Abstract

Many bamboo species are well suited for agroforestry as they are more versatile and rapidly renewable than trees. Bamboo is an important income source for rural villagers around the world, especially in tropical developing countries, such as Lao PDR (Lao People’s Democratic Republic). This study applied a value chain approach to compare potential incomes from different bamboo utilization models: (1) existing model of selling semi-processed raw materials (bamboo splits), and (2) new model of producing handcraft products locally. Using a rural village in eastern Lao PDR (Nongboua village in Vientiane Capital province) as a case study, we provided empirical assessments of two bamboo value chains. Based on interviews with the villagers and stakeholders and government statistical data from 2017 to 2019, existing and new bamboo production chains were evaluated. In the existing value chain, the final products, bamboo chopsticks, are worth $6.74/kg. The value chain starts with bamboo harvesting, collection, and management, which are done by villagers in Lao PDR and taxed by the Lao PDR government. Bamboo splits are then transported to Vietnam to make the final products to sell. Local villagers received only 4.9% of the total value. The new bamboo handicraft model could produce 9 bamboo cups and 60 medals from one bamboo stem worth $52.6–61.7 and $343.8. In this value chain, bamboo harvesting, management, and processing to final products are done by villagers. The handcrafts were collected by traders to be sold at souvenir shops. Local villagers could capture 29.4%–42.3% of the total values. Producing bamboo cup and medal could generate 1.12–2.17 and 234.8–244.6 times higher income for villagers per labor hour and per bamboo stem, respectively, and allow them to use more bamboo resource than producing bamboo splits to export to Vietnam. If applied to other rural areas in Lao PDR, the new bamboo product model for handicrafts can be a better income source for local villagers in Lao PDR with sustainable use of bamboo resources than the existing model. However, it requires extensive bamboo handicrafts training over a year. Although alternative uses of bamboo would be different depending on social, economic, and market contexts, the value chain analysis demonstrated in this study can be applied elsewhere to increase local retention of economic values generated from agroforestry.

1. Introduction

Agroforestry is a collection of land-use systems and practices where woody plants are integrated with other crops and animals [1]. Agroforestry consists of agrisilviculture, silvopasture, forest farming, and other practices, of which the forest farming plays a key role in offering timber and non-timber forest products (NTFPs) in tropical and subtropical region [2]. Recently, bamboo has gained increasing recognitions as a substitute for timber and a viable resource for rural poverty alleviation, as well as a high potential for carbon sequestration and climate change adaption [3,4,5]. Bamboo-based agroforestry can be used to improve land productivity, sustainability, and resource conservation, and is well suited for agroforestry [6,7,8].

Bamboo is regarded as one of the fastest-growing plants on earth [9]. It belongs to Gramineae family and Bambusoideae subfamily that has approximately 121 genera and 1662 species of bamboo, of which 232 (14%) have been found worldwide beyond their native ranges [10]. Bamboo, which has played an important role in rural economies for centuries, became an indispensable part of emerging economies around the world as one of the most traded NTFPs especially in tropical regions [11,12,13,14].

Sustainably managing natural resources in tropical developing countries must be balanced with addressing livelihood needs of local communities that would ensure community participation [15,16,17]. For bamboo to fulfill its potential for conservation and development, we need to better understand the current uses and value chains and develop and introduce new income models that allows local villagers to actively participate and improve their livelihoods while managing their bamboo resource sustainably.

A value chain analysis is a widely used method to assess business activities and recognize which activities are the most valuable and which ones could be improved to create competitive advantage for a business [18]. The value chain consists of a set of activities that a specific industry firm carries out to produce and deliver a product of value, which is either or both good and service, to the market [18]. It helps identify weak points in the chain and actions to add more value. The value chain approach is a method for “decomposing an enterprise into strategically important activities” [19,20], and the overall logic of a value chain can be applied to any industry [18,20]. We applied a value chain approach to compare the existing and potential bamboo product models using Vientiane Capital province in Lao PDR as a case study.

Bamboo is one of the most important natural resources in Lao PDR. Local governments and organizations consider bamboo as “green gold” to alleviate poverty, and promote production, processing, and trading of bamboo by the smallholders [21]. For many rural communities in Lao PDR, bamboo is an abundant and accessible resource. It is commonly used as a house building material, foods such as bamboo shoot, and a raw material for handicraft to make furniture, baskets, chopsticks, and incense sticks. With improved transportation infrastructure in northern part of Lao PDR over the past decades, increasing demand from neighboring countries, such as Vietnam, China, and Thailand, is adding pressure on bamboo resources of Lao PDR [22]. Recently, semi-processed products, such as dried bamboo splits, are exported to Vietnam and Thailand in large quantities. While producing bamboo splits may increase income of local villagers and improve their livelihoods, it may encourage overharvest. Bamboo splits are often sold directly to Vietnamese companies at a low price, and much of value adding economic activities occur outside Lao PDR without contributing much to local economy. When bamboo handicrafts are produced and sold to tourists, it can be an income source that generates multiple economic activities for local villagers [23]. However, little is known about different bamboo-based income models and their local economic impacts.

The objective of this study is to assess bamboo-based income generations for local villagers in Vientiane Capital province in Lao PDR from the existing and new bamboo product models using a value chain approach. We developed value chains for the existing bamboo product, bamboo chopsticks in Vietnam, and the new bamboo products, bamboo handicrafts such as bamboo cups and medals. The two value chains were compared to assess the impacts of the two models on local villagers’ livelihoods and sustainable use of bamboo resources. Understanding the value chains for the existing and new bamboo products provides useful information for local communities and policy makers in Lao PDR, as well as future studies in other developing countries.

2. Materials and Methods

2.1. Study Area

The Sangthong district is one of the poorest districts in Vientiane Capital province. Total area of the district is 75,980 ha, of which forest area accounts for 55%, agriculture land 33%, and wetland and other land use 10% of the land area. Existing forestlands are highly fragmented and degraded [24].

Four main soil groups (FAO/UNESCO Classification) in Sangthong district are: Alisols, Acrisols, Luvisols, and Regosols. The Acrisols and Alisols are dominant soils, covering about 80% of the total area. The climate is monsoonal, with a rainy season from May to October and a dry season during the rest of the year. The average annual rainfall is 1558 mm, of which over 90% occurs between May and October. The average mean temperature of the study area is 31.9 °C and maximum mean temperature of 35.9 °C has been recorded in April. The study area receives the average daily sunlight of 6.5 h [24].

