Drivers and Barriers for Efficient Energy Management Practices in Energy-Intensive Industries: A Case-Study of Iron and Steel Sector

Abstract

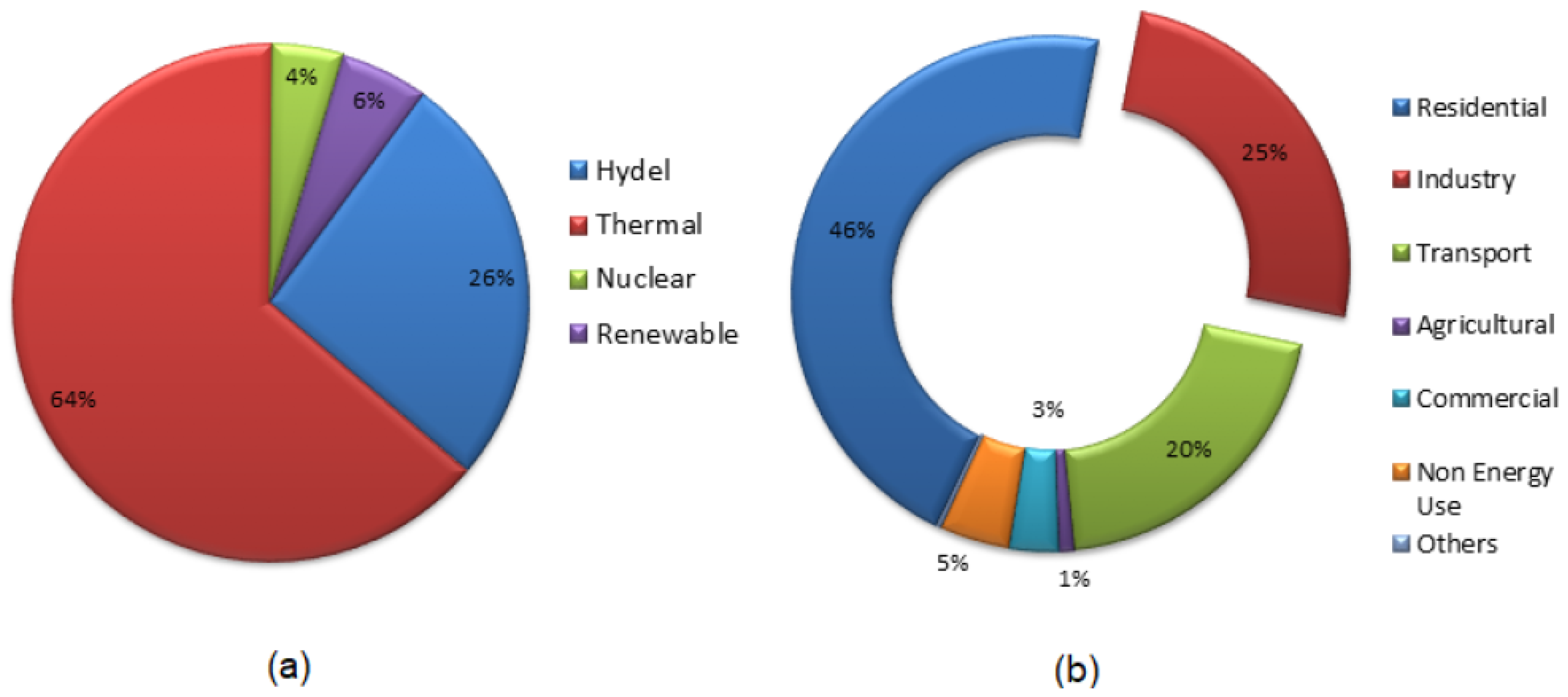

1. Introduction

1.1. Energy Management System Programs for Industrial Sector in Pakistan

1.2. Steel Sector in Pakistan

2. Methodology

- Major barriers to energy efficiency

- Major driving forces for energy efficiency

- Major non-energy benefits with energy efficiency

3. Results and Discussions

3.1. Barriers to Energy Efficiency

3.2. Driving Forces to Work for Energy Efficiency

3.3. Non-Energy Benefits with Energy Efficiency Energy Management Potential

3.4. Useful Energy Efficiency Information Sources

4. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ADD | Anti-Dumping Duty |

| ADF | Asian Development Bank |

| AFD | Agence Française de Développement (French Development Agency) |

| CCPP | Combined Cycle Power Plant |

| CPEC | China Pakistan Economic Corridor |

| EE | Energy Efficiency |

| EECP | Energy Efficiency and Capacity Project |

| EEMP | Energy Efficiency Management Project |

| ENERCON | National Energy Conservation Centre |

| EMS | Environmental Management System |

| IoT | Internet of Things |

| IPPs | Independent Power Producers |

| JICA | Japan International Cooperation Agency |

| GIZ | Gesellschaft für Internationale Zusammenarbeit (Society of International Cooperation) |

