Abstract

The logistics sector plays a critical role in global trade but faces significant risks due to geopolitical instability, economic downturns, and environmental disruptions. This study investigates risk and crisis management strategies within the logistics industry by integrating qualitative expert interviews with quantitative analysis using the Analytic Hierarchy Process (AHP). It identifies key risks, such as supply chain disruptions, fluctuating market conditions, and infrastructure challenges, and assesses the most effective mitigation strategies. Findings indicate that diversifying transport routes and implementing business continuity planning are the most critical strategies, while technological advancements, including artificial intelligence and predictive analytics, significantly enhance resilience. Collaboration among logistics companies, suppliers, and policymakers is essential for effective crisis management. The AHP analysis ranks crisis management strategies, providing a practical framework for logistics firms to improve risk preparedness. This study contributes to the field by offering actionable recommendations to enhance crisis response and long-term sustainability. The results underscore the necessity of adaptive and proactive risk management approaches in an increasingly volatile global logistics landscape.

Keywords:

logistics; risk; crisis; management; supply; resilience; disruptions; technology; strategy; adaptability 1. Introduction

The logistics sector plays a vital role in global trade, enabling the efficient movement of goods, services, and information across international markets; however, its complexity and interconnectedness expose it to various risks, including geopolitical tensions, economic instability, environmental disruptions, and operational inefficiencies. Effective risk and crisis management strategies are crucial for maintaining supply chain stability in an increasingly uncertain global environment.

Transport operators face considerable challenges in managing large-scale, complex issues while endeavouring to balance cost-efficiency with service quality. The intricate relationships within logistics networks heighten risks, as supply chains depend on multiple stakeholders, infrastructure elements, and external factors such as regulatory changes and weather conditions. Disruptions in one segment can have cascading effects on the entire system, making crisis management a priority [1].

Transportation systems, in particular, display nonlinear characteristics wherein components are deeply intertwined, and the dynamics of each element cannot be isolated. The increasing uncertainty in global supply chains, prompted by trade restrictions, cyber threats, and natural disasters, further complicates logistics management [2].

Technology and digitalisation play a key role in crisis management. The adoption of telematics, artificial intelligence (AI), and predictive analytics was identified as a game-changer for logistics companies. These technologies provide real-time tracking, enhance decision-making, and improve operational efficiency, allowing companies to respond more effectively to unexpected disruptions.

Real-World Examples:

- Artificial Intelligence (AI): DB Schenker deployed AI-driven demand forecasting tools analysing shipping history and weather data, improving load factor by 15% and reducing last-minute capacity shortages [3].

- Blockchain: Maersk and IBM’s TradeLens platform offered customs agencies near real-time access to shipping documentation, cutting border processing times by up to 40% during the COVID-19 disruptions [4].

- Predictive Analytics: DHL’s predictive maintenance using IoT sensors decreased unplanned vehicle downtime by 20%, improving fleet availability during peak periods [5].

- Telematics: Kuehne+Nagel rerouted cargo using weather-integrated GPS data to avoid delays caused by Central European floods [6].

- Digital Twin Simulation: Siemens Logistics used digital twins of warehouse operations to simulate labour shortage recovery scenarios, reducing process reconfiguration time by 25% [7].

Despite these benefits, technology implementation faces barriers, particularly for small and medium enterprises (SMEs). High upfront investment costs, limited internal expertise, and integration difficulties remain substantial obstacles. Additionally, the return on investment for some innovations—especially those like blockchain—may not be immediately apparent to decision-makers.

Recent global events have underscored the vulnerability of logistics networks, emphasising the urgent need for proactive risk mitigation. The COVID-19 pandemic caused significant disruptions, including supply shortages, port congestion, and rising transportation costs. Similarly, climate-related disasters have affected essential infrastructure, prompting logistics firms to adopt more sustainable and resilient practices [8].

Geopolitical tensions in vital trade routes persist, challenging supply chain stability. This underscores the importance of diversification and adaptability. In response, logistics companies are re-evaluating their strategies to bolster resilience and diminish reliance on single-source suppliers.

The evolving risk landscape necessitates a shift from reactive crisis management to proactive risk mitigation. Traditional approaches focus on short-term responses to disruptions, while modern strategies integrate predictive analytics, artificial intelligence (AI), and digital modelling to anticipate and mitigate risks. Decision-making frameworks such as the Analytic Hierarchy Process (AHP) provide structured methodologies for assessing risk factors and optimising resource allocation [1].

As will be discussed further, however, AHP is not without its limitations. Its static nature and dependence on expert judgment emphasise the need for more adaptive and data-driven alternatives in the future.

According to Mizrak [8], logistics companies are implementing various strategic initiatives, including the following:

- Business continuity planning to ensure operational stability during crises;

- Supply chain diversification to mitigate dependency risks;

- Technological innovations, including real-time tracking, blockchain-enabled supply chain management, and AI-driven forecasting.

These tools improve decision-making, enhance risk monitoring, and reduce operational downtime. Nevertheless, challenges persist, including labour shortages, regulatory uncertainties, and ageing infrastructure, which impede the effectiveness of crisis response measures.

Successful crisis management requires co-operation among diverse stakeholders, including industry professionals, policymakers, and emergency response teams. Although these professionals belong to different organisational groups, they share common goals, fostering a collective approach to crisis resolution. Effective collaboration enhances response efficiency and strengthens resilience in the logistics sector [9].

Beyond strategic planning methods, modern logistics increasingly relies on advanced technologies to reduce risk and manage disruptions. Innovations such as artificial intelligence (AI), blockchain, predictive analytics, and digital twins are vital in enhancing visibility, efficiency, and resilience. Understanding how companies integrate these tools is crucial for identifying scalable and effective solutions, especially for small and medium-sized enterprises (SMEs) that often face resource limitations.

This study explores the complexities of risk and crisis management in the logistics sector by integrating insights from expert interviews, literature analysis, and quantitative methodologies. The primary objectives include the following:

- Identifying the most pressing risks affecting logistics operations;

- Evaluating existing crisis management frameworks;

- Highlighting innovative strategies to enhance logistics resilience.

This research aims to provide valuable insights for industry practitioners, policymakers, and researchers by exploring both theoretical and practical perspectives. As the logistics sector continues to navigate an increasingly volatile environment, developing adaptive, technology-driven risk management strategies will be essential for ensuring long-term sustainability and operational efficiency.

