Abstract

Pervious concrete is characterized by its open-void structure, which gives it a number of specific properties and allows specific applications, including pervious pavements, residential roads, alleys, sidewalks, parking lots, patios, and so on. Permeable areas are extremely important for the creation of sustainable cities in terms of the water cycle. Due to its high void content and low cement/mortar content, pervious concrete generally may have significantly reduced strength when compared with conventional concrete. That is why a wide range of research activities is devoted to the balance between acceptable void content, strength, as well as other significant properties. Knowledge of the relationships between the individual properties is very important for understanding this specific material. In this paper, a wide range of 38 different composition variants has been tested to determine the dependencies between the essential properties of pervious concrete. The variables related to the type of aggregate, maximum grain size, the grain-size composition, the amount of binder, and the kind (composition) of binder. The dependencies reported in the article are defined with high reliability R2 ranging from 0.75 to 0.95. On the basis of the dependencies thus determined, it can be predicted that a density of min. 1740 kg/m3 must be reached to meet the requirement of min. 10 MPa for nonpavement applications, while a density of min. 1960 kg/m3 must be achieved to meet min. 20 MPa for pavement applications. The criteria of the void ratio for pavement applications can be set at 20 ± 3%, while the criteria for nonpavement applications can be set at 28 ± 6%.

1. Introduction

Pervious concrete pavement is a pavement type that allows rainwater and other sources of water to percolate into the base layer below the concrete, thus allowing the base material to absorb and control the flow rate of the water as it moves off site. The storm-water management potential is related too. Pervious concrete creates a pavement that allows infiltration of rainwater rather than creating runoff. Because of the infiltration, ground water supplies are recharged, and pollutants are treated. Permeable pavements provide an alternative to traditional impervious pavements; among other things, they contribute to reducing the effect of “heat islands” in cities, thus contributing to the sustainability of urban areas.

Pervious concrete consists of a carefully controlled amount of paste and an aggregate system with a uniform particle size or a narrow particle size distribution and with little or no sand [1,2]. The paste in pervious concrete forms a thick coating around the aggregate particles, binding all the particles together while remaining a substantial amount (15–25%) of interconnected macrovoids in the concrete. As a result, pervious concrete is a highly permeable material.

Because of its environmental benefits, pervious concrete is increasingly used in a variety of infrastructures, including pavements, residential roads, alleys, driveways, sidewalks and pathways, parking lots, low water crossings, tennis courts, subbase for conventional concrete pavements, patios, artificial reefs, slope stabilization, well linings, tree grates in sidewalks, foundations/floors for greenhouses, fish hatcheries, aquatic amusement centers and zoos, hydraulic structures, swimming pool decks, pavement edge drains, groins and seawalls, noise barriers, and walls [3].

These extended applications have demanded that pervious concrete have superior strength and durability. Unfortunately, due to its high porosity and low cement/mortar content, pervious concrete generally may have significantly reduced strength when compared with conventional concrete [1]. That is why a wide range of research activities is devoted to the balance between acceptable porosity and strength [4,5,6].

In order to maintain the functional properties of the permeable concrete, complete procedures must be followed, from the design of the appropriate composition, through the execution steps, to the final quality control, as described in the ACI (American Concrete Institute) 522.1-13 [7] and also in [3,8,9]. Quality control procedures include construction inspection and testing in which a density test is usually used to ensure quality and acceptable values depending on the mix design, but they are usually between 1600 kg/m3 and 2000 kg/m3. Acceptance criteria typically are +/−80 kg/m3 of the target value for the mix design. Postconstruction inspection and testing usually includes thickness of layer and density as quality acceptance tests. Compression testing for strength is not recommended because of the dependence on compaction. However, on-site quality control includes specifications in force at the place of use; this applies to both criteria for specific use and testing methods. The following can be given for properties of hardened pervious concrete:

Density: For pavement applications, density is required to be from 1600 kg/m3 to 2000 kg/m3 [3,8], while according to ACI [7], it should be 1680 to 1920 kg/m3. According to [7,9], the average hardened density of cores shall be +/−5% of the approved hardened density from the test panels. Slovak National Standard [10] requires less than 2000 kg/m3, while a variability of +/−30 kg/m3 is allowed.

Void content (porosity): Different values are specified, starting with min. 15% according to [7], following by 15–25% according to [8,11], min. 20% according to [3] and 18–23% according to [10]. Porosity and density of hardened concrete should be tested according to ASTM C 138 [12], ISO 17785-2 [13], EN 12390-7 [14] or ASTM 1754 [15], which is widely used in experimental works [16,17,18,19].

