Abstract

The efficient utilization of waste heat from industrial processes can provide a significant source of energy savings for production plants, as well as be a driver of sustainable operations and the abatement of emissions. Industrial waste heat usually is contained in liquid or gaseous outlet streams. Although the possible ways to utilize waste heat are discussed in a wide variety of papers, these either provide only a general overview of utilization options and opportunities or focus on a narrow range of industrial processes. The aim of the present paper is to discuss the practical aspects of waste heat utilization in the European Union so that the reader can gain perspective on (i) the thermal classification of waste heat, (ii) liquid and gaseous waste streams and their typical temperatures for industrial use cases, (iii) the technical, economic, physical, and environmental aspects barring full utilization of the available waste heat, (iv) waste heat sources in various industries, and (v) standardized equipment and technologies applicable to industrial waste heat utilization, including their advantages, disadvantages, and weak points.

1. Introduction

Industrial waste heat is the energy that is generated in industrial processes but cannot be put to any practical use [1]. Jouhara et al. [2] extended this definition by adding that this heat can be used, but instead it is wasted into the environment. Grönkvist et al. [3] defined waste heat as the extra heat that is produced in a thermodynamically optimized process. Bendig et al. [4] improved this definition by discriminating between waste heat that can be avoided, because it comes from unoptimized processes and can further be utilized, and waste heat that is unavoidable, because it comes from already optimized processes. It is important to note that apart from the term “waste heat”, one can also encounter “low-quality heat” [5], “secondary heat” [6], or “energy losses” [7].

Utilizing the available waste heat would not only increase the sustainability of industrial processes and products, but also markedly reduce greenhouse gas emissions [8]. This is especially relevant regarding the worldwide efforts to reduce energy consumption related to the ever-stricter legislation [9]. Although it is difficult to determine for a given industrial process the actual amount of input energy that is lost as waste heat, various studies report that it generally is between 20% and 50% and that 18% to 30% of this waste heat could be utilized (see, e.g., the 2006 report prepared for the U.S. Department of Energy [10]). Forman et al. [7] stated that in industrial processes, 30% of the overall energy consumption constitutes unused energy exiting via liquid or gaseous waste streams and 21% constitutes other losses, i.e., only 49% of the input energy represents actual energy service. Bianchi et al. [11] provided in their study similar data: 29% of the input energy exited via liquid or gaseous waste streams, 20% was otherwise lost, and 51% accounted for energy service. Likewise, Agathokleous et al. [12] estimated waste heat to make up 23% of the total amount of input energy, with other losses constituting 30% and the actual energy service being attributable to the remaining 47%. According to Pashchenko [13], in selected energy-intensive industries (e.g., the iron and steel industry or glass industry), the overall losses could be as large as 75%.

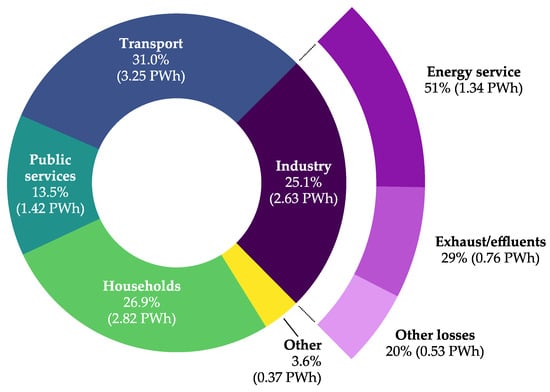

Therefore, it is obvious that the amount of waste heat (that is, wasted energy) in industrial processes is not negligible. For instance, Arzbaecher et al. [14] estimated the annual energy cost savings reachable through systematic industrial waste heat recovery to be 10–20%. If one assumes that, e.g., only 51% of the primary energy is transformed into a usable form [11], then industrial waste heat would amount to approx. 1.29 PWh/y solely in the European Union (see Figure 1). This clearly indicates that energy sources are being not utilized properly (or, at least, it points to significant limitations of the currently available technologies) and that greenhouse gas emissions, as well as the corresponding energy costs, could be much reduced.

Figure 1.

Yearly energy consumption in the European Union [15]; the percentages of energy services vs. exhaust/effluents and other losses in the industry as a whole were taken from [11].

Waste heat is contained in a wide variety of heat carrier media [16]. Gaseous media include exhaust and flue gases, low-grade steam, and cooling air. Liquid media most often are hot thermal oil or cooling water. As for solid media, these include hot products of any kind (e.g., steel ingots) and solid combustion residues (e.g., slag). Moreover, waste streams are available at various temperatures, and the ultra-low temperature level has been identified in multiple studies (e.g., [17,18]) as the most important one because such streams still contain large amounts of energy but are most likely to be discarded due to the recovery being more difficult. For instance, Luberti et al. [18] estimated that in the power industry, 75% of energy could be recovered from ultra-low-temperature waste streams, while in the (petro)chemical or pulp and paper industries, the fraction of utilizable heat in these waste streams approached 100%.

Before the recovery of waste heat can take place, one must first consider the waste heat potential (discussed in detail in Section 3), which determines whether any waste heat can actually be recovered and, if so, the recoverable amount. The respective heat recovery processes and technologies can then be classified into four main groups [19]:

- Energy recycling within the process;

- Waste heat recovery (WHR) for the purposes of other on-site processes;

- Electricity generation (combined heat and power installations, thermoelectric generation);

- Building/district heating systems.

Each group presents its own challenges, primarily the following:

- Group 1: retrofits of existing processes can be problematic (e.g., due to insufficient space) [20], while some technologies require specific conditions to work properly [21];

- Group 2: the selection of the best technology may not be straightforward [22], and corrosion, erosion, and fouling of the heat transfer surfaces can severely limit the prospective operator’s options [23];

- Group 3: the environmental impact of the working fluids [24] and their degradation at higher temperatures [25] may prove to be problematic, higher exergy losses [26] and low conversion efficiencies of conventional thermoelectric materials [27] have often been reported, and some technologies are still under development and are largely unproven (thus risky and unattractive to, e.g., shareholders);

- Group 4: the seasonal nature of the demand [28] as well as the greater distances between the heat source and sink [29] are often major challenges, and some technologies have also been shown to suffer from low efficiency [30];

- All groups: long(er) payback periods may discourage the investors [31].

What is more, it generally holds true that the lower the stream temperature, the more difficult the implementation of a suitable heat recovery technology. The mentioned factors are thus crucial in determining the suitable heat recovery methods.

The present paper focuses on the analysis of waste heat in the European Union with the main aim being to improve the understanding of its utilization and integration into processes as a source of energy. Only industrial gaseous and liquid waste heat streams from which direct heat recovery is possible (in contrast to general “energy recovery” such as thermoelectric generation [32], etc.) are considered. Additionally, only heat exchange between nearby heat sources and sinks is discussed because it is the most economic waste heat recovery option [33] and, by extension, the one most likely to be implemented by prospective users.

2. Waste Heat Stream Temperature

Current industrial processes involve waste heat streams available at different temperature levels. These usually are classified as low, medium, or high, but some studies also include ultra-low and ultra-high temperature levels—see Table 1. From this table, it is obvious that no clear consensus exists among the studies in terms of the temperature level stratification. It is also important to note that the situation becomes even more clouded when considering the percentages of waste heat available per level. This is because many studies—after a priori defining the temperature levels—report the waste heat availability for entirely different, arbitrarily chosen temperature ranges. However, good agreement can be observed in that most of the waste heat is available at low or low-to-medium temperatures, generally in the range of 100–300 °C (see, e.g., [34]). A detailed breakdown of the actual origins of waste heat, i.e., the processes that generate it, is provided in Section 4.

Table 1.

Typical waste heat stream temperature levels and the corresponding percentages of waste heat available per the individual levels (“N/A” if not listed in the respective studies).

3. Waste Heat Potential

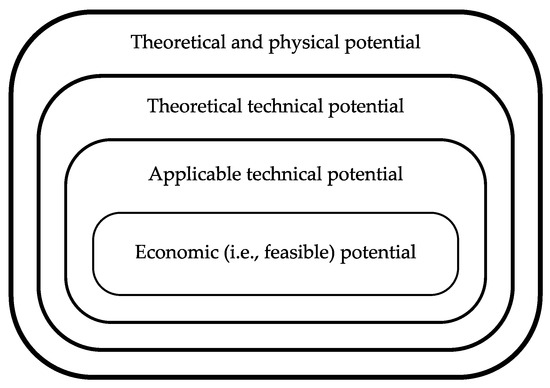

Panayiotou et al. [8] expand the original definition of waste heat potential by Brückner et al. [38] and specify four distinct layers (Figure 2):

- Theoretical and physical potential;

- Theoretical technical potential;

- Applicable technical potential;

- Economic (i.e., feasible) potential.

Figure 2.

Waste heat potential (adapted from [8]).

The broadest layer, technical and physical potential, is concerned only with the technical and environmental constraints (i.e., whether there exists a suitable heat recovery technology and a prospective user) and the physical constraints (e.g., the Second Law of Thermodynamics; this generally is given by the heat losses in the heat carrier during transfer, the minimum safe operating temperature, limitations imposed by the legislation, etc. [43]). The following theoretical technical potential encompasses scenarios where suitable heat recovery technologies exist and physical constraints are satisfied, irrespective of whether such heat recovery would be applicable in the given process or whether it would be economical. In other words, it is connected to the efficiency of energy transformation in the process [44] and must consider the heating (or cooling) demand in the region [45]. As implied by Figure 3 (see below), one must be aware of the possible fluctuations—not only whether the amount of waste heat is constant or fluctuates (e.g., seasonal fluctuation), but also in terms of changes in the demand for it. Moreover, any waste heat recovery technology must meet a wide range of requirements if it is to be implemented successfully. This is a matter of applicable technical potential, which concerns situations where there is heat available for recovery and at the same time there exists a technology—or technologies—applicable on site for the respective purpose (note that economic factors still are not considered). Please refer to Section 4 for details. Lastly, economic—or feasible—potential includes only the scenarios where heat recovery from the corresponding stream is not only possible, but also brings about economic benefits (i.e., it is profitable). However, this last potential and the eventual related savings depend to a large extent on the market prices of energy sources as well as any additional costs imposed by the implementation of the heat recovery technology. Thekdi and Nimbalkar [46] claimed that the cost of energy, especially that from fossil fuels, ultimately is the most important parameter in the decision-making process. Compared to technical potential, which can be evaluated with relative ease using available statistical data, the evaluation of economic potential is much more difficult and often requires stochastic modeling or forecasting to properly include the fluctuations in energy and commodity prices, interest and tax rates, subsidies, planned changes in environmental protection legislation, etc.

