Abstract

The article presents the results of thermo-mechanical densification tests conducted on Scots pine timber. The densification process was carried out in industrial conditions with a high-pressure press, which allowed flat compression of boards that were up to 2.5 m long. A phenomenon of elastic redeformations was observed in the densified boards after each pulse of compression. As a result of thermo-mechanical compression, the average timber moisture content dropped to 9%, and the average density increased by 13.5%, from the level of 547 to 621 kg/m3. As a result of thermo-mechanical densification, the strength class C of most Scots pine timber pieces improved. Most timber pieces that were subjected to thermo-mechanical densification have improved their strength class, C, by one (72.7% of the tested batch) or two C classes (3.6% of the batch under study).

1. Introduction

The growing demand for wood and engineered wood products for construction and the limited availability of high-quality wooden resources have stimulated the search for new, alternative materials to use in construction. One of the possible directions to solve the problem of raw materials is to develop treatments and processes to modify conventional materials in order to complement or replace the domestic forest species [1]. One of the factors of an effective economy that takes into account the need to simultaneously mitigate climate change is an ecologically sustainable wood treatment that consists of exposing it to appropriate temperature and pressure at the same time, without the need to add any chemical substances [2,3]. Thermo-mechanical treatment (TMD) of wood is a process of densification that has been known for decades and results in the increase of material density through compression perpendicular to the grain [4]. The density of wood and engineered wood products (EWP) is one of the criteria for conditioning the technical quality of a material. In general, wood species and EWP with greater density are preferred for many applications in the construction industry, due to their higher resistance and natural durability [5]. However, the availability of high-density wood is limited, and as a result, their purchase requires significant financial spending. Therefore, the use of wood with low or medium density subjected to a process of densification can improve its technical parameters, while at the same time taking into account the aspect of affordability.

There are many premises that justify the application of TMD as a structural timber modification process. For example, exposing wood to high temperatures increases its resistance to biological factors [6,7,8,9] and its dimensional stability [10,11], and reduces its hygroscopicity [12,13,14,15]. By adding the compression (densification) process, we can improve the physical and mechanical properties of wood [16,17,18,19,20]. As a result of the surface densification of wood, it is possible to increase its hardness even twice [21] and significantly improve the durability of the material. These features translate into the potential for the application of densified wood, especially in external layers of layered floor materials [22,23,24]. The concept of using a material that was initially worse, and whose resistance properties improve after modification, is especially important in the case of wood with low initial density, such as poplar [25,26], coniferous species [27,28], or eucalyptus [29,30]. One of the areas where wood with originally worse quality can be used is construction. As a result of the densification of spruce wood, it is possible to improve both MOE and MOR by up to 200%–300% in comparison with native (not densified) wood [31,32]. In the case of pine sapwood, the MOE of wood subjected to thermo-mechanical treatment amounted to 14.4 GPa (a 150% increase compared to native wood), while its density incremented from 385 kg/m3 to 1040 kg/m3 [33]. Similar results have been obtained for pine wood by Esteves et al. [34], who densified wood between press shelves at temperatures of 150 °C, 180 °C, and 200 °C. Wood with an initial density of 615 kg/m3, 614 kg/m3, and 512 kg/m3 after densification achieved the following values: 1048 kg/m3, 1031 kg/m3 and 1041 kg/m3, respectively. The MOE of densified wood was higher than native wood by 42%, 40%, and 71%, respectively. In the case of spruce wood, at a compression rate (CR) equal to 22%, 50%, 60%, and 67%, the density increase of native wood was in the range between 33% and 78%, while the elasticity modulus was between 79% and 114% [35]. Excessively elevated temperatures in the densification process affect the mechanical properties of wood negatively. This can be caused by the growing chemical degradation, which exacerbates together with rising temperatures. The most optimal temperature level for densification is considered to be 120 °C. For pine wood, a densification process performed at a temperature of 120 °C resulted in an 85% density increase, leading to an improvement of bending strength by 42%, shear strength by 20%, and compressive strength by 47% [35]. In the case of poplar wood, depending on the treatment temperature (120–200 °C), wood density increased by 144%–188%, which translated into an MOE that was 73%–130% higher and MOR higher by 3%–72% [36]. As to sugi wood, the densification process allows us to achieve an MOE increase by even 309%, and MOR by up to 183% [37]. TM wood processing is a scientific field that has been well-studied, which is confirmed by multiple literature publications on this topic, focusing on analysing the influence of CR, steam temperature, pressure, species tested, the direction of compression, etc. Nonetheless, it should be taken into account that most studies were carried out on small samples, at a laboratory scale, which—of course—does allow us to observe the influence of a given factor on the densification effect or lack thereof. However, study results obtained at a laboratory scale, looking at the physical and mechanical properties of wooden samples, can be affected by the so-called scale effect [38], which is a very important aspect when it comes to considerations of wood applications in engineering. In the stochastic aspect, the higher the volume of a wooden element (laboratory/full-scale technical sample), the higher the probability of defects in the structure of the wood.