| GoP | Government of Pakistan |

| LEAP | Long-range Energy Alternatives Planning System |

| LNG | Liquefied Natural Gas |

| MFF | Multi-tranche Financing Facility |

| NEECA | National Energy Efficiency and Conservation Authority |

| NEPRA | National Energy and Power Regulatory Authority |

| NGO | Non-Governmental Organization |

| OGRA | Oil & Gas Regulatory Authority |

| PEECB | Pakistan Energy Efficiency and Conservation Board |

| RE&EE | Renewable Energy and Energy Efficiency |

| RNE | Royal Netherlands Embassy |

| TEG | Thermoelectric Generator |

| UNIDO | United Nations Industrial Development Organization |

| USAID | United States Agency for International Development |

| WHRS | Waste Heat Recovery System |

References

- Hye, Q.M.; Riaz, S. Causality between Energy Consumption and Economic Growth: The Case of Pakistan. Lahore J. Econ. 2008, 13, 45–58. [Google Scholar]

- Ahmed, M.; Azam, M. Causal nexus between energy consumption and economic growth for high, middle and low income countries using frequency domain analysis. Renew. Sustain. Energy Rev. 2016, 60, 653–678. [Google Scholar] [CrossRef]

- Siddiqui, R.; Jalil, H.H.; Nasir, M.; Malik, W.S.; Khalid, M. The Cost of Unserved Energy: Evidence from Selected Industrial Cities of Pakistan. Pakistan Dev. Rev. 2008, 47, 227–246. [Google Scholar]

- Ahmed, M.; Riaz, K.; Khan, A.; Bibi, S. Energy consumption–economic growth nexus for Pakistan: Taming the untamed. Renew. Sustain. Energy Rev. 2015, 52, 890–896. [Google Scholar] [CrossRef]

- Policy Review and Recommendations on the Promotion of Renewable Energy and Energy Efficiency; Project Report; United Nations Industrial Development Organization: Islamabad, Pakistan, 2016.

- Sabir, U.; Ariwa, E.; Taylor, A. Green technology and energy management systems in developing countries: A case study of Pakistan Textile Industry. In Proceedings of the Third International Conference on Innovative Computing Technology (INTECH 2013), London, UK, 29–31 August 2013; pp. 449–451. [Google Scholar]

- Akhtar, M.; Qamar, A.; Farooq, M.; Amjad, M.; Asim, M. Development of an effective energy management system in power plants of Pakistan. Fac. Eng. Technol. 2016, 23, 77–87. [Google Scholar]

- Zeb, K.; Ali, S.; Khan, B.; Mehmood, C.; Tareen, N.; Din, W.; Farid, U.; Haider, A. A survey on waste heat recovery: Electric power generation and potential prospects within Pakistan. Renew. Sustain. Energy Rev. 2017, 75, 1142–1155. [Google Scholar] [CrossRef]

- Worrell, E.; Martin, N.; Price, L. Potentials for energy efficiency improvement in the US cement industry. Energy 2000, 25, 1189–1214. [Google Scholar] [CrossRef]

- Worrell, E.; Price, L.; Martin, N. Energy efficiency and carbon dioxide emissions reduction opportunities in the US iron and steel sector. Energy 2001, 26, 513–536. [Google Scholar] [CrossRef]

- Fabina, L.; Brockway, W. Alcoa and ArcelorMittal. Available online: https://www.osti.gov/sciencecinema/biblio/1133263 (accessed on 12 December 2013).

- Thollander, P.; Kimura, O.; Wakabayashi, M.; Rohdin, P. A review of industrial energy and climate policies in Japan and Sweden with emphasis towards SMEs. Renew. Sustain. Energy Rev. 2015, 50, 504–512. [Google Scholar] [CrossRef]

- Price, L.; Wang, X.; Yun, J. China’s Top-1000 Energy-Consuming Enterprises Program: Reducing Energy Consumption of the 1000 Largest Industrial Enterprises in China; Technical Report; Ernest Orlando Lawrence Berkeley National Laboratory (LBNL): Berkeley, CA, USA, 2008. [Google Scholar]

- Sun, W.; Cai, J.; Ye, Z. Advances in Energy Conservation of China Steel Industry. Sci. World J. 2013, 2013, 247035. [Google Scholar] [CrossRef]

