Abstract

Wherever there are construction activities, there is waste generation. In Ethiopia, the popular material for wall construction is a hollow concrete block that can be broken on the production site or the construction site during loading and unloading and is also found abundantly in demolished buildings. This research aimed at searching for alternative construction materials through recycling and examined the properties of recycled fine aggregate from demolished (old) and construction (new) hollow concrete block (HCB) wastes. The study examined the effect of the recycled HCB on fresh and hardened C-25 concrete properties and the possible replacement percentage of river sand by those recycled fine aggregates. The research also examined the comparative properties of the two recycled fine aggregates. The replacement percentage was in steps of 25%, starting from 25% up to 100%, and 0% represented the reference mix. In general, the recycled fine aggregate exhibited relatively lower physical properties than natural river sand but satisfied the American Society for Testing and Materials (ASTM) standard requirements. The demolished recycled fine aggregate (DRFA) had slightly lower physical properties than the construction recycled fine aggregate (CRFA). The properties of fresh and hardened concrete were decreased as percentage replacement of DRFA and CRFA increased. The optimum percentage replacement of river sand by recycled fine aggregate was between 50% to 75% but was much closer to 75% for that of recycled from construction (new) and closer to 50% for that of recycled from demolished (old) HCB. Recycling wastes can reduce environmental impact due to sand mining and waste disposal as well as partially conserve the natural resource depletion.

1. Introduction

The construction industry’s quick growth has developed a high demand for resource materials. Concrete is one of the most common construction materials used worldwide and will likely remain so in the future, too [1]. Concrete is a composite material that consists of cement as a binding material, sand, and gravel. Sand and gravel are used extensively in the preparation of concrete for buildings and roads. This sand and gravel are mined world-wide and account for the largest volume of solid material extracted globally [2]. A researcher in Ethiopia tried to identify the effects of sand mining on marine biology and concluded that sand mining activities interfere with fish migration and affect the spawning populations early in their life stage by polluting the water, destroying the spawning grounds (especially the gravel beds), removing vegetation, and damaging the fishes [3]. It can affect marine life as well as lead to the depletion of natural resources due to the lack of sustainability/rejuvenation of materials.

The construction industry is one of the sectors that contributes waste to the environment in large quantities. The waste generated from the construction industry in developing countries is enormous due to poor management practices. Additionally, the rate of construction is high due to quick urbanization, industrialization, and economic development [4]. The major problem in the construction industry is the disposal of construction wastes. These waste materials are directly dumped into the environment as landfills, and this can cause environmental pollution. However, the environmental impact must be reduced by using waste for different purposes. To better preserve the environment for sustainable development, finding all possibilities and opportunities for reducing the waste products of work areas has to be a major focus [1,5].

For the construction of walls, the popular material used in Ethiopia is HCB [6]. Most construction sites as well as HCB production sites have plenty of HCB wastes. HCB can be broken on production sites or construction sites during loading and unloading, which of itself can create wastage. These wastes are found collectively in a site with different sizes and different amounts and are disposed to the disposal site as landfill. The recycling of concrete structures as concrete aggregate in Ethiopia was investigated, and promising results were found [4]. The physical properties of recycled concrete aggregate are within the range of normal weight aggregate. However, the properties of recycled concrete aggregate are lower than the properties of natural coarse aggregate. Recycling of wall materials, HCB wastes, is crucial due to their abundancy in demolished as well as in construction/production site wastes.

This research focused on the recycling of wastes generated from HCB as an alternative construction material. This research consisted of preparation of recycled fine aggregate from HCB wastes (resizing, crushing, gradation, and purification), characterization of the recycled fine aggregate (silt content, sieve analysis, moisture content, specific gravity, water absorption), and investigation of the effect of recycled fine aggregate on properties of concrete at fresh and hardened states.

2. Literature Review

The recycling issue was started at the end of the second world war by recycling the demolished brick as aggregate by crushing [7]. Recycled concrete aggregate from demolished and construction wastes was used as a subbase for past decades; recently, however, advanced investigation into the properties of recycled concrete aggregate is occurring.

In recycling the demolished concrete waste, Yadhu et al. [8] reused the demolished concrete waste as fine aggregate. From the study, the compressive strength of concrete with crushed demolished waste as a replacement of fine aggregate had a lower value than the normal concrete. However, it could be used in construction members that do not carry much load. Thus, in general, they concluded that the crushed demolished and construction waste can be used as a replacement of conventional sand as a fine aggregate but needs further investigation into how extensively it can be used as a replacement.

