Abstract

Agility is the dynamic capability of an organization which helps it to manage a change and uncertainties in the environment. The purpose of this research is to review the literature from the perspective of agility in Industry 4.0. This paper systematically reviews 381 relevant articles from peer-reviewed academic journals in the period of the last five years. The results show that agility is important for an organization to adopt Industry 4.0 technologies as it helps companies to cope with the changes that arise along with the adoption of Industry 4.0 technologies. Further, it also indicates that by adopting Industry 4.0 technologies, companies can significantly enhance their agility capability into various aspects with different technologies. The technologies which enhance the agility are: smart manufacturing, internet of things, cyber-physical system, big data and analytics and cloud computing. On the other hand, important aspects of agility include supply chain, workforce, information system, facilities, management, manufacturing and technology agility.

1. Introduction

The world is about to enter into the era of Industry 4.0 manufacturing and production [1]. This era is dominated by an amalgamation of mechanical and digital technology, which refers to a transformation from machine-dominant to digital- and services-dominant production of goods and services [2]. The Industry 4.0 provides immense opportunities to industries in efficiency of resource utilization and achieving strategic goals [3]. However, a radical change is about to be witnessed in the organization with respect to culture, work system and operations, with immense opportunities to come with implementing and adopting Industry 4.0 [4]. It is supposed that company’s external and competitive environment will become more uncertain with wide-ranging adaptation of Industry 4.0 across the different industries [5]. The pressure from areas such as mass customization and managing supply and value chain more quickly and efficiently than it is today will be evident [6]. This kind of external pressure will also influence the resource allocation priority within organizations [7], where companies will be mired with decision constraints to channel resources to a particular chain of value creation and supply, as well as quick designing, testing and commercialization of products and services [8]. Thus, organizations in the Industry 4.0 need to be quick to manage such uncertainties and pressure both outside and within the organization, although Industry 4.0 ecosystem, which refers to a combination of Industry 4.0 technologies adopted by a company, will significantly help in managing such uncertainties and pressure. A dynamic capability will help companies to use Industry 4.0 ecosystem to respond to such changes and pressure quickly and efficiently [9]. The literature refers to such dynamic capability as organizational agility [10].

The organizational agility is defined as a “learned, permanently available dynamic capability that can be performed to a necessary degree in a quick and efficient fashion, and whenever needed in order to increase business performance in a volatile market environment” [11]. The researchers have long argued about the positive impact of organizational agility on various aspect of business performance [8]. However, agility in the era of Industry 4.0 has a special place [12]. It is claimed that agility provides a necessary capability and guideline to companies to efficiently configure their Industry 4.0 technologies [13], so that the company is able to manage the external uncertainty effectively [14]. The research on the relationship between agility and Industry 4.0 is in the initial stage, but it is gaining pace as organizational agility is positioned as a must-have dynamic capability to realize the full potential of adopting Industry 4.0 ecosystem and to gain and sustain the competitive advantage [15]. Moreover, it is noticed that the agility of organizations can enhance the resilience of the organization, which is defined as the ability of the organization to bounce back from crises due to any internal and external or environmental changes [16]. It is pointed out that as agility is going to be impacted due to the adoption of Industry 4.0, organizational resilience can also be a result of the enhanced agility [17]. Furthermore, it can be noted that the adoption of Industry 4.0 technologies can be a result of the motivation of organizations to develop resilience. For example, the current pandemic situation due to a novel coronavirus pushes various organizations to develop resilience to all kinds of unexpected events [16,17,18]. Thus, the organizations increasingly look for the adoption of Industry 4.0 technologies as they can offer the organization the ability to become both agile and resilient. Moreover, the contemporary organizations strive for the corporate sustainability performance [19], where the drivers and motivations for aligning business goals with sustainability are customers, government regulations, environmental activists and suppliers [20]. There are various measures of performance on sustainability goals, but triple bottom line (TBL), which refers to social, economic and environmental performance [21], is perceived as a very important and effective one [22,23]. Reporting on the measures of TBL, a problem can be posed [24] as its measures are dynamic in nature, which requires the organization to be flexible and innovative [25]. Therefore, it is noticed that agility in the era of Industry 4.0 can provide organizations with dynamic capability, flexibility and innovation to successfully plan, organize and manage their corporate sustainability goals from social, economic and environmental perspectives [26,27]. Therefore, the purpose of the current research is to systematically review past research which has studied the relationship and context of organizational agility within the Industry 4.0 and its ecosystem.

Previous researchers have systematically reviewed the literature on both Industry 4.0 and organizational agility, separately. Most of the systematic studies in the context of Industry 4.0 address issues and current states of Industry 4.0 technologies, innovation and development [28,29,30,31], and the context of drivers, transition and application of Industry 4.0 technologies [32]. The researchers have also investigated the issues of Industry 4.0 along with lean management and manufacturing [33], digitization and automation of manufacturing, supply chain and other technologies [34]. Although, agility has been reviewed systematically with Industry 4.0, but under the framework named lean, agile, resilient and green (LARG) [35]. Therefore, a gap in the current literature exists which calls for developing a holistic view of organizational agility in the era of Industry 4.0. Thus, the current research shall try to answer questions such as, Q1: What is the current state of knowledge on organizational agility in Industry 4.0? Q2: What is the role of Industry 4.0 technologies in organizational agility? Q3: What is the future research direction in the scope of the agility of organizations in the context of Industry 4.0?

The adoption of Industry 4.0 ecosystem presents a change management challenge to the organization. The adoption of Industry 4.0 ecosystem will significantly change the culture, work system and operation of organizations. Therefore, in the literature, it is argued that, to cope with such change with adoption of technologies, organizations need to have a degree of flexibility and agility [10]. Thus, the objective of the current research is to review how the existing dynamic capability of agility is helping organizations to adopt and cope with such changes. Secondly, it is also argued and suggested in the literature that by adopting the Industry 4.0 ecosystem, organizations can also significantly enhance their dynamic capability of agility [15]. Furthermore, it is argued that by adopting the Industry 4.0 ecosystem, aspects of agility will also change [9]. Therefore, the current research reviews the literature and identifies different aspects of Industry 4.0 in terms of dimension, enabler group and capability, and also reviews how each technology of Industry 4.0 is contributing to each aspect of organizational agility.

The paper is organized as follows: Section 2 focuses on the description of the research methodology. Section 3 illustrates descriptive statistics referring to year-wise publication, highly contributing papers, authors, journals, publishers, databases, countries and network analysis. Finally, Section 4 presents a discussion and Section 5 concludes the paper.

2. Materials and Methods

The review of literature is considered to be a basic building block of any research work [36]. It is the review of literature which helps a researcher to frame a question and develop a logical answer [37]. The undertaking of a review of the literature needs to be such that it helps to identify the critical gaps and questions which exist in the field of study [38], and answers to such research questions can help to contribute to the evolution of the field of research and particular theory [39]. Therefore, it is necessary that a methodology through which a review of the literature is undertaken and analyzed addresses the matter of contribution to the field of study and relevant theory and constructs [40]. Thus, many researchers, such as [41,42], have provided an effective guideline on developing a methodology of reviewing literature that helps to fulfil this purpose. It is also observed that such methodology of reviewing literature is being followed by others [43,44]. The current systematic review of the literature follows guidelines established within the literature. The following elements best describe our methodology, such as justification of the choice of keywords and search strings, limitation criteria and quality assessment.

2.1. Selection of Databases

In the current research, for the purpose of the identification of relevant literature to be systematically reviewed, we have selected the research databases Web of Science, Scopus and Google Scholar, as widely suggested [45]. These databases are considered to be imminent as they have indexing of peer-reviewed journals in our field. The research articles are published by recognized publishing houses, such as Emerald Insight, Springer, MDPI, Sage and Taylor and Francis, among others.

2.2. Identification of Keywords and Search Strings

The variety of relevant keywords were first identified and listed, and secondly, search strings were developed from identified keywords, which have been used to search and track down the literature from these databases. For the identification of keywords, the previous literature review papers on both Industry 4.0 and agility have been referred to [28,46], and such papers provided positive direction in this regard. Table 1 provides a brief overview of the keywords and search strings used.

Table 1.

Keywords and search strings.

2.3. Results of Search

The results of running keywords and search strings into the databases yielded 359 results, which included journal papers, conference papers and proceedings and book chapters. It was made certain that the maximum amount of relevant literature needed to be extracted using different keywords and search strings was reached, which are mentioned in Table 1. Other kinds of publications, such as editorial notes, white papers and commentaries, were excluded to ensure that only relevant and academic literature was searched and considered for the current systematic review.

2.4. Inclusion and Exclusion Criteria

The results of searching the databases were checked against the inclusion and exclusion criteria. The inclusion criteria included whether any of the keywords of agility and Industry 4.0 mentioned in Table 1 above were used in the topic line, abstract or keywords of particular papers. The total number of articles resulting from the original search was 381, and after applying the inclusion and exclusion criteria and removing the duplicates, 95 articles were included for the review and analysis.

2.5. Quality Assessment

There were 21 articles about which there had been some considerable doubts as to whether these articles were (ir)relevant and could be included in the current systematic literature review. Therefore, to ensure inclusion and exclusion of such articles, qualities of these articles were assessed by reading their introduction and conclusion sections. The articles that clearly stated that they studied the phenomena of Industry 4.0 along with agility were included in the current review. The result of the quality assessment showed that 14 articles out of 21 were deemed relevant and 7 articles were completely irrelevant. Therefore, the total number of articles included in the systematic literature review was 109.