- Yang, M. Energy efficiency policy impact in India: Case study of investment in industrial energy efficiency. Energy Policy 2006, 34, 3104–3114. [Google Scholar] [CrossRef]

- Patange, G.; Khond, M. Some studies on energy consumptions and identification of suitable energy management techniques in indian foundry industries. Eur. Sci. J. 2013, 9, 241–252. [Google Scholar]

- Panigrahy, R.K.; Panda, A.K.; Patnaik, S. Automation of energy management system in Rourkela steel plant: A case study. Int. J. Energy Technol. Policy 2011, 7, 417–432. [Google Scholar] [CrossRef]

- Alam Hossain Mondal, M.; Kamp, L.M.; Pachova, N.I. Drivers, barriers, and strategies for implementation of renewable energy technologies in rural areas in Bangladesh–An innovation system analysis. Energy Policy 2010, 38, 4626–4634. [Google Scholar] [CrossRef]

- Azad, K.; Rasul, M.; Rahman, M.M.; Bhuiya, M.; Mondal, S.; Sattar, M. Energy and waste management for petroleum refining effluents: A case study in Bangladesh. Int. J. Automot. Mech. Eng. 2015, 11, 2170–21877. [Google Scholar] [CrossRef]

- Hasan, A.S.M.M.; Hoq, M.T.; Thollander, P. Energy management practices in Bangladesh’s iron and steel industries. Energy Strategy Rev. 2018, 22, 230–236. [Google Scholar] [CrossRef]

- Telaga, A.S.; Hartanto, I.D. Industrial Energy Efficiency Practices in Indonesia: Lesson Learned from Astra Green Energy (AGen) Award. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd: Bristol, UK, 2017; Volume 180, p. 012110. [Google Scholar] [CrossRef]

- Apeaning, R.W.; Thollander, P. Barriers to and driving forces for industrial energy efficiency improvements in African industries—A case study of Ghana’s largest industrial area. J. Clean. Prod. 2013, 53, 204–213. [Google Scholar] [CrossRef]

- Kannan, R.; Boie, W. Energy management practices in SME—Case study of a bakery in Germany. Energy Convers. Manag. 2003, 44, 945–959. [Google Scholar] [CrossRef]

- Fleiter, T.; Schleich, J.; Ravivanpong, P. Adoption of energy-efficiency measures in SMEs—An empirical analysis based on energy audit data from Germany. Energy Policy 2012, 51, 863–875. [Google Scholar] [CrossRef]

- Fawkes, S.D. A comparison of British and Japanese industrial energy management. R&D Manag. 1986, 16, 309–316. [Google Scholar] [CrossRef]

- Thollander, P.; Ottosson, M. Energy management practices in Swedish energy-intensive industries. J. Clean. Prod. 2010, 18, 1125–1133. [Google Scholar] [CrossRef]

- Brunke, J.; Johansson, M.; Thollander, P. Empirical investigation of barriers and drivers to the adoption of energy conservation measures, energy management practices and energy services in the Swedish iron and steel industry. J. Clean. Prod. 2014, 84, 509–525. [Google Scholar] [CrossRef]

- Gordić, D.; Babić, M.; Jovičić, N.; Šušteršič, V.; Končalović, D.; Jelić, D. Development of energy management system—Case study of Serbian car manufacturer. Energy Convers. Manag. 2010, 51, 2783–2790. [Google Scholar] [CrossRef]

- Thollander, P.; Backlund, S.; Trianni, A.; Cagno, E. Beyond barriers—A case study on driving forces for improved energy efficiency in the foundry industries in Finland, France, Germany, Italy, Poland, Spain, and Sweden. Appl. Energy 2013, 111, 636–643. [Google Scholar] [CrossRef]

- Ates, S.A.; Durakbasa, N.M. Evaluation of corporate energy management practices of energy intensive industries in Turkey. Energy 2012, 45, 81–91. [Google Scholar] [CrossRef]

- Abdelaziz, E.; Saidur, R.; Mekhilef, S. A review on energy saving strategies in industrial sector. Renew. Sustain. Energy Rev. 2011, 15, 150–168. [Google Scholar] [CrossRef]

- Schulze, M.; Nehler, H.; Ottosson, M.; Thollander, P. Energy management in industry—A systematic review of previous findings and an integrative conceptual framework. J. Clean. Prod. 2016, 112, 3692–3708. [Google Scholar] [CrossRef]

- Nehler, T. A systematic literature review of methods for improved utilisation of the non-energy benefits of industrial energy efficiency. Energies 2018, 11, 3241. [Google Scholar] [CrossRef]

- Worrell, E.; Bernstein, L.; Roy, J.; Price, L.; Harnisch, J. Industrial energy efficiency and climate change mitigation. Energy Effic. 2009, 2, 109. [Google Scholar] [CrossRef]