2. Literature Overview

2.1. Risk and Crisis Management in the Logistics Industry

Leading logistics companies recognise the importance of identifying risks early to develop appropriate mitigation strategies. They conduct comprehensive risk assessments to evaluate various risks’ potential impact and likelihood, including transportation delays, supplier disruptions, and market volatility [10].

Many logistics companies adopt supply chain diversification and redundancy measures to minimise the impact of supplier disruptions and transportation delays. By partnering with multiple suppliers and maintaining redundant distribution centres or transportation routes, these firms can quickly pivot in the face of unexpected disruptions [11].

Real-time tracking systems, predictive analytics, and AI-powered algorithms enable logistics companies to monitor their operations, detect potential risks, and make data-driven decisions [12].

Recent advancements in digital technologies have transformed the logistics sector’s ability to anticipate and respond to risks. For instance, artificial intelligence (AI) has been increasingly applied to predict demand fluctuations and optimise logistics routing, particularly during post-pandemic disruptions. Similarly, blockchain applications in logistics have proven effective in enhancing transparency, traceability, and supplier trust across fragmented supply chains [13].

Furthermore, logistics firms utilising digital twins and predictive analytics were able to reduce unplanned downtime and make more resilient operational decisions [14].

Logistics companies develop comprehensive business continuity plans (BCPs) to ensure continuity during crises. These plans outline procedures for various crisis scenarios and delineate the roles and responsibilities of employees during emergencies [15].

The logistics industry occupies a pivotal position at the nexus of global commerce, making it vulnerable to a multifaceted array of risks and crises. The complexities of crises compel supply chain managers to develop crisis-induced strategies that differ from the conventional strategy prioritising competitive concerns [16]. Implementing effective risk and crisis management strategies in this sector is crucial for maintaining operational efficiency and protecting the intricate interconnected supply chains that constitute the backbone of contemporary economies. The academic study of risk and crisis management in logistics encompasses a wide range of theoretical frameworks and empirical methodologies, reflecting the inherent complexity and variability of the challenges faced by the industry.

A foundational component of risk management in logistics involves the systematic identification and classification of risks. These risks encompass a diverse range of operational challenges, such as equipment malfunctions and workforce deficits, alongside macroeconomic variables, including trade barriers and fluctuations in currency valuation. Furthermore, environmental vulnerabilities, typified by extreme meteorological phenomena and climate change, have emerged as critical focal points for logistics enterprises striving to ensure continuity and resilience. In response to increasing environmental and operational uncertainties, logistics enterprises must adopt a structured approach that includes risk identification, assessment, and mitigation strategies to ensure sustainable development [17].

Theoretical paradigms in logistics risk and crisis management discourse often draw upon interdisciplinary insights from systems theory, decision sciences, and organisational behaviour. Such frameworks furnish a structured lens through which the propagation of risks across supply chains may be comprehended and the potential interventions capable of mitigating their adverse effects elucidated. For instance, systems theory delineates the interdependencies inherent within logistical networks, wherein disruptions to a singular node may induce cascading repercussions throughout the system. This perspective accentuates the necessity for comprehensive risk assessment and management strategies.

In practical application, logistics firms implement many crisis management techniques to address foreseen and unforeseen disruptions. By utilising the analytic hierarchy process, logistics enterprises can calculate the relative weight of various risk factors, enabling a systematic approach to prioritisation and mitigation [17]. Prominent strategies encompass business continuity planning, which endeavours to sustain operations amid crises, alongside the deployment of advanced monitoring systems facilitating real-time risk detection. Leading logistics companies recognise the importance of identifying risks early on to develop appropriate mitigation strategies. They conduct comprehensive risk assessments to evaluate the potential impact and likelihood of various risks, including transportation delays, supplier disruptions, and market volatility [10]. Moreover, there is a growing trend towards the integration of digital innovations, such as telematics and predictive analytics, to bolster organisational capabilities in anticipating and responding to prospective disruptions.

Historical contingencies and sector-specific challenges have profoundly influenced the trajectory of risk and crisis management within the logistics sector. Notably, the COVID-19 pandemic elucidated the frailties endemic to global supply chains, engendering a reinvigorated emphasis on resilience and adaptive capacity. Similarly, geopolitical tensions and trade disputes have precipitated the adoption of strategies such as supply chain diversification and regionalisation, aimed at ameliorating reliance on singular markets or suppliers.

The academic discourse within this domain has also investigated the significance of collaboration and information sharing among various stakeholders as pivotal elements of effective risk management. Empirical research suggests that partnerships among logistics providers, manufacturers, and governmental entities can markedly amplify the sector’s capacity to navigate crises. Such collaborative efforts facilitate the synergistic pooling of resources, knowledge, and expertise, thereby enabling more coherent and effective responses to disruptions.

In summation, risk and crisis management within the logistics sector constitutes a complex and evolving field that necessitates an amalgamation of theoretical insights and practical applications. As the industry persists in contending with an ever-evolving risk landscape, the incorporation of innovative technologies, robust planning paradigms, and co-operative practices will be indispensable in fostering resilience and ensuring the sustainability of global supply chains.

2.2. Common Risks and Crises Faced by Logistics Companies

The logistics sector is frequently confronted with a diverse range of risks and crises that significantly impinge upon its operational efficiency and sustainability. These risks can be systematically categorised into four principal types: geopolitical, economic, environmental, and operational risks. The logistics industry faces a diverse range of risks, including transportation delays, inventory management challenges, supplier disruptions, regulatory changes, and geopolitical events. Each of these risks can have far-reaching consequences on the timely and cost-efficient delivery of goods, as well as customer satisfaction [18].

Geopolitical crises exert a profound influence on the logistics industry, as they often disrupt established trade routes and supply chains. Illustrative instances include trade sanctions, political instability, and notable events such as the blockage of the Suez Canal, which exemplify the global ramifications of such crises. For example, the 2021 Suez Canal blockage precipitated extensive delays and escalated costs across various sectors, thereby underscoring the inherent vulnerabilities present within global logistics frameworks. Cyberattacks targeting logistics companies’ IT systems and networks can lead to data breaches, operational disruptions, and financial losses. Ransomware attacks, in particular, can paralyse logistics operations and compromise sensitive information, highlighting the need for robust cybersecurity measures and incident response plans [19].