Coefficient of permeability: A wide range of recommended values up to 17.5 mm/s is presented [17,20,21], with a minimum value of 1.1 mm/s [11] and 2 mm/s [3]. ACI [7] sets this parameter from 1.4 to 12.2 mm/s. Methods for testing the flow rate of pervious concrete include ASTM 1701 [22], ASTM 1781 [23], ISO 17785-1 [24], and the “falling head method” which is widely used in experimental works [16,17,25].

Compressive strength: Typically, 17 MPa is required [3,8], while other authors state min. 20 MPa for pavement applications and 10–20 MPa for nonpavement applications [26]. According to [10], min. 10 MPa is required for the drainage layer and min. 25 MPa for the abrasive top layer of pavement. Tests should be done according to ASTM C 39 [27], EN 12504-1 [28] or EN 12390-3 [29]. In generally available publications, it is possible to find specific results of experiments typically commented on in two ways:

- By expressing the influence of the composition of concrete on its properties: for example, research has shown that the major factors of mix composition that affect pervious concrete strength include the water-to-cementitious material ratio (w/cm), paste characteristic, and size and volume content of coarse aggregates—cement–aggregate proportion [6,17,30,31]. Other works present the influence of composition parameters on the void content and permeability of pervious concrete. A vital role in these properties of the pervious concrete plays the size of the aggregate. Void content and permeability decrease with a decrease in aggregate grain size [32] and presence and amount of fine aggregate [4]. The same is connected with an increasing amount of cement paste [5]. The unit weight of no-fines concrete is found to be marginally affected by the variation in aggregate gradation, cement–aggregate proportion, and w/c ratio [30].

- By expressing the relationships between individual properties: for example, the relationship between porosity and compressive strength for the prediction of compressive strength was defined by [3,33]. A reduction in the void ratio of the pervious concrete mixtures was found to result in an increase in the compressive strength [1,5]. It was also shown that the compressive strength is linearly proportional to unit weight but inversely proportional to porosity [34]. On the basis of summarization of various publications, the relationship between the porosity and permeability of pervious concrete has been found to be exponential—permeability increases exponentially with increasing porosity [35].

However, data for the definition of relationships are often based on testing the narrow range of recipes, focusing on selected parameters of mix composition (i.e., variants in w/c ratio or variants in aggregate/cement ratio) [32,36]. Rarely is the mathematical dependence of properties expressed on a larger range of recipes with different variables, which would describe the material in a more complex way.

In this paper, 38 different composition variants have been tested to determine the dependencies between the essential properties of pervious concrete, so that the identified dependencies are relevant for a wider range of practical applications. The variables related to the following: water/cement ratio (w/c), type of aggregate, maximum grain size (Dmax), the grain-size composition of the aggregate, the amount of binder, and the kind (composition) of binder. The search for significant dependencies was focused on the dependence on the void content as a property that represents the essence of the structure of this concrete and the dependence on the density, which is considered practically useful for the prediction of related properties because of simplicity of laboratory testing. The study was carried out in order to determine as reliable dependencies as possible for practical use in regional conditions based on the inclusion of a certain range of available raw materials as well as generally valid recommendations for the composition of concrete mixtures. The novelty lies in the systematic inclusion of a wide range of raw materials and recipes in testing, thanks to which a high reliability of mathematical dependencies and thus relationships for the prediction of properties has been achieved. Dependencies are analyzed in terms of equilibrium point and equilibrium areas, respectively. The results are commented upon both in terms of general requirements and in terms of the requirements of the Slovak national standard for concrete drainage layers.

2. Materials and Methods

2.1. Materials and Variants of Mixtures

The aim was to determine the influence of various parameters of the composition of pervious concrete on its essential properties and to determine the dependence between them. For this purpose, several groups of experiments were carried out, which were logically connected to each other, each focused on testing practical technological parameters of the composition of mixtures. A total of 38 recipes resulted from their variations, which were tested by the following experimental program:

- Verification of w/c ratio of mixtures with local raw materials (CEM II/A-S 42.5 R, natural aggregate-gravel G, Dmax 8) was chosen as a first step of experimental program. For this purpose, the basic recipe was calculated by volume principle, taking into account the density of individual components. Three variants of w/c were tested (Table 1).

Table 1. Recipes for verification of water/cement ratio.

Table 1. Recipes for verification of water/cement ratio.

- Verification of the kind of aggregate: After analyzing the results, w/c = 0.3 was applied for the following steps of the experiment. Using the same mix composition, five kinds of aggregate were tested (recipes 4–8), including gravel (Geča locality), crushed aggregate (granodiorit-Hradová locality, andesite-Vechec, and Vyšná Šebastová localities) and air-cooled blast-furnace slag aggregate (ACBFSA-US Steel Košice)—5 variants.

