2.1. Inspected Specimens

Toray

TM (formerly TenCate

TM) Cetex

TM TC1100 is a high-end cost-effective laminate reinforced with 5 HS, T300JB carbon fibre woven pre-impregnated with thermoplastic semi-crystalline polyphenylene sulfide polymer (hereafter PPS-C laminate) for excellent mechanical properties and outstanding chemical and solvent resistance. Six

plies were hot pressed for a 2 mm-thick,

laminate array. The final laminate is supplied with a thin glass fiber-reinforced PPS matrix top layer to protect a partly metallic assembly against galvanic corrosion. Basic properties are listed in

Table 1 and

Table 2.

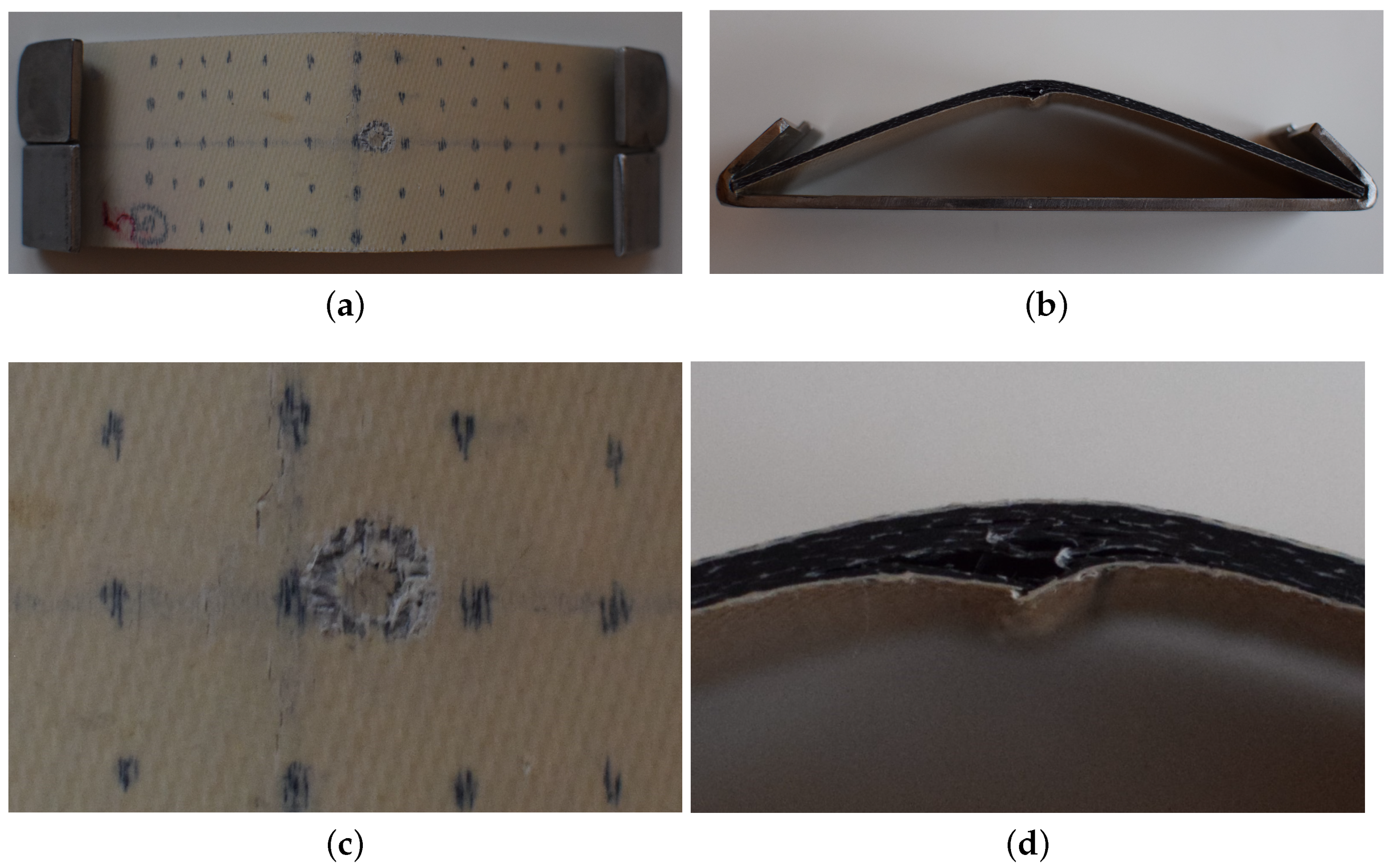

Test specimens with in-plane dimensions of 150 × 45

were carefully machined from the PPS-C laminate and subsequently curved (curvature radius 120

) at ambient temperature. The curve-shaped specimens were permanently stabilized using metallic clamps and subjected to thermal shock cycles. For this purpose, they were repeatedly immersed in boiling water (100

) and liquid nitrogen (

), respectively. They remained immersed for 3 min in each liquid medium to guarantee thermal stabilization. Once they were retrieved from the boiled water contained, they were immediately transferred to the liquid nitrogen one, and vice-versa, to permanently warrant harsh thermal-shock conditions; 150, 300, and 500 thermal-shock cycles were applied to different specimens aiming at simulating thermal conditions experienced by geostationary satellites operating in low-earth orbit (LEO) environment. It is worth mentioning that some specimens were not heat-treated. Finally, the test coupons were transversely impacted (

Figure 1) with air-driven (CBC

TM 5.5 Standard air rifle) caliber

cylindrical lead projectile weighting

, traveling at a speed of 250

/

under ambient temperature. Estimated impact energy was 50

, which approaches typical energies for simulating micrometeoroid collisions [

21] that may lead to severe damage to thin laminate composites. It is worth noticing that some test coupons were not impacted. A total of eight specimens were tested in this work.