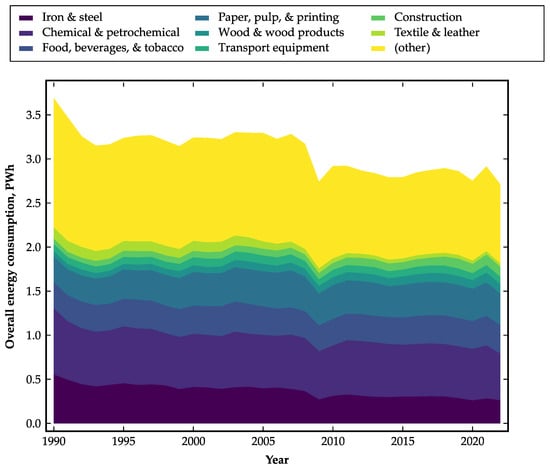

Figure 3.

Overall energy consumption (PWh) across EU27 industries in the last 32 years [47].

The initial and most important step in determining waste heat potential is finding the areas in which heat is not fully utilized and quantifying the available waste heat, as well as areas where waste this heat could be used as a secondary energy source. This is especially relevant considering the ever-growing energy demand and more stringent environmental legislation where waste heat can help meet the respective requirements. In any case, to quantify the available waste heat, it is paramount to first understand which sectors are the largest producers of waste heat.

The latest statistical data for 2022 and the individual sectors within EU27 [47] (datasets newer than 2022 are not yet available) show that the industry as a whole accounts for 25% of the total energy consumption (see Figure 1). Figure 3, which is based on the same statistical data source, presents the overall energy consumption in specific industries for the last 32 years. An earlier study by Brückner et al. [38] claimed that in the European Union, the industries with the greatest production of waste heat are the (petro)chemical, iron and steel, food and tobacco, and pulp and paper industries. Judging by the latest EU27 data (Figure 3), this still is the case. Bianchi et al., in their 2019 study [11], stated that these four industries accounted for almost 60% of the overall theoretical potential, while according to Figure 3, this would in 2022 amount to approx. 54%, or 1.47 PWh.

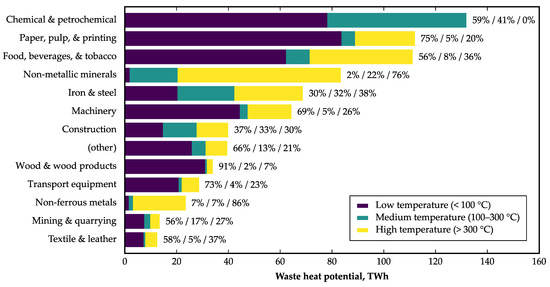

The estimated overall waste heat potential in the major EU27 industries is shown in Figure 4. The necessary energy consumption data were taken from the latest dataset [47], while the waste heat ratios and temperature distributions per industry correspond to those published by Bianchi et al. [11].

Figure 4.

Waste heat potential in individual industries obtained using the latest EU27 data [47]; the temperature distribution and waste heat ratios per industry were taken from the study by Bianchi et al. [11].

In essence, estimating the waste heat potential involves determining the following data for each source stream that is not yet fully utilized:

- Temperature level or range (incl. to what temperature the stream can be cooled);

- Composition, physical properties, fouling propensity, corrosivity, and whether the condensation of stream components could be an issue;

- Mass flow rate;

- Availability (year-round, seasonal, only specific days or parts of days, etc.).

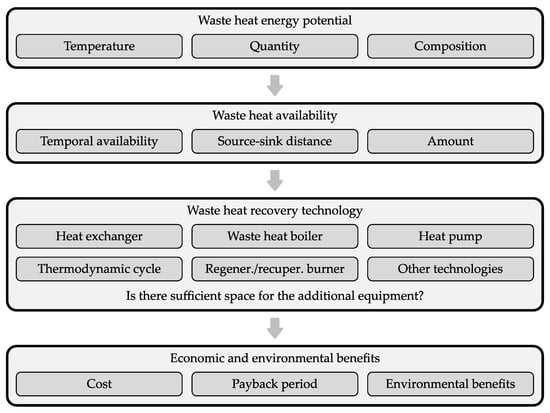

Then, these data are compared to the demand, and one must ask primarily the following questions (see also Figure 5):

- Is the stream temperature sufficient for the intended purpose(s)?

- Is the amount of heat available from the stream sufficient, or would an additional heat source be needed?

- Is the distance between the heat source and the heat sink sufficiently small to make heat recovery possible?

- Is there a suitable heat recovery technology? Is there sufficient space for the additional equipment within the plant?

- Would the payback period be acceptable? That is, would the cost of the necessary technology (and the connecting pipeline, if needed) be reasonable compared to the yearly financial savings due to waste heat recovery?

- Would the implementation of the selected waste heat recovery technology bring measurable environmental benefits?

Figure 5.

Main steps of the waste heat recovery decision algorithm.

4. Factors Limiting the Full Utilization of Waste Heat

As noted in the papers published by Christodoulides et al. [22,48], the major limitations and barriers to the widespread adoption of waste heat recovery technologies are as follows (in order from the most common to least common, according to the reported survey results):

- Insufficient information and know-how available to the prospective technology operators (see also [49]);

- The risks associated with new and unproven technology (see also [36], where organizational barriers stemming from the involvement of stakeholders and their likely resistance to unproven technologies and financial risks are highlighted);

- The requirements imposed by legislation;

- High investment and operating costs, long payback periods (due to comparably lower primary energy prices, etc.), and, in many cases, relatively low internal rates of return (see also [36]);

- Insufficient financial incentives and subsidies;

- Space limitations with regard to the sizes of the necessary technologies;

- Insufficient infrastructure;

- Limitations of the production process (see also [50], where this point is discussed in detail in the context of harsh environments for which specialized waste heat recovery equipment may be required) and the risk of production process disruptions.

Earlier studies (e.g., [46,51]) stressed that conventional heat recovery technologies often may not have been suitable in the respective industrial processes or waste heat temperature ranges. However, Benedetti et al. [36] has argued that this is no longer the case. According to both Miró et al. [51] and Xu et al. [52], the problem is further compounded by the temporal and geographical inconsistencies between waste heat availability and demand and the lack of a global optimization methodology for the design of distributed waste heat recovery systems.

As for technological barriers in particular, the data reported by Christodoulides et al. [22] suggest that by far the most common reason for not recovering waste heat has been the high capital cost per unit of energy recovered (i.e., low efficiency of the available waste heat recovery solutions). The second most common concern has been the low or variable waste heat source quality. Other reasons included, e.g., the problematic nature of long-distance transport of low-grade heat (i.e., the previously mentioned spatial mismatch between the heat source and heat sink) or high chemical activity of the source barring the use of common materials. Jouhara and Olabi [53] mentioned the legislative limitations stemming from efforts to limit the production of greenhouse gases as one of the factors limiting the implementation of waste heat recovery technologies. Such legislation forces the operators of industrial plants to adapt their processes so that they meet these new regulatory requirements, and then waste heat recovery may not be economical or even feasible.

A common consequence of the aforementioned economic barriers (high investment costs, etc.) is that a more economic yet less ecological technology is often selected. Moreover, the survey carried out by Christodoulides et al. [22] among waste heat recovery operators showed that the majority (12 out of 16 implemented cases, i.e., 75%) were not profitable. This is why new support mechanisms would make waste heat recovery projects more appealing to prospective operators. The absence of a binding EU waste heat policy is a closely related and no less important factor influencing operators in their decisions regarding whether to implement waste heat recovery solutions.

In summary, to promote waste heat recovery and make it more appealing to the prospective operators, an innovative approach is needed involving education and edification, close cooperation between the industries and the public and private sectors, and government subsidies. Once the discussed barriers are removed, waste heat can become one of the pillars of sustainable energy policies. The following section focuses on specific sources of waste heat across industries to provide the information necessary for the identification of suitable waste heat recovery strategies.

5. Industrial Sources of Waste Heat

Waste heat is generated in almost every thermal and mechanical process and includes both sensible heat and latent heat. Some authors also include chemical waste among the sources of waste heat [54]. Su et al. [55] published an overview of waste heat sources in individual industries. Waste heat potential together with the temperature levels corresponding to selected industries has also been provided, e.g., by Bianchi et al. [11] or Panayiotou et al. [8]. Panayiotou et al., in their more recent paper [56], also mentioned information related to the iron and steel industry, while Oliveira et al. [57] focused solely on waste heat sources in the ceramics industry. Benedetti et al. [36] discussed industrial processes with low-temperature waste heat production. Typical applications of waste heat from various sources were listed by Huang et al. [58].

Waste heat source temperature ranges typical for the main industries have been summarized by Arzbaecher et al. [14], or, in terms of the actual industrial heating process temperatures, by Garofalo et al. [59]. A common rule of thumb is that most of the high- and medium-temperature waste heat comes from combustion processes, while low-temperature waste heat is available from products or the equipment in production units [38]. Table 2 lists the most common industrial waste heat sources and their corresponding temperature levels.

Table 2.

Common waste heat sources and their temperature levels; individual sources were classified according to Benedetti et al. [36] if the specific temperatures were provided in the respective references instead.

While some heat losses are inevitable, there often exists a wide range of technologies capable of transforming waste heat into utilizable energy. Implementation of such technologies can significantly improve the efficiency and competitiveness of the respective process as well as decrease its environmental impact. Selected waste heat recovery technologies and equipment are discussed together with their advantages, disadvantages, and limitations in the following text.

6. Technologies and Equipment Applicable to Waste Heat Recovery

Zhang et al. [70] classified waste heat recovery technologies into three main categories, namely direct utilization, transformation into electricity, and cascading systems which involve direct use of the higher-temperature heat, while the remaining portion is transformed to electricity. Similarly, Brueckner et al. [71] identified four modes of waste heat recovery:

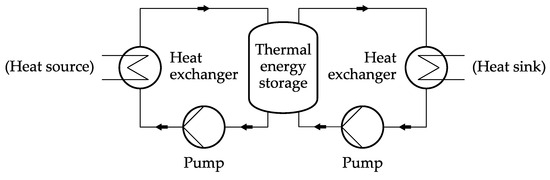

- Direct recovery (e.g., using heat exchangers or thermal energy storage);

- Transformation to a higher temperature level (e.g., via heat pumps);

- Transformation to a lower temperature level (i.e., cooling via absorption or adsorption chillers etc.);

- Transformation to electricity (e.g., through an organic Rankine cycle).

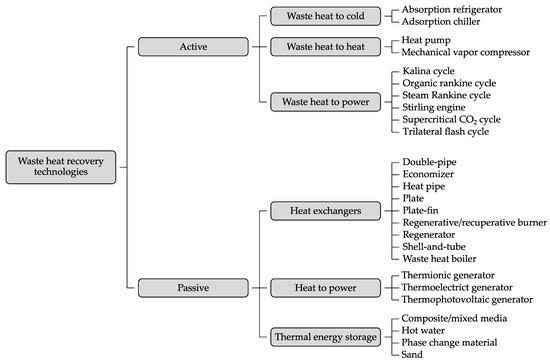

Heat recovery technologies and equipment sometimes also are classified as “active” or “passive” depending on the actual manner of energy recovery or transformation (see Figure 6).

