Environmental and Economic Life Cycle Analysis of Primary Construction Materials Sourcing under Geopolitical Uncertainties: A Case Study of Qatar

Abstract

:1. Introduction

1.1. Uncertainties and the Associated Environmental and Economic Impact

1.2. Construction Sector Worldwide and in the State of Qatar

1.3. Assessment Methods

1.4. Sourcing of Primary Construction Materials in the State of Qatar

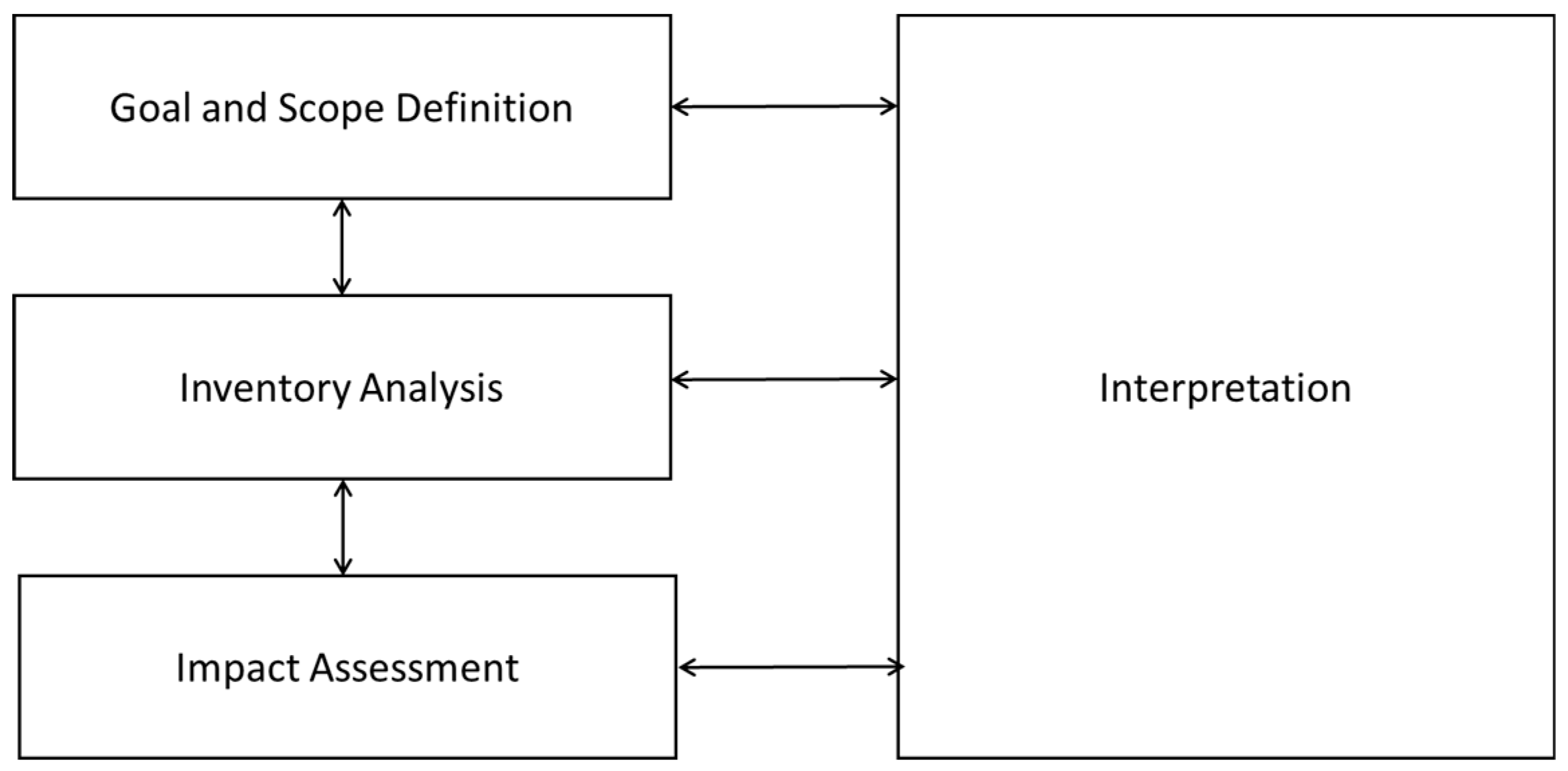

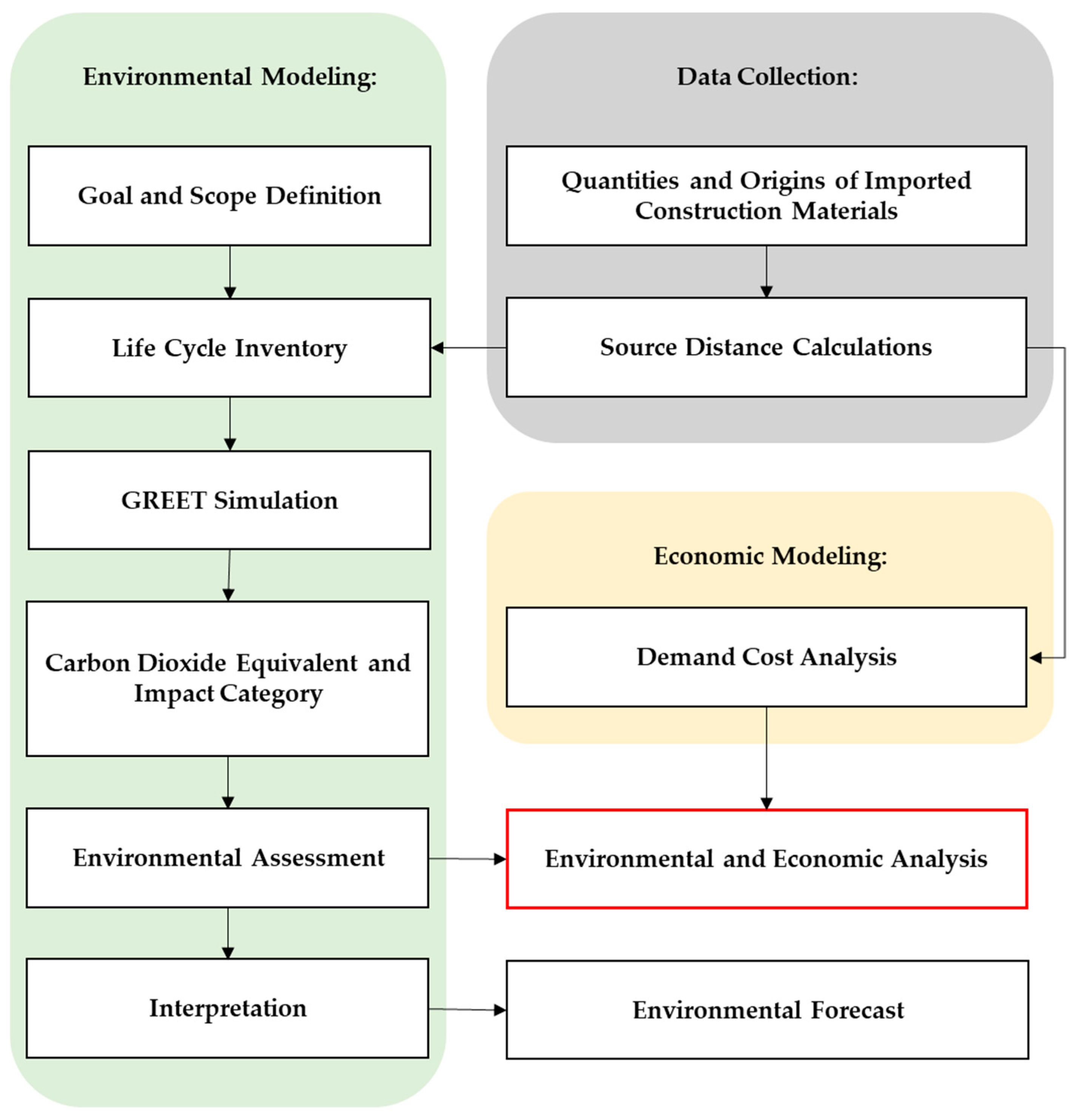

2. Materials and Methodology

2.1. LCA Study Goal and Scope

2.2. Life-Cycle Inventory

2.3. Life Cycle Impact Assessment

2.4. Economic Modeling

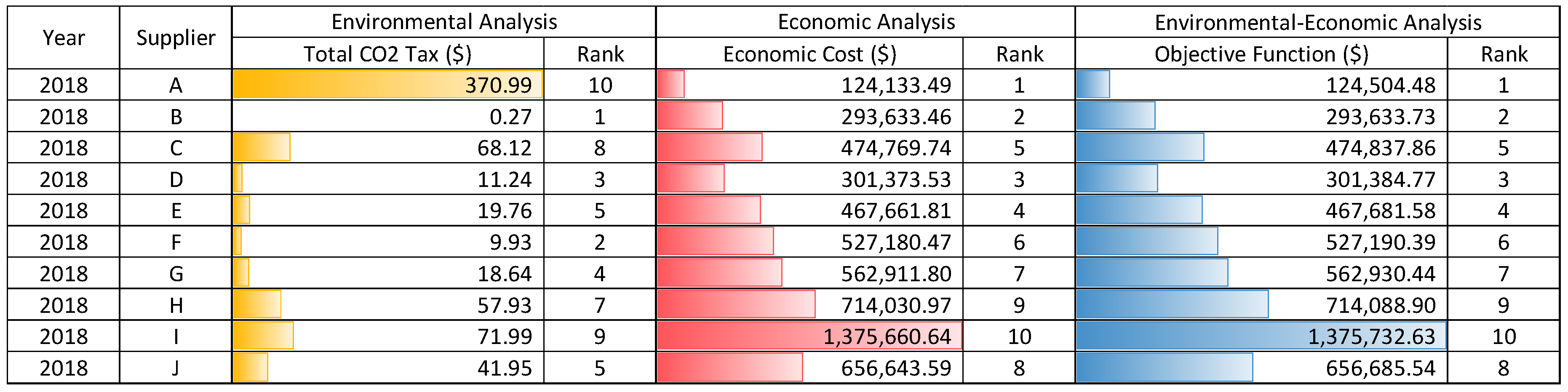

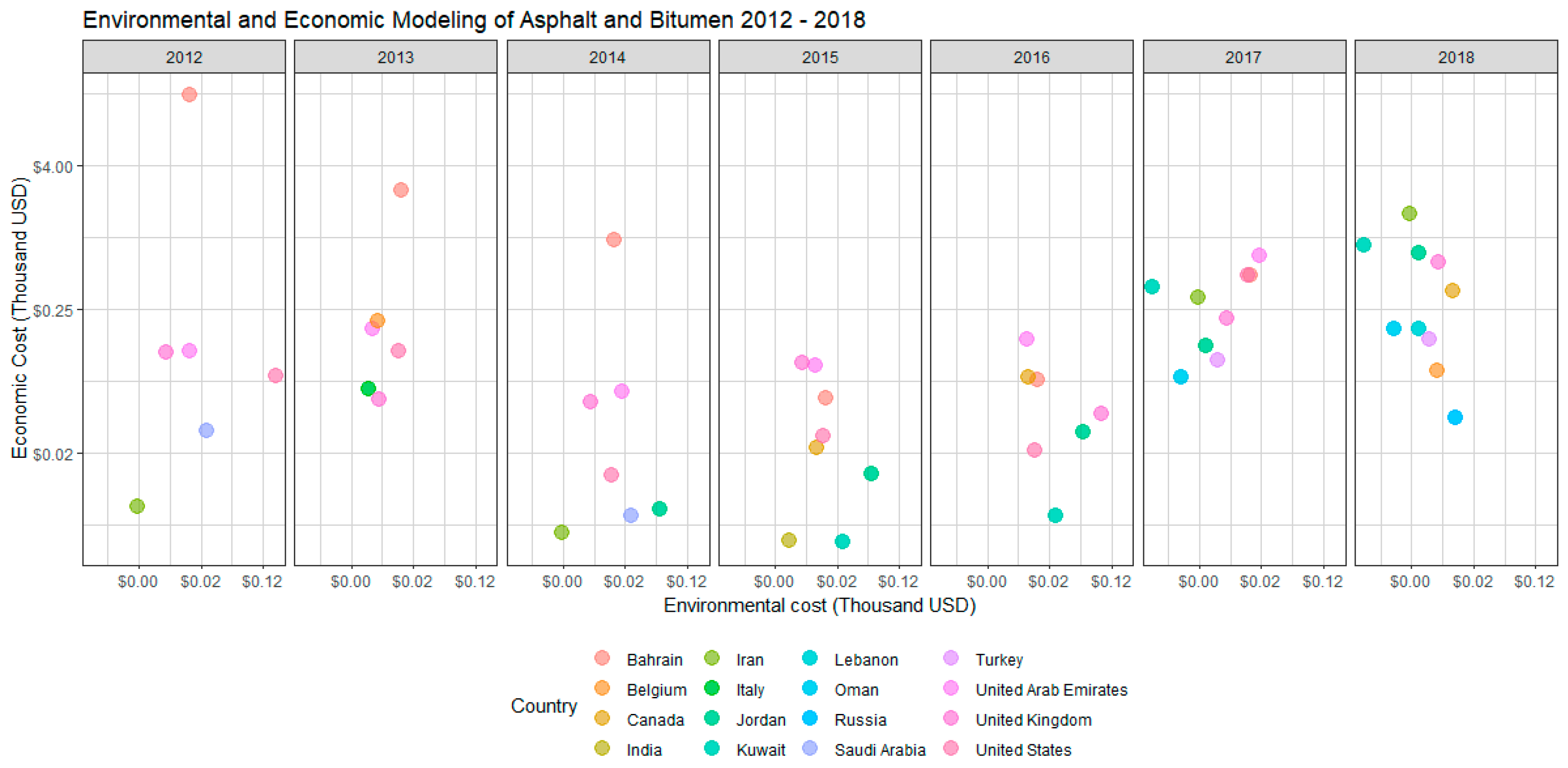

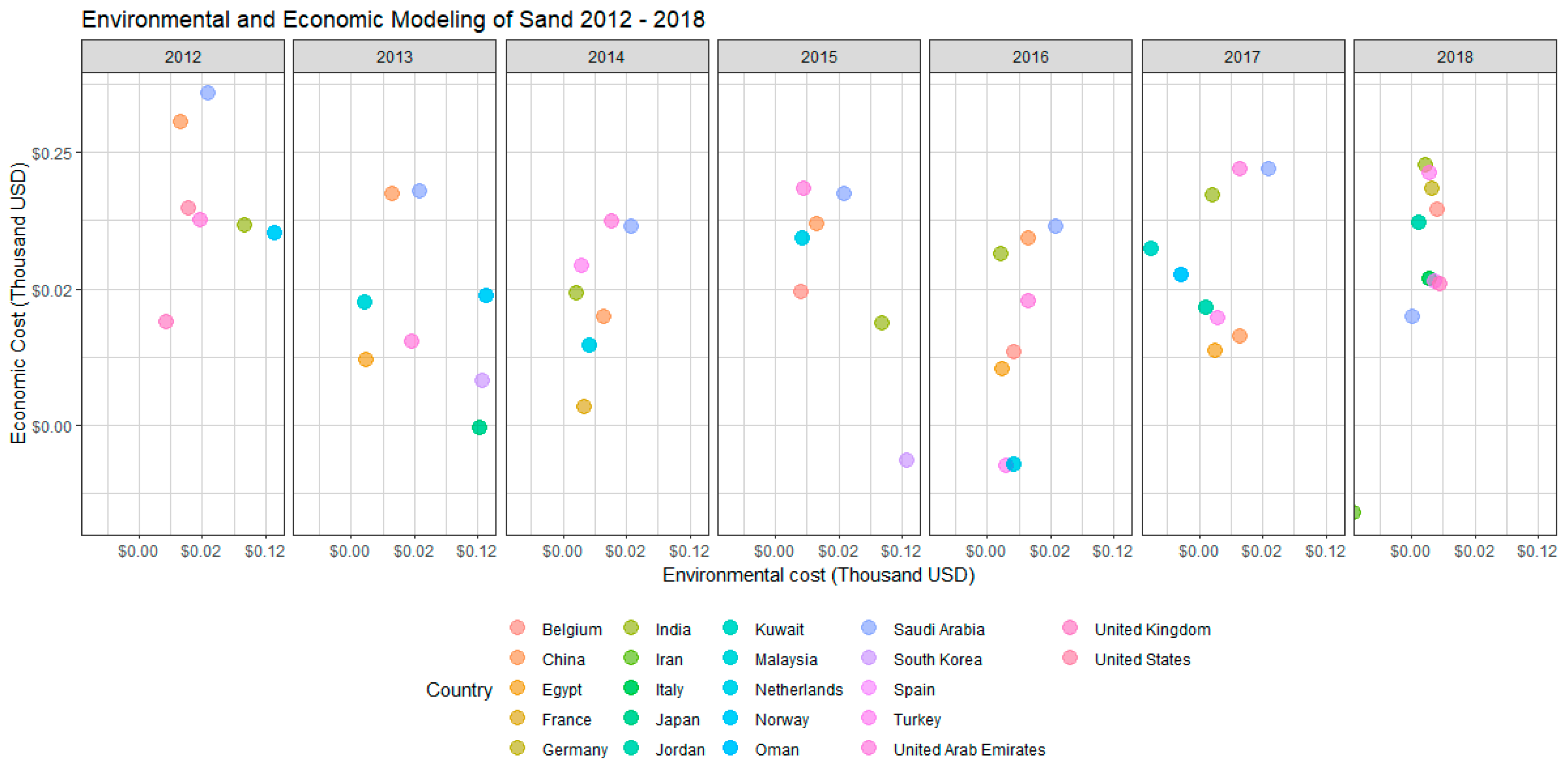

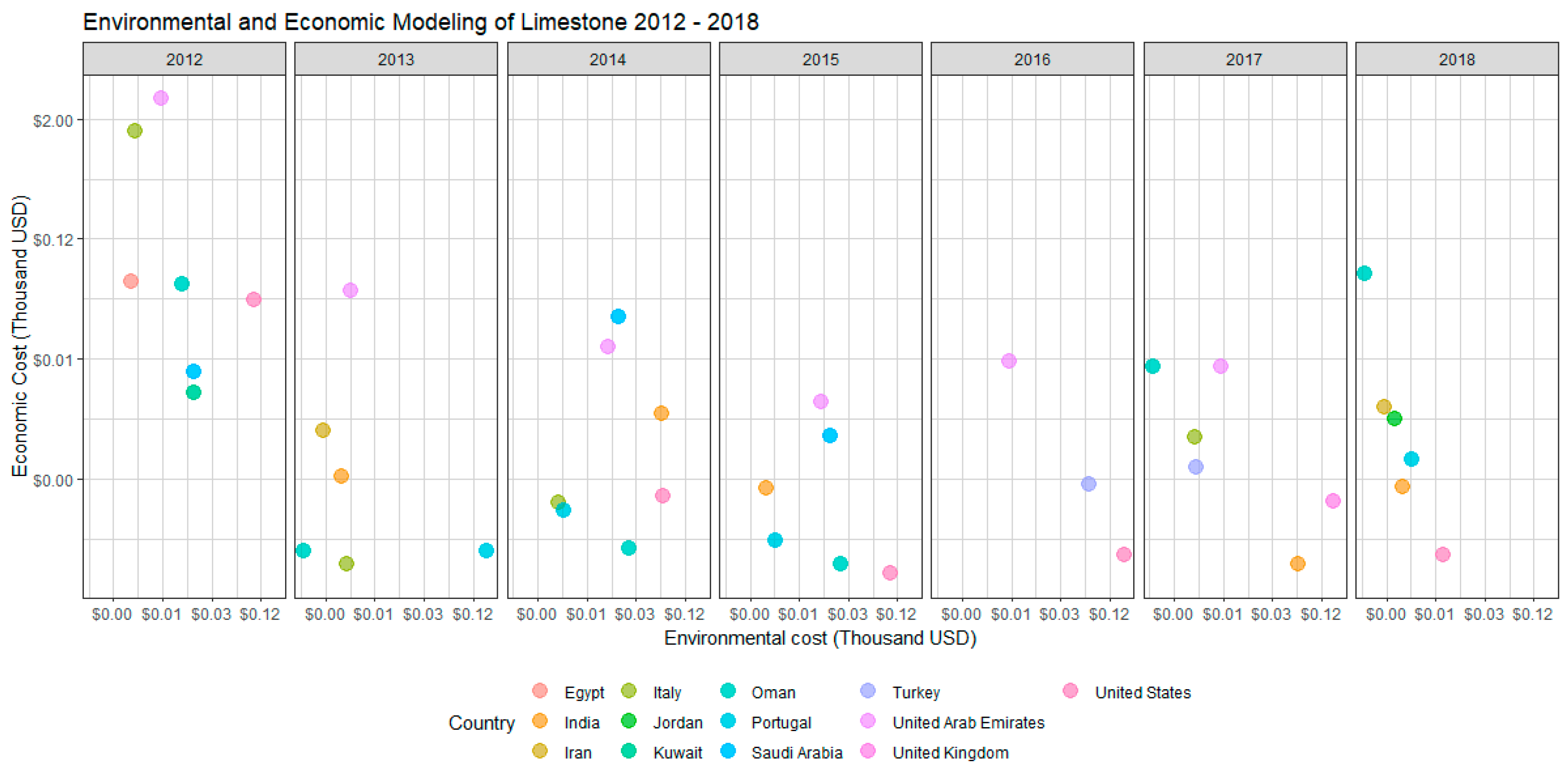

2.5. Environmental and Economic Modeling

2.6. Environmental Forecasting Method

3. Results and Discussion

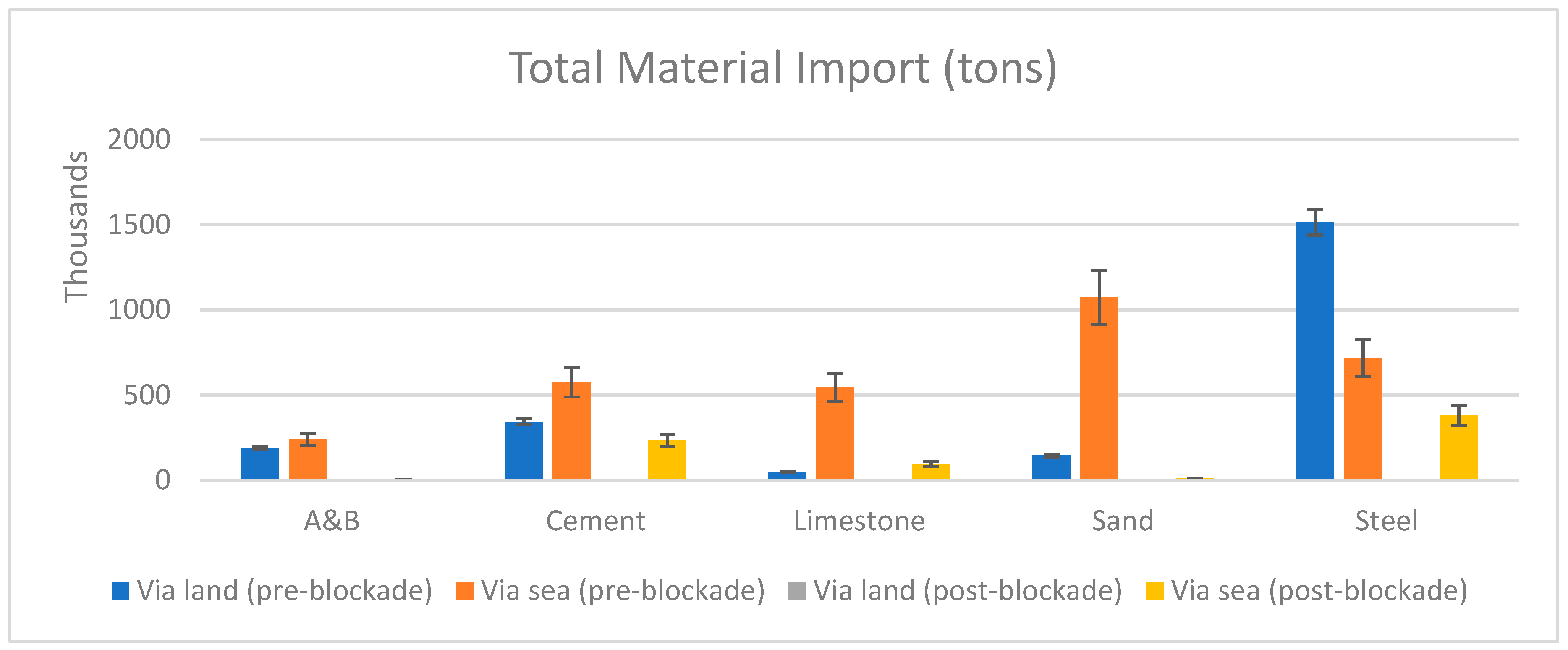

3.1. Results Based on Quantities of Imported Construction Materials

