in values is not significant as the waste percentage increases from 2.5 to 10 percent. The composites containing wheat straw show a slightly lower value of shore C hardness compared to those having rice husk, which is due to the higher stiffness of rice husk particles. The CoV for specimens tested in shore C hardness is below 10%.

Figure 12.

Shore C hardness at different amounts of waste percentages.

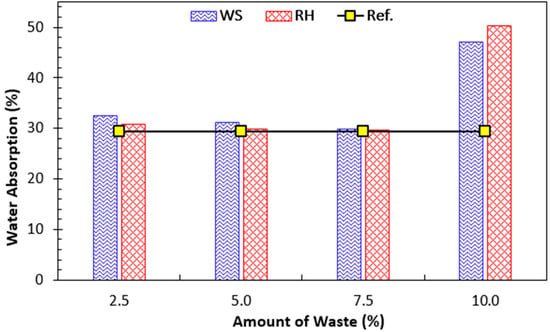

4.1.3. Water Absorption

The results of the water absorption test for all the composites investigated in this study are shown in Figure 13. The water absorption values for gypsum composites with an agricultural waste dosage of up to 7.5% are close to the reference specimen because all these mixes have a water/gypsum ratio of 0.55. However, in the case of gypsum composites with 10% agricultural residue dosage, the water absorption values show an increase compared to control gypsum composites due to the availability of excess water and hence porosity because of the greater water gypsum ratio of 0.8. Further, more exposed residue particles on the sample’s surface are another reason for the increased water absorption in the case of mixes containing 10% waste. No thickness swelling was observed for samples of any mix as a result of this 24 h immersion. The CoV for gypsum composite samples in the water absorption test is below 5%.

Figure 13.

Effect of amount of waste on water absorption of composites.

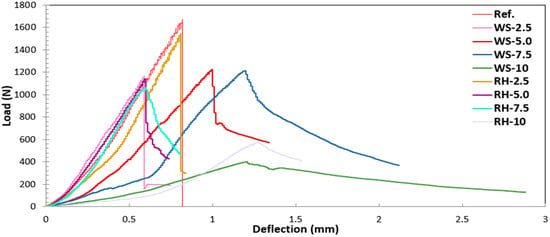

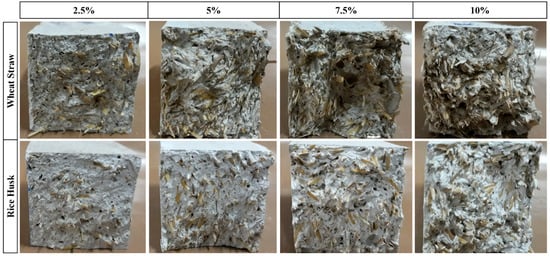

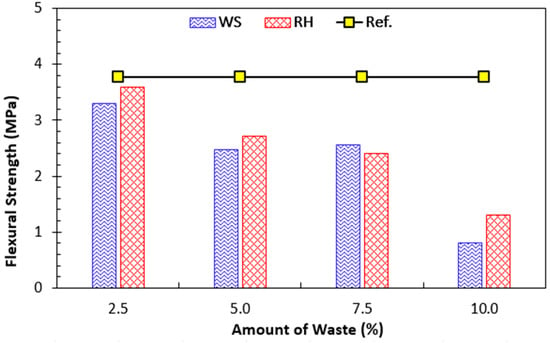

4.1.4. Flexure Strength

The load-deflection response of all the prism specimens tested in flexure is shown in Figure 14. The control mix prisms (0% waste dosage) suddenly failed under the gradually applied load after reaching a maximum load, showing the brittle nature of the reference mix. However, with the addition of both types of agricultural residues, the prism specimens showed improved post-peak behavior. Although the ultimate load carried by the prisms decreased with the increase in waste percentage, the ultimate deflection of the prism before failure increased as shown in Figure 14. In Figure 15, the crack planes of the tested gypsum prisms obtained because of the flexure strength test are shown. The crack planes of each gypsum prism show the homogenous distribution of wheat straw and rice husk across the cross-section. Grains of both types of residues were uniformly surrounded and separated by gypsum. Figure 16 shows the ultimate flexural strength values for all the mixes studied. A decreasing trend in flexure strength with the increase in agricultural wastes’ dosage can be observed, which is due to the decrease in the quantity of the binder in mixes containing waste dosages up to 7.5% and also due to a higher W/G ratio for mixes containing a 10% waste dosage. However, flexural strength values of all the mixes remained above the minimum limiting mean value of 1 MPa [43], except for the prism specimens with a 10 percent wheat straw replacement level. The CoV for specimens in the flexure strength test is below 10%.