For further experimental steps, the following aggregates were chosen:

- -

- natural aggregate-gravel (G, ρd = 2550 kg/m3), based on excellent results as well as the fact that it is one of the most used in the conditions of eastern Slovakia), and

- -

- air-cooled blast-furnace slag aggregate (ACBFSA, ρd = 2595 kg/m3), due to satisfactory results and environmental reasons—the aggregate is locally available and, as waste from the metallurgical industry, arouses high interest in its utilization.

- Verification of the amount of fine aggregate (10%, 15% and 25% of the total weight of the aggregate) and amount of binder (280 kg/m3 and 340 kg/m3)—Table 2. Six variants for G-aggregate + 6 variants for ACBFSA aggregate were tested.

Table 2. Recipes for verification of the amount of fine aggregate and amount of cement.

Table 2. Recipes for verification of the amount of fine aggregate and amount of cement. - Verification of the kind of binder: the best recipe for each aggregate (recipe “11” for G-aggregate and recipe “20” for ACBFSA) were tested with 3 other binder compositions (CEM III/A 32.5 R, 80% CEM II/A-S 42.5 R + 20% of fly ash, 80% CEM III/A 32.5 R + 20% of fly ash), i.e., 3 variants for G-aggregate + 3 variants for ACBFSA aggregate (recipes 21–23 and 24–26).

- Testing the recipes with Dmax 16: keeping the same input parameters (CEM II/A-S 42.5 R, w/c = 0.3, natural aggregate-gravel (G)), as well as the same amounts of binder (280 kg/m3 and 340 kg/m3), different ratios of fractions 0/4, 4/8, and 8/16 were tested—a total of 12 variants (Table 3). The reason for this part lies in obtaining a wider set of results for optimizing grain size in practice.

Table 3. Recipes for verification of different ratios of fractions 0/4, 4/8, and 8/16.

Table 3. Recipes for verification of different ratios of fractions 0/4, 4/8, and 8/16.

The individual concrete mixtures were mixed under laboratory conditions in a laboratory mixer with a forced circulation and a useful volume of 75 L. The mixing procedure consisted of filling the mixer with the whole amount of aggregate, then water was added in an amount of 90% of the total water amount, and the mixture was mixed for 10 s. The whole amount of binder and the remaining amount of water with plasticizer were added to the moistened mixture thus prepared.

Subsequently, the production of test specimens was performed, which were of a cylinder shape with a height of 200 mm and a diameter of 100 mm. Each mold was filled in two layers. The compaction consisted of 15 strokes of a Proctor hammer evenly distributed over the entire cross-section of the sample. The making procedure was in accordance with STN 73 6124-2 [10].

Samples were taken from the molds after 48 h of curing and stored in a water storage. The curing conditions were in accordance with STN EN 12390-2 [37]. The properties were determined after 28 days of setting and hardening.

2.2. Properties

The testing included 4 essential properties of pervious concrete, which were performed according to the following methods:

• Dry Density

The density was determined in accordance with STN EN 12390-7 [14], using samples dried in an oven at 105 °C ± 5 °C. This methodology was chosen with a view to achieving an exact and repeatable state of moisture for the whole set of tested concrete samples. In the testing of building materials, it is common practice to determine the density of saturated, surface-dried samples or samples with natural moisture. In the case of pervious concrete, a different amount of water is present in the saturated, surface-dried state due to variations in its structure. This fact would add a degree of uncertainty to the density values. Volume was determined by measuring the dimensions of samples. Density values were calculated using the Equation (1):

where:

ρd—dry density [kg/m3]

md—mass of dry samples [kg]

V—volume of samples [m3]

• Compressive Strength

Compressive strength was determined in accordance with STN EN 12390-3 [29], according to which the load rate was 0.6 ± 0.2 MPa/s. Steel caps were used to ensure the steadiness of the test surface. The relevant Equation is following (2):

where:

fc—compressive strength [MPa]

F—maximum load at failure [N]

Ac—cross-sectional area of the specimen, on which the load acts [mm2]

• Coefficient of Permeability

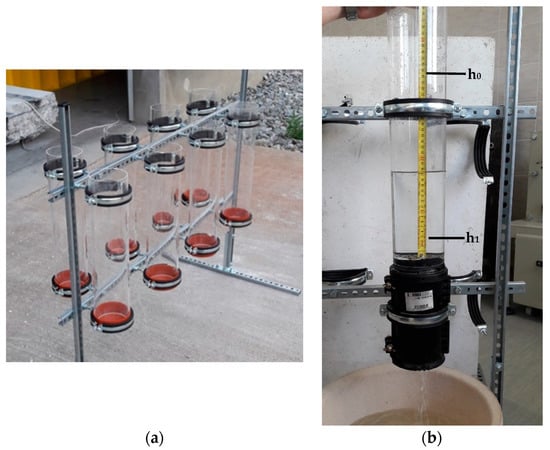

The permeability of the samples was determined using the falling head permeability principle with variable water height, according to [16,17,18]. A suitable device was constructed as shown in Figure 1a. Figure 1b shows the water flowing through the sample placed in the mold (black part of the column) and measuring water levels. The time required for the water level to drop from 350 mm (initial water level in the pipe) to 50 mm (final water level) was measured. The average coefficient of permeability (k) was determined using Equation (3):

where:

Figure 1.

