Durability Assessment of Wooden Pellets in Relation with Vibrations Occurring in a Logistic Process of the Final Product

Abstract

1. Introduction

The Meaning of Pellets Quality and Chosen Transportation Conditions

2. Materials and Methods

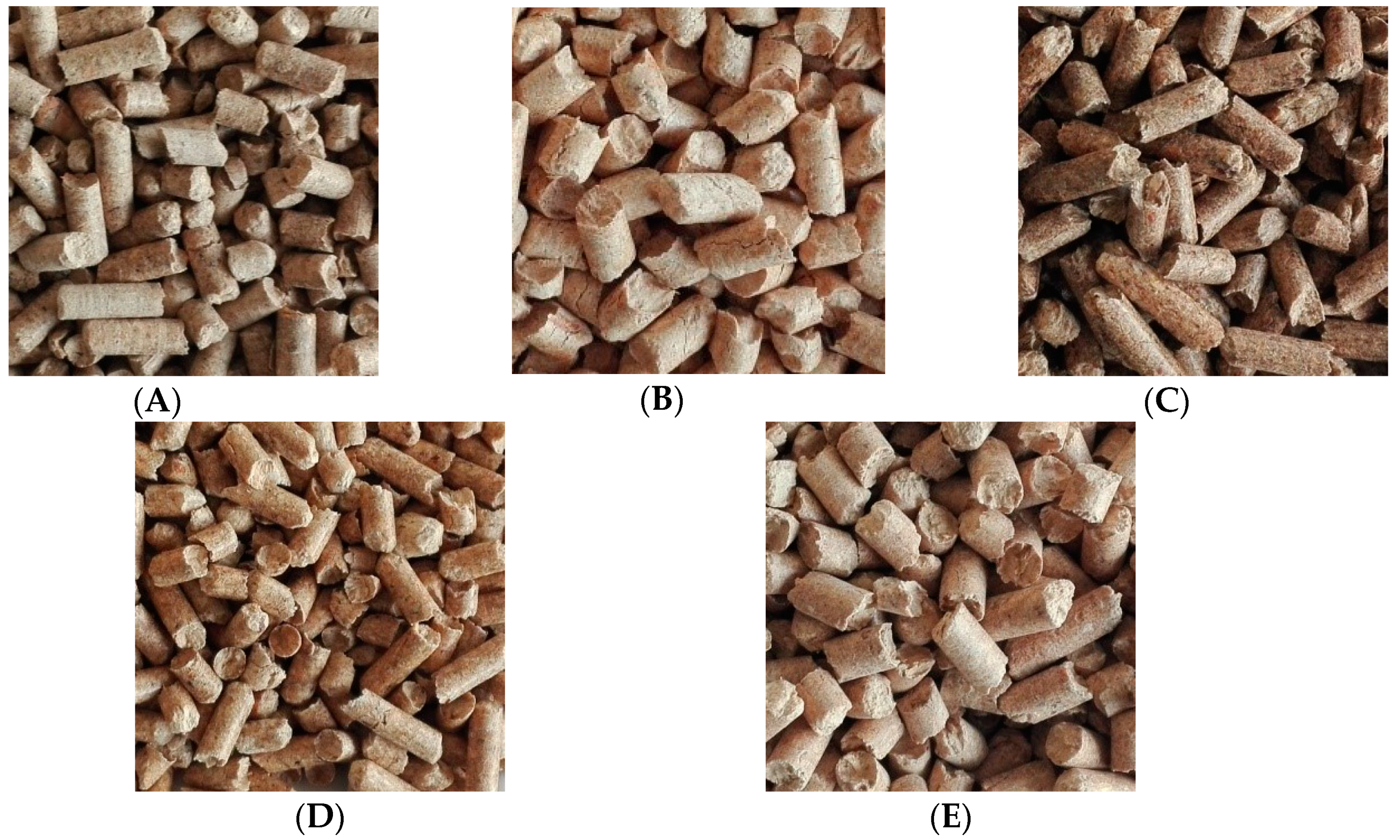

2.1. Characteristics of the Research Material

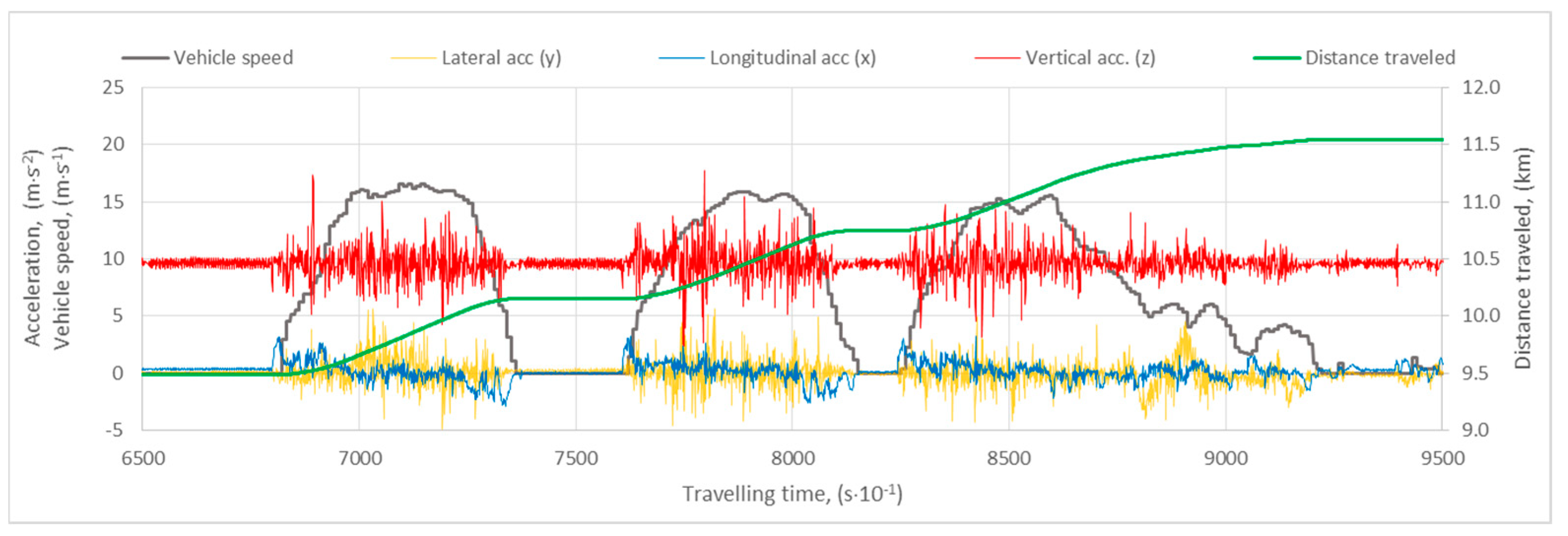

2.2. Research Methods

2.3. Mechanical Durability Investigations

