Abstract

Drilling in high-pressure high-temperature (HPHT) conditions is a challenging task. The drilling fluid should be designed to provide high density and stable rheological properties. Barite is the most common weighting material used to adjust the required fluid density. Barite settling, or sag, is a common issue in drilling HPHT wells. Barite sagging may cause many problems such as density variations, well-control problems, stuck pipe, downhole drilling fluid losses, or induced wellbore instability. This study assesses the effect of using a new copolymer (based on styrene and acrylic monomers) on the rheological properties and the stability of an invert emulsion drilling fluid, which can be used to drill HPHT wells. The main goal is to prevent the barite sagging issue, which is common in drilling HPHT wells. A sag test was performed under static (vertical and 45° incline) and dynamic conditions in order to evaluate the copolymer’s ability to enhance the suspension properties of the drilling fluid. In addition, the effect of this copolymer on the filtration properties was performed. The obtained results showed that adding the new copolymer with 1 lb/bbl concentration has no effect on the density and electrical stability. The sag issue was eliminated by adding 1 lb/bbl of the copolymer to the invert emulsion drilling fluid at a temperature >300 °F under static and dynamic conditions. Adding the copolymer enhanced the storage modulus by 290% and the gel strength by 50%, which demonstrated the power of the new copolymer to prevent the settling of the barite particles at a higher temperature. The 1 lb/bbl copolymer’s concentration reduced the filter cake thickness by 40% at 400 °F, which indicates the prevention of barite settling at high temperature.

1. Introduction

HPHT conditions may reach pressures greater than 10,000 psi and temperatures greater than 300 °F [1]. Drilling wells at HPHT conditions require a special design, especially for the drilling fluid properties. The drilling fluid should provide a high density (19 ppg or more) and stable rheological properties.

Zhang et al. [2] stated that the drilling fluid should provide stable and optimal rheological properties by providing shear thinning and thixotropic properties. Polymers and nanoparticles play a vital role in providing stable rheological properties and reducing the filtration of the drilling fluid into the formation [3]. Li et al. [4] evaluate the effect of using cellulose nanoparticles (CNPs) as a modifier for rheological and filtration properties of bentonite water-based drilling fluid (BT-WBDF). They concluded that adding cellulose nanocrystals (CNCs) to the BT-WBDF enhanced the rheological properties, especially at higher temperature, and reduced the fluid loss into the formation, and in addition, the formed filter cake was thin when compared with BT-WBDF. Rasool et al. [5] developed a nanocomposite of ZnO-interlinked chitosan (Ch) nanoparticles (CZNCs) as a new biocide. They concluded that the developed green biocide can be used for the oil and gas industry with no impact on the environment.

Barite is the most common weighting materials used to provide the required density for HPHT wells. Barite settling, also known as sagging, is a common issue when using barite as a weighting material to drill HPHT wells [6,7,8]. Barite sagging causes mud density variations in both vertical and deviated wellbores, but especially in deviated wells. Barite sagging may also lead to many problems such as well control problem, mud losses, stuck pipe, or wellbore instability [9,10].

Sag is often seen when a driller circulates the mud out after a period of tranquil, leading to the confidence that the static settling of mud is the main indicator of barite sagging. Sag occurs in vertical and deviated wells, although potentially happens at angles between 30°–75° in the deviated section [11,12,13,14,15].

Zamora and Bell [16] stated that a large change of the drilling fluid density might result from dynamic sag. Temple et al. [17] used a low molecular weight polymer to reduce the barite sagging. They concluded that using polyalkyl methacrylate with an average molecular weight ranging from about 40,000 to about 90,000 prevented the barite sagging and at the same time did not cause a change in the rheological properties of the drilling fluid. Dynamic sag can be predicted from the low shear rheological properties [18,19,20].

Sag factor greater than 0.53, implying that the drilling fluid will create sag tendency, and a change in mud density of the top and bottom greater than 0.5 ppg along the mud column is an indicator of a barite sag occurrence [19].

Sag may occur more rapidly in a fluid that has a weaker gel structure. Sag issues occur under dynamic or static conditions. Dynamic sag is related to low shear viscosity and it can be severe even if there is no static sag issue [21,22].

Dye et al. [23,24] reported that at an annular velocity of 100 ft/min, the dynamic barite sag is low. They concluded that at a low shear rate, less than 4 S−1, dynamic sag occurs in deviated wells that are drilled using invert emulsion mud as the well-section angle increases from 45° to 60°, in this case, the mud weight has less impact than shear rate viscosity.

Nguyen et al. [25,26] found that under the static condition, when the yield stress is greater than 12 lb/100 ft2, no sag occurs. They stated that annular velocity and pipe rotation contribute individually to sag prevention by nearly 60% and 21%, respectively. Bern [27] studied the effect of the annular velocity on barite sag and they found that an annular velocity closer to 30 ft/min motivated barite sagging.

Wagle et al. [28,29] showed that invert emulsion drilling fluids (IEFs) formulated with nanoparticles and rheology modifiers (RM) were stable at 250 °F and 300 °F and exhibited no sag tendency for 9, 12, and 16 ppg drilling fluid density in both vertical and 45° deviated tests. In addition, the HPHT rheology of IEFs showed consistency before and after adding nanoparticles.