Figure 6.

Classification of waste heat recovery technologies and equipment.

A brief overview of common waste heat recovery technologies and the typical operating temperature ranges, as listed in various studies, is provided in Table 3. The review of published papers has shown that in industry, the largest portion of waste heat is available at low temperatures. For example, Haddad et al. [39] estimated that 66% of industrial waste heat is in streams at temperatures up to 200 °C. To make use of such heat, several new technologies have recently been developed. These typically involve heat pumps [72], organic Rankine cycles [36], Kalina cycles, adsorption chillers, absorption refrigerators, liquid desiccants [73], thermal energy storage [74], or solid or liquid thermal storage to match the spatial or temporal discrepancy between heat source and heat sink [52]. Of these, organic Rankine cycles were reported to be most suitable under constant (possibly low) waste heat stream temperatures [75]. Brueckner et al. [71] also mentioned several emerging technologies applicable even at ultra-low temperatures (up to ca. 120 °C), e.g., thermoacoustic, electrochemical, piezoelectric, or pyroelectric systems.

Table 3.

Common waste heat recovery technologies as listed in various studies; temperature levels (unless provided in the respective studies) are classified according to Benedetti et al. [36].

At temperatures above ca. 200 °C, well established technologies are prevalent if the source of waste heat (e.g., flue gas) is clean [50]. Attempts to use such technologies when the waste heat sources were fouled reportedly resulted in short maintenance periods as well as lifespans, especially so when the stream temperature was high. Similar scenarios were common when the flue gas temperature decreased below the condensation point of the contained acidic compounds (which has bearing not only on the selection of equipment, but also on the selection of construction materials, thus greatly influencing the capital cost). The survey results presented by Christodoulides et al. [22] indicated a pattern similar to the findings in [50], that is, by far the most common waste heat recovery equipment were air preheaters, economizers, waste heat boilers, or steam generators, with the corresponding waste stream temperatures ranging up to 650 °C. This was especially true if the waste heat stream temperature was fluctuating [75]. Several novel and more efficient waste heat recovery technologies making use of heat pipes (e.g., heat pipe condensing economizers) also were put forth at the temperatures of up to 1000 °C by the respondents in the same survey, but these were used much less often due to being costly. As for, e.g., supercritical CO2 cycles, which overall should perform much better than other waste heat recovery options [22], none of the respondents in the mentioned survey stated that they even considered them as an option.

Despite the large amounts of waste heat available, Benedetti et al. [36] pointed out that the number of recovery applications has been limited, and that there still has remained a large disproportion between the available waste heat and the waste heat that has actually been utilized. The barriers limiting the wider acceptance and implementation of waste heat recovery technologies are outlined in Section 4. Xu et al. [52] noted that high-temperature waste heat could be recovered more easily without the need for novel or specialized technology and meet the demand of a wider range of users. These authors also mentioned that the efficient recovery of low-temperature heat was challenging and often necessitated optimization. Brückner et al. [38] listed two additional factors with great influence on the waste heat recovery process, namely the composition of the waste stream and the space available for the respective technology.

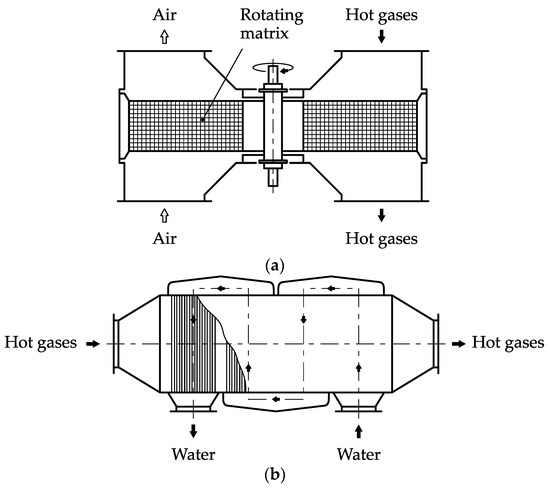

6.1. Regenerative and Recuperative Heat Exchangers

Both regenerative (Figure 7a) and recuperative (Figure 7b) heat exchangers are proven and widely used technologies. Rotary and stationary regenerators are often employed for ultra-high-temperature waste heat recovery from fouled flue gas (e.g., glass or coke production) [103]. Their major disadvantages are the large built-up area they require [104] (although comparatively smaller than that of an equivalent recuperative heat exchanger [105]), bypass streams [106], and possible structural issues stemming from the utilization of materials having different thermal expansion characteristics (e.g., ceramic matrices and steel shells) [107].

Figure 7.

(a) Rotary regenerator; (b) recuperative heat exchanger.

Recuperative heat exchangers are, according to Jouhara et al. [103], most commonly used for medium- and high-temperature waste heat recovery. Metallic recuperators can be used at up to ca. 1100 °C, and those made from ceramics can withstand temperatures up to ca. 1500 °C [1]. Considering cost savings, Akhan and Eryener [108], for example, evaluated the heating of buildings using waste heat recovered from a compressor unit’s cooling water in a plate heat exchanger in combination with further heating of the heat carrier in a capillary tube solar collector, and found that it reached 14%/y. The implementation of low-temperature heat recovery is generally limited to using either enhanced (e.g., fins) tubular heat exchangers or plate heat exchangers [104], and necessitates waste heat sources with a low fouling propensity. Similarly, heavily fouled streams that absorb the waste heat [109] and tube-side stream maldistribution [110] can also cause severe issues.

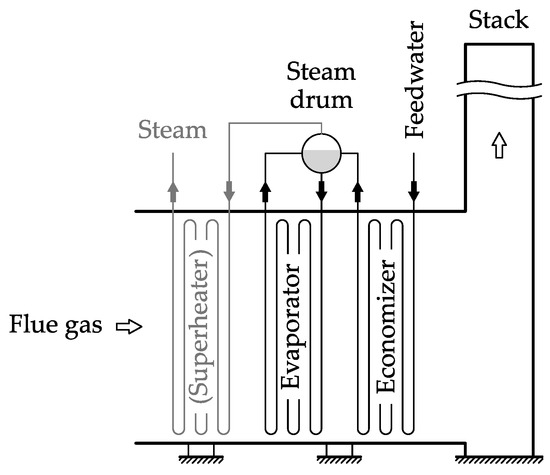

6.2. Waste Heat Boilers

Waste heat boilers (Figure 8) are also a widely used type of heat recovery equipment and typically are employed to produce steam from medium-to-high-temperature flue gas [111]. These apparatuses are efficient and easy to maintain; this makes them ideal for waste heat recovery, even in industries where waste heat streams are fouled (be it at the typical high temperatures [112] or low-to-medium temperatures [113]). Other studies also mention reduced emissions among their advantages [114]. It is important to note that due to the conditions in which waste heat boilers are commonly used (flue gas containing acidic compounds, etc.), in many cases, they tend to fail—or at least require frequent servicing—because of corrosion [23], erosion, or a combination of both [115].

Figure 8.

Typical arrangement of a waste heat boiler; the superheater is only present if the waste stream temperature is high enough.

6.3. Regenerative and Recuperative Burners

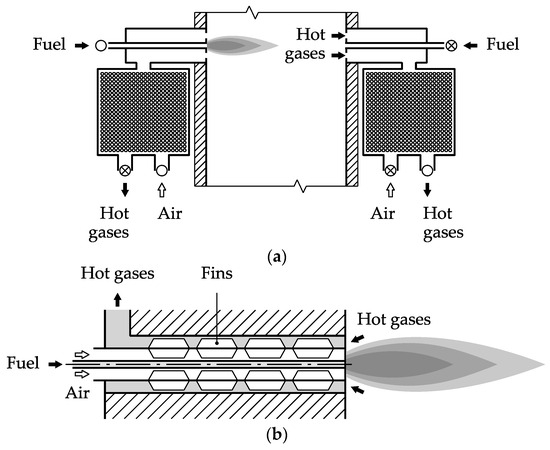

Both regenerative (Figure 9a) and recuperative (Figure 9b) burners are more compact and feature better thermal efficiency than regular burners, leading to a 25–23% reduction in fuel consumption due to the integrated preheating of combustion air [116]. Some studies mention even greater fuel savings of up to 43% compared to conventional recuperative systems in reheating furnaces [117]. According to Wu et al. [118], these burners produce lower amounts of NOx emissions than conventional burners. However, they must be installed in pairs and may require additional heat storage equipment [2], i.e., the resulting capital cost generally is much higher. The more complex nature of these burners also may require more careful design in terms of the gas and air velocities, etc. [119].

Figure 9.

(a) Regenerative burner; (b) recuperative burner.

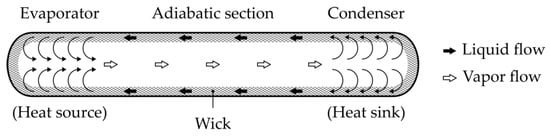

6.4. Heat Pipes

Heat pipes (Figure 10) can be used to recover waste heat from sources at up to 600 °C [120] or, according to some sources [12], even 1000 °C, but the selection of the working fluid inside the heat pipe as well as the material of the pipe must reflect the actual operating conditions [121]. For example, liquid metals must be used when operation under high temperatures is required [122]. The compatibility of the fluid and pipe material must also be ensured [81]. Heat pipes feature thermal conductivity rates of up to 200,000 W m−1 K−1 (thus making them suitable for the transfer of heat over relatively long distances [123]), great reliability, and a long service life [103]. The main weakness of heat pipes—primarily in cases when the working medium is solid at ambient temperatures—is their “frozen” startup [122].

Figure 10.

Heat transfer via a heat pipe.

The application of heat pipes is common not only in thermal management (typically in the IT sector or the automotive or power generation industries) [120], but also in glass production or solar concentrators [48]. Major benefits of heat pipe application in terms of CO2 emission savings have been observed in the iron and steel and (petro)chemical industries and in cement production [12].