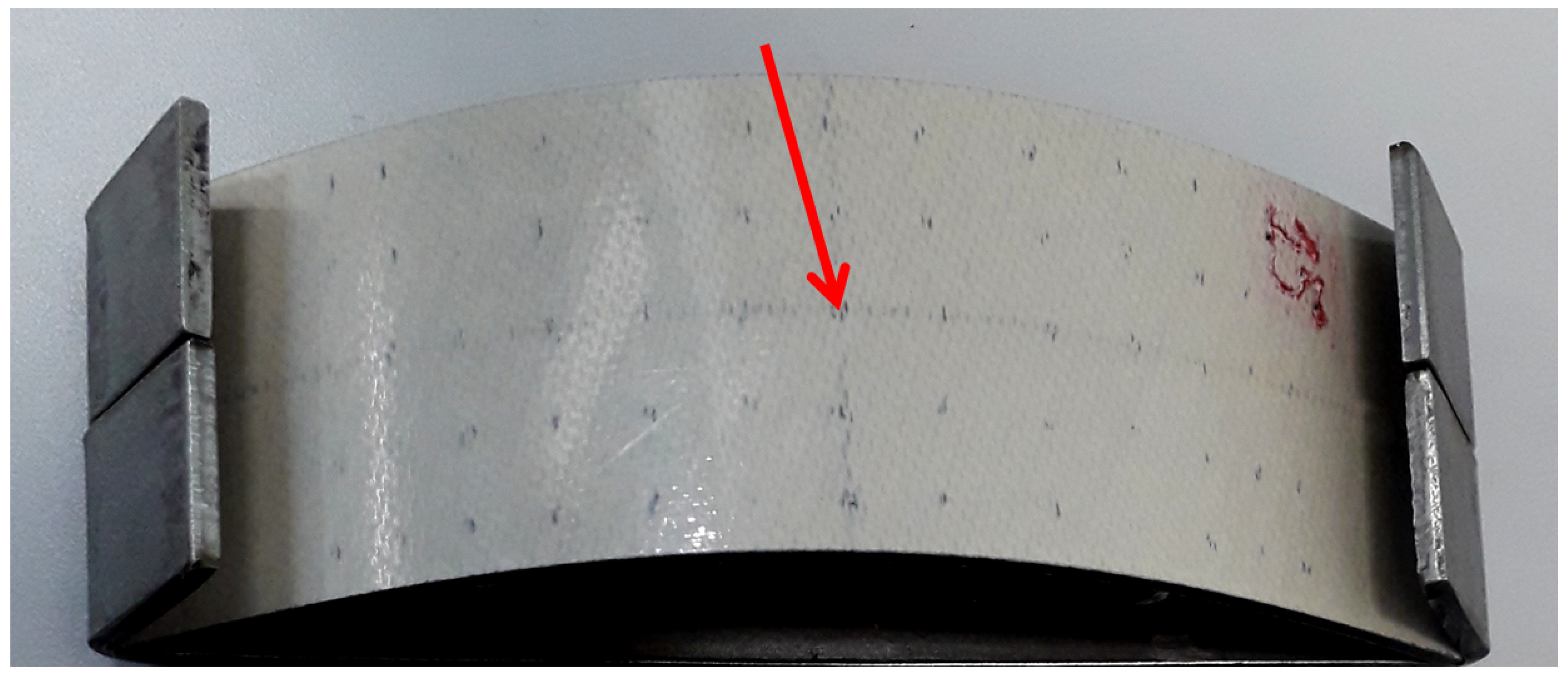

Figure 2 shows a curved specimen previously submitted to 300 thermal-shock cycles followed by impact.

Table 3 lists all inspected specimens.

2.2. Infrared Thermography

NDT&E has been defined as comprising those methods used to examine or inspect a part, material, or system without impairing its future usefulness [

14]. IRT and thermal methods for NDT&E are based on the principle that heat flow in a material is altered by the presence of some types of anomalies. These changes in heat flow cause localized temperature differences in the material surface. Some advantages of IRT are fast surface inspection, ease of deployment, and safety. In the active IRT approach, an external heat (or cold) source is used to produce a thermal contrast between the feature of interest and the background. There are some heat sources that could be used for this purpose. Here, an optical energy source was used.