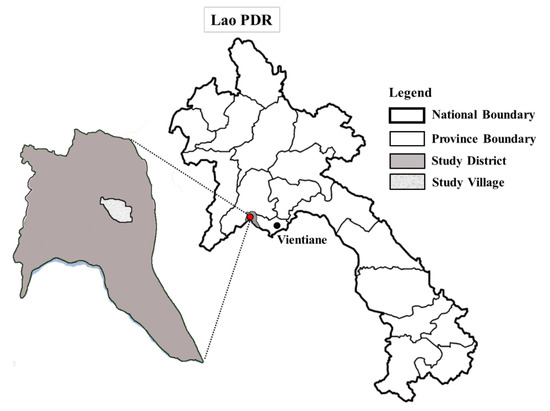

The Sangthong district consists of 35 villages of which the Nongboua village was selected for this study. Nongboua village in Sangthong district, about 60 km to the north of Vientiane (Figure 1), represents a low-income rural village in Lao PDR with rich bamboo resources. The Nongboua village consisted of 83 households and had a total population of 377 inhabitants, of which 177 inhabitants were women. The 80% of the total population was engaged in agriculture, and relied on paddy rice cultivation, shifting cultivation, gardening, livestock raising, and collection of non-timber forest products.

Figure 1.

Location of the project site in Sangthong district.

Land area of the Nongboua is 1135.92 ha, of which forest area is 504.40 ha and agricultural land is 599.52 ha (Table 1). These land use data were collected at the village and district level by the Department of Forestry in Lao PDR (hereafter called DOF). There were three major land use types: forest, agriculture, and settlement. The details of each land use are described below.

Table 1.

Land use of Nongboua village.

The Sangthong district has one of the richest bamboo resources in Vientiane Capital province. The bamboo area of Sangthong district accounted for 1.3% (20,565 ha; 7,094,803 stems) of the total bamboo area of 1,612,000 ha in Lao PDR [11,12,25]. The Nongboua village was estimated to account for 2.6% (530 ha; 182,367 stems) of the bamboo resources in Sangthong district.

In Nongboua village there are a total of nine bamboo species: Mai phai, Mai Phang (small), Mai Phang (big), Mai Sang Phai, Mai Khao Larm, Mai Xord, Mai Bong, Mai Hia, and Mai Ria (Table 2). Usually, villagers harvest bamboo stems of Mai Phang and Mai Sang Phai, which have a wider space between internodes than the others and are therefore preferred by bamboo companies for efficient product processing.

Table 2.

List of Bamboo species in Sangthong district, Lao PDR.

2.2. Methods

To identify the underlying structure of value chains associated with bamboo, first we mapped existing and new bamboo value chains in Nongboua village to assess various barriers, weak points, solutions, and the position of each actor in the value chain. We compared two value chains to analyze a way for local villagers to improve added value using their bamboo resources. We collected data through survey of selected villagers, field observation of the research team, as well as stakeholder interview and Focus Group Interview (F.G.I.).

2.2.1. Data Collection of Existing Bamboo Products Value Chain

Survey Questionnaires

To find out the status of bamboo-based income, the survey was conducted on 50 households out of 83 households in Nongboua village for a week in mid-October of 2019. The questions in the survey were as follows:

- Whether there was bamboo-based income or not

- Bamboo harvesting or not

- Annual working period for bamboo harvesting

- Average monthly and daily working hours for bamboo harvesting

- Labor type, self or hired

- Daily bamboo sales (kg) and income (kip)

- Total income related to bamboo

- Other bamboo income such as handicraft

Field Observation

In mid-October 2019, a total of six villagers participated in demonstrating bamboo harvesting and trading in Nongboua village. We observed and measured how much local villagers harvested and sold bamboos from forest to a Vietnamese company.

Stakeholder Interview

We conducted stakeholder interviews to examine bamboo value-chain for Nongboua village and Sangthong district in 2019. The interviews were conducted on key stakeholders of the bamboo value chain, including two local villagers from Nongboua village, two national and two local government officials in Lao PDR, and one staff of a Vietnamese bamboo company from Sangthong district. To each stakeholder group, the following questions were asked.

- Local villagers: Status and problems of the existing bamboo production system.

- Government officials of Sangthong District Agriculture and Forestry Office (DAFO) and DOF: Bamboo import and export data, annual bamboo harvesting quota, and regional bamboo tax and royalty of Sangthong district in 2017–2019. Especially, in Lao PDR, commercial uses of NTFPs are regulated with a quota system to protect bamboo forests [26]. Harvesting bamboos in Sangthong district also followed the quota system. Each company needs to obtain their business and quota licenses from the Provincial Agriculture and Forestry Office (PAFO) and Department of Industry and Commerce (DIC) annually. Different government agencies require appropriate licenses for harvesting, collecting, and transporting bamboo resource [27]. The quota was issued at a provincial level [28].

Once provincial annual quota was approved by the Ministry of Agriculture and Forestry (MAF), the PAFO held a meeting with the Provincial Trade Office and District Governor Office where the provincial quota was allocated to the DAFO. These quotas were issued for specific zones within each district and were further divided to traders contracted with the DAFO. These contractors were not allowed to collect NFTPs directly from forests, but to buy them from villagers. The actual harvesting of bamboo stems mostly took place during the dry season (November to April). Lack of information on bamboo resources made it difficult to calculate the reasonable quota [27,28]. Annual bamboo quota and actual harvest from 2017 to 2019 were reported in the Sangthong DAFO (The Sangthong DAFO had not collected official statistics of bamboo quotas prior to 2017). The quota in 2018 was 2,100,000 stems (16,800 ton), but the actual harvest increased to 2,625,000 stems (21,004 ton), harvesting 525,500 stems (4204 ton) more than the quota. In addition, the quota in 2019 was twice of the quota in the previous year.

The quota was allocated by district level, so each village’s quota depended on demand from the Vietnamese companies rather than reliable estimates of available bamboo resource. It is difficult to provide unit basis quota in Nongboua village, thus raising a question about sustainability of bamboo forests in the area.

Vietnamese bamboo companies that sought to buy NTFPs from villagers had to contract the village chief. Each company paid $0.02/stem (200 kip/stem or 25 kip/green kg) as a contribution to village development fund at village level, in accordance with the quota allocated by the Lao PDR government. When bamboo companies transported dried bamboo splits from the collection sites, they had to pay an export tax of $0.0044/kg (40 kip/kg) at district level. In addition, the companies needed to pay one-time $5.6 (50,000 kip) and $2.2/year (20,000 kip/year) for registration and annual fees to the PAFO.

- Staff of Vietnamese bamboo company: In the existing bamboo value chain, the Vietnamese company is an important actor. The company headquarter and factory were located in Vietnam. The company sent and hired workers to collect and manage bamboos from the Sangthong district. It was difficult to access detailed data and visit the bamboo-collecting areas where the harvested bamboos were transported and sold to the company. Therefore, we relied on interviews with Laotian staff who were working for the company and collected the information on the existing bamboo value chain, such as average cost and amount of bamboo materials to produce final bamboo products (e.g., chopsticks and incense stick).