(a) Apparatus for testing the coefficient of permeability. (b) Illustration of measurement of the water level when flowing through the sample.

k—coefficient of permeability [mm/s]

a— cross-sectional area of the standpipe [mm2]

L—length of sample [mm]

A—cross-sectional area of specimen [mm2]

h0—initial water level [mm]

h1—final water level [mm]

t—time for water to drop from h0 to h1 [s]

• Void Ratio

The void ratio of pervious concrete was determined according to [15,17,18] by calculating the difference in weight between the oven-dried sample and the saturated sample in water and using Equation (4). This methodology determines the so-called overall void content, which includes voids and pores that are accessible to water. The weight of sample in water was determined as the difference between the apparent weight of the immersed carrying stirrup with the specimen and the weight of the immersed empty stirrup.

where:

Vr—total void ratio [%]

w1—weight of sample in water [kg]

w2—weight of oven-dried sample [kg]

ρw—density of water [kg/m3]

V—volume of sample [m3]

3. Results and Discussion

The set of results consists of the data of four tested properties (dry density, compressive strength, void ratio, permeability) and 38 different variants of pervious concrete mixtures. Each value represents the arithmetic mean of the results of two (mixtures 9–26) and three (mixtures 1–8 and 27–38) specimens. The range of values of results for tested variants of pervious concrete composition and for subsequent analysis of relationships is as follows:

The bulk density of the tested samples is in the range of 1670–2090 kg/m3. Concretes in accordance with this type of structure mostly belong to the category of lightweight concretes, according to the standard classification [10] (ρ < 2000 kg/m3). Only one of the tested variants exceeded the defined value—a recipe with natural aggregate (G), a high proportion of fine aggregates (25%), and binder (340 kg).

The compressive strength of the tested samples is in the range of 7.1–29.9 MPa. It can be said that the range of strength is sufficient for different requirements, these being different according to the specific practical application. The range of 3.5 MPa–28 MPa is required, with the most common requirement being around 17 MPa [3]. For pavement layers, more than 10 MPa is required for the drainage layer and more than 25 MPa for the abrasive layer [10].

The void ratio of the tested samples is in the range of 16–38%. The applicable range according to [31] is 15–25%, but according to [10] it is 18–23%.

The coefficient of permeability of the tested samples is in the range of 0.9–17.5 mm/s. The most common required value is >2 mm/s [3], while the permeability coefficient at 1 mm/s is the minimum value according to [11].

Next, the relationships between important properties were sought to obtain functions for predicting dependent properties. Coefficients of determination above 0.5 are generally considered highly reliable in predicting the dependent variable, while values above 0.8 represent very high reliability. The dependencies reported in this article were defined with reliability in the range of R2 = 0.75–0.95, as reported below.

3.1. Relationships between Compressive Strength, Permeability, and Void Ratio

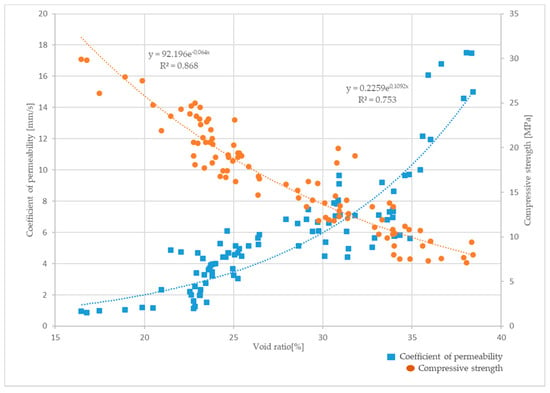

To characterize the pervious concrete in terms of the property that represents the essence of its structure-voidage, dependences with permeability and compressive strength were sought, while all individual sample results were plotted, i.e., 96 values (mixtures 1–8 and 27–38: three specimens and mixtures 9–26: two specimens). These two properties form the basis of the functionality and efficiency of pervious concrete. The exponential dependences were characterized as strongest, as shown in Figure 2.

Figure 2.

Relationship between compressive strength and void ratio and permeability and void ratio.

Relationship between permeability (k) and void ratio (Vr): exponential: (R2 = 0.753). The relationship was found to be similar to that of other authors, who also show that permeability increases exponentially with increasing void ratio by following the functions: (R2 = 0.82) [38], (R2 = 0.79) [39], (R2 = 0.99) [40], and (R2 = 0.993) [1]. Linear functions were also presented, for example by [8]: (R2 = 0.73).