Economic crises constitute another substantial challenge. Market downturns, inflationary pressures, and intensified price competition directly undermine profitability. During economic instability, logistics enterprises frequently experience diminished demand for transportation services, coupled with intensified competition that may lead to unsustainable pricing strategies and subsequent financial distress. Smaller entities, in particular, are disproportionately affected by these dynamics, primarily due to their constrained resources and limited market reach.

Environmental crises, encompassing natural disasters and increasingly stringent environmental regulations, introduce an additional layer of complexity within the logistics domain. Events like earthquakes, hurricanes, floods, or public health emergencies can damage infrastructure, disrupt transportation, and hinder logistics operations. To prepare for such occurrences, logistics companies should develop disaster recovery plans and establish communication protocols to ensure swift response and recovery [20]. Operational risks are endemic within the logistics sector, propelled by labour shortages, infrastructure inadequacies, and rising operational costs. The European logistics sector, for instance, routinely contends with insufficient infrastructure to accommodate burgeoning demand. Furthermore, shortages of qualified drivers and upward pressure on wages exacerbate operational challenges, compelling organisations to rethink their workforce strategies and invest in automation where viable.

The multifaceted nature of these risks necessitates formulating bespoke strategies tailored to effectively mitigate their impacts. While geopolitical and economic risks typically call for diversification and strategic agility, environmental and operational challenges demand concerted long-term planning and investment in innovation. A comprehensive understanding of these disparate risks is critical for logistics firms aspiring to cultivate resilience and sustain competitiveness within an increasingly volatile global environment.

2.3. Risk and Crisis Management Strategies in the Logistics Sector

The implementation of effective risk and crisis management strategies is essential for enhancing resilience and sustainability within logistics enterprises. These strategies encompass both proactive and reactive methodologies designed to tackle the complex risks outlined in previous sections. Key strategies include the following:

Business Continuity Planning. Business continuity planning constitutes a fundamental strategy for logistics organisations to maintain operational stability amid crises. This strategy entails the development of comprehensive contingency plans intended to mitigate potential disruptions within supply chains, transportation systems, and workforce availability. Furthermore, establishing financial reserves represents a critical aspect of business continuity planning, as such reserves empower organisations to absorb the economic shocks resulting from unforeseen events. Scenario analysis, which employs the modelling of diverse crisis scenarios alongside their corresponding impacts, serves as another crucial element of this strategy. Organisations can devise targeted response plans and implement pre-emptive measures by proactively anticipating potential risks. Moreover, crisis simulations facilitate the assessment of organisational preparedness, allowing for the identification of vulnerabilities within existing plans. These proactive measures give logistics companies the requisite tools to respond effectively to crises, thereby minimising operational downtime and sustaining service levels.

Route and Supplier Diversification. Reducing reliance on singular regions, routes, or suppliers emerges as an essential risk mitigation strategy within the logistics sector. Geopolitical tensions, trade restrictions, and natural disasters can severely disrupt supply chains, thereby underscoring the necessity for diversification. By cultivating relationships with multiple suppliers and establishing alternative transportation routes, organisations can mitigate the risk of significant disruptions [11]. Furthermore, diversification enables logistics companies to adapt with greater agility to changes in market conditions or regulatory landscapes. This strategic approach requires a comprehensive understanding of global trade patterns, along with the ability to identify emerging markets and suppliers. In practical application, successful diversification not only involves an expansion of geographical reach but also necessitates the fostering of robust partnerships with suppliers and clients to ensure both reliability and flexibility.

Technological Innovations. The adoption of advanced technological solutions has fundamentally transformed risk and crisis management paradigms within the logistics sector. Tools such as telematics, predictive analytics, and artificial intelligence provide logistics companies with real-time data and insights, thereby enhancing their capacity to detect and respond to emerging risks [12]. Telematics systems offer real-time tracking capabilities for vehicles and shipments, thus improving operational visibility and efficiency. Predictive analytics utilise historical data to foresee potential disruptions, allowing preventative measures to be implemented. Artificial intelligence enhances decision-making processes by analysing complex datasets to identify patterns that indicate risk. Collectively, these technologies empower logistics companies to optimise operational effectiveness, reduce costs, and enhance service quality. Investments in technological innovations are considered a competitive necessity, essential for fostering resilience in an increasingly complex and dynamic risk environment.

Strengthening Collaboration. Collaboration is fundamental to effective risk and crisis management within the logistics sector. Establishing strong partnerships with suppliers, clients, and other stakeholders enhances resilience by promoting resource sharing and co-ordinated responses during crises [15]. Collaborative initiatives can lead to the development of industry-wide best practices and standards, benefiting the broader logistics ecosystem. For instance, alliances with technology providers may accelerate the adoption of innovative solutions, while collaborations with governmental bodies can improve access to critical infrastructure and resources during emergencies. Moreover, collaboration involves transparent communication and information sharing, essential for maintaining trust and ensuring effective co-ordination. By strengthening relationships with key stakeholders, logistics companies can boost their ability to manage risks and recover from disruptions.

Sustainability Initiatives. The commitment to sustainability through investment in green technologies and practices addresses both environmental risks and the increasing demand for sustainable logistics solutions. Sustainability initiatives, including carbon-neutral transportation and the adoption of renewable energy sources, mitigate the environmental impacts associated with logistics operations while simultaneously fulfilling regulatory requirements and consumer expectations [20]. Such initiatives often necessitate substantial initial investments but yield lasting benefits in terms of cost savings, enhanced corporate reputation, and compliance with environmental standards. For example, integrating electric vehicles and alternative fuel sources can significantly reduce greenhouse gas emissions, while energy-efficient warehousing solutions may greatly lower operational costs. Sustainability is increasingly perceived as a competitive differentiator, positioning firms as leaders within a sector under heightened scrutiny from regulators, investors, and consumers alike.

Collectively, each of these strategies plays an integral role in mitigating the repercussions of crises while positioning logistics companies for sustained long-term success. Incorporating these approaches into organisational risk management frameworks ensures that companies retain agility and adaptability in an ever-evolving risk landscape.

2.4. Studies in Literature on Risk Management in the Logistics Sector

Recent studies continue to validate the usefulness of AHP in transportation and logistics decision-making due to its structured approach and clarity [7]; however, the method’s static nature remains a concern, especially in dynamic risk environments. Researchers emphasise that, while AHP facilitates expert-based prioritisation, it may not adequately respond to real-time changes in the business context [7].

To overcome these limitations, scholars have proposed combining AHP with dynamic or fuzzy models that allow for updating priorities based on evolving data inputs and uncertainty factors [21].