Elkatatny et al. [30,31] and Al-Bagoury [32] investigated the use of micronized ilmenite as a weighting martial in both water-based mud (WBM) and oil-based mud (OBM). The result showed that micronized ilmenite reduced dynamic sag better than barite with no effect on rheology and HPHT filtration. Mohamed et al. [33] assessed the effect of reducing the barite particles’ size to micro-sized and they showed that micronized barite yielded insignificant improvement in preventing sag.

Ofei et al. [34] evaluated the adding of ionic liquid to water-based polymer drilling fluid and they found that adding 1-butyl-3-methylimidazolium chloride (BMIM-Cl) stabilized the rheological properties of the drilling fluid. In addition, adding BMIM-Cl to the drilling fluid enhanced the capacity of the solid suspension and the filtration properties at a higher temperature (356 °F).

Ahmad et al. [35] stated that a combination of bentonite and polymers improve the rheological and filtration properties of water-based drilling fluid. They found that the mixing of a copolymer of acrylamide and acrylic acid with bentonite showed a big enhancement in rheological properties when compared with other dispersants. They concluded that using a high molecular weight polymer provides excellent rheological properties and very high thermal stability in addition to enhancing the filtration properties.

The invert emulsion drilling fluid consists of oil as a continuous phase and water as the dispersed phase, which contains various electrolytes. The multiphase system should be stabilized using surfactants [36]. The main goal of this paper is to assess the effect of using a new copolymer to eliminate and prevent barite sagging in HPHT conditions under static and dynamic situations for invert emulsion drilling fluid. In addition, the effect of using the new copolymer on the rheological and filtration properties of the invert emulsion drilling fluid was evaluated.

2. Experimental Work

2.1. Material

The invert emulsion consisted of the following components: diesel (172 mL), as a continuous phase; water (50 mL), as a dispersed phase; EZ-mul (15 g), as an emulsifier and oil-wetting agent; invermul (11 g), as a primary emulsifier; lime (6 g), as a contaminate remover; geltone II (2 g), as a viscosifier, which is an organophilic clay used to impart viscosity and suspension properties; calcium chloride (2 g), as a shale inhibitor; calcium carbonate (30 g), as a bridging material; RM-63 (1 g), as a rheology modifier to improve rheological and suspension characteristics of invert emulsion fluids; and barite (560 g), as a weighting agent. The composition of the drilling fluid is listed in Table 1.

Table 1.

Drilling fluid formulation for lab scale, equivalent to 1 bbl.

The new copolymer was added to the invert emulsion drilling fluid to evaluate its effect on the sag performance. The new copolymer was obtained from a service company and it consisted of styrene and acrylic monomers with a bulk density of 3–5 ppg and a pH of 9–11 at 10% solution. The new copolymer is soluble in oil and dispersible in water. The main functions of this copolymer are as a rheology modifier and cutting suspension.

2.2. Experimental Procedure

The following procedure was performed in order to evaluate the effect of using the copolymer on the invert emulsion drilling fluid properties:

- Prepare the drilling fluid mixture at ambient temperature;

- Measure the density and electrical stability at ambient temperature;

- Perform the static sag test at different temperatures under vertical and decline situations;

- Perform the dynamic sag test using the sag shoe and the rheometer at 120 °F and 100 rpm;

- Perform the amplitude sweep test at 350 °F to determine the linear elastic region of the fluid;

- Perform the angular frequency test at 350 °F to determine the storage modulus of the invert emulsion drilling fluid;

- Measure the rheological properties over a wide range of temperatures (200–400 °F);

- Measure the filtration properties at 400 °F and 400 psi differential pressure.

2.3. Dynamic Sag Test

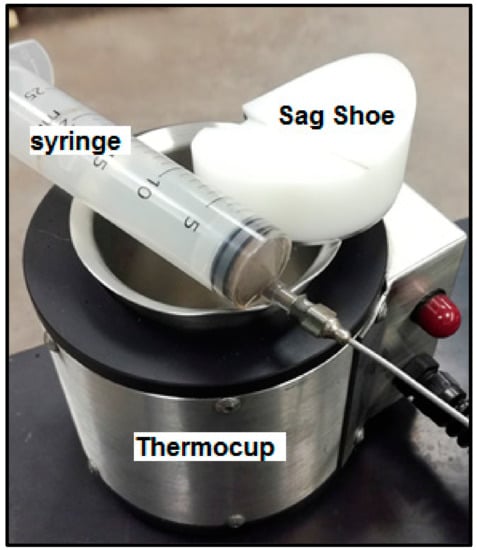

The viscometer sag shoe test (VSST) is a well site and laboratory test to measure the weight-material sag tendency of a field and lab-prepared drilling fluid under dynamic conditions [16]. The idea is that the inclined surface of the thermoplastic shoe helps accelerate settling and concentrates the weighting material into a single collection well at the bottom of the thermos cup, as shown in Figure 1.

Figure 1.

Basic equipment for dynamic sag test (VSST excluding the viscometer).

The following procedure is recommended for the sag test [16]:

- Insert the sag shoe into the thermo cup and put it together on the viscometer plate.