Figure 14.

Load deflection response for each prism under flexure strength test.

Figure 15.

Failure planes of prisms after failure in flexure strength test.

Figure 16.

Effect of amount of waste on flexure strength of composites.

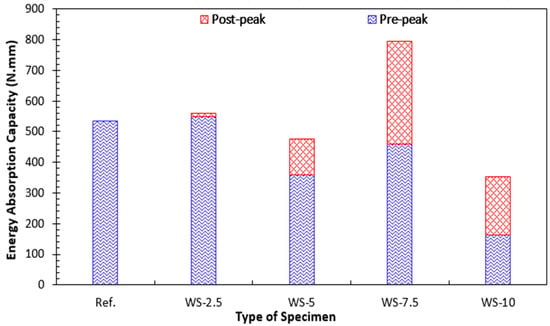

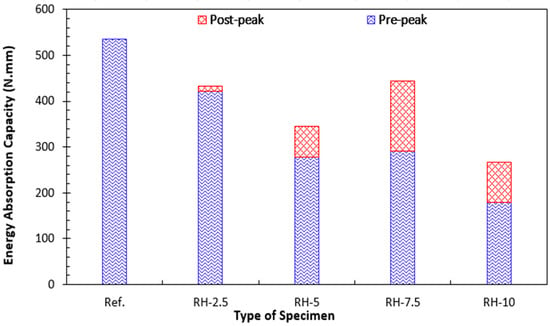

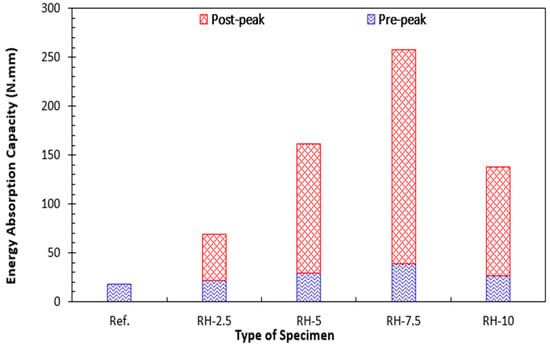

To quantify the effect of incorporating agricultural wastes on the post-peak behavior in flexure of the developed gypsum composites, the energy absorption values were calculated from the load-deflection curves presented in Figure 14 by calculating the area under the curve. Two energy values were calculated for each composite, i.e., energy up to the peak load (pre-peak) and the energy absorbed in the post-peak range. The results of energy absorption in flexure by the gypsum composites incorporating wheat straw are shown in Figure 17. The pre-peak values of energy absorption of samples containing wheat straw up to a dosage of 7.5% are close to the control gypsum prism (0% waste) values but decrease when 10% wheat straw is added. Figure 18 shows the results of energy absorbed in flexure for the composites containing rice rusk. Gypsum rice husk prisms show smaller deflections compared to gypsum wheat straw prisms because rice husk is smaller and stiffer compared to wheat straw.

Figure 17.

Energy absorption in flexure by gypsum prisms incorporating wheat straw.

Figure 18.

Energy absorption in flexure by gypsum prisms incorporating rice husk.