Recycling was advanced by enhancing the quality of the recycled aggregate. Medhat et al. [5] investigated the properties of the recycled concrete aggregate of high quality that were produced through the technique of preserving the original properties of the aggregate. As per the comparison made on the effect of recycled concrete aggregate and commercial recycled concrete aggregate, the preserved quality had better compressive strength, drying shrinkage, and salt scaling resistance. This investigation enhanced the recycled concrete aggregate quality by preserving the recycled concrete aggregate. Martinelli et al. [9] investigated the procedure of removing impurities of recycled concrete aggregate and examined their influence on physical and mechanical properties of concrete at fresh and hardened states. The researchers came with the feasibility of autogenous cleaning that could remove the surface impurities of recycled concrete aggregate as well as reduce particle heterogeneities. To reduce heterogeneity, they removed the residual wood, plastics, and steels from demolished debris, and to reduce the amount of fine particles attached on the surface of recycled concrete, autogenous cleaning was performed. The cleaning procedure enhanced the recycled aggregate quality, and this improved the properties of the concrete with recycled aggregate at fresh and hardened states. The fine particles attached on the surface of the recycled concrete aggregate increased the water absorption capacity of recycled fine aggregate and also had a lower density than natural aggregate [4,5,9]. Thus, the compressive strength was less than the conventional concrete due to the high water absorption capacity of the recycled fine aggregate. Park et al. [10] evaluated the surface modification of recycled fine aggregate to reduce the water absorption rate and increase density by aqueous H2SiF6 solution. The modified recycled aggregate showed more improvement than the recycled aggregate before modification in mechanical properties of both compressive and flexural strength. Thus, they concluded that the surface treatment method using the H2SiF6 solution is effective in improving high water absorption capacity and low density of recycled fine aggregate. The recycling of demolished and construction waste is prompted from time to time worldwide with enhanced treatment procedures, but not in Ethiopia.

Ethiopia is one of the developing countries in which the concept of recycling construction and demolition waste has not yet been implemented [4]. In Ethiopia, the solid waste management proclamation No. 513/2007 enforces the disposal of construction and demolition wastes to use as landfill. This indicates that Ethiopia is behind on the recycling of construction and demolition wastes. However, for the last seven years, some research [4,11] was undertaken on the recycling of construction and demolition wastes. Woubishet [4] assessed the suitability of recycled aggregate in concrete and the effect of recycled concrete aggregate on concrete properties. The crushed concrete as coarse aggregate in concrete was checked for workability, compressive strength, and permeability properties as compared to the control mix. The researcher concluded that the physical properties of recycled concrete aggregate had fewer physical properties than the original aggregate but was within the required standard limit. Lucy et al. [11] investigated the recycling of demolished hollow concrete blocks as fine aggregate in concrete. The physical properties of recycled fine aggregate and the effect of replacement of natural sand by recycled fine aggregate on fresh and hardened properties of concrete were investigated through local technology and methods. The replacement of natural sand by recycled fine aggregate of up to 50% was attained at the standard limit but was slightly lower than the conventional concrete.

Recycling demolished and construction waste in Ethiopia is far behind compared to the achievement in other parts of the world. This study is significant in that the recycling issue is directly related to sustainability. This study aimed to recycle the construction wastes to fine aggregate by enhancing the quality of the recycled fine aggregate and to compare the effect of fine aggregate recycled from demolished waste (old) and construction waste (new) on concrete properties. In recycling, homogenization of demolished and construction wastes, cleaning, and washing were the procedures to enhance the quality of the recycled fine aggregate.

3. Experimental Program

In this section, the materials used for experimental purposes are elaborated. The properties of all materials used were checked per standards. Further treatment occurred after crushing to enhance the quality of recycled fine aggregate from construction and demolition wastes. Some tests were conducted to determine the properties of recycled fine aggregate. In this study, 81 experimental samples were prepared for nine different tests of fresh and hardened concrete properties. The data were collected from Jimma, Ethiopia, and experimental studies were undertaken in Jimma University’s construction laboratory. All experiments were conducted and compared to the American Society for Testing and Materials (ASTM), American Concrete Institute (ACI), and Ethiopian Standard (ES) standards according to the local technical specification [12]. Some standards used in Ethiopia were amended according to local methodology and technology.

3.1. Materials

3.1.1. Cement

As a binding material, Dangote Ordinary Portland cement with a strength class of 42.5 N was used. The cement obtained from a single batch was used throughout the test with compliance to ASTM standard specifications. The cement specific gravity, fineness, and normal consistency were conducted as per the ASTM standard.

3.1.2. Water

Potable tap water was used for concrete mixing and curing. For the coarse aggregate, locally available crushed stone aggregate with a nominal size of 20 mm was used. The specific gravity, water absorption, and fineness modulus properties of coarse aggregates were checked as per the ASTM standard [11]. The coarse aggregate used in this experiment is well graded.

