Abstract

To date, energy recovery from biological sewage sludge (BSS) by anaerobic digestion has been very popular. However, it can often happen that anaerobic reactors are volumetrically undersized, thus reducing performance in terms of biogas production. A continuous-flow pilot-scale plant was used to investigate, for the first time, the effects of mesophilic anaerobic co-digestion (MACoD) of sewage sludge and aqueous residue (AR) from a biosolids treatment plant (BTP) on methanogenic activity under low hydraulic retention time (HRT) conditions (to simulate the undersizing of the reactor). The results showed that the digestate is always more rapidly biodegradable than the matrices fed, while particulate COD hydrolyzed (12 ± 1.3%) is independent of the quantity of AR dosed. Feeding over 35% of soluble OLR, the total VFAs in the system strongly decreased, despite the low HRT. In correspondence with higher dosages of AR, the percentage of CH4 increased up to 77–78% and the CO2 CH4−1 ratio decreased to 0.25 ± 0.2. Specific methane production increased from 0.09 ± 0.01 m3CH4 kgCODremoved−1 with BSS alone to 0.28 ± 0.01 m3CH4CH4 kgCODremoved−1 in the case of BSS co-digested with AR. Moreover, co-digestion with AR from a BTP allowed continuous specific methanogenic activity to be enhanced from 1.76 ± 0.02 m3CH4 tVSS−1 d−1 to 6.48 ± 0.88 m3CH4 tVSS−1 d−1. Therefore, the MACoD of BSS and AR from a BTP could be a good solution to enhance methanogenic activity in a volumetrically undersized anaerobic digester with reduced HRT.

1. Introduction

The production of biological sewage sludge (BSS) is bound to increase in the coming years due to increases in population and in the number of wastewater treatment plants (WWTPs) [1,2]. In addition, the tightening of legislation regarding the quality of effluents treated by WWTPs is another factor that is contributing to an increase in the overall production of BSS [3].

As already developed for the management of other waste, adopting a hierarchical approach that stimulates the recovery and reuse of material and energy before final disposal is also necessary for BSS. The European Union has developed a hierarchical model based on four priority levels: (i) waste prevention/minimization at source, (ii) matter recovery, (iii) energy recovery, and (iv) waste disposal [4].

From a circular economy perspective, of which the main goal is the rational and sustainable use/reuse of resources [5,6,7,8], there are already numerous examples of possible forms of sludge recovery [9,10,11] but this trend is destined to increase given the ambitious plan promoted by the European Commission [12]. Recently, many studies have highlighted the effectiveness of minimization treatments against BSS production in WWTPs [13,14,15,16]. In some cases, these interventions also allow optimization of the subsequent recovery of material from biosolids (treated BSS [17]) [18]. However, the development of technologies that allow maximum recovery/reuse of matter and energy form residues, promoting the transformation of WWTPs into water resources recovery facilities (WRRFs), is also strongly encouraged [19,20,21,22,23].

For instance, possible alternatives include composting [24,25] and anaerobic digestion [26]. Moreover, thermochemical treatments such as combustion [27,28], gasification [28,29], and pyrolysis [28,30] are currently under study. However, two major disadvantages must be highlighted. Firstly, untreated BSS generally cannot directly feed these processes due to its very low calorific value: pre-dehydration and drying of BSS is a necessary requirement [31]. Secondly, the application of some of these processes to biosolids (e.g., pyrolysis and gasification) is not yet widespread [14,32].

Therefore, mesophilic and thermophilic anaerobic digestion represents an important opportunity in the organic matter management strategy, allowing recovery of matter (through the agronomic use of the digestate) and energy (through biogas production and subsequent combustion) [33,34]. In this case, the possibility of having a product with a high fertilizing power reduces the costs related to its disposal, enhancing the economic and environmental sustainability of the process [35]. In fact, the agronomic use of digestate as a fertilizer allows the replacement of synthetic chemical fertilizers and the closure of the carbon and nutrient cycle [36].

In the literature, several examples of mesophilic anaerobic co-digestion of sludge and solid waste [37,38] or aqueous waste [39,40,41] in good hydraulic retention time (HRT) conditions have already been reported, thus highlighting its feasibility. However, often, the anaerobic reactors can be volumetrically undersized, thus limiting performance in terms of biogas production due to the reduction in (i) degradation of the organic substance and (ii) transformation of volatile fatty acids (VFAs). This study aims to assess if the mesophilic anaerobic co-digestion (MACoD) of BSS and an aqueous residue (AR) from a biosolids treatment plant (BTP) allowed stimulation of methanogenic activity even with low HRT. In this study, an HRT equal to 17 d has been used to simulate the volumetric undersizing of the reactor, instead of the value higher than 20 d conventionally necessary in a mesophilic anaerobic digester located in the sludge line of a WWTP [42,43]. A continuous-flow-rate pilot plant was monitored for 310 d by feeding BSS and AR in different ratios to understand the effects on the digestate biodegradability and COD, and on the production and composition of biogas.