2.2.2. Data Collection of New Bamboo Products Value Chain

We surveyed bamboo handicraft items in the neighboring villages and markets in 2017. Most of bamboo handicrafts were weaved items such as rice basket, bag, mat, chicken cage, fishing trap, and furniture. For the new model we decided to make small bamboo products for foreign tourists (i.e., cup, medal, and hairpin) that required relatively low handicraft skills and could be sold to a trader.

The bamboo quota and tax by imposed by the DOF involves only the existing bamboo chain, e.g., collecting bamboo splits for Vietnamese company. The existing quota and tax do not apply to the new value chain of bamboo handicrafts in this study.

Survey Questionnaires

We used the same field survey that was conducted on 50 households in Nongboua village for the existing bamboo product model.

Field Observation

In 2018, a total of 12 people volunteered for a new bamboo-based income model. We recruited seven male participants in their early-40s to 60s and five female participants in their mid-30s to 40s through the DOF. As of 2019, only six villagers were still participating in the new income model (one male early-40s and five females). A total of five trainings were conducted: two times in 2018, and three times in 2019. Each training averaged about 10 days. Their motives for the participation were to contribute to family livelihoods and to learn advanced bamboo handicraft skills. We observed the participants’ engagements during the trainings and changes in their motivation, skill proficiency, and income generation.

Focus Group Interview (F.G.I.)

The F.G.I. is a qualitative data collection method for small groups [29]. A focus group in this study consisted of the volunteered participants. The participants were interviewed in 2018 and 2019 about income generation and contribution to their livelihoods before and after the participation of the new bamboo income model.

3. Results

3.1. Exisiting Bamboo Products Value Chain in Nongboua Village

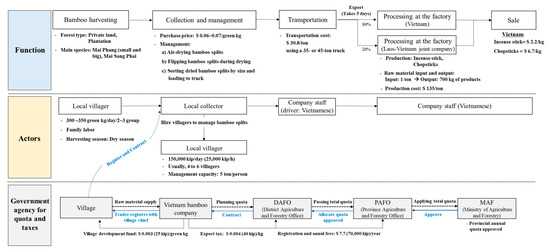

The value chain of the existing bamboo products produced mostly bamboo chopsticks and incense stick in Vietnamese markets, which required raw materials (i.e., dried bamboo splits) from local villages in Lao PDR. This value chain had the functions in the following order: bamboo harvesting, collection and management of bamboo splits, transportation, processing at factories, and sales (Figure 2).

Figure 2.

Overview of the existing bamboo products value chain in Nongboua village.

3.1.1. Bamboo Harvesting

During the dry season, local villagers harvested bamboo stems from bamboo forest to supply raw materials for chopsticks and incense stick in Vietnam. The procedure for the villagers to harvest bamboo stems was as follows:

- Vietnamese bamboo companies registered at the MAF in Lao PDR to acquire raw bamboo materials from Sangthong district.

- The companies received annual quotas and villages allocated by the MAF, and established collection sites in town.

- The companies usually either hire local villagers to harvest bamboos on a daily basis or purchase harvested split bamboos from local villagers. At the time of our interview, the company in the Nongboua village purchased the bamboos from the villagers.

- Nongboua villagers harvested bamboos at plantation sites near the village. Following the MAF regulation, only bamboos 3 years or older were harvested [26].

- After cutting down bamboo stands, the villagers split the bamboos into seven sizes: 65 cm, 75 cm, 82 cm, 92 cm, 102 cm, 112 cm, and 122 cm (Figure 3a,b).

Figure 3. Bamboo harvesting and semi-processing steps: (a) villagers harvested whole bamboos in forest, (b) villagers cut and split bamboo stems (internodes) into smaller pieces on-site, and (c) villagers sold bamboo splits by weight to a company at the collecting area in town.

Figure 3. Bamboo harvesting and semi-processing steps: (a) villagers harvested whole bamboos in forest, (b) villagers cut and split bamboo stems (internodes) into smaller pieces on-site, and (c) villagers sold bamboo splits by weight to a company at the collecting area in town. - Bamboo splits were gathered by the same size and tied up. Finally, bamboo splits were carried by a tractor and sold to the company at a collection site (Figure 3c).

The interviews and field observations found that more than 60% of Nongboua villagers earned cash income from harvesting and selling bamboos during the dry season (about 5 months). Bamboo harvesting was a highly labor-intensive work and required a minimum of three people to work efficiently. A three-person family could produce 300–350 green kg bamboo splits at a time, which would take an average of 2 h. The interviewed villagers worked 5 times a month to harvest bamboos. The labor and income information by a three-person family is shown in Table 3.

Table 3.

Labor and income information on bamboo harvesting for a three-person village family.

3.1.2. Collection and Management

The villagers in Sangthong district sold bamboo splits to a Vietnamese company at bamboo collection sites that were distributed to villages nearby, thus it would be easy to sell the bamboo splits. According to a local official in the Sangthong DAFO, there were estimated to be a total number of 20 collection sites in 35 villages of Sangthong district.

The collected bamboo splits were sorted by size and dried until a truck arrived. The villagers mainly worked as follows: (1) positioning and air-drying bamboo splits for at least 3–4 weeks (Figure 4a), (2) flipping top to bottom of bamboo splits during the drying, (3) classifying bamboo splits by the seven sizes, and (4) storing and loading dried bamboo splits to a truck. The company hired local villagers in two ways: On daily basis, $16.9/day (150,000 kip/day) for which a worker could manage 167 kg of bamboo splits (5 tons/month), and on a regular basis, $0.9/ton (8000 kip/ton) for which a worker stayed in a collection site to dry bamboo splits.

Figure 4.

Bamboo collection and management: (a) air drying bamboo splits and (b) loading bamboo splits into a truck owned by a Vietnamese company.

3.1.3. Transportation

Vietnamese bamboo companies transported bamboo splits completely dried to processing factories in Vietnam and near Lao PDR-Vietnam border. Most of the dried bamboo splits (about 80%) were transported to factories in Vietnam and some (20%) were transported to factories near the border in Lao PDR. Over the past several years, road networks in northern and central Lao PDR have been improved (e.g., road No. 1 and 13), and enabled to trade NTFPs with neighboring countries (e.g., Vietnam and China).