- Pour the drilling fluid inside the thermo cup and raise it until the upper surface touches the lower part of the viscometer sleeve. Then lower the cup around 7 mm.

- Heat the 140 mL drilling fluid with the sag shoe to 120 °F ± 2 °F.

- Set the viscometer at 100 rpm and start a 30 min timer.

- Using the syringe with the cannula, extract a 10 mL sample and record the weight of the drilling fluid-filled syringe, W1.

- Stop the viscometer after 30 min and take another sample of 10 mL.

- Record the weight of the drilling fluid-filled syringe (W2).

- Calculate the VSST using Equation (1).

VSST = 0.833 × (W2 − W1)

A VSST value of 1.0 ppg or less would imply a drilling fluid with the minimal sagging tendency [6]. A VSST value above 1.6 ppg would indicate the beginning of a possible sag problem [37].

2.4. Rheology and Filtration Tests

After preparing the drilling fluid, a Grace M5600 HPHT rheometer was used for the HPHT rheology measurements. The test was performed at different temperatures (200, 300, and 400 °F) under a wide range of shear rates ranging from 5.1 to 1020 S−1. Using the shear stress data at a different shear rate, the rheological properties were determined such as plastic viscosity and the yield point. The gel strength was measured at a low shear rate of 5.1 S−1 at different time periods (10 s and 10 min).

An HPHT filter press was used to perform the filtration test for the drilling fluid at 400 °F and applied pressure of 400 psi. A ceramic disk of 63.5 mm diameter and 6.35 mm thickness was used as a filtration medium.

3. Results and Discussions

The invert emulsion drilling fluid was prepared and mixed as explained in Table 1. The density of the drilling fluid was 19 ppg, which indicates that this fluid could be used for controlling the pressure for high-pressure wells. The electrical stability at ambient temperature was 1180 V. After adding 1 lb/bbl of the new copolymer, the density and electrical stability were measured again and showed no changes in their values.

3.1. Effect of Temperature on Static Sag Test

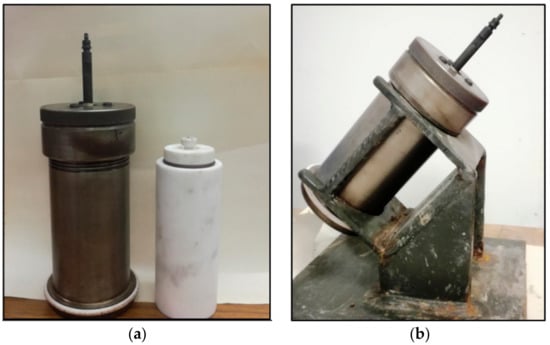

A static vertical sag test was performed using an aging cell with a Teflon liner (Figure 2a). The sag factor of deviated well was evaluated using a 45° base setup as illustrated in Figure 2b. The drilling fluid was placed in the Teflon liner inside the aging cell. The cell was pressured (400 psi) and heated in an oven for 24 h at 250 °F under a static condition, then left to cool down and the pressure was released. Two drilling fluid samples were taken from the top and bottom of the Teflon liner. The sag factor was calculated using Equation (2).

where SF is static sag factor, and ρbottom and ρtop are the bottom and top drilling fluid densities, respectively.

Figure 2.

Basic equipment for static sag test: (a) vertical setup aging cell and (b) 45° setup aging cell.

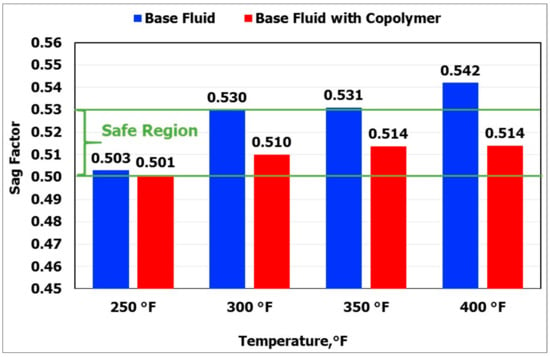

Figure 3 shows that at 250 °F, the sag factor was 0.503 indicating the stability of the drilling fluid and no barite settling occurred. At 300 °F, the sag factor increased to 0.530, which is the border of the safe region. At 350 °F, the sag factor increased to 0.531, which indicates the start of the instability of the weighting material in the drilling fluid. The sag factor increased to 0.542 at 400 °F, which confirmed that at this temperature, the invert emulsion drilling fluid was not stable and could not provide the required suspension for the weighting materials that settled down in the Teflon liner, Figure 3.

Figure 3.

Static vertical sag factor for the drilling fluid with and without the copolymer at different temperatures.

After adding the new copolymer, the static vertical sag test was repeated under the same above-mentioned conditions. Figure 3 shows that the sag factor for the drilling fluid with the copolymer was 0.501 at 250 °F. At 300 °F, the sag factor increased to 0.51, which is in the safe region. By increasing the temperature to 350 and 400 °F, the sag factor for the drilling fluid with the copolymer stayed in the safe region with a constant value of 0.514. These results confirmed that adding the copolymer (1 lb/bbl) enhanced the sag factor for the invert emulsion drilling fluid at a higher temperature (>300 °F) for vertical wells.