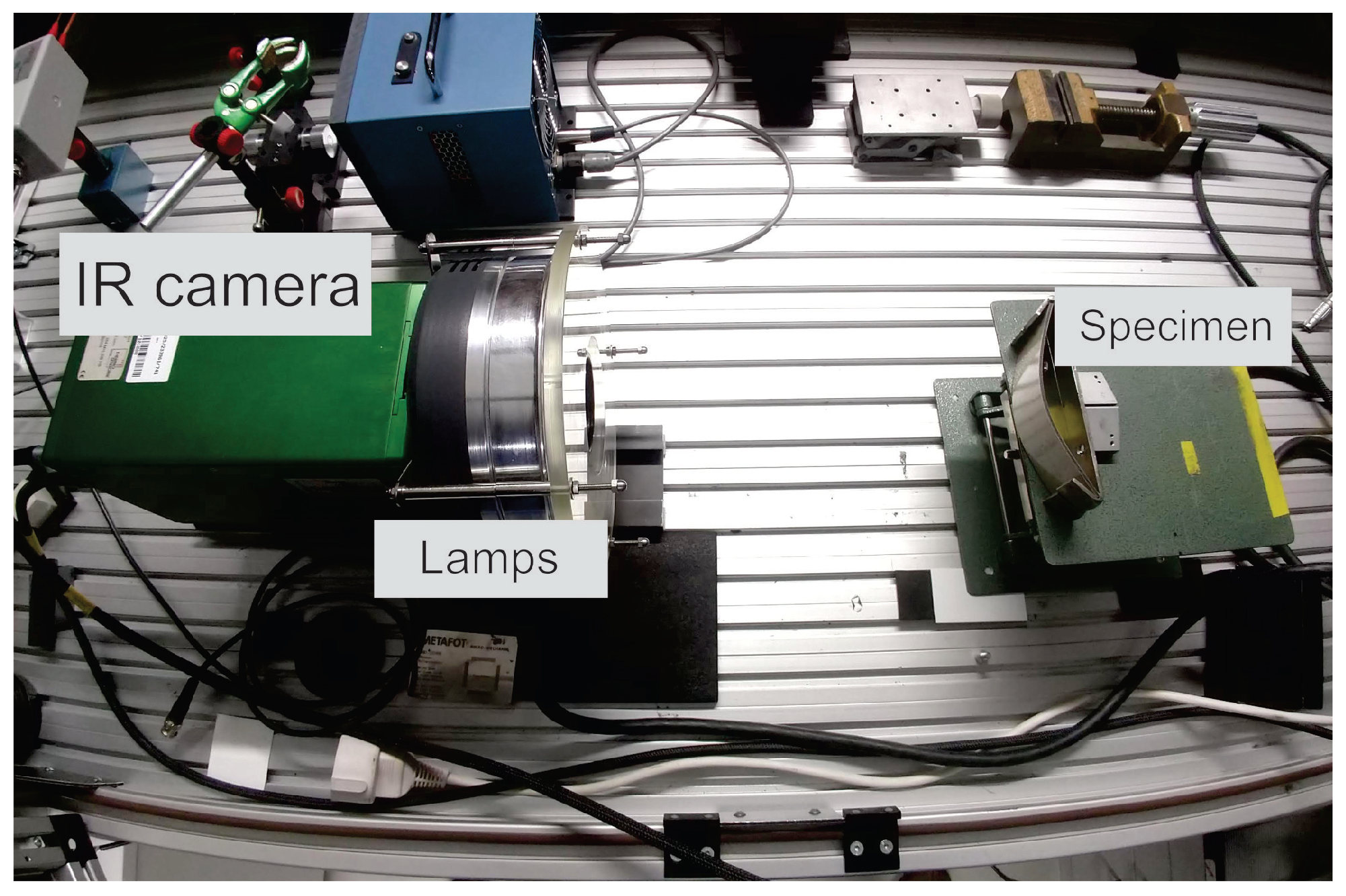

To inspect the specimens, an IR camera equipped with a circular flash acting as an optical energy source was used, as shown in

Figure 3. Both camera and optical energy source were placed in before the target, i.e., reflection mode, and a short flash pulse was triggered while the camera captured a sequence of images during some seconds. This inspection approach is called pulsed thermography (PT) [

22]. A Thermosensorik QWIP Dualband 384 infrared dual-band camera was employed working simultaneously within the

–

(mid-wave infrared-MWIR) and

–

(long-wave infrared-LWIR) bands. A Xenon round flash with maximal 6

was used. A 10

flash ( 3

) was fired while the infrared camera started recording a 7

long video at a frame rate of 150 fps, so that two raw sequences (respectively MWIR and LWIR ranges) were registered. The distance between the camera/flash and the inspected specimen was approximately 29 cm and the surfaces of the specimens were not damaged during the inspections. The entire set-up was surrounded by dark glass where the ambient temperature was

and ambient humidity around 42%. Emissivity of the inspected surface was considered to be around 0.95. All experiments were performed in the same day.