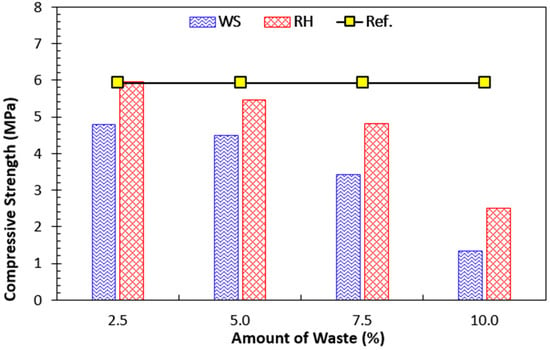

4.1.5. Compressive Strength

Compressive strength values for all the composites are shown in Figure 19. The compressive strength values are decreased due to the addition of waste and show a decreasing trend with the increase in the replacement ratios of both the wastes. However, these values of compressive strength remain above the minimum limiting mean value of 2 MPa [43], except for the prism specimens with a 10 percent wheat straw replacement level. The CoV for specimens tested for compressive strength is below 10%. It should be noted that for gypsum mixtures containing rice husk as a replacement material, the compressive strength values are higher than gypsum mixture with wheat straw, which is due to the higher stiffness and rough surface of the rice husk particles.

Figure 19.

Effect of amount of waste on compressive strength of gypsum agricultural waste composites.

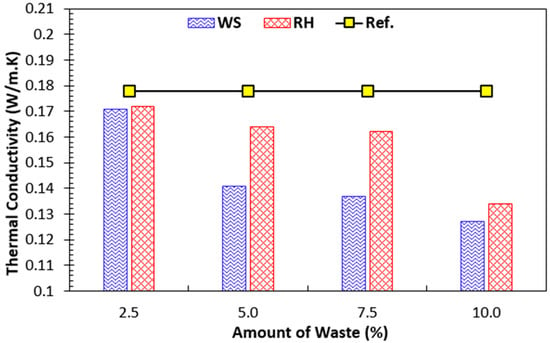

4.1.6. Thermal Behavior

The thermal conductivity plates were placed in between the hot and cold plates of the guarded hot plate apparatus (see Figure 4). The plate heat flux (W/m2), plate thickness (m), and average temperature difference between two sides of the plates (°C) are determined to measure the thermal conductivity. The results of thermal conductivity obtained by performing the test according to EN 12667:2001 [42] in guarded hot plate apparatus on gypsum plates measuring 300 mm × 300 mm × 15 mm are shown in Figure 20. It is evident from the results that the thermal conductivity of the composites decreases with the increase in the percentage of waste, therefore providing superior thermal performance for the developed composites. At the same waste dosage level, gypsum plates containing wheat straw showed better performance compared to the gypsum rice husk plates. Gypsum plates with 10% of wheat straw achieved the lowest density, i.e., 898 kg/m3 as well as the lowest thermal conductivity, i.e., 0.127 W/m·K, which is 29% lower than the reference gypsum plate. The improved thermal insulation of the developed composites as compared to the reference mix is encouraging for the utilization of the agricultural waste to develop eco-friendly gypsum composites for use in buildings as an insulating material.

Figure 20.

Effect of amount of waste on thermal behavior of composites.

4.2. Tests on False Ceiling Plates

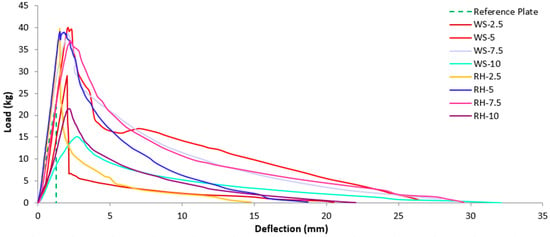

As mentioned in the previous section, all the plates passed the bending test of carrying a 6 kg centered linear load for 30 min as per European standard EN 14246:2006 [39]. The complete load-deflection curves for the plates made of all the mixes are shown in Figure 21. The reference plate (0% waste dosage) failed suddenly after reaching the peak load, showing the brittleness of the reference mix. However, for the plates made of the other developed composites, an improved load-carrying capacity and the post-peak behavior are evident in these curves as compared to the reference specimen.

Figure 21.

Load deflection response of gypsum false ceiling plates for bending strength test.