3. Descriptive Statistics

The extracted and sorted literature was applied with the indices of descriptive statistics for the purpose of describing the numerical properties of literature to be reviewed systematically. The descriptive statistics properties are helpful in understanding the ongoing academic and research work regarding the agility in the age of the fourth industrial revolution.

3.1. Year-Wise Publication

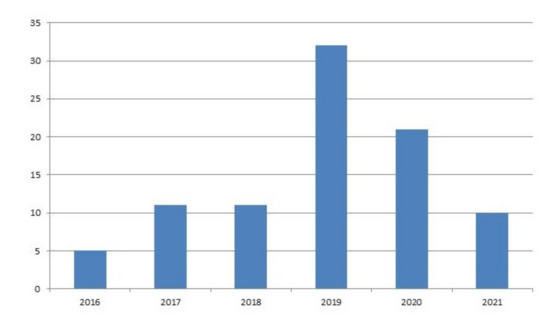

The year-wise publication rate within the field of agility and Industry 4.0 showed a sharp increase from the year 2016 to 2018, and a drastic increase from 2018 to 2019, as shown in Figure 1.

Figure 1.

Year-wise publication trend.

The year 2019 reported more than 30 items articles in the single year. The year 2020 observed a decline in the number of publications as compared to 2019. However, this trend seems to be on track to reverse again in 2021, as within four months, the year 2021 achieved a sharp increase in publications, accounting for up to more than 10 articles. Therefore, it can be predicted that by the end of the current year (2021), there will be a higher amount of publications within the field of agility in Industry 4.0.

3.2. Highly Contributing Papers and Authors

Table 2 shows a list of 10 research papers and authors whose academic work highly contributed in the area of agility and Industry 4.0, on the basis of the number of citations. As it can be noticed, the paper written by [47] in 2016 has received the highest amount, i.e., 295, of citations at the time of writing.

Table 2.

Highest citations per paper.

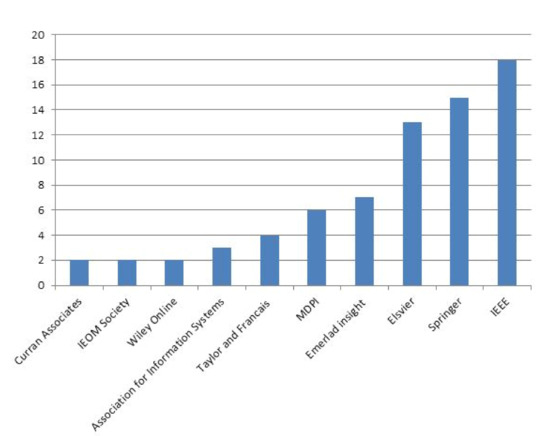

3.3. Contribution of Publishers

Figure 2 shows the contribution of various publishers in publishing the research and academic work in the area of agility and Industry 4.0.

Figure 2.

Contribution of publishers.

The descriptive statistics show that the top five publishers in the area of agility and Industry 4.0 include: IEEE, Springer, Elsevier, Emerald Insight and Multidisciplinary Digital Publishing Institute (MDPI). They published 59 papers, which constitutes more than 50% of all analyzed papers.

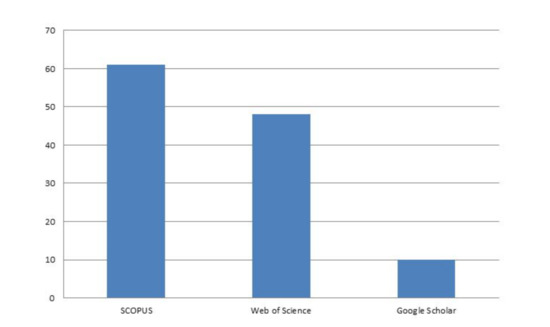

3.4. Contribution of Databases

Figure 3 shows the contributions of different databases in collecting and maintaining the data regarding the research and academic work in the area of agility and Industry 4.0.

Figure 3.

Contribution of databases.

The current research employed the databases Web of Science, Scopus and Google Scholar. According to the descriptive statistics, Scopus takes a lead in publishing the most research in the area of agility and Industry 4.0. It should be noted that Google Scholar referred to in the case of information on papers from Scopus and Web of Science is incomplete, inadequate or ambiguous.

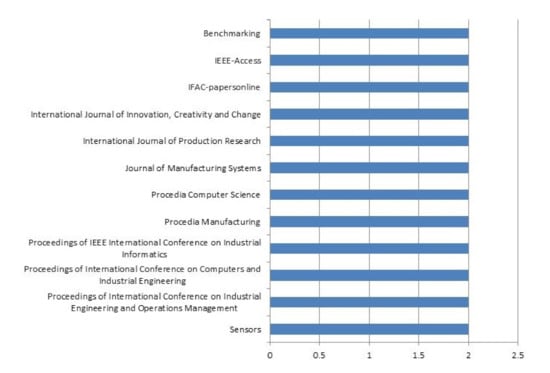

3.5. Contribution of Journals

The research on agility in Industry 4.0 is scattered across different journals, conferences and book chapters. Figure 4 shows journals and conferences reporting more than 1 contribution.

Figure 4.

Contribution of journals and conferences.

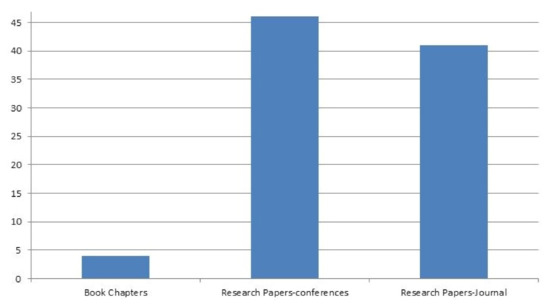

3.6. Type of Publication

The literature extracted from the previously mentioned research sources contains different types of publications in the area of agility and Industry 4.0, such as journal papers, conference papers and book chapters (Figure 5).

Figure 5.

Types of publication.

As it can be seen in the figure, the conference papers take a lead by publishing 46 full papers, whereas there are 41 journal papers. Only 4 publications were published as chapters in books.

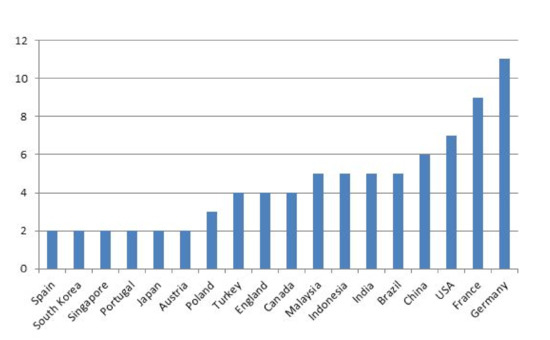

3.7. Contribution by Country

The authors’ affiliation to research published on agility in Industry 4.0 (Figure 6) shows that most of the authors came from Germany (11 articles), followed by France (9), the United States of America (7) and China (6 articles).

Figure 6.

Contribution by country.

The contribution of the authors from Brazil, India, Indonesia and Malaysia is 5 papers per each country. Moreover, there were also some authors from Canada, Turkey and England who contributed to this field by writing 4 papers, followed by Poland with 3 papers and various other countries who contributed 2 articles. Figure 7 illustrates the research publication distribution on a map. Its results clearly show that Europe is the top research area of Industry 4.0 and agility.

Figure 7.

Map of contribution by country.

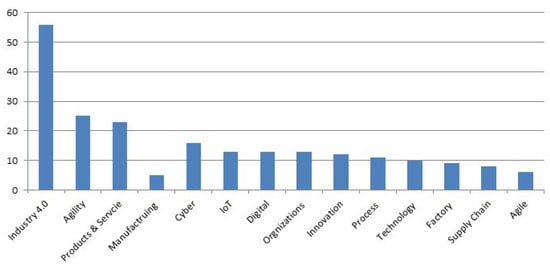

3.8. Keyword Statistics

The keyword lists used in each paper provided by the databases were extracted from all of the papers for further analysis. For this aim, IBM-SPSS was used to generate the keywords statistics. In these statistics, the keywords which were repeatedly used or used more than once were included. Figure 8 shows the final results.

Figure 8.

Keyword statistics.

The “Industry 4.0” remains the most popular keyword, followed by “Agility”. The other keywords, which were repeatedly used along with Industry 4.0 and Agility, included: “Product and Services”, “Manufacturing”, “IoT”, “Cyber and Physical system”, “Digital”, “Innovation” and others.

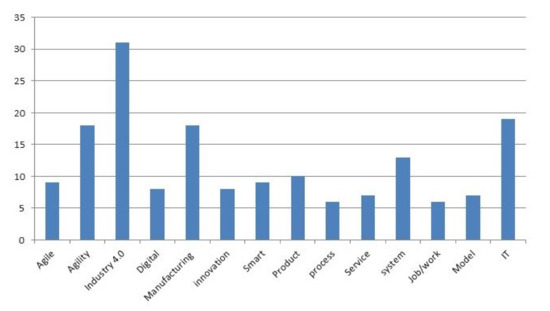

3.9. Title Keyword Statistics

The title keyword lists used in each paper were extracted from the papers manually. We used IBM-SPSS to generate the title keyword statistics. Figure 9 shows the results of such descriptive statistics.