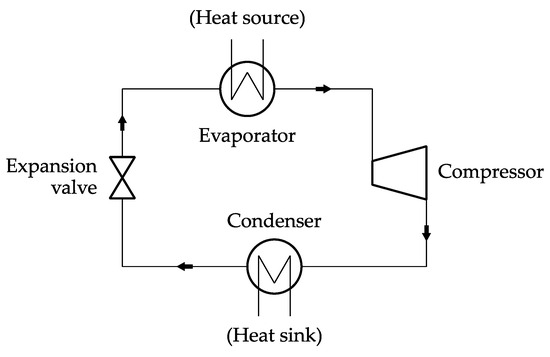

6.5. Heat Pumps

Heat pumps (Figure 11) are a reliable [124] and efficient [125] waste heat recovery solution especially suitable for ultra-low and low temperature levels [126]. Their average temperature lifts are about 30 °C [127], while high-temperature heat pumps have been reported to increase the heat carrier stream temperature by up to 150 °C [128]. According to Ma et al. [129], high-temperature heat pumps are crucial when converting heat from low-to-medium-temperature industrial effluents to high-grade energy. The same authors also evaluated six different refrigerants across several industrial applications and found the binary refrigerant MC-1 to be the best overall. Liu et al. [130] stated that for high-temperature waste heat recovery, pure substances are not suitable, and recommended a ternary mixture of CO2, R600a, and R1233zd(E) for the best performance. In ultra-low-temperature applications, on the other hand, cryogenic fluids or nano-fluids may be required [83].

Figure 11.

Working principle of a heat pump.

Heat pumps are typically utilized to extract waste heat from cooling media (air, water, lubricants, etc.) [126]. Tan et al. [131] evaluated four different types of heat pumps (a mechanical heat pump, an absorption heat pump, an absorption heat transformer, and a steam jet pump) and argued that any heat pump was always more efficient than a thermodynamic cycle, and that, e.g., the organic Rankine cycle was more efficient in terms of exergy than a steam turbine. The only mentioned scenario where heat pumps were not competitive was when, locally, the price ratio of electricity to heat was greater than five. Still, the main factors limiting the widespread use of heat pumps are their high capital costs and the environmental impact of refrigerants [132].

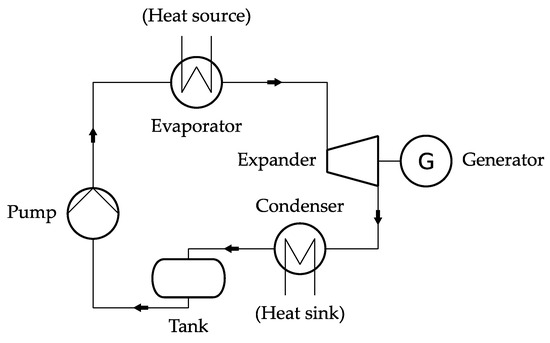

6.6. Thermodynamic Cycles

Thermodynamic cycles (Figure 12)—typically the organic Rankine cycle (ORC) or Kalina cycle (KC), which make use of low-boiling-point working fluids—can cost-effectively transform waste heat to electricity [133]. Douvartzides and Karmalis [134] estimated the primary energy savings in industrial processes resulting from the implementation of ORC waste heat recovery to be 6–13%. Carcasci et al. [135] stated that the ORC was suitable for low-to-medium-temperature waste heat recovery where a steam cycle could not be implemented. However, Chen et al. [136] stipulated that the working fluid must be selected carefully because it influences the cycle efficiency as well as the capital cost. According to Jiménez-García et al. [137], the most cost-effective fluids are R1234yf (at temperatures below 120 °C) and cyclohexane (at higher temperatures). R600, R601, R123, and R134a and toluene, respectively, were identified as the best fluids from an environmental perspective for these two temperature levels. Additionally, the ORC is not strictly limited to industrial use cases as it has also been successfully implemented in, e.g., geothermal, ocean thermal, and solar applications [93].

Figure 12.

Basic arrangement of a thermodynamic cycle.

Compared to the ORC, the KC has been reported to feature greater efficiency [138] but require careful selection of the necessary components [139]. Similarly, Iqbal et al. [140] stated that the trilateral flash cycle (TFC) was up to 50% more efficient than the ORC and could be implemented even under temperatures below 80 °C, where the ORC was economically infeasible [141]. A different study [12] reported the TFC to even be twice as efficient as the ORC, but for waste heat recovery at higher temperature levels (200–500 °C), supercritical CO2 cycles were recommended. Zamfirescu and Dincer [142] evaluated the ORC, KC, and TFC and found that the TFC outperformed both the ORC and KC. They also stated that, when implemented into a combined heat and power generation system, the TFC’s efficiency was above 70%. In general, thermodynamic cycles have been deemed the best waste heat recovery technology in cases of ultra-low-temperature waste heat streams at up to 120 °C [32].

6.7. Thermal Energy Storage

Waste heat can be recovered and stored (Figure 13) in a wide variety [143] of media—typically water (e.g., as part of a district heating system) [144], sand [145], zeolite [146], phase change materials [147] (possibly mixed, e.g., with either regular [148] or volcanic [149] sand for improved heat capacity), graphite matrices filled with paraffin wax [150], or molten metals [151] or salts [152]. According to Tetteh et al. [153], thermal energy storage can be more efficient and cheaper than the transformation of waste heat to electricity coupled with the utilization of Li-ion batteries.

Figure 13.

Working principle of thermal energy storage.

7. Case Studies

A concise list of selected case studies available in the literature is provided in Table 4. This literature review has shown that thermodynamic cycles, most notably organic Rankine cycles, are prevalent and are used across a very wide temperature range—from less than 100 °C to 1400 °C. It also is clear that waste heat recovery case studies have been carried out primarily in the context of processes with a heavy use of energy (i.e., the production of cement, ceramics, or iron and steel). Overall, the studies found in the literature state that industrial waste heat recovery is possible and desirable from both an energy-saving and an environmental point of view.

Table 4.

Selected waste heat recovery case studies incl. their main characteristics; pieces of information not provided in the respective studies are denoted with “N/A”.

In addition to Table 4, the paper by Benedetti et al. [36] should also be mentioned. Although it did not discuss any case study in detail, it presented the concept of a “database of case studies and technologies” which should help users identify suitable technologies for their specific use cases. Similarly, one could refer to the paper by Jegla and Daxner [176] when deciding which waste heat recovery technology to use in order to minimize the environmental impact.

8. Perspective and Outlook

The utilization of waste heat provides economic and environmental benefits, and therefore it has become an increasingly important topic in the industry. There are four main factors that will drive the implementation of future industrial waste heat recovery solutions:

- The ever-widening range of and improvements made to waste heat recovery technologies and equipment;

- Economic benefits;

- Changes in environmental legislation;

- The availability of waste heat.

Due to the recent technological innovations, it has never been easier for companies to implement waste heat recovery solutions and benefit from the increased energy efficiency that these solutions bring. This is closely followed by lower primary energy consumption and lower operating costs. Even if a company is not able to utilize the recovered waste heat on site, the overall economic balance can often be improved by exporting the excess energy (possibly transformed to electricity or cold) to nearby consumers. Also related to the cost–benefit analysis of any such waste heat recovery project is the diversification of energy sources, which is ever more important given the volatility of energy prices—especially when it comes to fossil fuels.

Considering the ongoing changes in legislation (e.g., the European Green Deal), one can reasonably expect the laws and regulations to become more and more stringent in terms of the emission limits, etc. The increasing cost of European Emission Allowances, fines and/or penalties issued for non-compliance, as well as EU/government subsidies will inevitably motivate those that have not yet implemented waste heat recovery technologies to do so. The operators will in their own interest follow the latest technological developments and consider which technologies would best suit their needs. It can also be expected that due to the non-negligible capital costs, some companies will cooperate and spread the financial burden among themselves.

One could assume that with respect to the technological progress, the amount of available waste heat will gradually decrease. However, there are many uncertain factors involved, and to make any reasonably accurate predictions, one would have to make use of stochastic modeling, employ neural networks, or rely on the emerging artificial intelligence tools. What is certain, though, is that due to the developing technological innovations, new legislation and EU/government subsidies, and increased awareness, there will be in the upcoming years an upswing in the rate of implementation of industrial waste heat recovery solutions.

9. Discussion

The present paper summarizes the latest European Union data on industrial energy consumption and waste heat potential and highlights the significance of the proper utilization of industrial waste heat and its bearing on the efficiency of operation and reduction in environmental impact of industries in the European Union. According to the available data, the overall yearly energy consumption in these industries reaches approx. 2.63 PWh, of which—according to multiple studies—only ca. 50% is transformed to a usable form of energy. The rest of the energy is marred in various waste streams or other energy losses. However, the energy in these waste streams amounts to ca. 29% of the total energy consumption [11] and can further be utilized. It is shown that the industries with the largest potential are the chemical and petrochemical; paper, pulp, and printing; and food, beverages, and tobacco industries, and that the total waste heat potential in just these three industries reaches more than 350 TWh/y (i.e., a significant amount of energy that, if utilized, could markedly reduce the primary energy consumption).

The scope of this paper also covers the identification of a wide spectrum of factors hindering industrial waste heat utilization. One such barrier is the quantification of waste heat available at various temperature levels. As presented in Table 1, there exists a multitude of differing classifications, and although no consensus can be observed, many studies agree that the majority of waste heat is available at temperatures up to 200 °C. For each of the main EU industries, the representative sources of waste heat and their temperature levels were compiled from the available literature and are provided.

Our extensive literature review assessing research on industrial waste heat recovery technologies and equipment yielded a wide range of equipment suitable for various temperature levels. According to the results of this review, the greatest research effort seems to have been devoted to thermodynamic cycles and heat pumps. The development and improvements of these technologies in recent years have resulted in their superior performance and ability to function at (ultra-)low temperatures, which is especially desirable given the fact that most waste heat is available at 200 °C or less.

A representative selection of 35 industrial waste heat recovery case studies found in the literature is also provided. Although these examples confirm that the utilization of industrial waste heat represents a major opportunity for primary energy savings and emission reduction across the entire range of industries, they also show that further research is needed to solve the challenges related to the implementation of waste heat recovery technologies and equipment in varied industrial processes. In other words, the results and recommendations listed in the available case studies, each of which is related to a specific process and conditions, must be extended and generalized. Only then could the decisions of prospective operators be made easier, and consequently, there could be a significant shift in and proliferation of waste heat recovery and utilization.