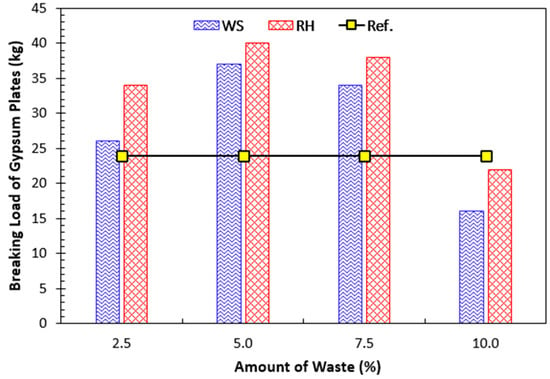

The results of the ultimate load for plates in the bending test are shown in Figure 22. For the plates made from the composite mixes, the load-carrying capacity of the plates was improved, which is due to the fibrous action of the agricultural waste in the 15 mm thickness of the plate. Further, the load-carrying capacity of plates with rice husk is more compared to the plates with wheat straw because rice husk is a stiffer material with a rougher surface compared to wheat straw. With the replacement of 2.5% of gypsum with wheat straw, better flexure behavior of the plate was observed. The post-peak behavior shows that the brittleness of reference gypsum false ceiling plate can be avoided by replacing gypsum with wheat straw. The deflection to carry the load also increased with the addition of wheat straw as compared to the control gypsum plate. The 5% wheat straw gypsum false ceiling plates carry more load and greater deflection values compared to the reference gypsum plate and 2.5% wheat straw gypsum plate. The 5% wheat straw is the optimum content when compared to the control gypsum plate. A similar load-deflection behavior is seen in gypsum false ceiling plates with a 7.5% dosage of wheat straw but with lower load-carrying capacity compared to that of 5% wheat straw plates. But, the deflections carried by 7.5% wheat straw plates were more than 5% wheat straw plates. The load-carrying capacity of gypsum false ceiling plates with 10% wheat straw is lower compared to the reference plate and for gypsum plates with a wheat straw dosage of 2.5%, 5%, and 7.5%. Although the load is smaller compared to reference gypsum plates, in 10% wheat straw gypsum plates, better post-peak behavior is observed compared to the sudden failure of the control gypsum plate.

Figure 22.

Gypsum false ceiling plates breaking load variation with the amount of waste.

At 2.5% dosage, deflection values of gypsum false ceiling plates with rice husk are smaller than the plates containing wheat straw. Both the load-carrying capacity and deflection values of the plates with 5% rice husk are greater than the values for plates containing 2.5% rice husk. The 5% dosage is a significant dosage both in the case of wheat straw and rice husk for replacing gypsum. The load-carrying capacity of 7.5% rice husk gypsum plates is lower than gypsum plates with 2.5% and 5% dosages, but they can carry the load with more deflections. The lowest load-carrying capacity is shown by the 10% rice husk gypsum plate compared to the 2.5%, 5%, and 7.5% rice husk dosages. At 10% waste dosage, deflection values in wheat straw gypsum plates are higher than in rice husk plates, however, the load-carrying capacity is superior for rice husk plates compared to wheat straw at a 10% dosage.

It is noticed that the trend of flexural strength of composites as obtained from the prism tests is different than the trend of peak loads obtained from the flexural testing of the plates. This is possibly due to the significantly smaller thickness as compared to the span for the case of plate-type specimens as compared to the prism-type specimens. The positive effect of the incorporation of agricultural residues has been observed for the plate-type specimens as compared to the plates containing the control mixture (100% gypsum). This improved performance of plates containing waste has also been observed in previous research [13].