2.3. Thermal Data Analysis

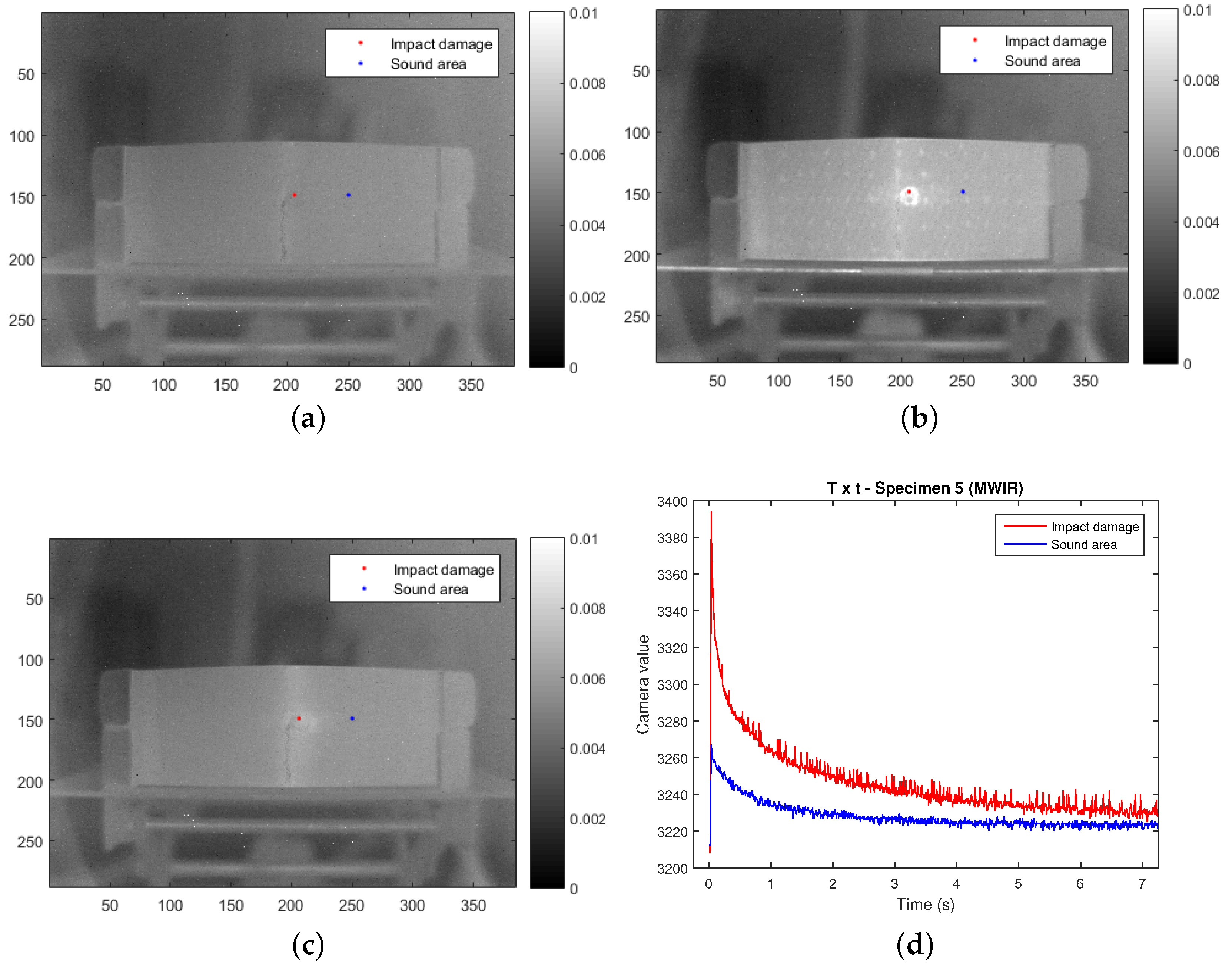

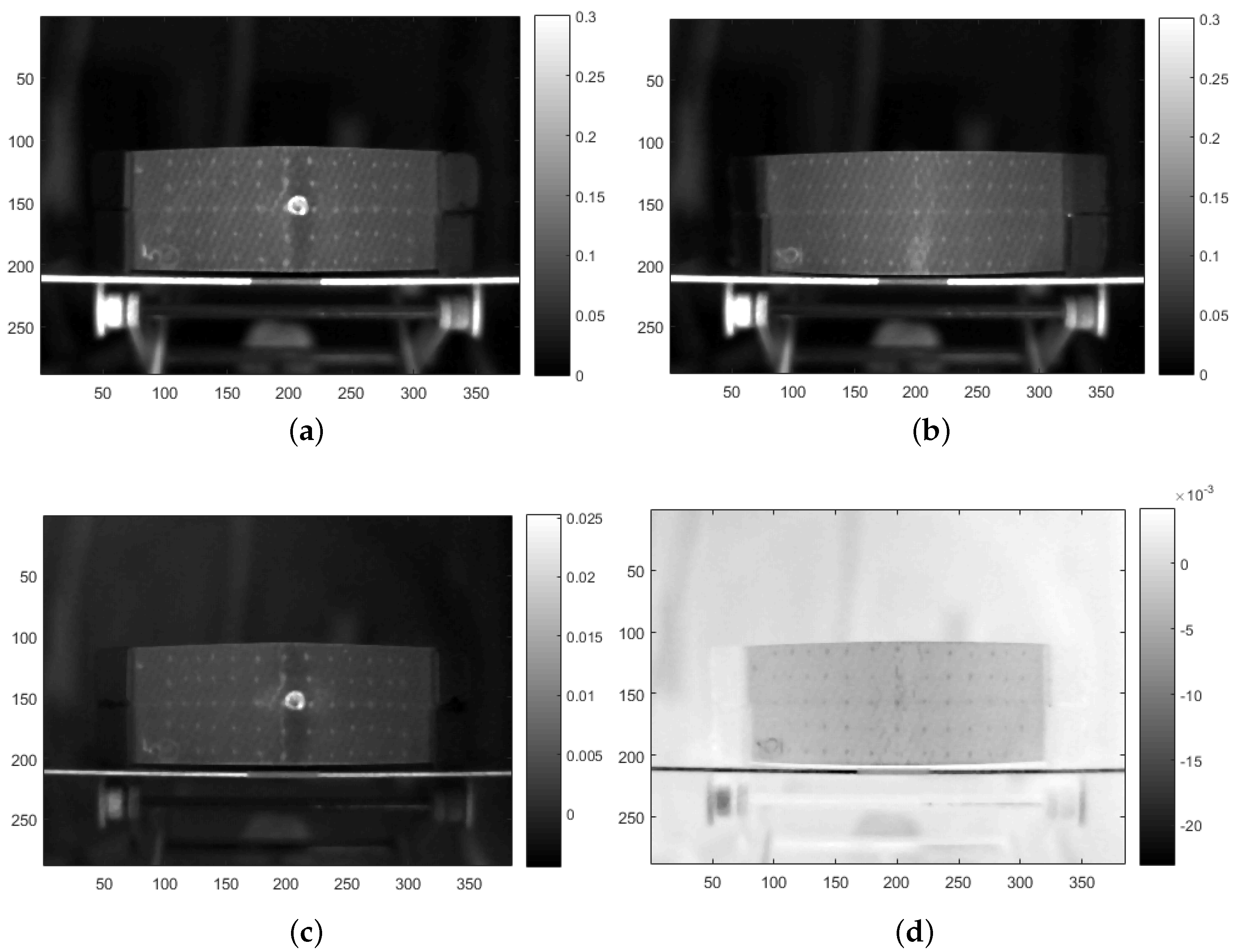

MWIR and LWIR sequences having 1050 images of 288 × 384 pixels are available for each specimen. Examples of a MWIR sequence are provided in

Figure 4.

Figure 4a shows the raw cold image, i.e., the image before flash pulse;

Figure 4b shows the image which corresponds to

after the flash pulse; and

Figure 4c shows the image which corresponds to 3

after the flash pulse. The ballistic impact damage is clearly differentiated from sound areas in the raw image shown in

Figure 4b. Two points, one on the impact area and another on a sound area (red and blue, respectively), are plotted on these images. Temperature profiles of these two points are shown in