Extant research underscores the paramount significance of synthesising qualitative and quantitative methodologies for assessing risks and prioritising strategic initiatives within the logistics sector. Qualitative methods, encompassing expert interviews and case studies, yield profound contextual insights into the distinctive challenges encountered by logistics enterprises, thereby facilitating a nuanced comprehension of risk dynamics. These methodologies frequently elucidate the subtleties inherent in decision-making processes, stakeholder interactions, and organisational behaviours that quantitative models may inadequately address. Scenario planning and simulation exercises are crucial for logistics firms to assess their preparedness for potential crises, allowing them to test response strategies and identify gaps in crisis management plans [16].

Conversely, quantitative methodologies proffer a systematic and data-centric framework for risk assessment and strategy evaluation. Instruments such as the Analytic Hierarchy Process (AHP), Monte Carlo simulations, and multi-criteria decision analysis (MCDA) are frequently utilised to assess the likelihood and repercussions of risks and rank and prioritise management strategies. The study employs the Analytic Hierarchy Process (AHP) method, a widely recognised multi-criteria decision-making technique. AHP enables systematic comparisons and evaluations of risk and crisis management strategies by establishing hierarchies of criteria and sub-criteria [9]. By utilising the analytic hierarchy process, logistics enterprises can calculate the relative weight of various risk factors, enabling a systematic approach to prioritisation and mitigation [17]. Such methodologies empower decision-makers to allocate resources judiciously, optimise operational efficiencies, and mitigate potential losses effectively.

The amalgamation of these methodological paradigms has been delineated as an exemplary practice within the scholarly discourse, as it integrates the strengths inherent in qualitative and quantitative approaches. For instance, qualitative insights can substantiate the formulation of quantitative models, ensuring their fidelity to the complexities of real-world scenarios. Likewise, quantitative findings can corroborate qualitative observations, providing robust evidence support for substantiated decision-making.

Numerous empirical studies have explored the application of integrated methodologies within the logistics sector. Research focusing on supply chain resilience, for instance, has highlighted the benefits of combining scenario analysis with simulation techniques to anticipate and strategise for potential disruptions. While the potential of emerging technologies is well recognised, their adoption among small and medium-sized enterprises (SMEs) remains limited due to high upfront investment costs, lack of in-house experience, and integration challenges. This technological gap raises concerns about uneven resilience across different company sizes and regions, indicating a need for scalable, resource-sensitive solutions. Further studies have underscored the importance of stakeholder collaboration in risk management, employing qualitative data to clarify critical partnerships while utilising quantitative models to assess their consequential impact. Real-time tracking systems, predictive analytics, and AI-powered algorithms enable logistics companies to monitor their operations, detect potential risks, and make data-driven decisions [12].

The extant literature accentuates the necessity for a comprehensive and interdisciplinary paradigm in risk management within the logistics domain. By leveraging qualitative and quantitative methodologies, researchers and practitioners are better positioned to formulate comprehensive strategies addressing the sector’s multifaceted and evolving challenges. An increasing body of research emphasises that risk management strategies are interdependent rather than isolated. For example, telematics optimises route planning and facilitates business continuity planning and collaboration with supply chain partners [22]. This suggests that integrated strategy portfolios offer better protection against compound disruptions than single-strategy approaches. This integrative approach enhances the precision and reliability of risk assessments and facilitates the design of innovative and efficacious crisis management solutions.

2.5. Characteristics of the Logistics Sector

The logistics sector is a fundamental component of global trade, facilitating the seamless transportation and distribution of goods across extensive networks

A key feature of the logistics industry is its pronounced dependence on global market dynamics and geopolitical stability. Global freight volumes exhibited an approximate annual growth of 6% from 2015 to 2020, underscoring the sector’s expansive growth trajectory [23]. Geopolitical risks are inherent in global logistics operations. Political instability, civil unrest, or trade disputes in different regions can affect logistics operations and supply chain routes [24].

The logistics sector also faces intense competitive pressures and elevated operational costs. The competition in the logistics industry is robust, especially in relatively simple processes such as full truckload transportation. Companies engaging in these services face lower profit margins, making cost control a crucial factor in maintaining profitability [9].

Furthermore, driver shortages exacerbate these issues. The International Road Transport Union (IRU) reports a global deficit of approximately 2.6 million drivers by 2021, and Europe experiences a 20% shortfall in the trucking workforce. There is a growing gap between the need for drivers due to increasing transportation demand and the stagnant or even decreasing number of truck drivers [16].

An additional challenge resides in regulatory constraints and infrastructural inadequacies. Changes in trade regulations, customs requirements, or environmental standards can impact cross-border logistics operations, requiring logistics firms to stay updated and compliant with evolving regulations [25].

Despite these challenges, the logistics sector remains dynamic and exhibits a notable capacity for adaptation. Digital transformation can enhance the supply chain stability of businesses by embracing digital applications that provide real-time tracking, AI-based decision-making, and predictive analytics for risk assessment [26].

A pertinent illustration of this trend is Amazon’s investment in robotics and drone delivery systems, which aims to augment last-mile delivery efficiencies. Companies are adopting digital freight matching platforms and blockchain technology to improve supply chain operations’ transparency, security, and efficiency [27].

In conclusion, while the logistics sector is a critical engine of global commerce, it is beset by many challenges that necessitate astute navigation. From geopolitical risks and economic variances to labour shortages and infrastructural constraints, these characteristics delineate the operational landscape of the industry. Managing risk in logistics requires proactive strategies, including contingency planning, supplier diversification, and leveraging digital transformation to enhance resilience [28]. The effective management of these multifaceted elements will ultimately dictate the strength of the sector and its capability to meet the exigencies of an evolving global milieu.

3. Methodology

Python scripts used for data visualisation (including tables and graphs) were partially generated with the assistance of ChatGPT (OpenAI, GPT-4). The authors verified, modified, and implemented all outputs.

This study employs a mixed-methods approach, integrating qualitative insights from expert interviews with a quantitative analysis of the Analytic Hierarchy Process (AHP). Combining these methods allows for a comprehensive understanding of risk management in the logistics sector, balancing real-world perspectives with structured, data-driven decision-making. While AHP provides a systematic framework for prioritising risk factors and crisis management strategies, insights from expert interviews ensure that the findings are grounded in practical industry experience.