Nevertheless, the high effectiveness of thermo-mechanical treatment, confirmed by the improvement of physical and mechanical properties of wood, allows us to conclude that with appropriate scaling and adjustment of treatment parameters, the process of wood densification can be used to enhance wood quality, not only in timber from plantations but also in traditional, domestic species, whose average density values are low, which will allow for their use in construction applications (as independent structural elements or for the production of layered composites). One of the necessary conditions for safe building with timber is the use of wood with adequate strength parameters. Sawn timber used in construction for structural purposes must be subjected to strength grading. There are two methods for strength grading of structural sawn timber: visual and machine. Machine strength grading results in much higher efficiency and wood pieces are classified into higher classes, with fewer timber pieces rejected in comparison to the results of visual strength grading of the same batch of wood [39]. As a result of machine strength grading, the timber pieces are classified into C strength classes in accordance with the EN 338 standard [40].

The study described herein refers to the analysis of the effects of thermo-mechanical timber densification in industrial conditions on the selected physical and mechanical properties of wood. The technical scale of the study permits us to directly apply the obtained results to the characteristic resistance of wood, corresponding to a given sorting class and C strength grade [40]. It is also possible to specify the structure of C strength classes of a given batch of timber before and after densification, which has both an economical and ecological dimension.

2. Material and Methods

The study was conducted on a batch of boards made of pine wood (Pinus silvestris L.) that contained 400 pieces with an average moisture content of 13%. The timber originated from the Masovian Forestry Region (central Poland). The nominal board dimensions were: 24 × 90 × 2400 mm. The boards had a flatsawn growth ring layout (tangential sections on the wide board surfaces). The average growth ring width amounted to 1.50 mm, and timber was obtained from sapwood, with a small share of resin substances and a low amount of knots.

The scope of the research included: specifying the values of density (DEN), dynamic modulus of elasticity before thermo-mechanical modification (MOE), the performance of thermo-mechanical timber modification in industrial conditions, as well as specifying the density and modulus of elasticity of modified timber (DENTMD, MOETMD). The density of the timber under examination was determined with the stereometric method. The determination of the modulus of elasticity was carried out with the MTG device (Brookhuis Microelectronics BV, Holland). The device uses the impact method to determine MOEdyn. The machine was also used for the strength grading of the timber batch under research before and after thermo-mechanical modification. The density profile of sample planks was determined with the use of a profile meter: Laboratory Density Analyser DAX GreCon (Fagus-Grecon Greten GmbH & Co. KG, Alfeld, Germany). A density measurement was made every 0.02 mm at the measurement speed of 0.05 mm/s. Before the test, the samples used to determine the density profile were planed on both sides to avoid any concave or convex areas on the wide surfaces of the boards. The samples used to specify the density profile had the dimensions of 50 × 50 mm and thickness remaining after planing on both sides and were cut from the middle part of the compressed boards.

In order to carry out the densification process in industrial conditions at the Wersal company, a high-pressure press was used, produced by Italpress, model GL/260-PS, which allowed flat compression of boards that were up to 2.5 m long. Before densification, timber, MC, 11.5%, was heated between the press shelves at a temperature of 90 °C, over the course of 20 min, in order to soften the lignin, and then it was densified in three steps. In the first step, the timber was flattened from 24 mm to 22 mm (4 mm, press shelf move), and the press was opened (the top shelf was moved upwards from the compressed timber piece); in the second pulse, timber was compressed to 20 mm (6 mm press shelf move), and the shelf was opened once again, separating it from the compressed board, to allow for stress relaxation. In the third pulse, the timber was compressed to 18 mm (8 mm press shelf move). In the last pulse of compression, the timber remained closed tightly in the press for 30 s, after which the press shelves were opened.

Statistical analysis of the results was carried out using Statistica version 13 (TIBCO Software Inc., Palo Alto, CA, USA). The analysis of variance (ANOVA) was used to test (α = 0.05) for significant differences between factors. A comparison of the means was performed using Tukey’s test, with α = 0.05.