3.1.3. Sand

There were two types of sand used for this research work, locally available river sand and recycled fine aggregate. The local river sand used was checked for silt content, gradation, absorption capacity, moisture content, unit weight, and bulk specific gravity as per ASTM standards [11].

The recycled fine aggregate from the construction waste of HCB was collected from HCB production sites found in the city of Jimma, which is called Degene Tsedale Hebret and Lemlem (DTHL), as shown in Figure 1, to avoid contamination in construction sites such as mortar, gypsum, and painting. The HCB used for this experimental purpose had an age of two months and was stocked to be used in construction. The HCB was processed to get recycled fine aggregate as per the following steps and as per the technique shown in Figure 2.

Figure 1.

Site of the sample collection.

Figure 2.

Different phases of preparing recycled fine aggregate.

- Selection: non-load bearing HCB, which was manufactured according to the specification of ASTM C 129–70 [13], and those that had the same aging were selected. According to ES 596–2001, a non-load bearing HCB used for partition was recycled;

- Re-sizing/crushing: re-sizing included breaking the HCB by rock hammer to the appropriate size for the crushing machine. Then, the crushing machine was crushed to a different size, which had both fine and coarse aggregate sizes;

- Grading: identifying different sizes of recycled aggregate to recycled fine and coarse aggregate through sieving. The recycled aggregates that passed through 4.75 mm sieve size were considered as fine aggregate, and fine particles that passed through sieve size No.100 (150 µm) were avoided;

- Washing and floatation: the crushed recycled fine aggregate had the fine particle from mortar and some lightweight floating materials. Washing the recycled fine aggregate reduced the silt content and increased the quality of the materials.

The physical properties of recycled fine aggregate, silt content, sieve analysis, unit weight, moisture content, specific gravity, and water absorption were tested as per the ASTM standard, and the results are summarized in Table 1. For river sand, the silt content was within the required limit at less than 6% [11], but the silt content of recycled fine aggregate from construction HCB was washed to attain the limit. The cement powder from HCB and fracture dust during crushing was the cause for high fine particles that passed through the 150 µm sieve size. The silt content of the recycled fine aggregate from a demolished HCB was higher than the recycled fine aggregate from production site HCB wastes. From Table 1 and Table 2, the fine particles that passed through the 150 µm sieve size were 1.5% for demolition recycled fine aggregate (DRFA) and 1% for construction recycled fine aggregate (CRFA). The silt content test was done by washing the finer particle less than 75 µm as per ASTM C 117–90 [14]. From Table 1, the silt contents of DRFA and CRFA were 4.2% and 3.9%, respectively. The DRFA had more fine particles than the CRFA due to fine particles from plastering, gypsum, and mortar between the HCBs as a joint. In CRFA, the fine particles were from the cement in HCB and were due to fracture from crushing.

Table 1.

Sieve analysis of recycled fine aggregate from demolished hollow concrete block (HCB) waste.

Table 2.

Sieve analysis of recycled fine aggregate from construction HCB waste.

The unit weight of the CRFA was less than that of the river sand and was the same as previous research findings [4,11]. Less unit weight was due to the porous cement mortar materials attached on the surface of the CRFA and the finer particles from old cement. The unit weights of DRFA and CRFA were nearly the same and were also within an acceptable range of ASTM standards, and the test was done as per ASTM Designation C-29 procedure [15].

The water absorption capacities of CRFA and DRFA were checked since water absorption capacity is a vital criterion for mix design. As per ASTM requirements, the water absorption capacities of recycled fine aggregate from both sources were higher due to fine particles and due to adhered mortar. The water absorption capacity of the DRFA (6.84%) was higher than those of CRFA (5.1%) and river sand (1.73%) [11].

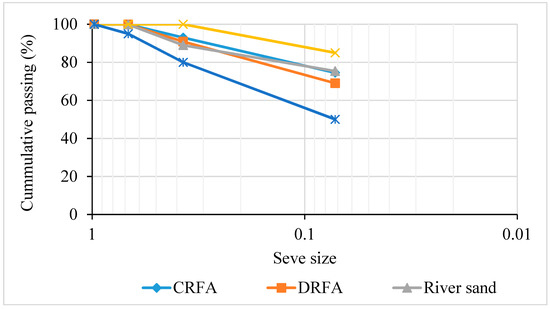

From Figure 3, the particle size distribution curve of river sand and both types of RFA was between the upper and the lower limit, which satisfied the ASTM standard requirement. The fineness modulus of the sand varied from fine sand 2.2–2.6, medium sand from 2.6–2.9, and coarser sand from 2.9–3.2. The fineness modulus of both types of RFA was in the range of 2.6–2.9. Therefore, both DRFA and CRFA were medium sand types.

Figure 3.

