Formation of the Cu+Nb Interlayer in the Inconel 718/Ti6Al4V Multi-Material Obtained by Selective Laser Melting

Abstract

1. Introduction

2. Materials and Methods

2.1. Starting Materials, L-PBF Process Parameters, and Inconel 718/Ti6Al4V Multi-Material Samples

2.2. Characterization

3. Results and Discussion

3.1. Porosity and Microstructure of the Inconel 718/Ti6Al4V Multi-Material Samples

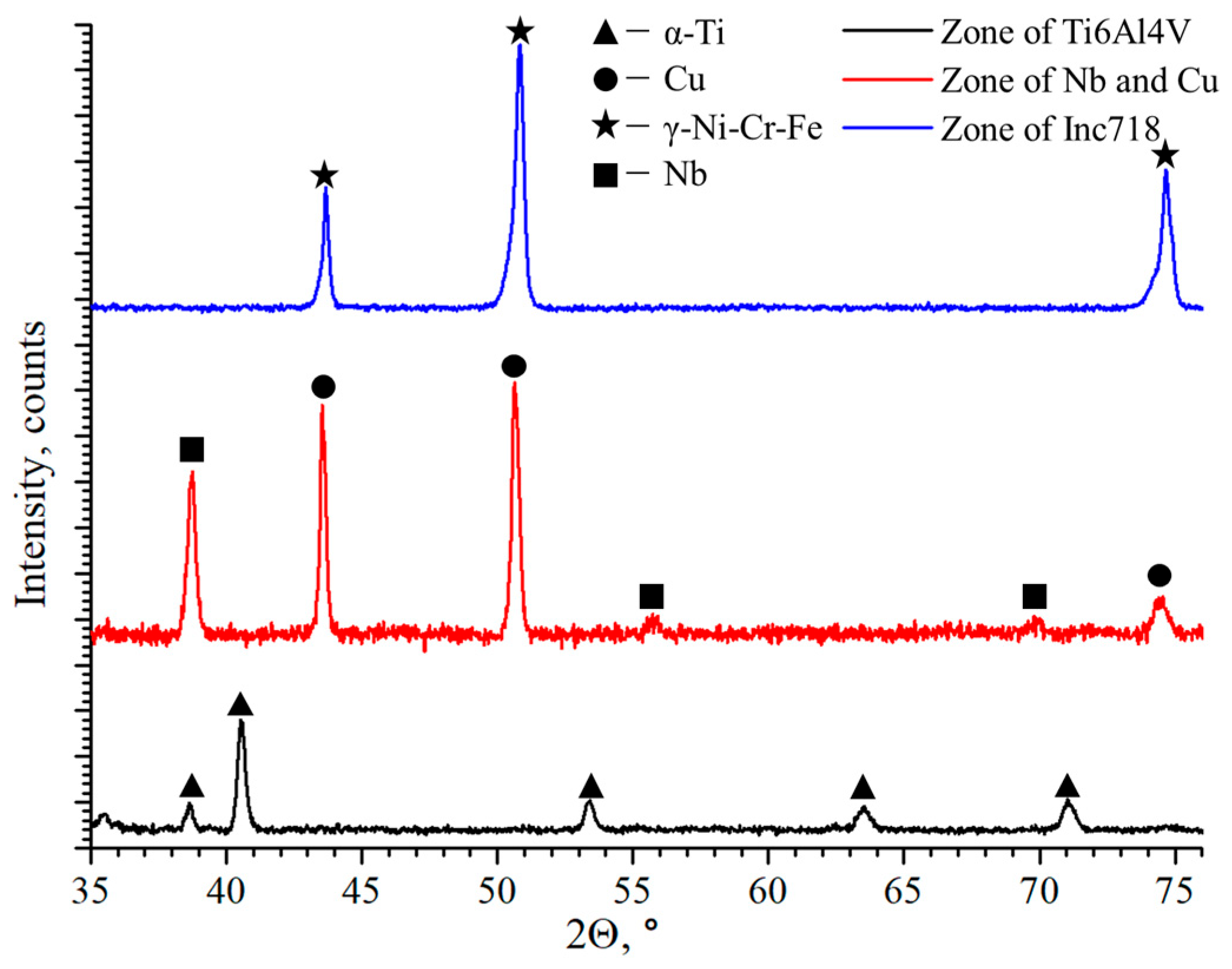

3.2. Chemical and Phase Composition of the Inconel 718/Ti6Al4V Multi-Material Samples

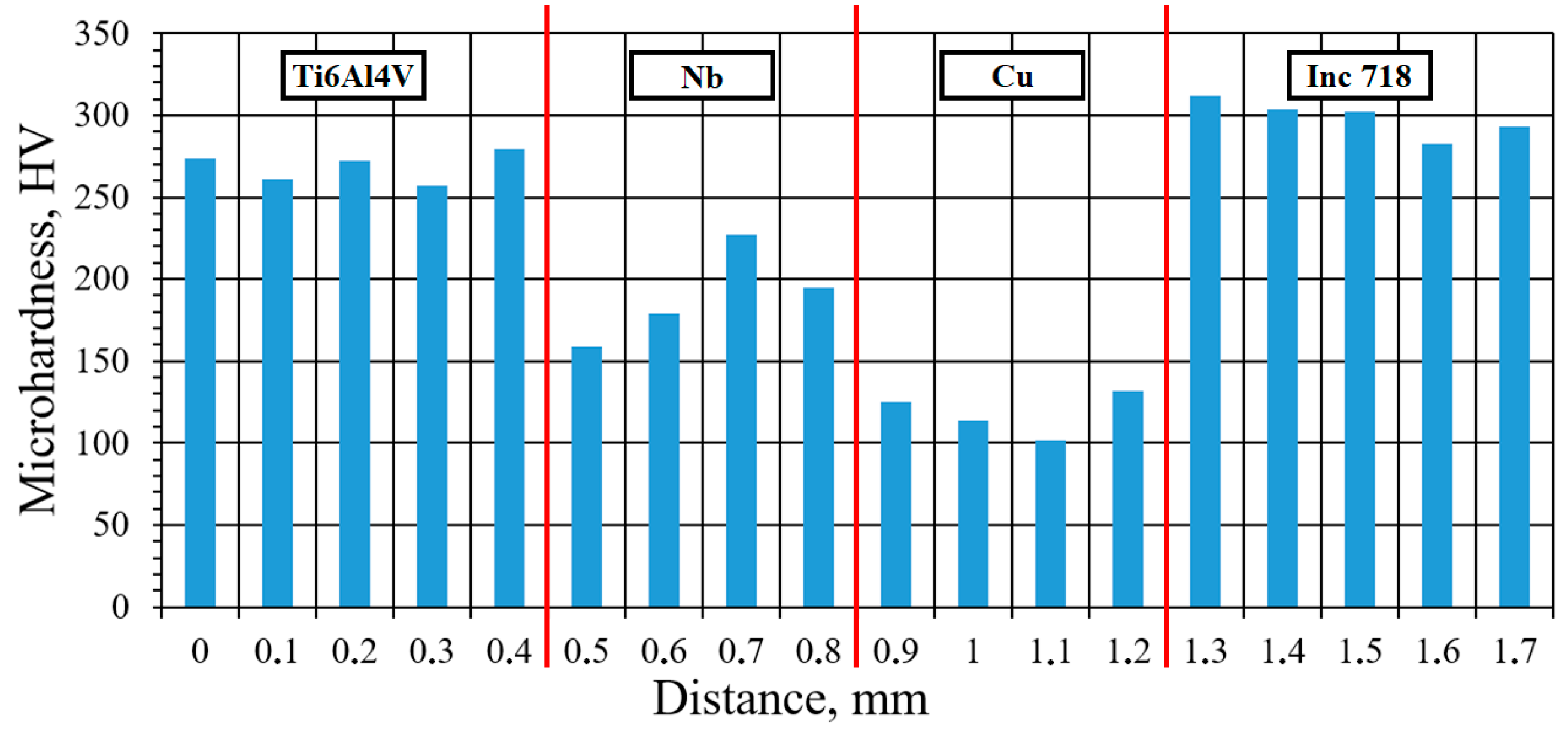

