Experimental Methods and Equivalence Research on Inter-Turn Short Circuits in Power Transformers

Abstract

1. Introduction

- 1

- Existing studies on transformer inter-turn short-circuits have been predominantly conducted through multi-physics coupling simulations using electromagnetic simulation software. During these simulations, the models are often established under idealized conditions, incorporating equivalent simplifications of actual transformer configurations. This inevitably introduces discrepancies between simulation results and practical scenarios.

- 2

- In current full-scale prototype experiments, the substantial short-circuit currents circulating within the fault loops may cause irreversible damage to experimental transformers. Consequently, safety protocols typically require series-connected current-limiting resistors in short-circuit windings or voltage reduction to control fault current magnitudes. However, these modifications significantly deviate from actual inter-turn short-circuit operating conditions, thereby compromising the accurate characterization of transformer behaviors under such faults.

2. Simulation Method and Theoretical Derivation of Inter-Turn Short Circuit

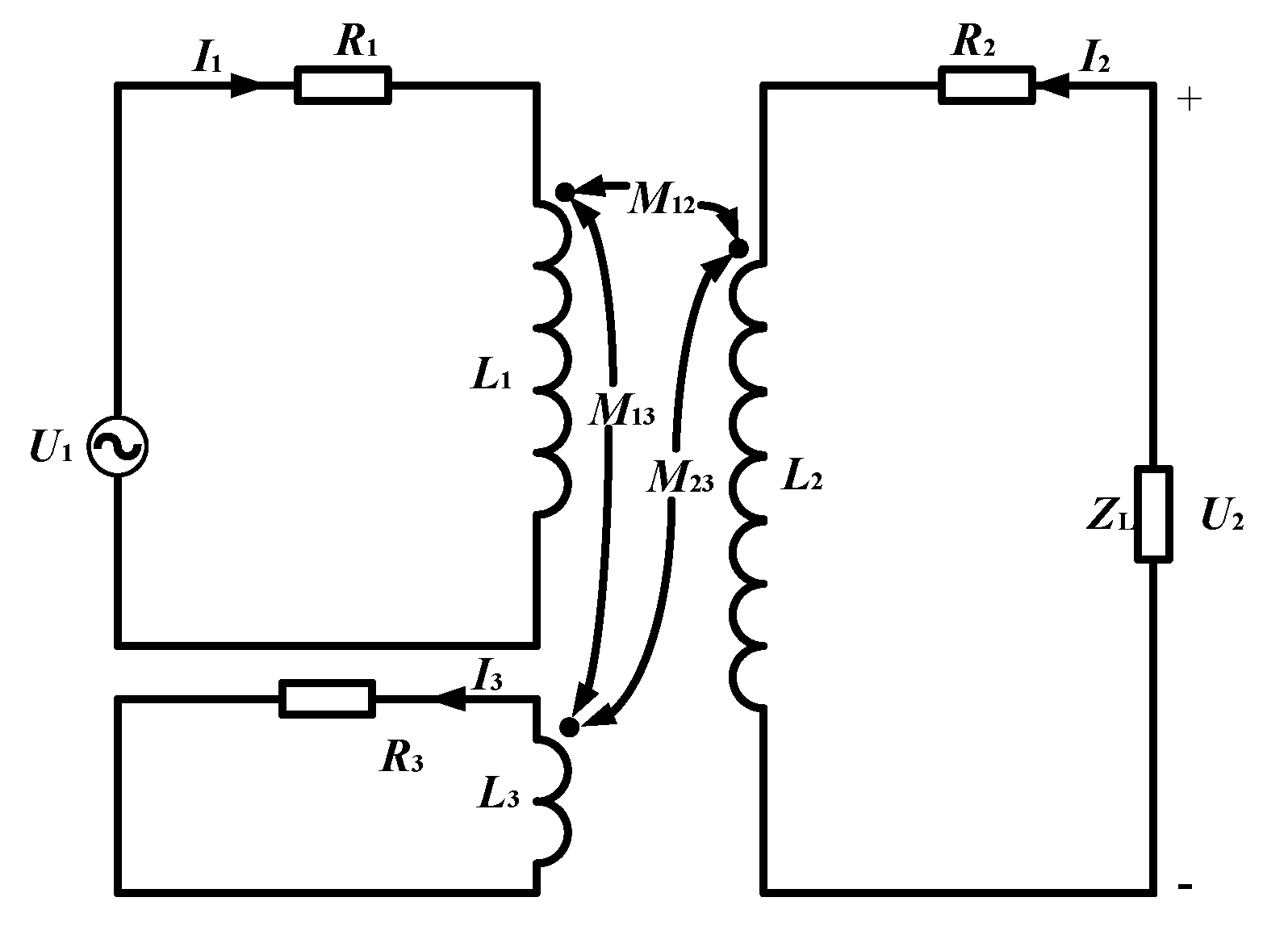

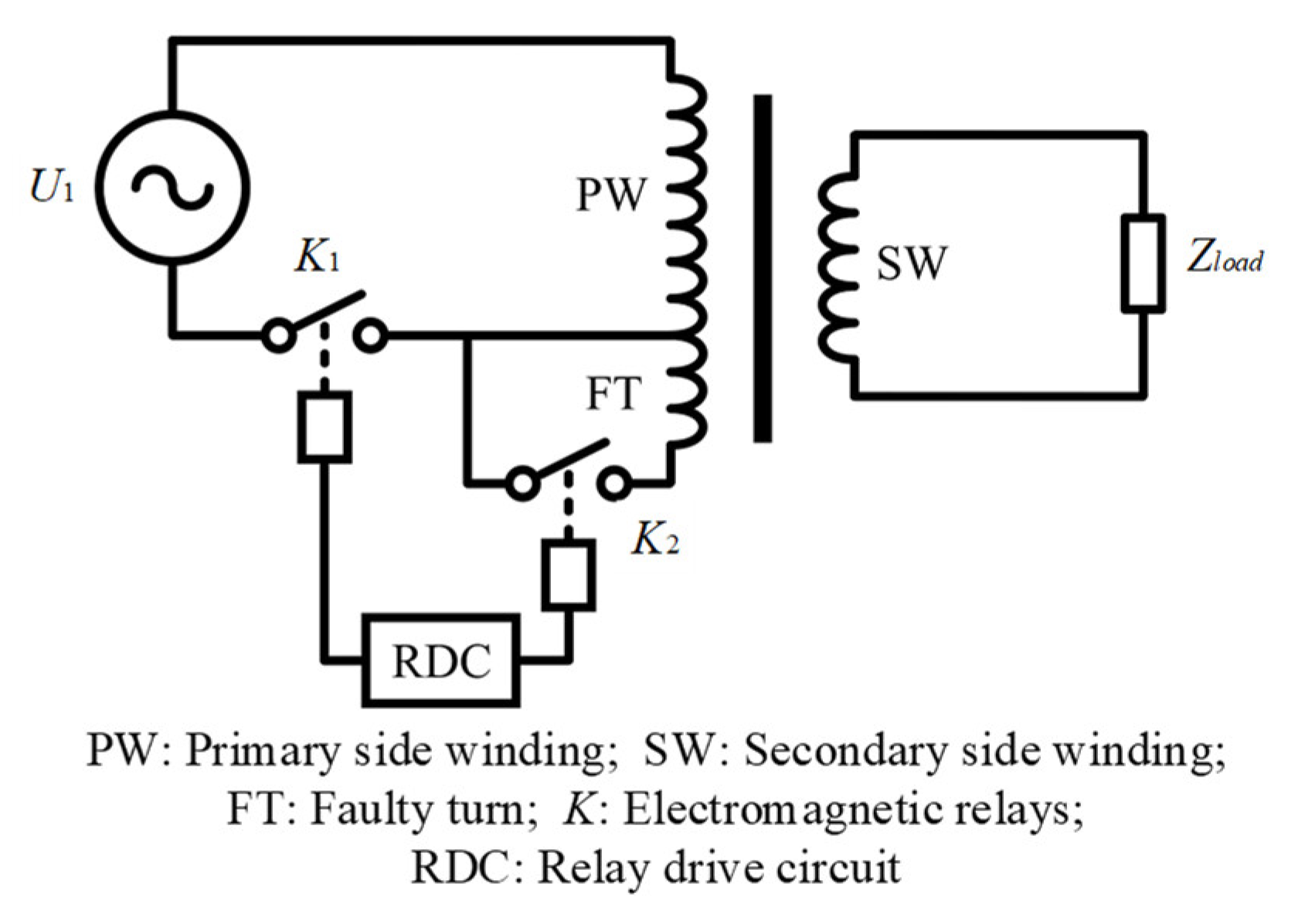

2.1. Equivalent Method for Inter-Turn Short Circuit

2.2. Theoretical Calculation of Circuit Models

3. Winding Equivalence Simulation Model Verification

3.1. Simulation Model Establishment

- The current in transformer windings was assumed to be uniformly distributed, with each 1% axial segment equivalently represented as identical turns.

- Winding manufacturing irregularities and coil arrangement variations were neglected, assuming uniform coil distribution throughout the winding.

- External non-electromagnetic components such as transformer bases and clamps were excluded to reduce computational complexity while maintaining accuracy.

- In subsequent simulation and experimental processes, the transient process of inter-turn short circuits in the transformer is ignored, and only the steady-state process formed after the inter-turn short circuit is considered.