Gradation curve of recycled fine aggregate and river sand.

3.2. Tests

For the results obtained from crushed and processed demolished and construction HCB wastes, three different mixtures were designed to analyze the properties of fresh and hardened concrete. The concrete mix type with only natural sand was used as a control mix or reference mix with “Co” designation. “DRFA“ was a mixture type with recycled fine aggregate from demolished HCB wastes, and “CRFA” was a mixture type with recycled fine aggregate from construction HCB wastes with a different replacement percentage. For both mixtures with recycled fine aggregate, replacement percentages of 25%, 50%, 75%, and 100% were designed. All the concrete mixes were prepared according to the weight-based batching system as per ACI 211.1.91 [16]. All ingredients were the same for all mixes except the water/cement (w/c) ratio and the fine aggregate proportions. The reference mix samples were produced with 370 kg/m3 and 0.55 w/c ratios. For concrete with recycled fine aggregate, additional water was poured during the mixing to compensate for the water absorption capacity according to the test results of water absorption capacity of CRFA and DRFA in Table 3.

Table 3.

Summary of properties of CRFA and DRFA.

A slump test is the most common technique for evaluating the workability. The freshly mixed concrete was placed in a mold shape as frustum and compacted by rodding. The cone with a 10 cm top diameter, a 20 cm bottom diameter, and a 30 cm height was filled with freshly prepared concrete in three stages. Each layer was tamped 25 times using a rod of standard dimensions (16 mm) [20]. The settlement of concrete was measured from the molded truncated cone.

The mix design in Table 4, was done to achieve a compressive strength of 25 MPa with different percentages of replacement of CRFA for non-air entrained normal strength concrete. C-25 concrete is commonly used in Ethiopia in structural members such as beams, columns, and slabs [21]. For the compressive strength test, the concrete specimens were cast in a 150 mm ∗ 150 mm ∗ 150 mm cube steel mold, and the experiments were performed at the seventh, the 14th, and the 28th days of the curing period. The specimens were demolded after 24 h of casting and placed in a water bath at room temperature (23 °C) until tested. The tests were undertaken in Jimma University’s construction laboratory in December 2018. During the testing of compressive strength, a calibrated compression machine with a uniform rate of 5 N/mm2 per second loading was maintained, and the maximum load to failure at which the specimen broke were noted. The compressive machine provided the compressive strength directly, or it could be found by dividing peak load by area of the sample.

Table 4.

The mix composition of concrete cubes.

4. Results and Discussions

This section reports the summary of the experimental test results with the discussion of concrete with recycled fine aggregate as compared to the reference mix as well as the comparison of the concrete properties at fresh and hardened states of concrete with recycled aggregate from demolished and construction wastes.

4.1. Fresh Concrete Properties

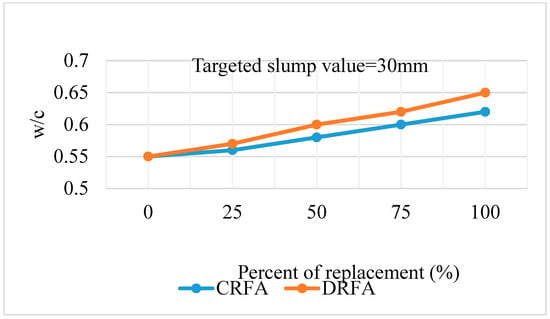

Workability test: The consistency of the concrete mixes at a fresh stage was determined in the laboratory by the slump test as per ASTM C 143 [20]. In the concrete mix design, a maximum aggregate size of 20 mm, a slump range between 25 and 50 mm, and 185 kg of water were used in accordance with ACI standard procedure [19]. The slump value for adjusted w/c ratio of normal concrete was 30 mm. To maintain uniform workability of concrete containing recycled fine aggregate, the w/c was increased. The slump value for the concrete with recycled fine aggregate with a constant w/c ratio (0.55) was less than 15 mm. As per ASTM C143 [20], concrete that had a slump value of less than 15 mm may not be adequately plastic, and concrete with a slump value higher than 230 mm may not be sufficiently cohesive. The workability of the concrete mix is mostly affected by consistency. The wetter the mix is, the more workable the concrete is. A concrete mix with the same consistency may vary in workability. The mix was dry due to the water absorption capacity of the CRFA. Adjusting for moisture and the water absorption capacity of the CRFA enabled us to attain uniform workability of concrete. Thus, the water required for the mix increased as the percentage of replacement of CRFA increased.