3.3. Microhardness of the Inconel 718/Ti6Al4V Multi-Material Samples

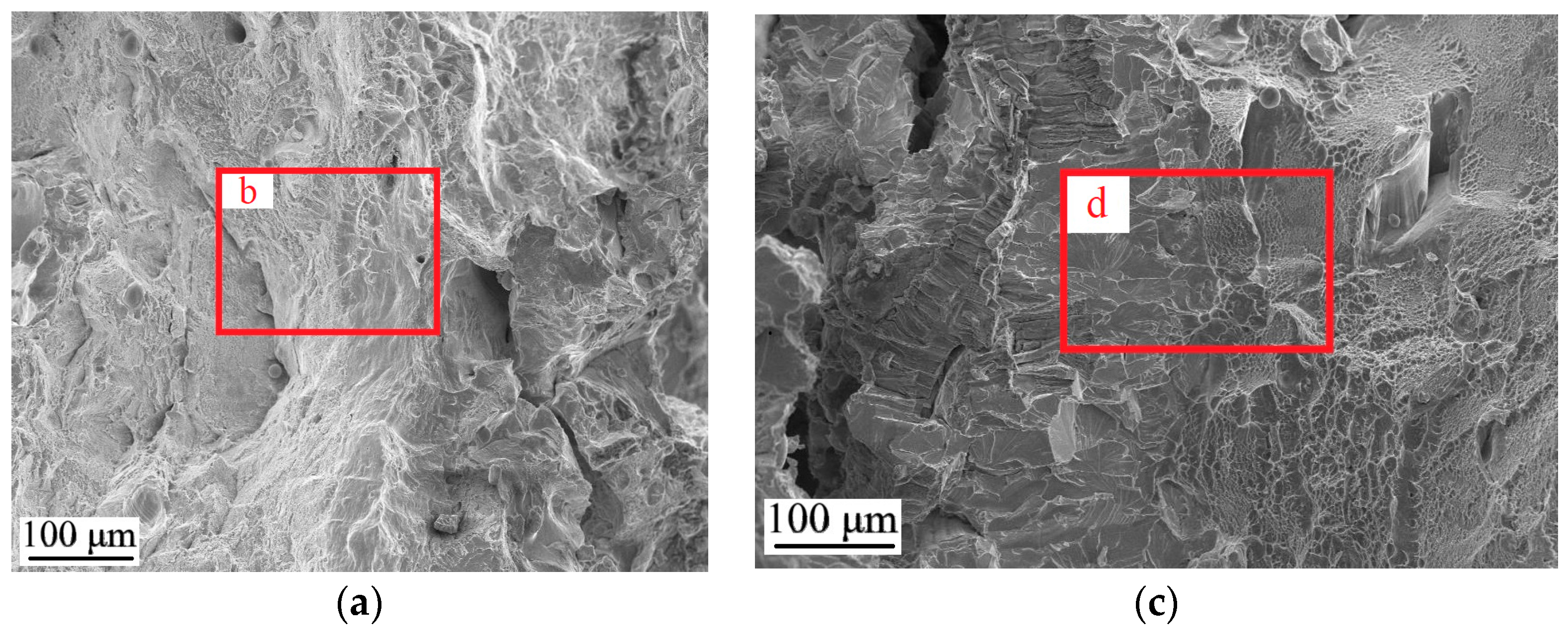

3.4. Room-Temperature Tensile Properties and Fracture Analysis of the Inconel 718/Ti6Al4V Multi-Material Samples

4. Conclusions

- No significant defects were observed in the zones of the alloys (the Ti6Al4V and the Inconel 718) and pure metals (Cu and Nb). However, such defects were observed in the Cu/Nb interfacial zone. The formation of island macro-segregations was observed in all interfacial zones: Ti6Al4V/Nb, Nb/Cu, and Cu/Inconel 718. The Ti6Al4V/Nb and Inconel 718/Cu interfacial zones exhibited a relatively sharp transition in chemical composition. In contrast, the Nb/Cu interfacial zone exhibited a gradual transition from one element to another. The results of the chemical composition study indicated that the width of the Nb/Cu transition zone was approximately 700 μm. No new phases were observed during the manufacturing process of the multi-material samples. The alloy zones were characterized by the presence of phases that are typical for such materials, as well as for the Cu-Nb interlayer. Thus, it can be assumed that the formation of brittle IMCs was prevented.