3. Results and Discussion

3.1. Density of Wood before and after Thermo-Mechanical Densification

A phenomenon of elastic redeformations was observed in the densified boards after each pulse of compression, and after the last pulse, there was a redeformation back to the average thickness of ca. 20 mm. Timber pieces, whose initial nominal thickness amounted to 24 mm, were compressed to 20 mm (CR compression ratio 20%), while the initial board width, 90 mm, increased to 92 mm. The obtained cross-sections of the boards after compression were not flat. As a result of the thermo-mechanical compression, the average timber moisture content dropped to 9% and the average density increased by 13.5%, from of 547 to 621 kg/m3.

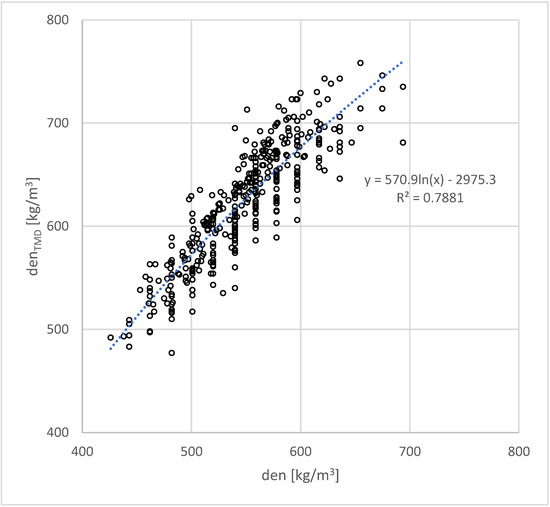

Figure 1 presents the relation between timber density before and after TMD. Both sets have a normal distribution. It has been observed that as a result of thermo-mechanical densification, timber density increased in a statistically significant manner (p < 0.05), compared to the initial density before TMD. The average density of the entire timber batch (400 pcs.) increased by 14%. The relation between timber density before and after TMD is high (determination coefficient equals 0.78). A high determination coefficient reflects a quite uniform augmentation of the density of individual timber pieces as a result of TMD. Of course, the increase in density of a single piece of timber depended on its initial density. In the case of timber pieces with high initial density (and, at the same time, low porosity), the increase in density caused by thermo-mechanical densification was smaller (Table 1).

Figure 1.

Relation between timber density before and after densification.

Table 1.

Timber density before and after thermo-mechanical densification for timber classified in different strength grades before thermo-mechanical densification.

The density of wood before and after thermo-mechanical densification, taking into account the results of strength grading before and after thermo-mechanical densification has been presented in Table 1 and Table 2. The results refer to the same batches of boards classified in a given class before densification.

Table 2.

Timber density after thermo-mechanical densification for timber classified in different strength grades after densification.

By analysing the results presented in Table 1, it can be concluded that the highest density increase took place in the case of boards classified into class C30 after TMD (14.3%), and the smallest in the case of boards classified in the C40 class (6.7%). The density increase for all the boards amounted to 13.5%. In the case of densified timber from class C18, it stands out for its high density in comparison with the remaining C classes of densified timber (Table 2) and is 25.9% higher than the density of C18 timber before thermo-mechanical densification.

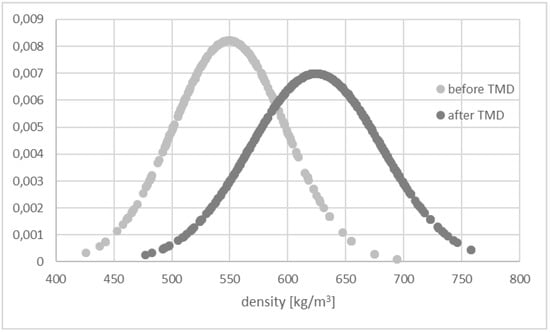

Figure 2 presents density distribution curves for the timber under research before and after modification. The curves show the changes in density that happened as a result of thermo-mechanical modification. TMD caused an increase in the density of timber under research by about 14%. Both before and after TMD modification, there is a negative kurtosis, which indicates a left-skewed asymmetry of distribution. The obliqueness, in both cases, is close to zero (distribution similar to a symmetrical one). After the modification, the obliqueness is skewed to the left (domination of lower-density values). The distribution is close to the normal distribution (kurtosis value = 0). Kurtosis is negative, which means there are fewer positive outliers than in a normal distribution.

Figure 2.

Timber density distribution before and after thermo-mechanical modification.