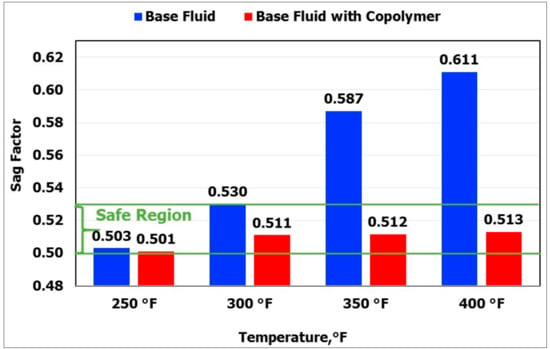

The static sag factor was calculated under static conditions for the base fluid using the inclined position of the aging cell (45°). Figure 4 shows that the based fluid had a good stability at a temperature equal to or less than 300 °F where the sag factor was in the safe region. At 350 °F, the sag factor increased to 0.587 confirming the critical condition for the barite sagging. At 400 °F, the sag factor increased to 0.611 confirming the need for another additive to prevent the barite settling at high temperatures. The sag factor was calculated, after adding the copolymer, at a range of temperatures for the inclined setup (45°). Figure 4 shows that adding the new copolymer to the invert emulsion drilling fluid enhanced its stability where the sag factor remained in the safe region, even at 400 °F. The sag factor was 0.531 at 400 °F. These results confirmed that adding the copolymer (1 lb/bbl) to the drilling fluid enhanced its suspension properties and prevented barite settlement in an inclined position.

Figure 4.

Static inclined (45°) sag factor under different temperatures for the drilling fluid with and without the copolymer.

3.2. Dynamic Sag Test

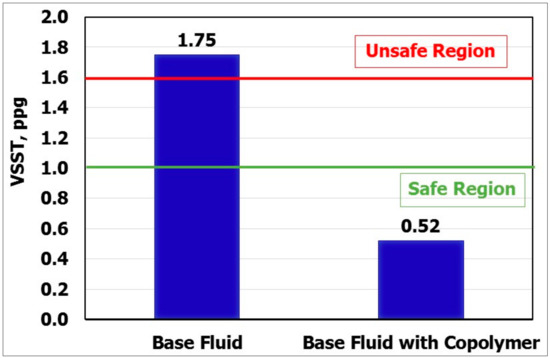

The dynamic sag test was performed as explained in the experimental procedure section. Figure 5 shows that the invert emulsion drilling fluid had a viscometer sag shoe test value (VSST) of 1.75 ppg after 30 min of rotation (100 rpm) at 120 °F. This result confirms the instability of the suspension property of the invert emulsion under dynamic conditions, where a VSST value greater than 1.6 indicates the occurrence of settling [37].

Figure 5.

Dynamic sag test for the drilling fluid with and without the copolymer.

The dynamic sag test was repeated after adding the copolymer to the invert emulsion drilling fluid. Figure 5 shows that the VSST value was 0.52 ppg after 30 min of rotation (100 rpm) at 120 °F. This result confirms the stability of the drilling fluid after adding the copolymer, where a VSST value less than 1 ppg indicates a minimal sag tendency [6].

3.3. Storage Modulus

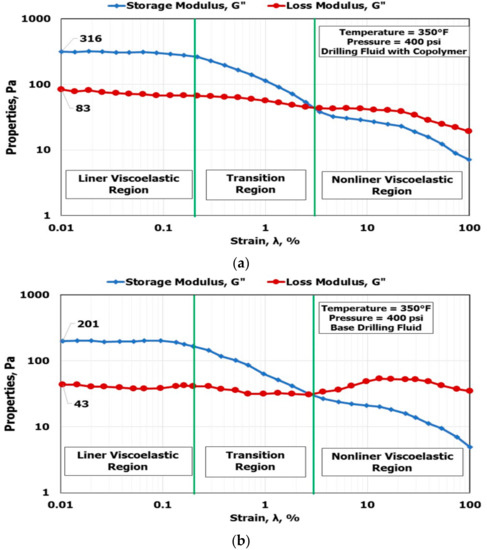

The objective of the oscillation amplitude test is to investigate time-dependent viscoelastic properties, which are the storage modulus and the loss modulus. The linear viscoelastic region (LVE) region is defined when storage modulus (G′) and loss modulus (G″) do not change with increasing strain. The LVE can be determined by plotted (G′) and (G″) against the strain (Figure 6). In the case where (G′) is greater than (G″), i.e., the elastic behavior dominates the viscous behavior and the fluid exhibits a gel structure, this indicates a linear viscoelastic region. In contrast, when (G′) is less than (G″), i.e., the viscous behavior dominates elastic behavior and the material exhibits characteristics of a liquid [38,39], this indicates a nonlinear viscoelastic region. After the LVE range is determined, the oscillation frequency is applied by letting frequency free and holding the amplitude constant. Figure 6a shows that for the drilling fluid with the copolymer, the linear viscoelastic region existed until a strain of 0.2%, where the G′ was greater than G′’ and both were nearly constant. When the strain exceeded 3%, the G″ became greater than G′, indicating a nonlinear viscoelastic region. The oscillation amplitude test was performed at 350 °F and an applied pressure of 400 psi to prevent vaporization. The same test was repeated for the base drilling fluid under the same conditions. A linear viscoelastic region existed until a strain of 0.2%, where the G′ was greater than G′’ and when strain exceeded 3%, the G″ became greater than G′, indicating a nonlinear viscoelastic region, Figure 6b. Based on these results, the frequency sweep test was performed using a constant strain of 0.2%.