2. Materials and Methods

2.1. Description of the System

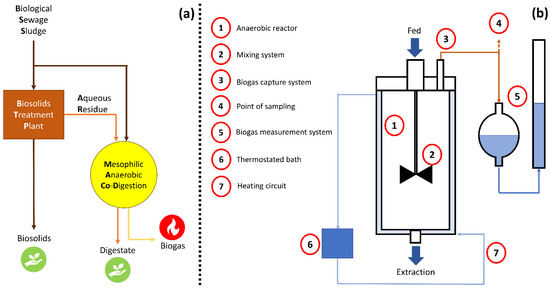

The scheme of co-digestion of BSS and AR from a BTP is presented in Figure 1a. The experimental part of the present study was conducted in a glass reactor pilot plant (available volume: 5 L) to simulate an anaerobic digester (Figure 1b). The reactor was equipped with an external jacketed vessel to maintain a constant internal temperature of 35 °C. The matrix inside the digester was kept in constant stirring by means of a double blade mechanical mixer. A graduated cylinder connected to a containment vessel with water was used to monitor the biogas production. The digester was hermetically closed during the experimentation.

Figure 1.

(a) Scheme of co-digestion of biological sewage sludge and aqueous residue from biosolids treatment plant. (b) Structure of the mesophilic anaerobic co-digester.

2.2. Management of the Continuous-Flow Reactor

Two main operational phases were followed as reported in Table 1. Before phase 1 (P1), biomass taken from an anaerobic digester serving a municipal WWTP was used as the inoculum. Generally, the optimal HRT for mesophilic anaerobic digestion of BSS is up to 40 d [44]. In this work, the HRT was maintained at equal to 17 days to stress critical conditions and simulate the undersizing of the anaerobic digester. In order to obtain stable conditions of the system and slowly reduce the HRT to 17 days, the pilot plant was fed daily in P1 with the excess BSS from a conventional activated sludge (CAS) plant treating municipal wastewater for 92 days.

Table 1.

Feeding conditions of the continuous-flow anaerobic reactor during phase 1 and phase 2.

Table 2.

Characteristics of BSS and AR used to feed the continuous-flow anaerobic digester.

2.3. Analytic Procedures

The Standard Methods for the Examination of Water and Wastewater [45] were followed to determine total suspended solids (TSS) and volatile suspended solids (VSS) (method 2540), biochemical oxygen demand measured in 5 days (BOD5) and in 20 days (BOD20) (method 5210) of substrate fed and digestate, and volatile fatty acids (VFAs) in biogas (method 5560). The biogas composition in terms of CH4, CO2, O2, and H2S was monitored by gas detector Mentor PGD 2 (Status Scientific Controls Ltd., Mansfield, Nottinghamshire, UK). COD in feeding substrate and digestate was measured with procedure 5220 described in the Standard Methods for the Examination of Water and Wastewater [45], both on samples as is (total COD) and on supernatant after centrifugation (10 min; 6000 RPM) with ROTOFIX 32A (Andreas Hettich GMBH & CO. KG, Tuttlingen, Germany), as an indication of soluble organic substance (sCOD). Particulate COD (pCOD) was evaluated as the difference between total COD and sCOD.

The biodegradability index (BI) and the rapidity of biodegradation index (RBI) were also calculated according to Equations (1) and (2), respectively:

BI [-] = BOD20/COD

RBI [-] = BOD5/BOD20

BI represents the ratio between the potentially biologically degradable organic substance (usually indicated as BOD20) and the total degradable organic substances (usually indicated as COD). RBI indicates the amount of highly biodegradable organic substance (usually indicated as BOD5) with respect to the total biodegradable organic substance. In order to evaluate and compare the effectiveness of the MACoD, the specific methane production (SMP) and the continuous specific methanogenic activity (CSMA) were calculated as reported in Equations (3) and (4), respectively:

where QCH4 and Vreactor represent the daily flow rate of methane expressed in normal conditions (T = 0 °C; P = 1 atm) and the volume of the reactor, respectively. xVSS is the concentration of VSS in the reactor, and LCODremoved represents the load of COD removed by the anaerobic digestion calculated as the difference between the load of COD fed to the reactor and the residual load.