Interviews with a local DAFO official and a Vietnamese company staff identified that the main transportation route was Sangthong district → Vientiane capital → No.13 Road south-bound → No. 8 Road east-bound → Nam Phao international checkpoint in Khamkerd district → Vinh in Vietnam. Total traveling distance was about 500 km and it took 5 days to travel. An average transportation cost from the Sangthong district to the factories in Vietnam was about $30.8/ton (265,000 kip/ton), including gas and depreciation. Typically, a company transportation truck (35 or 45 ton) visited a collection site at least every two months, depending on the company’s demand of raw materials (Figure 4b).

3.1.4. Processing and Production

Dried bamboo splits were unloaded and processed at bamboo factories in Vietnam or near the border in Lao PDR. The bamboo products made in all factories were consumed in Vietnamese markets.

According to an interview with the company staff, one ton of dried bamboo split could produce an average of 700 kg of bamboo products regardless of items (bamboo chopsticks and incense stick). The average production cost was about $135/ton (1,200,000 kip/ton).

3.1.5. Sales

The bamboo sector in Lao PDR was undeveloped and depended heavily on Vietnamese industries. All bamboo products that used bamboos in Sangthong district, including Nongboua village, were sold in Vietnamese markets. Based on the interview with the company staff, the selling prices of bamboo chopsticks and incense stick were $6.7/kg (60,000 kip/kg) and $2.2/kg (20,000 kip/kg), respectively.

3.1.6. Estimation of the Existing Bamboo Value Chain: Bamboo Chopsticks

Bamboo splits dried in Nongboua village were used to produce mainly chopsticks. Local villagers sold green bamboos to the Vietnamese companies; on the other hand, bamboo chopsticks factories used dried bamboos. We converted green kg to dry kg to estimate resource volume and values to have been used for bamboo chopsticks.

Normally green bamboo has an average of 60–75% moisture content [30]. When bamboos are dried, the moisture content drops to 12–12.5% [31,32,33,34], losing 48–63% moisture. This study assumed 50% weight loss from the air drying in the Nongboua village. In addition, the bamboo processing factories in Vietnam used 1 kg dried bamboo material to produce 0.7 kg of bamboo chopsticks. In other words, 1 kg of bamboo chopsticks needs 1.429 kg of dry bamboos or 2.858 kg of green bamboos.

The green bamboo splits were sold at an average price of $0.065/green kg (575 kip/green kg), which was $0.13/kg (1150 kip/kg) and $0.18/kg chopsticks (1643 kip/kg chopsticks). The costs for collection and management, tax, transportation, and processing in Vietnam were $0.14 (1286 kip), $0.01 (129 kip), $0.04 (379 kip), and $0.19 (1715 kip), respectively, to produce 1 kg of bamboo chopsticks that were sold at a price of $6.74 (60,000 kip) in Vietnamese markets. Therefore, the production cost of bamboo chopsticks excluding wages and salaries of drivers and workers in the factories was $0.58/kg chopsticks, which was only 8.6% of the bamboo chopsticks market value.

Local villagers were a key actor in the bamboo chopsticks value chain as part of bamboo harvesting and collection and management, which generated low values ($0.18 and $0.14/kg chopsticks). On the contrary, the Vietnamese bamboo company was a key actor as part of transportation, processing, and sales, which generated a total value of $6.341/kg chopsticks or 95.1% of the total value (Table 4). Although Lao PDR was able to generate added-values of bamboo resource domestically, most added-values were created by the Vietnamese companies out of the villages.

Table 4.

Bamboo chopsticks value chain in Nongboua village, Sangthong district, in 2018.

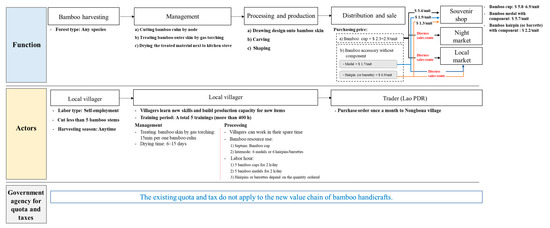

3.2. New Bamboo Products Value Chain in Nongboua Village

This study attempted to strengthen and build capacity of residents and to develop a new bamboo handicraft product model. The new model allowed local villagers to actively participate in the production of bamboo handicrafts and contributed to the socio-economic improvement and sustainable bamboo resource management within the area. A value chain approach shows how much values were added by local villagers (Figure 5) compared with the values added from the existing bamboo products.

Figure 5.

Overview of the new bamboo products value chain in Nongboua village.

3.2.1. Bamboo Harvesting

The new handicraft model was able to use any bamboo species more than 3 years old, unlike the existing model that used only two species (Mai Pahang and Mai Sang Phai). When six participants in the new model needed raw materials from bamboo forest, they harvested green bamboos to meet their demands. During the period from 2018 to 2019, each participant cut an average of five green bamboo stems that were more than 3 years old to make bamboo handicraft products.

The new model does not need a large quantity of bamboos. The villagers harvested a small quantity for dry season (November to April) [35]. On the other hand, villagers harvested bamboos for the existing model even in the rainy season depending on company orders.

3.2.2. Management

After harvesting green bamboos, the participants cut bamboo culm by node (Figure 6a), treated bamboo outer skin by gas torching (Figure 6b), and dried the treated material next to a kitchen stove (Figure 6c). This process was a key step for producing high quality bamboo handicrafts and improving the product life. This drying method is similar to kiln oven drying that is a commonly used method to dry bamboo culms [4]. Advantages of kiln drying is easy to control drying conditions and the required final moisture content in short time. It can also ensure higher level dried bamboo quality than air drying. However, the kiln oven/machine is difficulty to build/purchase and maintain in rural areas and only a small amount of bamboo is needed for handicrafts. A kitchen stove was used instead, which can result in similar effects.

Figure 6.

Bamboo harvesting, collection, and management steps: (a) cutting bamboo culm by node, (b) treating bamboo outer skin with gas torch, and (c) drying the treated bamboo material using a kitchen stove.

It took 6–15 days for villagers to dry bamboo material in this way. This drying method did not require a lot of manpower, took short drying time, and prevented a fungal infection inside bamboo.

3.2.3. Processing and Production

The processing and production of the new model required bamboo handicraft skills that local villagers did not have initially. It took time and efforts at this step to build the processing and production capacity of the villagers by training them. This study conducted a total of five training sessions for bamboo processing and handicraft production from 2018 to 2019. A Korean bamboo handicraftsman was invited to train local villagers to have enough bamboo craftsmanship skills for handicrafts. Each technique training took a total of 80 h for 10 days.