- The microhardness of the alloys and metals under examination correlated with the mean values for these materials. During the transition from the Ti6Al4V zone to the Inconel 718 zone through the Nb and Cu zones, the average microhardness values changed as follows: 270 → 190 → 120 → 300 HV. The change in microhardness values in the transition from alloys to pure metals was abrupt. However, the interfacial zone between Nb and Cu exhibited a more gradual change. The tensile strength of the multi-material samples reached 910 MPa, which is a relatively high value. However, the obtained results were below the properties of Ti6Al4V and Inconel 718. It is also noteworthy that the yield strength was relatively low, at approximately 140 MPa.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vaghasia, V.; Parmar, H.; Chaudhari, R.; Vora, J.K.; Abhishek, K.; Kumari, S. Recent advancements in the fabrication of multi-material structures by additive manufacturing. AIP Conf. Proc. 2024, 2960, 030017. [Google Scholar]

- Putra, N.E.; Mirzaali, M.J.; Apachitei, I.; Zhou, J.; Zadpoor, A.A. Multi-material additive manufacturing technologies for Ti-, Mg-, and Fe-based biomaterials for bone substitution. Acta Biomater. 2020, 109, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Rafiee, M.; Farahani, R.D.; Therriault, D. Multi-Material 3D and 4D Printing: A Survey. Adv. Sci. 2020, 7, 1902307. [Google Scholar] [CrossRef]

- Verma, A.; Kapil, A.; Klobčar, D.; Sharma, A. A Review on Multiplicity in Multi-Material Additive Manufacturing: Process, Capability, Scale, and Structure. Materials 2023, 16, 5246. [Google Scholar] [CrossRef]

- Hasanov, S.; Alkunte, S.; Rajeshirke, M.; Gupta, A.; Huseynov, O.; Fidan, I.; Alifui-Segbaya, F.; Rennie, A. Review on Additive Manufacturing of Multi-Material Parts: Progress and Challenges. J. Manuf. Mater. Process. 2022, 6, 4. [Google Scholar] [CrossRef]

- Han, D.; Lee, H. Recent advances in multi-material additive manufacturing: Methods and applications. Curr. Opin. Chem. Eng. 2020, 28, 158–166. [Google Scholar] [CrossRef]

- Mussatto, A. Research progress in multi-material laser-powder bed fusion additive manufacturing: A review of the state-of-the-art techniques for depositing multiple powders with spatial selectivity in a single layer. Results Eng. 2022, 16, 100769. [Google Scholar] [CrossRef]

- Chen, K.; Wang, C.; Hong, Q.; Wen, S.; Zhou, Y.; Yan, C.; Shi, Y. Selective laser melting 316L/CuSn10 multi-materials: Processing optimization, interfacial characterization and mechanical property. J. Mater. Process. Technol. 2020, 283, 116701. [Google Scholar] [CrossRef]

- Wei, C.; Li, L.; Zhang, X.; Chueh, Y.H. 3D printing of multiple metallic materials via modified selective laser melting. CIRP Ann. 2018, 67, 245–248. [Google Scholar] [CrossRef]

- Chen, J.; Yang, Y.; Song, C.; Zhang, M.; Wu, S.; Wang, D. Interfacial microstructure and mechanical properties of 316L /CuSn10 multi-material bimetallic structure fabricated by selective laser melting. Mater. Sci. Eng. A 2019, 752, 75–85. [Google Scholar] [CrossRef]

- Chen, J.; Yang, Y.; Song, C.; Wang, D.; Wu, S.; Zhang, M. Influence mechanism of process parameters on the interfacial characterization of selective laser melting 316L/CuSn10. Mater. Sci. Eng. A 2020, 792, 139316. [Google Scholar] [CrossRef]

- Mohd Yusuf, S.; Mazlan, N.; Musa, N.H.; Zhao, X.; Chen, Y.; Yang, S.; Nordin, N.A.; Mazlan, S.A.; Gao, N. Microstructures and Hardening Mechanisms of a 316L Stainless Steel/Inconel 718 Interface Additively Manufactured by Multi-Material Selective Laser Melting. Metals 2023, 13, 400. [Google Scholar] [CrossRef]

- Mei, X.; Wang, X.; Peng, Y.; Gu, H.; Zhong, G.; Yang, S. Interfacial characterization and mechanical properties of 316L stainless steel/inconel 718 manufactured by selective laser melting. Mater. Sci. Eng. A 2019, 758, 185–191. [Google Scholar] [CrossRef]