Figure 6.

Storage and shear moduli at different stain for (a) drilling fluid with the copolymer and (b) base drilling fluid.

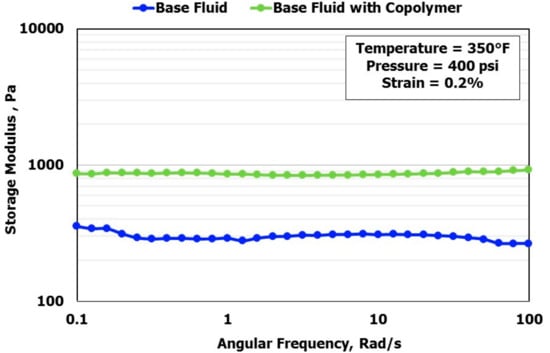

The frequency sweep test is used to measure the response of a fluid to deformation as a time-dependent behavior. Figure 7 shows that the storage modulus of the base fluid with the copolymer was much greater than the storage modulus of the base fluid at different frequencies. The average G′ for the base fluid was 300 Pa and increased to 865 Pa after adding the copolymer, which means that adding the copolymer increased the storage modulus by almost 290% at a temperature of 350 °F and applied pressure of 400 psi. Increasing the storage modulus improved the gel strength and the suspension capacity of the fluid. This result confirmed the results from the sag test, which illustrated that adding the copolymer to the invert emulsion drilling fluid enhanced the suspension capacity and eliminated the sag issue.

Figure 7.

Storage modulus G′ of the drilling fluid at a temperature of 350 °F, pressure of 400 psi, and a shear strain of 0.2%.

3.4. Rheological Properties

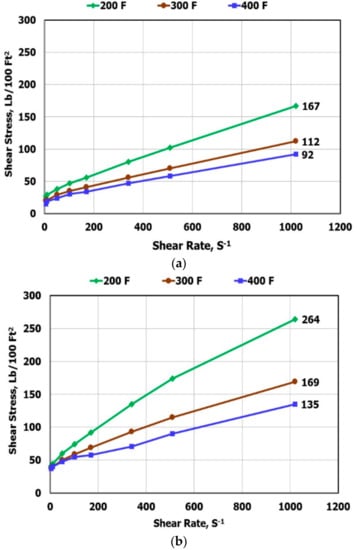

Figure 8 depicts the effect of adding the copolymer to the shear stress at different temperatures. Adding the copolymer increased the shear stress of the drilling fluid at a temperature greater than 300 °F. At a high shear rate (1020 S−1), the base fluid had a shear stress of 112 and 92 lb/100 ft2 at 300 and 400 °F respectively, while at the same shear rate, the enhanced drilling fluid with the copolymer had a shear stress of 169 and 135 lb/100 ft2 at 300 and 400 °F, respectively. The increase in the shear stress at higher shear rate indicates the better rheology at a higher temperature.

Figure 8.

Effect of temperature on shear stress versus shear rate relationship at a different temperature: (a) base fluid and (b) base fluid with copolymer.

The yield stress of the base fluid was 26.68 lb/100 ft2 at 200 °F and it was noted that it dropped to 16 lb/100 ft2 as the temperature increased to 400 °F (Figure 8a). The yield stress was determined by applying the Herschel–Bulkley model. The reduction in the yield stress, an almost 40% reduction, by increasing the temperature caused a loss of the suspension properties and indicates the settling of the solids from the fluid at a low shear rate. Adding the copolymer to the drilling fluid enhanced its yield stress at a different temperature. The yield stress of the base fluid with the copolymer was 40.5 lb/100 ft2 at 200 °F and it was reduced to 37.5 lb/100 ft2 at 400 °F (Figure 8b). The yield stress stability of the drilling fluid at high temperatures (200–400 °F) confirms the enhancement of the suspension property after adding the copolymer. This result allies with the sag test and the storage modulus results to prove the importance of adding the copolymer to the drilling fluid to enhance the suspension property and prevent the sag.

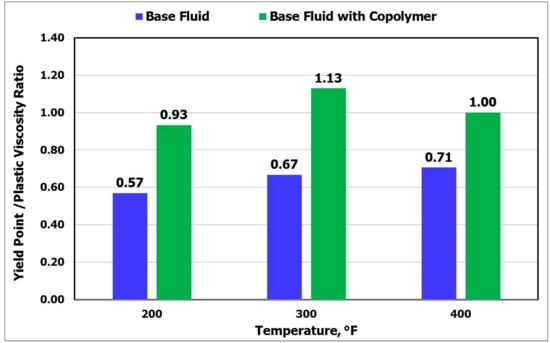

A higher yield point (YP) to plastic viscosity (PV) ratio is better for enhancing the hole-cleaning efficiency. Results presented in Figure 9 display that the YP/PV ratio had increased after adding the copolymer in all cases. For example, at 400 °F, the base fluid had a YP/PV value of 0.71 that increased to 1.0 after adding the copolymer.