Relationship between compressive strength (fc) and void ratio (Vr): exponential: (R2 = 0.868). A similar result was specified by [5]: (R2 = 0.77). As for the relationship between strength and voidage/porosity, different opinions are presented. While [8] presents a linear function (R2 = 0.75), other authors [41] point out that the existing linear functions relating the strength with pore size characteristics of cement-based material are inadequate in the context of concrete. Therefore, the compressive strength and effective porosity of concrete cannot exhibit a simple linear function, and the relationship is fitted with different functions. Authors say that, among these, the correlation of the logarithmic function was found to be the best (R2 = 0.971).

Figure 2 also shows the equilibrium point of the compressive strength and permeability coefficient variation with the void ratio of the pervious concrete. It helps to find effective ranges of functionality for dependent properties. The effective void ratio of the equilibrium point of the compressive strength and permeability coefficient is approximately 31%, where the compressive strength is 13.0 MPa, and the water permeability is 7.5 mm/s. This is a little bit different than that of [1], with an equilibrium point at 16% of Vr, 21.5 MPa of fc, and 3.2 mm/s of k. This can be explained by a different range of properties, resulting from a smaller set of tested recipes and variants. The authors present the results of 10 recipes with variations in the amount of binder and w/c ratio. Relationships are practically usable for determining the allowed range of void ratio for defined limits of compressive strength and permeability. For example, for pavement applications and limits for functionality of compressive strength (fc = min 20 MPa) and permeability coefficient (k > 1 mm/s), the functional zone for void ratio was found to be 17–23%, which means the criteria of void ratio for pavement applications can be set at 20 ± 3%. This fits with the usual request for Vr = 15–25%, as well as the limits of the national standard (18–23%) [10]. For the tested variants, recipes 3, 11, 13, 14, 21, 23, 27, and 32 are good candidates that meet these requirements. For the same limits for functionality, [1] defines the optimum range from 7.5% to 16.5% as that of providing a theoretical basis for the mix design and performance for the preparation of pervious concrete.

For nonpavement zones, such as gardens, sidewalk, and other similar zones, limits for functionality of compressive strength is 10–20 MPa. In this case, the functional zone for the void ratio is 23–34%, which means the criteria of void ratio for nonpavement applications can be set at 28 ± 6%. Coefficient of permeability falls within 2.8–10.0 mm/s. For the tested variants, all recipes meet these criteria, with the exception of 15, 16, 18, and 19 due to the compressive strength below 10 MPa.

These data are valuable for optimization of the mix-design procedure, which often is based on target value of void ratio/porosity.

3.2. Relationships between Properties and Density

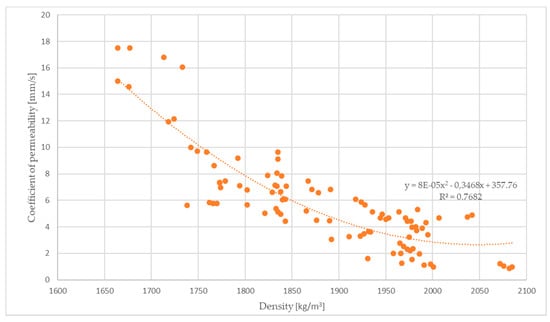

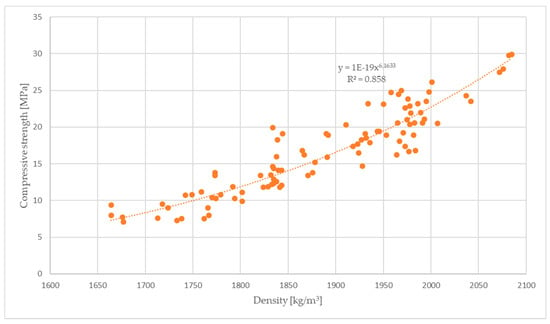

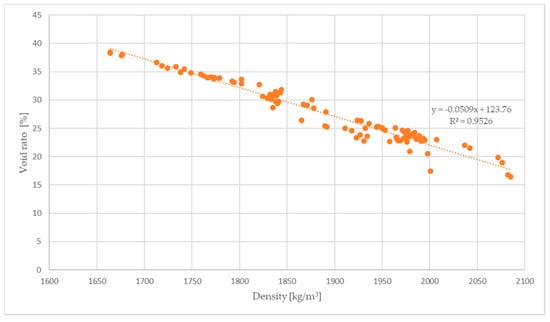

In Figure 2, Figure 3 and Figure 4, the permeability, compressive strength and void ratio are shown in relation to density. Based on the trend line, the following dependencies were found for the given data:

Figure 3.

Relationship between the coefficient of permeability and density.

Figure 4.

Relationship between compressive strength and density.