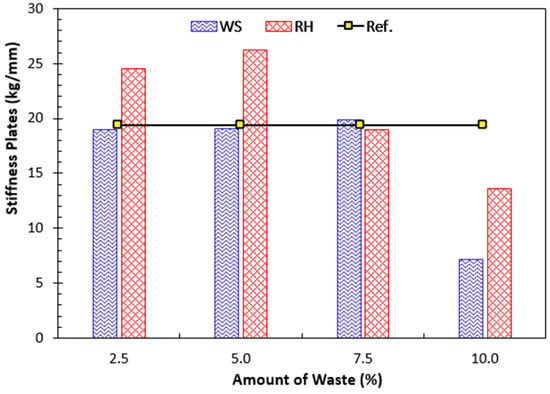

The stiffness variation results for both control and the false ceiling plates containing agricultural residues are shown in Figure 23. The stiffness is calculated as the slope in the elastic zone of the load versus deflection curve of the gypsum plates presented in Figure 21. The results show that stiffness for wheat straw up to the 7.5% dosage remains close to that of the control sample but decreases at 10% dosage. In the case of gypsum false ceiling plates with rice husk, the stiffness values increase up to the 5% replacement level and then decrease for 7.5% and 10% rice husk dosage.

Figure 23.

Effect of amount of waste on the stiffness of false ceiling plates.

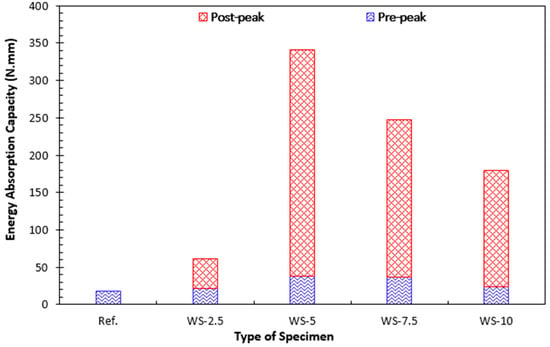

The results of energy absorption, calculated as the area under the load-deflection curve, for gypsum false ceiling plates with wheat straw and rice husk are shown in Figure 24 and Figure 25, respectively. The results of energy absorption up to the peak load for both wheat straw and rice husk plates are close to the reference plate, which is due to the smaller thickness of the plate as compared to the span and the smaller length fibers added not contributing to the dissipation of energy up to the peak load of the plates. However, after the peak load, the presence of fibers contributes to the dissipation of energy by providing greater deflection capacity to the plates as compared to the sudden failure for the case of the control specimen. The post-peak dissipated energy is maximum for the 5% dosage of wheat straw and the 7.5 dosage of rice husk.

Figure 24.

Energy absorption variations of plates with amount of wheat straw.

Figure 25.

Energy absorption variations of plates with amount of rice husk.

5. Conclusions

The main aim of this experimental study was to investigate the possibility of incorporating abundantly available agricultural residues in the development of an eco-friendly construction product. Based on the results, it can be concluded that the flexural strength and compressive strength of all gypsum composites showed a decreasing trend with the increase of wheat straw and rice husk dosages. But even after the decrease and incorporation of a significant quantity of waste in all cases, the values remain above the acceptable limits of 1 MPa and 2 MPa, respectively, as per EN 13279-1 [43], except for the 10% wheat straw dosage wherein the values of 0.81 MPa and 1.33 MPa were observed for flexural strength and compressive strength, respectively. With the increase in agricultural waste percentage, density and shore C hardness showed a reduction in values, while thermal insulation showed superior performance for gypsum agricultural waste composites compared to the control gypsum matrix. This reduction in density was due to the porous structure of residues, which resulted in porosity increment, and the flexible structure of the fibers present at the sample’s surface are the possible reason for the decreasing shore C hardness values. In the case of water absorption, similar values have been found for the control gypsum mix and the developed composites up to 7.5% waste dosage. Further, the developed composites incorporating wheat straw showed a relatively higher reduction in properties than those that include rice husk in the same percentage, possibly due to the significantly rough surface of rice husk compared to the surface of wheat straw. At 10% dosage of both the wheat straw and rice husk, a higher water/gypsum ratio was used in the gypsum matrix to maintain the workability. However, this resulted in a significant reduction of the mechanical properties of developed gypsum composites containing 10% waste dosage. All the false ceiling plates tested in bending satisfied the 6 kg mid-span load criteria as per EN 14246-2006 [39]. The flexure strength of false ceiling plates increases up to the 5 percent wheat straw and rice husk dosage and decreases with further replacement of residues with gypsum material.