- Hinojos, A.; Mireles, J.; Reichardt, A.; Frigola, P.; Hosemann, P.; Murr, L.E.; Wicker, R.B. Joining of Inconel 718 and 316 Stainless Steel using electron beam melting additive manufacturing technology. Mater. Des. 2016, 94, 17–27. [Google Scholar] [CrossRef]

- Marques, A.; Cunha, Â.; Gasik, M.; Carvalho, O.; Silva, F.S.; Bartolomeu, F. Inconel 718–copper parts fabricated by 3D multi-material laser powder bed fusion: A novel technological and designing approach for rocket engine. Int. J. Adv. Manuf. Technol. 2022, 122, 2113–2123. [Google Scholar] [CrossRef]

- Walker, J.; Middendorf, J.R.; Lesko, C.C.C.; Gockel, J. Multi-material laser powder bed fusion additive manufacturing in 3-dimensions. Manuf. Lett. 2022, 31, 74–77. [Google Scholar] [CrossRef]

- Repnin, A.V.; Borisov, E.V.; Popovich, A.A.; Shamshurin, A.I. Selective laser melting of multimaterial VZh159-CuCr1Zr samples. Glob. Energy 2023, 29, 175–188. [Google Scholar]

- Repnin, A.V.; Borisov, E.V.; Popovich, A.A.; Golubkov, N.A. Mechanical properties of the VZh159–CuCr1Zr alloy multi-material samples manufactured by selective laser melting. Powder Metall. Funct. Coat. 2024, 18, 52–61. [Google Scholar] [CrossRef]

- Wang, R.; Gu, D.; Lin, K.; Chen, C.; Ge, Q.; Li, D. Multi-material additive manufacturing of a bio-inspired layered ceramic/metal structure: Formation mechanisms and mechanical properties. Int. J. Mach. Tools Manuf. 2022, 175, 103872. [Google Scholar] [CrossRef]

- Tey, C.F.; Tan, X.; Sing, S.L.; Yeong, W.Y. Additive manufacturing of multiple materials by selective laser melting: Ti-alloy to stainless steel via a Cu-alloy interlayer. Addit. Manuf. 2020, 31, 100970. [Google Scholar] [CrossRef]

- Scaramuccia, M.G.; Demir, A.G.; Caprio, L.; Tassa, O.; Previtali, B. Development of processing strategies for multigraded selective laser melting of Ti6Al4V and IN718. Powder Technol. 2020, 367, 376–389. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Ma, W.; Min, L. Interfacial characteristic and mechanical performance of maraging steel-copper functional bimetal produced by selective laser melting based hybrid manufacture. Mater. Des. 2018, 155, 77–85. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Kuang, T. Selective laser melting of tungsten-copper functionally graded material. Mater. Lett. 2019, 237, 328–331. [Google Scholar] [CrossRef]

- Shang, C.; Wang, C.; Li, C.; Yang, G.; Xu, G.; You, J. Eliminating the crack of laser 3D printed functionally graded material from TA15 to Inconel718 by base preheating. Opt. Laser Technol. 2020, 126, 106100. [Google Scholar] [CrossRef]

- Wu, D.; Song, C.; Di, T.; Niu, F.; Ma, G. Intermetallic regulation mechanism of inconel 718/Ti6Al4V composite by novel follow-up ultrasonic assisted laser additive manufacturing. Compos. Part B Eng. 2022, 235, 109736. [Google Scholar] [CrossRef]

- Meng, W.; Xiaohui, Y.; Zhang, W.; Junfei, F.; Lijie, G.; Qunshuang, M.; Bing, C. Additive manufacturing of a functionally graded material from Inconel625 to Ti6Al4V by laser synchronous preheating. J. Mater. Process. Technol. 2020, 275, 116368. [Google Scholar] [CrossRef]

- Godec, M.; Malej, S.; Feizpour, D.; Donik; Balažic, M.; Klobčar, D.; Pambaguian, L.; Conradi, M.; Kocijan, A. Hybrid additive manufacturing of Inconel 718 for future space applications. Mater. Charact. 2021, 172, 110842. [Google Scholar] [CrossRef]