Figure 9.

Effect of temperature on the yield point/plastic viscosity ratio.

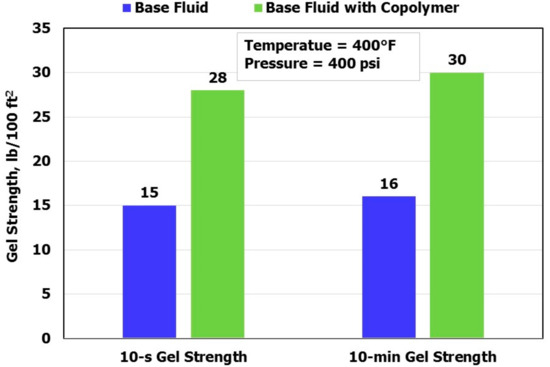

The gel strength property is the ability of the drilling fluid to keep the cuttings and weighting materials in suspension while there is no circulation. Figure 10 shows that adding the copolymer enhanced the gel strength values of the drilling fluid. At 400 °F and 400 psi applied pressure, the gel strength at 10 s was 15 lb/100 ft2. The gel strength value increased to 28 lb/100 ft2 after adding the copolymer. The 10 min gel strength was 16 lb/100 ft2 for the base fluid, which increased to 30 lb/100 ft2 after adding the copolymer. This result showed that adding the copolymer doubled the values of the gel strength, i.e., it enhanced the suspension property under static conditions. The slight change in the gel strength between 10 s and 10 min indicates, in general, a flat rheology. Enhancing the gel strength at a high temperature helps in reducing the settling of solid particles under static conditions.

Figure 10.

Effect of temperature of the gel strength.

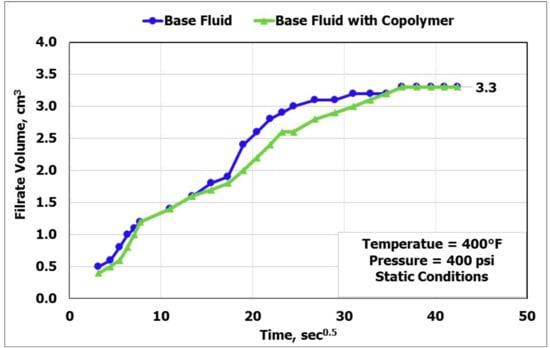

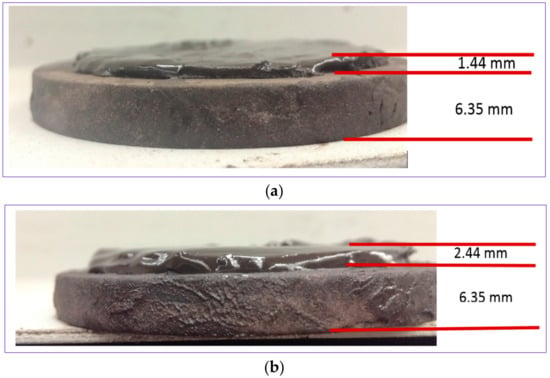

3.5. Filtration Properties

The filtration test was conducted on the drilling fluid with and without the copolymer under a static condition at a high temperature, 400 °F, and differential pressure, 400 psi. Results (Figure 11) show that the filtrate volume was the same, 3.3 cm3 after 30 min, for both fluids. The filter cake thickness (Figure 12) was 2.43 mm after 30 min filtration of the base fluid at 400 °F. Under the same conditions, the filter cake thickness was reduced by 40% to become 1.44 mm, which reflects the stability of the weighting materials in the drilling mud after adding the copolymer. Whereas, in the case of the base mud, the solids precipitated and increased the thickness of the filter cake.

Figure 11.

Effect of the copolymer on the filtration properties.

Figure 12.

Effect of the copolymer on the filter cake thickness: (a) formed filter cake for the drilling fluid with the copolymer and (b) formed filter cake for the base drilling fluid.

4. Conclusions

Extensive lab work was conducted to evaluate the effect of using a new copolymer on the stability and the rheological properties of the invert emulsion drilling fluid for HPHT applications. Based on the obtained results, the following conclusions can be drawn:

- Adding the copolymer (1 lb/bbl) had no effect on the density and electrical stability of the invert emulsion drilling fluid.

- The sag issue was eliminated under static and dynamic conditions for both vertical and inclined borehole sections after adding the copolymer.

- Adding the copolymer increased the fluid storage modulus by nearly 290% at a temperature of 350 °F, which indicates better suspension properties.

- The gel strength after 10 s and 10 min was increased by almost 50%, which confirms the power of the copolymer’s ability to keep cutting in suspension.

- The filter cake thickness was reduced by 40% when using 1 lb/bbl of the copolymer at 400 °F at the same filtrate volume, which assures the prevention of barite settling.

Funding

This research received no external funding.

Conflicts of Interest

The author declares no conflict of interest.

References

- Smithson, T. The Defining Series HPHT Wells. Available online: https://www.slb.com/-/media/Files/resources/oilfield_review/defining_series/Defining-HPHT.pdf?la=en&hash=3FF8F894C76522C77D31DAF3B136B24371E7CCDC (accessed on 10 September 2018).