2.4. Statistical Analysis Methods

3. Results and Discussion

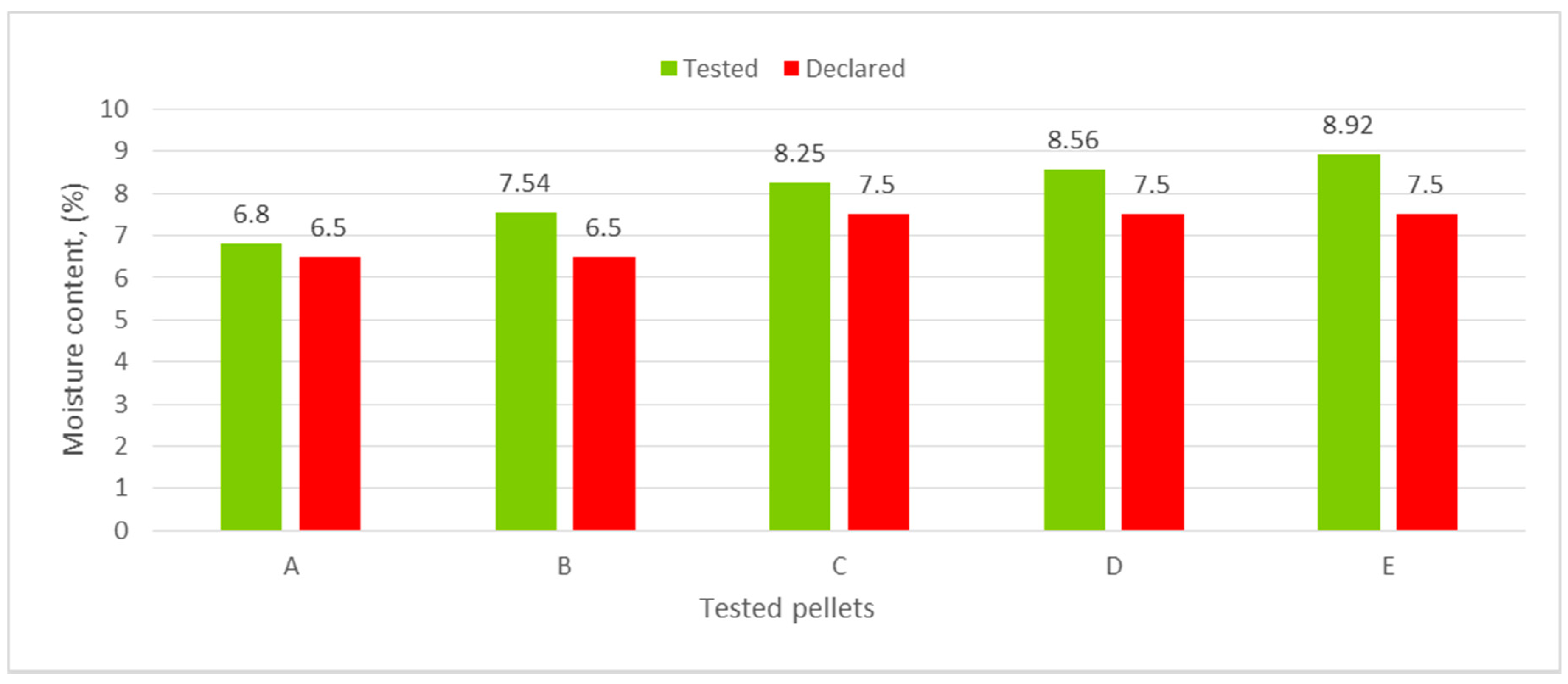

3.1. Moisture Content in Tested Pellets

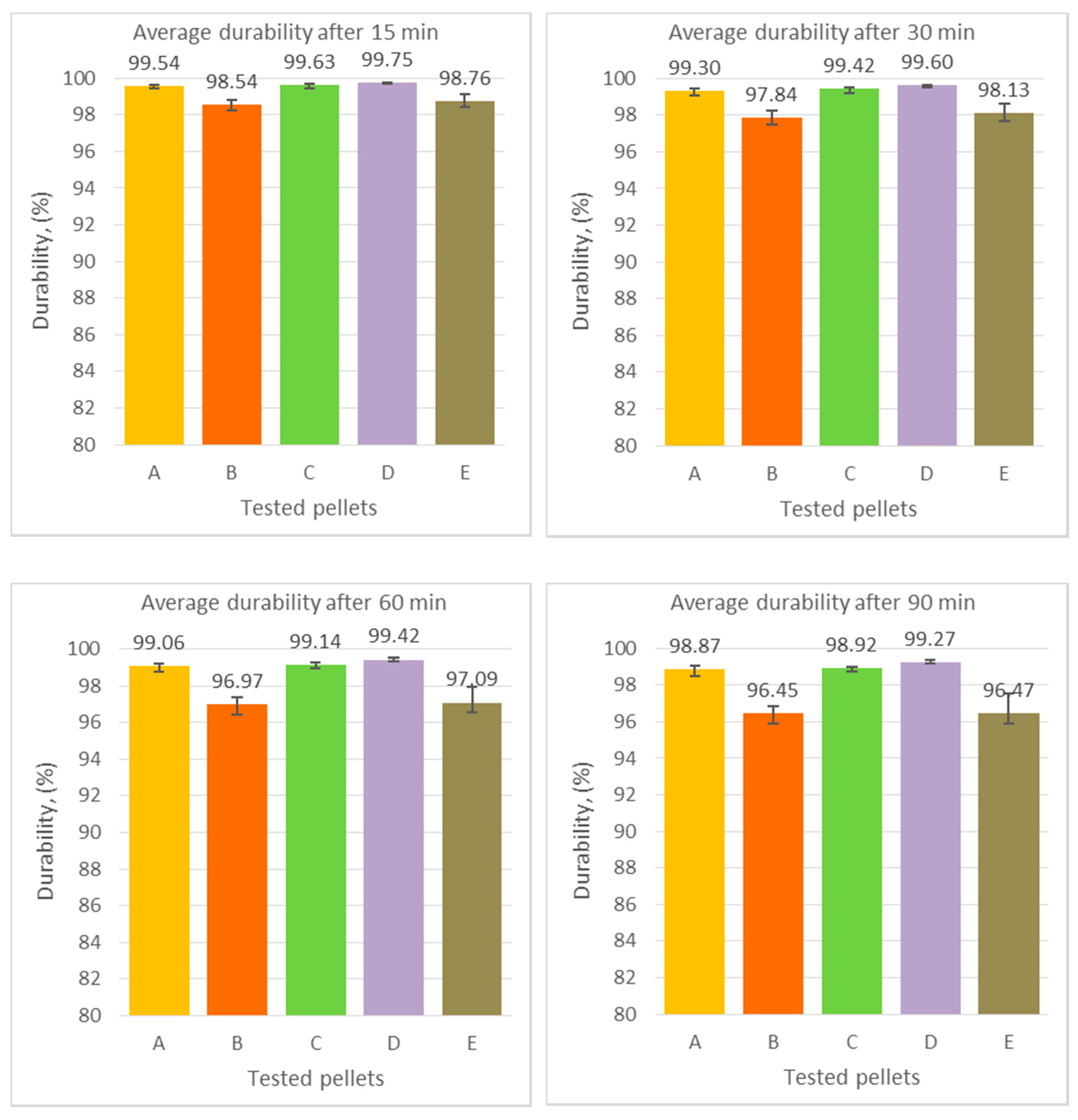

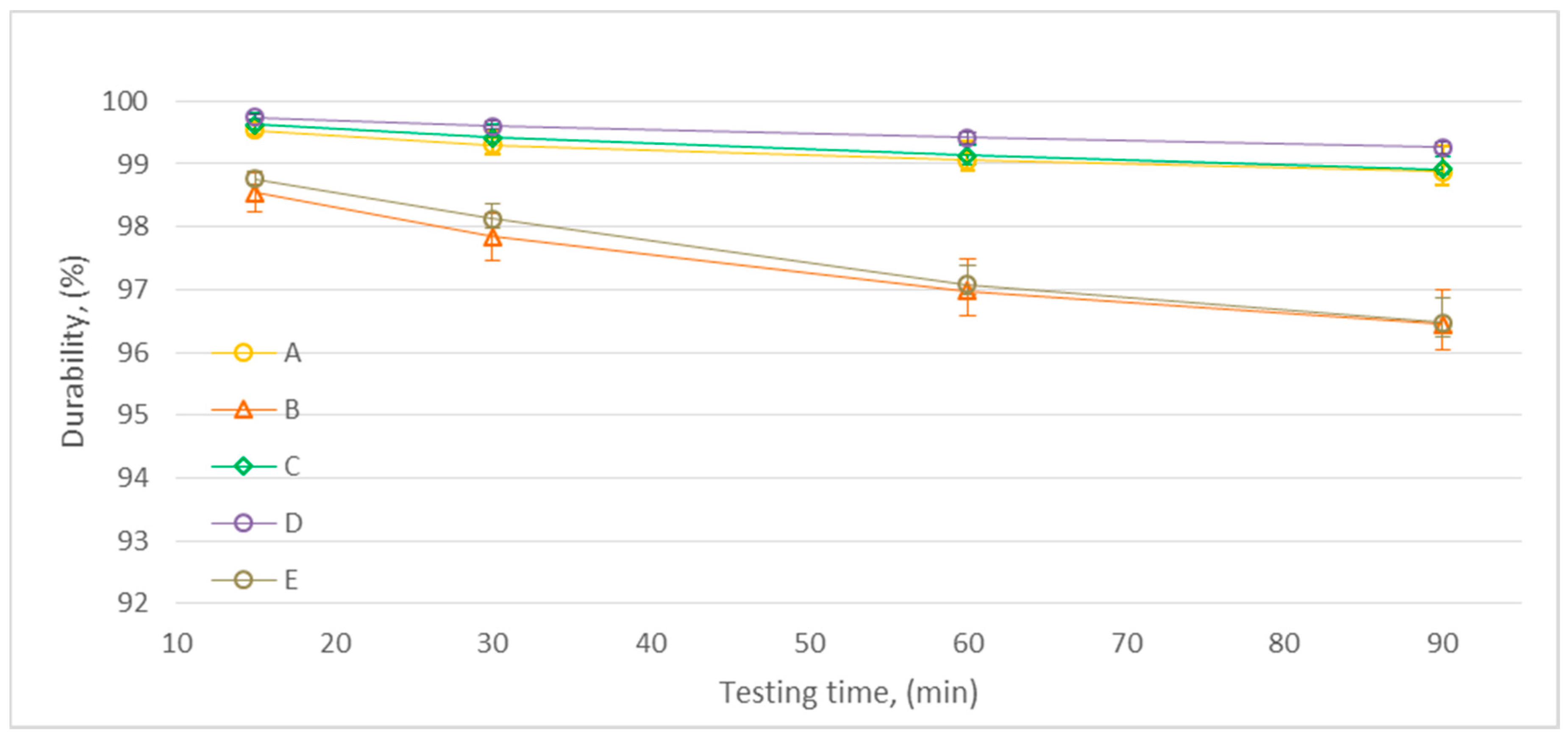