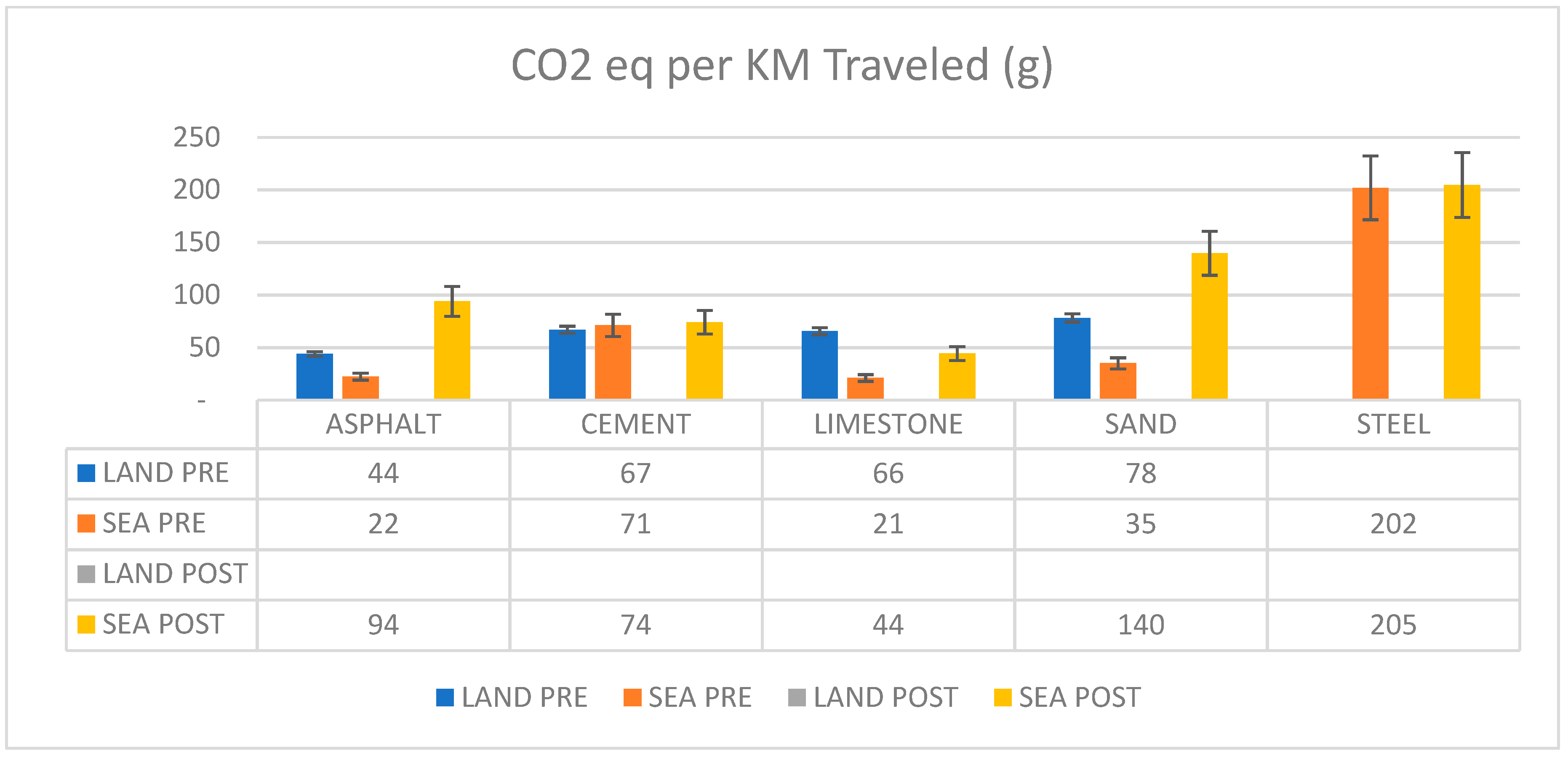

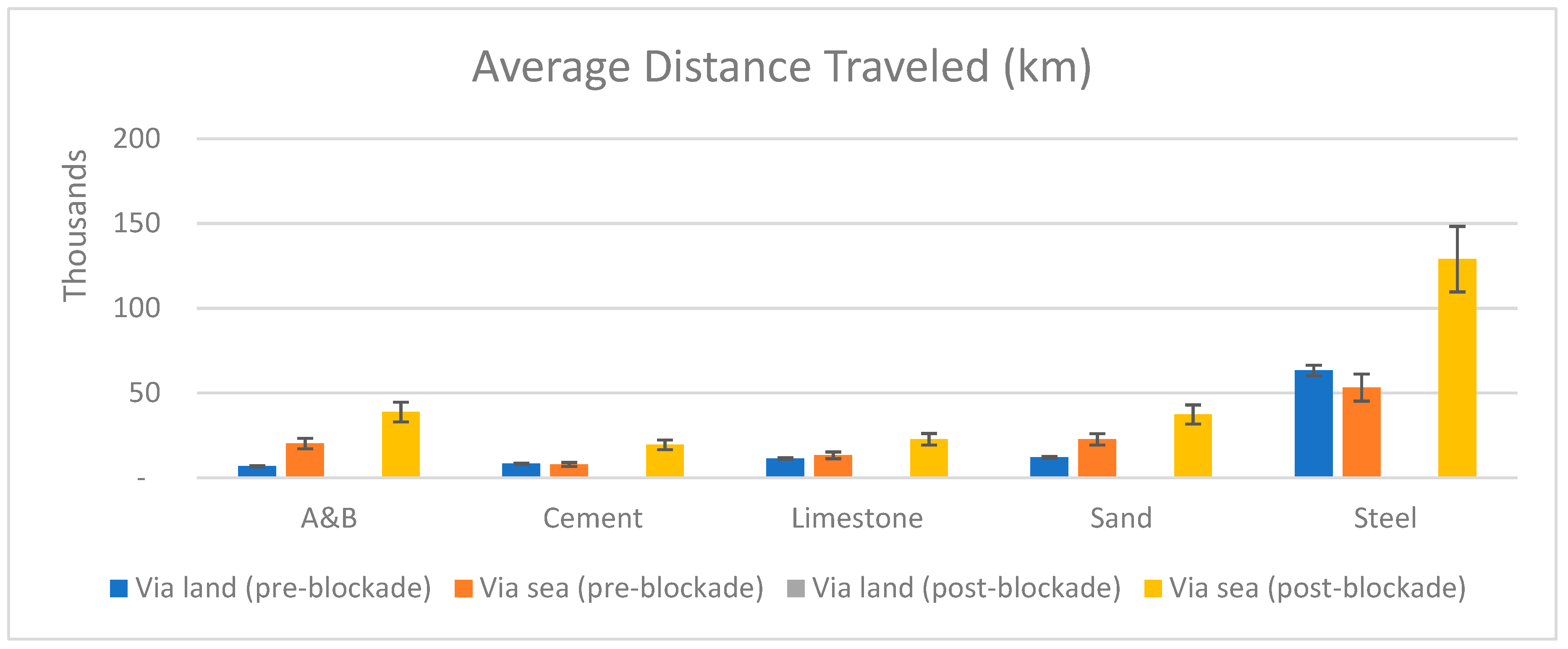

3.2. Results Based on Distance Traveled by Each Material

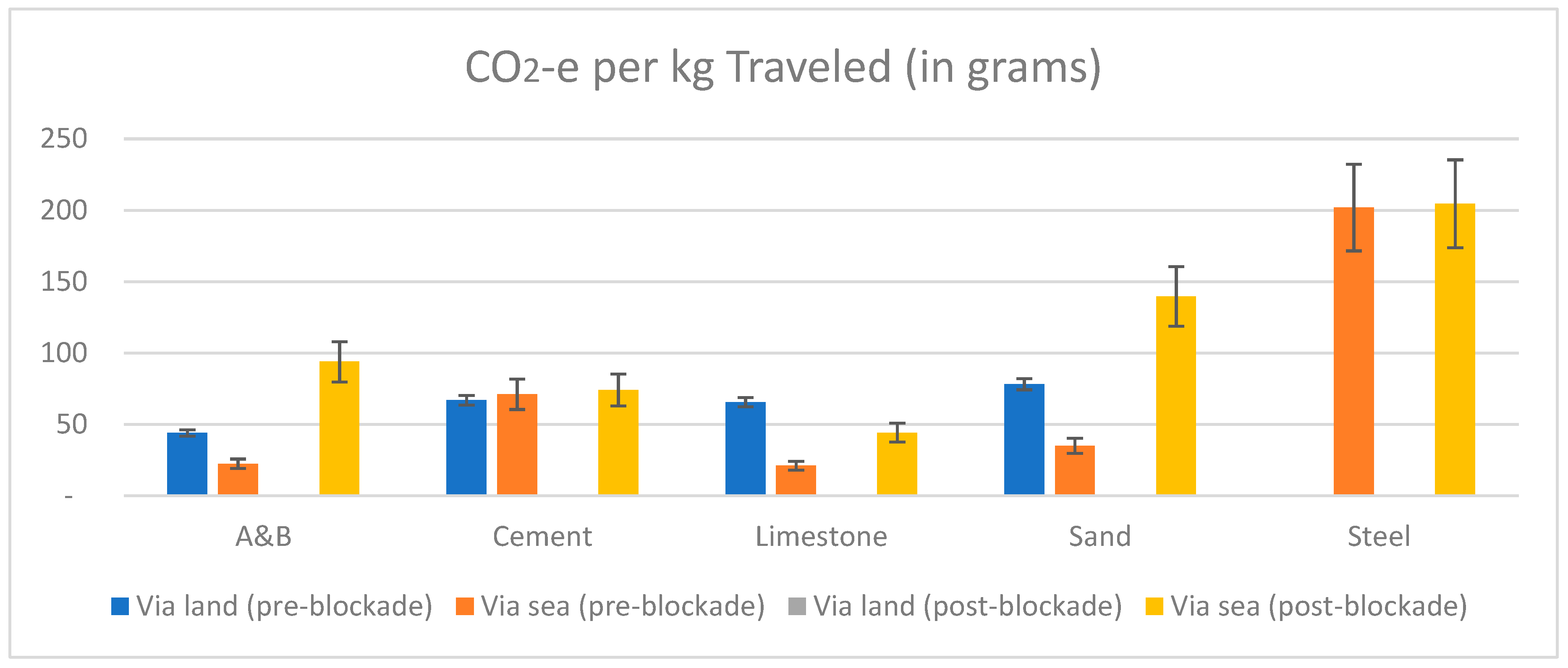

3.3. Results Relating to GHG Emissions

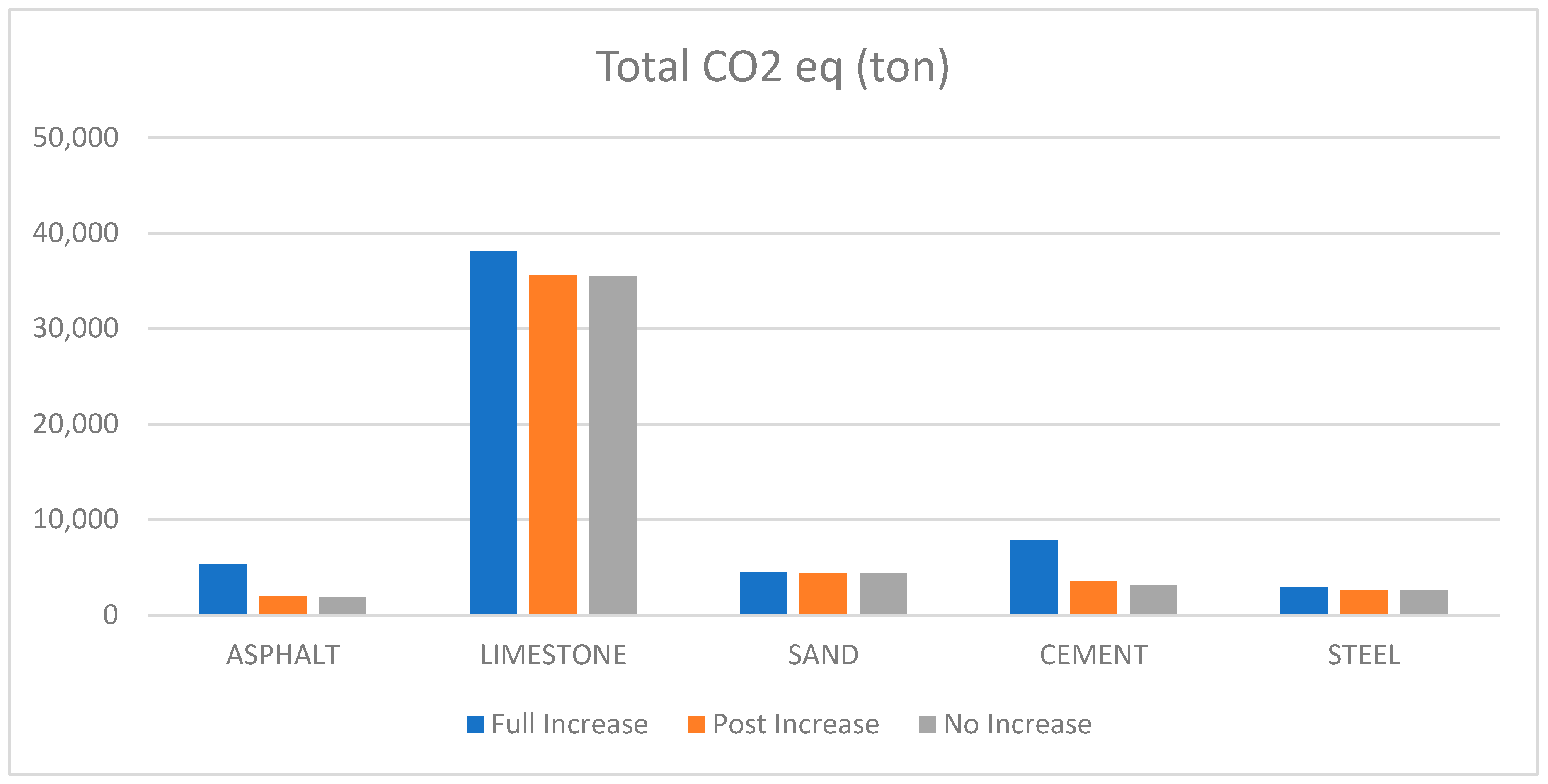

3.4. Environmental Forecast

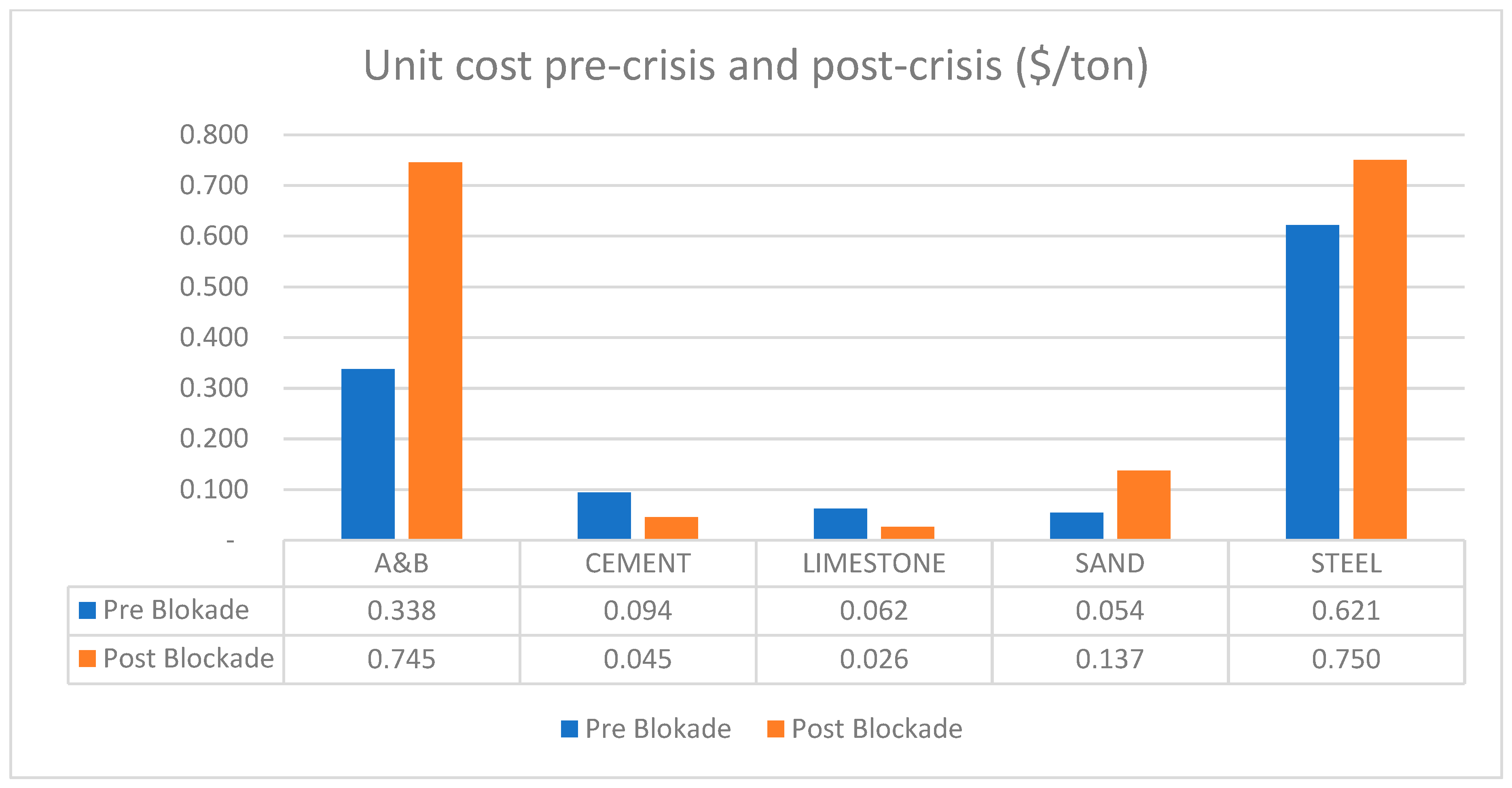

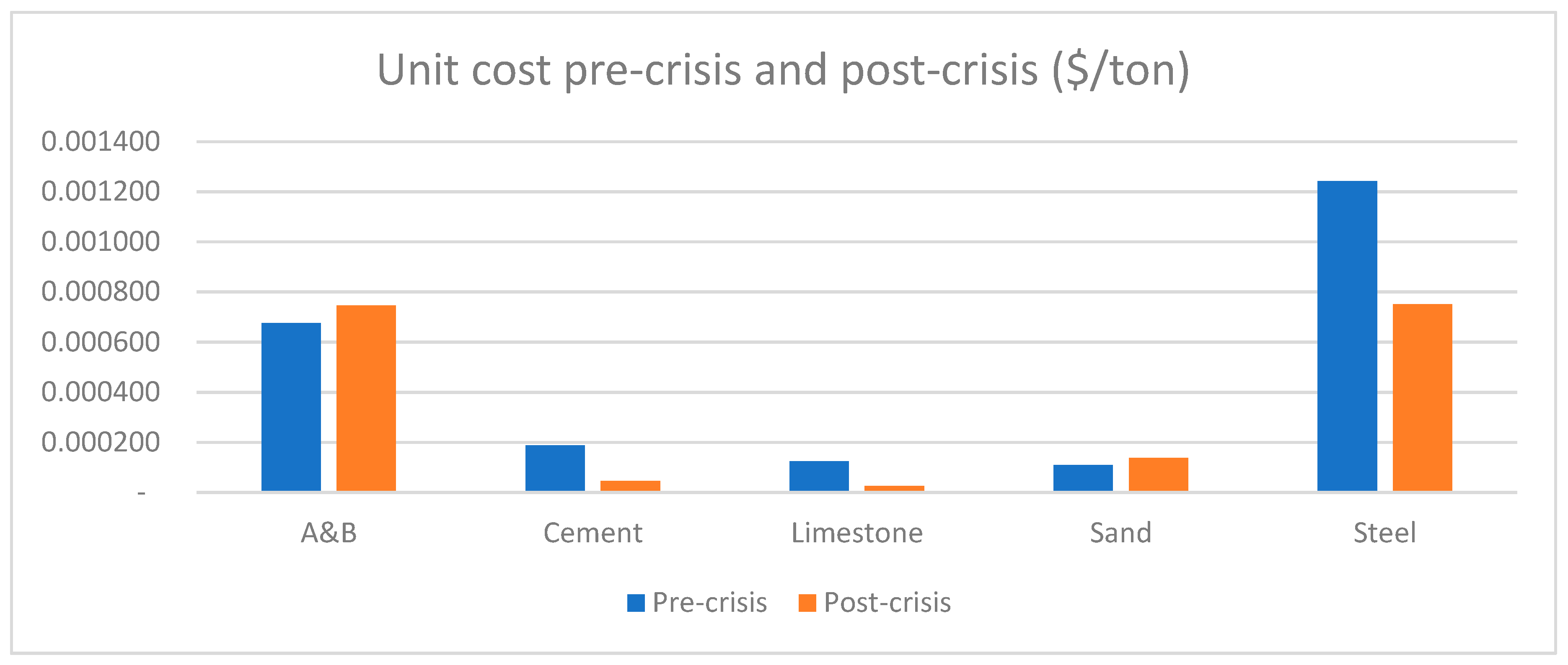

Cost of Construction Materials

3.5. Discussion and Interpretation

3.6. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Al-Ansary, M.; Iyengar, S.R. Physiochemical Characterization of Coarse Aggregates in Qatar for Construction Industry. Int. J. Sustain. Built Environ. 2013, 2, 27–40. [Google Scholar] [CrossRef]

- Mallidis, I.; Dekker, R.; Vlachos, D. The Impact of Greening on Supply Chain Design and Cost: A Case for a Developing Region. J. Transp. Geogr. 2012, 22, 118–128. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Prajapati, H.; Kant, R.; Shankar, R. Bequeath Life to Death: State-of-Art Review on Reverse Logistics. J. Clean. Prod. 2019, 211, 503–520. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H. A Review of Reverse Logistics and Closed-Loop Supply Chains: A Journal of Cleaner Production Focus. J. Clean. Prod. 2017, 142, 371–384. [Google Scholar] [CrossRef]

- Peidro, D.; Mula, J.; Poler, R.; Lario, F.-C. Quantitative Models for Supply Chain Planning under Uncertainty: A Review. Int. J. Adv. Manuf. Technol. 2009, 43, 400–420. [Google Scholar] [CrossRef]

- Gupta, A.; Maranas, C.D. Managing Demand Uncertainty in Supply Chain Planning. Comput. Chem. Eng. 2003, 27, 1219–1227. [Google Scholar] [CrossRef]

- Jung, J.Y.; Blau, G.; Pekny, J.F.; Reklaitis, G.V.; Eversdyk, D. A Simulation Based Optimization Approach to Supply Chain Management under Demand Uncertainty. Comput. Chem. Eng. 2004, 28, 2087–2106. [Google Scholar] [CrossRef]

- Al-Thani, S.; Skelhorn, C.; Amato, A.; Koc, M.; Al-Ghamdi, S. Smart Technology Impact on Neighborhood Form for a Sustainable Doha. Sustainability 2018, 10, 4764. [Google Scholar] [CrossRef]

- Léonardi, J.; Baumgartner, M. CO2 Efficiency in Road Freight Transportation: Status Quo, Measures and Potential. Transp. Res. Part D Transp. Environ. 2004, 9, 451–464. [Google Scholar] [CrossRef]

- IPCC. AR5 Climate Change 2014: Mitigation of Climate Change; Cambridge University Press: New York, NY, USA, 2014. [Google Scholar]

- U.S. Green Building Council. LEED 2009 for New Construction and Major Renovations Rating System; U.S. Green Building Council: Washington, DC, USA, 2009. [Google Scholar]

- Akbarnezhad, A.; Ahmadian, A.; Akbarnezhad, A.; Rashidi, T.H.; Waller, S.T. Importance of Planning for the Transport Stage in Procurement of Construction Materials. In Proceedings of the International Symposium on Automation and Robotics in Construction; IAARC Publications: Sydney, Australia, 2014. [Google Scholar]

- Ahmadian, F.F.A.; Akbarnezhad, A.; Rashidi, T.H.; Waller, S.T. Accounting for Transport Times in Planning Off-Site Shipment of Construction Materials. J. Constr. Eng. Manag. 2016, 142, 04015050. [Google Scholar] [CrossRef]