Relationship between permeability coefficient k and density ρd: as shown in Figure 3, the permeability coefficient of pervious concrete decreased as the density increased in the polynomic function k = 8.10−5.ρd2−0.3468ρd + 357.76 for which the coefficient of determination R2 = 0.768 was found to be the best.

Relationship between compressive strength fc and density ρd: as shown in Figure 4, compressive strength of pervious concrete increased as the density increased in power function, while R2 = 0.858; .

Relationship between void ratio Vr and density ρd: as shown in Figure 5, void ratio of pervious concrete decreased as the density increased in the strong linear function, while R2 = 0.953: . Similar was found by [1]: , R2 = 0.87 (although it was expressed for fresh concrete, the principles of matter are maintained) and by [42]: , R2 = 0.86.

Figure 5.

Relationship between void ratio and density.

For practical reasons, relationships between density and other properties were researched. These could be used to predict permeability, 28-day compressive strength, and the void ratio based on the density values, while limits for allowed variations can be controlled. The practical benefit lies in the simplicity of determining the density of the samples. In this way, it is possible to predict the following using the given relationships:

Nonpavement applications: ACI defines a lower density limit of 1680 kg/m3 with a tolerance of 5%, which allowed 1596 kg/m3 value. However, with the presented range of recipes, to meet the requirement of min. 10 MPa, min. 1740 kg/m3 must be reached. Densities from 1740–1960 kg/m3 provide a strength zone of 10–20 MPa for nonpavement applications. This also meets the national requirement according to [10] for use for drainage layers (min. 10 MPa). In relation to the stated range of density, the coefficient of permeability can be predicted for the values of 10.7–3.3 mm/s, which also meets the stricter limit of at least 2 mm/s. At the same time, the voidage can be predicted in the values of 35–24%, which meets the requirements of the ACI (more than 15%), as well as the Slovak national limit (18–23%).

Pavement applications: In order to meet the requirement of min. 20 MPa compressive strength, a density of min. 1960 kg/m3 must be achieved. Densities from 1960–2010 kg/m3 provide more than 20 MPa for pavement applications. The stated densities are also in tolerance, according to the ACI at the upper limit, i.e., 2016 kg/m3 (1920 kg/m3 + 5%). In relation to the stated range of density according to ACI, the coefficient of permeability can be predicted in the values of 3.3–2.9 mm/s, which also meets the stricter limit of at least 2 mm/s. At the same time, the voidage can be predicted with values of 24–22%, which meets the ACI requirement (more than 15%). For abrasive pavement layers according to national standard [10], min. 25 MPa of compressive strength should be achieved. Only few recipes are promising to achieve this limit, ranging from 1960 to 2010 kg/m3 of density (recipes 21–23). This range complies with the prescribed value (less than 2000 kg/m3, tolerance max. +30 kg/m3, i.e., max 2030 kg/m3). For this allowed tolerance, a coefficient of permeability of min. 2.9 mm/s and voidage of min. 22% can be expected, which fall within a tolerance of 18–23%.

4. Conclusions

The article was focused on the specification of the dependencies between the essential properties of pervious concrete, which could contribute to a deeper understanding of this specific material. At the same time, dependencies are also of practical importance in the possibility of predicting some properties, while the need for real experiments decreases. Then, it is appropriate to choose a simpler property (in terms of procedure or necessary equipment) for the measurement and to derive a more complex property on the basis of dependencies. Of course, these must be defined on the basis of a sufficient set of results and with an acceptable degree of reliability. The dependencies reported in this article are defined based on the results of 38 different variants of recipes and were defined with reliability in the range of R2 = 0.75–0.95. Conclusions may be formulated as follows:

- (1)

- the permeability coefficient of pervious concrete, ranging from 0.9 mm/s–17.5 mm/s, can be predicted as a function of the void ratio, as displayed and a function of density, as displayed k = 8.10−5.ρd2 − 0.3468ρd + 357.76

- (2)

- the compressive strength of pervious concrete, ranging from 7.1–29.9 MPa can be predicted as a function of the void ratio, as displayeds , and a function of density, as displayed ;

- (3)

- the criteria of the void ratio for pavement applications can be set at 20 ± 3%;

- (4)

- the criteria of void ratio for nonpavement applications can be set at 28 ± 6%;

- (5)

- with the presented range of recipes, min. 1740 kg/m3 must be reached to meet min. 10 MPa for nonpavement applications, while min. 1960 kg/m3 must be achieved to meet min. 20 MPa for pavement applications;

- (6)

- recipes 21–23 are promising to achieve the limit of compressive strength above 25 MPa for abrasive pavement layers according to the national standard [10] for which a density ranging from 1960 to 2010 kg/m3 can be predicted.