This study adopts a mixed-method approach to bridge the gap between qualitative insights and quantitative prioritisation. Integrating expert interviews with AHP analysis is intended to capture contextual expertise and structured decision-making. This combination is particularly relevant in the logistics sector, where risk and crisis management decisions need to be informed by both empirical data and nuanced, experience-based judgement.

3.1. Expert Interviews

Expert interviews were conducted to gather qualitative insights into logistics risk management and crisis response strategies. These interviews provided firsthand perspectives from industry professionals, offering practical knowledge of risk factors, crisis preparedness, and mitigation techniques. The study aimed to capture the most pressing challenges logistics firms face and their strategies for navigating disruptions and enhancing resilience.

Participants were selected based on their expertise and organisational roles, ensuring a diverse representation of the logistics industry. Interviewees included the following:

- Small and medium-sized logistics firms’ managers affected by regional disruptions and financial constraints;

- Executives from multinational logistics companies overseeing global supply chain risk management and strategic crisis response;

- Trade association representatives advocating for policy improvements and industry-wide risk mitigation strategies;

- Technology innovators specialising in AI and telematics-based risk assessment tools;

- Customs officials responsible for regulatory compliance and cross-border trade facilitation.

By engaging a broad set of professionals, the study ensures that its findings reflect multiple perspectives on crisis management, ranging from operational challenges at the ground level to high-level strategic decision-making.

The expert interviews provided insights into the nature of risks affecting logistics, crisis management approaches, and the role of technology in mitigating disruptions. Participants were asked about the following:

- The defining characteristics of the logistics sector, highlighting market volatility, regulatory pressures, and technological advancements;

- Periods of stability versus crisis, emphasising how economic downturns, trade disputes, and pandemics reshape logistics operations;

- Differences between geopolitical, economic, and environmental crises, with interviewees noting varying impacts on trade routes, demand cycles, and compliance requirements;

- Crisis management strategies, including supplier diversification, alternative routing, and digital transformation;

- The role of governments and trade associations focusing on financial aid, regulatory flexibility, and industry collaboration during crises.

Technology was repeatedly highlighted as a key enabler of resilience, with experts emphasising the role of predictive analytics, real-time tracking, and automated risk assessment tools in enhancing crisis preparedness. Many logistics firms invest in AI-driven forecasting models, enabling them to anticipate disruptions and adapt operations in real time.

Furthermore, interviewees highlighted the escalating significance of sustainability, as environmental risks and regulatory pressures urge firms to implement green logistics solutions. Experts also underscored the critical workforce shortages, particularly in truck driving and skilled logistics personnel. They indicated that companies increasingly resort to automation and AI-assisted workforce management to bridge operational gaps.

Interview Questions and Summary of Responses:

- What are the defining characteristics of the logistics sector? The sector is highly dynamic and influenced by global market trends, competition, and operational costs. Challenges include fluctuating demand, regulatory burdens, labour shortages, and technological advancements that require continuous adaptation.

- What constitutes good times and bad times for the logistics sector? Good times are characterised by high cargo demand, strong supply chain continuity, and profitable freight rates. Bad times arise due to economic downturns, increased costs, low cargo availability, and supply chain disruptions.

- What defines a crisis in the logistics sector, and how is it managed? A crisis occurs when supply and demand become misaligned due to external shocks such as geopolitical tensions, pandemics, or economic instability. Management strategies involve business diversification, cost-cutting, and alternative routing.

- Are there differences between geopolitical, economic, and environmental crises? Yes, geopolitical crises (e.g., trade sanctions) affect cross-border operations; economic crises reduce demand and profitability; environmental crises (e.g., extreme weather) disrupt transport networks and increase costs.

- How have geopolitical and economic crises affected your company? Participants highlighted disruptions from trade restrictions, fuel price volatility, and labour shortages. Some companies had to shift their supply chains, adopt new trade routes, or downsize their operations.

- How do governments and trade associations support logistics companies during crises? Governments assist through regulatory adjustments and financial aid, while associations advocate for industry-friendly policies and facilitate knowledge-sharing among companies.

- What crisis management strategies are employed in your company? Strategies include route diversification, supplier and client collaboration, digital transformation, and inventory adjustments to cope with supply chain shocks.

- What innovative solutions are being adopted to improve crisis management? Companies are investing in telematics, artificial intelligence, blockchain for supply chain transparency, and automation to optimise costs and reduce human dependency.

- How would you rank the following crisis management strategies: route diversification, business continuity planning, supplier-client collaboration, and telematics? Participants ranked route diversification as the most crucial, followed by business continuity planning, supplier collaboration, and telematics, aiding operational efficiency.

3.2. Summary of the Interview Answers

The interviews conducted for this study offer valuable insights into risk and crisis management strategies within the logistics sector. Industry experts, logistics managers, and supply chain analysts highlighted several key themes that define the contemporary challenges and solutions in logistics risk management [29].

Expert interview data were transcribed and analysed thematically to uncover repeating patterns, shared themes, and unique insights. The interview findings were compared with results from the literature review and various data sources, enhancing the understanding of risk and crisis management strategies adopted by international logistics firms in Turkey. These industry experts’ insights and practical knowledge play a crucial role in shaping practical risk management approaches within the logistics field. Table 1 contains details about the interviewees who participated in the study.

Table 1.

Details about the interviewees.

One of the most pressing concerns raised by the interviewees is the vast array of risks affecting global logistics operations. Geopolitical risks, economic fluctuations, environmental regulations, and operational inefficiencies were all identified as significant threats to the sector. Political instability, trade disputes, and economic downturns can disrupt supply chains, causing considerable financial and operational setbacks. Furthermore, price competition in the logistics industry is intensifying, making cost control a critical factor in maintaining profitability, particularly for companies engaged in road transportation.

Technology is increasingly vital in mitigating risks within the logistics industry. Interviewees emphasised the importance of digital transformation in enhancing supply chain resilience. Adopting real-time tracking systems, artificial intelligence-driven decision-making, and predictive analytics enables logistics firms to anticipate risks and respond proactively. By leveraging these tools, companies can improve operational efficiency, reduce disruptions, and enhance visibility across the supply chain. Using blockchain technology and digital freight matching platforms also contributes to increased transparency and security in logistics operations.

The logistics sector is also contending with a severe workforce shortage, especially regarding the availability of truck drivers. Many interviewees voiced concerns over the widening gap between the growing demand for transportation services and the declining number of available drivers. This shortage is exacerbating transportation costs and delaying deliveries, adding to the existing pressures on supply chains. Consequently, companies are increasingly investing in automation and alternative workforce strategies to mitigate the impact of labour shortages on their operations.