- The U.S. Census Bureau. Monthly Construction Spending. Available online: https://www.census.gov/construction/c30/pdf/release.pdf (accessed on 21 October 2019).

- Tserng, H.P.; Yin, S.Y.L.; Li, S. Developing a Resource Supply Chain Planning System for Construction Projects. J. Constr. Eng. Manag. 2006, 132, 393–407. [Google Scholar] [CrossRef]

- Yılmaz, E.; Arslan, H.; Bideci, A. Environmental Performance Analysis of Insulated Composite Facade Panels Using Life Cycle Assessment (LCA). Constr. Build. Mater. 2019, 202, 806–813. [Google Scholar] [CrossRef]

- Jang, M.; Hong, T.; Ji, C. Hybrid LCA Model for Assessing the Embodied Environmental Impacts of Buildings in South Korea. Environ. Impact Assess. Rev. 2015, 50, 143–155. [Google Scholar] [CrossRef]

- Babaizadeh, H.; Haghighi, N.; Asadi, S.; Broun, R.; Riley, D. Life Cycle Assessment of Exterior Window Shadings in Residential Buildings in Different Climate Zones. Build. Environ. 2015, 90, 168–177. [Google Scholar] [CrossRef]

- Abd Rashid, A.F.; Yusoff, S. A Review of Life Cycle Assessment Method for Building Industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- Alhaj, M.A.; Mohammed, S.; Darwish, M.; Hassan, A.; Al-Ghamdi, S.G. A Review of Qatar’s Water Resources, Consumption and Virtual Water Trade. Desalin. WATER Treat. 2017, 90, 70–85. [Google Scholar] [CrossRef]

- Qatar Economic Outlook 2018-2022. Available online: https://www.mdps.gov.qa/en/knowledge/Doc/QEO/Qatar-Economic-Outlook-2018-2020-En.pdf (accessed on 16 October 2019).

- el Mallakh, R. Qatar (RLE Economy of Middle East); Routledge: Abingdon, UK, 2015. [Google Scholar]

- Economides, M.J.; Wood, D.A. The State of Natural Gas. J. Nat. Gas Sci. Eng. 2009, 1, 1–13. [Google Scholar] [CrossRef]

- Al-Tamimi, A.; Al-Ghamdi, S.G. Multiscale Integrated Analysis of Societal and Ecosystem Metabolism of Qatar. Energy Rep. 2019. [Google Scholar] [CrossRef]

- Qatar Real GDP Growth (2012 - 2019]. Available online: https://www.ceicdata.com/en/indicator/qatar/real-gdp-growth (accessed on 28 October 2019).