Water/cement ratio: The water/cement ratio varied for each percentage replacement of the CRFA due to the absorption capacity of the CRFA as shown in Figure 4. The amount of water required increased as the percentage of replacement of recycled fine aggregate increased. To maintain the workability of concrete containing recycled fine aggregate, the water/cement ratio ranged from 0.55 for the reference mix to 0.61 for the mix with 100% CRFA. The reason for the increment of w/c was due to the high absorption capacity of CRFA, which was 5.1%. From Figure 1, the water absorption capacity of DRFA (6.84%) [11] was slightly higher than that of CRFA (5.1%). The previous studies also agreed on the high water absorption capacity of the recycled fine aggregate due to the dust and the hardened porous cement mortar adhered to it [4,11,22]. DRFA could have had remaining gypsum, plastering, painting, and ceramics wastes after separation and purification processes were undertaken since the materials were from a demolished student dormitory. The water absorption capacity of recycled fine aggregates was higher than the normal aggregates, and the researcher [23] found that recycled aggregate can have 8–10% water absorption capacity.

Figure 4.

Comparison of water/cement ratio of CRFA and DRFA.

4.2. Properties of Hardened Concrete

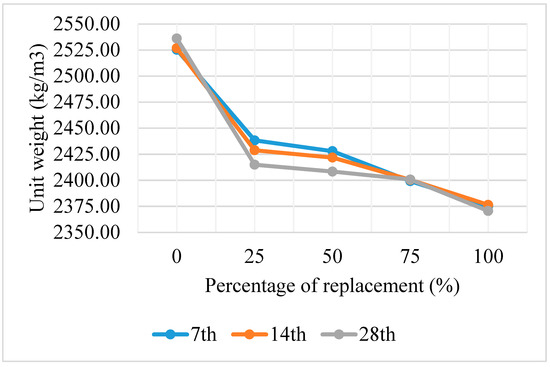

4.2.1. Unit Weight of Hardened Concrete

The unit weight of hardened concrete was measured before the compressive strength test. The unit weight of hardened concrete with recycled fine aggregate with different percentages was compared to the control/reference specimen in Figure 5. There was a decrement of unit weight of hardened concrete as a percentage of replacement of recycled fine aggregate increased [4,23]. This decrement was due to fine particles from mortar and old mortar attached to it. From the material unit weight test, it was checked that the unit weight of the CRFA (1202 kg/m3) was less dense than the natural river sand (1605 kg/m3). The unit weight of CRFA was also very closer to that of DRFA (1229.1 kg/m3). Therefore, the unit weight of the hardened concrete from CRFA and DRFA nearly had a closer density but was lesser than the reference mix density of hardened concrete.

Figure 5.

Unit weight of hardened concrete.

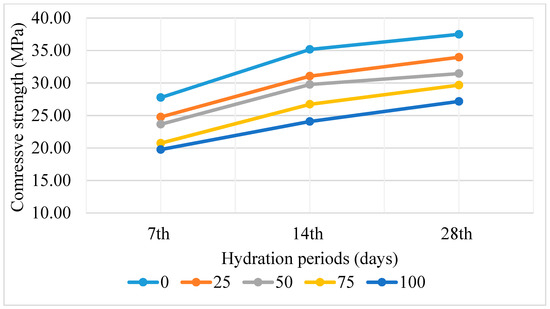

4.2.2. Compressive Strength

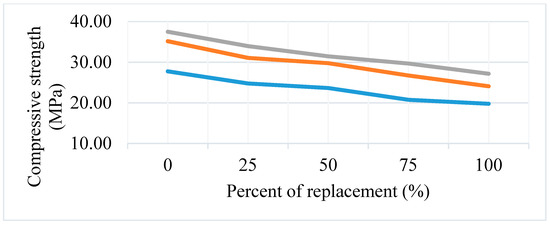

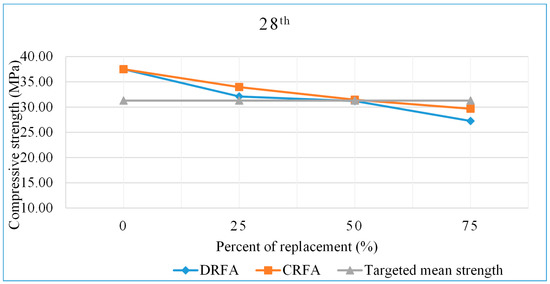

The compressive strength test was performed using 150 ∗ 150 ∗ 150 mm cubes in which the specimens were cast. In a compressive strength test, to be accurate and consistent, replication of the consecutive results was applied by taking three samples for each percentage and each curing period. Figure 6 provides the results of the compressive strength test of reference mixes and mixes with recycled fine aggregate. The compressive strength result of the reference mix sample for the seventh, the 14th, and the 28th days of the hydration period increased from day to day due to the ongoing hydration process. As can be observed from Figure 4, the compressive strength of concrete samples with CRFA had a lower compressive strength value than the control mix. For the 28th day compressive strength, the sample with CRFA was reduced by 9.43% from the reference mix for 25% replacement and by 16.1% for the 50% replacement. Thus, the compressive strength decreased as the percentage of the replacement of the CRFA increased. Additional water was added to the mix due to water required for the compensation of the high water absorption capacity of CRFA. This extra water added to the mix increased the w/c ratio. From a previous study [9], the compressive strength of concrete with recycled aggregate concrete was reduced by 20% compared to the reference mix, and they concluded that this was due to the high amount of absorption compensation water that increased the w/c ratio.