Figure 9.

Title keyword statistics.

The “Industry 4.0” remains the most popular keyword, followed by “Agility”, in the titles of the papers. The other keywords which were used together with Industry 4.0 and Agility were: “Manufacturing”, “IT”, “System”, “Digital”, “Product”, “Agile”, “Smart” “Innovation”, “Digital” and “Model”. It was also possible to identify such words as “telecommunication 4.0” and “leadership 4.0”.

3.10. Network Analysis

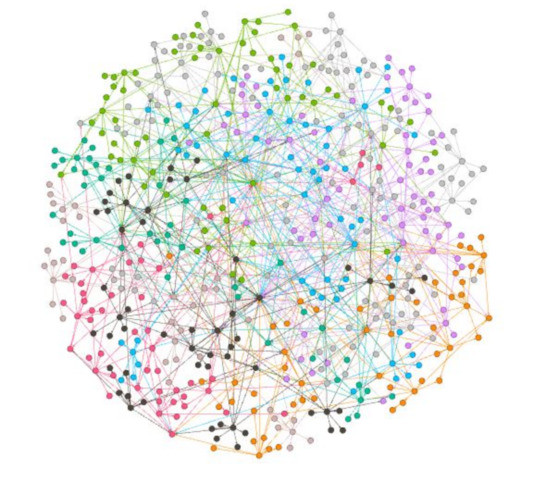

The current research led to perform a co-citation analysis and generate the map of co-citation shown in Figure 10.

Figure 10.

Co-citation map.

In order to achieve the map, we applied a Gephi tool. The obtained co-citation map shows that the nodes with overlapping networks are papers which contain the most co-citations in the extracted literature. Therefore, the current map shows that nodes in the middle of the map are the papers with the most overlapping networks. Thus, it can be said that these are papers which report the most co-citations in the systematic review of the literature.

4. Review Discussion

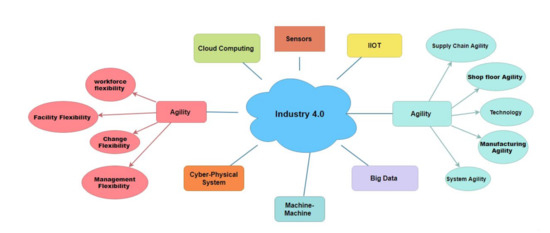

4.1. Industry 4.0 and Agility

The literature reviewed on Industry 4.0 shows that the authors from across different areas of research tend to define Industry 4.0 in diverse ways [48]. Thus, in the current study, we follow the definition of the Industry 4.0 concept as an industrial infrastructure which tends to embed different technologies, such as machine, electrical, operational and information technology, with the purpose to create efficient, effective and sustainable products and services. The key technologies, which create such an infrastructure, are discussed in the proceeding sections.

The literature shows that agility is an important element in I4.0 infrastructure. Some studies argued that organizational agility is a consequence of implementation of I4.0 technologies [49]. However, other studies showed that implementing the I4.0 technologies is all about bringing important changes in the organization, culture and work setting. Thus, agility is a necessary requirement to successfully implement I4.0 technologies and integrate the organization with the fourth industrial revolution environment [50]. Therefore, it is concluded here that agility is an important aspect of I4.0 industrial infrastructure. For organization to successfully integrate with the I4.0 environment, implementing agility and technologies will go hand in hand [51].

4.2. Agility in Organization

The (organizational) agility is defined as the capacity, ability and flexibility of an organization to adopt quickly to a changing external environment and landscape [11]. The Industry 4.0 ecosystem, referred to as implementation and adoption of I4.0 technologies to leverage a competitive advantage, presents significant external challenges faced by organizations [52]. Agility is often referred to as an organization’s (dynamic) capability to gain and leverage the competitive advantage by adopting and implementing I.40 technologies [11]. Further, it is argued that I4.0 technologies are themselves agile in nature. The organizations will significantly achieve agility in terms of supply chain, manufacturing and workforce, etc. [9,49,53]. Other researchers claim that organizations which are agile in nature, and quickly and easily adapt to external changes, are going to be the first to adopt and implement I4.0 technologies and leverage the competitive advantages provided by Industry 4.0 ecosystem. These studies point out that Industry 4.0 ecosystem is highly sophisticated as it requires significant reconfiguration in terms of organizational culture, facilities and management. Therefore, implementing Industry 4.0 ecosystem would present a challenge for the organization in terms of reconfiguration of culture, management and facility. The organization with agility as a (dynamic) capability will be able to quickly reconfigure and pave a smooth way for adopting and implementing I4.0 technologies [54,55,56]. Thus, a debate exists in the literature as to whether agility is a driver in the implementation of I4.0 or a consequence of it.

4.2.1. Agility as a Consequence

The findings of the current review show that agility is being considered by some authors as a consequence and a result of implementation of I4.0 technologies [57,58]. The researchers who theorize agility as a consequence of I4.0 technologies’ implementation conclude that technologies such as industrial internet of things, cloud computing, machine to machine communication, Cyber-physical system and big data increase an organization’s ability and flexibility to manage uncertainty in consumer demand and supply chain [59,60]. This review allowed us to find that due to implementation of I4.0 technologies, organizations achieve agility in the shop floor, organizational facility, workforce and management [61,62].

The novel I4.0 technologies increase the ability and flexibility of organizations to meet any uncertainty in the value and supply chain. These technologies will significantly improve organizations’ decision-making regarding new product development and testing. Thus, I4.0 will help organizations to respond to competitive challenges quickly through new products’ development and placement. Further, I4.0 technologies will make shop floors more lean, increase communication between different functional units and amass and analyze more data on market needs and wants. Therefore, organizational staff at the manufacturing and management levels will find it easier to respond to changes in the external environment by allocating necessary resources without disturbing current functions.

4.2.2. Agility as a Driver

The current review also shows that an organization’s existing agility is being considered by other authors as a driver for the companies to adopt I4.0 technologies [10,14]. In contrast to a driver, some researchers also define agility as just one prerequisite for companies to adopt I4.0 technologies [13,15]. The researchers who consider agility as a prerequisite or driver conclude in their findings that Industry 4.0 ecosystem will bring enormous changes into the organization with respect to the work-setting, management, culture and dealing with customers and suppliers. The existing or traditional structure of organizations will be obsolete and incompatible with the Industry 4.0 ecosystem [63,64,65]. Therefore, for smooth operation and working of I4.0 technologies, some necessary changes in work-setting, management and culture are required by the organization. The research reviewed in the current study theorizes that effective change management and orientation systems can bring about such changes in the organization with respect to work-setting, management and culture, which pave the way for successful implementation and adoption of I4.0 technologies. The effective change management structure is only possible for organizations which already have the (dynamic) capability of agility [66,67,68].

Considering the above, as it is shown in Figure 11, having agility as a prerequisite is necessary before implementing and adopting the I4.0 technologies because it helps organizations to smoothly transition towards Industry 4.0 ecosystem.

Figure 11.

Agility as a consequence and a driver.

Further, the organizations which have achieved some level of agility in their operations are more energetic in adopting and implementing I4.0 technologies. It can be concluded that agility remains their core and competitive advantage [69]. By adopting I4.0 technologies, organizations want to enhance their agility further and sustain their competitive advantage.

4.3. Key I4.0 Technologies of Agility

The current research briefly reviewed the technologies in the literature which are being used by the different companies throughout the different industries to increase and introduce agility within the organizations. Here, we provide in-depth reviews on both aspects and dimensions of agility and I4.0 technologies [11,28], as discussed in Section 4.3.1–Section 4.3.9.

4.3.1. Smart Manufacturing

Smart manufacturing is a computer-aided and integrated manufacturing system which automates the stream of manufacturing activities [70]. The researchers discuss smart manufacturing technologies with respect to agility in the organizations [71,72] as they significantly enhance supply chain [73], workforce [47], process [74], information system [75], organizational flexibility [76], management [77], manufacturing [78] and technology [79] agility in the organizations. Moreover, they provide wide-ranging agility to the companies [80]. For example, the smart manufacturing through technology, supply chain, workforce, information system and manufacturing agility helps companies to meet uncertainty in the demands of consumers [81]. It is concluded that smart manufacturing technologies are also a useful tool to transition companies from traditional to agile manufacturing [82]. Finally, it is concluded that smart manufacturing technologies make facilities or the shop floor lean and agile through technology agility [83]. The management, information system and workforce become highly flexible in undertaking decisions to satisfy customer needs and supplier demands [84].

4.3.2. Cyber-Physical System

The cyber-physical system (CPS) is an important I4.0 technology which controls the interconnection between the computer system and physical system and networking [85]. The CPS is also one of the most important I4.0 technologies which is being used by companies to fulfil their transition goals towards Industry 4.0 ecosystem [86] and increase the agility of company [87]. Our current review shows that CPS is highly effective in creating organizational agility [88]. The results of the literature review show that companies use or can use CPS to develop process [89], information system [90], facilities [91], flexibility [89], management [58], manufacturing [78] and technology [91] agility.