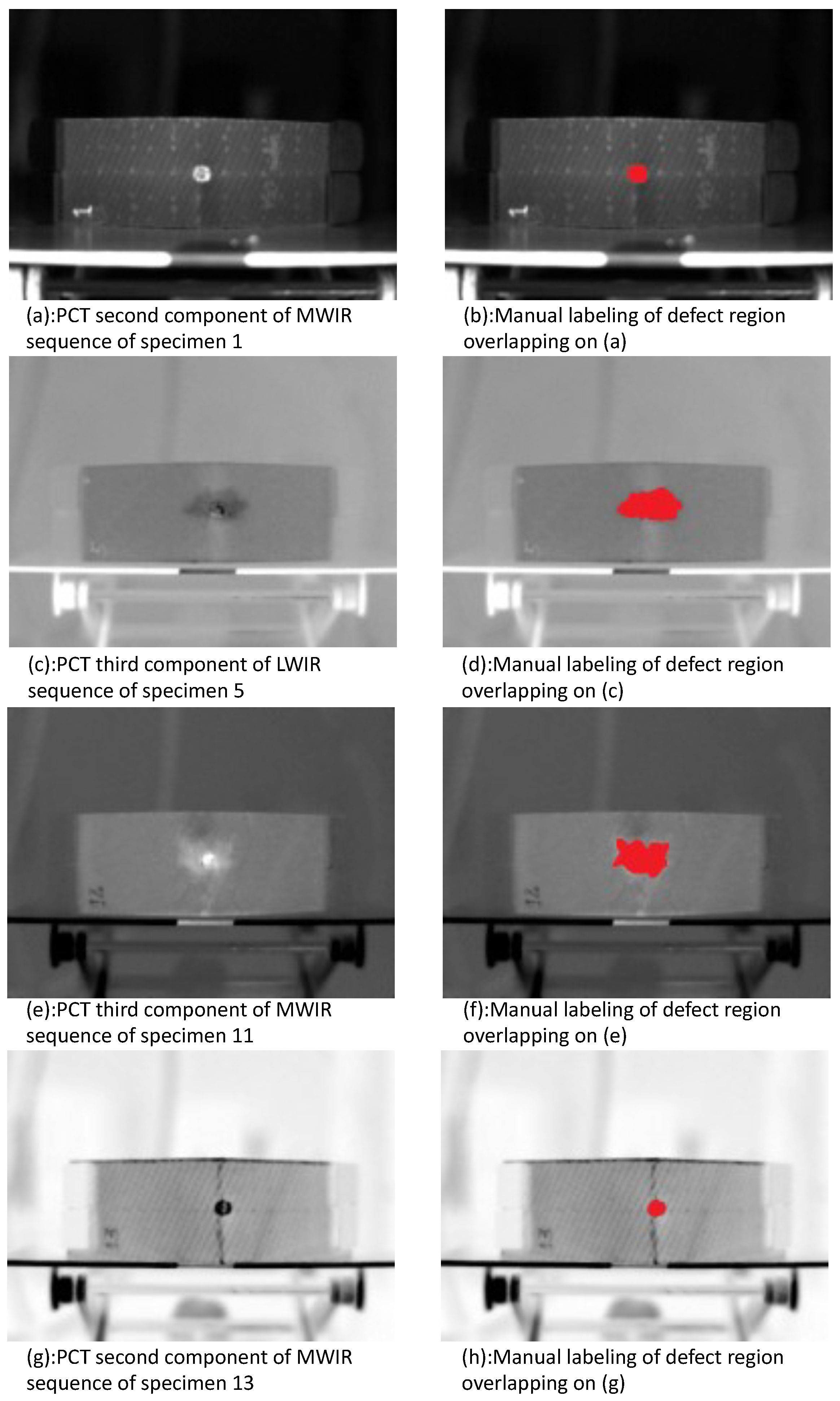

Figure 4d. MWIR and LWIR raw sequences were used to train and test two different deep learning models for impact damage segmentation (one spectral band for each model).

PT is probably the most extensively investigated approach because it is fast (from a few seconds for high conductivity materials to several seconds for low conductivity materials) and easy to deploy. Raw PT data, however, is difficult to handle and analyze. Therefore, some damage could not be identified if one analyzes only the raw IR sequence. There are a great variety of processing techniques available to enhance the subtle IR signatures.

A very simple approach is a thermal contrast technique. Thermal contrast is a basic operation that despite its simplicity is at the origin of most of the PT analysis. Various thermal contrast definitions exist [

14], but they all share the need to specify a sound area

: a non-defective region within the field of view. The absolute thermal contrast

:

where

is the temperature at time

t,

is the temperature of a single pixel or the average of a group of pixels, and

is the temperature at time

t for a sound area. No defect can be detected at a particular time

t if

.

Another processing technique proposed in [

23] is called principal component thermography (PCT). It relies on singular value decomposition (SVD), which is a tool to extract spatial and temporal data from a matrix in a compact manner by projecting original data onto a system of orthogonal components known as empirical orthogonal functions (EOF). By sorting the principal components in such a way that the first EOF represents the most characteristic variability of the data, the second EOF contains the second most important variability, and so on.

The SVD of a

matrix

A, where

, can be calculated as follows:

where

U is a

matrix,

R is a diagonal

matrix (with singular values of

A present in the diagonal), and

is the transpose of a

orthogonal matrix (characteristic time) as proposed in [

23].

Hence, in order to apply the SVD to thermographic data, the 3D thermogram matrix representing time and spatial variations has to be reorganised as a 2D matrix A. This can be done by rearranging the thermograms for every time as columns in A, in such a way that time variations will occur column-wise while spatial variations will occur row-wise. Under this configuration, the columns of U represent a set of orthogonal statistical modes known as EOF that describe the data spatial variations. On the other hand, the principal components (PCs), which represent time variations, are arranged row-wise in matrix . The first EOF will represent the most characteristic variability of the data, the second EOF will contain the second most important variability, and so on. Usually, original data can be adequately represented with only a few EOFs. Typically, an IR sequence of 1000 images can be replaced by 10 or less EOFs.