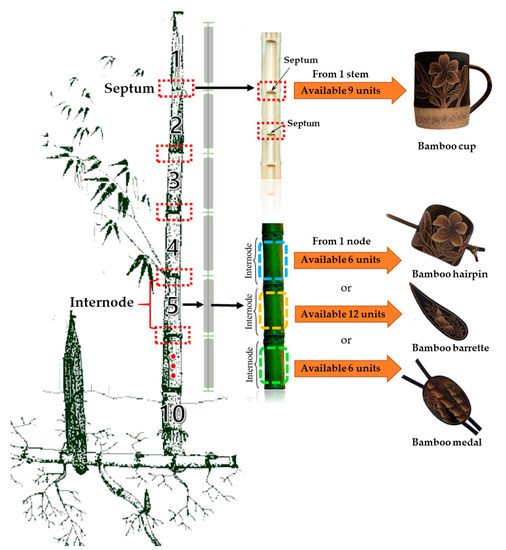

Each bamboo item needs a different part from bamboo culm (Figure 7). Bamboo cups need a septum for the cup bottom. The internode of which the septum was taken away for a bamboo cup can be used to produce 6 round-shaped medals, 6 ornamental hairpins, or 6 barrettes (hairclips), thus creating highly added value per bamboo stem.

Figure 7.

The bamboo parts used for the new bamboo handicraft model (modified after [36]).

3.2.4. Distribution and Sales

Small agriculture producers in developing countries are often linked with buyers through spot market-type transactions. Thus, the new bamboo model also needs to secure sales routes for the products. In 2019, a distributor (middle trader) visited the village and purchased bamboo handicrafts (Figure 8a). The purchase price of bamboo cup was $2.3–2.9 (20,000–25,000 kip) per unit depending on the cup size, which was decided based on the sales trial price. The price of bamboo medal was decided to be $1.7 (15,000 kip), and the hairpin and barrette were $0.9 (8000 kip) per piece. The distributor sold the bamboo cup, medal, hairpin, and barrette to souvenir shops at prices of $3.4 (30,000 kip), $1.9 (17,000 kip), $1.3 (12,000 kip), and $1.3 (12,000 kip). These bamboo products were sold at prices of $5.8–6.9 (52,000–61,000 kip), $5.7 (51,000 kip), $2.2 (20,000 kip), and $2.2 (20,000 kip), respectively, at the souvenir shops (Figure 5).

Figure 8.

Distribution and sales of the new bamboo products: (a) display and sales of bamboo products in a souvenir shop and (b) night market booth in Vientiane, Lao PDR.

Another sales route was direct sales by participating in events such as local festivals or national handcraft festivals (Figure 8b). In this case, local villagers were the only actor in the value chain from bamboo harvesting to sales. For example, the villagers went to the Sangthong District Festival and sold 25 bamboo cups, generating a total revenue of $70.2 (625,000 kip) by six people or $11.7/person (104,000 kip/person) in a day. Lao PDR had a monthly minimum wage of $124 (1,100,000 kip) as of 2018 [37] and a daily wage of $5.4–6.7 (50,000–60,000 kip) in rural areas [38]. Therefore, the new bamboo model could be highly profitable, thus contributing to cash circulation, and improve local livelihoods in Lao PDR.

Despite the high potential income increase, this model lacks a stable sales route. The new model needs to expand market-based sales by strengthening partnerships with local governments and associations that already have sales routes, such as the DAFO, PAFO, LHA (Lao Handicraft Association, The Lao Handicraft Association is a group of over 100 handicrafts producers in Lao PDR. The products include jewelry, textiles, carpets, metal work, wood crafts, and other handicraft items, all of which are made of local materials by local artisans [39]), and GDA (Gender Development Association, The GDA, formerly the Gender and Development Group (GDG) and Women in Development (WID) network, was formed in 1991. This association plays a role as a platform for knowledge sharing on gender issues. Especially, the GDA in Sangthong district has implemented building women’s capacity on bamboo weaving with the Lao Women’s Union (LWU). Therefore, it is one of the Sangthong bamboo value chain producer groups [40]).

3.2.5. Estimation of New Bamboo Value Chain: Bamboo Cup and Medal

Table 5 shows the new bamboo value chain. Local villagers were restricted to providing raw material to the supplier in the existing bamboo value chain. However, being able to process the final products, they became a key actor who played important roles as producers in the new value chain and negotiated the price of their bamboo products with traders.

Table 5.

New bamboo products value chain in Nongboua village, Sangthong district.

Local villagers started acting on their own to engage in new activities, such as showing their skills and products in domestic festivals and other events, and to teach bamboo handicraft skills to other villagers as a Trainer of Trainers (TOT). However, this study did not include the opportunity cost of participants such as villagers’ time and efforts to learn bamboo handicraft skills. The villagers received a total of five trainings and spent more than 400 h (10 day/training × 8 h/day × 5 trainings) to acquire the new skills.

3.3. Comparison of the Exisiting and New Bamboo Products Value Chains for Nongboua Villagers

It is necessary to compare income generation and use of bamboo resource between the existing and new models to assess their impacts on local villagers’ livelihood and sustainability of bamboo forest. However, the existing and new value chains were assessed using different units: unit weight (1 kg) of the final bamboo products and one bamboo stem. This study compares the income generations from the two models for Nongboua villagers in two ways: labor hour and use of bamboo resource.

3.3.1. Labor Hour

The bamboo harvesting in the existing value chain required a minimum of three people, which would take an average of 2 h. A three-person family was assumed to work 5 times a month and could produce 300–350 green kg bamboo splits at a time, which was purchased at an average price of $0.06/green kg (575 kip/green kg). Thus, the hourly income of one person for bamboo splits was $3.23–3.77 (28,750–33,542 kip) (Table 6).

Table 6.

Comparison of Nongboua villager’s incomes from the existing and new bamboo product models by labor hour.

On the other hand, a villager could make about five bamboo cups for two hours a day. The purchase price was $2.25–2.81/unit (20,000–25,000 kip/unit), and therefore the hourly income for one person was $5.62–7.02 (50,000–62,500 kip). Alternatively, a villager could make about five bamboo medals for two hours a day. The purchase price was $1.69/unit (15,000 kip/unit), and the hourly income for one person was $4.21 (37,500 kip) (Table 6). The new models for bamboo cup and medal can generate 1.49–2.17 and 1.12–1.30 times higher income than the existing model for bamboo splits.

Labor hour of bamboo splits included harvesting and splitting bamboos; however, that of bamboo cups and medals included only processing products. The bamboo harvesting and management in the new model were conducted as needed, which took over 6–15 days, and was therefore excluded in the comparison. Also, the existing model required highly labor-intensive outdoor work during the daytime, while the new model did not require heavy labor so villagers can work on bamboo handicrafts indoor regardless of outside weather conditions. However, the new model required a certain level of bamboo handicraft skills that took 5 sessions of bamboo skill trainings, equivalent to 400 h of training.