SMP [m3CH4 kgCODremoved−1] = QCH4/LCODremoved

CSMA [m3CH4 tVSS−1 d−1] = QCH4/(xVSS. Vreactor)

3. Results and Discussion

3.1. Effect of MACoD on Digestate Biodegradability and COD

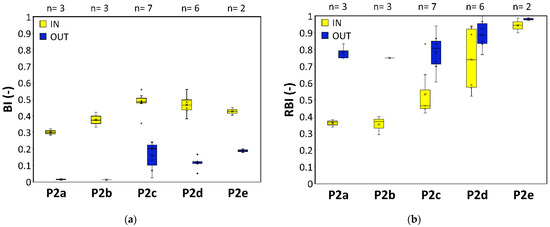

The effect of the MACoD of BSS and AR from a BTP on the biodegradability of the digestate was investigated. In terms of BI, the matrices fed to the reactor showed higher values than the outlet digestate (Figure 2a). This aspect is mainly due to effective removal of the biodegradable organic substance during anaerobic digestion despite the reduced HRT. As the percentage of sOLR increased, the BI of the digestate leaving the MACoD also increased, up to 18.9 ± 0.1 in P2e. This aspect could be related to the greater reduction in the overall organic substance in the P2d and P2e phases (about 40–45%) compared with the previous phases (18–25%).

Figure 2.

(a) BI and (b) RBI during phase P2 (HRT = 17 d). Boxplots represent the distance between the first and third quartiles, while whiskers are set as the most extreme (lower and upper) data points not exceeding 1.5 times the quartile range from the median. Values outside such a range are outliers. BI: biodegradability index; n: number of data; RBI: rapidity of biodegradation index.

By testing the matrices with a mesophilic biomass taken from a CAS plant, the digestate is always more rapidly biodegradable than the matrices fed at the inlet (Figure 2b). Although the inlet organic substance is already largely rapidly biodegradable, MACoD allowed this value to be further increased up to 0.98 ± 0.1 in the case of P2e. Even if with a lower dosage of AR, in P2a and P2b, the RBI of digestate was 0.78 ± 0.2 and 0.75 ± 0.1, respectively.

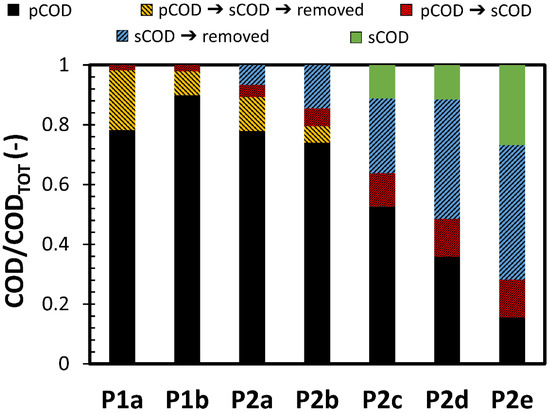

The transformation of COD during the MACoD was evaluated considering the COD present in particulate (pCOD) and in soluble form (sCOD). The increase in biological activity in the reactor following the dosage of AR seems to be confirmed by the comparison between pCOD and sCOD in the fed matrix and in the digestate (Figure 3). As the dosage of AR increases, the removal efficiency of COD increases up to 45% in P2e. The results also show that pCOD hydrolyzed and transformed into sCOD in the phases with HRT equal to 17 d (12 ± 1.3%) is independent of the quantity of AR dosed. Therefore, the increase in COD removal yield is mainly attributable to the higher sCOD present in the fed matrix.

Figure 3.

Transformation of pCOD into sCOD during different phases of the experimentation. pCOD: particulate COD; sCOD: soluble COD.

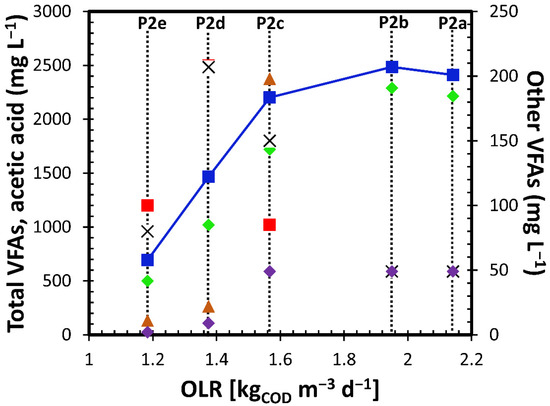

3.2. Volatile Fatty Acids

The mean concentration of VFAs in the system was monitored. In the anaerobic digestion process, an accumulation of VFAs could be a signal of a lack of balance in the system between the organic substance hydrolyzed and the volatile acids transformed in biogas [46,47]. Feeding over 35% of sOLR (P2c, P2d, and P2e), the total concentration of VFAs in the system strongly decreased, reaching values of 693 mg L−1 in P2e (Figure 4), despite the criticality given by the reduced HRT. The predominant part of VFAs was made up of acetic acid (C2H4O2) (80.8 ± 8.4%). The other VFAs therefore constituted only a minority in percentage terms. The presence of longer-chain VFAs could be an indicator of incomplete hydrolysis of the initial organic matter [48]. During this study, the concentration of caproic acid (C10H20O2) always remained as a minority compared with the other VFAs (<50 mg L−1) and further decreased significantly in P2d and P2e. Based on these results, it is therefore possible to exclude significant phenomena of imbalance in the digestion process and significant accumulations of long-chain VFAs when AR from a BTP was used. Particularly better results were obtained when increasing the addition of AR. This result could be attributed to the lower OLR associated with the phases in which the BSS is mixed with AR. This resulted in a lower overload of the digester, a lower imbalance in the anaerobic digestion process, and a consequent reduction in the accumulation of VFAs.