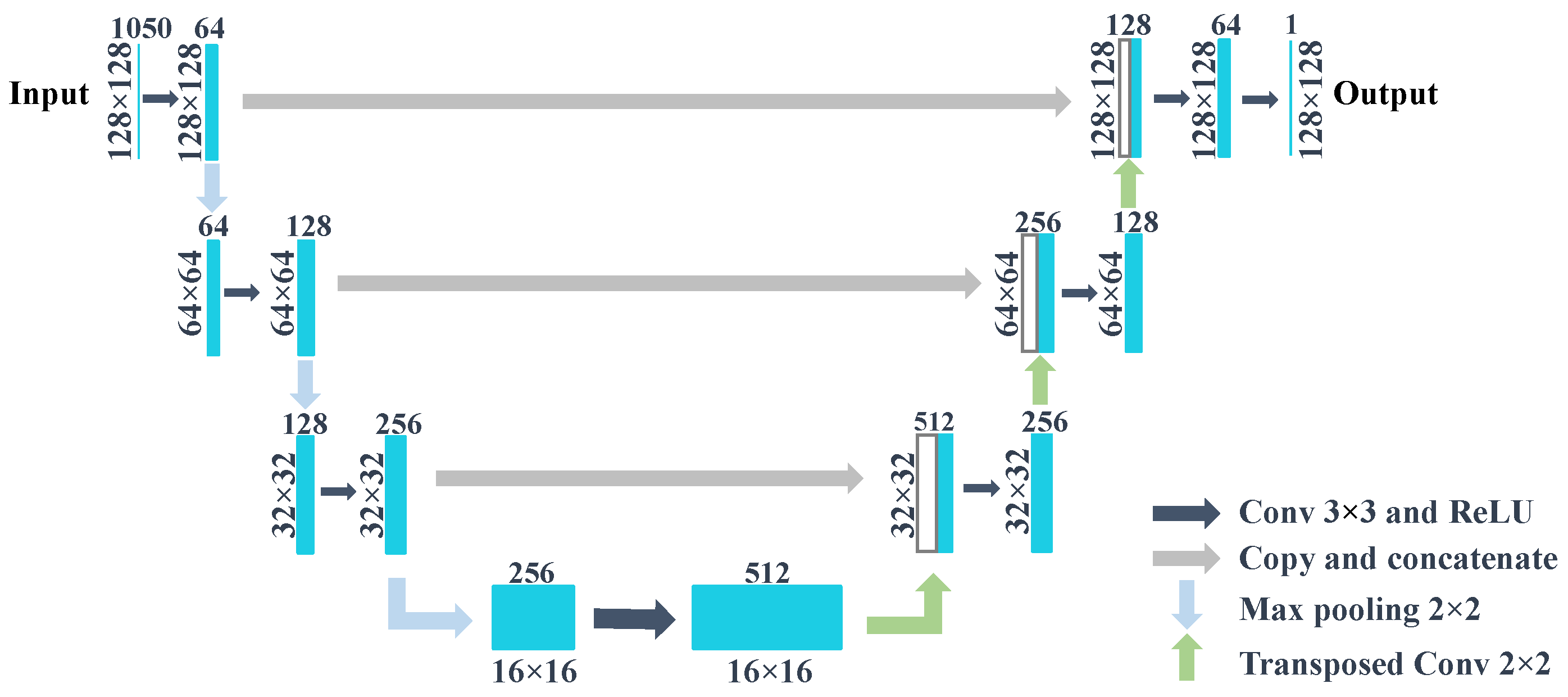

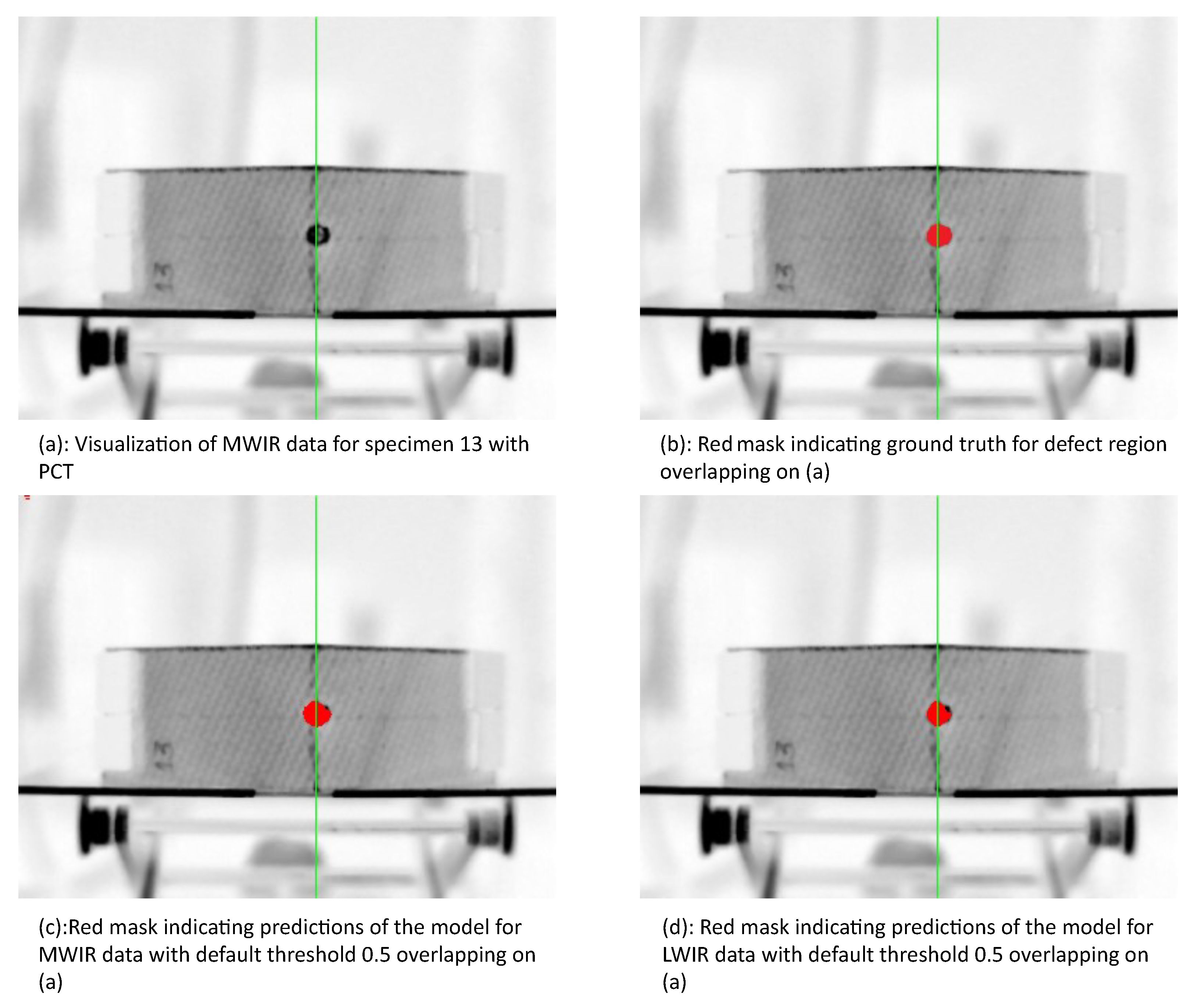

In this study, to correctly label the data for training, PCT was applied for defect visualization enhancement.

Figure 5 shows the second components obtained for specimens 5 (impacted) and 6 (non-impacted) on MWIR data. Even though the first EOF brings the most characteristic variability of the data, it does not brought useful information for damage detection. Therefore, second and third EOFs were used. In general, for PT, the first EOF is affected by the flash pulse being slightly saturated. Thus, second and third EOFs are usually used for the purpose of damage detection. In

Figure 5b we can confirm that there was no damage in the sound specimen, as was expected. The entire extent of the impact damage is clearly visible in

Figure 5a. Results shown in

Figure 5a are from the sequence of images shown in

Figure 5c.

Figure 5c,d shows results for the same specimen but with images from the LWIR data sequence. Impact damage defect shape and position were considered from these images, i.e., PCT results, for network labeling target classes. Other defects are visible in the PCT images, such as cracks and delaminations. In this work, the goal was to segment only the impact damage region.