3.2. Study on Equivalence-Influencing Factors

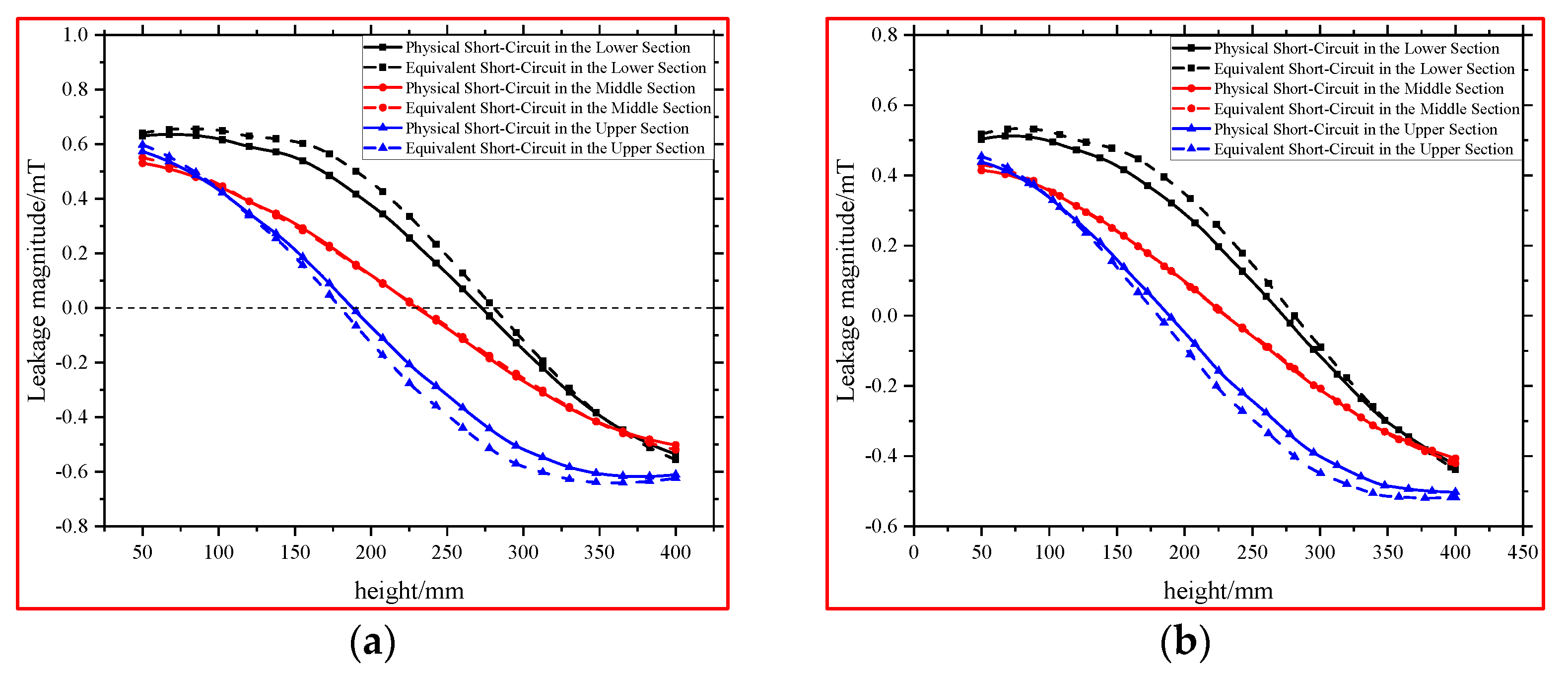

3.2.1. Influence of Short-Circuit Position on Equivalence

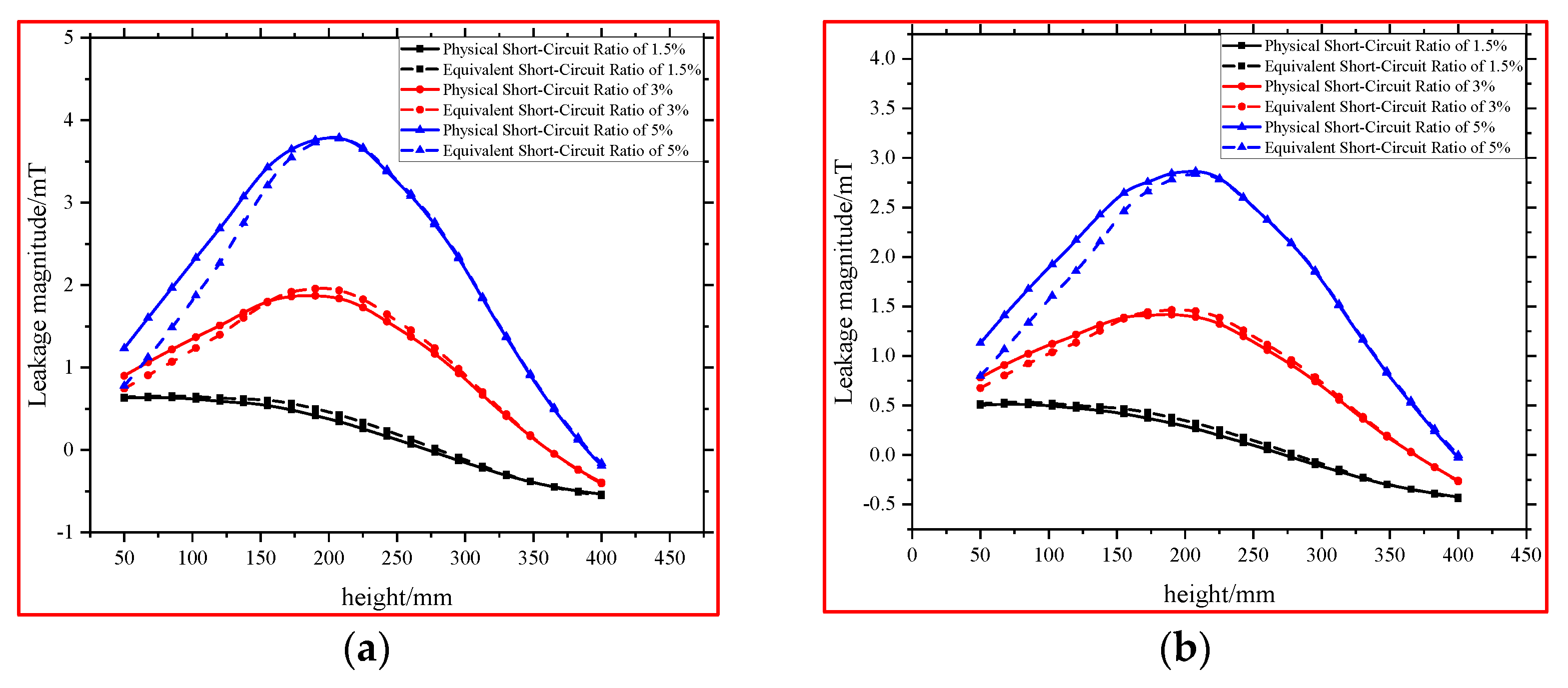

3.2.2. Impact of Short-Circuit Proportion on Equivalence

4. Experimental Validation of Winding Equivalence

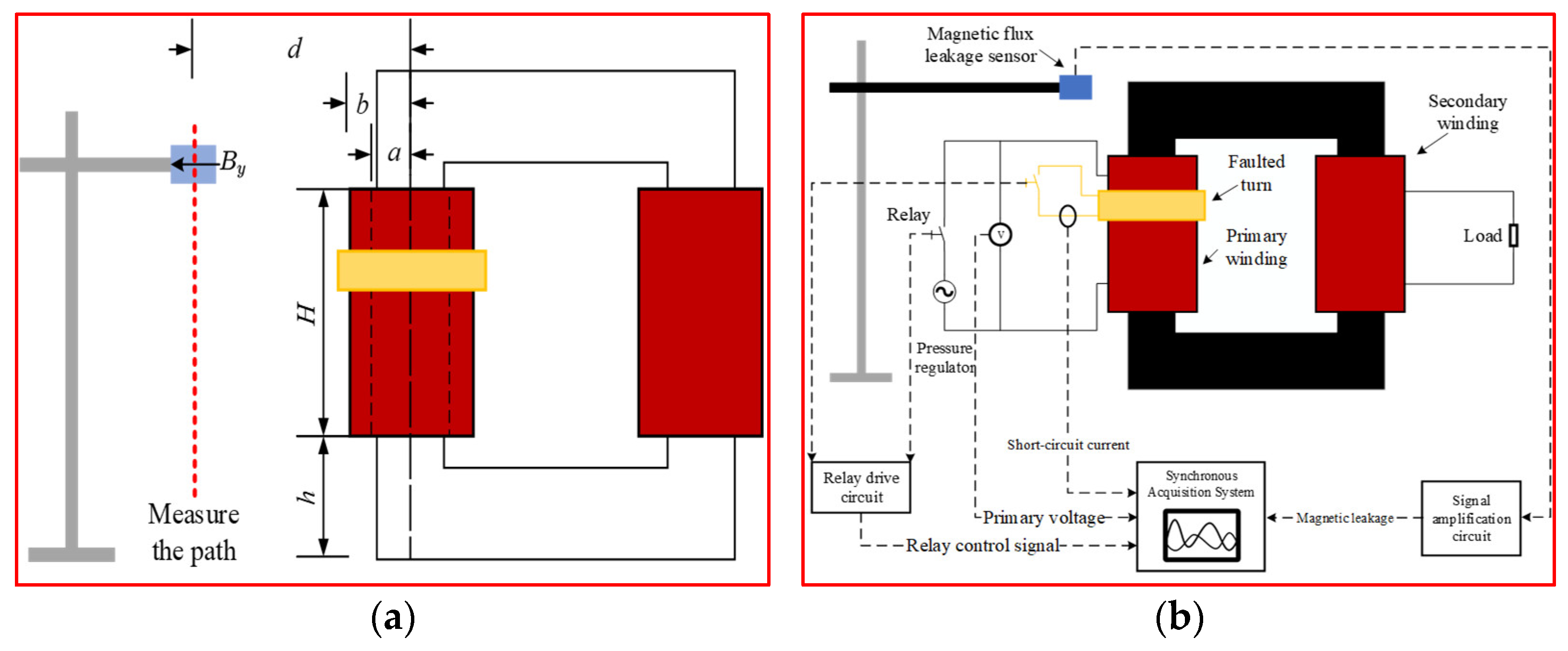

4.1. Experimental Platform Configuration

4.2. Experimental Validation