- Marques, A.; Cunha, A.; Gasik, M.; Carvalho, O.; Silva, F.S.; Bartolomeu, F. 3D multi-material laser powder bed fusion: Ti6Al4V–CuNi2SiCr parts for aerospace applications. Prog. Addit. Manuf. 2023, 9, 391–400. [Google Scholar] [CrossRef]

- Song, C.; Ma, G.; He, A.; Li, Y.; Niu, F.; Wu, D. Multi-phases transformation mechanism of Ti6Al4V/Inconel 718 composite by laser additive manufacturing. Mater. Charact. 2021, 179, 111363. [Google Scholar] [CrossRef]

- Godfrey, D.G.; Morris, M.C.; Menon, M. Multi-Material Turbine Components. U.S. Patent US9266170B2, 23 February 2016. [Google Scholar]

- Rockstroh, T.J.; Tewari, S.K.; Sabato, J.G.; Desander, D.B.; Abbott, D.H.; Gledhill, M.D. Turbine Airfoil Casting Method. U.S. Patent US20090165988A1, 7 February 2009. [Google Scholar]

- Li, Q. A Study on Dissimilar Metal Functionally Graded Material via Multi-material Selective Laser Melting. Ph.D. Thesis, The University of Manchester, Manchester, UK, 2024. [Google Scholar]

- Onuike, B.; Bandyopadhyay, A. Additive manufacturing of Inconel 718—Ti6Al4V bimetallic structures. Addit. Manuf. 2018, 22, 844–851. [Google Scholar] [CrossRef]

- Shang, C.; Wang, C.; Xu, G.; Li, C.; Yang, G.; You, J. Dissimilar jointing of TA15 to Inconel718 by laser additive manufacturing using Nb/Cu bilayer. J. Manuf. Process. 2020, 55, 153–160. [Google Scholar] [CrossRef]

- Chenyang, W.; Fei, X.; Guojian, X.; Xiangyu, L.; Hongyou, B. Ta/Cu transition region in TC4/Inconel718 bimetallic structure fabricated by laser deposition manufacturing. Sci. Technol. Weld. Join. 2023, 28, 200–208. [Google Scholar] [CrossRef]

- Wang, W.; Xu, N.; Liu, X.; Jing, Z.; Xu, G.; Xing, F. Laser melting deposition of Inconel625/Ti6Al4V bimetallic structure with Cu/V interlayers. Mater. Res. Express 2023, 10, 076516. [Google Scholar] [CrossRef]

- Hosseini, E.; Popovich, V.A. A review of mechanical properties of additively manufactured Inconel 718. Addit. Manuf. 2019, 30, 100877. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Pramanik, A.; Basak, A.K.; Dong, Y.; Prakash, C.; Debnath, S.; Shankar, S.; Jawahir, I.S.; Dixit, S.; Buddhi, D. A critical review on additive manufacturing of Ti-6Al-4V alloy: Microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 18, 4641–4661. [Google Scholar] [CrossRef]

- Borisov, E.; Polozov, I.; Starikov, K.; Popovich, A.; Sufiiarov, V. Structure and properties of Ti/Ti64 graded material manufactured by laser powder bed fusion. Materials 2021, 14, 6140. [Google Scholar] [CrossRef]

- Zhang, S.; Cheng, X.; Yao, Y.; Wei, Y.; Han, C.; Shi, Y.; Wei, Q.; Zhang, Z. Porous niobium coatings fabricated with selective laser melting on titanium substrates: Preparation, characterization, and cell behavior. Mater. Sci. Eng. C 2015, 53, 50–59. [Google Scholar] [CrossRef]

- Bai, Y.; Zhao, C.; Zhang, Y.; Chen, J.; Wang, H. Additively manufactured CuCrZr alloy: Microstructure, mechanical properties and machinability. Mater. Sci. Eng. A 2021, 819, 141528. [Google Scholar] [CrossRef]

- Moussaoui, K.; Rubio, W.; Mousseigne, M.; Sultan, T.; Rezai, F. Effects of Selective Laser Melting additive manufacturing parameters of Inconel 718 on porosity, microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 735, 182–190. [Google Scholar] [CrossRef]

- Soysal, T.; Kou, S.; Tat, D.; Pasang, T. Macrosegregation in dissimilar-metal fusion welding. Acta Mater. 2016, 110, 149–160. [Google Scholar] [CrossRef]