3.3.2. Use of Bamboo Resource

A fully-grown bamboo stem could produce 8 green kg of bamboo splits, of which the purchase price was $0.06/green kg (575 kip/green kg). Therefore, one bamboo stem could generate a total income of $0.52 (4600 kip) for the villagers by making bamboo splits. For the new model, one bamboo stem could produce 9 cups and 60 medals of which the purchase prices were $2.25–2.81/unit (20,000–25,000 kip/unit) and $1.69/unit (15,000 kip/unit), respectively. Therefore, one bamboo stem could generate a total income of $121.35–126.40 (1,080,000–1,125,000 kip) for the villagers by making bamboo cups and medals. From one bamboo stem, the new model for bamboo cup and medal can generate 234.8–244.6 times higher income than the existing model for bamboo splits. The new bamboo product model has more benefits than the existing model considering higher income generation for local villagers and much less use of local bamboo resource.

4. Discussion

The existing value chain for bamboo chopsticks proceeded as follows: bamboo harvesting, collection and management by villagers in Lao PDR, taxed by Lao PDR government, transportation to Vietnam, processing, and sales. Each function of the value chain produced $0.18 (2.7%), $0.14 (2.1%), $0.01 (0.2%), $0.04 (0.6%), $0.19 (2.9%), and $6.16 (91.4%) from 1 kg of bamboo chopsticks that was worth $6.74 (100%). Our analysis indicated that local villagers received only 4.9% of the total product value and Lao PDR, i.e., local villagers and Lao PDR government, received 5.1%. Lao PDR provided a raw material, bamboo, but most of the value (94.9%) was created by Vietnamese bamboo companies. Providing bamboo splits for bamboo chopsticks contributes little to livelihoods of local villagers.

The new model value chain for bamboo handicrafts proceeded as follows: bamboo harvesting, management, processing by villagers, distribution by traders, and sales by souvenir shops. One bamboo stem was estimated to produce 9 bamboo cups and 60 medals that were worth $52.6–61.7 and $343.8, respectively, totaling $396.4–405.5. From the 9 bamboo cups, bamboo harvesting, management, and processing produced $20.2–25.3 (37.9%–42.6%); distribution, $5.1–10.1 (10.6–15.2%); and sales, $22.2–31.3 (46.8–47.0%). From the 60 bamboo medals, bamboo harvesting, management, and processing produced $101.1 (29.4%); distribution, $13.5 (3.9%); and sales, $229.2 (66.7%). Most of the values (46.8%–66.7%) were created by souvenir shops, but 29.4%–42.6% of the values was retained by local villagers. Thus, producing bamboo handicrafts can potentially increase income and expand livelihood options of local villagers.

A comparison of the value chains of the existing and new bamboo products by labor hour showed that producing bamboo cup and medal could generate 1.49–2.17 and 1.12–1.30 times higher income for local villagers than producing bamboo splits to be exported to Vietnam. Also, a comparison of the two value chains by use of bamboo resource (i.e., bamboo stem) showed producing bamboo cup and medal could generate 234.8–244.6 times higher income than producing bamboo splits. Therefore, this study concludes that the new bamboo product model for handicrafts is better for local villagers in Lao PDR than the existing model for chopsticks made in Vietnam, considering both higher income generation and less use of bamboo resource. The new model enables local villagers to increase their income while sustainably using the bamboo resource. Similar results can be found in the previous study in India [41] where bamboo handicrafts produced much higher income (2700 USD) than selling raw bamboo (800 USD) annually, and boosted farmers’ income.

The new model, however, required a certain level of bamboo handicraft skills that needed 5 sessions of bamboo skill trainings, which took 400 h of training. To apply the new bamboo handicraft model to other rural areas in Lao PDR and potentially other developing countries, an intensive bamboo handicraft skill training would be required, which is a difficult task.

One solution is TOT model that educates a group of local villagers to acquire enough bamboo crafts skills, which allows them to train others with less skills, spreading bamboo handicrafts skill and expanding the new bamboo handicrafts model throughout a region. TOT for the new bamboo income model can be designed based on the lessons learned from the strategy of Saemaul Undong (New Village Movement), which was a community-driven development program and a government-initiated movement in the 1970s in the Korea [42]. Recently, this movement have been promoted by Korea in more than 30 developing countries across Africa, Asia, and Latin America as an integrated rural development model to increase income of rural poor through small-scale and self-help projects [43]. In particular, TOT has been one of the main activities in Saemaul Undong of Vietnam, where the government leaders organized TOT for poverty reduction and rural development. To develop the new bamboo model in Lao PDR would need various social, economic, and technical supports by the Lao PDR government who can develop TOT that can systematically facilitate spreading bamboo handicrafts skill and expanding the new bamboo handicrafts model throughout a region. Already Na Lad villagers adjacent to the Nongboua village requested bamboo handicraft trainings to the DOF, which shows potential applicability of the new model.

The new model needs more diverse and stable sales routes that this study did not explore. Without stable market demand for bamboo handicrafts, local villagers cannot continue producing the handicraft products. Also, understanding market trends of bamboo handicrafts will ensure local villagers to produce and supply the bamboo handicrafts that the market demands. More efforts should be made to bridge the supplier, local villagers, and the market of the new bamboo handicraft model. The needs to link bamboo resource and consumers, and to expand extension education for producers are found in other developing country [44].

In the Mekong basin region such as Cambodia, Laos, Myanmar, Thailand, and Vietnam, more than 400,000 people rely on their livelihoods from bamboo, and it could expect to increase 800,000 people [45] who are mostly lower income group in need of economic security. Processing raw bamboo and producing value-added products can generate local employment opportunities by enhancing the local bamboo value chain [46]. Although alternative uses of bamboo would be different depending on social, economic, and market contexts, the value chain analysis demonstrated in this study can be applied elsewhere. The first step is to evaluate an alternative approach for utilizing local resources that increases local value capture. Then, assessing available labor force characteristics with necessary job skills and providing targeted job trainings can increase livelihoods of local villagers and improve local economies while sustainably using bamboo resources.

5. Conclusions

This study assessed bamboo-based income generations from the existing and new bamboo product models for local villagers using a value chain approach and provided empirical assessments of local economic impacts that can be enhanced by the new bamboo utilization approach. About 60% of the Nongboua households relied on bamboo-based income during the dry season. Most of them engaged in simply cutting and selling green bamboos. A new income model should encourage local villagers to increase their roles within the value chain by selling more value-added products with local bamboo resources. The new income model made it possible for villagers to build their capacities to make and sell their own products from local bamboo resources.