Crisis management and business continuity planning emerged as key themes in the discussions. Experts emphasised that businesses must adopt proactive strategies to manage supply chain disruptions caused by natural disasters, cyberattacks, or supplier failures. Contingency planning, supplier diversification, and investment in digital transformation are crucial elements of an effective risk management strategy. Companies that fail to implement these measures risk prolonged operational downtime and financial losses in the event of an unexpected crisis.

Regulatory and environmental challenges are also reshaping the logistics industry. Stricter emissions regulations and sustainability initiatives are compelling logistics companies to invest in green technologies and alternative fuel sources. Interviewees noted that these regulatory changes, while necessary for environmental sustainability, demand substantial financial investments and operational adjustments. Businesses must stay informed about evolving trade regulations and compliance requirements to maintain seamless cross-border logistics operations.

Supply chain diversification was repeatedly cited as a crucial adaptive strategy for logistics firms. Experts concurred that relying on a single supplier or transportation route poses a significant risk, as geopolitical tensions, natural disasters, or trade restrictions can severely disrupt operations. Many companies now prioritise diversification by expanding supplier networks, establishing alternative transportation routes, and strengthening collaborative relationships with key stakeholders. This strategic approach enhances flexibility and ensures operational stability during times of crisis.

The interview responses reaffirm the importance of proactive risk management, technological advancements, workforce development, and sustainability efforts within the logistics industry. While labour shortages, geopolitical tensions, and rising operational costs persist, companies can navigate these risks through strategic planning, digitalisation, and collaboration across supply chain networks. The insights from these interviews contribute to a broader understanding of risk mitigation strategies and future industry trends, offering valuable recommendations for logistics practitioners and policymakers.

3.3. Application of the Analytic Hierarchy Process (AHP)

One widely utilised methodology in logistics crisis management is the Analytic Hierarchy Process (AHP). This structured decision-making tool facilitates the systematic prioritisation of risk factors and assists firms in resource allocation [16]. As logistics networks become increasingly complex, with growing interdependencies among suppliers, transportation hubs, and regulatory environments, organisations must adopt multi-criteria decision-making (MCDM) frameworks to evaluate and mitigate risks effectively. The AHP method, initially developed by Saaty [30], enables decision-makers to quantify and compare diverse risk factors, ensuring that resources are allocated to the most critical areas of vulnerability. While the Analytic Hierarchy Process (AHP) provides a structured framework for prioritising strategic alternatives, it has limitations. AHP relies heavily on expert judgement, introducing subjectivity into pairwise comparisons. Additionally, the method’s static nature makes it less suitable for contexts characterised by rapidly changing risk dynamics. In response to these concerns, recent literature suggests integrating AHP with fuzzy logic or adopting dynamic extensions to more accurately reflect real-time variability in logistics environments [21].

Logistics companies face multiple simultaneous risks in crises, ranging from transportation disruptions and inventory shortages to regulatory challenges and geopolitical instability. The AHP framework provides a structured approach for ranking these risks based on their severity, likelihood, and impact on supply chain operations. By using a hierarchical decision model, logistics managers can perform the following:

- Define the problem and criteria—Identify the primary risk categories, such as supply chain disruptions, fuel price fluctuations, labour shortages, or cybersecurity threats;

- Develop a pairwise comparison matrix—Evaluate the relative importance of each risk factor by comparing them in pairs using expert judgement or historical data;

- Calculate weighted priorities—Assign quantitative weights to each risk based on their impact on overall supply chain performance;

- Derive a consistency ratio—Ensure decision-making judgements remain logically coherent and unbiased;

- Determine final risk rankings—Use the computed priority values to allocate mitigation resources efficiently.

A recent study has demonstrated that logistics firms using AHP for crisis response planning could reduce financial losses by up to 35% during supply chain disruptions [17,31]. By systematically prioritising risks, companies could proactively adjust their logistics strategies, redirect shipments, and optimise their warehouse networks.

The study applied AHP in a systematic six-step process to evaluate logistics crisis management strategies:

- Defining the decision problem—Identifying the most effective strategies for mitigating logistics crises;

- Establishing the hierarchical structure—Categorising risk management strategies into core decision criteria (e.g., operational resilience, cost-effectiveness, adaptability);

- Conducting pairwise comparisons—Experts ranked the relative importance of various crisis response strategies using Saaty’s 1–9 scale;

- Calculating priority weights—The relative importance of each strategy was computed using AHP’s mathematical framework;

- Performing consistency checks—Ensuring that expert judgments were logically consistent to minimise bias;

- Ranking the final decision alternatives—Identifying the most impactful risk management approaches based on weighted scores.

The AHP analysis revealed that route diversification was ranked as the most critical strategy, followed by business continuity planning, supplier-client collaboration, and telematics-based risk mitigation. This ranking reflects industry trends, indicating that companies diversifying their supply chains and logistics routes are more resilient to disruptions compared to those relying on single-source suppliers [11].

The findings underscored the increasing significance of digitalisation, with experts identifying telematics and predictive analytics as vital instruments for real-time risk oversight and operational enhancement [2]. Nevertheless, it was observed that financial limitations and implementation expenses continue to hinder the broad adoption of advanced logistics technologies.

While AHP provides a robust framework for decision-making, it is not without its limitations. One of the primary concerns is its dependence on expert judgement, which introduces subjectivity and potential biases. Although consistency checks were performed, expert opinions are still influenced by individual experiences and organisational priorities.

Another limitation is that AHP does not account for real-time variability in risk factors, as it relies on static pairwise comparisons. In rapidly changing environments, such as pandemic-induced supply chain disruptions, alternative decision-making methodologies—such as dynamic simulation models—may complement AHP for more adaptive risk management.

3.4. Integration of Qualitative and Quantitative Insights

By combining qualitative expert insights with AHP’s structured decision analysis, this study presents a holistic approach to logistics risk management. The expert interviews provided industry-specific knowledge, while AHP quantified the relative importance of crisis management strategies, ensuring that recommendations are both theoretically sound and practically actionable. The findings suggest that logistics firms must balance traditional risk mitigation strategies with digital innovations, ensuring their crisis response frameworks are resilient and adaptive. While route diversification and business continuity planning remain fundamental pillars of crisis management, emerging technologies such as AI-driven predictive analytics, blockchain, and telematics are reshaping logistics risk assessment and decision-making [12]. As supply chain risks evolve, future research should explore hybrid decision-making approaches, integrating AHP with machine learning-based risk modelling to enhance logistics resilience in an increasingly uncertain global landscape.