Figure 4.

Concentration of total VFAs (■ and blue line), acetic acid (♦), propionic acid (■), butyric acid (▲), valeric acid (x), and caproic acid (♦) as a function of OLR (HRT = 17 d). OLR: organic loading rate; VFA: volatile fatty acid.

3.3. Biogas Characteristics

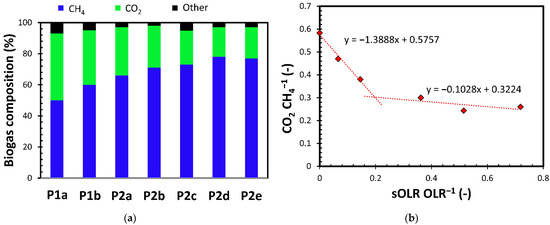

The composition of the biogas produced was analyzed (Figure 5a). During P1a and P1b (BSS alone), the percentage of CH4 in the biogas was 50–60%, consistent with the literature values [49,50]. Following the increase in the dosage of AR, the percentage of CH4 increased up to 77–78% in phases P2d (52% sOLR, 48% pOLR) and P2e (72% sOLR, 28% pOLR). This result can be attributed to the reduction state of carbon in the fed matrix. The BSS can be represented as C5H7NO2 [51] in which carbon has an oxidation number equal to zero. In the case of feeding only BSS, as in P1b, this explains a ratio between CO2 and CH4 equal to or close to 1 (also considering soluble CO2) (Figure 5b). By maintaining the same HRT and co-digesting the AR containing carbon in the reduced state, a higher production of CH4 is promoted and therefore a lower CO2 CH4−1 ratio can be evaluated, as highlighted in P2c, P2d, and P2e. Moreover, the alkalinity of the system can also influence the CO2 CH4−1 ratio. Conductivity strongly increased from 7000 μS cm−1 in P1 to more than 15,000 μS cm−1 in P2c, P2d, and P2e (Supplementary Materials: Figure S1). As the dosage of AR increased, the CO2 CH4−1 ratio decreased to 0.25 ± 0.2, in correspondence with P2d and P2e. These results confirmed that the MACoD of BSS and AR from a BTP stimulated a higher rate of CH4 even under low HRT conditions.

Figure 5.

(a) Biogas composition and (b) CO2 CH4−1 produced as a function of sOLR OLR−1 ratio with HRT of 17 days. Boxplots represent the distance between the first and third quartiles, while whiskers are set as the most extreme (lower and upper) data points not exceeding 1.5 times the quartile range from the median. Values outside such a range are outliers. OLR: organic loading rate; sOLR: organic loading rate in soluble form.

3.4. Methane Production

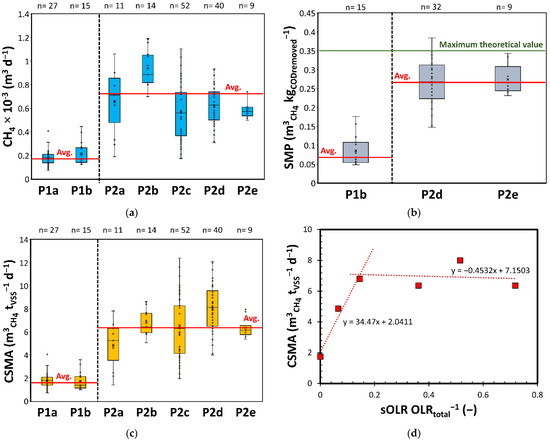

The results highlighted that CH4 production in P1 was limited (0.20 × 10−3 ± 0.03 × 10−3 m3CH4 d−1), both in phase P1a (HRT = 24 d), probably due to the recent start-up and limited initial stability of the system, and in phase P1b due to the reduced HRT (Figure 6a). Considering this critical HRT condition (17 d) in P1b, the low values of the production of CH4 in P1b are consistent with the results that show an accumulation of VFAs as the percentage of BSS fed increases. In fact, according to Yuan and Zhu [52], high concentration of accumulated VFAs leads to the inhibition of methanogenic bacteria by a rapid acidification phenomenon.

Figure 6.

(a) CH4 production, (b) SMP (the green line represents the maximum theoretical value of SMP), (c) CSMA, and (d) CSMA as a function of sOLR OLR−1 ratio with HRT of 17 days. Boxplots represent the distance between the first and third quartiles, while whiskers are set as the most extreme (lower and upper) data points not exceeding 1.5 times the quartile range from the median. Values outside such a range are outliers. Avg.: average value; CSMA: continuous specific methanogenic activity; n: number of data; OLR: organic loading rate; SMP: specific methane production; sOLR: organic loading rate in soluble form.