- Pan, S.Y.; Du, M.A.; Huang, I.T.; Liu, I.H.; Chang, E.; Chiang, P.C. Strategies on implementation of waste-to-energy (WTE) supply chain for circular economy system: A review. J. Clean. Prod. 2015, 108, 409–421. [Google Scholar] [CrossRef]

- Shrouf, F.; Ordieres, J.; Miragliotta, G. Smart factories in Industry 4.0: A review of the concept and of energy management approached in production based on the Internet of Things paradigm. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Bandar Sunway, Malaysia, 9–12 December 2014; pp. 697–701. [Google Scholar] [CrossRef]

- Mirjat, N.H.; Uqaili, M.A.; Harijan, K.; Valasai, G.; Shaikh, F.; Waris, M. A review of energy and power planning and policies of Pakistan. Renew. Sustain. Energy Rev. 2017, 79, 110–127. [Google Scholar] [CrossRef]

- Latif, K.; Raza, M.Y.; Chaudhary, G.M.; Arshad, A. Analysis of Energy Crisis, Energy Security and Potential of Renewable Energy: Evidence from Pakistan. J. Account. Financ. Emerg. Econ. 2020, 6, 167–182. [Google Scholar] [CrossRef]

- Rafique, M.M.; Rehman, S. National energy scenario of Pakistan—Current status, future alternatives, and institutional infrastructure: An overview. Renew. Sustain. Energy Rev. 2017, 69, 156–167. [Google Scholar] [CrossRef]

- Mujahid Rafique, M.; Shakir, M.; Zahid, I.; Chohan, G. An Integrated Long Term Energy Forecasting Approach for Sustainable Energy Mix in Pakistan. In Proceedings of the 2018 International Conference on Power Generation Systems and Renewable Energy Technologies (PGSRET), Islamabad, Pakistan, 10–12 September 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Solangi, Y.A.; Tan, Q.; Mirjat, N.H.; Valasai, G.D.; Khan, M.W.A.; Ikram, M. An Integrated Delphi-AHP and Fuzzy TOPSIS Approach toward Ranking and Selection of Renewable Energy Resources in Pakistan. Processes 2019, 7, 118. [Google Scholar] [CrossRef]

- Ali, Y.; Rasheed, Z.; Muhammad, N.; Yousaf, S. Energy optimization in the wake of China Pakistan Economic Corridor (CPEC). J. Control Decis. 2017, 5, 1–19. [Google Scholar] [CrossRef]

- Junaid, M.; Aasim, M.; Manzoor, S. Potential Barriers to Implementing Energy Management System in Pakistan: A Case of Wet Processing in the Textile Sector. J. Energy Technol. Policy 2020, 10, 36–46. [Google Scholar] [CrossRef]

- Aslam, W.; Soban, M.; Akhtar, F.; Zaffar, N.A. Smart meters for industrial energy conservation and efficiency optimization in Pakistan: Scope, technology and applications. Renew. Sustain. Energy Rev. 2015, 44, 933–943. [Google Scholar] [CrossRef]

- Masood, A.; Muhammad, S.; Iftikhar, S.; Altaf, H.; Ullah, W.; Shabbir, F. Energy Efficiency in Textile Sector of Pakistan: Analysis of Energy Consumption of Air-Conditioning Unit. Int. J. Environ. Sci. Dev. 2015, 6, 498–503. [Google Scholar] [CrossRef][Green Version]

- Nadeem, F. Barriers, Drivers and Policy Options for Improving Industrial Energy Efficiency in Pakistan. Int. J. Eng. 2014, 8, 49–59. [Google Scholar]

- Hassan, M.T.; Burek, S.; Asif, M. Barriers to Industrial Energy Efficiency Improvement—Manufacturing SMEs of Pakistan. Energy Procedia 2017, 113, 135–142. [Google Scholar] [CrossRef]

- NEPRA. State of Industry Report; Technical Report; National Electric Power Regulatory Authority: Islamabad, Pakistan, 2018. [Google Scholar]

- Knoema Enterprose Data Solutions. Available online: https://knoema.com/EIAINTL2018May/international-energy-data-monthly-update (accessed on 1 May 2020).

- Pakistan Economy Survey 2017–18; Ch. 14, Energy; Ministry of Finance, Government of Pakistan: Islamabad, Pakistan, 2018; pp. 209–218.