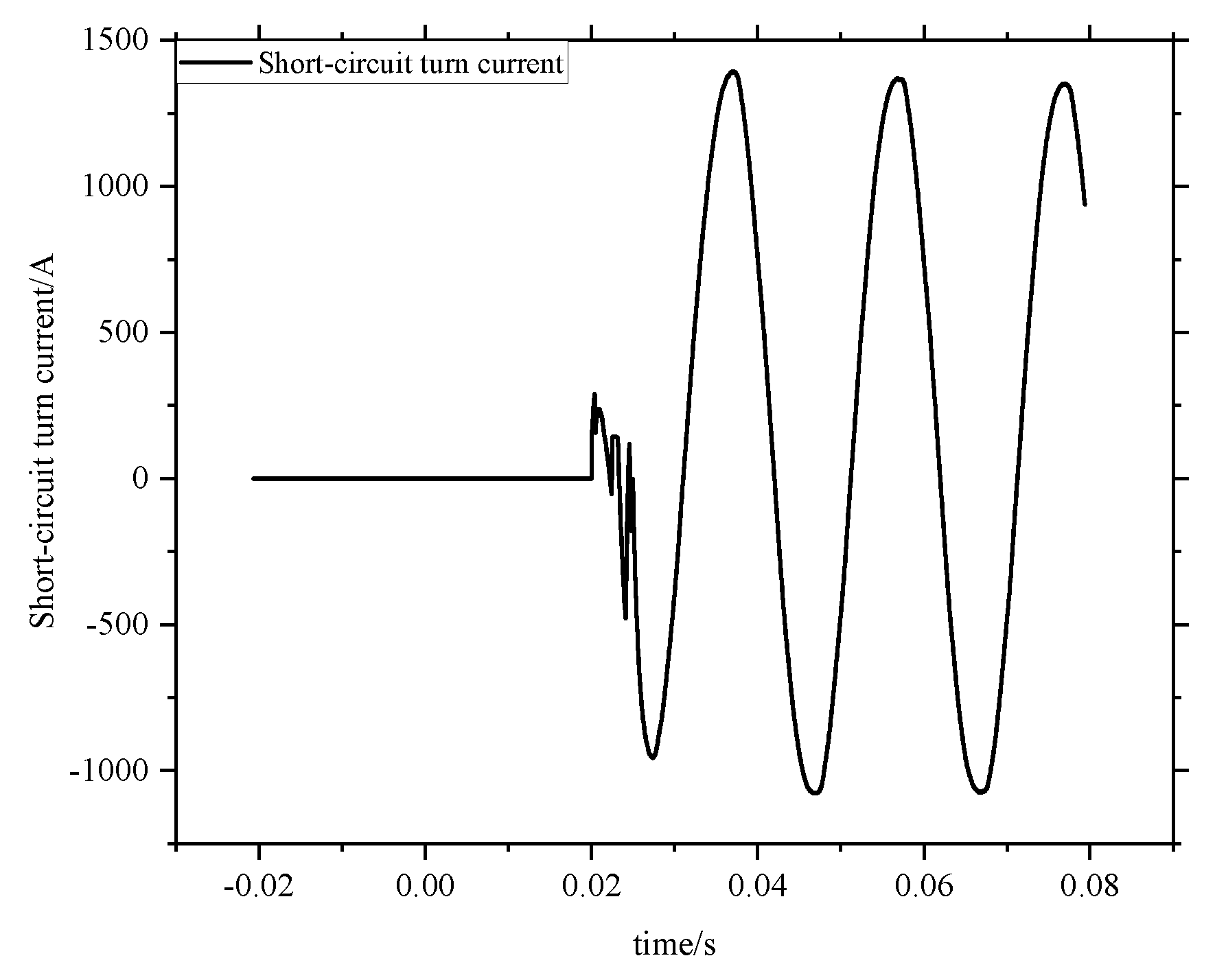

4.2.1. Validation of Inter-Turn Short-Circuit Current

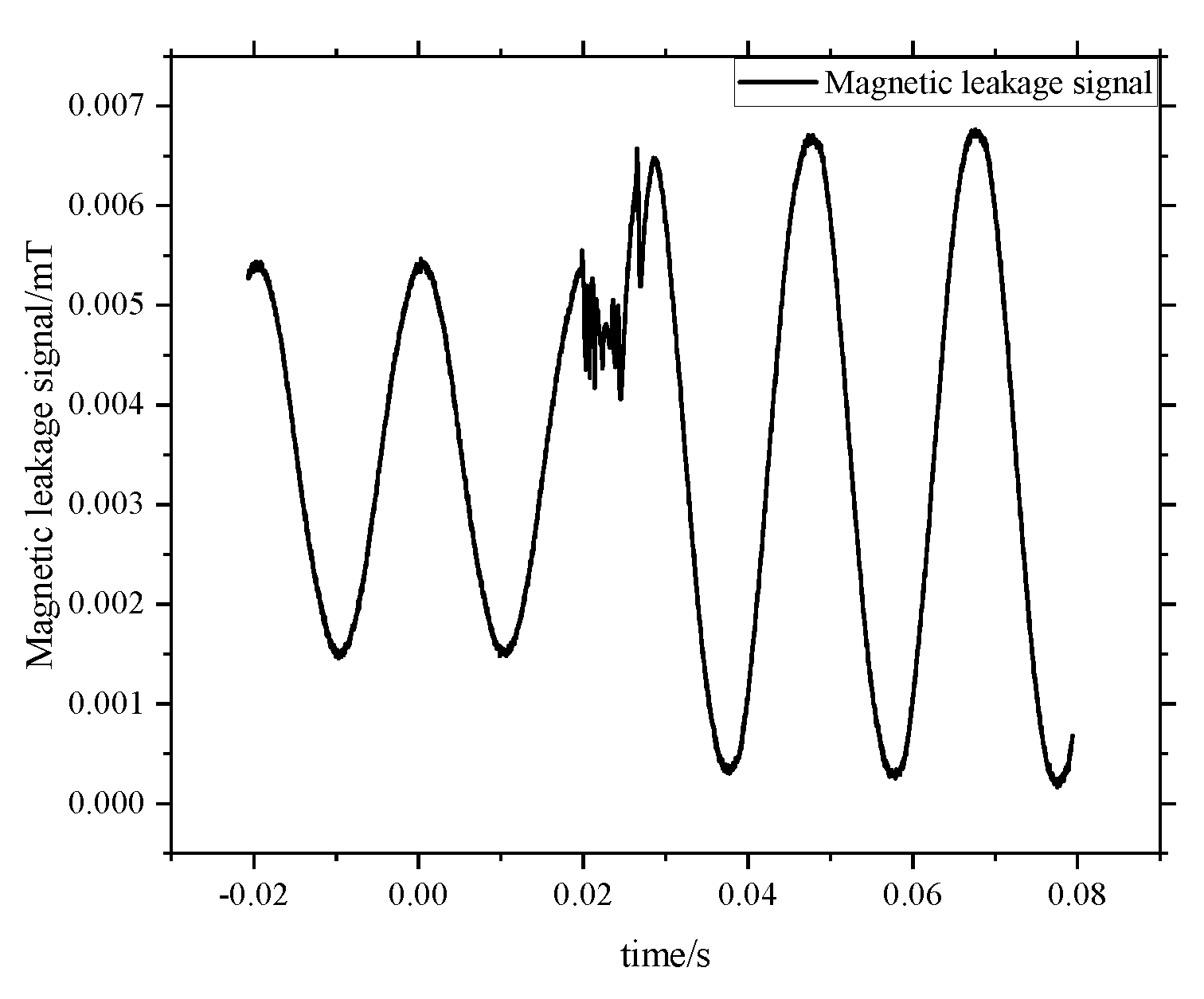

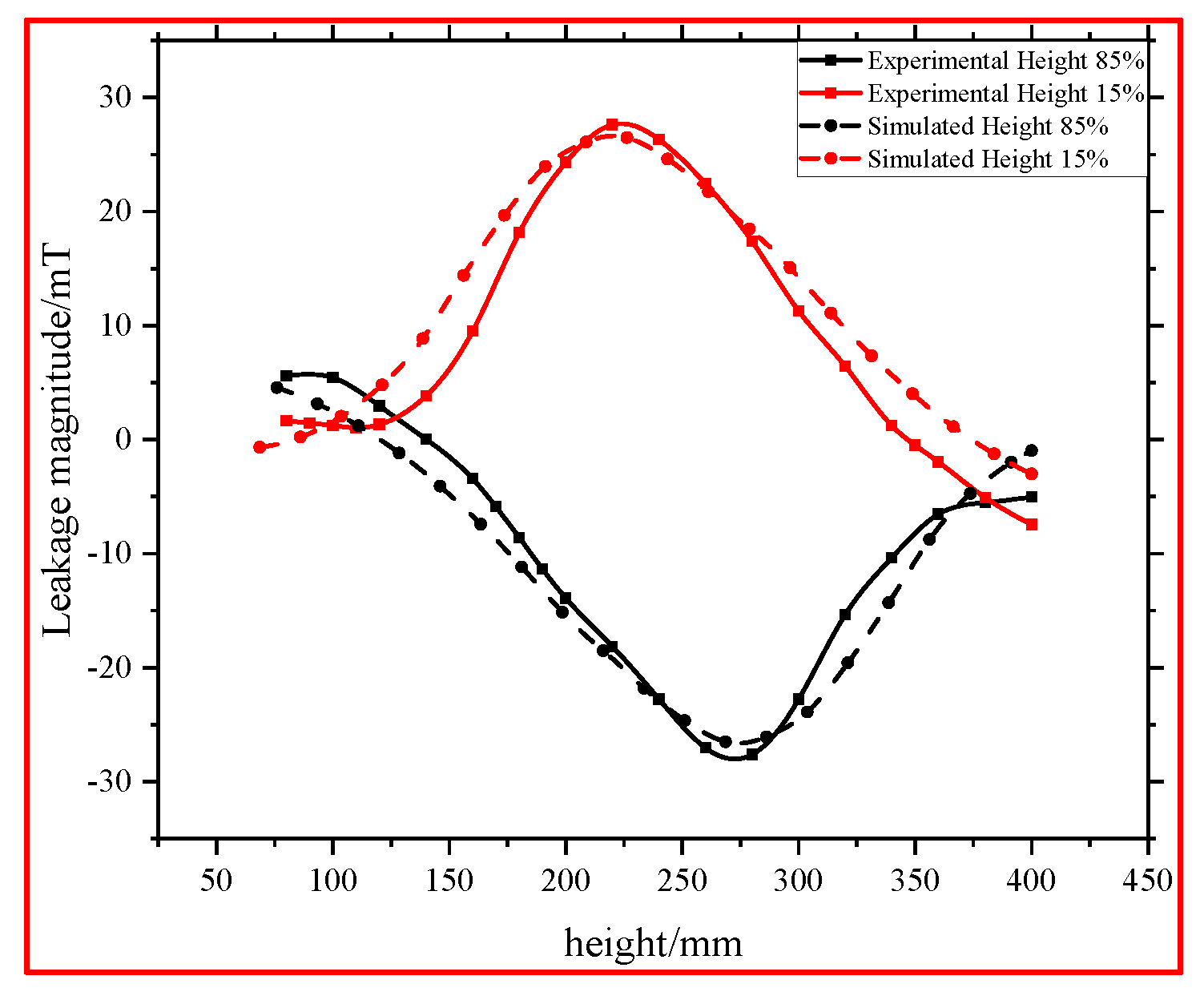

4.2.2. Validation of Radial Leakage Magnetic Field in Inter-Turn Short Circuits

5. Conclusions

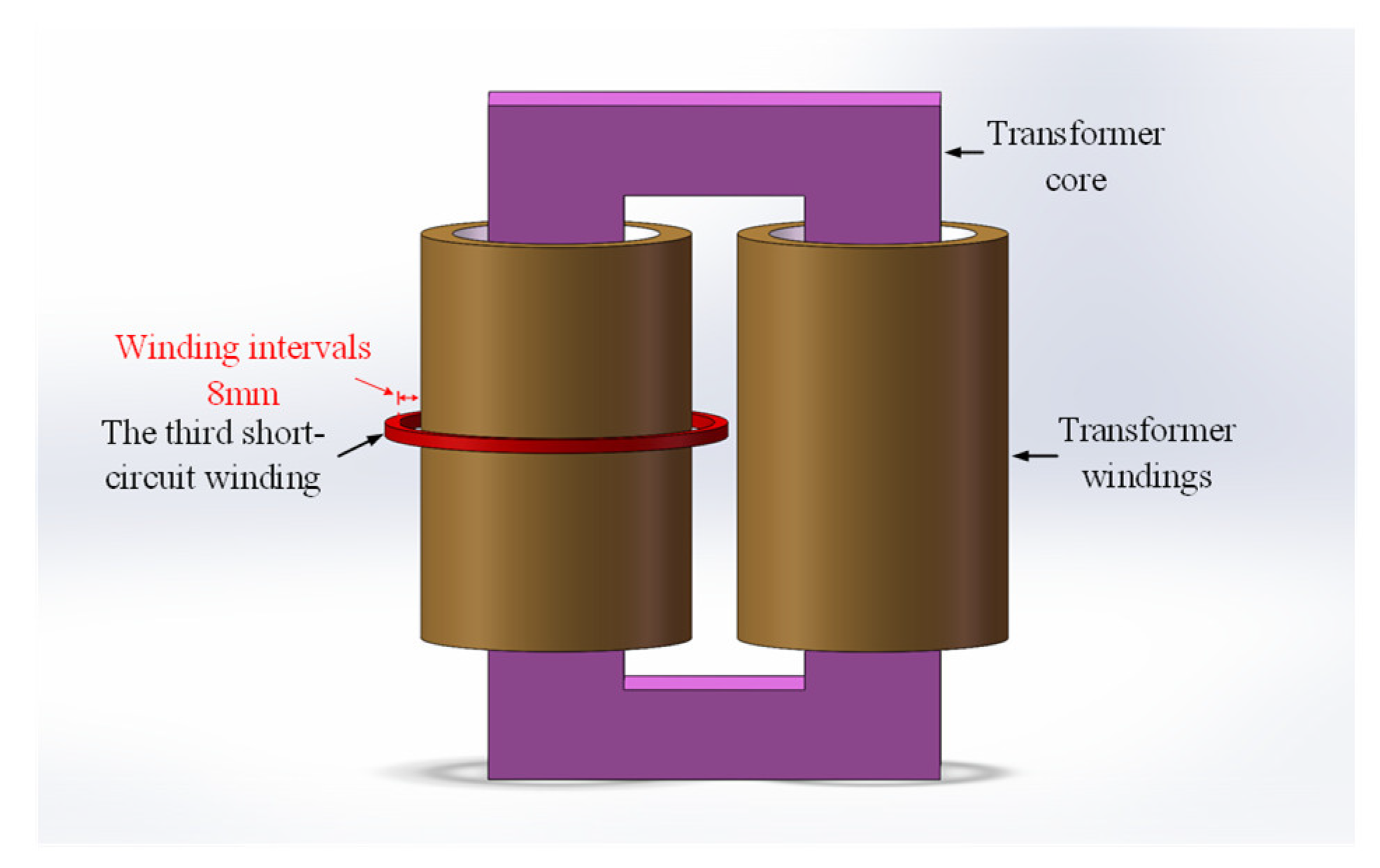

- An experimental method utilizing an external third short-circuit winding to simulate inter-turn short-circuit faults is proposed. This method improves the current-carrying capacity, thermal dissipation conditions, and control strategies of the short-circuit winding, enabling it to withstand short-circuit currents up to tens of times the rated current without damaging the transformer’s normal winding structure, ensuring safety and repeatability.

- A simulation model for inter-turn short-circuit faults in a single-phase dual-winding transformer is developed. The study investigates the primary/secondary winding currents, short-circuit winding currents, and spatial leakage magnetic field distributions under the influence of magnetic coupling degree, short-circuit positions, and proportions. This validates the equivalence in electrical and magnetic effects between the third short-circuit winding simulation method and actual inter-turn short-circuit faults.