The superior thermal insulation, reduced density, and better bending behavior of the plates prove the usefulness of these composites for their application as a building material for making false ceiling plates and gypsum boards. Investigation of the durability and acoustic characteristics of the developed composites and their possible application as eco-friendly masonry units will be the focus of future research in the continuation of this study.

Author Contributions

Conceptualization, M.R.R.; methodology, M.F.E. and R.A.; software, A.F.; validation, R.H., A.F.D. and A.M.M.; formal analysis, M.F.E. and A.F.; investigation, R.A., R.H., A.F.D. and A.M.M.; data curation, M.F.E.; writing—original draft preparation, M.F.E., R.A. and A.F.; writing—review and editing, M.R.R.; supervision, M.R.R., R.H., A.F.D. and A.M.M.; project administration, M.R.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Happho. Why Is False Ceiling Design Important in a House? Available online: https://happho.com/why-is-false-ceiling-design-important-in-a-house/ (accessed on 13 April 2021).

- Gharpedia. Things to Know about False Ceiling for Your Interior! Available online: https://gharpedia.com/blog/things-to-know-about-false-ceiling-for-your-interior/ (accessed on 28 November 2017).

- Space, T.A. False Ceilings—Types, Advantages and Its Materials. Available online: https://thearchspace.com/false-ceilings-and-its-materials/ (accessed on 17 July 2020).

- Farooqui, Y.N. Trade Development Authority of Pakistan Report on Analysis of Minerals and Metals Sector of Pakistan; The Case of Gypsum: Karachi, Pakistan, 2021. [Google Scholar]

- SAARC Energy Center Report. In Possible Uses of Crop Residue for Energy Generation Instead of Open Burning; SAARC Energy Centre: Islamabad, Pakistan, 2019.

- Saeed, M.A.; Irshad, A.; Sattar, H.; Andrews, G.E.; Phylaktou, H.N.; Gibbs, B.M. Agricultural waste biomass energy potential in Pakistan. In Proceedings of the International Bioenergy Exhibition and Asian Bioenergy Conference, Shanghai, China, 21–23 October 2015. [Google Scholar]

- Ghani, H.U.; Mahmood, A.; Ullah, A.; Gheewala, S.H. Life Cycle Environmental and Economic Performance Analysis of Bagasse-Based Electricity in Pakistan. Sustainability 2020, 12, 10594. [Google Scholar] [CrossRef]

- Habib, A.; Nasim, S.; Shahab, A. Charting Pakistan’s Air Quality Policy Landscape; International Growth Centre: London, UK, 2021. [Google Scholar]

- Raza, W.; Saeed, S.; Saulat, H.; Gul, H.; Sarfraz, M.; Sonne, C.; Sohn, Z.-H.; Brown, R.J.C.; Kim, K.H. A review on the deteriorating situation of smog and its preventive measures in Pakistan. J. Clean. Prod. 2021, 279, 123676. [Google Scholar] [CrossRef]

- Arroyo, R.; Horgnies, M.; Junco, C.; Rodríguez, A.; Calderón, V. Lightweight structural eco-mortars made with polyurethane wastes and non-Ionic surfactants. Constr. Build. Mater. 2019, 197, 157–163. [Google Scholar] [CrossRef]

- Boquera, L.; Olacia, E.; Fabiani, C.; Pisello, A.L.; D’Alessandro, A.; Ubertini, F.; Cabeza, L.F. Thermo-acoustic and mechanical characterization of novel bio-based plasters: The valorisation of lignin as by-product from biomass extraction for green building applications. Constr. Build. Mater. 2021, 278, 122373. [Google Scholar] [CrossRef]

- Dolezelova, M.; Krejsova, J.; Scheinherrova, L.; Vimmrova, A. Comparison of structure and properties of gypsum mortars with different types of aggregates. IOP Conference Series: Materials Science and Engineering, International Conference Building Materials, Products and Technologies (ICBMPT 2020), Telč, Czech Republic, 2–4 June 2022; IOP Publishing: Bristol, UK; Volume 1039, p. 012009. [Google Scholar]