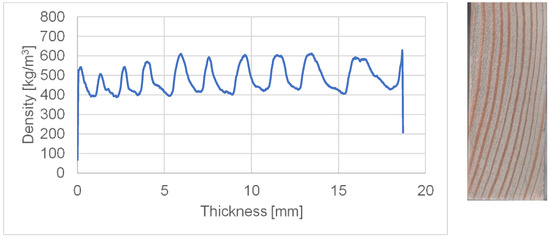

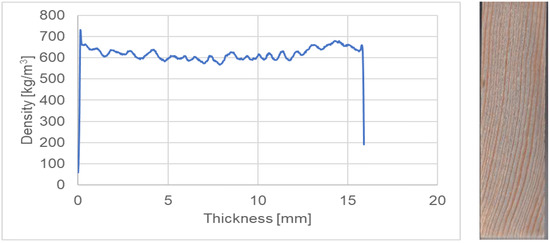

Examples of density profiles before and after thermo-mechanical densification have been presented in Figure 3 and in Figure 4. The thickness of pieces after TMD for which the density profile has been determined was smaller than the thickness of timber pieces for which strength class was determined, which resulted from their planing in order to achieve flatness. The obtained density profiles confirm that timber has been densified in a uniform manner throughout its entire volume. As a result of the thermo-mechanical densification of pine wood, the differences between earlywood and latewood become smaller. Before thermo-mechanical modification, the density of the entire batch of tested timber was between 426 kg/m3 and 694 kg/m3. After thermo-mechanical modification, the density of the tested batch of timber was between 477 kg/m3 and 758 kg/m3.

Figure 3.

Density profile and cross-section of sawn timber before thermo-mechanical densification, average density of sample 482 kg/m3. Sawn timber samples before modification were planed on both sides to achieve flatness.

Figure 4.

Density profile and cross-section of sawn timber after thermo-mechanical densification, average density of sample 615 kg/m3. Sawn timber after densification was planed on both sides to achieve flatness.

The thermo-mechanical modification of pine wood influences both its internal structure and its properties. The density profile of pine boards became more homogenous. Before densification, there were visible differences between the density of earlywood and latewood (Figure 3). After the modification, the density of pine wood in the element’s thickness became more uniform (Figure 4), and more intense material densification occurred in earlywood areas. The same has also been confirmed by the observations of Nilsson et al. (2011) [41]. This is due to the fact that in coniferous wood, earlywood cells have bigger cross-section dimensions and thinner cell walls than latewood. A similar effect has been reported in the literature in reference to densified spruce wood [13,42,43]. In turn, the way cells are densified has a very significant influence on the mechanical and physical properties of the material under modification [43].

3.2. Dynamic Modulus of Elasticity before and after Thermo-Mechanical Densification

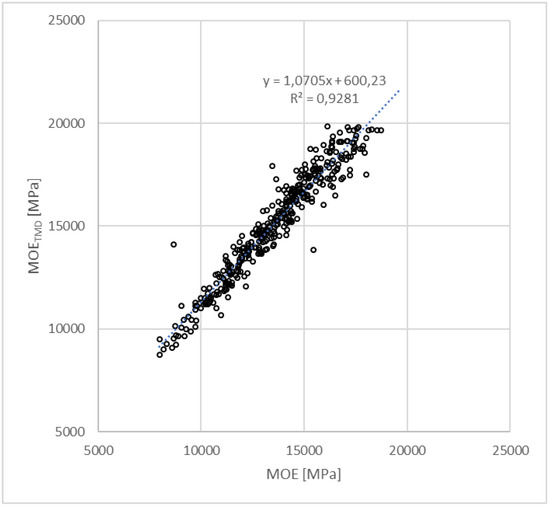

The relation between the modulus of elasticity before and after TMD modification, for the entire batch of timber under study, has been presented in Figure 5 and Figure 6. For both sets, departures from normality were observed.

Figure 5.

Relation between MOE before and after densification.

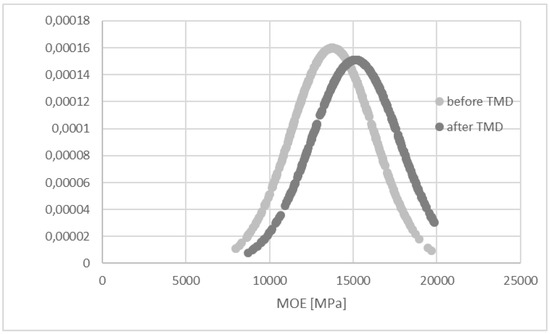

Figure 6.

MOE distribution before and after thermo-mechanical modification in the timber under study.

Figure 6 shows an increase in MOE as a result of TMD modification. The main value of MOE incremented by ca. 10%. Both before and after TMD modification, there is a negative kurtosis, which indicates a left-skewed asymmetry of distribution. The obliqueness, in both cases, is close to zero (distribution similar to a symmetrical one). After the modification, the obliqueness is skewed to the left (domination of lower MOE values). The distribution is close to the normal distribution (kurtosis value = 0). Kurtosis is negative, which means there are fewer positive outliers than in a normal distribution.