3.4.1. The Boxplot Result Analysis

The Boxplot was chosen as the analytical tool to effectively interpret expert evaluations and their variability. Given its ability to illustrate data distribution, highlight the presence of outliers, and visually represent the dispersion of ratings, the Boxplot provides valuable insights into how experts perceive various risk management strategies. Unlike traditional statistical measures, which can sometimes obscure data variability, Boxplots offer a clear and intuitive way to assess agreement levels among experts. This method allows for a nuanced understanding of the stability and divergence in strategy evaluations, making it particularly useful for identifying consensus-driven approaches and areas requiring further investigation.

The Boxplot is a powerful visualisation tool that facilitates the analysis of data distribution, the identification of extreme values (outliers), and the variation in expert evaluations for each risk management strategy. By providing a graphical representation of data dispersion and central tendency, it enables experts to compare multiple methods in a structured manner. The visual format highlights data consistency and potential anomalies, thereby aiding decision-making processes. Understanding Boxplots is particularly advantageous in risk management, where identifying variations in expert opinions can inform strategic adjustments. This tool clearly represents levels of agreement across different strategies and underscores any significant deviations that may necessitate deeper analysis.

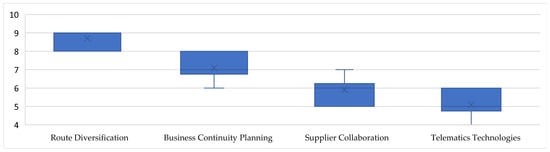

A boxplot visualisation consists of five main components (Figure 1):

- Median (Q2, black line within the box)—This central value indicates that 50% of the data lie above it, while 50% lie below;

- First quartile (Q1, lower edge of the box)—This threshold represents 25% of the smallest values below it;

- Third quartile (Q3, upper edge of the box)—This boundary denotes that 75% of the smallest values lie beneath it;

- Whiskers—Represent the smallest and largest values that are not considered outliers;

- Outliers (points beyond the whiskers)—These values significantly differ from the rest of the data.

Figure 1.

Expert evaluation of risk management strategies.

Understanding these components provides a foundation for analysing the data presented in Table 2. The table summarises the key statistics for each risk management strategy, allowing for a direct comparison of median values, dispersion, and outliers.

Table 2.

Boxplot interpretation based on given data.

The analysis of expert evaluations highlights differences in perception regarding the effectiveness of various risk management strategies. Route diversification was identified as the most crucial strategy, as experts consistently provided high ratings with minimal variation. This suggests a strong agreement among professionals on its importance. Business continuity planning, while also rated positively, exhibited slightly more variation; however, the absence of extreme values indicates a stable perception of its significance.

In contrast, supplier collaboration had a more varied evaluation, reflecting differing opinions on its effectiveness. Some experts assigned lower scores, indicating that this strategy might not be as universally accepted as the previous two. Telematics technologies exhibited the highest degree of dispersion, with certain experts deeming it highly relevant while others assigned significantly lower ratings. The presence of potential outliers suggests that this strategy is more contentious, possibly due to differing levels of technological adoption or sector-specific variations in perceived utility.

Route diversification emerged as the most critical strategy, so it should be emphasised in crisis management planning. The high level of consensus among experts justifies prioritising its implementation. Business continuity planning, with its stable ratings, warrants further investigation into the most effective measures for ensuring operational resilience. Although supplier collaboration received mixed evaluations, additional research is needed to understand why specific experts rated it lower. Identifying these concerns could enhance its perceived value and effectiveness.

Telematics technologies require further scrutiny due to conflicting assessments from experts. Determining whether the variation stems from technological disparities within the sector or subjective differences in evaluations is essential. Understanding these factors will aid organisations in making informed decisions regarding their adoption and integration into risk management frameworks. The insights gained from this box plot analysis can guide policymakers and industry leaders in refining their strategies, ensuring a data-driven approach to crisis management in the logistics sector.

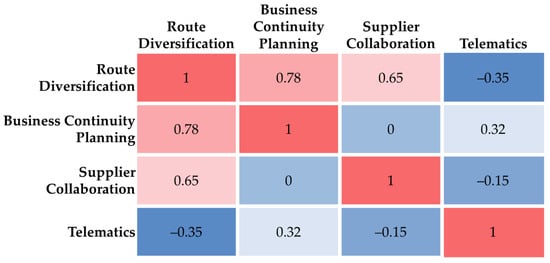

3.4.2. Heatmap Analysis—Correlations Between Risk Management Strategies

A heatmap is a visualisation tool that aids in identifying relationships among different variables. In this case, it illustrates the strength of correlations between various risk management strategies based on expert evaluations. By analysing these correlations, it is possible to comprehend which strategies are commonly employed together and which function independently.

The intensity of colours (Figure 2) in a heatmap represents the strength of correlations between two strategies:

- Red/Orange Shades (close to +1) indicate a strong positive correlation, meaning that, when one strategy receives a high rating, the other is also rated highly;

- Blue Shades (close to −1) indicate a strong negative correlation, suggesting that, when one strategy is rated highly, the other tends to be rated lower;

- Gray/Light Shades (close to 0) indicate a weak or non-existent correlation, meaning the two strategies do not significantly influence each other.

- Correlation coefficients range from −1 to +1:

- +1.0 → Perfect positive correlation (both strategies always increase or decrease together);

- 0.0 → No correlation (strategies are independent);

- −1.0 → Perfect negative correlation (when one strategy increases, the other continuously decreases).

Figure 2.

Correlation between risk management strategies.

These correlations (Table 3) provide valuable insights into how different experts perceive risk management strategies.

Table 3.

Heatmap correlation result.

These correlations provide valuable insights into how different experts perceive risk management strategies. A strong positive correlation, such as the one between route diversification and business continuity planning, suggests that these strategies are often implemented together. Conversely, weak or negative correlations, such as the one between route diversification and telematics, indicate that these strategies are viewed as alternatives rather than complementary measures.

The strong correlation between route diversification and business continuity planning indicates that companies adopting one of these strategies are likely to gain benefits from incorporating the other. Supplier collaboration is somewhat linked to route diversification, yet it does not demonstrate a significant connection with telematics or business continuity planning, suggesting that firms perceive supplier networks more as a strategic asset than as an operational tool.