In the subsequent phases of co-digestion of BSS with AR from a BTP, the flow rate of produced biogas increased significantly (0.68 × 10−3 ± 0.12 × 10−3 m3CH4 d−1), while maintaining an HRT equal to 17 d. By comparing P1b (BSS alone, 100% pOLR) with P2d (52% sOLR, 48% pOLR) and P2e (72% sOLR, 28% pOLR), the SMP increased considerably from 0.09 ± 0.01 m3CH4 kgCODremoved−1 to 0.28 ± 0.01 m3CH4 kgCODremoved−1, close to the maximum theoretical value (0.35 m3CH4 kgCODremoved−1) [53,54] (Figure 6b). Therefore, despite the low HRT, not enough to guarantee a satisfactory production of CH4 in the case of feeding with BSS alone due to the volumetric undersize of the reactor, the MACoD with AR from a BTP allowed more than triple values to be reached.

The CSMA followed a behavior similar to the CH4 flow rate, with a growth trend between P1 and P2, highlighting a high methanogenic activity of the biomass present (Figure 6c). By comparing P1 with P2, the CSMA increased consistently from 1.76 ± 0.02 m3CH4 tVSS−1 d−1 to 6.48 ± 0.88 m3CH4 tVSS−1 d−1 and remained almost constant, increasing the sOLR OLR−1 ratio to over 0.15 (Figure 6d).

4. Conclusions

This work demonstrates the feasibility of anaerobically co-digesting BSS and AR from a BTP to strongly enhance the methanogenic activity in reduced HRT (17 d) due to volumetric undersizing of the reactor. Moreover, the COD and biodegradability of the digestate was also studied. The results showed that the greater reduction in the overall organic substance in the P2d and P2e phases (40–45%) compared with the previous phases (18–25%) enhanced the BI of the digestate with higher AR dosages. The digestate was always more rapidly biodegradable than the matrices fed: MACoD allowed this value to be increased up to 0.98 ± 0.1 in the case of P2e. pCOD hydrolyzed (12 ± 1.3%) is independent of the quantity of AR dosed, and the increase in COD removal yield is mainly attributable to the higher sCOD present in the fed matrix. Feeding over 35% of soluble OLR, the total VFAs in the system strongly decreased, despite the low HRT, excluding significant phenomena of imbalance in the digestion process and significant accumulations of long-chain VFAs. In correspondence with higher dosages of AR, the percentage of CH4 increased up to 77–78% and the CO2 CH4−1 ratio decreased to 0.25 ± 0.2, probably thanks to the reduced state of carbon contained in AR. SMP increased from 0.09 ± 0.01 m3CH4 kgCODremoved−1 with BSS alone to 0.28 ± 0.01 m3CH4CH4 kgCODremoved−1 in the case of BSS co-digested with AR (sOLR > 52%), close to the maximum theoretical value. Moreover, co-digestion with AR from a BTP allowed CSMA to be enhanced from 1.76 ± 0.02 m3CH4 tVSS−1 d−1 to 6.48 ± 0.88 m3CH4 tVSS−1 d−1 and then remain almost constant, increasing the sOLR OLR−1 ratio to over 0.15.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/su13147728/s1, Figure S1: Conductivity in the anaerobic digester during the experimentation.

Author Contributions

Conceptualization, V.T., M.B., M.C.M. and M.C.C.; methodology, V.T., M.B. and M.C.C.; validation, V.T., M.B. and M.C.C.; formal analysis, A.K.T. and M.C.M.; investigation, F.M.C., M.B. and M.C.C.; resources, M.C.C.; data curation, A.K.T., M.C.M. and M.B.; writing—original draft preparation, A.K.T., I.A.K., M.C.M. and M.C.C.; writing—review and editing, V.T., A.K.T., I.A.K., F.M.C. and M.C.M.; visualization, A.K.T., I.A.K., F.M.C. and M.C.M.; supervision, V.T. and M.C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data generated or analyzed during this study are included in this published article.

Acknowledgments

The authors wish to thank Paola Bini for her technical support during the research.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

AR: aqueous residue; BI: biodegradability index; BOD20: biochemical oxygen demand measured in 20 days; BOD5: biochemical oxygen demand measured in 5 days; BSS: biological sewage sludge; BTP: biosolids treatment plant; CAS: conventional activated sludge plant; CSMA: continuous specific methanogenic activity; HRT: hydraulic retention time; MACoD: mesophilic anaerobic co-digestion; OLR: organic loading rate (based on COD); pOLR: organic loading rate in particulate form; sOLR: organic loading rate in soluble form; P1: phase 1; P2: phase 2; RBI: rapidity of biodegradation index; SMP: specific methane production; TKN: total Kjeldahl nitrogen; TSS: total suspended solids; VSS: volatile suspended solids; VFA: volatile fatty acid; WRRF: water resources recovery facility; WWTP: wastewater treatment plant.