The dynamic modulus of elasticity of wood (MOE_dyn) before and after thermo-mechanical densification, for the various C classes of strength-graded timber determined before densification, has been presented in Table 3.

Table 3.

Dynamic modulus of elasticity before and after thermo-mechanical densification for timber classified in different strength grades before thermo-mechanical densification.

By analysing the results presented in Table 3, it can be concluded that the largest increase of MOE_dyn took place in the case of boards classified into the C18 strength grade before densification (13.6%) and the smallest in the case of boards classified as C40 (1.2%). For the remaining classes, the changes in MOE values were the following: C24 (12.1%), C30 (12.0%) and C35 (9.9%). The increase of dynamic modulus of elasticity for all the boards amounted to 11.4%. In the case of the group of boards that, before densification, was classified as C40, the increase of the modulus of elasticity was the smallest. For a part of the boards, 17 pieces, including 4 pieces from the C40 class and 13 pieces from the C35 class (graded before densification), whose density increased, as a result of compression, from 613 kg/m3 to 705 kg/m3, we were not able to specify the strength class using the MTG device. C classes and average MOE_dyn board after wood densification are presented in Table 4.

Table 4.

Dynamic modulus of elasticity after thermo-mechanical densification for timber classified in different strength grades specified after thermo-mechanical densification.

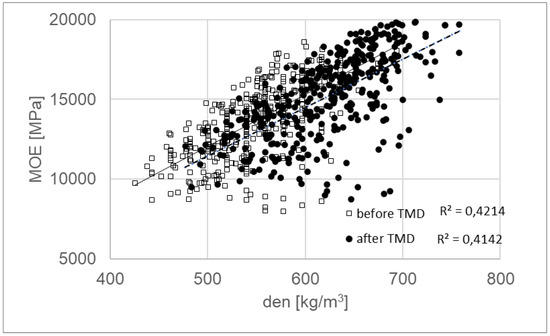

Figure 7 presents the relation between the density and MOE of timber, taking into account the results of strength grading.

Figure 7.

Relation between density and MOE (before and after TMD modification).

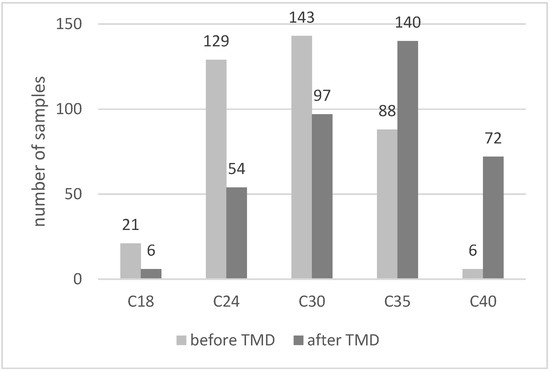

3.3. Structure of C Strength Grades before and after Thermo-Mechanical Densification

As a result of the thermo-mechanical densification of pine-sawn timber, there have been changes in the structure of share of strength classes in the batch of timber under study (Figure 8). In the case of the set of timber pieces strength graded with the machine method before thermo-mechanical densification, the dominant timber classes were C24 and C30. As a result of thermo-mechanical densification, C35 became the most dominant timber class. The second largest share corresponded to class C30, while C40 came third.

Figure 8.

Structure of C classes before and after thermo-mechanical densification.

The obtained results permit us to conclude that, as a result of thermo-mechanical densification of timber, its density grows, which translates, as a consequence, into an increase of the dynamic modulus of elasticity specified with a non-destructive method, using the MTG device (Mobile Timber Grader). The strength grading of timber before and after densification results in a significant increase in the share of pieces in higher C classes.

The effectiveness of board densification (density increase) fell within the range of 8%–14%. The highest densification (12%–14%) has been observed for timber from classes C18, C24, C30, and C35. In each case, the observed differences in density values before and after densification were statistically significant (different homogeneous groups in Table 5). In the case of modification of wood from the C40 class, the density increase we observed (8%) was visible but statistically insignificant (the same homogeneous group “f” in Table 5). It is worth noting that the highest percentual influence on material densification (54.1%—Table 6) resulted from the initial class of wood, which depended on the material’s initial parameters. Both the densification process itself and the interaction between the densification process and the initial class of timber were characterised by a lower influence on the density increase than other factors that have not been taken into account in the current study (error = 36.2%).

Table 5.

Properties (homogeneous groups).

Table 6.

ANOVA for selected factors affecting density and MOE of tested wood.