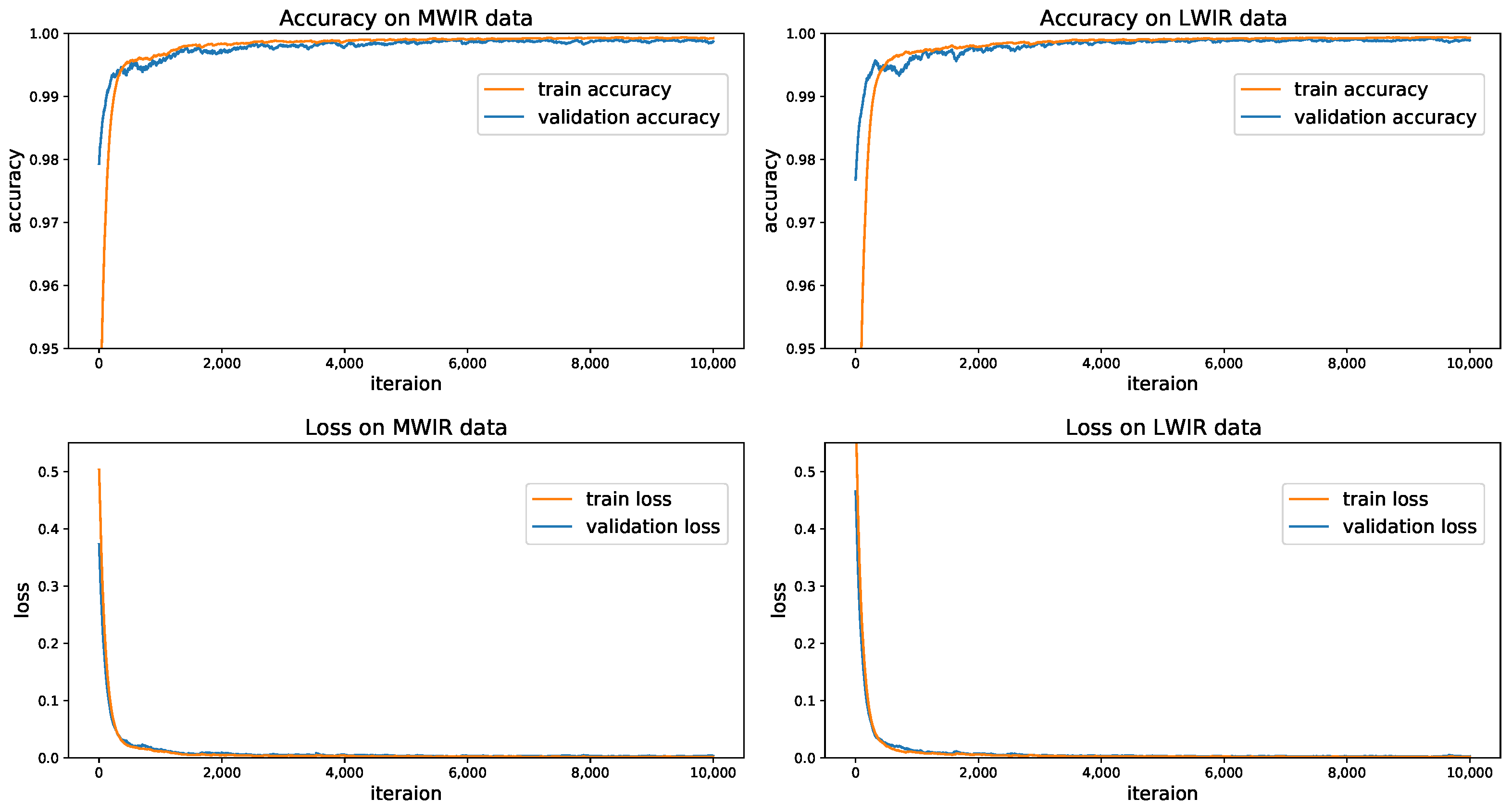

2.6. Model Explainability

Deep learning methods have drawn a lot of attention from the industrial area. The wide scale of deployments in industry, for example, has not yet been realized. One of the main reasons is that in real applications, a rare case that the model has never seen before might happen, and in this case the model’s behavior might be unpredictable. Another important reason is about the deep model’s low level of transparency and explainability. It is hard for end user to fully trust a machine that makes decision based on a black box. However, the deep model’s lack of explainability is due to its complexity. For example, a typical CNN model contains multiple convolutional layers, and each layer is composed of dozens of filters and non-linear activation functions. It is challenging to figure out every detail in the inference process.

Due to its importance, this area has been quite actively researched in recent years [

40,

41,

42,

43]. There are several approaches addressing this problem: visualizing input patches that maximize a output unit activation [

44]; the input attribution method to highlight certain input data areas that contribute the most to a model’s decision [

40,

45]. In this case the layer activation method implemented in the framework Captum [

46] for Explainable AI is applied on the trained model. The layer activation method is simply to compute the activation of each neuron in the identified layer. With this method, layer activation at the end of each step in the U-Net is calculated and visualized. As