References

- Kelessidis, A.; Stasinakis, A.S. Comparative study of the methods used for treatment and final disposal of sewage sludge in European countries. Waste Manag. 2012, 32, 1186–1195. [Google Scholar] [CrossRef]

- Sharma, B.; Sarkar, A.; Singh, P.; Singh, R.P. Agricultural utilization of biosolids: A review on potential effects on soil and plant grown. Waste Manag. 2017, 64, 117–132. [Google Scholar] [CrossRef] [PubMed]

- Demirbas, A.; Edris, G.; Alalayah, W.M. Sludge production from municipal wastewater treatment in sewage treatment plant. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 999–1006. [Google Scholar] [CrossRef]

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef]

- Rada, E.C.; Ragazzi, M.; Torretta, V.; Castagna, G.; Adami, L.; Cioca, L.I. Circular economy and waste to energy. AIP Conf. Proc. 2018, 1968, 030050. [Google Scholar]

- Wan, C.; Shen, G.Q.; Choi, S. Waste Management Strategies for Sustainable Development. In Encyclopedia of Sustainability in Higher Education; Springer International Publishing: Cham, Switzerland, 2019; pp. 1–9. [Google Scholar]

- Torretta, V.; Ferronato, N.; Katsoyiannis, I.; Tolkou, A.; Airoldi, M. Novel and Conventional Technologies for Landfill Leachates Treatment: A Review. Sustainability 2016, 9, 9. [Google Scholar] [CrossRef] [Green Version]

- Collivignarelli, M.C.; Abba, A.; Padovani, S.; Frascarolo, M.; Sciunnach, D.; Turconi, M.; Orlando, M. Recovery of Sewage Sludge on agricultural land in Lombardy: Current issues and regulatory scenarios. Environ. Eng. Manag. J. 2015, 14, 1477–1486. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Cillari, G.; Ricciardi, P.; Miino, M.C.; Torretta, V.; Rada, E.C.; Abbà, A. The Production of Sustainable Concrete with the Use of Alternative Aggregates: A Review. Sustainability 2020, 12, 7903. [Google Scholar] [CrossRef]

- Ricciardi, P.; Cillari, G.; Carnevale Miino, M.; Collivignarelli, M.C. Valorization of agro-industry residues in building and environmental sector: A review. Waste Manag. Res. 2020, 1–26. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Abbà, A.; Carnevale Miino, M.; Cillari, G.; Ricciardi, P. A review on alternative binders, admixtures and water for the production of sustainable concrete. J. Clean. Prod. 2021, 126408. [Google Scholar] [CrossRef]

- European Commission. Circular Economy—Implementation of the Circular Economy Action Plan. Available online: https://ec.europa.eu/environment/circular-economy/index_en.htm (accessed on 13 September 2019).

- Wang, Q.; Wei, W.; Gong, Y.; Yu, Q.; Li, Q.; Sun, J.; Yuan, Z. Technologies for reducing sludge production in wastewater treatment plants: State of the art. Sci. Total Environ. 2017, 587–588, 510–521. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Abbà, A.; Carnevale Miino, M.; Torretta, V. What Advanced Treatments Can Be Used to Minimize the Production of Sewage Sludge in WWTPs? Appl. Sci. 2019, 9, 2650. [Google Scholar] [CrossRef] [Green Version]

- Bertanza, G.; Papa, M.; Canato, M.; Collivignarelli, M.C.; Pedrazzani, R. How can sludge dewatering devices be assessed? Development of a new DSS and its application to real case studies. J. Environ. Manag. 2014, 137, 86–92. [Google Scholar] [CrossRef] [PubMed]

- Collivignarelli, M.C.; Abbà, A.; Castagnola, F.; Bertanza, G. Minimization of municipal sewage sludge by means of a thermophilic membrane bioreactor with intermittent aeration. J. Clean. Prod. 2017, 143, 369–376. [Google Scholar] [CrossRef]

- EPA Basic Information about Biosolids. Available online: https://www.epa.gov/biosolids/basic-information-about-biosolids (accessed on 20 May 2019).