Together with the densification increase, we also observed an increase in MOE for the timber under research. It fell within the range of 9%–14% for timber from classes C18, C24, C30, and C35. In each case, the increase of MOE values was statistically significant (different homogeneous groups in Table 5). The highest improvement of this parameter (14%) was observed for the lowest initial class, C18. In the case of the initial class C40, the modification process did not cause an improvement in MOE values (the same homogeneous group “H” in Table 1). It is worth noting that, similarly to density, the highest percentual influence on MOE values increase (81.5%—Table 6) resulted from the initial class of wood, which depended on the material’s initial parameters. Both the densification process itself and the interaction between the densification process and the initial class of timber were characterised by a lower influence on the MOE values increase than other factors that have not been taken into account in the current study (error = 17.5%).

4. Conclusions

The thermo-mechanical densification of flatsawn pine timber boards increases the values of its density by 13.5% on average, which translates into the average increase of the dynamic modulus of elasticity by 9% and causes changes in the number of timber pieces classified into the individual C strength grades.

As a result of thermo-mechanical densification in industrial conditions, the strength class C of most Scots pine timber pieces improves. Most timber pieces that were subjected to thermo-mechanical densification have improved their strength class, C, by one (72.7% of the tested batch) or two C classes (3.6% of the batch under study).

Thermo-mechanical densification causes an increase in the quality (expressed by average values of density and dynamic modulus of elasticity) of timber for construction applications.

Author Contributions

Conceptualization, I.B. and S.K.; methodology, I.B. and S.K.; software, I.B. and P.B., validation, I.B. and S.K.; formal analysis, I.B., P.M., P.B. and S.K.; investigation, I.B., P.M. and S.K.; resources, I.B., M.G. and S.K.; data curation, I.B, P.M. and P.B.; writing—original draft preparation, I.B., P.M., M.G., P.B. and S.K.; writing—review and editing, I.B.; visualization, I.B.; supervision, S.K.; project administration, I.B. and S.K.; funding acquisition, S.K. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful for the support of the National Centre for Research and Development, Poland, under “Environment, agriculture and forestry” – BIOSTRATEG strategic R&D programme, Agreement No. BIOSTRATEG3/344303/14/NCBR/2018.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Payn, T.; Carnus, J.-M.; Freer-Smith, P.; Kimberley, M.; Kollert, W.; Liu, S.; Orazio, C.; Rodriguez, L.; Silva, L.N.; Wingfield, M.J. Changes in planted forests and future global implications. For. Ecol. Manag. 2015, 352, 57–67. [Google Scholar] [CrossRef]

- Canadell, J.G.; Schulze, E.D. Global potential of biosphericcarbon management for climate mitigation. Nat. Commun. 2014, 5, 5282. [Google Scholar] [CrossRef]

- Sandberg, D.; Haller, P.; Navi, P. Thermo-hydro and thermo-hydro-mechanical wood processing: An opportunity for future environmentally friendly wood products. Wood Mater. Sci. Eng. 2013, 8, 64–88. [Google Scholar] [CrossRef]

- Hajihassani, R.; Mohebby, B.; Najafi, S.K.; Navi, P.; Hajihassani, R.; Mohebby, B.; Najafi, S.K.; Navi, P. Influence of combined hygro-thermo-mechanical treatment on technical characteristics of poplar wood. Maderas-Cienc. Tecnol. 2018, 20, 117–128. [Google Scholar] [CrossRef]

- Knapic, S.; Santos, J.; Santos, J.A.D.; Pereira, H. Natural durability assessment of thermo-modified young wood of eucalyptus. Maderas-Cienc. Tecnol. 2018, 20, 489–498. [Google Scholar] [CrossRef]

- Kamperidou, V. The Biological Durability of Thermally- and Chemically-Modified Black Pine and Poplar Wood Against Basidiomycetes and Mold Action. Forests 2019, 10, 1111. [Google Scholar] [CrossRef]

- Dubey, M.K.; Pang, S.S.; Chauhan, S.; Walker, J. Dimensional Stability, Fungal Resistance and Mechanical Properties of Radiata Pine after Combined Thermo-Mechanical Compression and Oil Heat-Treatment. Holzforschung 2016, 70, 793–800. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. IForest 2017, 10, 895–908. [Google Scholar] [CrossRef]

- Lesar, B.; Humar, M.; Kamke, F.A.; Kutnar, A. Influence of the thermo-hydro-mechanical treatments of wood on the performance against wood-degrading fungi. Wood Sci. Technol. 2013, 47, 977–992. [Google Scholar] [CrossRef]

- Fang, C.H.; Cloutier, A.; Blanchet, P.; Koubaa, A. Densification of veneers combined with oil-heat treatment. Part I: Dimensional stability. BioResources 2011, 6, 373–385. [Google Scholar] [CrossRef]