The literature argues that CPS connects and integrates the physical assets with computer programs. The connection and integration significantly enhances the agility of manufacturing and process. The CPS helps companies to automate and quickly shift their manufacturing resources to face any perspective uncertainty. The computation program used in CPS for integration with physical assets also facilitates the ability of technology through self-learning or use of machine learning. Along with technological agility, CPS significantly adds to facility and information system agility. The automation and integration of machines with computers makes facility of factory more resilient, flexible and agile through leanness. Finally, CPS is a highly important technology of Industry 4.0 ecosystem. The CPS helps companies to increase their agility in a range of activities, which leads them to achieve a dynamic capability of facing any environmental uncertainty around organizations.

4.3.3. Cloud Computing

The cloud computing is referred to as a system resourced with advanced data storage and user capability which does not require any direct human maintenance [92]. In manufacturing it integrates manufacturing resources and capabilities into services by allowing the manufacturing system to operate manufacturing resources and capabilities in an intelligent way [93]. It is referred to as a key technology of Industry 4.0 ecosystem, and especially within manufacturing it helps to transition the companies towards Industry 4.0 [94]. Moreover, it enables to create on-demand, cost-effective and high-quality manufacturing services which can help companies to gain competitive advantages [95]. Cloud computing is increasingly referred to with increasing agility in the organizations [96].

The literature clearly supports a relationship between agility and cloud computing technologies. Our systematic review concludes that cloud computing effectively enhances agility in process [89], information system [97], flexibility [98], manufacturing [66] and technology [79]. Cloud computing makes information systems more flexible and agile by increasing the power of the system and self-management with lower human input. It makes manufacturing more agile through servitization by integrating resources and capability, such as technology, thus making the technology of the company agile as well. Therefore, it is concluded that more and more companies adopt cloud computing technologies to increase agility within organizations [99], as the literature clearly supports the evidence of cloud computing and agility [100].

4.3.4. Big Data and Analytics

The big data is referred to as data of higher volume generated with greater velocity and a higher amount of variety, often referred to in the literature as the 3V’s [101,102]. The source of creating such data is due to technologies, i.e., IoT, cloud computing and social media [58]. In the last years, a shift has been observed in the concept, where big data is increasingly discussed along with analytics [103]. The analytics in big data offers companies to extract valuable insight from the data to support decision-making [104]. The studies found that one of the most important advantages the companies gain by using big data analytics is agility [105].

The big data and analytics are important contributors towards the Industry 4.0 ecosystem. Adopting the big data and analytics technologies significantly helps companies to transition towards Industry 4.0 [106]. They contribute to the organizational agility. Given the nature of Industry 4.0 ecosystem, companies rely more upon the data-driven approach of decision-making [107]. The big data supported by analytics brings accuracy in the predictive models of demand and supply [108]. Thus, the predictive accuracy in decision-making, more access to data about consumer and supply trends and internal resource reconfiguration develop a dynamic capability of organizations to increasingly face and address uncertainty in making themselves more agile [105].

4.3.5. Augmented and Virtual Reality

The augmented and virtual realities are two different technologies of I4.0. The augmented realty (AR) refers to technology which further augments or supplements real-world objects using smart technologies such as 3D and other computer technologies [109]. The virtual reality (VR) refers to simulated re-creation of reality virtually, which can be both similar and different to real-world experience of reality based upon the objective of the VR program [110]. The AR and VR technologies initially started in gaming, retailing and marketing [111], but now they are also used in manufacturing and increasingly considered to be part of Industry 4.0 ecosystem [54]. The AR and VR technologies can significantly enhance the organizational agility [112]. The AR and VR automate the manufacturing and supply chain activities and help a company to create more collaboration with other stakeholders [51]. Controlling activities through AR and VR eliminates a lot of waste, which makes the process leaner. Thus, it is concluded that AR and VR have the potential to make organizations more agile and lean. However, literature reviewed on the role of AR and VR in creating agile organizations is limited. Therefore, it is a future research recommendation to collect empirical data on the role of AR and VR in creating agility in organizations.

4.3.6. Simulation

The technology of simulation refers to the imitation of process or system through the use of models which represent key elements of process or system which are supposed to be imitated [113]. The simulation is considered to be an important part of the Industry 4.0 ecosystem [114], especially in the additive and 3D-printing manufacturing ecosystem [115]. Simulation has important implications towards increasing agility in the organizations, and simulation as a research technique was used by different researchers [116,117]. However, current knowledge is very limited on the impact of simulation on agility. The simulation would make the supply and value chains more lean and agile [118]. Thus, it is necessary to measure the impact of the use of simulation in both the supply and value chains on the agility of the organizations.

4.3.7. Internet of Things Platforms

The internet of things (IoT) is often referred to as the internet of everything or industrial internet of things, which is a technology platform which connects physical objects such as machines with the internet and its platform, including sensors, software and others [119]. The embedding of things with the internet stimulates the process of data collection and enhances the communication between physical objects through the exchange of data over the internet [120]. The IoT is one of the most important parts of Industry 4.0 ecosystem [121], and transitioning from traditional to Industry 4.0 environment requires the implementation of IoT and platforms [122]. Moreover, IoT platforms are also instruments used in enhancing the organizational agility [100] as they increase the agility of organizations with respect to the process [60], information system [91], facility [89], flexibility [71], management [117], manufacturing [61] and technology [79]. The embedding of (organizational) objects with the internet creates communication between them, and these objects start to exchange data among themselves [69], which results in the effective automation in the organization. The connection of objects over internet platforms, subsequent automation and leanness creates agility in the shop floor and process [60]. Furthermore, it makes information systems respond to changes quickly in any uncertainty of such changes in consumer demand [62]. The IoT also makes technology capability and manufacturing systems more agile through rapid communication and creation of more data through different touch points. Such data and subsequent analytics enhance the self-learning process, which makes machines respond to changes quickly [77].

4.3.8. Machine-to-Machine Communication

The machine-to-machine communication (M-M-C) is a direct communication between different machines using any channel of communication, such as wired and wireless. The sensors and meters in M-M-C record and transmit information from one machine to another [123]. The M-M-C is considered to be an important technology of Industry 4.0 ecosystem [118]. Currently, it is used in supply chain and manufacturing with the help of radio-frequency identification (RFID) as a M-M-C tool, which helps to identify and track tags attached to objects [124]. The automated guided vehicle identifies tags and transports them accordingly in manufacturing and supply chain activities [125]. The M-M-C technology can make the facilities more lean and agile as it increases efficiency, speed and remove hurdles [126]. However, the research on the relationship between M-M-C and agility is highly limited. There are only a few studies in our systematic review which have studied M-M-C in relation to agility. Thus, future research should empirically study such gap in the literature.

4.3.9. Sensors

A sensor is any device which is designed to detect changes and events in its surrounding environment, and which communicates such information to central data storage, typically a computer system [127]. The sensors are considered to be a key part of Industry 4.0 ecosystem [128] as they are used to automate the factory and manufacturing activities [129]. They facilitate to gain knowledge on the stage of production of a specific product and also help to communicate information regarding the state of machinery and equipment and update about the need of maintenance [130]. Although the sensors are an important part of Industry 4.0 ecosystem, their implication on agility of organizations is highly limited [62]. It may be due to fact that the sensors are new in Industry 4.0 [86], and thus less attention is given to the impact of sensors on agility. Therefore, the future research recommendation is to conduct empirical evidence supporting the association between agility and Industry 4.0.

4.4. Aspect of Agility in Industry 4.0

The systematic literature revealed that agility is an advanced capability which allows different industries to gain competitive advantage and sustain their performance in the long term [12,131,132,133,134]. It is also confirmed that companies want to build their agility capability through adopting Industry 4.0 technologies [135,136,137]. However, the authors argued whether adopting the Industry 4.0 technologies increase agility in a dynamic way [138,139], or whether adopting the Industry 4.0 technologies presents a change management challenge [140]. Moreover, it is suggested that the change induced by adopting Industry 4.0 technologies is not ordinary but rather a radical change in culture, structure and operations of organizations [139,141,142,143]. Thus, only organizations which develop a nascent capability of agility will be better off by adopting Industry 4.0 technologies [107,144,145,146]. Therefore, it can be concluded that organizations that have agility will be able to adopt Industry 4.0 technologies, and once adopted, the capability of agility will become highly dynamic [144,147,148]. In the following section, the major aspects of agility are discussed with respect to Industry 4.0, as suggested by [147,149,150,151].

4.5. Agility Dimensions

One of the most important aspects of agility is its dimensions [11]. It is possible to identify the following six dimensions, such as:

- Supply chain

- Workforce

- Processes

- Strategy

- Information system

- Facilities

All of the dimensions mentioned above facilitate to adopt the I4.0 technologies, such as smart manufacturing, cyber-physical system, cloud computing and internet of things.

4.6. Agility Capabilities

According to Walter [11], there are different varieties of agility capabilities. However, in our systematic literature review, we refer only to the capabilities which refer to Industry 4.0, such as:

- Facilities agility

- Flexibility agility

The facilities agility is defined as the ‘ability of manufacturing facility or shop floor to accommodate any uncertain change in the product manufacturing preferences’. On the other hand, the flexibility agility refers to the organizational capability needed to undertake work on different objectives at the same time. In both capabilities, the technologies such as smart manufacturing, cyber-physical system, internet of things and big data analytics are used to increase the facilities and flexibility agility.