Figure 6.

Variation of the compressive strength with hydration period.

The compressive strength of concrete with 25% and 50% CRFA replacement attained the targeted mean strength of C-25 concrete, but for concrete with 75% CRFA, it failed to attain the targeted strength. The optimum percentage of replacement of CRFA fell between 50% and 75% but was closer to 75%. Thus, we need to investigate in small interval replacement percentages from 50% to 75% to find the exact optimum replacement percent. From previous research, the optimum percentage of replacement of crushed waste sandcrete blocks [24] was 50%. The same phenomena existed for a similar investigation on demolished HCB replacement as fine aggregate, and the optimum replacement percentage was 50% [11]. Figure 6 shows the relationship between the compressive strength and the rate of replacement of recycled fine aggregate on the seventh, the 14th, and the 28th days of curing.

In this experiment of different mixes for different percentages of recycled fine aggregate replacement for the seventh, the 14th, and the 28th days, the consistency among the value was checked and is shown in Figure 7. The coefficient of determination (R2-value) ranged from 0.9725 to 0.986. The results were closer to one, which implied that the concrete properties had a high degree of accuracy and consistency throughout the tests.

Figure 7.

Relationship of the compressive strength with CRFA replacement.

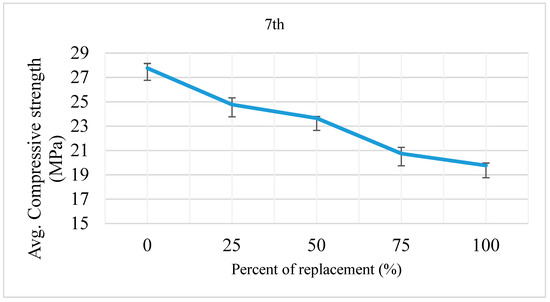

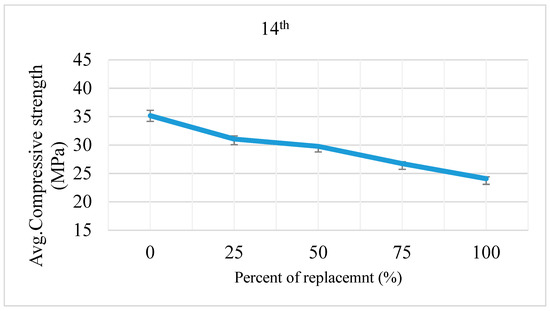

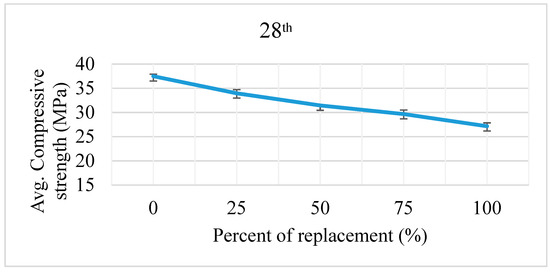

Figure 8, Figure 9 and Figure 10 show the error bar for the compressive strength of the seventh day, the 14th, and the 28th day. This shows how much the measurements of the samples were spread out from the average result. For different samples of concrete mix, the error bar shows how much the data varied and how much they scattered.

Figure 8.

Error bar for the seventh day compressive strength.

Figure 9.

Error bar for the 14th day compressive strength.

Figure 10.

Error bar for the 28th day compressive strength.

4.3. Comparison of CRFA and DRFA

The CRFA, as compared to the DRFA [11], had slightly higher physical properties. Both were tested after floatation and washing as well as handpicking for demolished wastes. The silt content of DRFA (4.2%) was higher than that of CRFA (3.9%) due to many sources of fine particles in DRFA. These fine particles increased the water absorption capacity of the DRFA (6.84%), and the CRFA had 5.1%. The silt content and the water absorption capacity of recycled fine aggregate could directly affect fresh and hardened concrete properties.