- Navi, P.; Girardet, F. Effects of thermo-hydro-mechanical treatment on the structure and properties of wood. Holzforschung 2000, 54, 287–293. [Google Scholar] [CrossRef]

- Fang, C.H.; Cloutier, A.; Blanchet, P.; Koubaa, A. Densification of veneers combined with oil-heat treatment. Part II: Hygroscopicity and mechanical properties. BioResources 2012, 7, 925–935. [Google Scholar] [CrossRef]

- Heger, F.; Groux, M.; Girardet, F.; Welzbacher, C.; Rapp, A.O.; Navi, P. Mechanical and Durability Performance of THM-Densified Wood. In Proceedings of the Final Conference COST Action E22 Environmental Optimization of Wood Protection, Estoril, Portugal, 22–23 March 2004; pp. 1–10. [Google Scholar]

- Pelaez-Samaniego, M.R.; Yadama, V.; Lowell, E.; Espinoza-Herrera, R. A review of wood thermal pretreatments to improve wood composite properties. Wood Sci. Technol. 2013, 47, 1285–1319. [Google Scholar] [CrossRef]

- Kubovský, I.; Kačiková, D.; Kačik, F. Structural changes of oak wood main components caused by thermal modification. Polymers 2020, 12, 485. [Google Scholar] [CrossRef] [PubMed]

- Grześkiewicz, M.; Poddębski, K. Thermal properties and density profile of poplar wood (Populus nigra L.) thermally and thermo-mechanically modified. In Proceedings of the 9th European Conference on Wood Modification, Arnhem, The Netherlands, 17–18 September 2018; pp. 1–6. [Google Scholar]

- Kozakiewicz, P.; Drożdżek, M.; Laskowska, A.; Grześkiewicz, M.; Bytner, O.; Radomski, A.; Zawadzki, J. Effects of thermal modification on selected physical properties of sapwood and heartwood of black poplar (Populus nigra L.). BioResources 2019, 14, 8391–8404. [Google Scholar] [CrossRef]

- Kozakiewicz, P.; Drożdżek, M.; Laskowska, A.; Grześkiewicz, M.; Bytner, O.; Radomski, A.; Mróz, A.; Betlej, I.; Zawadzki, J. Chemical Composition as a Factor Affecting the Mechanical Properties of Thermally Modified Black Poplar (Populus nigra L.). BioResources 2020, 15, 3915–3929. [Google Scholar] [CrossRef]

- Anshari, B.; Guan, Z.; Kitamori, A.; Jung, K.; Hassel, I.; Komatsu, K. Mechanical and moisture-dependent swelling properties of compressed Japanese cedar. Constr. Build. Mater. 2011, 25, 1718–1725. [Google Scholar] [CrossRef]

- Huang, C.; Chui, Y.; Gong, M.; Chana, F. Mechanical behaviour of wood compressed in radial direction: Part II. Influence of temperature and moisture content. J. Bioresour. Bioprod. 2020, 5, 266–275. [Google Scholar] [CrossRef]

- Rautkari, L.; Laine, K.; Kutnar, A.; Medved, S.; Hughes, M. Hardness and density profile of surface densifies and thermally modified Scots pine in relation to degree of densification. J. Mater. Sci. 2013, 48, 2370–2375. [Google Scholar] [CrossRef]

- Zhou, Q.; Chen, C.; Tu, D.; Zhu, Z.; Li, K. Surface densification of poplar solid wood: Efects of the process parameters on the density profile and hardness. BioResources 2019, 14, 4814–4831. [Google Scholar] [CrossRef]

- Welzbacher, C.R.; Wehsener, J.; Rapp, A.O.; Haller, P. Thermo-mechanical densification combined with thermal modification of Norway spruce (Picea abies Karst) in industrial scale—Dimensional stability and durability aspects. Holz Roh. Werkst. 2008, 66, 39–49. [Google Scholar] [CrossRef]

- Yoshihara, H.; Tsunematsu, S. Bending and shear properties of compressed Sitka spruce. Wood Sci. Technol. 2007, 41, 117–131. [Google Scholar] [CrossRef]

- Bao, M.; Huang, X.; Jiang, M.; Yu, W.; Yu, Y. Effect of thermo-hydro-mechanical densification on microstructure and properties of poplar wood. J. Wood Sci. 2017, 63, 591–605. [Google Scholar] [CrossRef]