Author Contributions

Conceptualization, Z.J.; methodology, all authors; investigation, B.K., D.B.F., J.D. and V.T.; data curation, B.K. and J.D.; writing—original draft preparation, B.K., D.B.F., J.D. and V.T.; writing—review and editing, V.T.; visualization, B.K. and V.T.; supervision, Z.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Technology Agency of the Czech Republic, grant number TN02000025, and the Czech Ministry of Education, Youth and Sports/EU Operational Programme Research, Development and Education, grant number CZ.02.1.01/0.0/0.0/16_026/0008413.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Johnson, I.; Choate, W.; Davidson, A. Waste Heat Recovery. Technology and Opportunities in U.S. Industry; U.S. Department of Energy, Office of Scientific and Technical Information (OSTI): Oak Ridge, TN, USA, 2008. [Google Scholar]

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste Heat Recovery Technologies and Applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Grönkvist, S.; Dahlberg, L.; Lundberg, H.; Martinsson, C.; Stenkvist, M. Analys av Metoder för att öka Incitament för Spillvärmesamarbete [Analysis of Methods to Increase the Incentives for Excess Heat Use]; Swedish Energy Agency Eskilstuna: Eskilstuna, Sweden, 2008. [Google Scholar]

- Bendig, M.; Maréchal, F.; Favrat, D. Defining “Waste Heat” for Industrial Processes. Appl. Therm. Eng. 2013, 61, 134–142. [Google Scholar] [CrossRef]

- Lu, P.; Liang, Z.; Luo, X.; Xia, Y.; Wang, J.; Chen, K.; Liang, Y.; Chen, J.; Yang, Z.; He, J.; et al. Design and Optimization of Organic Rankine Cycle Based on Heat Transfer Enhancement and Novel Heat Exchanger: A Review. Energies 2023, 16, 1380. [Google Scholar] [CrossRef]

- Hnat, J.G.; Coles, W.F. A Feasibility Assessment of Cogeneration from a Regenerative Glass Furnace. IEEE Trans. Ind. Applicat. 1985, IA-21, 1064–1069. [Google Scholar] [CrossRef]

- Forman, C.; Muritala, I.K.; Pardemann, R.; Meyer, B. Estimating the Global Waste Heat Potential. Renew. Sustain. Energy Rev. 2016, 57, 1568–1579. [Google Scholar] [CrossRef]

- Panayiotou, G.P.; Bianchi, G.; Georgiou, G.; Aresti, L.; Argyrou, M.; Agathokleous, R.; Tsamos, K.M.; Tassou, S.A.; Florides, G.; Kalogirou, S.; et al. Preliminary Assessment of Waste Heat Potential in Major European Industries. Energy Procedia 2017, 123, 335–345. [Google Scholar] [CrossRef]

- Varga, Z.; Palotai, B. Comparison of Low Temperature Waste Heat Recovery Methods. Energy 2017, 137, 1286–1292. [Google Scholar] [CrossRef]

- Viswanathan, V.V.; Davies, R.W.; Holbery, J. Opportunity Analysis for Recovering Energy from Industrial Waste Heat and Emissions; U.S. Department of Energy, Office of Scientific and Technical Information (OSTI): Oak Ridge, TN, USA, 2006. [Google Scholar]

- Bianchi, G.; Panayiotou, G.P.; Aresti, L.; Kalogirou, S.A.; Florides, G.A.; Tsamos, K.; Tassou, S.A.; Christodoulides, P. Estimating the Waste Heat Recovery in the European Union Industry. Energ. Ecol. Environ. 2019, 4, 211–221. [Google Scholar] [CrossRef]

- Agathokleous, R.; Bianchi, G.; Panayiotou, G.; Aresti, L.; Argyrou, M.C.; Georgiou, G.S.; Tassou, S.A.; Jouhara, H.; Kalogirou, S.A.; Florides, G.A.; et al. Waste Heat Recovery in the EU Industry and Proposed New Technologies. Energy Procedia 2019, 161, 489–496. [Google Scholar] [CrossRef]

- Pashchenko, D. Natural Gas Reforming in Thermochemical Waste-Heat Recuperation Systems: A Review. Energy 2022, 251, 123854. [Google Scholar] [CrossRef]

- Arzbaecher, C.; Fouche, E.; Parmenter, K. Industrial Waste-Heat Recovery: Benefits and Recent Advancements in Technology and Applications. In Proceedings of the ACEEE Summer Study on Energy Efficiency in Industry, Washington, DC, USA, 25 July 2007; pp. 2:1–2:13. Available online: https://www.eceee.org/library/conference_proceedings/ACEEE_industry/2007/Panel_2/p2_1/ (accessed on 27 March 2024).

- Energy Statistics—An Overview. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Energy_statistics_-_an_overview#Final_energy_consumption (accessed on 1 February 2024).

- Papapetrou, M.; Kosmadakis, G.; Cipollina, A.; La Commare, U.; Micale, G. Industrial Waste Heat: Estimation of the Technically Available Resource in the EU per Industrial Sector, Temperature Level and Country. Appl. Therm. Eng. 2018, 138, 207–216. [Google Scholar] [CrossRef]

- Daniarta, S.; Sowa, D.; Błasiak, P.; Imre, A.R.; Kolasiński, P. Techno-Economic Survey of Enhancing Power-to-Methane Efficiency via Waste Heat Recovery from Electrolysis and Biomethanation. Renew. Sustain. Energy Rev. 2024, 194, 114301. [Google Scholar] [CrossRef]

- Luberti, M.; Gowans, R.; Finn, P.; Santori, G. An Estimate of the Ultralow Waste Heat Available in the European Union. Energy 2022, 238, 121967. [Google Scholar] [CrossRef]

- Crook, A.W. Profiting from Low-Grade Heat: Thermodynamic Cycles for Low-Temperature Heat Sources; IET: Stevenage, UK, 1994; ISBN 978-0-85296-835-2. [Google Scholar]

- Jegla, Z.; Freisleben, V. Practical Energy Retrofit of Heat Exchanger Network Not Containing Utility Path. Energies 2020, 13, 2711. [Google Scholar] [CrossRef]

- Oyedepo, S.O.; Fakeye, B.A. Waste Heat Recovery Technologies: Pathway to Sustainable Energy Development. J. Therm. Eng. 2021, 7, 324–348. [Google Scholar] [CrossRef]

- Christodoulides, P.; Agathokleous, R.; Aresti, L.; Kalogirou, S.A.; Tassou, S.A.; Florides, G.A. Waste Heat Recovery Technologies Revisited with Emphasis on New Solutions, Including Heat Pipes, and Case Studies. Energies 2022, 15, 384. [Google Scholar] [CrossRef]

- Ebara, R.; Tanaka, F.; Kawasaki, M. Sulfuric Acid Dew Point Corrosion in Waste Heat Boiler Tube for Copper Smelting Furnace. Eng. Fail. Anal. 2013, 33, 29–36. [Google Scholar] [CrossRef]

- Tian, H.; Liu, P.; Shu, G. Challenges and Opportunities of Rankine Cycle for Waste Heat Recovery from Internal Combustion Engine. Prog. Energy Combust. Sci. 2021, 84, 100906. [Google Scholar] [CrossRef]

- Jiménez-Arreola, M.; Pili, R.; Dal Magro, F.; Wieland, C.; Rajoo, S.; Romagnoli, A. Thermal Power Fluctuations in Waste Heat to Power Systems: An Overview on the Challenges and Current Solutions. Appl. Therm. Eng. 2018, 134, 576–584. [Google Scholar] [CrossRef]

- Nyakuma, B.B.; Mahyon, N.I.; Chiong, M.S.; Rajoo, S.; Pesiridis, A.; Wong, S.L.; Martinez-Botas, R. Recovery and Utilisation of Waste Heat from Flue/Exhaust Gases: A Bibliometric Analysis (2010–2022). Environ. Sci. Pollut. Res. 2023, 30, 90522–90546. [Google Scholar] [CrossRef]

- Manna, N. Study on Piezoelectric Elements for Energy Harvesting. In Proceedings of the 2014 1st International Conference on Non Conventional Energy (ICONCE 2014), Kalyani, India, 16–17 January 2014; pp. 334–338. [Google Scholar]

- Pakere, I.; Blumberga, D.; Volkova, A.; Lepiksaar, K.; Zirne, A. Valorisation of Waste Heat in Existing and Future District Heating Systems. Energies 2023, 16, 6796. [Google Scholar] [CrossRef]

- Marx, N.; Blakcori, R.; Forster, T.; Maggauer, K.; Ralf-Roman, S. Risk Assessment in District Heating: Evaluating the Economic Risks of Inter-Regional Heat Transfer Networks with Regards to Uncertainties of Energy Prices and Waste Heat Availability Using Monte Carlo Simulations. Smart Energy 2023, 12, 100119. [Google Scholar] [CrossRef]

- Sasidharan, M.; Mohd Sabri, M.F.; Wan Muhammad Hatta, S.F.; Ibrahim, S. A Review on the Progress and Development of Thermoelectric Air Conditioning System. Int. J. Green Energy 2024, 21, 283–299. [Google Scholar] [CrossRef]

- Wang, X.-Q.; Li, X.-P.; Li, Y.-R.; Wu, C.-M. Payback Period Estimation and Parameter Optimization of Subcritical Organic Rankine Cycle System for Waste Heat Recovery. Energy 2015, 88, 734–745. [Google Scholar] [CrossRef]

- Ji, D.; Cai, H.; Ye, Z.; Luo, D.; Wu, G.; Romagnoli, A. Comparison between Thermoelectric Generator and Organic Rankine Cycle for Low to Medium Temperature Heat Source: A Techno-Economic Analysis. Sustain. Energy Technol. Assess. 2023, 55, 102914. [Google Scholar] [CrossRef]

- Law, R.; Harvey, A.; Reay, D. Opportunities for Low-Grade Heat Recovery in the UK Food Processing Industry. Appl. Therm. Eng. 2013, 53, 188–196. [Google Scholar] [CrossRef]

- Ji, D.; Liu, G.; Romagnoli, A.; Rajoo, S.; Besagni, G.; Markides, C.N. Low-Grade Thermal Energy Utilization: Technologies and Applications. Appl. Therm. Eng. 2024, 244, 122618. [Google Scholar] [CrossRef]

- Ammar, Y.; Joyce, S.; Norman, R.; Wang, Y.; Roskilly, A.P. Low Grade Thermal Energy Sources and Uses from the Process Industry in the UK. Appl. Energy 2012, 89, 3–20. [Google Scholar] [CrossRef]

- Benedetti, M.; Dadi, D.; Giordano, L.; Introna, V.; Lapenna, P.E.; Santolamazza, A. Design of a Database of Case Studies and Technologies to Increase the Diffusion of Low-Temperature Waste Heat Recovery in the Industrial Sector. Sustainability 2021, 13, 5223. [Google Scholar] [CrossRef]

- Bonilla-Campos, I.; Nieto, N.; del Portillo-Valdes, L.; Egilegor, B.; Manzanedo, J.; Gaztañaga, H. Energy Efficiency Assessment: Process Modelling and Waste Heat Recovery Analysis. Energy Convers. Manag. 2019, 196, 1180–1192. [Google Scholar] [CrossRef]

- Brückner, S.; Liu, S.; Miró, L.; Radspieler, M.; Cabeza, L.F.; Lävemann, E. Industrial Waste Heat Recovery Technologies: An Economic Analysis of Heat Transformation Technologies. Appl. Energy 2015, 151, 157–167. [Google Scholar] [CrossRef]

- Haddad, C.; Périlhon, C.; Danlos, A.; François, M.-X.; Descombes, G. Some Efficient Solutions to Recover Low and Medium Waste Heat: Competitiveness of the Thermoacoustic Technology. Energy Procedia 2014, 50, 1056–1069. [Google Scholar] [CrossRef]