3.2. Results of Vertical Vibration Tests

3.3. Results of Lateral Vibration Tests

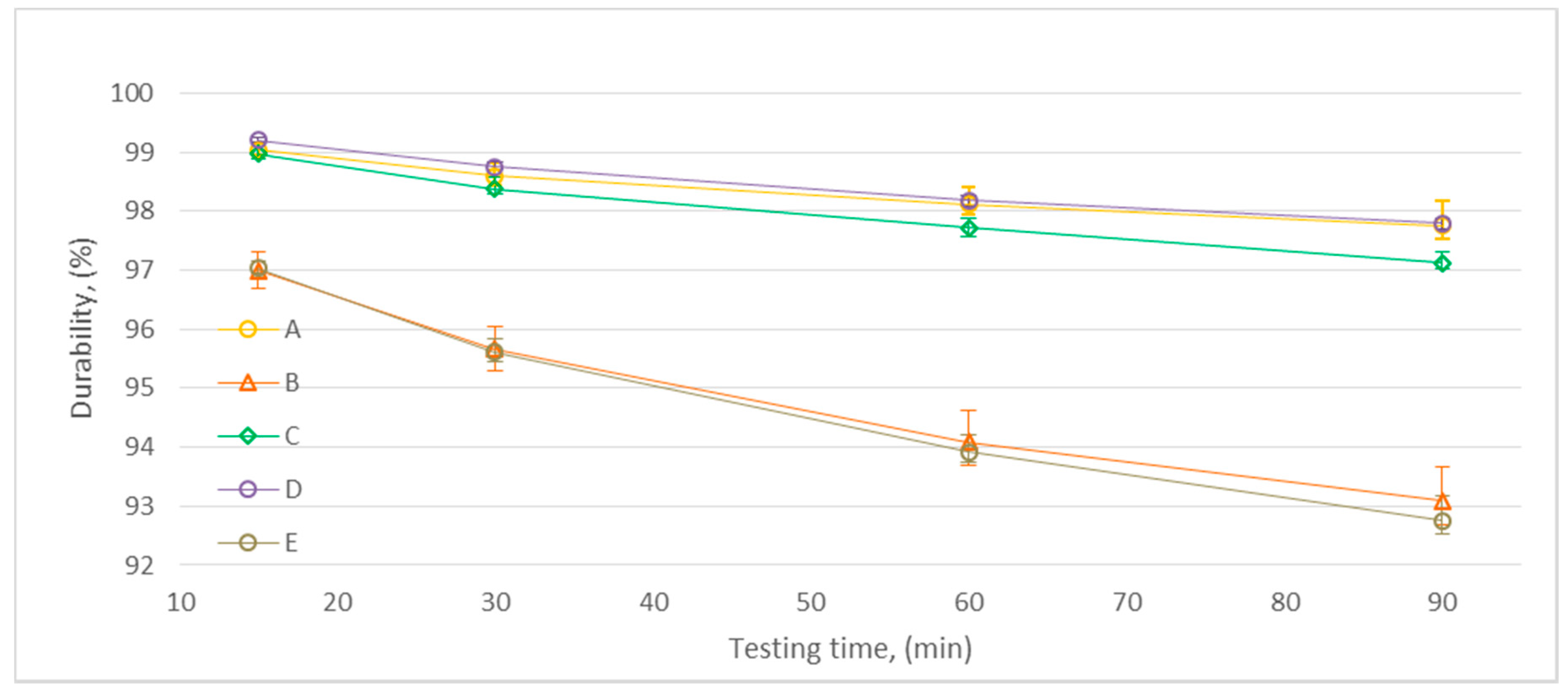

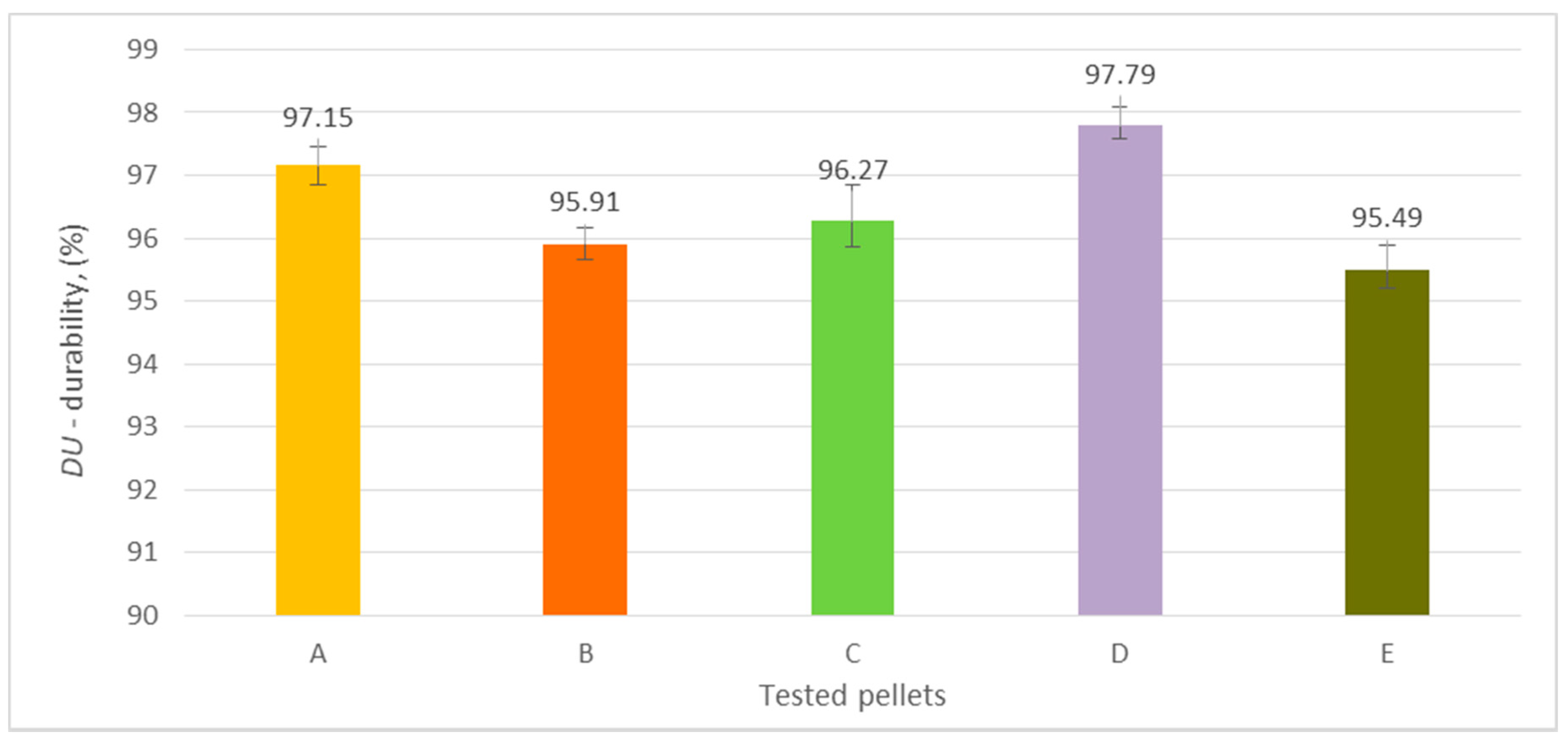

3.4. Durability Test according to EN ISO 17831

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- José-Vicente, O.-V.; Enrique, G.-A.; Patricia, G.-G. Analysis of durability and dimensional stability of hydrothermal carbonized wooden pellets. Wood Res. 2016, 61, 321–330. [Google Scholar]