4.7. Agility Enablers

The agility enabler groups refer to units of organization which are interested in bringing about an increase of the agility in the organization. The systematic review found the following enabler groups of agility which are studied along with the Industry 4.0:

- Management agility

- Manufacturing agility

- Technology

Management or manufacturing agility enablers are the most important drivers of adopting the Industry 4.0 technologies such smart manufacturing, cyber-physical system, big data and analytics, internet of things and cloud computing. Moreover, these technologies also increase manufacturing agility further along with facility or shop floor agility. As far as technology is concerned, it is perceived as a unit of organization responsible for the development and adoption of technology and innovation. Thus, it is responsible for and a driver of adopting the Industry 4.0 technologies in the organization. Such adoption of Industry 4.0 technologies enhances the agility of organizational technology. The technology will be able and better positioned to face the uncertainty in the environment.

5. Conclusions

The purpose of the current systematic literature review was to study the underlying relationship between Industry 4.0 ecosystem and agility in organizations. For this aim, we considered 381 papers, but after applying inclusion and exclusion criteria, we finally analyzed 91 of them. The results of this investigation showed that the adoption of the technologies of Industry 4.0 can enhance the organizational agility. It would also result in significant changes in culture, operation, supply and value chain. Furthermore, only organizations which have agility as a (dynamic) capability can effectively cope with the changes and become key drivers for adopting such technologies. The results also showed that technologies such as smart manufacturing, cyber-physical system, big data and analytics, cloud computing and IoT help companies to enhance their agility in both value and supply chains. The technologies such as machine-to-machine communication, sensors, simulation and augmented and virtual reality are also critical in enhancing the agility of organizations, but at present, less research has been carried out in this area. Therefore, it is necessary to study the role of these technologies in the agility of organizations.

The current systematic literature review allowed to identify the categorization of agility into dimensions, capabilities and enablers in reference to Industry 4.0 ecosystem. The results show that dimensions of agility include workforce, supply chain, process and information system, whereas agility capabilities include facilities and flexibility, and agility enablers include management, manufacturing and technology. In all of these categories, the technologies such as smart manufacturing, cyber-physical system, big data and analytics, cloud computing and IoT play important roles. However, other categories such as strategy agility, speed agility, competitiveness agility and competency agility are less discussed in the literature. Thus, this gap in the literature also calls for studies on these types of agility, along with and in relation to the I4.0 technologies.

Regarding the organizational resilience, it can be noted that organizations across different industry branches look to develop the dynamic capability of resilience. The present pandemic in the form of a novel coronavirus has taught organizations that Industry 4.0 technologies are a need of the time. These technologies can not only enhance the organizations’ agility but can also boost their resilience to help them to bounce back from crises. Therefore, future research is needed to address the Industry 4.0 technologies from both agility and resilience perspectives.

Lastly, the current research attempted to provide an insight into the relationship of organization and agility and Industry 4.0 ecosystem from the perspective of corporate sustainability goals, especially from the triple bottom line perspective. The technologies of Industry 4.0 help companies to meet their corporate sustainability goals from social, economic and environmental perspectives. Various technologies are designed to address ecological sustainability, causing very low harm. The technologies are also efficient from an economic perspective as they make production processes more lean and agile, which helps companies to achieve their economic objectives such as low costs and higher profits. Furthermore, as organizations become more agile due to the adoption of Industry 4.0 technologies, new economic opportunities, jobs and goods and services are created that can serve the society. In conclusion, it can be stated that the agility of organizations in Industry 4.0 will be highly important to achieve corporate sustainability goals and enhance the ability to report effectively on the TBL perspective.

Author Contributions

Conceptualization, B.M. and J.A.; methodology, B.M. and J.A.; software, J.A.; validation, B.M. and J.A.; formal analysis, B.M. and J.A.; investigation, B.M. and J.A.; resources, B.M.; data curation, J.A.; writing—original draft preparation, B.M. and J.A.; writing—review and editing, B.M. and J.A.; visualization, J.A.; supervision, B.M.; project administration, B.M. and J.A.; funding acquisition, B.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by POZNAN UNIVERSITY OF TECHNOLOGY, grant number 0811/SBAD/1030.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Cimini, C.; Boffelli, A.; Lagorio, A.; Kalchschmidt, M.; Pinto, R. How do industry 4.0 technologies influence organisational change? An empirical analysis of Italian SMEs. J. Manuf. Technol. Manag. 2020, 32, 695–721. [Google Scholar] [CrossRef]

- Schumacher, A.; Erol, S.; Sihn, W. A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia Cirp 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Zawadzki, P.; Żywicki, K. Smart product design and production control for effective mass customization in the Industry 4.0 concept. Manag. Prod. Eng. Rev. 2016, 7, 105–112. [Google Scholar] [CrossRef]

- Kohnová, L.; Papula, J.; Salajová, N. Internal factors supporting business and technological transformation in the context of Industry 4.0. Bus. Theory Pract. 2019, 20, 137–145. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K. Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Saf. Environ. Prot. 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Götz, M. The industry 4.0 induced agility and new skills in clusters. Forsight Sti Gov. 2019, 13, 72–83. [Google Scholar]

- Matthiae, M.; Richter, J. Industry 4.0-Induced Change Factors and the Role of Organizational Agility. Muduli, A. Workforce agility: Examining the role of organizational practices and psychological empowerment. Glob. Bus. Organ. Excell. 2018, 36, 46–56. [Google Scholar]

- Walter, A.T. Organizational agility: Ill-defined and somewhat confusing? A systematic literature review and conceptualization. Manag. Rev. Q. 2021, 71, 343–391. [Google Scholar] [CrossRef] [Green Version]

- Kurniawan, R.; Hamsal, M. Shaping Business Process Agility in Telecommunication 4.0. Int. J. Appl. Sci. Eng. 2019, 16, 15–23. [Google Scholar]

- Kurniawana, R.; Hamsalb, I.M. Achieving Decision-Making Quality and Organisational Agility in Innovation Portfolio Management in Telecommunication 4.0. Int. J. Innov. Creat. Chang. 2019, 8, 332–356. [Google Scholar]

- Elnagar, S.; Weistroffer, H.; Thomas, M. Agile requirement engineering maturity framework for industry 4.0. In Proceedings of the European, Mediterranean, and Middle Eastern Conference on Information Systems, Limassol, Cyprus, 4–5 October 2018; pp. 405–418. [Google Scholar]

- Akkaya, B. Leadership 5.0 in Industry 4.0: Leadership in perspective of organizational agility. In Managing Operations Throughout Global Supply Chains; IGI Global: Hershey, PA, USA, 2019; pp. 136–158. [Google Scholar]

- Tarigan, Z.J.H.; Siagian, H.; Jie, F. Impact of Internal Integration, Supply Chain Partnership, Supply Chain Agility, and Supply Chain Resilience on Sustainable Advantage. Sustainability 2021, 13, 5460. [Google Scholar] [CrossRef]

- Miceli, A.; Hagen, B.; Riccardi, M.P.; Sotti, F.; Settembre-Blundo, D. Thriving, not just surviving in changing times: How sustainability, agility and digitalization intertwine with organizational resilience. Sustainability 2021, 13, 2052. [Google Scholar] [CrossRef]

- Al-Omoush, K.S.; Simón-Moya, V.; Sendra-García, J. The impact of social capital and collaborative knowledge creation on e-business proactiveness and organizational agility in responding to the COVID-19 crisis. J. Innov. Knowl. 2020, 5, 279–288. [Google Scholar] [CrossRef]

- Landrum, N.E.; Ohsowski, B. Identifying worldviews on corporate sustainability: A content analysis of corporate sustainability reports. Bus. Strategy Environ. 2018, 27, 128–151. [Google Scholar] [CrossRef] [Green Version]

- Lozano, R. A holistic perspective on corporate sustainability drivers. Corp. Soc. Responsib. Environ. Manag. 2015, 22, 32–44. [Google Scholar] [CrossRef]

- Elkington, J. Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Elkington, J. Enter the triple bottom line. In The Triple Bottom Line; Routledge: London, UK, 2013; pp. 23–38. [Google Scholar]

- Goh, C.S.; Chong, H.Y.; Jack, L.; Faris, A.F.M. Revisiting triple bottom line within the context of sustainable construction: A systematic review. J. Clean. Prod. 2020, 252, 119884. [Google Scholar] [CrossRef]

- Norman, W.; MacDonald, C. Getting to the bottom of “triple bottom line”. Bus. Ethics Q. 2004, 14, 243–262. [Google Scholar] [CrossRef] [Green Version]

- Muñoz-Pascual, L.; Curado, C.; Galende, J. The triple bottom line on sustainable product innovation performance in SMEs: A mixed methods approach. Sustainability 2019, 11, 1689. [Google Scholar] [CrossRef] [Green Version]

- Ejsmont, K.; Gladysz, B.; Kluczek, A. Impact of industry 4.0 on sustainability—Bibliometric literature review. Sustainability 2020, 12, 5650. [Google Scholar] [CrossRef]