- Collivignarelli, M.C.; Abbà, A.; Bertanza, G.; Baldi, M.; Setti, M.; Frattarola, A.; Carnevale Miino, M. Treatment of high strength wastewater by thermophilic aerobic membrane reactor and possible valorisation of nutrients and organic carbon in its residues. J. Clean. Prod. 2021, 280. [Google Scholar] [CrossRef]

- Seco, A.; Aparicio, S.; González-Camejo, J.; Jiménez-Benítez, A.; Mateo, O.; Mora, J.F.; Noriega-Hevia, G.; Sanchis-Perucho, P.; Serna-García, R.; Zamorano-López, N.; et al. Resource recovery from sulphate-rich sewage through an innovative anaerobic-based water resource recovery facility (WRRF). Water Sci. Technol. 2018, 78, 1925–1936. [Google Scholar] [CrossRef]

- Baquerizo, G.; Fiat, J.; Buffiere, P.; Girault, R.; Gillot, S. Modelling the dynamic long-term performance of a full-scale digester treating sludge from an urban WRRF using an extended version of ADM1. Chem. Eng. J. 2021, 423, 128870. [Google Scholar] [CrossRef]

- Donoso-Bravo, A.; Olivares, D.; Lesty, Y.; Bossche, H. Vanden Exploitation of the ADM1 in a XXI century wastewater resource recovery facility (WRRF): The case of codigestion and thermal hydrolysis. Water Res. 2020, 175, 115654. [Google Scholar] [CrossRef]

- AlSayed, A.; Soliman, M.; Eldyasti, A. Anaerobic-Based Water Resources Recovery Facilities: A Review. Energies 2020, 13, 3662. [Google Scholar] [CrossRef]

- Bryant, C.; Coats, E.R. Integrating dairy manure for enhanced resource recovery at a WRRF: Environmental life cycle and pilot-scale analyses. Water Environ. Res. 2021, wer.1574. [Google Scholar] [CrossRef]

- Ayilara, M.; Olanrewaju, O.; Babalola, O.; Odeyemi, O. Waste Management through Composting: Challenges and Potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Song, J.H.; Murphy, R.J.; Narayan, R.; Davies, G.B.H. Biodegradable and compostable alternatives to conventional plastics. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2127–2139. [Google Scholar] [CrossRef]

- Ileleji, K.E.; Martin, C.; Jones, D. Basics of Energy Production through Anaerobic Digestion of Livestock Manure. In Bioenergy; Elsevier: Amsterdam, The Netherlands, 2015; pp. 287–295. [Google Scholar]

- Velvizhi, G.; Shanthakumar, S.; Das, B.; Pugazhendhi, A.; Priya, T.S.; Ashok, B.; Nanthagopal, K.; Vignesh, R.; Karthick, C. Biodegradable and non-biodegradable fraction of municipal solid waste for multifaceted applications through a closed loop integrated refinery platform: Paving a path towards circular economy. Sci. Total Environ. 2020, 731, 138049. [Google Scholar] [CrossRef] [PubMed]

- Gao, N.; Kamran, K.; Quan, C.; Williams, P.T. Thermochemical conversion of sewage sludge: A critical review. Prog. Energy Combust. Sci. 2020, 79, 100843. [Google Scholar] [CrossRef]

- Heidenreich, S.; Müller, M.; Foscolo, P.U. Advanced Process Combination Concepts. In Advanced Biomass Gasification; Elsevier: Amsterdam, The Netherlands, 2016; pp. 55–97. [Google Scholar]

- Dwivedi, P.; Mishra, P.K.; Mondal, M.K.; Srivastava, N. Non-biodegradable polymeric waste pyrolysis for energy recovery. Heliyon 2019, 5, e02198. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tunçal, T.; Uslu, O. A Review of Dehydration of Various Industrial Sludges. Dry. Technol. 2014, 32, 1642–1654. [Google Scholar] [CrossRef]

- Mininni, G.; Blanch, A.R.; Lucena, F.; Berselli, S. EU policy on sewage sludge utilization and perspectives on new approaches of sludge management. Environ. Sci. Pollut. Res. 2015, 22, 7361–7374. [Google Scholar] [CrossRef]

- Manyi-Loh, C.E.; Mamphweli, S.N.; Meyer, E.L.; Okoh, A.I. Microbial anaerobic digestion: Process dynamics and implications from the renewable energy, environmental and agronomy perspectives. Int. J. Environ. Sci. Technol. 2019, 16, 3913–3934. [Google Scholar] [CrossRef]

- Zhao, G.; Garrido-Baserba, M.; Reifsnyder, S.; Xu, J.-C.; Rosso, D. Comparative energy and carbon footprint analysis of biosolids management strategies in water resource recovery facilities. Sci. Total Environ. 2019, 665, 762–773. [Google Scholar] [CrossRef]

- Grobelak, A.; Grosser, A.; Kacprzak, M.; Kamizela, T. Sewage sludge processing and management in small and medium-sized municipal wastewater treatment plant-new technical solution. J. Environ. Manag. 2019, 234, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Koszel, M.; Lorencowicz, E. Agricultural Use of Biogas Digestate as a Replacement Fertilizers. Agric. Agric. Sci. Procedia 2015, 7, 119–124. [Google Scholar] [CrossRef] [Green Version]