- Ferrández, D.; Álvarez, M.; Saiz, P.; Zaragoza, A. Experimental Study with Plaster Mortars Made with Recycled Aggregate and Thermal Insulation Residues for Application in Building. Sustainability 2022, 14, 2386. [Google Scholar] [CrossRef]

- Guna, V.; Yadav, C.; Maithri, B.R.; Ilangovan, M.; Touchaleaume, F.; Saulnier, B.; Grohens, Y.; Reddy, N. Wool and coir fiber reinforced gypsum ceiling tiles with enhanced stability and acoustic and thermal resistance. J. Build. Eng. 2021, 41, 102433. [Google Scholar] [CrossRef]

- Pedreno-Rojas, M.; Flores-Colen, I.; De Brito, J.; Rodríguez-Linán, C. Influence of the heating process on the use of gypsum wastes in plasters: Mechanical, thermal and environmental analysis. J. Clean. Prod. 2019, 215, 444–457. [Google Scholar] [CrossRef]

- Porras Amores, C.; Santa Cruz Astorqui, J.; Del Río Merino, M.; Villoria Sáez, P.; Viñas Arrebola, C. Thermal behavior of traditional lightweight gypsum with construction and demolition waste materials. DYNA 2019, 94, 431–436. [Google Scholar] [CrossRef] [Green Version]

- Santa-Cruz-Astorqui, J.; Del-Río Merino, M.; Villoria-Sáez, P.; Porras-Amores, C. Analysis of the viability of prefabricated elements for partitions manufactured with plaster and EPS from waste recycling. DYNA 2019, 94, 415–420. [Google Scholar]

- Villoria Sáez, P.; del Río Merino, M.; Sorrentino, M.; Porras Amores, C.; Santa Cruz Astorqui, J.; Viñas Arrebola, C. Mechanical Characterization of Gypsum Composites Containing Inert and Insulation Materials from Construction and Demolition Waste and Further Application as A Gypsum Block. Materials 2020, 13, 193. [Google Scholar] [CrossRef] [Green Version]

- Yedra, E.; Ferrández, D.; Morón, C.; Saiz, P. New test methods to determine water absorption by capillarity. Experimental study in masonry mortars. Constr. Build. Mater. 2022, 319, 125988. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.; Morales-Conde, M.; Pérez-Gálvez, F.; Rodríguez-Liñán, C. Eco-efficient acoustic and thermal conditioning using false ceiling plates made from plaster and wood waste. J. Clean. Prod. 2017, 166, 690–705. [Google Scholar] [CrossRef]

- Morales-Conde, M.; Rodríguez-Liñán, C.; Pedreño-Rojas, M. Physical and mechanical properties of wood-gypsum composites from demolition material in rehabilitation works. Constr. Build. Mater. 2016, 114, 6–14. [Google Scholar] [CrossRef]

- ASTMC62-01; Standard Specification for Building Brick (Solid Masonry Units Made From Clay or Shale). ASTM International: Philadelphia, PA, USA, 2001.

- Dai, D.; Fan, M. Preparation of bio-composite from wood sawdust and gypsum. Ind. Crops Prod. 2015, 74, 417–424. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Pérez-Gálvez, F.; Rubio-de-Hita, P. Reuse of CD and DVD Wastes as Reinforcement in Gypsum Plaster Plates. Materials 2020, 13, 989. [Google Scholar] [CrossRef] [Green Version]

- Morales-Segura, M.; Porras-Amores, C.; Villoria-Sáez, P.; Caballol-Bartolomé, D. Characterization of Gypsum Composites Containing Cigarette Butt Waste for Building Applications. Sustainability 2020, 12, 7022. [Google Scholar] [CrossRef]

- Fantilli, A.P.; Jóźwiak-Niedźwiedzka, D.; Denis, P. Bio-Fibres as a Reinforcement of Gypsum Composites. Materials 2021, 14, 4830. [Google Scholar] [CrossRef]