- Duarte, S.; do Rosário Cabrita, M.; Cruz-Machado, V. Business model, lean and green management and industry 4.0: A conceptual relationship. In Proceedings of the International Conference on Management Science and Engineering Management, Phuket, Thailand, 24–26 May 2019; pp. 359–372. [Google Scholar]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Kerin, M.; Pham, D.T. A review of emerging industry 4.0 technologies in remanufacturing. J. Clean. Prod. 2019, 237, 117805. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the industry 4.0: A literature review on technologies for manufacturing systems. Eng. Sci. Technol. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Zheng, T.; Ardolino, M.; Bacchetti, A.; Perona, M. The applications of Industry 4.0 technologies in manufacturing context: A systematic literature review. Int. J. Prod. Res. 2021, 59, 1922–1954. [Google Scholar] [CrossRef]

- Buer, S.V.; Strandhagen, J.O.; Chan, F.T. The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.H. A review of cyber-physical system research relevant to the emerging IT trends: Industry 4.0, IoT, big data, and cloud computing. J. Ind. Integr. Manag. 2017, 2, 1750011. [Google Scholar] [CrossRef]

- Amjad, M.S.; Rafique, M.Z.; Hussain, S.; Khan, M.A. A new vision of LARG Manufacturing—A trail towards Industry 4.0. CIRP J. Manuf. Sci. Technol. 2020, 31, 377–393. [Google Scholar] [CrossRef]

- Knopf, J.W. Doing a literature review. PS Political Sci. Politics 2006, 39, 127–132. [Google Scholar] [CrossRef] [Green Version]

- Rozas, L.W.; Klein, W.C. The value and purpose of the traditional qualitative literature review. J. Evid.-Based Soc. Work 2010, 7, 387–399. [Google Scholar] [CrossRef]

- Broekkamp, H.; van Hout-Wolters, B. The gap between educational research and practice: A literature review, symposium, and questionnaire. Educ. Res. Eval. 2007, 13, 203–220. [Google Scholar] [CrossRef] [Green Version]

- Webster, J.; Watson, R.T. Analyzing the past to prepare for the future: Writing a literature review. MIS Q. 2002, 26, xiii–xxiii. [Google Scholar]

- Dunne, C. The place of the literature review in grounded theory research. Int. J. Soc. Res. Methodol. 2011, 14, 111–124. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Pittaway, L.; Robertson, M.; Munir, K.; Denyer, D.; Neely, A. Networking and innovation: A systematic review of the evidence. Int. J. Manag. Rev. 2004, 5, 137–168. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Key ingredients for evaluating Industry 4.0 readiness for organizations: A literature review. Benchmarking Int. J. 2019, 27, 2213–2232. [Google Scholar] [CrossRef]

- Saucedo-Martínez, J.A.; Pérez-Lara, M.; Marmolejo-Saucedo, J.A.; Salais-Fierro, T.E.; Vasant, P. Industry 4.0 framework for management and operations: A review. J. Ambient. Intell. Humaniz. Comput. 2018, 9, 789–801. [Google Scholar] [CrossRef]

- Pattinson, S.; Preece, D.; Dawson, P. In search of innovative capabilities of communities of practice: A systematic review and typology for future research. Manag. Learn. 2016, 47, 506–524. [Google Scholar] [CrossRef]

- Fayezi, S.; Zutshi, A.; O’Loughlin, A. Understanding and development of supply chain agility and flexibility: A structured literature review. Int. J. Manag. Rev. 2017, 19, 379–407. [Google Scholar] [CrossRef]

- Thames, L.; Schaefer, D. Software-defined cloud manufacturing for industry 4.0. Procedia Cirp 2016, 52, 12–17. [Google Scholar] [CrossRef] [Green Version]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the definition of Industry 4.0: Analysis and open questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- Rane, S.B.; Narvel, Y.A.M. Re-designing the business organization using disruptive innovations based on blockchain-IoT integrated architecture for improving agility in future Industry 4.0. Benchmarking Int. J. 2019, 28, 1883–1908. [Google Scholar]

- Genest, M.C.; Gamache, S. Prerequisites for the Implementation of Industry 4.0 in Manufacturing SMEs. Procedia Manuf. 2020, 51, 1215–1220. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Pradhan, N.; Macias de Anda, E.; Trevino Martinez, S.; Sawhney, R.; Kumar, M. Designing lean value streams in the fourth industrial revolution era: Proposition of technology-integrated guidelines. Int. J. Prod. Res. 2020, 58, 5020–5033. [Google Scholar] [CrossRef]

- Perakovic, D.; Perisa, M.; Cvitic, I.; Zoric, P. Identification of the relevant parameters for modeling the ecosystem elements in Industry 4.0. In Proceedings of the 4th EAI International Conference on Management of Manufacturing Systems; Springer: Cham, Switzerland, 2020; pp. 111–123. [Google Scholar]

- Hyun, Y.; Hosoya, R.; Kamioka, T. The Moderating Role of Democratization Culture: Improving Agility through the Use of Big Data Analytics. In Proceedings of the Pacific Asia Conference on Information Systems (PACIS 2019), Xi’an, China, 8–12 July 2019; p. 181. [Google Scholar]

- Lee, J.; Um, C.; Shin, J.; Jeong, J. Design and Applications of Agile Factory AaaS Architecture Based on Container-based Virtualized Automation Control Unit. Procedia Comput. Sci. 2019, 151, 622–629. [Google Scholar] [CrossRef]

- Bauer, W.; Vocke, C. Transforming to an Agile Enterprise–How to Handle the Challenge of Organizational Ambidexterity. In Proceedings of the International Conference on Applied Human Factors and Ergonomics, Orlando, FL, USA, 21–25 July 2018; pp. 415–423. [Google Scholar]

- Saengchai, S.; Jermsittiparsert, K. Coping Strategy to Counter the Challenges towards Implementation of Industry 4.0 in Thailand: Role of Supply Chain Agility and Resilience. Int. J. Supply Chain. Manag. 2019, 8, 733. [Google Scholar]

- Bauer, W.; Schlund, S.; Vocke, C. Working life within a hybrid world–how digital transformation and agile structures affect human functions and increase quality of work and business performance. In Proceedings of the International Conference on Applied Human Factors and Ergonomics, Los Angeles, CA, USA, 17–21 July 2017; pp. 3–10. [Google Scholar]

- Shu, B.; Solvang, B. Architecture for task-dependent human-robot collaboration. In Proceedings of the 2021 IEEE/SICE International Symposium on System Integration (SII), Iwaki, Japan, 11–14 January 2021; pp. 207–212. [Google Scholar]

- Butt, J. A Conceptual Framework to Support Digital Transformation in Manufacturing Using an Integrated Business Process Management Approach. Designs 2020, 4, 17. [Google Scholar] [CrossRef]

- Yao, F.; Alkan, B.; Ahmad, B.; Harrison, R. Improving Just-in-Time Delivery Performance of IoT-Enabled Flexible Manufacturing Systems with AGV Based Material Transportation. Sensors 2020, 20, 6333. [Google Scholar] [CrossRef]

- Elnagar, S.; Thomas, M.A. Federated Deep Learning: A Conceptual Model and Applied Framework for Industry 4.0. 2020. Available online: https://aisel.aisnet.org/amcis2020/?utmsource=aisel.aisnet.org (accessed on 15 May 2021).

- Lyu, M.; Biennier, F.; Ghodous, P. Integration of ontologies to support Control as a Service in an Industry 4.0 context. Serv. Oriented Comput. Appl. 2021, 15, 127–140. [Google Scholar] [CrossRef]

- Hizam-Hanafiah, M.; Soomro, M.A. The situation of technology companies in industry 4.0 and the open innovation. J. Open Innov. Technol. Mark. Complex. 2021, 7, 34. [Google Scholar] [CrossRef]

- Li, W.; Huynh, B.H.; Akhtar, H.; Myo, K.S. Discrete Event Simulation as a Robust Supporting Tool for Smart Manufacturing. In Implementing Industry 4.0: The Model Factory as the Key Enabler for the Future of Manufacturing; Springer: Cham, Switzerland, 2021; p. 287. [Google Scholar]

- Del Giudice, M.; Scuotto, V.; Papa, A.; Tarba, S.; Bresciani, S.; Warkentin, M. A self-tuning model for smart manufacturing SMEs: Effects on digital innovation. J. Prod. Innov. Manag. 2020, 38, 68–89. [Google Scholar] [CrossRef]

- Sharma, M.; Sehrawat, R. Quantifying SWOT analysis for cloud adoption using FAHP-DEMATEL approach: Evidence from the manufacturing sector. J. Enterp. Inf. Manag. 2020, 33, 1111–1152. [Google Scholar] [CrossRef]

- Garbie, I.; Garbie, A. Outlook of Requirements of Manufacturing Systems for Industry 4.0. In Proceedings of the 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 4 Februaty–9 April 2020; pp. 1–6. [Google Scholar]

- Alkan, D.P. Re-Shaping Business Strategy in the Era of Digitization. In Handbook of Research on Strategic Fit and Design in Business Ecosystems; IGI Global: Hershey, PA, USA, 2020; pp. 76–97. [Google Scholar]

- Koch, C.; Blind, K. Towards Agile Standardization: Testbeds in Support of Standardization for the IIoT. IEEE Trans. Eng. Manag. 2020, 68, 59–74. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- D’Souza, F.; Costa, J.; Pires, J.N. Development of a solution for adding a collaborative robot to an industrial AGV. Ind. Robot. Int. J. Robot. Res. Appl. 2020, 47, 723–735. [Google Scholar] [CrossRef]