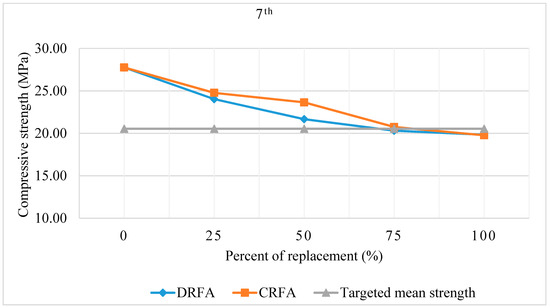

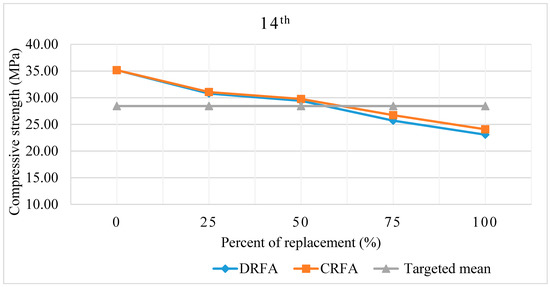

The compressive strength of concrete with DRFA was relatively lower than the concrete with CRFA. In the experimental investigation, the concrete with both types of recycled fine aggregates attained the targeted mean strength at 50% but failed to attain the target at 75%. However, the compressive strength of concrete with DRFA at 50% was less than that of CRFA concrete at 50% replacement. The concrete with CRFA could replace the natural sand above 50 %, but DRFA could not replace natural sand above 50% without further treatment. From Figure 11, Figure 12 and Figure 13, the compressive strength of concrete with CRFA and DRFA for the seventh, the 14th, and the 28th days of the curing period were decreased as percentage of replacement increased. For the seventh day curing period, the compressive strengths of both DRFA and CRFA attained the targeted mean strength up to 75% of replacement. For the 14th and the 28th days of curing, the intersection of compressive strength of CRFA and DRFA with mean targeted strength was between 50% and 75% replacement percentage, indicating the optimum amount of replacement was between 50% to 75%.

Figure 11.

The seventh day compressive strength of DRFA and CRFA.

Figure 12.

The 14th day compressive strength of DRFA and CRFA.

Figure 13.

The 28th day compressive strength of DRFA and CRFA.

5. Conclusions

In this research, the properties of the recycled fine aggregate from a production site of HCB were examined and compared with the ASTM standard requirement of fine aggregates. The recycled fine aggregate from production site HCB was compared to the recycled fine aggregate from demolished HCB.

Generally, the recycled fine aggregate exhibited relatively lower physical properties than natural river sand. Gradation, silt content, specific gravity, water absorption capacity, moisture content, and bulk density satisfied the ASTM requirements.

- Recycled fine aggregates had high water absorption capacity and higher silt content than the natural river sand, which could affect the concrete properties at fresh and hardened states.

- High silt content was due to fine particles from crushing and from the mortar in the HCB, which could increase the absorption capacity of the recycled fine aggregate.

- In recycling construction waste to increase the quality of the recycled fine aggregate, some purification procedures had to be applied, such as identifying different wastes in their category and types. After crushing, washing reduced the silt content, and floatation could reduce lightweight materials in recycled fine aggregate.

- The recycled fine aggregate had a lower unit weight than the natural river sand, and thus the density of hardened concrete was also lower than the reference mix unit weight, and this was due to the old mortar.

- The concrete from recycled fine aggregate had a higher w/c ratio than the reference mix for uniform workability.

- As the percentage of replacement of CRFA increased, the compressive strength decreased. The CRFA could replace the natural river sand by more than 50% but not up to 75%.

- The compressive strength of concrete with 50% CRFA replacement attained the targeted mean strength of C-25 concrete, but for concrete with 75% CRFA, it failed to attain the targeted strength. The optimum percentage of replacement of CRFA fell between 50% and 75% but was closer to 75%.

- The recycled fine aggregate from demolished HCB (old) wastes had slightly fewer physical properties compared to the construction (new) HCB wastes. The DRFA had higher silt content and high water absorption capacity due to different wastes from plastering, gypsum, painting, and joint mortar of HCB construction.

- This research indicated that the replacement percentage of CRFA was higher than that of DRFA [11] and also higher than [24] previous studies on recycling demolition waste sandcrete as aggregate.

From this research, the construction and the demolition HCB wastes could replace the natural river sand up to 50%, and this could reduce environmental impacts due to waste disposal and river sand mining.

Author Contributions

Conceptualization, L.F.N.; Methodology, L.F.N.; Data collection and Formal analysis, L.F.N.; Investigation, L.F.N.; Validation, L.F.N.; Original draft writing and editing, L.F.N.; Supervision and editing, M.M.D., T.G.; Project Administration, M.M.D., T.G.