The relationships were developed on the basis of complex analysis of mix compositions respecting regionally available raw materials of Slovakia, hence they can reduce time for designers to find suitable designs for specific applications, such as pavements, parking lots, subbases for conventional concrete pavements, etc. Moreover, since a large part of the variables covers the generally applicable range of concrete composition, the results may be useful in countries with a similar raw material base (standard blended cements, gravel, granodiorite, andesite, and blast-furnace slag aggregate).

Author Contributions

Conceptualization, A.S.; data curation, M.K.; investigation, A.S. and M.K.; methodology, A.S.; writing—original draft, A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Slovak Scientific Grant Agency VEGA, Grant No. 1/0524/18.

Acknowledgments

This paper was published thanks the Slovak Scientific Grant Agency VEGA.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, Y.; Zhang, Q.; Gao, Y. Manufacturing technology of porous cement concrete for highway construction. In Road Pavement Material Characterization and Rehabilitation, Proceedings of the GeoHunan International Conference; American Society of Civil Engineers: Reston, VA, USA, 2009. [Google Scholar]

- Chen, Y.; Wang, K.; Wang, X.; Zhou, W. Strength, fracture and fatigue of pervious concrete. Constr. Build. Mater. 2013, 42, 97–104. [Google Scholar] [CrossRef]

- Tennis, P.D.; Leming, M.L.; Akers, D.J. Pervious Concrete Pavements; Portland Cement Association: Skokie, IL, USA, 2004; p. 28. [Google Scholar]

- Huang, B.; Wu, H.; Shu, X.; Burdette, E.G. Laboratory evaluation of permeability and strength of polymer-modified pervious concrete. Constr. Build. Mater. 2010, 24, 818–823. [Google Scholar] [CrossRef]

- Deo, O.; Neithalath, N. Compressive response of pervious concretes proportioned for desired porosities. Constr. Build. Mater. 2011, 25, 4181–4189. [Google Scholar] [CrossRef]

- Deo, O.; Neithalath, N. Compressive behavior of pervious concretes and a quantification of the influence of random pore structure features. Mater. Sci. Eng. 2010, 528, 402–412. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI 522.1-13 Specification for Pervious Concrete Pavement; American Concrete Institute: Farmington Hills, MI, USA, 2013; ISBN 9780870318221. [Google Scholar]

- Obla, K.H. Pervious Concrete—An overview. Indian Concr. J. 2010, 84, 9–18. [Google Scholar]

- Ohio Ready Mixed Concrete Association—PCP-2795. Specifier´s Guide for Pervious Concrete Pavement with Detention. 1 December 2014. Available online: https://www.ohioconcrete.org/wp-content/uploads/2015/03/Updated-Final-Dec-1-2014-Ohio-Specifiers-Guide-Pervious-Conc1.pdf (accessed on 18 July 2020).

- Slovak Office of Standards, Metrology and Testing. STN 73 6124-2: Road Construction—Part 2: Concrete Drainage Layers; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2013. [Google Scholar]

- Yahia, A.; Kabagire, K.D. New approach to proportion pervious concrete. Constr. Build. Mater. 2014, 62, 38–46. [Google Scholar] [CrossRef]

- ASTM International. ASTM C138/C138M-17a, Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- International Organization for Standardization. ISO 17785-2: 2018 Testing Methods for Pervious Concrete—Part 2: Density and Void Content; International Organization for Standardization: Geneva, Switzerland, 2018. [Google Scholar]

- Slovak Office of Standards, Metrology and Testing. STN EN 12390-7: Testing Hardened Concrete—Part 7: Density of Hardened Concrete; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2020. [Google Scholar]

- ASTM International. ASTM C1754/C1754M-12, Standard Test Method for Density and Void Content of Hardened Pervious Concrete; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Kevern, J.T.; Wang, K.; Schaefer, V.R. Test Methods for Characterizing Air Void Systems in Portland Cement Pervious Concrete. J. ASTM Int. 2009, 6, JAI102451. [Google Scholar]

- Schaefer, V.R.; Wang, K.; Suleiman, M.T.; Kevern, J.T. Mix design development for pervious concrete in cold weather climates. In Final Report, National Concrete Pavement Technology Center; Iowa State University: Ames, IA, USA, 2006; p. 67. [Google Scholar]

- Montes, F.; Valavala, S.; Haselbach, L.M. A New Test Method for Porosity Measurements of PortlandCement Pervious Concrete. J. ASTM Int. 2005, 2, JAI1293. [Google Scholar]

- Nassiri, S.; Rangelov, M.; Chen, Z. Preliminary Study to Develop Standard Acceptance Tests for Pervious Concrete; Washington State Transportation Center (TRAC), Department of Civil and Environmental Engineering, Washington State University: Pullman, WA, USA, 2017. [Google Scholar]