- He, Z.; Qi, Y.; Zhang, G.; Zhao, Y.; Dai, Y.; Liu, B.; Lian, C.; Dong, X.; Li, Y. Mechanical Properties and Dimensional Stability of Poplar Wood Modified by Pre-Compression and Post-Vacuum-Thermo Treatments. Polymers 2022, 14, 1571. [Google Scholar] [CrossRef] [PubMed]

- Şenol, S.; Budakçı, M. Effect of Thermo-Vibro-Mechanic Densification Process on the Gloss and Hardness Values of Some Wood Materials. BioResources 2019, 14, 9611–9627. [Google Scholar] [CrossRef]

- Cruz, N.; Avila, C.; Aguayo, M.G.; Cloutier, A.; Castillo, R. Impact of the Chemical Composition of Pinus radiata Wood on its Physical and Mechanical Properties Following Thermo-Hygromechanical Densification. BioResources 2018, 13, 2268–2282. [Google Scholar] [CrossRef]

- Balasso, M.; Kutnar, A.; Niemelä, E.P.; Mikuljan, M.; Nolan, G.; Kotlarewski, N.; Hunt, M.; Jacobs, A.; O’Reilly-Wapstra, J. Wood Properties Characterisation of Thermo-Hydro Mechanical Treated Plantation and Native Tasmanian Timber Species. Forests 2020, 11, 1189. [Google Scholar] [CrossRef]

- Pertuzzatti, A.; Missio, A.L.; Cademartori, P.H.G.; Santini, E.J.; Haselein, C.R.; Berger, C.; Gatto, D.A.; Tondi, G. Effect of Process Parameters in the Thermomechanical Densification of Pinus elliottii and Eucalyptus grandis Fast-growing Wood. BioResources 2018, 13, 1576–1590. [Google Scholar] [CrossRef]

- Carbal, J.P.; Kafle, B.; Subhani, M.; Reiner, J.; Ashraf, M. Densification of timber: A review on the process, material properties and application. J. Wood Sci. 2022, 68, 24. [Google Scholar] [CrossRef]

- Kutnar, A.; Kamke, F.A. Compression of wood under saturated steam, superheated steam, and transient conditions at 150 °C, 160 °C, and 170 °C. Wood Sci. Technol. 2012, 46, 73–88. [Google Scholar] [CrossRef]

- Kamke, F.A. Densified radiata pine for structural composites. Maderas. Cienc. Tecnol. 2006, 8, 83–92. [Google Scholar] [CrossRef]

- Esteves, B.; Ribeiro, F.; Gruz-Lopes, L.; Domingos, J.F.I. Densification and heat treatment of Martine pine wood. Wood Res. 2017, 62, 373–388. [Google Scholar]

- Ulker, O.; Imirzi, O.; Burdurlu, E. The effect of densification temperature on some physical and mechanical properties of Scots pine (Pinus sylvestris L.). BioResources 2012, 7, 5581–5592. [Google Scholar] [CrossRef]

- Sözbir, G.D.; Bektaş, İ.; Ak, A.K. Influence of combined heat treatment and densification on mechanical properties of poplar wood. Maderas Cienc. Tecnol. 2019, 21, 481–492. [Google Scholar] [CrossRef]

- Tanaka, K.; Demoto, Y.; Ouchi, J.; Inoue, M. Strength property of densified SUGI adopted as material of connector. In Proceedings of the 11th World Conference on Timber Engineering (WCTE 2010), Trentino, Italy, 20–24 June 2010; pp. 1696–1701. [Google Scholar]

- Malaga-Toboła, U.; Łapka, M.; Tabor, S.; Niesłony, A.; Findura, P. Influence of wood anisotropy on its mechanical properties in relation to the scale effect. Int. Agrophys. 2019, 33, 337–345. [Google Scholar] [CrossRef]

- Burawska-Kupniewska, I.; Krzosek, S.; Mańkowski, P. Efficiency of Visual and Machine Strength Grading of Sawn Timber with Respect to Log Type. Forests 2021, 12, 1467. [Google Scholar] [CrossRef]

- EN 338; Timber Structures—Strength Classes. European Committee for Standardisation: Brussels, Belgium, 2016.

- Nilsson, J.; Johansson, J.; Kifetew, G.; Sandberg, D. Shape stability of modified engineering wood product subjected to moisture variation. Wood Mater. Sci. Eng. 2011, 6, 42–49. [Google Scholar] [CrossRef]

- Schrepfer, V.; Schweingruber, F.H. Anatomical Structures in Reshaped Press-Dried Wood. Holzforschung 1998, 52, 615–622. [Google Scholar] [CrossRef]

- Kamke, F.A.; Sizemore, H. Viscoelastic Thermal Compression of Wood. U.S. Patent 7,404,422 B2, 29 July 2008. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).