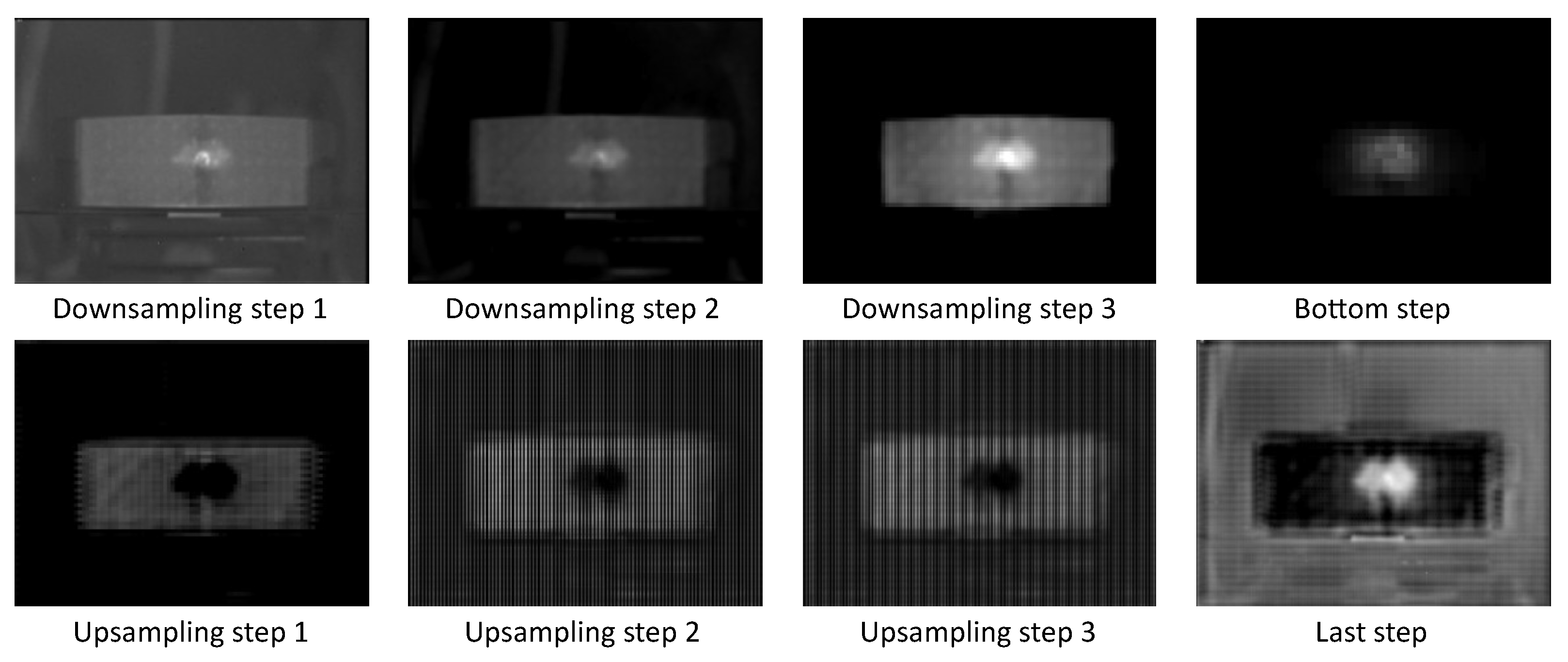

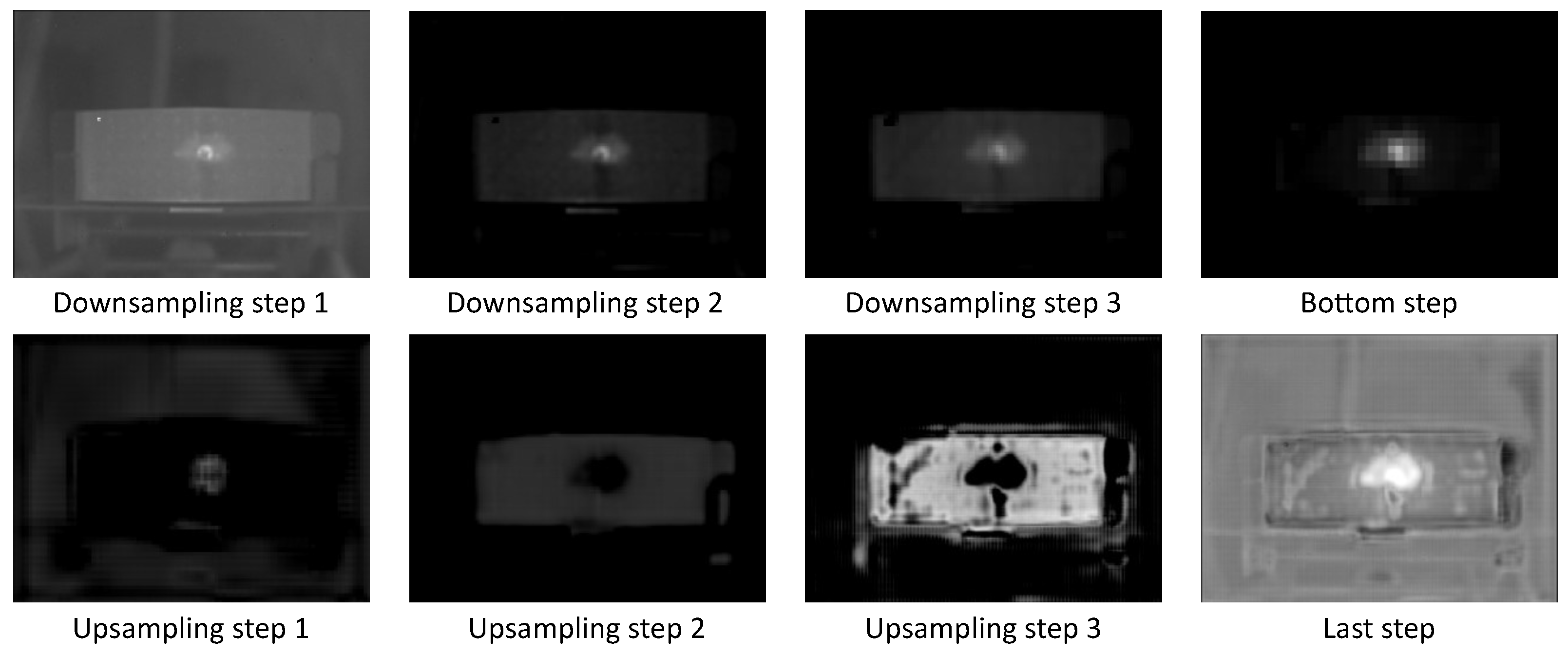

Figure 9 and

Figure 10 demonstrate, the model tends to generate hot spots on the damaged regions. In this way, the inner functionality can be revealed to a certain extent.

Several activation maps are shown in

Figure 9 and

Figure 10. There are eight steps in total over the network, each of which comprises convolutional layer, max pooling or transposed convolutional layer, and a ReLU as activation function. For each step, one of the activation maps was selected and enhanced for visualization. The eight activation maps were able to provide an overview of the data process during both networks’ inferences (the network for MWIR data and the network for LWIR data). The input data for both networks were gathered from specimen 5. The data indicate that after the first step (downsampling step 1), the input image was only seeming to be enhanced, and afterwards the network tended to highlight the central damage spot. Right after the bottom step, the central white spot is the only visible object on the image, which means that the network has already detected the damage location in early steps, and the following steps could be possibly used only to predict the exact boundary of the damage spot. Additionally, the last step output, i.e., the final output of the network, is a reconstructed two-dimensional heat map which describes both the component outline and the damage location.