- Zhang, X.; Jiang, G.; Xuan, Y.; Wang, L.; Huang, X. Associating Copolymer Acrylamide/Diallyldimethylammonium Chloride/Butyl Acrylate/2-Acrylamido-2-methylpropanesulfonic Acid as a Tackifier in Clay-Free and Water-Based Drilling Fluids. Energy Fuels 2017, 31, 4655–4662. [Google Scholar] [CrossRef]

- Vryzas, Z.; Kelessidis, V.C. Nano-Based Drilling Fluids: A Review. Energies 2017, 10, 540. [Google Scholar] [CrossRef]

- Li, M.-C.; Wu, Q.; Song, K.; Qing, Y.; Wu, Y. Cellulose nanoparticles as modifiers for rheology and fluid loss in bentonite water-based fluids. ACS Appl. Mater. Interfaces 2015, 7, 5006–5016. [Google Scholar] [CrossRef] [PubMed]

- Rasool, K.; Nasrallah, G.K.; Younes, N.; Pandey, R.P.; Abdul Rasheed, P.; Mahmoud, K.A. “Green” ZnO-Interlinked Chitosan Nanoparticles for the Efficient Inhibition of Sulfate-Reducing Bacteria in Inject Seawater. ACS Sustain. Chem. Eng. 2018, 6, 3896–3906. [Google Scholar] [CrossRef]

- Aldea, C.; Growcock, F.B.; Lee, L.J.; Friedheim, J.E.; van Oort, E. Prevention of Dynamic Sag in Deepwater Invert Emulsion Fluids. In Proceedings of the AADE National Drilling Conference, Houston, TX, USA, 27–29 March 2001. [Google Scholar]

- Meeten, G.H. Dynamic Sag Monitor for Drilling Fluids. U.S. Patent 6,330,826B1, 18 December 2001. [Google Scholar]

- Xiao, J. Experimental Studies of Ilmenite as a Weighting Material in Oil-based Drilling Fluids for HPHT Operations. Master’s Thesis, Texas A&M University, College Station, TX, USA. Available online: http://hdl.handle.net/1969.1/151876 (accessed on 10 September 2018).

- Tehrani, A.; Zamora, M.; Power, D. Role of Rheology in Barite Sag in SBM and OBM. In Proceedings of the AADE Drilling Fluids Conference, Houston, TX, USA, 6–7 April 2004. [Google Scholar]

- Massam, J.; Popplestone, A.; Burn, A. A Unique Technical Solution to Barite Sag in Drilling Fluid. In Proceedings of the AADE Drilling Fluids Conference, Houston, TX, USA, 6–7 April 2004. [Google Scholar]

- Bern, P.A.; Zamora, M.; Slater, K.S.; Hearn, P.J. The Influence of Drilling Variables on Barite Sag. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 6–9 October 1996. [Google Scholar]

- Skalle, P.; Backe, K.R.; Lyomov, S.K.; Sveen, J. Barite segregation in inclined boreholes. J. Can. Pet. Technol. 1999, 38, 40–41. [Google Scholar] [CrossRef]

- Hanson, P.M.; Trigg, T.K.; Rachal, G.; Zamora, M. Investigation of Barite “Sag” in Weighted Drilling Fluids in Highly Deviated Wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 23–26 September 1990. [Google Scholar]

- Jefferson, D.T. New procedure helps monitor sag in the field. In Proceedings of the ASME Energy Sources Technology Conference, New Orlands, LA, USA, 20–24 January 1991. [Google Scholar]

- Amighi, M.R.; Shahbazi, K. Effective Ways to Avoid Barite Sag and Technologies to Predict Sag in HPHT and Deviated Wells. In Proceedings of the SPE Deep Gas Conference and Exhibition, Manama, Bahrain, 24–26 January 2010. [Google Scholar]

- Zamora, M.; Bell, R. Improved Wellsite Test for Monitoring Barite Sag. In Proceedings of the AADE Drilling Fluids Conference, Houston, TX, USA, 6–7 April 2004. [Google Scholar]

- Temple, C.; Aterson, A.F.; Leith, C.D. Method for Reducing Sag in Drilling, Completion and Workover Fluids. U.S. Patent WO2004113467A1, 29 December 2004. [Google Scholar]

- Dye, W.; Hemphill, T.; Gusler, W.; Mullen, G. Correlation of Ultralow-Shear-Rate Viscosity and Dynamic Barite Sag. SPE Drill. Complet. 2001, 16, 27–34. [Google Scholar] [CrossRef]

- Maxey, J. Rheological Analysis of Static and Dynamic Sag in Drilling Fluids. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.659.9186&rep=rep1&type=pdf (accessed on 10 September 2018).