This study was conducted at a village level and did not provide complete information on the whole value chains, especially for bamboo chopsticks made in Vietnam, which would have provided a better view on the existing and new bamboo product models. Further study is needed to demonstrate the potential increase in income from the new model with respect to sales route, bamboo handcraft design, and skill level as well as the economic and ecological impacts at different scale, such as regional and provincial levels. The value chain assessment provides the government and policymakers useful information so that they can find a way to improve livelihoods of local villagers and to manage bamboo forests in a sustainable way. As this model can utilize any bamboo species, it can be applied to other local villagers in Lao PDR, as well as neighboring countries.

Author Contributions

B.L., H.R., S.K. (Sebin Kim), J.-W.L. and S.K. (Seungmo Koo) conceived and designed the study; B.L., H.R., S.-J.L. and P.A. collected the data; B.L. and H.R. analyzed the data; and B.L., H.R. and Y.-S.K. wrote the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This study was carried out with the support of “R & D Program for Forest Science Technology (Project No. 2019126A00-1920-0001)” provided by Korea Forest Service (Korea Forestry Promotion Institute).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to personal information protection.

Acknowledgments

The authors would like to thank bamboo craftsman, Dongsuk Park, from the Korea, for his help in bamboo technique trainings and Oupakone Alounsavath at Department of Forestry, Ministry of Agriculture and Forestry, Lao People’s Democratic Republic, for his help in data collection.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Leakey, R.R.B. Definition of agroforestry revisited. Agrofor. Today 1996, 8, 5–7. [Google Scholar]

- Shin, S.; Soe, K.T.; Lee, H.; Kim, T.H.; Lee, S.; Park, M.S. A systematic map of agroforestry research focusing on ecosystem services in the Asia-Pacific Region. Forests 2020, 11, 368. [Google Scholar] [CrossRef]

- Nang’ole, E.M.; Mithöfer, D.; Franzel, S. Review of Guidelines and Manuals for Value Chain Analysis for Agricultural and Forest Products; Occasional Paper No. 17; World Agroforestry Centre: Nairobi, Kenya, 2011; pp. 1–30. [Google Scholar]

- Liese, W.; Köhl, M. Bamboo: The Plant and Its Uses, 1st ed.; Springer International Publishing: Cham, Switzerland, 2015; pp. 5–6. [Google Scholar] [CrossRef]

- Partey, S.T.; Sarfo, D.A.; Frith, O.; Kwaku, M.; Thevathasan, N.V. Potentials of bamboo-based agroforestry for sustainable development in Sub-Saharan Africa: A review. Agric. Res. 2017, 6, 22–32. [Google Scholar] [CrossRef]

- Christanty, L.; Kimmins, J.P.; Mailly, D. ‘Without bamboo, the land dies’: A conceptual model of the biogeochemical role of bamboo in an Indonesian agroforestry system. For. Ecol. Manag. 1997, 91, 83–91. [Google Scholar] [CrossRef]

- Nath, A.J.; Das, A.K. Carbon pool and sequestration potential of village bamboos in the agroforestry system of northeast India. Trop. Ecol. 2012, 53, 287–293. [Google Scholar]

- Tewari, S.; Banik, R.L.; Kaushal, R.; Bhardwaj, D.R.; Chaturvedi, O.P.; Gupta, A. Bamboo based agroforestry systems. In Bamboos in India, 1st ed.; Kaushik, S., Singh, Y.P., Kumar, D., Thapliyal, M., Barthwal, S., Eds.; ENVIS Centre on Forestry: Dehradun, India, 2015; pp. 261–284. Available online: http://frienvis.nic.in/WriteReadData/UserFiles/file/Publication/Books/2015-Bamboos-in-India.pdf (accessed on 11 November 2020).

- Buckingham, K.C.; Wu, L.; Lou, Y. Can’t see the (bamboo) forest for the trees: Examining bamboo’s fit within international forestry institutions. Ambio 2014, 43, 770–778. [Google Scholar] [CrossRef] [PubMed]

- Canavan, S.; Richardson, D.M.; Visser, V.; Le, J.J.; Vorontsova, M.S.; Wilson, J.R.U. The global distribution of bamboos: Assessing correlates of introduction and invasion. AoB Plants 2016, 9, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Lovovikov, M.; Paudel, S.; Piazza, M.; Ren, H.; Wu, J. World Bamboo Resources: A Thematic Study Prepared in the Framework of the Global Forest Resources Assessment 2005; Non-Wood Forest Products 18; FAO: Rome, Italy, 2007; p. 81. Available online: http://www.fao.org/3/a1243e/a1243e00.htm (accessed on 27 October 2020).

- Lovovikov, M.; Lou, Y.; Schoene, D.; Widenoja, R. The Poor Man’s Carbon Sink: Bamboo in Climate Change and Poverty Alleviation; Non-Wood Forest Products Working Document No 8; FAO: Rome, Italy, 2009; p. 72. Available online: http://www.fao.org/tempref/docrep/fao/012/k6887e/k6887e00.pdf (accessed on 27 October 2020).

- Warner, K.; McCall, E.; Garner, S. The Role of NTFPs in Poverty Alleviation and Biodiversity Conservation; International Union for Conservation of Nature (IUCN): Hanoi, Vietnam, 2008; p. 260. [Google Scholar]

- Paudyal, K.; Adhikari, S.; Sharma, S.; Samsudin, Y.B.; Paudyal, B.R.; Bhandari, A.; Birhane, E.; Darcha, G.; Trinh, T.L.; Baral, H. Framework for Assessing Ecosystem Services from Bamboo Forests: Lessons from Asia and Africa; Working paper 255; CIFOR: Bogor, Indonesia, 2019; pp. 1–42. [Google Scholar]

- Sakala, W.D.; Moyo, S. Socio-economic benefits of community participation in wildlife management in Zambia. Sustain. Res. Manag. J. 2017, 2, 1–18. [Google Scholar]

- Jabeen, S.; Nisar, M.; Saq, U.I.; Hussain, I. Community participation in socio-economic development through secondary education in one of the remotest regions of Pakistan. J. Nat. Soc. Sci. 2018, 7, 663–680. [Google Scholar]

- Alexander, A.F.; Hezekiah, A.A. Socioeconomic characteristics and community participation in infrastructure provision in Akure. Cogent Soc. Sci. 2018, 4, 1–13. [Google Scholar] [CrossRef]

- Porter, M. Competitive Advantage: Creating and Sustaining Superior Performance; Free Press: New York, NY, USA, 1985; p. 592. [Google Scholar]

- Stabell, C.B.; Fjeldstad, O.D. Configuring value for competitive advantage: On chains, shops, and networks. Strateg. Manag. J. 1998, 19, 413–437. [Google Scholar] [CrossRef]

- Koc, T.; Bozdag, E. Measuring the degree of novelty of innovation based on Porter’s value chain approach. Eur. J. Oper. Res. 2017, 257, 559–567. [Google Scholar] [CrossRef]

- World Wide Fund for Nature (WWF). Bamboo Can Become the Green Gold of Small Holders to Decrease Poverty. 2016. Available online: https://www.wwf.org.la/?271273/Launching-of-a-Lao-Bamboo-Platform-and-National-strategy (accessed on 2 November 2020).