- Tabil, L., Jr.; Sokhansanj, S. Process conditions affecting the physical quality of alfalfa pellets. Appl. Eng. Agric. 1996, 12, 345–350. [Google Scholar] [CrossRef]

- Lisowski, A.; Kostrubiec, M.; Dąbrowska-Salwin, M.; Świętochowski, A. Cechy peletów z biomasy roślinnej w aspekcie logistyki dostaw—Features of plant biomass pellets in terms of supply logistics. Logistyka 2015, 5, 351–356. [Google Scholar]

- Zafari, A.; Kianmehr, M.H. Effect of temperature, pressure and moisture content on durability of cattle manure pellet in open-end die method. J. Agric. Sci. 2012, 4, 203–208. [Google Scholar] [CrossRef]

- Colley, Z.; Fasina, O.; Bransby, D.; Lee, Y. Moisture effect on the physical characteristics of switchgrass pellets. Trans. ASABE 2006, 49, 1845–1851. [Google Scholar] [CrossRef]

- Gaze, B.; Noszczyk, T.; Romański, L.; Ufnarski, J. Pelet z torfu jako alternatywne paliwo dla stałych nośników energii- Peat pellets as an alternative fuel for solid energy carriers. Przemysł Chem. 2019, 98, 1069–1074. [Google Scholar]

- Ståhl, M.; Berghel, J.; Williams, H. Energy efficiency, greenhouse gas emissions and durability when using additives in the wood fuel pellet chain. Fuel Process. Technol. 2016, 152, 350–355. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Vicente, E.; Vicente, A.; Evtyugina, M.; Tarelho, L.; Almeida, S.; Alves, C. Emissions from residential combustion of certified and uncertified pellets. Renew. Energy 2020, 161, 1059–1071. [Google Scholar] [CrossRef]

- Kalyan, N.; Morey, R. Factors affecting strengh and durability of desified biomass product. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Gil Matellanes, M.V.; Oulego Blanco, P.; Casal Banciella, M.D.; Pevida García, C.; Pis Martínez, J.J.; Rubiera González, F. Mechanical durability and combustion characteristics of pellets from biomass blends. Bioresour. Technol. 2010, 101, 8859–8867. [Google Scholar]

- Larsson, S.H.; Rudolfsson, M.; Nordwaeger, M.; Olofsson, I.; Samuelsson, R. Effects of moisture content, torrefaction temperature, and die temperature in pilot scale pelletizing of torrefied Norway spruce. Appl. Energy 2013, 102, 827–832. [Google Scholar] [CrossRef]

- Järvinen, T.; Agar, D. Experimentally determined storage and handling properties of fuel pellets made from torrefied whole-tree pine chips, logging residues and beech stem wood. Fuel 2014, 129, 330–339. [Google Scholar] [CrossRef]

- Arranz, J.; Miranda, M.; Montero, I.; Sepúlveda, F.; Rojas, C. Characterization and combustion behaviour of commercial and experimental wood pellets in South West Europe. Fuel 2015, 142, 199–207. [Google Scholar] [CrossRef]

- Rudolfsson, M.; Borén, E.; Pommer, L.; Nordin, A.; Lestander, T.A. Combined effects of torrefaction and pelletization parameters on the quality of pellets produced from torrefied biomass. Appl. Energy 2017, 191, 414–424. [Google Scholar] [CrossRef]

- Agar, D.A.; Rudolfsson, M.; Kalén, G.; Campargue, M.; Da Silva Perez, D.; Larsson, S.H. A systematic study of ring-die pellet production from forest and agricultural biomass. Fuel Process. Technol. 2018, 180, 47–55. [Google Scholar] [CrossRef]

- Riva, L.; Nielsen, H.K.; Skreiberg, Ø.; Wang, L.; Bartocci, P.; Barbanera, M.; Bidini, G.; Fantozzi, F. Analysis of optimal temperature, pressure and binder quantity for the production of biocarbon pellet to be used as a substitute for coke. Appl. Energy 2019, 256, 113933. [Google Scholar] [CrossRef]

- Carroll, J.P.; Finnan, J. Physical and chemical properties of pellets from energy crops and cereal straws. Biosyst. Eng. 2012, 112, 151–159. [Google Scholar] [CrossRef]

- Williams, O.; Lester, E.; Kingman, S.; Giddings, D.; Lormor, S.; Eastwick, C. Benefits of dry comminution of biomass pellets in a knife mill. Biosyst. Eng. 2017, 160, 42–54. [Google Scholar] [CrossRef]

- Lehtikangas, P. Quality properties of pelletised sawdust, logging residues and bark. Biomass Bioenergy 2001, 20, 351–360. [Google Scholar] [CrossRef]

- Ahn, B.J.; Chang, H.; Lee, S.M.; Choi, D.H.; Cho, S.T.; Han, G.; Yang, I. Effect of binders on the durability of wood pellets fabricated from Larix kaemferi C. and Liriodendron tulipifera L. sawdust. Renew. Energy 2014, 62, 18–23. [Google Scholar] [CrossRef]