- Dye, W.M.; Mullen, G.A.; Gusler, W.J. Field-Proven Technology to Manage Dynamic Barite Sag. In Proceedings of the IADC/SPE Drilling Conference, Miami, FL, USA, 21–23 February 2006. [Google Scholar]

- Saasen, A.; Liu, D.; Marken, C.D. Prediction of Barite Sag Potential of Drilling Fluids from Rheological Measurements. In Proceedings of the IADC/SPE Drilling Conference, Amsterdam, The Netherlands, 28 February–2 March 1995. [Google Scholar]

- Bui, B.; Saasen, A.; Maxey, J.; Ozbayoglu, M.E.; Miska, S.Z.; Yu, M.; Takach, N.E. Viscoelastic Properties of Oil-Based Drilling Fluids. Available online: https://pdfs.semanticscholar.org/4f8d/49537ea3efd8ed6756c46ceafcfaafab6bc0.pdf (accessed on 10 September 2018).

- Dye, W.; Hemphill, T.; Gusler, W.; Mullen, G. Correlation of ultra-low shear rate viscosity and dynamic barite sag in invert-emulsion drilling fluids. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 3–6 October 1999. [Google Scholar]

- Dye, W.; Mullen, G.; Gusler, W. Drilling Processes: The Other Half of the Barite Sag Equation. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 9–11 September 2003. [Google Scholar]

- Nguyen, T.; Miska, S.; Yu, M.; Takach, N.; Ahmed, R.; Saasen, A.; Omland, T.H.; Maxey, J. Experimental study of dynamic barite sag in oil-based drilling fluids using a modified rotational viscometer and a flow loop. J. Pet. Sci. Eng. 2011, 78, 160–165. [Google Scholar] [CrossRef]

- Nguyen, T.; Miska, S.; Saasen, A.; Maxey, J. Using Taguchi and ANOVA methods to study the combined effects of drilling parameters on dynamic barite sag. J. Pet. Sci. Eng. 2014, 121, 126–133. [Google Scholar] [CrossRef]

- Bern, P.A.; van Oort, E.; Neustadt, B.; Ebeltoft, H.; Zurdo, C.; Zamora, M.; Slater, K.S. Barite Sag: Measurement, Modeling, and Management. SPE Drill. Complet. 2000, 15, 25–30. [Google Scholar] [CrossRef]

- Wagle, V.; Maghrabi, S.; Kulkarni, D. Formulating Sag-Resistant, Low-Gravity Solids-Free Invert Emulsion fluids. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 10–13 March 2013. [Google Scholar]

- Wagle, V.; Al-Yami, A.S.; Alabdullatif, Z. Using Nanoparticles to Formulate Sag-Resistant Invert Emulsion Drilling Fluids. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, London, UK, 17–19 March 2015. [Google Scholar]

- Elkatatny, S.M.; Nasr-El-Din, H.A.; Al-Bagoury, M. Evaluation of Ilmenite as Weighting Material in Water-Based Drilling Fluids for HPHT Applications. In Proceedings of the SPE Kuwait International Petroleum Conference and Exhibition, Kuwait City, Kuwait, 10–12 December 2012. [Google Scholar]

- Elkatatny, S.M.; Nasr-El-Din, H.A.; Al-Bagoury, M. Properties of Ilmenite Water-Based Drilling Fluids for HPHT Applications. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2013. [Google Scholar]

- Al-Bagoury, M. Micronized Ilmenite—A Non-damaging Non-Sagging New Weight Material for Drilling Fluids. In Proceedings of the SPE Bergen One Day Seminar, Bergen, Norway, 2 April 2014. [Google Scholar]

- Mohamed, A.K.; Elkatatny, S.A.; Mahmoud, M.A.; Shawabkeh, R.A.; Al-Majed, A.A. The Evaluation of Micronized Barite as a Weighting Material for Completing HPHT Wells. In Proceedings of the SPE Middle East Oil & Gas Show and Conference, Manama, Bahrain, 6–9 March 2017. [Google Scholar]

- Ofei, T.N.; Bavoh, C.B.; Rashidi, A.B. Insight into ionic liquid as potential drilling mud additive for high temperature wells. J. Mol. Liq. 2017, 242, 931–939. [Google Scholar] [CrossRef]

- Ahmad, H.M.; Kamal, M.S.; Al-Harthi, M.A. High molecular weight copolymers as rheology modifier and fluid loss additive for water-based drilling fluids. J. Mol. Liq. 2018, 252, 133–143. [Google Scholar] [CrossRef]

- Salager, J.-L.; Forgiarini, A.M.; Antón, R.E.; Quintero, L. Available Know-how in Transforming an Emulsified Drilling Fluid to Be Removed from an Unwanted Location into a Low-Viscosity Single-Phase System. Energy Fuels 2012, 26, 4078–4085. [Google Scholar] [CrossRef]

- Bern, P.A.; Zamora, M.; Hemphill, A.T.; Marshall, D.; Omland, T.H.; Morton, E. Field Monitoring of Weight-Material Sag. In Proceedings of the 2010 AADE Fluids Conference and Exhibition, Houston, TX, USA, 6–7 April 2010. [Google Scholar]

- Sharman, T. Characterization and Performance Study of OBM at Various Oil-Water Ratios. Master’s Thesis, University of Stavanger, Stavanger, Norway, 15 June 2015. [Google Scholar]

- Sharman, T.; Belayneh, M. Dynamic Viscoelasticity and Dynamic Sagging Correlation of Four Oil Based Drilling Fluids (OBM). Int. J. Fluids Eng. 2017, 9, 9–19. [Google Scholar]

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).