- A single-phase dual-winding transformer inter-turn short-circuit simulation platform is constructed. The accuracy of the simulation model is verified, further confirming the equivalence of the proposed inter-turn short-circuit fault simulation method. Additionally, the short-circuit current in the third short-circuit winding and the radial leakage magnetic field distribution after transformer inter-turn short-circuit faults are analyzed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Laayati, O.; El Hadraoui, H.; Bouzi, M.; Chebak, A. Smart Energy Management System: Oil Immersed Power Transformer Failure Prediction and Classification Techniques Based on DGA Data. In Proceedings of the 2022 2nd International Conference on Innovative Research in Applied Science, Engineering and Technology (IRASET), Meknes, Morocco, 3–4 March 2022. [Google Scholar] [CrossRef]

- Sriyono, S.; Khayam, U.; Suwarno, S. SFRA Characteristics of Power Transformer Internal Winding Considering the Resonant Effect. In Proceedings of the 2020 8th International Conference on Condition Monitoring and Diagnosis (CMD), Phuket, Thailand, 25–28 October 2020; pp. 302–305. [Google Scholar] [CrossRef]

- Cai, Y.; Yu, D.; He, Y.; Ding, K. Research on Fault Diagnosis Method of Transformer Winding Based on Transient Signal and Frequency Response Information. In Proceedings of the 2025 IEEE International Conference on Power Systems and Smart Grid Technologies (PSSGT), Chongqing, China, 11–13 April 2025; pp. 176–182. [Google Scholar] [CrossRef]

- Chunyan, Z.; Bingyang, L.; Dandan, Z.; Peng, L.; Shuqi, Z.; Huanchao, C. Research on the Checking for Anti-short Circuit Ability of 500kV Power Transformer. In Proceedings of the 2023 IEEE 6th International Electrical and Energy Conference (CIEEC), Hefei, China, 12–14 May 2023. [Google Scholar] [CrossRef]

- Yan, C.; Liu, H.; Yang, H.; Yang, X.; Zhang, P.; Zhang, B. Toward a Novel Characterization of Transformer Interturn Faults Based on Arc-Induced Transients in Winding Magnetomotive Force. IEEE Trans. Magn. 2024, 60, 1–6. [Google Scholar] [CrossRef]

- Farzin, N.; Vakilian, M.; Hajipour, E. Transformer Turn-to-Turn Fault Protection Based on Fault-Related Incremental Currents. IEEE Trans. Power Deliv. 2019, 34, 700–709. [Google Scholar] [CrossRef]

- Quan, Y.; Zhang, Z.; Chen, G.; Wang, D. Research on detection method of transformer interturn short circuit based on wavelet analysis. Appl. Mech. Mater. 2014, 521, 358–361. Available online: https://www.scientific.net/AMM.521.358 (accessed on 22 September 2025).

- Quan, Y.; Zhang, Z.; Chen, G.; Wang, D. Study on Method Detecting Turn-to-Turn short circuit of Transformer Based on Kalman Filter. Appl. Mech. Mater. 2014, 521, 371–374. Available online: https://www.scientific.net/AMM.521.371 (accessed on 22 September 2025).

- Zou, D.; Hou, X.; Quan, H.; Zhou, T.; Peng, Q.; Wang, S.; Dai, W.; Hong, Z. Transformer Inter-Turn Short-Circuit Fault Recognition Based on Deep Learning. In Proceedings of the 2024 5th International Conference on Clean Energy and Electric Power Engineering (ICCEPE), Yangzhou, China, 9–11 August 2024; pp. 1002–1010. [Google Scholar] [CrossRef]

- Chen, Z.; Yang, R.; Wang, J.; Xiang, N.; Liu, X. Simulation Analysis and Scaling Test of Transformer Turn to Turn Short--Circuit Transient Characteristics Based on Field-Circuit Cooperation. IEEJ Trans. Electr. Electron. Eng. 2025, 20, 1016–1024. [Google Scholar] [CrossRef]

- Su, Z.; Luo, L. Research on inter-turn short-circuit fault of power transformer by using third harmonic. IET Renew. Power Gener. 2023, 17, 2791–2800. [Google Scholar] [CrossRef]

- Prasad, U.R.; Vyjayanthi, C.; Jaison, K. Modeling and Detection of Inter-turn Faults in Distribution Transformer. In Proceedings of the 2019 8th International Conference on Power Systems (ICPS), Jaipur, India, 20–22 December 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Zheng, X.; Xian, R.; Wang, L.; Chen, L.; Hu, Y.; Hao, H.; Liu, G. Online identification method for inter-turn short-circuit fault of grounding transformer winding and phase distinction. Measurement 2025, 256, 118367. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, Q.; Bian, X. Research on Electromagnetic Characteristics of Interturn Short Circuit in Three Phase Transformers. In Proceedings of the 2024 3rd International Conference on Energy, Power and Electrical Technology (ICEPET), Chengdu, China, 17–19 May 2024; pp. 1039–1043. [Google Scholar] [CrossRef]

- Wu, Y.; Lin, J.; Ji, T.; Pan, Q.; Huang, S.; Wang, W.; Liu, S.; Jin, Y. Study on Leakage Magnetic Characteristics under Inter-Turn Short Circuit Fault of Transformer. In Proceedings of the 2024 IEEE PES 16th Asia-Pacific Power and Energy Engineering Conference (APPEEC), Nanjing, China, 25–27 October 2024; pp. 1–4. [Google Scholar] [CrossRef]

- Peng, Q.; Zhu, X.; Hong, Z.; Zou, D.; Guo, R.; Chu, D. Research into the Fast Calculation Method of Single-Phase Transformer Magnetic Field Based on CNN-LSTM. Energies 2024, 17, 3913. [Google Scholar] [CrossRef]