- Vidales-Barriguete, A.; Santa-Cruz-Astorqui, J.; Piña-Ramírez, C.; Kosior-Kazberuk, M.; Kalinowska-Wichrowska, K.; Atanes-Sánchez, E. Study of the Mechanical and Physical Behavior of Gypsum Boards with Plastic Cable Waste Aggregates and Their Application to Construction Panels. Materials 2021, 14, 2255. [Google Scholar] [CrossRef]

- Lakrafli, H.; Tahiri, S.; Albizane, A.; El Otmani, M. Effect of wet blue chrome shaving and buffing dust of leather industry on the thermal conductivity of cement and plaster based materials. Constr. Build. Mater. 2012, 30, 590–596. [Google Scholar] [CrossRef]

- Rivero, A.J.; de Guzmán Báez, A.; Navarro, J.G. New composite gypsum plaster–ground waste rubber coming from pipe foam insulation. Constr. Build. Mater. 2014, 55, 146–152. [Google Scholar] [CrossRef] [Green Version]

- Herrero, S.; Mayor, P.; Hernández-Olivares, F. Influence of proportion and particle size gradation of rubber from end-of-life tires on mechanical, thermal and acoustic properties of plaster–rubber mortars. Mater. Des. 2013, 47, 633–642. [Google Scholar] [CrossRef] [Green Version]

- Serna, Á.; del Río, M.; Palomo, J.G.; González, M. Improvement of gypsum plaster strain capacity by the addition of rubber particles from recycled tyres. Constr. Build. Mater. 2012, 35, 633–641. [Google Scholar] [CrossRef]

- López-Zaldívar, O.; Lozano-Díez, R.; del Cura, S.H.; Mayor-Lobo, P.; Hernández-Olivares, F. Effects of water absorption on the microstructure of plaster with end-of-life tire rubber mortars. Constr. Build. Mater. 2017, 150, 558–567. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Donnini, J.; Nardinocchi, A. Lightweight plasters containing plastic waste for sustainable and energy-efficient building. Constr. Build. Mater. 2015, 94, 337–345. [Google Scholar] [CrossRef]

- Durgun, M.Y. Experimental research on gypsum-based mixtures containing recycled roofing tile powder at ambient and high temperatures. Constr. Build. Mater. 2021, 285, 122956. [Google Scholar] [CrossRef]

- Cuenca-Romero, L.A.; Calderón, V.; Rodríguez, Á.; Gutiérrez-González, S. Comparative Life Cycle Assessment (LCA) between standard gypsum ceiling tile and polyurethane gypsum ceiling tile. Energy Build. 2022, 259, 111867. [Google Scholar]

- EN 13279-2; Gypsum Binders and Gypsum Plasters-Part. 2: Test. Methods. British Standards: London, UK, 2014.

- Wang, Y.; Ji, X.-X.; Liu, S.; Tian, Z.; Si, C.; Wang, R.; Yang, G.; Wang, D. Effects of two different enzyme treatments on the microstructure of outer surface of wheat straw. Adv. Compos. Hybrid Mater. 2022, 5, 1–14. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, Y.; Shivkumar, S. Microstructure and tensile properties of various varieties of rice husk. J. Sci. Food Agric. 2018, 98, 1061–1070. [Google Scholar] [CrossRef]

- EN 14246; Gypsum Elements for Suspended Ceilings—Definitions, Requirements and test Methods. British Standards: London, UK, 2006.

- EN 102042; Plasters and Construction Plasters Other Test Methods. British Standards: London, UK, 2013.

- Kim, S. Incombustibility, physico-mechanical properties and TVOC emission behavior of the gypsum–rice husk boards for wall and ceiling materials for construction. Ind. Crops Prod. 2009, 29, 381–387. [Google Scholar] [CrossRef]

- EN 12667:2001; Thermal Performance of Building Materials and Products. Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods. Products of High and Medium Thermal Resistance. British Standards: London, UK, 2001.

- EN 13279-1; Gypsum Binders and Gypsum Plasters: Part 1: Definitions and Requirements. European Committee for Standardization: Brüssels, Belgium, 2006.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).