- Al-Thani, S.K.; Amato, A.; Koç, M.; Al-Ghamdi, S.G. Urban Sustainability and Livability: An Analysis of Doha’s Urban-Form and Possible Mitigation Strategies. Sustainability 2019, 11, 786. [Google Scholar] [CrossRef]

- Trading Economics. Qatar GDP. Available online: https://tradingeconomics.com/qatar/gdp (accessed on 16 October 2019).

- Shoeb, M. Construction sector to grow by 7% until ’19: SAK-The Peninsula Qatar. Available online: https://www.thepeninsulaqatar.com/article/02/04/2018/Construction-sector-to-grow-by-7-until-’19-SAK (accessed on 16 October 2019).

- Nessi, S.; Rigamonti, L.; Grosso, M. LCA of Waste Prevention Activities: A Case Study for Drinking Water in Italy. J. Environ. Manag. 2012, 108, 73–83. [Google Scholar] [CrossRef]

- Tasca, A.L.; Nessi, S.; Rigamonti, L. Environmental Sustainability of Agri-Food Supply Chains: An LCA Comparison between Two Alternative Forms of Production and Distribution of Endive in Northern Italy. J. Clean. Prod. 2017, 140, 725–741. [Google Scholar] [CrossRef]

- Paksoy, T.; Bektaş, T.; Özceylan, E. Operational and Environmental Performance Measures in a Multi-Product Closed-Loop Supply Chain. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 532–546. [Google Scholar] [CrossRef]

- Hoen, K.M.R.; Tan, T.; Fransoo, J.C.; van Houtum, G.J. Effect of Carbon Emission Regulations on Transport Mode Selection under Stochastic Demand. Flex. Serv. Manuf. J. 2014, 26, 170–195. [Google Scholar] [CrossRef]

- Palak, G.; Ekşioğlu, S.D.; Geunes, J. Analyzing the Impacts of Carbon Regulatory Mechanisms on Supplier and Mode Selection Decisions: An Application to a Biofuel Supply Chain. Int. J. Prod. Econ. 2014, 154, 198–216. [Google Scholar] [CrossRef]

- Neely, A.; Gregory, M.; Platts, K. Performance Measurement System Design. Int. J. Oper. Prod. Manag. 1995, 15, 80–116. [Google Scholar] [CrossRef]

- Aramyan, L.H.; Meuwissen, M.P.M.; Oude Lansink, A.G.J.M.; van der Vorst, J.G.A.J.; van Kooten, O.; van der Lans, I.A. The Perceived Impact of Quality Assurance Systems on Tomato Supply Chain Performance. Total Qual. Manag. Bus. Excell. 2009, 20, 633–653. [Google Scholar] [CrossRef]

- Shen, L.; Olfat, L.; Govindan, K.; Khodaverdi, R.; Diabat, A. A Fuzzy Multi Criteria Approach for Evaluating Green Supplier’s Performance in Green Supply Chain with Linguistic Preferences. Resour. Conserv. Recycl. 2013, 74, 170–179. [Google Scholar] [CrossRef]

- Khasreen, M.M.; Banfill, P.F.G.; Menzies, G.F. Life-Cycle Assessment and the Environmental Impact of Buildings: A Review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Van Der Lugt, P.; Van Den Dobbelsteen, A.A.J.F. An Environmental, Economic and Practical Assessment of Bamboo as a Building Material for Supporting Structures. Constr. Build. Mater. 2006, 20, 648–656. [Google Scholar] [CrossRef]

- Schmidt, M.; Crawford, R.H. Developing an Integrated Framework for Assessing the Life Cycle Greenhouse Gas Emissions and Life Cycle Cost of Buildings. Procedia Eng. 2017, 196, 988–995. [Google Scholar] [CrossRef]

- Xue, X.; Li, X.; Shen, Q.; Wang, Y. An Agent-Based Framework for Supply Chain Coordination in Construction. Autom. Constr. 2005, 14, 413–430. [Google Scholar] [CrossRef]

- Cheng, J.C.P.; Law, K.H.; Bjornsson, H.; Jones, A.; Sriram, R. A Service Oriented Framework for Construction Supply Chain Integration. Autom. Constr. 2010, 19, 245–260. [Google Scholar] [CrossRef]

- Shi, Q.; Ding, X.; Zuo, J.; Zillante, G. Mobile Internet Based Construction Supply Chain Management: A Critical Review. Autom. Constr. 2016, 72, 143–154. [Google Scholar] [CrossRef]

- ISO 14040:2006. ISO 14040:2006 - Environmental management -- Life cycle assessment -- Principles and framework. Available online: https://www.iso.org/standard/37456.html (accessed on 28 October 2019).

- Sapkota, K.; Oni, A.O.; Kumar, A. Techno-Economic and Life Cycle Assessments of the Natural Gas Supply Chain from Production Sites in Canada to North and Southwest Europe. J. Nat. Gas Sci. Eng. 2018, 52, 401–409. [Google Scholar] [CrossRef]

- Ware, N.R.; Singh, S.P.; Banwet, D.K. A Mixed-Integer Non-Linear Program to Model Dynamic Supplier Selection Problem. Expert Syst. Appl. 2014, 41, 671–678. [Google Scholar] [CrossRef]

- Scott, J.; Ho, W.; Dey, P.K.; Talluri, S. A Decision Support System for Supplier Selection and Order Allocation in Stochastic, Multi-Stakeholder and Multi-Criteria Environments. Int. J. Prod. Econ. 2015, 166, 226–237. [Google Scholar] [CrossRef]

- Hsu, C.-W.; Kuo, T.-C.; Chen, S.-H.; Hu, A.H. Using DEMATEL to Develop a Carbon Management Model of Supplier Selection in Green Supply Chain Management. J. Clean. Prod. 2013, 56, 164–172. [Google Scholar] [CrossRef]

- Ho, W.; Xu, X.; Dey, P.K. Multi-Criteria Decision Making Approaches for Supplier Evaluation and Selection: A Literature Review. Eur. J. Oper. Res. 2010, 202, 16–24. [Google Scholar] [CrossRef]

- Sanayei, A.; Farid Mousavi, S.; Yazdankhah, A. Group Decision Making Process for Supplier Selection with VIKOR under Fuzzy Environment. Expert Syst. Appl. 2010, 37, 24–30. [Google Scholar] [CrossRef]

- Önüt, S.; Kara, S.S.; Işik, E. Long Term Supplier Selection Using a Combined Fuzzy MCDM Approach: A Case Study for a Telecommunication Company. Expert Syst. Appl. 2009, 36, 3887–3895. [Google Scholar] [CrossRef]

- Rezaei, J.; Fahim, P.B.M.; Tavasszy, L. Supplier Selection in the Airline Retail Industry Using a Funnel Methodology: Conjunctive Screening Method and Fuzzy AHP. Expert Syst. Appl. 2014, 41, 8165–8179. [Google Scholar] [CrossRef]

- Yadav, V.; Sharma, M.K. Multi-Criteria Decision Making for Supplier Selection Using Fuzzy AHP Approach. Benchmarking An Int. J. 2015, 22, 1158–1174. [Google Scholar] [CrossRef]

- Jain, V.; Kumar, S.; Kumar, A.; Chandra, C. An Integrated Buyer Initiated Decision-Making Process for Green Supplier Selection. J. Manuf. Syst. 2016, 41, 256–265. [Google Scholar] [CrossRef]

- Bruno, G.; Esposito, E.; Genovese, A.; Simpson, M. Applying Supplier Selection Methodologies in a Multi-Stakeholder Environment: A Case Study and a Critical Assessment. Expert Syst. Appl. 2016, 43, 271–285. [Google Scholar] [CrossRef]

- Amorim, P.; Curcio, E.; Almada-Lobo, B.; Barbosa-Póvoa, A.P.F.D.; Grossmann, I.E. Supplier Selection in the Processed Food Industry under Uncertainty. Eur. J. Oper. Res. 2016, 252, 801–814. [Google Scholar] [CrossRef]

- Gheidar Kheljani, J.; Ghodsypour, S.H.; O’Brien, C. Optimizing Whole Supply Chain Benefit versus Buyer’s Benefit through Supplier Selection. Int. J. Prod. Econ. 2009, 121, 482–493. [Google Scholar] [CrossRef]

- Shaw, K.; Shankar, R.; Yadav, S.S.; Thakur, L.S. Supplier Selection Using Fuzzy AHP and Fuzzy Multi-Objective Linear Programming for Developing Low Carbon Supply Chain. Expert Syst. Appl. 2012, 39, 8182–8192. [Google Scholar] [CrossRef]

- Kannan, D.; Khodaverdi, R.; Olfat, L.; Jafarian, A.; Diabat, A. Integrated Fuzzy Multi Criteria Decision Making Method and Multi-Objective Programming Approach for Supplier Selection and Order Allocation in a Green Supply Chain. J. Clean. Prod. 2013, 47, 355–367. [Google Scholar] [CrossRef]

- Kokangul, A.; Susuz, Z. Integrated Analytical Hierarch Process and Mathematical Programming to Supplier Selection Problem with Quantity Discount. Appl. Math. Model. 2009, 33, 1417–1429. [Google Scholar] [CrossRef]

- The Ministry of Development Planning and Statistics. Results of The Survey for The Future Demand of Primary Materials 2013 Executive Summary; Ministry of Development Planning and Statistics: Doha, Qatar, 2013. Available online: https://www.mdps.gov.qa/en/statistics/Statistical (accessed on 21 October 2019).