- Wang, P.; Huang, P.; Ng, F.L.; Sin, W.J.; Lu, S.; Nai, M.L.S.; Dong, Z.L.; Wei, J. Additively manufactured CoCrFeNiMn high-entropy alloy via pre-alloyed powder. Mater. Des. 2019, 168, 107576. [Google Scholar] [CrossRef]

- Wang, H.; Xie, J.; Chen, Y.; Liu, W.; Zhong, W. Effect of CoCrFeNiMn high entropy alloy interlayer on microstructure and mechanical properties of laser-welded NiTi/304 SS joint. J. Mater. Res. Technol. 2022, 18, 1028–1037. [Google Scholar] [CrossRef]

- Repnin, A.; Kim, A.; Popovich, A. Interfacial Characterization of Selective Laser Melting of a SS316L/NiTi Multi-Material with a High-Entropy Alloy Interlayer. Crystals 2023, 13, 1486. [Google Scholar] [CrossRef]

- Shrestha, S.; Starr, T.; Chou, K. A Study of Keyhole Porosity in Selective Laser Melting: Single-Track Scanning with Micro-CT Analysis. J. Manuf. Sci. Eng. Trans. ASME 2019, 141, 071004. [Google Scholar] [CrossRef]

- Fan, Y.; Fan, J.; Wang, C. Formation of typical Cu–Ti intermetallic phases via a liquid-solid reaction approach. Intermetallics 2019, 113, 106577. [Google Scholar] [CrossRef]

- Ifergane, S.; Barkay, Z.; Beeri, O.; Eliaz, N. Study of fracture evolution in copper sheets by in situ tensile test and EBSD analysis. J. Mater. Sci. 2010, 45, 6345–6352. [Google Scholar] [CrossRef]

| Vol. % | Powders | |||

|---|---|---|---|---|

| Ti6Al4V | Nb | CuCr1Zr | Inconel 718 | |

| <μm | <μm | <μm | <μm | |

| 10 | 19 | 47 | 14 | 20 |

| 50 | 35 | 83 | 29 | 38 |

| 90 | 63 | 128 | 52 | 66 |

| Materials | Parameters | |||

|---|---|---|---|---|

| Laser Power | Scanning Speed | Hatch Distance | Layer Thickness | |

| Watt | mm/s | mm | mm | |

| Ti6Al4V | 275 | 805 | 0.12 | 0.05 |

| Nb | 275 | 200 | 0.1 | 0.05 |

| CuCr1Zr | 250 | 200 | 0.1 | 0.05 |

| Inconel718 | 275 | 760 | 0.1 | 0.05 |

| No. of Sample | Properties | ||

|---|---|---|---|

| Yield Strength | Ultimate Tensile Strength | Strain | |

| MPa | MPa | % | |

| 1 | 145.77 | 891.72 | 15.51 |

| 2 | 114.06 | 915.93 | 18.91 |

| 3 | 151.71 | 910.7 | 13.51 |

| Average | 137.18 ± 15.41 | 906.11 ± 9.6 | 15.98 ± 1.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Repnin, A.; Borisov, E.; Popovich, A. Formation of the Cu+Nb Interlayer in the Inconel 718/Ti6Al4V Multi-Material Obtained by Selective Laser Melting. Materials 2024, 17, 5801. https://doi.org/10.3390/ma17235801

Repnin A, Borisov E, Popovich A. Formation of the Cu+Nb Interlayer in the Inconel 718/Ti6Al4V Multi-Material Obtained by Selective Laser Melting. Materials. 2024; 17(23):5801. https://doi.org/10.3390/ma17235801

Chicago/Turabian StyleRepnin, Arseniy, Evgenii Borisov, and Anatoly Popovich. 2024. "Formation of the Cu+Nb Interlayer in the Inconel 718/Ti6Al4V Multi-Material Obtained by Selective Laser Melting" Materials 17, no. 23: 5801. https://doi.org/10.3390/ma17235801

APA StyleRepnin, A., Borisov, E., & Popovich, A. (2024). Formation of the Cu+Nb Interlayer in the Inconel 718/Ti6Al4V Multi-Material Obtained by Selective Laser Melting. Materials, 17(23), 5801. https://doi.org/10.3390/ma17235801