- Hosseini Koupaie, E.; Barrantes Leiva, M.; Eskicioglu, C.; Dutil, C. Mesophilic batch anaerobic co-digestion of fruit-juice industrial waste and municipal waste sludge: Process and cost-benefit analysis. Bioresour. Technol. 2014, 152, 66–73. [Google Scholar] [CrossRef]

- De la Rubia, M.A.; Villamil, J.A.; Rodriguez, J.J.; Borja, R.; Mohedano, A.F. Mesophilic anaerobic co-digestion of the organic fraction of municipal solid waste with the liquid fraction from hydrothermal carbonization of sewage sludge. Waste Manag. 2018, 76, 315–322. [Google Scholar] [CrossRef] [PubMed]

- Villamil, J.A.; Mohedano, A.F.; Rodriguez, J.J.; De la Rubia, M.A. Anaerobic co-digestion of the aqueous phase from hydrothermally treated waste activated sludge with primary sewage sludge. A kinetic study. J. Environ. Manag. 2019, 231, 726–733. [Google Scholar] [CrossRef]

- Seyedi, S.; Venkiteshwaran, K.; Benn, N.; Zitomer, D. Inhibition during Anaerobic Co-Digestion of Aqueous Pyrolysis Liquid from Wastewater Solids and Synthetic Primary Sludge. Sustainability 2020, 12, 3441. [Google Scholar] [CrossRef] [Green Version]

- Ripoll, V.; Agabo-García, C.; Perez, M.; Solera, R. Improvement of biomethane potential of sewage sludge anaerobic co-digestion by addition of “sherry-wine” distillery wastewater. J. Clean. Prod. 2020, 251, 119667. [Google Scholar] [CrossRef]

- Masotti, L. Water Treatment. Techniques and Plants for the Treatment of Wastewater; Calderini: Milan, Italy, 2011. (In Italian) [Google Scholar]

- Tchobanoglous, G.; Burton, F.L.; Stensel, H.D. Wastewater Engineering: Treatment and Reuse, 4th ed.; Metcalf & Mc Graw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Bolzonella, D.; Pavan, P.; Battistoni, P.; Cecchi, F. Mesophilic anaerobic digestion of waste activated sludge: Influence of the solid retention time in the wastewater treatment process. Process Biochem. 2005, 40, 1453–1460. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater, 22nd ed.; Rice, E.W., Baird, R.B., Eaton, A.D., Clesceri, L.S., Eds.; American Public Health Association: Washington, DC, USA, 2012. [Google Scholar]

- Ahring, B.K.; Sandberg, M.; Angelidaki, I. Volatile fatty acids as indicators of process imbalance in anaerobic digestors. Appl. Microbiol. Biotechnol. 1995, 43, 559–565. [Google Scholar] [CrossRef]

- Shi, X.; Lin, J.; Zuo, J.; Li, P.; Li, X.; Guo, X. Effects of free ammonia on volatile fatty acid accumulation and process performance in the anaerobic digestion of two typical bio-wastes. J. Environ. Sci. 2017, 55, 49–57. [Google Scholar] [CrossRef] [PubMed]

- Yirong, C.; Zhang, W.; Heaven, S.; Banks, C.J. Influence of ammonia in the anaerobic digestion of food waste. J. Environ. Chem. Eng. 2017, 5, 5131–5142. [Google Scholar] [CrossRef] [Green Version]

- Dimitrov, R.; Ivanov, Z.; Zlateva, P.; Mihaylov, V. Optimization of biogas composition in experimental studies. E3S Web Conf. 2019, 112, 02007. [Google Scholar] [CrossRef]

- Demirbas, A.; Taylan, O.; Kaya, D. Biogas production from municipal sewage sludge (MSS). Energy Sources Part A Recovery Util. Environ. Eff. 2016, 38, 3027–3033. [Google Scholar] [CrossRef]

- Gaudy, A.F.J.; Bhatla, M.N.; Gaudy, E.T. Use of Chemical Oxygen Demand Values of Bacterial Cells in Waste-Water Purification. Appl. Microbiol. 1964, 12, 254–260. [Google Scholar] [CrossRef] [PubMed]

- Yuan, H.; Zhu, N. Progress in inhibition mechanisms and process control of intermediates and by-products in sewage sludge anaerobic digestion. Renew. Sustain. Energy Rev. 2016, 58, 429–438. [Google Scholar] [CrossRef]

- Im, S.; Mostafa, A.; Kim, D.-H. Use of citric acid for reducing CH4 and H2S emissions during storage of pig slurry and increasing biogas production: Lab- and pilot-scale test, and assessment. Sci. Total Environ. 2021, 753, 142080. [Google Scholar] [CrossRef] [PubMed]

- Tsigkou, K.; Tsafrakidou, P.; Kopsahelis, A.; Zagklis, D.; Zafiri, C.; Kornaros, M. Used disposable nappies and expired food products valorisation through one- & two-stage anaerobic co-digestion. Renew. Energy 2020, 147, 610–619. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).