- Loni, R.; Najafi, G.; Bellos, E.; Rajaee, F.; Said, Z.; Mazlan, M. A Review of Industrial Waste Heat Recovery System for Power Generation with Organic Rankine Cycle: Recent Challenges and Future Outlook. J. Clean. Prod. 2021, 287, 125070. [Google Scholar] [CrossRef]

- Pehnt, M.; Bödeker, J.; Arens, M.; Jochem, E.; Idrissova, F. Industrial Waste Heat—Tapping into a Neglected Efficiency Potential. In Proceedings of the ECEEE 2011 Summer Study, Belambra Presqu’ile de Giens, France, 6–11 June 2011; pp. 691–700. [Google Scholar]

- Sollesnes, G.; Helgerud, H.E. Potensialstudie for Utnyttelse av Spillvarme fra Norsk Industri [Survey of Potentials for Exploitation of Waste Heat from Norwegian Industry]; Norsk Energi, NEPAS: Oslo, Norway, 2009. [Google Scholar]

- Blesl, M.; Kempe, S.; Ohl, M.; Fahl, U.; König, A.; Jenssen, T.; Eltrop, L. Wärmeatlas Baden-Württemberg—Erstellung eines Leitfadens und Umsetzung für Modellregionen [Baden Württemberg Heat Atlas—Preparation of the Guidelines and Their Implementation for Exemplary Regions]; University of Stuttgart: Stuttgart, Germany, 2009; p. 167. [Google Scholar]

- Pérez-Lombard, L.; Ortiz, J.; Velázquez, D. Revisiting Energy Efficiency Fundamentals. Energy Effic. 2012, 6, 239–254. [Google Scholar] [CrossRef]

- Miró, L.; Brückner, S.; Cabeza, L.F. Mapping and Discussing Industrial Waste Heat (IWH) Potentials for Different Countries. Renew. Sustain. Energy Rev. 2015, 51, 847–855. [Google Scholar] [CrossRef]

- Thekdi, A.; Nimbalkar, S.U. Industrial Waste Heat Recovery—Potential Applications, Available Technologies and Crosscutting R&D Opportunities; U.S. Department of Energy, Office of Scientific and Technical Information (OSTI): Oak Ridge, TN, USA, 2015. [Google Scholar]

- Eurostat. Simplified Energy Balances (nrg_bal_s); [Data Set]; Eurostat: Luxembourg, 2024. [Google Scholar] [CrossRef]

- Christodoulides, P.; Aresti, L.; Panayiotou, G.P.; Tassou, S.; Florides, G.A. Adoption of Waste Heat Recovery Technologies: Reviewing the Relevant Barriers and Recommendations on How to Overcome Them. Oper. Res. Forum 2022, 3, 3. [Google Scholar] [CrossRef]

- Giordano, L.; Benedetti, M. A Methodology for the Identification and Characterization of Low-Temperature Waste Heat Sources and Sinks in Industrial Processes: Application in the Italian Dairy Sector. Energies 2022, 15, 155. [Google Scholar] [CrossRef]

- Vance, D.; Nimbalkar, S.; Thekdi, A.; Armstrong, K.; Wenning, T.; Cresko, J.; Jin, M. Estimation of and Barriers to Waste Heat Recovery from Harsh Environments in Industrial Processes. J. Clean. Prod. 2019, 222, 539–549. [Google Scholar] [CrossRef]

- Miró, L.; Gasia, J.; Cabeza, L.F. Thermal Energy Storage (TES) for Industrial Waste Heat (IWH) Recovery: A Review. Appl. Energy 2016, 179, 284–301. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Wang, R.Z.; Yang, C. Perspectives for Low-Temperature Waste Heat Recovery. Energy 2019, 176, 1037–1043. [Google Scholar] [CrossRef]

- Jouhara, H.; Olabi, A.G. Editorial: Industrial Waste Heat Recovery. Energy 2018, 160, 1–2. [Google Scholar] [CrossRef]

- Skop, H.; Chudnovsky, Y. Energy Efficiency and Advanced Heat Recovery Technologies. In Handbook of Thermal Science and Engineering; Kulacki, F.A., Ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 1–16. ISBN 978-3-319-32003-8. [Google Scholar]

- Sun, L.; Yan, H.; Xin, K.; Tao, T. Contamination Source Identification in Water Distribution Networks Using Convolutional Neural Network. Environ. Sci. Pollut. Res. 2019, 26, 36786–36797. [Google Scholar] [CrossRef]

- Panayiotou, G.; Agathokleous, R.; Florides, G.; Christodoulides, P. Assessment of Energy Potential for Heat Recovery in the EU Industry. J. Phys. Conf. Ser. 2020, 1687, 012027. [Google Scholar] [CrossRef]

- Castro Oliveira, M.; Iten, M.; Cruz, P.L.; Monteiro, H. Review on Energy Efficiency Progresses, Technologies and Strategies in the Ceramic Sector Focusing on Waste Heat Recovery. Energies 2020, 13, 6096. [Google Scholar] [CrossRef]

- Huang, F.; Zheng, J.; Baleynaud, J.M.; Lu, J. Heat Recovery Potentials and Technologies in Industrial Zones. J. Energy Inst. 2017, 90, 951–961. [Google Scholar] [CrossRef]

- Garofalo, E.; Bevione, M.; Cecchini, L.; Mattiussi, F.; Chiolerio, A. Waste Heat to Power: Technologies, Current Applications, and Future Potential. Energy Technol. 2020, 8, 2000413. [Google Scholar] [CrossRef]

- Elkoumy, M.M.; El-Anwar, M.; Fathy, A.M.; Megahed, G.M.; El-Mahallawi, I.; Ahmed, H. Simulation of EAF Refining Stage. Ain Shams Eng. J. 2018, 9, 2781–2793. [Google Scholar] [CrossRef]

- Pashchenko, D.; Nikitin, M. Forging Furnace with Thermochemical Waste-Heat Recuperation by Natural Gas Reforming: Fuel Saving and Heat Balance. Int. J. Hydrogen Energy 2021, 46, 100–109. [Google Scholar] [CrossRef]

- Fruehan, R.J.; Fortini, O.; Paxton, H.W.; Brindle, R. Theoretical Minimum Energies to Produce Steel for Selected Conditions; U.S. Department of Energy, Office of Scientific and Technical Information (OSTI): Oak Ridge, TN, USA, 2000. [Google Scholar]

- Rattner, A.S.; Garimella, S. Energy Harvesting, Reuse and Upgrade to Reduce Primary Energy Usage in the USA. Energy 2011, 36, 6172–6183. [Google Scholar] [CrossRef]

- Fluid Catalytic Cracking Handbook, 3rd ed.; Sadeghbeigi, R., Ed.; Butterworth-Heinemann: Oxford, UK, 2012; ISBN 978-0-12-386965-4. [Google Scholar]

- Nagy, R.; Mečiarová, Ľ.; Vilčeková, S.; Krídlová Burdová, E.; Košičanová, D. Investigation of a Ventilation System for Energy Efficiency and Indoor Environmental Quality in a Renovated Historical Building: A Case Study. Int. J. Environ. Res. Public Health 2019, 16, 4133. [Google Scholar] [CrossRef]

- Navarro-Esbrí, J.; Amat-Albuixech, M.; Molés, F.; Mateu-Royo, C.; Mota-Babiloni, A.; Collado, R. HCFO-1224yd(Z) as HFC-245fa Drop-in Alternative in Low Temperature ORC Systems: Experimental Analysis in a Waste Heat Recovery Real Facility. Energy 2020, 193, 116701. [Google Scholar] [CrossRef]

- Zhai, H.; An, Q.; Shi, L.; Lemort, V.; Quoilin, S. Categorization and Analysis of Heat Sources for Organic Rankine Cycle Systems. Renew. Sustain. Energy Rev. 2016, 64, 790–805. [Google Scholar] [CrossRef]

- Veselovskaya, J.V.; Tokarev, M.M.; Aristov, Y.I. Novel Ammonia Sorbents “Porous Matrix Modified by Active Salt” for Adsorptive Heat Transformation: 1. Barium Chloride in Various Matrices. Appl. Therm. Eng. 2010, 30, 584–589. [Google Scholar] [CrossRef]

- Fen, H.; van den Berg, R. Improvement Opportunities for IGCC*. In Integrated Gasification Combined Cycle (IGCC) Technologies; Wang, T., Stiegel, G., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 833–846. ISBN 978-0-08-100167-7. [Google Scholar]

- Zhang, Q.; Zhao, X.; Lu, H.; Ni, T.; Li, Y. Waste Energy Recovery and Energy Efficiency Improvement in China’s Iron and Steel Industry. Appl. Energy 2017, 191, 502–520. [Google Scholar] [CrossRef]

- Brueckner, S.; Miró, L.; Cabeza, L.F.; Pehnt, M.; Laevemann, E. Methods to Estimate the Industrial Waste Heat Potential of Regions—A Categorization and Literature Review. Renew. Sustain. Energy Rev. 2014, 38, 164–171. [Google Scholar] [CrossRef]

- Simeone, A.; Luo, Y.; Woolley, E.; Rahimifard, S.; Boër, C. A Decision Support System for Waste Heat Recovery in Manufacturing. CIRP Ann. 2016, 65, 21–24. [Google Scholar] [CrossRef]

- Ling-Chin, J.; Bao, H.; Ma, Z.; Taylor, W.; Paul Roskilly, A. State-of-the-Art Technologies on Low-Grade Heat Recovery and Utilization in Industry. In Energy Conversion—Current Technologies and Future Trends; Al-Bahadly, I.H., Ed.; IntechOpen: Rijeka, Croatia, 2019; ISBN 978-1-78984-904-2. [Google Scholar]

- Chan, C.W.; Ling-Chin, J.; Roskilly, A.P. A Review of Chemical Heat Pumps, Thermodynamic Cycles and Thermal Energy Storage Technologies for Low Grade Heat Utilisation. Appl. Therm. Eng. 2013, 50, 1257–1273. [Google Scholar] [CrossRef]

- Kwak, D.-H.; Binns, M.; Kim, J.-K. Integrated Design and Optimization of Technologies for Utilizing Low Grade Heat in Process Industries. Appl. Energy 2014, 131, 307–322. [Google Scholar] [CrossRef]

- Kumar, A.; Rakshit, D. A Critical Review on Waste Heat Recovery Utilization with Special Focus on Organic Rankine Cycle Applications. Clean. Eng. Technol. 2021, 5, 100292. [Google Scholar] [CrossRef]

- Chowdhury, J.I.; Hu, Y.; Haltas, I.; Balta-Ozkan, N.; Matthew, G., Jr.; Varga, L. Reducing Industrial Energy Demand in the UK: A Review of Energy Efficiency Technologies and Energy Saving Potential in Selected Sectors. Renew. Sustain. Energy Rev. 2018, 94, 1153–1178. [Google Scholar] [CrossRef]