- Graham, S.; Ogunfayo, I.; Hall, M.R.; Snape, C.; Quick, W.; Weatherstone, S.; Eastwick, C. Changes in mechanical properties of wood pellets during artificial degradation in a laboratory environment. Fuel Process. Technol. 2016, 148, 395–402. [Google Scholar] [CrossRef]

- Temmerman, M.; Rabier, F.; Jensen, P.D.; Hartmann, H.; Böhm, T. Comparative study of durability test methods for pellets and briquettes. Biomass Bioenergy 2006, 30, 964–972. [Google Scholar] [CrossRef]

- Abdulmumini, M.M.; Zigan, S.; Bradley, M.S.A.; Lestander, T.A. Fuel pellet breakage in pneumatic transport and durability tests. Renew. Energy 2020, 157, 911–919. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Anukam, A.I.; Berghel, J.; Frodeson, S.; Famewo, E.B.; Nyamukamba, P. Characterization of Pure and Blended Pellets Made from Norway Spruce and Pea Starch: A Comparative Study of Bonding Mechanism Relevant to Quality. Energies 2019, 12, 4415. [Google Scholar] [CrossRef]

- Anukam, A.; Mamphweli, S.; Reddy, P.; Meyer, E.; Okoh, O. Pre-processing of sugarcane bagasse for gasification in a downdraft biomass gasifier system: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 66, 775–801. [Google Scholar] [CrossRef]

- Ioelovich, M. High-Energy Fuel Pellets. SciEnvironm 2020, 3, 147–152. [Google Scholar]

- Svedberg, U.; Samuelsson, J.; Melin, S. Hazardous Off-Gassing of Carbon Monoxide and Oxygen Depletion during Ocean Transportation of Wood Pellets. Ann. Occup. Hyg. 2008, 52, 259–266. [Google Scholar] [CrossRef]

- Selkimäki, M.; Mola-Yudego, B.; Röser, D.; Prinz, R.; Sikanen, L. Present and future trends in pellet markets, raw materials, and supply logistics in Sweden and Finland. Renew. Sustain. Energy Rev. 2010, 14, 3068–3075. [Google Scholar] [CrossRef]

- Pirraglia, A.; Gonzalez, R.; Saloni, D.; Wright, J. Wood pellets: An expanding market opportunity. Biomass Mag. 2010, 6, 68–75. [Google Scholar]

- Thomson, H.; Liddell, C. The suitability of wood pellet heating for domestic households: A review of literature. Renew. Sustain. Energy Rev. 2015, 42, 1362–1369. [Google Scholar] [CrossRef]

- Rominiyi, O.L.; Adaramola, B.A.; Ikumapayi, O.M.; Oginni, O.T.; Akinola, S.A. Potential Utilization of Sawdust in Energy, Manufacturing and Agricultural Industry; Waste to Wealth. World J. Eng. Technol. 2017, 5, 526–539. [Google Scholar] [CrossRef]

- Abadi, M.H.M.G.; Moravej, H.; Shivazad, M.; Torshizi, M.A.K.; Kim, W.K. Effect of different types and levels of fat addition and pellet binders on physical pellet quality of broiler feeds. Poult. Sci. 2019, 98, 4745–4754. [Google Scholar] [CrossRef] [PubMed]

- Bradfield, J.; Levi, M. Effect of species and wood to bark ratio on pelleting of southern woods. For. Prod. J. 1984, 34, 61–63. [Google Scholar]

- Rynkiewicz, M.; Dobek, T.K. Wybrane właściwości fizyczne i mechaniczne peletów w zależności od składu i temperatury ich przechowywania—Selected physical and mechanical properties of pellets depending on the composition and temperature of their storage. Inżynieria Rol. Agric. Eng. 2013, 3, 321–330. [Google Scholar]

- Sławiński, K.; Zdanowicz, A. Techniki transportu drogowego pelletu—Pellet road transport techniques. Autobusy Tech. Eksploat. Syst. Transp. 2016, 17, 240–244. [Google Scholar]

- Searcy, E.; Hess, J.R.; Tumuluru, J.; Ovard, L.; Muth, D.J.; Trømborg, E.; Wild, M.; Deutmeyer, M.; Nikolaisen, L.; Ranta, T.; et al. Optimization of Biomass Transport and Logistics. In International Bioenergy Trade: History, Status & Outlook on Securing Sustainable Bioenergy Supply, Demand and Markets; Lecture Notes in Energy; Junginger, M., Goh, C.S., Faaij, A., Eds.; Springer: Dordrecht, The Netherlands, 2014; pp. 103–123. ISBN 978-94-007-6982-3. [Google Scholar]

- Lacoa, U.; Velarde, G.; Kay, M.; Blanco, E.; Saloni, D.E. Design and Development of Logistics Models for Residential and Commercial Biomass Pellets for Heat and Power Generation in the U.S. BioResources 2017, 12, 1506–1531. [Google Scholar] [CrossRef]

- Khatwani, P.A.; Nag, S. Review on the Study of structure of Polypropylene for development of different textile based products for packaging industries. Int. J. Res. Anal. Rev. 2018, 6, 4. [Google Scholar]