- Phounvisouk, L.; Zuo, T.; Kiat, N.C. Non-timber forest products marketing: Trading network of trader and market chain in Luang Namtha Province, Lao PDR. J. Humanit. Soc. Sci. 2013, 18, 48–57. [Google Scholar] [CrossRef]

- Yumkella, K.K.; Hai, D.T.; Dinh, D.N. Greening Value Chains for Sustainable Handicrafts Production in Vietnam; United Nations Industrial Development Organization (UNIDO): Hanoi, Vietnam, 2013; pp. 1–44. [Google Scholar]

- Department of Forestry (DOF). Work Plan: Village Based Forest Rehabilitation Project in Lao PDR; DOF: Vientiane, Lao PDR, 2015; p. 78.

- Lee, B.; Rhee, H.; Lee, S.; Alounsavath, P.; Lee, J.; Koo, S.; Kim, S. Effectiveness analysis on new bamboo-based income system of Lao PDR: Case study of Nongboua mountain village. J. Korean Soc. Int. Agric. 2019, 31, 312–321. [Google Scholar] [CrossRef]

- Greijmans, M.; Oudomvilay, B.; Banzon, J. Houaphanh Bamboo Value Chain Analysis: Identifying SNV’s Potential Advisory Services for the Development of the Bamboo Value Chain; Stichting Nederlandse Vrijwilligers (SNV) Netherlands Development Organisation: Hague, The Netherland, 2007; p. 19. [Google Scholar]

- Phimmavong, B.; Chanthavong, V. Challenges and Opportunities for Lao DPR’s Small and Medium Forest Enterprises (SMFEs); Food and Agriculture Organization (FAO): Rome, Italy, 2009; pp. 9–10. [Google Scholar]

- Phommasane, S.; Foppes, J.; Wanneng, P.; Sirithirath, S. Positioning Study of the Bamboo Value Chain in Sang Thong District; SNV Netherlands Development Organisation: Hague, The Netherlands, 2007; pp. 10–52. [Google Scholar]

- McLafferty, I. Focus group interviews as a data collecting strategy. J. Adv. Nurs. 2004, 48, 187–194. [Google Scholar] [CrossRef] [PubMed]

- Wakchaure, M.R.; Kute, S.Y. Effect of moisture content on physical and mechanical properties of bamboo. Asian J. Civ. Eng. 2012, 13, 753–763. [Google Scholar]

- Gandhi, Y. Preliminary study on the drying the bamboo (Bambusa blumeana) in a wood waste fired kiln. In Proceedings of the 5th International Bamboo Congress and the 6 International Bamboo Workshop, San Jose, Costa Rica, 2–6 November 1998. [Google Scholar]

- Chung, W.F.; Yu, W.K. Mechanical properties of structural bamboo for bamboo scaffoldings. Eng. Struct. 2002, 24, 429–442. [Google Scholar] [CrossRef]

- Montoya-Arango, J.A. Trocknungsverfahren für die Bambusart Guadua Angustifolia unter Tropischen Bedingungen. Ph.D. Dissertation, University Hamburg, Hamburg, Germany, 2006. [Google Scholar]

- Qingfeng, X.; Kent, H.; Xiangmin, L.; Qiong, L.; Jennifer, G. Mechanical properties of structural bamboo following immersion in water. Eng. Struct. 2014, 81, 230–239. [Google Scholar]

- Ministry of Agriculture and Forestry (MAF). Forestry Strategy to the Year 2020 of the Lao PDR; MAF: Vientiane, Lao PDR, 2005; pp. 18–78.

- Zhu, Z. Bamboo industry’s impact evaluation on rural sustainable development. In International Training Workshop on Small Bamboo Daily Product Processing Technologies and Machines, Zhejiang, China, September 2004; Zhu, Z., Jiang, C., Eds.; International Farm Forestry Training Center, Chinese Academy of Forestry (CAF): Beijing, China, 2004. [Google Scholar]

- Bissinger, J. Discussion Paper on Minimal Wage Reforms: Key Considerations for Laos Employers; International Labour Organization (ILO), Bureau for Employers’ Activities (ACT/EMP): Geneve, Switzerland, 2019; p. 24. [Google Scholar]

- Food and Agriculture Organization (FAO). Special Report-2019 FAO/WFP Crop and Food Security Assessment Mission to the Lao People’s Democratic Republic; FAO: Rome, Italy, 2019; p. 20. [Google Scholar]

- Ukkerman, R. Bamboo Handicraft Products Fair trade/Marketing Study; Final Report; SNV Netherlands Development Organisation: Hague, The Netherland, 2010; pp. 1–16. [Google Scholar]

- Gender Development Association (GDA). Sangthong Bamboo Value Chain Producer Group. 2020. Available online: https://gdalaos.org/sangthong-bamboo-value-chain-producer-group/ (accessed on 18 December 2020).

- Dwivedi, A.K.; Kumar, A.; Baredar, P.; Prakash, O. Bamboo as a complementary crop to address climate change and livelihoods—Insights from India. Forest Policy Econ. 2019, 102, 66–74. [Google Scholar] [CrossRef]

- Lee, D.K.; Kwon, K.C.; Lee, Y.H. The role and contribution of sanlim-kyes during Seamaul Undong in the Korea in the 1970s. Forest Sci Technol. 2018, 14, 47–54. [Google Scholar] [CrossRef]

- United Nations Development Programme (UNDP). Saemaul Initiative Towards Inclusive and Sustainable New Communities: Implementation Guidance; UNDP: New York, NY, USA, 2015; pp. 43, 97. [Google Scholar]

- Endalamaw, T.B.; Lindner, A.; Pretzsch, J. Indicators and determinants of small-scale bamboo commercialization in Ethiopia. Forests 2013, 4, 710–729. [Google Scholar] [CrossRef]

- Pérez, M.R.; Maogong, Z.; Belcher, B.; Chen, X.; Maoyi, F.; Jinzhong, X. The role of bamboo plantations in rural development: The case of Anji County, Zhejiang, China. World Dev. 1999, 27, 101–114. [Google Scholar] [CrossRef]

- Ly, P.; Pillot, D.; Lamballe, P.; de Neergaard, A. Evaluation of bamboo as an alternative cropping strategy in the northern central upland of Vietnam: Above-ground carbon fixing capacity, accumulation of soil organic carbon, and socio-economic aspects. Agric. Ecosyst. Environ. 2012, 149, 80–90. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).