- NEPRA. State of Industry Report; Technical Report; National Electric Power Regulatory Authority: Islamabad, Pakistan, 2014. [Google Scholar]

- Wing, E.A. Pakistan Economic Survey; Technical Report; Finance Division, Government of Pakistan: Islamabad, Pakistan, 2017. [Google Scholar]

- Rehman, A.; Deyuan, Z. Investigating the Linkage between Economic Growth, Electricity Access, Energy Use, and Population Growth in Pakistan. Appl. Sci. 2018, 8, 2442. [Google Scholar] [CrossRef]

- Church, P.; Kumar, K.; Sowers, F. Assessment of A. I. D. Environmental Programs: Energy Conservation in Pakistan; Technical Report; Agency for International Development: Washington, DC, USA, 1993. [Google Scholar]

- Ortolano, L.; Sanchez-Triana, E.; Afzal, J.; Ali, C.L.; Rebellón, S.A. Cleaner production in Pakistan’s leather and textile sectors. J. Clean. Prod. 2014, 68, 121–129. [Google Scholar] [CrossRef]

- Flohr, H.; Rashid, S. International co-operation for an energetic Pakistani textile industry. Pak. Textile J. 2016, 65, 44. [Google Scholar]

- SBP. The State of Pakistan’s Economy; Second Quarterly Report; State Bank of Pakistan: Karachi, Pakistan, 2016. [Google Scholar]

- Protopopov, E.; Feyler, S. Analysis of current state and prospects of steel production development. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd: Bristol, UK, 2016; Volume 150, p. 012001. [Google Scholar] [CrossRef]

- Knoema Enterprose Data Solutions. Available online: https://knoema.com/SSY2018Dec/steel-statistical-yearbook-2019 (accessed on 1 May 2020).

- World Steel Association. Available online: https://www.worldsteel.org/steel-by-topic/statistics/steel-statistical-yearbook.html (accessed on 1 May 2020).

- SBP. The State of Pakistan’s Economy 2017–2018; Annual Report; State Bank of Pakistan: Karachi, Pakistan, 2018. [Google Scholar]

- Khan, A.S. Steel Bar Sales Slump. Available online: https://www.dawn.com/news/1450353 (accessed on 9 December 2018).

- Pakistan Stock Exchange (formerly known as Karachi Stock Exchange). Available online: http://www.ksestocks.com/ListedCompanies/SortByName (accessed on 1 May 2020).

- Worrell, E.; Van Gent, P.; Neelis, M.; Blomen, E.; Masanet, E. Energy Efficiency Improvement and Cost Saving Opportunities for the U.S. Iron and Steel Industry An ENERGY STAR(R) Guide for Energy and Plant Managers; Technical Rreport; Ernest Orlando Lawrence Berkeley National Laboratory (LBNL): Berkeley, CA, USA, 2010. [Google Scholar]

- Soepardi, A.; Thollander, P. Analysis of Relationships among Organizational Barriers to Energy Efficiency Improvement: A Case Study in Indonesia’s Steel Industry. Sustainability 2018, 10, 216. [Google Scholar] [CrossRef]

- Rohdin, P.; Thollander, P.; Solding, P. Barriers to and drivers for energy efficiency in the Swedish foundry industry. Energy Policy 2007, 35, 672–677. [Google Scholar] [CrossRef]

- Sectoral Analysis on Renewable Energy and Energy Efficiency; Project Report; United Nations Industrial Development Organization: Islamabad, Pakistan, 2019.

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, I.; Arif, M.S.; Cheema, I.I.; Thollander, P.; Khan, M.A. Drivers and Barriers for Efficient Energy Management Practices in Energy-Intensive Industries: A Case-Study of Iron and Steel Sector. Sustainability 2020, 12, 7703. https://doi.org/10.3390/su12187703

Ahmad I, Arif MS, Cheema II, Thollander P, Khan MA. Drivers and Barriers for Efficient Energy Management Practices in Energy-Intensive Industries: A Case-Study of Iron and Steel Sector. Sustainability. 2020; 12(18):7703. https://doi.org/10.3390/su12187703

Chicago/Turabian StyleAhmad, Iftikhar, Muhammad Salman Arif, Izzat Iqbal Cheema, Patrik Thollander, and Masroor Ahmed Khan. 2020. "Drivers and Barriers for Efficient Energy Management Practices in Energy-Intensive Industries: A Case-Study of Iron and Steel Sector" Sustainability 12, no. 18: 7703. https://doi.org/10.3390/su12187703

APA StyleAhmad, I., Arif, M. S., Cheema, I. I., Thollander, P., & Khan, M. A. (2020). Drivers and Barriers for Efficient Energy Management Practices in Energy-Intensive Industries: A Case-Study of Iron and Steel Sector. Sustainability, 12(18), 7703. https://doi.org/10.3390/su12187703