- Leppänen, T.; Romka, R.; Tervonen, P. Utilization of Data Center Waste Heat in Northern Ostrobothnia. Teh. Glas. 2020, 14, 312–317. [Google Scholar] [CrossRef]

- Ononogbo, C.; Nwosu, E.C.; Nwakuba, N.R.; Nwaji, G.N.; Nwufo, O.C.; Chukwuezie, O.C.; Chukwu, M.M.; Anyanwu, E.E. Opportunities of Waste Heat Recovery from Various Sources: Review of Technologies and Implementation. Heliyon 2023, 9, e13590. [Google Scholar] [CrossRef]

- Narendra Babu, N.; Kamath, H.C. Materials Used in Heat Pipe. Mater. Today Proc. 2015, 2, 1469–1478. [Google Scholar] [CrossRef]

- Faghri, A. Heat Pipes: Review, Opportunities and Challenges. Front. Heat Pipes 2014, 5, 1–48. [Google Scholar] [CrossRef]

- Thekdi, A.; Nimbalkar, S.; Sundaramoorthy, S.; Armstrong, K.; Taylor, A.; Gritton, J.; Wenning, T.; Cresko, J. Technology Assessment on Low-Temperature Waste Heat Recovery in Industry; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2021. [Google Scholar]

- Nandhini, R.; Sivaprakash, B.; Rajamohan, N. Waste Heat Recovery at Low Temperature from Heat Pumps, Power Cycles and Integrated Systems—Review on System Performance and Environmental Perspectives. Sustain. Energy Technol. Assess. 2022, 52, 102214. [Google Scholar] [CrossRef]

- Pili, R.; García Martínez, L.; Wieland, C.; Spliethoff, H. Techno-Economic Potential of Waste Heat Recovery from German Energy-Intensive Industry with Organic Rankine Cycle Technology. Renew. Sustain. Energy Rev. 2020, 134, 110324. [Google Scholar] [CrossRef]

- Law, R.; Harvey, A.; Reay, D. A Knowledge-Based System for Low-Grade Waste Heat Recovery in the Process Industries. Appl. Therm. Eng. 2016, 94, 590–599. [Google Scholar] [CrossRef]

- Singh, S.P.; Nagori, A. Refrigeration Waste Heat Utilization for Drying Applications: A Review. Int. J. Green Energy 2020, 17, 697–721. [Google Scholar] [CrossRef]

- Zhang, X.; He, M.; Zhang, Y. A Review of Research on the Kalina Cycle. Renew. Sustain. Energy Rev. 2012, 16, 5309–5318. [Google Scholar] [CrossRef]

- Khankari, G.; Karmakar, S. A Novel Solar Assisted Kalina Cycle System for Waste Heat Utilization in Thermal Power Plants. Int. J. Energy Res. 2021, 45, 17146–17158. [Google Scholar] [CrossRef]

- Liu, Z.; Xie, N.; Yang, S. Thermodynamic and Parametric Analysis of a Coupled LiBr/H2O Absorption Chiller/Kalina Cycle for Cascade Utilization of Low-Grade Waste Heat. Energy Convers. Manag. 2020, 205, 112370. [Google Scholar] [CrossRef]

- Karellas, S.; Leontaritis, A.-D.; Panousis, G.; Bellos, E.; Kakaras, E. Energetic and Exergetic Analysis of Waste Heat Recovery Systems in the Cement Industry. Energy 2013, 58, 147–156. [Google Scholar] [CrossRef]

- Yuan, X.; Liang, Y.; Hu, X.; Xu, Y.; Chen, Y.; Kosonen, R. Waste Heat Recoveries in Data Centers: A Review. Renew. Sustain. Energy Rev. 2023, 188, 113777. [Google Scholar] [CrossRef]

- Marchionni, M.; Bianchi, G.; Tassou, S. Review of Supercritical Carbon Dioxide (sCO2) Technologies for High-Grade Waste Heat to Power Conversion. SN Appl. Sci. 2020, 2, 611. [Google Scholar] [CrossRef]

- Quoilin, S.; Broek, M.V.D.; Declaye, S.; Dewallef, P.; Lemort, V. Techno-Economic Survey of Organic Rankine Cycle (ORC) Systems. Renew. Sustain. Energy Rev. 2013, 22, 168–186. [Google Scholar] [CrossRef]

- Konur, O.; Colpan, C.O.; Saatcioglu, O.Y. A Comprehensive Review on Organic Rankine Cycle Systems Used as Waste Heat Recovery Technologies for Marine Applications. Energy Sources A: Recovery Util. Environ. Eff. 2022, 44, 4083–4122. [Google Scholar] [CrossRef]

- Kajurek, J.; Rusowicz, A.; Grzebielec, A.; Bujalski, W.; Futyma, K.; Rudowicz, Z. Selection of Refrigerants for a Modified Organic Rankine Cycle. Energy 2019, 168, 1–8. [Google Scholar] [CrossRef]

- Hackl, R.; Harvey, S. Applying Process Integration Methods to Target for Electricity Production from Industrial Waste Heat Using Organic Rankine Cycle (ORC) Technology. In Proceedings of the World Renewable Energy Congress 2011, Linköping, Sweden, 8–13 May 2011; pp. 1716–1723. [Google Scholar]

- Kapustenko, P.; Klemeš, J.J.; Arsenyeva, O.; Tovazhnyanskyy, L. PHE (Plate Heat Exchanger) for Condensing Duties: Recent Advances and Future Prospects. Energies 2023, 16, 524. [Google Scholar] [CrossRef]

- Arsenyeva, O.P.; Čuček, L.; Tovazhnyanskyy, L.L.; Kapustenko, P.O.; Savchenko, Y.A.; Kusakov, S.K.; Matsegora, O.I. Utilisation of Waste Heat from Exhaust Gases of Drying Process. Front. Chem. Sci. Eng. 2016, 10, 131–138. [Google Scholar] [CrossRef]

- Shih, H.; Shih, T. Utilization of Waste Heat in the Desalination Process. Desalination 2007, 204, 464–470. [Google Scholar] [CrossRef]

- Gewald, D.; Siokos, K.; Karellas, S.; Spliethoff, H. Waste Heat Recovery from a Landfill Gas-Fired Power Plant. Renew. Sustain. Energy Rev. 2012, 16, 1779–1789. [Google Scholar] [CrossRef]

- Elsaid, K.; Taha Sayed, E.; Yousef, B.A.A.; Kamal Hussien Rabaia, M.; Ali Abdelkareem, M.; Olabi, A.G. Recent Progress on the Utilization of Waste Heat for Desalination: A Review. Energy Convers. Manag. 2020, 221, 113105. [Google Scholar] [CrossRef]

- Jiang, Z.; Xu, J.; Yu, G.; Yang, R.; Wu, Z.; Hu, J.; Zhang, L.; Luo, E. A Stirling Generator with Multiple Bypass Expansion for Variable-Temperature Waste Heat Recovery. Appl. Energy 2023, 329, 120242. [Google Scholar] [CrossRef]

- Jouhara, H.; Chauhan, A.; Nannou, T.; Almahmoud, S.; Delpech, B.; Wrobel, L.C. Heat Pipe Based Systems—Advances and Applications. Energy 2017, 128, 729–754. [Google Scholar] [CrossRef]

- Arsenyeva, O.; Klemeš, J.J.; Kapustenko, P.; Fedorenko, O.; Kusakov, S.; Kobylnik, D. Plate Heat Exchanger Design for the Utilisation of Waste Heat from Exhaust Gases of Drying Process. Energy 2021, 233, 121186. [Google Scholar] [CrossRef]

- Kilkovský, B. Review of Design and Modeling of Regenerative Heat Exchangers. Energies 2020, 13, 759. [Google Scholar] [CrossRef]

- Kuppan, T. Heat Exchanger Design Handbook; Mechanical Engineering; Marcel Dekker: New York, NY, USA, 2000; ISBN 978-0-8247-9787-4. [Google Scholar]

- Jebaraj, P.; Reddy, A. Prediction of Thermal Shock of Ceramic Shells Using Fused Silica as Reinforcing Filler at Casting Conditions. In Proceedings of the National Conference on Advances in Production Technology, Bangalore, India, 7–9 February 1998; pp. 52–56. [Google Scholar]

- Akhan, H.; Eryener, D. Building Integrated Solar Air Heating with Waste Heat Utilization. Energy Convers. Manag. 2018, 157, 136–145. [Google Scholar] [CrossRef]

- Turek, V.; Bělohradský, P.; Jegla, Z. Geometry Optimization of a Gas Preheater Inlet Region—A Case Study. Chem. Eng. Trans. 2012, 29, 1339–1344. [Google Scholar]

- Fialová, D.; Jegla, Z. Analysis of Fired Equipment within the Framework of Low-Cost Modelling Systems. Energies 2019, 12, 520. [Google Scholar] [CrossRef]

- Men, Y.; Liu, X.; Zhang, T. Performance Comparison of Different Total Heat Exchangers Applied for Waste Heat Recovery. Appl. Therm. Eng. 2021, 182, 115715. [Google Scholar] [CrossRef]

- Kilkovsky, B.; Stehlik, P.; Jegla, Z.; Tovazhnyansky, L.L.; Arsenyeva, O.; Kapustenko, P.O. Heat Exchangers for Energy Recovery in Waste and Biomass to Energy Technologies—I. Energy Recovery from Flue Gas. Appl. Therm. Eng. 2014, 64, 213–223. [Google Scholar] [CrossRef]

- Men, Y.; Liu, X.; Zhang, T. A Review of Boiler Waste Heat Recovery Technologies in the Medium-Low Temperature Range. Energy 2021, 237, 121560. [Google Scholar] [CrossRef]

- Al-Rabghi, O.M.; Beirutty, M.; Akyurt, M.; Najjar, Y.; Alp, T. Recovery and Utilization of Waste Heat. Heat Recovery Syst. CHP 1993, 13, 463–470. [Google Scholar] [CrossRef]

- Suwarno, S.; Jabar I’jazurrohman, A.; Dwi Yudanto, F.; Djanali, V.S. Failure Analysis of Waste Heat Boiler Tubing Caused by a High Local Heat Flux. Eng. Fail. Anal. 2022, 136, 106147. [Google Scholar] [CrossRef]

- Deonise, D.; Ioana, A.; Paunescu, L.; Pollifroni, M.; Deonise, C.A.; Petcu, F.-S.; Canuta, I.L. Experimental Results on the Implementation and Use of Recovery Burners. EJMSE 2022, 7, 284–287. [Google Scholar] [CrossRef]

- Manatura, K.; Tangtrakul, M. A Study of Specific Energy Consumption in Reheating Furnace Using Regenerative Burners Combined with Recuperator. Silpakorn Univ. Sci. Technol. J. 2010, 4, 7–13. [Google Scholar]