- Liu, B.; Glock, T.; Betancourt, V.P.; Kern, M.; Sax, E.; Becker, J. Model Driven Development Process for a Service-oriented Industry 4.0 System. In Proceedings of the 2020 9th International Conference on Industrial Technology and Management (ICITM), Oxford, UK, 11–13 February 2020; pp. 78–83. [Google Scholar]

- Witczak, M.; Majdzik, P.; Stetter, R.; Lipiec, B. Multiple agv fault-tolerant within an agile manufacturing warehouse. IFAC-PapersOnLine 2019, 52, 1914–1919. [Google Scholar] [CrossRef]

- Iqbal, A.; Zhao, G.; Suhaimi, H.; He, N.; Hussain, G.; Zhao, W. Readiness of subtractive and additive manufacturing and their sustainable amalgamation from the perspective of Industry 4.0: A comprehensive review. Int. J. Adv. Manuf. Technol. 2020, 111, 2475–2498. [Google Scholar] [CrossRef]

- Cheng, H.; Xue, L.; Wang, P.; Zeng, P.; Yu, H. Ontology-based web service integration for flexible manufacturing systems. In Proceedings of the 2017 IEEE 15th International Conference on Industrial Informatics (INDIN), Emden, Germany, 24–26 July 2017; pp. 351–356. [Google Scholar]

- Wan, J.; Tang, S.; Li, D.; Imran, M.; Zhang, C.; Liu, C.; Pang, Z. Reconfigurable smart factory for drug packing in healthcare industry 4.0. IEEE Trans. Ind. Inform. 2018, 15, 507–516. [Google Scholar] [CrossRef]

- Bueno, A.F.; Godinho Filho, M.; Frank, A.G. Smart production planning and control in the Industry 4.0 context: A systematic literature review. Comput. Ind. Eng. 2020, 149, 106774. [Google Scholar] [CrossRef]

- Niakan, F.; Baboli, A.; Moyaux, T.; Botta-Genoulaz, V. A bi-objective model in sustainable dynamic cell formation problem with skill-based worker assignment. J. Manuf. Syst. 2016, 38, 46–62. [Google Scholar] [CrossRef]

- Azarmipour, M.; Elfaham, H.; Gries, C.; Epple, U. Plc 4.0: A control system for industry 4.0. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; Volume 1, pp. 5513–5518. [Google Scholar]

- Seif, A.; Toro, C.; Akhtar, H. Implementing industry 4.0 asset administrative shells in mini factories. Procedia Comput. Sci. 2019, 159, 495–504. [Google Scholar] [CrossRef]

- Chen, D.; Ding, J.; Gao, M.; Ma, D.; Liu, D. Form gene clustering method about pan-ethnic-group products based on emotional semantic. Chin. J. Mech. Eng. 2016, 29, 1134–1144. [Google Scholar] [CrossRef]

- Lins, T.; Oliveira, R.A.R.; Correia, L.H.; Silva, J.S. Industry 4.0 Retrofitting. In Proceedings of the 2018 VIII Brazilian Symposium on Computing Systems Engineering (SBESC), Salvador, Brazil, 5–8 November 2018; pp. 8–15. [Google Scholar]

- Ramirez-Peña, M.; Abad Fraga, F.J.; Sánchez Sotano, A.J.; Batista, M. Shipbuilding 4.0 index approaching supply chain. Materials 2019, 12, 4129. [Google Scholar] [CrossRef] [Green Version]

- Moghaddam, M.; Nof, S.Y. Collaborative service-component integration in cloud manufacturing. Int. J. Prod. Res. 2018, 56, 677–691. [Google Scholar] [CrossRef]

- Bordel, B.; Alcarria, R.; Robles, T.; Martín, D. Cyber–physical systems: Extending pervasive sensing from control theory to the Internet of Things. Pervasive Mob. Comput. 2017, 40, 156–184. [Google Scholar] [CrossRef]

- Ding, K.; Jiang, P. Incorporating social sensors, cyber-physical system nodes, and smart products for personalized production in a social manufacturing environment. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 2323–2338. [Google Scholar] [CrossRef]

- Barenji, R.V.; Akdag, Y.; Yet, B.; Oner, L. Cyber-physical-based PAT (CPbPAT) framework for Pharma 4.0. Int. J. Pharm. 2019, 567, 118445. [Google Scholar] [CrossRef]

- Raygan, R.E.; Henry, S. Manifesto for Enterprise Agility. In Proceedings of the 2019 International Symposium on Systems Engineering (ISSE), Edinburgh, UK, 1–3 October 2019; pp. 1–6. [Google Scholar]

- Zwolińska, B.; Tubis, A.A.; Chamier-Gliszczyński, N.; Kostrzewski, M. Personalization of the MES System to the Needs of Highly Variable Production. Sensors 2020, 20, 6484. [Google Scholar] [CrossRef]

- Engelsberger, M.; Greiner, T. Self-organizing Service Structures for Cyber-physical Control Models with Applications in Dynamic Factory Automation-A Fog/Edge-based Solution Pattern Towards Service-Oriented Process Automation. In Proceedings of the International Conference on Cloud Computing and Services Science (CLOSER 2017), Porto, Portugal, 24–26 April 2017; pp. 238–246. [Google Scholar]

- Fischer, H.; Senft, B. Human-Centered Software Engineering as a Chance to Ensure Software Quality Within the Digitization of Human Workflows. In Human-Centered and Error-Resilient Systems Development; Springer: Berlin/Heidelberg, Germany, 2016; pp. 30–41. [Google Scholar]

- Ray, P.P. An introduction to dew computing: Definition, concept and implications. IEEE Access 2017, 6, 723–737. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, L.; Venkatesh, V.; Luo, Y.; Cheng, Y. Cloud manufacturing: A computing and service-oriented manufacturing model. Proc. Inst. Mech. Eng., Part B J. Eng. Manuf. 2011, 225, 1969–1976. [Google Scholar] [CrossRef]

- Ooi, K.B.; Lee, V.H.; Tan, G.W.H.; Hew, T.S.; Hew, J.J. Cloud computing in manufacturing: The next industrial revolution in Malaysia? Expert Syst. Appl. 2018, 93, 376–394. [Google Scholar] [CrossRef]

- Xu, X. From cloud computing to cloud manufacturing. Robot. Comput.-Integr. Manuf. 2012, 28, 75–86. [Google Scholar] [CrossRef]

- Li, D.; Tang, H.; Wang, S.; Liu, C. A big data enabled load-balancing control for smart manufacturing of Industry 4.0. Clust. Comput. 2017, 20, 1855–1864. [Google Scholar] [CrossRef]

- Theron, P. Through-life cyber resilience in future smart manufacturing environments. A research programme. Procedia Manuf. 2018, 16, 193–207. [Google Scholar] [CrossRef]

- Tang, H.; Li, D.; Wang, S.; Dong, Z. CASOA: An architecture for agent-based manufacturing system in the context of industry 4.0. IEEE Access 2017, 6, 12746–12754. [Google Scholar] [CrossRef]

- Rasanjani, P.; Sachini, W.; Sandamali, G.; Weerabahu, W. A Strategic Relationship Building through Procurement 4.0: An Analysis from the Apparel Industry. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bangkok, Thailand, 5–7 March 2019; pp. 1843–1855. [Google Scholar]

- Juan-Verdejo, A.; Surajbali, B. XaaS multi-cloud marketplace architecture enacting the industry 4.0 concepts. In Proceedings of the Doctoral Conference on Computing, Electrical and Industrial Systems, Costa de Caparica, Portugal, 2–4 May 2016; pp. 11–23. [Google Scholar]

- Lycett, M. ‘Datafication’: Making Sense of (Big) Data in a Complex World. Eur. J. Inf. Syst. Vol. 2013, 22, 381–386. [Google Scholar] [CrossRef] [Green Version]

- Wamba, S.F.; Akter, S.; Edwards, A.; Chopin, G.; Gnanzou, D. How ‘big data’can make big impact: Findings from a systematic review and a longitudinal case study. Int. J. Prod. Econ. 2015, 165, 234–246. [Google Scholar] [CrossRef]

- Akter, S.; Wamba, S.F.; Gunasekaran, A.; Dubey, R.; Childe, S.J. How to improve firm performance using big data analytics capability and business strategy alignment? Int. J. Prod. Econ. 2016, 182, 113–131. [Google Scholar] [CrossRef] [Green Version]

- Wamba, S.F.; Gunasekaran, A.; Akter, S.; Ren, S.J.f.; Dubey, R.; Childe, S.J. Big data analytics and firm performance: Effects of dynamic capabilities. J. Bus. Res. 2017, 70, 356–365. [Google Scholar] [CrossRef] [Green Version]

- Barlette, Y.; Baillette, P. Big data analytics in turbulent contexts: Towards organizational change for enhanced agility. Prod. Plan. Control 2020, 1–18. [Google Scholar] [CrossRef]

- Al-Qaralleh, R.E.; Atan, T. Impact of knowledge-based HRM, business analytics and agility on innovative performance: Linear and FsQCA findings from the hotel industry. Kybernetes 2021, in press. [Google Scholar] [CrossRef]