- Qian, Y.; McDow, W. The Wood Pellet Value Chain; US Endowment for Forestry and Communities: Greenville, SC, USA, 2013; Volume 59. [Google Scholar]

- Lu, F.; Ishikawa, Y.; Shiina, T.; Satake, T. Analysis of shock and vibration in truck transport in Japan. Packag. Technol. Sci. 2008, 21, 479–489. [Google Scholar] [CrossRef]

- Bernad, C.; Laspalas, A.; González, D.; Núñez, J.L.; Buil, F. Transport vibration laboratory simulation: On the necessity of multiaxis testing. Packag. Technol. Sci. 2011, 24, 1–14. [Google Scholar] [CrossRef]

- Chonhenchob, V.; Singh, S.P.; Singh, J.J.; Stallings, J.; Grewal, G. Measurement and Analysis of Vehicle Vibration for Delivering Packages in Small-Sized and Medium-Sized Trucks and Automobiles. Packag. Technol. Sci. 2012, 25, 31–38. [Google Scholar] [CrossRef]

- Graham, S.; Eastwick, C.; Snape, C.; Quick, W. Mechanical degradation of biomass wood pellets during long term stockpile storage. Fuel Process. Technol. 2017, 160, 143–151. [Google Scholar] [CrossRef]

- Gilvari, H.; De Jong, W.; Schott, D.L. The Effect of Biomass Pellet Length, Test Conditions and Torrefaction on Mechanical Durability Characteristics According to ISO Standard 17831-1. Energies 2020, 13, 3000. [Google Scholar] [CrossRef]

- Tang, Y.; Chandra, R.P.; Sokhansanj, S.; Saddler, J.N. The role of biomass composition and steam treatment on durability of pellets. BioEnergy Res. 2018, 11, 341–350. [Google Scholar] [CrossRef]

- Serrano, C.; Monedero, E.; Lapuerta, M.; Portero, H. Effect of moisture content, particle size and pine addition on quality parameters of barley straw pellets. Fuel Process. Technol. 2011, 92, 699–706. [Google Scholar] [CrossRef]

- Chico-Santamarta, L.; Chaney, K.; Godwin, R.J.; White, D.R.; Humphries, A.C. Physical quality changes during the storage of canola (Brassica napus L.) straw pellets. Appl. Energy 2012, 95, 220–226. [Google Scholar] [CrossRef]

| Manufacturer | Diameter | Humidity | Ash Content | Calorific Value | Package Mass |

|---|---|---|---|---|---|

| (mm) | (%) | (%) | (MJ·kg−1) | (kg) | |

| Pellet A | 6 | 6.5 | ˂0.4 | 18.5 | 15 |

| Pellet B | 8 | 6.5 | ˂0.5 | 18.5 | 25 |

| Pellet C | 6 | 7.5 | ˂0.5 | 18.5 | 15 |

| Pellet D | 6 | 7.5 | ˂0.4 | 18.5 | 15 |

| Pellet E | 8 | 7.5 | ˂0.5 | 18.5 | 25 |

| SS | df | MS | F | p | |

|---|---|---|---|---|---|

| Intercept | 1924.619 | 1 | 1924.619 | 5069.857 | <0.001 * |

| Manufacturer | 594.077 | 4 | 148.519 | 391.231 | <0.001 * |

| Time | 186.113 | 3 | 62.038 | 4183.885 | <0.001 * |

| Time*Manufacturer | 48.139 | 12 | 4.012 | 270.544 | <0.001 * |

| SS | df | MS | F | p | |

|---|---|---|---|---|---|

| Intercept | 387.1327 | 1 | 387.1327 | 2079.784 | <0.001 * |

| Manufacturer | 157.4438 | 4 | 39.3610 | 211.458 | <0.001 * |

| Time | 45.8229 | 3 | 15.2743 | 1211.122 | <0.001 * |

| Time*Manufacturer | 18.2944 | 12 | 1.5245 | 120.883 | <0.001 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuranc, A.; Stoma, M.; Rydzak, L.; Pilipiuk, M. Durability Assessment of Wooden Pellets in Relation with Vibrations Occurring in a Logistic Process of the Final Product. Energies 2020, 13, 5890. https://doi.org/10.3390/en13225890

Kuranc A, Stoma M, Rydzak L, Pilipiuk M. Durability Assessment of Wooden Pellets in Relation with Vibrations Occurring in a Logistic Process of the Final Product. Energies. 2020; 13(22):5890. https://doi.org/10.3390/en13225890

Chicago/Turabian StyleKuranc, Andrzej, Monika Stoma, Leszek Rydzak, and Monika Pilipiuk. 2020. "Durability Assessment of Wooden Pellets in Relation with Vibrations Occurring in a Logistic Process of the Final Product" Energies 13, no. 22: 5890. https://doi.org/10.3390/en13225890

APA StyleKuranc, A., Stoma, M., Rydzak, L., & Pilipiuk, M. (2020). Durability Assessment of Wooden Pellets in Relation with Vibrations Occurring in a Logistic Process of the Final Product. Energies, 13(22), 5890. https://doi.org/10.3390/en13225890