- Chindaprasirt, P.; Hatanaka, S.; Chareerat, T.; Mishima, N.; Yuasa, Y. Cement paste characteristics and porous concrete properties. Constr. Build. Mater. 2008, 22, 894–901. [Google Scholar] [CrossRef]

- Cackler, E.T.; Ferragut, T.; Harrington, D.S. Evaluation of U.S. and European Concrete Pavement Noise Reduction Methods; National Concrete Pavement Technology Center, Iowa State University: Ames, IA, USA, 2006; p. 96. [Google Scholar]

- ASTM International. ASTM C1701/C1701M-17a, Standard Test Method for Infiltration Rate of In Place Pervious Concrete; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM International. ASTM C1781/C1781M-18e1, Standard Test Method for Surface Infiltration Rate of Permeable Unit Pavement Systems; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- International Organization for Standardization. ISO 17785-1: 2016: Testing Methods for Pervious Concrete—Part 1: Infiltration Rate; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- Ong, S.K.; Wang, K.; Ling, Y.; Shi, G. Pervious Concrete Physical Characteristics and Effectiveness in Stormwater Pollution Reduction. In 2016 Final Report, Institute for Transportation; Iowa State University: Ames, IA, USA, 2006. [Google Scholar]

- Yan, T.; Yuntao, Z.; Henglin, X. Evaluation of the Hydraulic, Physical, and Mechanical Properties of Pervious Concrete Using Iron Tailings as Coarse Aggregates. Appl. Sci. 2020, 10, 2691. [Google Scholar] [CrossRef]

- ASTM International. ASTM C39/C39M-20, Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Slovak Office of Standards, Metrology and Testing. STN EN 12504-1: Testing Concrete in Structures. Part 1: Cored Specimens—Taking, Examining and Testing in Compression; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2020. [Google Scholar]

- Slovak Office of Standards, Metrology and Testing. STN EN 12390-3: Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2020. [Google Scholar]

- Tunio, Z.A.; Memon, B.A.; Memon, N.A.; Lakho, N.A.; Oad, M.; Buller, A.H. Effect of Coarse Aggregate Gradation and Water-Cement Ratio on Unit Weight and Compressive Strength of No-fines Concrete. Eng. Technol. Appl. Sci. Res. 2019, 9, 3786–3789. [Google Scholar]

- Thombre, K.B.; More, A.B.; Bhagat, S.R. Investigation of Strength and Workability in No-Fines Concrete. Int. J. Eng. Res. Technol. 2016, 5, 390–393. [Google Scholar]

- Kishore, R.; Guntakal, S.N. Experimental Investigations on Properties of Pervious Concrete for Its Application in Rural Pavements. Int. J. Eng. Res. Technol. 2017, 8, 111–120. [Google Scholar]

- Kevern, J.; Schaefer, V.; Wang, K.; Suleiman, M. Pervious Concrete Mixture Proportions for Improved Freeze-Thaw Durability. J. ASTM Int. 2008, 5, 1–12. [Google Scholar] [CrossRef]

- Zouaghi, A.; Kumagai, M.; Nakazawa, T. Fundamental study on some properties of pervious concrete and its applicability to control stormwater run-off. Trans. Jpn. Concr. Inst. 2000, 22, 43–50. [Google Scholar]

- Neithalath, N.; Sumanasooriya, M.S.; Deo, M. Characterizing pore volume, sizes, and connectivity in pervious concretes for permeability prediction. Mater. Charact. 2010, 61, 802–813. [Google Scholar] [CrossRef]

- Kovac, M.; Sicakova, A. Pervious Concrete as an Environmental Solution for Pavements: Focus on Key Properties. Environments 2018, 5, 11. [Google Scholar] [CrossRef]

- Slovak Office of Standards, Metrology and Testing. STN EN 12390-2: Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2020. [Google Scholar]

- Sonebi, M.; Bassuoni, M.; Yahia, A. Pervious Concrete: Mix Design, Properties and Applications. RILEM Tech. Lett. 2016, 1, 109–115. [Google Scholar] [CrossRef]

- Luck, J.D.; Workman, S.R.; Higgins, S.F.; Coyne, M. Hydraulic properties of pervious concrete. Trans. ASABE 2006, 49, 1807–1813. [Google Scholar] [CrossRef]

- Huang, B.; Cao, J.; Chen, X.; Shu, X. Laboratory and analytical study of permeability and strength properties of pervious concrete. In Proceedings of the National Ready Mix Concrete Association Concrete Technology Forum: Focus on Pervious Concrete, Nashville, TN, USA, 24–25 May 2006. [Google Scholar]

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and in situ strength of concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

- Putman, B.J.; Neptune, A.I. Comparison of test specimen preparation techniques for pervious concrete pavements. Constr. Build. Mater. 2011, 25, 3480–3485. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).