Funding

This research was funded by the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ), and the APC was funded by Jimma University Institute of Technology and Texas Tech University.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Said, M.; Ait-Medjber, F.; Safi, B.; Samar, M. Recycling of Aggregates from Construction Demolition Wastes in Concrete: Study of Physical and Mechanical Properties. Int. J. Civ. Environ. Struct. Constr. Archit. Eng. 2014, 8, 1307–1311. [Google Scholar]

- de Jorge, B.; Catarina, N.; Rosário, V. Using Fine Recycled Concrete Aggregate for Mortar Production. Mater. Res. 2014, 17, 168–177. [Google Scholar]

- Minwyelet, M.; Shewit, G. Could sand mining be a major threat for the declining endemic Labeobarbus species of Lake Tana, Ethiopia? Singap. J. Trop. Geogr. 2016, 37, 195–208. [Google Scholar]

- Taffese, W.Z. Suitability Investigation of Recycled Concrete Aggregates for Concrete Production: An Experimental Case Study. Adv. Civ. Eng. 2018, 2018, 8368351. [Google Scholar] [CrossRef]

- Andal, J.; Shehata, M.; Zacarias, P. Properties of concrete containing a recycled concrete aggregate of preserved quality. Constr. Build. Mater. 2016, 125, 842–855. [Google Scholar] [CrossRef]

- Sewnet, H.; Cherenet, Z. Building Ethiopia: Sustainability and Innovation in Architecture and Design; Ethiopian Institute of Architecture, Building Construction and City Development: Addis Ababa, Ethiopian, 2012. [Google Scholar]

- Castorina, S.; Paulo, M. Use of recycled construction and demolition materials in geotechnical. Resour. Conserv. Recycl. 2015, 103, 192–204. [Google Scholar]

- Yadhu, G.; Devi, S.A. An Innovative Study on Reuse of Demolished Concrete Waste. Civ. Environ. Eng. 2015, 5, 1–3. [Google Scholar]

- Martinelli, E.; Koenders, E.A.; Toledo, F.R.D.; Pepe, M. Alternative Processing procedures for recycled aggregates in structural concrete. Constr. Build. Mater. 2015, 69, 124–132. [Google Scholar]

- Park, W.-J.; Ryu, H.-S.; Kim, D.-M.; Shin, S.-H.; Lim, S.-M. Evaluation on the Surface Modification of Recycled Fine Aggregates in Aqueous H 2 SiF 6 Solution. Int. J. Concr. Struct. Mater. 2018, 12, 19. [Google Scholar]

- Nigussie, L.F.; Darwish, M.M.; Ghebrab, T. Recycling Fine Aggregate from Demolished Hollow Concrete Block for Green Concrete in Ethiopia. Glob. J. Eng. Sci. 2019, 3, 1–10. [Google Scholar]

- BATCoDA. Technical Specification & Method of Measurement; BATCoDA: Addis Ababa, Ethiopia, 1991. [Google Scholar]

- ASTM 129. Standard Specification for Non-Load-Bearing Concrete Masonry Units; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM C117. Standard Test Method for Materials Finer than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing; ASTM: West Conshohocken, PA, USA, 1995. [Google Scholar]

- ASTM C29/C29M. Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate; ASTM: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ACI Committee-211. Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete; ACI: Framington Hills, MI, USA, 2002. [Google Scholar]

- ASTM C136-06. Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates; ASTM: West Conshohocken, PA, USA, 2006. [Google Scholar]

- ASTM 566. Standard Test Method for Total Evaporable Moisture Content of Aggregate by Drying; ASTM: West Conshohocken, PA, USA, 1997. [Google Scholar]

- ASTM C128. Standard Test Method for Specific Gravity and Absorption of Fine Aggregate; ASTM: West Conshohocken, PA, USA, 1997. [Google Scholar]

- ASTMC143. Standard Test Method for Slump of Hydraulic Cement Concrete; ASTMC: West Conshohocken, PA, USA, 2001. [Google Scholar]

- EBCS 2. Structural Use of Concrete; Ministry of Works & Urban Development: Addis Ababa, Ethiopia, 1995.

- Deshmukh, M. REUCRETE: Replacement of Fine Aggregate by Demolished Waste Concrete. In Proceedings of the International Conference On Emanations in Modern Technology and Engineering, Maharashtra, India, 4–5 March 2017; Volume 5, No. 3. pp. 46–52. [Google Scholar]

- Özalp, F.; Yılmaz, H.D.; Kara, M.; Kaya, Ö.; Şahin, A. Effects of recycled aggregates from construction and demolition wastes on mechanical and permeability properties of paving stone, kerb and concrete pipes. Constr. Buil. Mater. 2016, 110, 17–23. [Google Scholar] [CrossRef]

- Umoh, A.A. Recycling demolition Waste Sandcrete Blocks as aggregate in Concrete. ARPN J. Eng. Appl. Sci. 2012, 7, 1111–1118. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).