- Zhai, Y.; Li, Q.; Gao, W. Simulation Research on the Influence of Winding Deformation Degree on Transformer Magnetic Field Distribution and Winding Force. In Proceedings of the 2023 IEEE 4th International Conference on Electrical Materials and Power Equipment (ICEMPE), Shanghai, China, 7–10 May 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Wang, B.; Wang, L. A fault diagnosis method for inter-turn short circuit based on magnetic field distribution. Sci. Rep. 2025, 15, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Haghjoo, F.; Mohammadi, H. Planar Sensors for Online Detection and Region Identification of Turn-to-Turn Faults in Transformers. IEEE Sens. J. 2017, 17, 5450–5459. [Google Scholar] [CrossRef]

- Chen, S.; Luo, Y.; Sheng, G.; Jiang, J. Thermal behaviour of a transformer mineral oil--tank surface under incipient turn--to--turn short--circuit fault. IET Sci. Meas. Technol. 2024, 18, 310–323. [Google Scholar] [CrossRef]

- Leal, G.G.L.; Meira, M.; Bossio, G.R.; Ruschetti, C.R.; Verucchi, C.J. Inter-Turn Short-Circuit Detection Through Differential Admittance Monitoring in Transformers. IEEE Trans. Instrum. Meas. 2024, 73, 1–8. [Google Scholar] [CrossRef]

- Jiang, H.; Feng, J.; Zhao, N.; Xu, H.; Wang, B.; Zhang, B. Fault Diagnosis of Transformer Inter-Turn Short Circuit Based on Automatic Multiscale-Based Peak Detection Algorithm Combined with Magnetic Flux Leakage Analysis. In Proceedings of the 2024 IEEE 13th Data Driven Control and Learning Systems Conference (DDCLS), Kaifeng, China, 17–19 May 2024; pp. 1668–1672. [Google Scholar] [CrossRef]

- Ortiz-Medina, R.A.; Aragon-Verduzco, D.A.; Maldonado-Ruelas, V.A.; Olivares-Galvan, J.C.; Escalera-Perez, R. Distinction Between Interturn Short-Circuit Faults and Unbalanced Load in Transformers. Appl. Syst. Innov. 2025, 8, 50. [Google Scholar] [CrossRef]

- Fei, L.; Ma, Z.; Cai, L.; Zhou, D.; Shu, X.; Liao, Z.; Lin, C.; Li, X. Analysis of interturn short circuit in regulating winding of power transformer based on field-circuit coupling. Front. Energy Res. 2024, 12, 1393436. [Google Scholar] [CrossRef]

| Transformer Parameters | Numeric Value |

|---|---|

| Rated frequency/Hz | 50 |

| Power rating/VA | 7000 |

| Number of turns of the primary winding | 200 |

| Number of turns of the secondary winding | 200 |

| Core radius D/mm | 160 |

| Inner diameter of the primary winding a/mm | 165 |

| Outer diameter of the primary winding b/mm | 190 |

| Height of the primary winding above ground h/mm | 120 |

| Height of the primary winding H/mm | 240 |

| Simulate Working Conditions | Primary Current/A | Secondary Side Current/A | Short-Circuit Turn Current/A |

|---|---|---|---|

| Actual inter-turn short-circuit at 15% height | 27.5 | 12.3 | 1010 |

| Actual inter-turn short-circuit at 50% height | 27.8 | 12.4 | 1040 |

| Actual inter-turn short-circuit at 85% height | 27.5 | 12.3 | 1010 |

| Equivalent inter-turn short-circuit at 15% height | 27.3 | 12.4 | 994 |

| Equivalent inter-turn short-circuit at 50% height | 27.5 | 12.4 | 1021 |

| Equivalent inter-turn short-circuit at 85% height | 27.3 | 12.4 | 994 |

| Simulate Working Conditions | Primary Current/A | Secondary Side Current/A | Short-Circuit Turn Current/A |

|---|---|---|---|

| Actual inter-turn short-circuit proportion 1.5% | 27.5 | 12.3 | 1010 |

| Actual inter-turn short-circuit proportion 3% | 53.8 | 12 | 1390 |

| Actual inter-turn short-circuit proportion 5% | 71.6 | 11.6 | 1230 |

| Equivalent inter-turn short-circuit proportion 1.5% | 27.3 | 12.4 | 994 |

| Equivalent inter-turn short-circuit proportion 3% | 52.9 | 11.7 | 1354 |

| Equivalent inter-turn short-circuit proportion 5% | 69.8 | 11.4 | 1206 |

| Short-Circuit Condition | Short-Circuited Turn Current/A |

|---|---|

| Simulated 15% height | 994 |

| Experimental 15% height | 998 |

| Simulated 50% height | 1021 |

| Experimental 50% height | 1024 |

| Short-Circuit Condition | Short-Circuited Turn Current/A |

|---|---|

| Simulated 1.5% short-circuit proportion | 994 |

| Experimental 1.5% short-circuit proportion | 998 |

| Simulated 1.5% short-circuit proportion | 1354 |

| Experimental 1.5% short-circuit proportion | 1347 |

| Simulated 1.5% short-circuit proportion | 1206 |

| Experimental 1.5% short-circuit proportion | 1109 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Yang, C.; Shuai, Y.; Wu, D.; Zhang, Z.; Yang, L. Experimental Methods and Equivalence Research on Inter-Turn Short Circuits in Power Transformers. Energies 2025, 18, 5453. https://doi.org/10.3390/en18205453

Li X, Yang C, Shuai Y, Wu D, Zhang Z, Yang L. Experimental Methods and Equivalence Research on Inter-Turn Short Circuits in Power Transformers. Energies. 2025; 18(20):5453. https://doi.org/10.3390/en18205453

Chicago/Turabian StyleLi, Xuelong, Chun Yang, Yuanming Shuai, Dongyang Wu, Zhengyang Zhang, and Lanjun Yang. 2025. "Experimental Methods and Equivalence Research on Inter-Turn Short Circuits in Power Transformers" Energies 18, no. 20: 5453. https://doi.org/10.3390/en18205453

APA StyleLi, X., Yang, C., Shuai, Y., Wu, D., Zhang, Z., & Yang, L. (2025). Experimental Methods and Equivalence Research on Inter-Turn Short Circuits in Power Transformers. Energies, 18(20), 5453. https://doi.org/10.3390/en18205453