- Houngbé, M.; Barthe-Delanoë, A.M.; Négny, S. Servitization of biomass processing for a virtual biorefinery: Application to the lignocellulosic biomass in a French local territory. In Working Conference on Virtual Enterprises; Springer: Berlin/Heidelberg, Germany, 2019; pp. 477–486. [Google Scholar]

- Centobelli, P.; Cerchione, R.; Ertz, M. Agile supply chain management: Where did it come from and where will it go in the era of digital transformation? Ind. Mark. Manag. 2020, 90, 324–345. [Google Scholar]

- Jung, T.; tom Dieck, M.C. Augmented Reality and Virtual Reality. In Empowering Human, Place and Business; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Olshannikova, E.; Ometov, A.; Koucheryavy, Y.; Olsson, T. Visualizing Big Data with augmented and virtual reality: Challenges and research agenda. J. Big Data 2015, 2, 1–27. [Google Scholar] [CrossRef]

- Damiani, L.; Demartini, M.; Guizzi, G.; Revetria, R.; Tonelli, F. Augmented and virtual reality applications in industrial systems: A qualitative review towards the industry 4.0 era. IFAC-PapersOnLine 2018, 51, 624–630. [Google Scholar] [CrossRef]

- Houngbé, M.; Barthe-Delanoë, A.M.; Négny, S. Towards virtual biorefineries. In Working Conference on Virtual Enterprises; Springer: Berlin/Heidelberg, Germany, 2018; pp. 571–580. [Google Scholar]

- Gunal, M.M. Simulation for Industry 4.0; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Alrabghi, A. Simulation based optimization frameworks as key enablers for the transformation to Industry 4.0. In Proceedings of the 48th International Conference on Computers and Industrial Engineering (CIE 48), Auckland, New Zealand, 2–5 December 2018; pp. 201-1–201-6. [Google Scholar]

- Lins, T.; Oliveira, R.A.R. Energy efficiency in industry 4.0 using SDN. In Proceedings of the 2017 IEEE 15th International Conference on Industrial Informatics (INDIN), Emden, Germany, 24–26 July 2017; pp. 609–614. [Google Scholar]

- Ebrahimi, M.; Baboli, A.; Rother, E. A Roadmap for evolution of existing production system toward the factory of the future: A case study in automotive industry. In Proceedings of the 2018 IEEE International Conference on Technology Management, Operations and Decisions (ICTMOD), Marrakech, Morocco, 21–23 November 2018; pp. 274–281. [Google Scholar]

- Mule, D.P.; Chaudhari, B. Design and performace ananlysis of IIoT topologies using SDN. In Proceedings of the 2018 International Conference on Recent Innovations in Electrical, Electronics & Communication Engineering (ICRIEECE), Bhubaneswar, India, 27–28 July 2018; pp. 2547–2551. [Google Scholar]

- Azevedo, A.; Santiago, S.B. Design of an Assessment Industry 4.0 Maturity Model: An application to manufacturing company. In Proceedings of the 4th North American IEOM Conference. IEOM 2019, Toronto, ON, Canada, 23–25 October 2019; pp. 208–217. [Google Scholar]

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Bus. Horizons 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A vision, architectural elements, and future directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef] [Green Version]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Wollschlaeger, M.; Sauter, T.; Jasperneite, J. The future of industrial communication: Automation networks in the era of the internet of things and industry 4.0. IEEE Ind. Electron. Mag. 2017, 11, 17–27. [Google Scholar] [CrossRef]

- Coda, F.A.; Salles, R.M.; Vitoi, H.A.; Pessoa, M.A.; Moscato, L.A.; Santos Filho, D.J.; Junqueira, F.; Miyagi, P.E. Big data on machine to machine integration’s requirement analysis within Industry 4.0. In Proceedings of the Doctoral Conference on Computing, Electrical and Industrial Systems, Costa de Caparica, Portugal, 8–10 May 2019; pp. 247–254. [Google Scholar]

- Micheler, S.; Goh, Y.M.; Lohse, N. Innovation landscape and challenges of smart technologies and systems—A European perspective. Prod. Manuf. Res. 2019, 7, 503–528. [Google Scholar] [CrossRef] [Green Version]

- Kaar, C.; Frysak, J.; Stary, C.; Kannengiesser, U.; Müller, H. Resilient ontology support facilitating multi-perspective process integration in industry 4.0. In Proceedings of the 10th International Conference on Subject-Oriented Business Process Management, Linz, Austria, 5–6 April 2018; pp. 1–10. [Google Scholar]

- Gamache, S.; Abdul-Nour, G.; Baril, C. Toward industry 4.0: Studies and practices in Quebec SMES. In Proceedings of the CIE47 Proceedings, Lisbon, Portugal, 11–13 October 2017. [Google Scholar]

- Fraden, J. Handbook of Modern Sensors; Springer: Berlin/Heidelberg, Germany, 2010; Volume 3. [Google Scholar]

- Rathee, G.; Balasaraswathi, M.; Chandran, K.P.; Gupta, S.D.; Boopathi, C. A secure IoT sensors communication in industry 4.0 using blockchain technology. J. Ambient. Intell. Humaniz. Comput. 2021, 12, 533–545. [Google Scholar] [CrossRef]

- Schmidt, D.; Villalba Diez, J.; Ordieres-Meré, J.; Gevers, R.; Schwiep, J.; Molina, M. Industry 4.0 Lean Shopfloor Management Characterization Using EEG Sensors and Deep Learning. Sensors 2020, 20, 2860. [Google Scholar] [CrossRef]

- Farahani, S.; Brown, N.; Loftis, J.; Krick, C.; Pichl, F.; Vaculik, R.; Pilla, S. Evaluation of in-mold sensors and machine data towards enhancing product quality and process monitoring via Industry 4.0. Int. J. Adv. Manuf. Technol. 2019, 105, 1371–1389. [Google Scholar] [CrossRef]

- Choudhury, A.; Behl, A.; Sheorey, P.A.; Pal, A. Digital supply chain to unlock new agility: A TISM approach. Benchmarking Int. J. 2021, 28, 2075–2109. [Google Scholar] [CrossRef]

- Alami, D.; ElMaraghy, W. A cost benefit analysis for industry 4.0 in a job shop environment using a mixed integer linear programming model. J. Manuf. Syst. 2021, 59, 81–97. [Google Scholar] [CrossRef]

- Arifin, V.; Jalaldeen, M.R.M.; Kartiwi, M.; Abdullah, L.M. Investigation of IT Competence and Readiness of IT Students Facing The Industrial Revolution 4.0. In Proceedings of the 2020 8th International Conference on Cyber and IT Service Management (CITSM), Pangkal, Indonesia, 23–24 October 2020; pp. 1–6. [Google Scholar]

- Neden, J.; Cleak, H.; Thomson, S. Towards agility: Scaffolding anticipative education in social work. Br. J. Soc. Work 2020, 50, 1258–1276. [Google Scholar] [CrossRef]

- Brenner, B. Transformative sustainable business models in the light of the digital imperative—A global business economics perspective. Sustainability 2018, 10, 4428. [Google Scholar] [CrossRef] [Green Version]

- Goti-Elordi, A.; de-la Calle-Vicente, A.; Gil-Larrea, M.J.; Errasti-Opakua, A.; Uradnicek, J. Aplicación de un sistema business intelligence en un contexto big data de una empresa industrial alimentaria. DYNA-Ingeniería Ind. 2017, 92, 347–353. [Google Scholar] [CrossRef]

- Tsukada, T.; Sakakibara, H. Risk assessment of fall-related occupational accidents in the workplace. J. Occup. Health 2016. [Google Scholar] [CrossRef] [Green Version]

- Piengang, F.C.N.; Pmp, M.; Jean-Pierre Kenné, P. Introduction to optimization of decision-making in coupled, dynamic and uncertain production, maintenance and product development environment. In Proceedings of the International Annual Conference of the American Society for Engineering Management; American Society for Engineering Management (ASEM): Huntsville, AL, USA, 2017; pp. 1–11. [Google Scholar]

- Kasim, K.N.; Auzair, S.M.; Amir, A.M.; Abdullah, N.L. Hubungan antara Sistem Pengukuran Prestasi Strategik, Kapasiti Penyerapan dan Ketangkasan Organisasi Berdasarkan Perspektif Keupayaan Dinamik. Asian J. Account. Gov. 2020, 14. [Google Scholar] [CrossRef]

- Tajudeen, F.P.; Nadarajah, D.; Jaafar, N.I.; Sulaiman, A. The impact of digitalisation vision and information technology on organisations’ innovation. Eur. J. Innov. Manag. 2021. [Google Scholar] [CrossRef]

- Le Grand, T.; Deneckere, R. COOC: An Agile Change Management Method. In Proceedings of the 2019 IEEE 21st Conference on Business Informatics (CBI), Moscow, Russia, 15–17 July 2019; Volume 2, pp. 28–37. [Google Scholar]

- Hassan, N.H.; Arshad, N.I. Proposing Construct for Organizational Agility Model in Malaysian Automotive Organization. In Proceedings of the 2019 6th International Conference on Research and Innovation in Information Systems (ICRIIS), Johor Bahru, Malaysia, 2–3 December 2019; pp. 1–6. [Google Scholar]

- Marnewick, A.L.; Marnewick, C. The ability of project managers to implement industry 4.0-related projects. IEEE Access 2019, 8, 314–324. [Google Scholar] [CrossRef]