- Wu, G.; Li, S.; Zhu, R.; Guo, H.; Liu, R.; Yang, X. Development and Experimental Research of a Self-Regenerative Burner. Chin. J. Eng. 2003, 25, 218–221. [Google Scholar]

- Park, B.-S.; Chung, D.-H.; Kim, W.-B.; Kim, Y. A Study on the Design of Recuperative Burner. Int. J. Energy Res. 1998, 22, 209–220. [Google Scholar] [CrossRef]

- Werner, T.C.; Yan, Y.; Karayiannis, T.; Pickert, V.; Wrobel, R.; Law, R. Medium Temperature Heat Pipes—Applications, Challenges and Future Direction. Appl. Therm. Eng. 2024, 236, 121371. [Google Scholar] [CrossRef]

- Orr, B.; Akbarzadeh, A.; Mochizuki, M.; Singh, R. A Review of Car Waste Heat Recovery Systems Utilising Thermoelectric Generators and Heat Pipes. Appl. Therm. Eng. 2016, 101, 490–495. [Google Scholar] [CrossRef]

- Tian, Z.; Wang, C.; Guo, K.; Zhang, D.; Su, G.H.; Tian, W.; Qiu, S. A Review of Liquid Metal High Temperature Heat Pipes: Theoretical Model, Design, and Application. Int. J. Heat Mass Transf. 2023, 214, 124434. [Google Scholar] [CrossRef]

- Yang, X.; Yan, Y.Y.; Mullen, D. Recent Developments of Lightweight, High Performance Heat Pipes. Appl. Therm. Eng. 2012, 33–34, 1–14. [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S.K.; Yang, W.M. Advances in Heat Pump Systems: A Review. Appl. Energy 2010, 87, 3611–3624. [Google Scholar] [CrossRef]

- Zühlsdorf, B.; Bühler, F.; Bantle, M.; Elmegaard, B. Analysis of Technologies and Potentials for Heat Pump-Based Process Heat Supply above 150 °C. Energy Convers. Manag. X 2019, 2, 100011. [Google Scholar] [CrossRef]

- Arpagaus, C.; Bless, F.; Schiffmann, J.; Bertsch, S.S. Multi-Temperature Heat Pumps: A Literature Review. Int. J. Refrig. 2016, 69, 437–465. [Google Scholar] [CrossRef]

- Wolf, S.; Fahl, U.; Voß, A. How Heat Pumps Can Be Used to Improve Energy Efficiency of Industrial Processes. In Proceedings of the 11th IEA Heat Pump Conference 2014, Montréal, Canada, 12–16 May 2014; International Energy Agency (IEA): Paris, France, 2014. [Google Scholar]

- Frate, G.F.; Ferrari, L.; Desideri, U. Analysis of Suitability Ranges of High Temperature Heat Pump Working Fluids. Appl. Therm. Eng. 2019, 150, 628–640. [Google Scholar] [CrossRef]

- Ma, D.; Sun, Y.; Ma, S.; Li, G.; Zhou, Z.; Ma, H. Study on the Working Medium of High Temperature Heat Pump Suitable for Industrial Waste Heat Recovery. Appl. Therm. Eng. 2024, 236, 121642. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, F.; Lyu, N.; Fan, H.; Zhang, X. Analysis of Low GWP Ternary Zeotropic Mixtures Applied in High-Temperature Heat Pump for Waste Heat Recovery. Energy Convers. Manag. 2023, 292, 117381. [Google Scholar] [CrossRef]

- Tan, Z.; Feng, X.; Yang, M.; Wang, Y. Energy and Economic Performance Comparison of Heat Pump and Power Cycle in Low Grade Waste Heat Recovery. Energy 2022, 260, 125149. [Google Scholar] [CrossRef]

- Vannoni, A.; Sorce, A.; Traverso, A.; Fausto Massardo, A. Techno-Economic Optimization of High-Temperature Heat Pumps for Waste Heat Recovery. Energy Convers. Manag. 2023, 290, 117194. [Google Scholar] [CrossRef]

- Nemati, A.; Nami, H.; Ranjbar, F.; Yari, M. A Comparative Thermodynamic Analysis of ORC and Kalina Cycles for Waste Heat Recovery: A Case Study for CGAM Cogeneration System. Case Stud. Therm. Eng. 2017, 9, 1–13. [Google Scholar] [CrossRef]

- Douvartzides, S.; Karmalis, I. Working Fluid Selection for the Organic Rankine Cycle (ORC) Exhaust Heat Recovery of an Internal Combustion Engine Power Plant. IOP Conf. Ser. Mater. Sci. Eng. 2016, 161, 012087. [Google Scholar] [CrossRef]

- Carcasci, C.; Ferraro, R.; Miliotti, E. Thermodynamic Analysis of an Organic Rankine Cycle for Waste Heat Recovery from Gas Turbines. Energy 2014, 65, 91–100. [Google Scholar] [CrossRef]

- Chen, H.; Goswami, D.Y.; Stefanakos, E.K. A Review of Thermodynamic Cycles and Working Fluids for the Conversion of Low-Grade Heat. Renew. Sustain. Energy Rev. 2010, 14, 3059–3067. [Google Scholar] [CrossRef]

- Jiménez-García, J.C.; Ruiz, A.; Pacheco-Reyes, A.; Rivera, W. A Comprehensive Review of Organic Rankine Cycles. Processes 2023, 11, 1982. [Google Scholar] [CrossRef]

- Cruz, G.; Manuel, M.C. A Literature Review of the Kalina Cycle and Trends. IOP Conf. Ser. Earth Environ. Sci. 2022, 1046, 012011. [Google Scholar] [CrossRef]

- Da Costa Horta, G.R.; Barbosa, E.P.; Moreira, L.F.; Arrieta, F.R.P.; De Oliveira, R.N. Comparison of Kalina Cycles for Heat Recovery Application in Cement Industry. Appl. Therm. Eng. 2021, 195, 117167. [Google Scholar] [CrossRef]

- Iqbal, M.A.; Rana, S.; Ahmadi, M.; Date, A.; Akbarzadeh, A. Trilateral Flash Cycle (TFC): A Promising Thermodynamic Cycle for Low Grade Heat to Power Generation. Energy Procedia 2019, 160, 208–214. [Google Scholar] [CrossRef]

- Iglesias Garcia, S.; Ferreiro Garcia, R.; Carbia Carril, J.; Iglesias Garcia, D. A Review of Thermodynamic Cycles Used in Low Temperature Recovery Systems over the Last Two Years. Renew. Sustain. Energy Rev. 2018, 81, 760–767. [Google Scholar] [CrossRef]

- Zamfirescu, C.; Dincer, I. Thermodynamic Analysis of a Novel Ammonia–Water Trilateral Rankine Cycle. Thermochim. Acta 2008, 477, 7–15. [Google Scholar] [CrossRef]

- Manente, G.; Ding, Y.; Sciacovelli, A. A Structured Procedure for the Selection of Thermal Energy Storage Options for Utilization and Conversion of Industrial Waste Heat. J. Energy Storage 2022, 51, 104411. [Google Scholar] [CrossRef]

- Kauko, H.; Rohde, D.; Hafner, A. Local Heating Networks with Waste Heat Utilization: Low or Medium Temperature Supply? Energies 2020, 13, 954. [Google Scholar] [CrossRef]

- Boubou, B.; Muritala, I.K.; Boukar, M.; Daho, T.; Nebié, J.; Rabani, A.; Bere, A. Assessment of Different Sands Potentiality to Formulate an Effective Thermal Energy Storage Material (TESM). J.P.SOAPHYS 2021, 2, C20A08. [Google Scholar] [CrossRef]

- Krönauer, A.; Lävemann, E.; Brückner, S.; Hauer, A. Mobile Sorption Heat Storage in Industrial Waste Heat Recovery. Energy Procedia 2015, 73, 272–280. [Google Scholar] [CrossRef]

- Royo, P.; Acevedo, L.; Ferreira, V.J.; García-Armingol, T.; López-Sabirón, A.M.; Ferreira, G. High-Temperature PCM-Based Thermal Energy Storage for Industrial Furnaces Installed in Energy-Intensive Industries. Energy 2019, 173, 1030–1040. [Google Scholar] [CrossRef]

- Barbi, S.; Barbieri, F.; Marinelli, S.; Rimini, B.; Merchiori, S.; Larwa, B.; Bottarelli, M.; Montorsi, M. Phase Change Material-Sand Mixtures for Distributed Latent Heat Thermal Energy Storage: Interaction and Performance Analysis. Renew. Energy 2021, 169, 1066–1076. [Google Scholar] [CrossRef]

- Rahmalina, D.; Adhitya, D.C.; Rahman, R.A.; Ismail, I. Improvement the Performance of Composite PCM Paraffin-Based Incorporate with Volcanic Ash as Heat Storage for Low-Temperature Application. EUREKA Phys. Eng. 2022, 1, 53–61. [Google Scholar] [CrossRef]

- Merlin, K.; Soto, J.; Delaunay, D.; Traonvouez, L. Industrial Waste Heat Recovery Using an Enhanced Conductivity Latent Heat Thermal Energy Storage. Appl. Energy 2016, 183, 491–503. [Google Scholar] [CrossRef]

- Niedermeier, K. A Perspective on High-Temperature Heat Storage Using Liquid Metal as Heat Transfer Fluid. Energy Storage 2023, 5, e530. [Google Scholar] [CrossRef]

- Goswami, R.; Das, R.; Ganguly, S. Performance Analysis of Salt Gradient Thermal Storage Device Driven by Waste Heat. In Proceedings of the 2023 3rd International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Tenerife, Canary Islands, Spain, 19–21 July 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

- Tetteh, S.; Yazdani, M.R.; Santasalo-Aarnio, A. Cost-Effective Electro-Thermal Energy Storage to Balance Small Scale Renewable Energy Systems. J. Energy Storage 2021, 41, 102829. [Google Scholar] [CrossRef]

- Chen, L.; Yang, B.; Shen, X.; Xie, Z.; Sun, F. Thermodynamic Optimization Opportunities for the Recovery and Utilization of Residual Energy and Heat in China’s Iron and Steel Industry: A Case Study. Appl. Therm. Eng. 2015, 86, 151–160. [Google Scholar] [CrossRef]

- Akter, S.; Hossain, I. Waste Heat Utilization in a Ceramic Industry. Int. J. Energy Res. 1997, 21, 1215–1221. [Google Scholar] [CrossRef]

- Niamsuwan, S.; Kittisupakorn, P.; Mujtaba, I.M. A Newly Designed Economizer to Improve Waste Heat Recovery: A Case Study in a Pasteurized Milk Plant. Appl. Therm. Eng. 2013, 60, 188–199. [Google Scholar] [CrossRef]