- Seuring, S.; Müller, M. From a Literature Review to a Conceptual Framework for Sustainable Supply Chain Management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Eskandarpour, M.; Dejax, P.; Miemczyk, J.; Péton, O. Sustainable Supply Chain Network Design: An Optimization-Oriented Review. Omega 2015, 54, 11–32. [Google Scholar] [CrossRef]

- Gambatese, J.A.; Rajendran, S. Sustainable Roadway Construction: Energy Consumption and Material Waste Generation of Roadways. In Construction Research Congress 2005; American Society of Civil Engineers: Reston, VA, USA, 2005. [Google Scholar]

- Binder, M.; Florin, H.; Kreissig, J. The Use of Life Cycle Engineering/Life Cycle Assessment within the Design Process of Production Facilities; A Business Case: Different Options of Handling Overspray. MRS Proc. 2005, 895, 0895-G01-03-S01-03. [Google Scholar] [CrossRef]

- ISO. ISO 14040:2006(En), Environmental Management — Life Cycle Assessment — Principles and Framework; The International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- General Authority of Customs. Foreign Trade System. Available online: http://www.customs.gov.qa/eng/opendata.php (accessed on 16 October 2019).

- Li, M.; Zhang, X.; Li, G. A Comparative Assessment of Battery and Fuel Cell Electric Vehicles Using a Well-to-Wheel Analysis. Energy 2016, 94, 693–704. [Google Scholar] [CrossRef]

- Argonne National Laboratory. GREET Model. Available online: https://greet.es.anl.gov/ (accessed on 16 October 2019).

- Midler, J.-C. Non-Euclidean Geographic Spaces: Mapping Functional Distances. Geogr. Anal. 2010, 14, 189–203. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Understanding Global Warming Potentials, Environ. Prot. Agency, US. 2016. Available online: https://www.epa.gov/ghgemissions/understanding-global-warming-potentials (accessed on 21 October 2019).

- Balaguera, A.; Carvajal, G.I.; Albertí, J.; Fullana-i-Palmer, P. Life Cycle Assessment of Road Construction Alternative Materials: A Literature Review. Resour. Conserv. Recycl. 2018, 132, 37–48. [Google Scholar] [CrossRef]

- European Emission Allowances (EUA). Available online: https://www.eex.com/en/market-data/environmental-markets/spot-market/european-emission-allowances#!/2019/04/02 (accessed on 2 April 2019).

- Rashid Khan, H.U.; Siddique, M.; Zaman, K.; Yousaf, S.U.; Shoukry, A.M.; Gani, S.; Sasmoko; Khan, A.; Hishan, S.S.; Saleem, H. The Impact of Air Transportation, Railways Transportation, and Port Container Traffic on Energy Demand, Customs Duty, and Economic Growth: Evidence from a Panel of Low-, Middle, and High -Income Countries. J. Air Transp. Manag. 2018, 70, 18–35. [Google Scholar] [CrossRef]

- Weldu, Y.W.; Assefa, G. The Search for Most Cost-Effective Way of Achieving Environmental Sustainability Status in Electricity Generation: Environmental Life Cycle Cost Analysis of Energy Scenarios. J. Clean. Prod. 2017, 142, 2296–2304. [Google Scholar] [CrossRef]

- Mallidis, I.; Dekker, R.; Vlachos, D. Greening Supply Chains: Impact on Cost and Design; Econometric Institute: Rotterdam, The Netherlands, 2010. [Google Scholar]

| Years | Construction Budget BL.R | Precast Concrete (Ton) | Asphalt (Ton) | Ready Mix Concrete (Cu.M.) | Spoil Removal and Disposal (Ton) | Bitumen (Ton) | Limestone (Ton) | Gabbro (Ton) | Fine Sand (Ton) | Washed Sand (Ton) | Cement (Ton) | Steel (Rebar) (Ton) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2012 | 9539 | 276,576 | 1,922,923 | 1,406,520 | 5,431,374 | 98,306 | 424,642 | 3,236,120 | 311,490 | 1,171,444 | 809,085 | 259,835 |

| 2013 | 16,004 | 844,719 | 5,704,030 | 2,901,665 | 18,544,038 | 653,343 | 33,282,538 | 18,997,545 | 749,710 | 6,779,516 | 3,964,287 | 1,332,205 |

| 2014 | 45,146 | 1,689,032 | 9,608,253 | 4,646,675 | 49,930,621 | 1,564,028 | 76,742,896 | 46,608,362 | 748,750 | 14,121,553 | 8,770,940 | 2,622,776 |

| 2015 | 43,634 | 4,496,335 | 17,176,142 | 8,180,588 | 56,366,518 | 3,705,007 | 174,567,017 | 86,611,452 | 658,716 | 29,062,598 | 18,260,592 | 4,283,039 |

| 2016 | 42,288 | 1,468,877 | 9,580,879 | 7,080,221 | 29,986,627 | 2,727,899 | 146,707,941 | 65,713,218 | 175,080 | 32,571,075 | 16,488,600 | 3,244,246 |

| 2017 | 28,148 | 227,759 | 1,528,444 | 3,134,943 | 5,155,424 | 963,652 | 60,767,844 | 22,237,587 | 112,766 | 6,981,958 | 3,905,495 | 1,084,207 |

| 2018 | 23,049 | 64,356 | 529,474 | 2,522,203 | 604,561 | 380,554 | 20,879,462 | 10,519,945 | 70,126 | 2,492,891 | 1,268,412 | 425,662 |

| 2019 | 22,566 | 44,737 | 88,184 | 2,103,811 | 106,509 | 10,243 | 324,127 | 2,456,757 | NA | 1,566,341 | 806,200 | 312,649 |

| 2020 | 21,421 | 105,014 | 315 | 2,081,134 | NA | 6037 | NA | 2,310,149 | NA | 1,524,205 | 785,114 | 343,116 |

| 2021 | 19,324 | NA | 188 | 1,722,116 | NA | 6016 | NA | 2,029,423 | NA | 1,339,031 | 690,036 | 253,139 |

| 2022 | 16,465 | 2514 | 112 | 698,017 | NA | 6011 | NA | 837,379 | NA | 552,451 | 284,696 | 105,533 |

| Kahrama 2012–2022 | - | - | - | - | - | - | 924,901 | 2,474,632 | 628,200 | 3,737,801 | 1,159,279 | 371,151 |

| TOTAL | 287,584 | 9,219,919 | 46,138,944 | 36,477,893 | 166,125,672 | 10,121,096 | 514,621,368 | 264,032,569 | 3,454,838 | 101,900,864 | 57,192,736 | 14,637,558 |

| Asphalt | Limestone | Sand | Cement | Steel |

|---|---|---|---|---|

| 282.5% | 107.4% | 102.0% | 246.5% | 115.0% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Nuaimi, S.; Banawi, A.-A.A.; Al-Ghamdi, S.G. Environmental and Economic Life Cycle Analysis of Primary Construction Materials Sourcing under Geopolitical Uncertainties: A Case Study of Qatar. Sustainability 2019, 11, 6000. https://doi.org/10.3390/su11216000

Al-Nuaimi S, Banawi A-AA, Al-Ghamdi SG. Environmental and Economic Life Cycle Analysis of Primary Construction Materials Sourcing under Geopolitical Uncertainties: A Case Study of Qatar. Sustainability. 2019; 11(21):6000. https://doi.org/10.3390/su11216000

Chicago/Turabian StyleAl-Nuaimi, Shaikha, Abdul-Aziz A. Banawi, and Sami G. Al-Ghamdi. 2019. "Environmental and Economic Life Cycle Analysis of Primary Construction Materials Sourcing under Geopolitical Uncertainties: A Case Study of Qatar" Sustainability 11, no. 21: 6000. https://doi.org/10.3390/su11216000

APA StyleAl-Nuaimi, S., Banawi, A.-A. A., & Al-Ghamdi, S. G. (2019). Environmental and Economic Life Cycle Analysis of Primary Construction Materials Sourcing under Geopolitical Uncertainties: A Case Study of Qatar. Sustainability, 11(21), 6000. https://doi.org/10.3390/su11216000