Telematics, in contrast, has low or negative correlations with other strategies. This indicates that it is not widely perceived as a core risk management method but rather as an auxiliary tool for operational processes. While telematics is valuable, it is not yet fully integrated into crisis management frameworks.

Organisations that adopt route diversification should also prioritise business continuity planning, as these strategies complement one another. Strengthening supplier collaboration can further enhance diversification efforts, thereby making supply chains more resilient. Given its weak correlation with other strategies, telematics should be integrated more actively into crisis management processes to enhance its strategic relevance. Additionally, businesses should carefully consider negative correlations, as they may suggest that some strategies are employed as alternatives rather than complementary measures.

Heatmap analysis offers valuable insights into the interrelationships among various risk management strategies. The strongest positive correlation is evident between route diversification and business continuity planning, underscoring their complementary nature. In contrast, telematics solutions seem less linked to strategic crisis management methods, indicating a potential area for further integration. These findings can assist businesses in making data-driven decisions about how best to combine risk management strategies for optimal resilience.

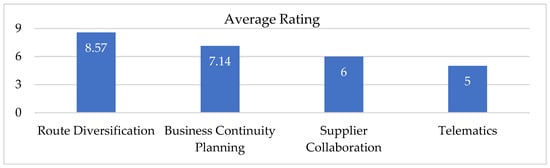

3.4.3. Bar Chart Analysis—Expert Evaluation Comparison

A bar chart visualisation (Figure 3) enables the comparison of average risk management strategy ratings based on expert opinions. It provides a straightforward method to identify which strategies are most important and rated lower.

Figure 3.

Bar chart analysis.

Understanding the Bar Chart

- X-Axis (Horizontal) represents risk management strategies (Route Diversification, Business Continuity Planning, Supplier Collaboration, Telematics);

- Y-Axis (Vertical) displays the average expert rating, ranging from 1 to 10 (higher values indicate a strategy is considered more important);

- Bars: The taller the bar, the higher the perceived importance of the strategy.

Table 4 presents the average ratings assigned by experts for each risk management strategy. These ratings reflect each strategy’s perceived effectiveness and significance in mitigating risks within the logistics sector. By examining these scores, organisations can better understand the most valued approaches and prioritise their implementation accordingly.

- Route Diversification—Average: 8.57This strategy received the highest rating from all experts, indicating that most specialists believe alternative supply routes are vital for managing logistics risks.

- Business Continuity Planning—Average: 7.14This strategy was rated highly but slightly lower than route diversification. While business continuity planning is crucial, it is frequently viewed as a supplementary measure rather than a primary approach to crisis management.

- Supplier Collaboration—Average: 6.00Supplier collaboration received a moderate rating, indicating that experts perceive this strategy as beneficial, though not universally essential. This may imply that some companies depend more on internal processes than on external suppliers in times of crisis.

- Telematics—Average: 5.00Telematics received the lowest rating, indicating that most experts do not view it as a primary crisis management solution. This may suggest that, while telematics is advantageous for operational improvements, it is not considered a critical risk reduction measure.

Table 4.

Expert evaluation result (average ratings).

Table 4.

Expert evaluation result (average ratings).

| Strategy | Average Rating |

|---|---|

| Route Diversification | 8.57 |

| Business Continuity Planning | 7.14 |

| Supplier Collaboration | 6.00 |

| Telematics | 5.00 |

The findings suggest that route diversification is considered to be the most vital strategy. This implies that companies ought to concentrate on developing alternative supply routes to effectively mitigate risks. Business continuity planning and supplier collaboration are viewed as moderately important measures, indicating that, while they offer value, companies may function without them depending on the situation.

Telematics is regarded as the least significant for crisis management, suggesting that this technology is mainly employed for daily operational efficiency rather than as a strategic risk mitigation tool.

Organisations should prioritise investments in route diversification, as it is regarded as the most effective strategy for managing logistics crises. Business continuity planning should be included as a supplementary measure but not necessarily as the primary approach to crisis management. Supplier collaboration should be considered an additional strategy but not the central method of risk mitigation, as expert opinions on its importance differ. Lastly, telematics should be employed to enhance operational improvements but should not be depended upon as a primary tool for risk management.

The bar chart analysis clearly illustrates that experts prioritise route diversification as the primary measure for risk reduction. Business continuity planning and supplier collaboration are deemed valuable but are not universally considered essential. Telematics is rated the least significant, indicating that, while it benefits daily operations, it does not play a major role in strategic crisis management.

While diverse in terms of professional background (including customs officers, logistics providers, and technology vendors), the expert sample remains limited in size and geographic scope. The findings should be interpreted cautiously when generalising to the entire logistics industry. Future studies could expand the sampling frame to include a broader range of regions and subsectors, thereby enhancing external validity.

The methodological triangulation in this study enhances the reliability of findings by combining qualitative depth with quantitative rigour. Expert interviews provide critical contextual insights and aid in structuring the AHP hierarchy, while the AHP technique ensures consistency in evaluating and ranking strategic alternatives. This approach reflects a growing consensus in logistics research on the value of hybrid methodologies in complex decision environments.

3.5. Findings

The study highlights key risk factors and the logistics sector’s most effective crisis management strategies. Integrating expert insights and AHP analysis provided a comprehensive understanding of sector vulnerabilities and solutions. The primary findings are as follows:

- Geopolitical and Economic Crises Are the Most Disruptive: Experts agreed that geopolitical tensions, such as trade sanctions and political instability, and economic downturns, such as inflation and global recessions, pose the greatest threats to the logistics sector. These crises create supply chain disruptions, increase operational costs, and force companies to seek alternative markets and routes.

- Diversification of Transport Routes and Suppliers Is Crucial: Route diversification emerged as the most effective strategy in mitigating disruptions caused by geopolitical and economic crises. Companies that diversified their supply chains and transportation networks were better positioned to navigate crises with minimal disruptions.

- Business Continuity Planning Enhances Resilience: The study identified business continuity planning as a critical factor in maintaining stability during crises. Companies with robust contingency plans, including financial reserves and alternative logistics arrangements, were more adaptable and less vulnerable to market shocks.

- Technology and Digitalisation Play a Key Role in Crisis Management: The adoption of telematics, artificial intelligence (AI), and predictive analytics was identified as a game-changer for logistics companies. These technologies provide real-time tracking, enhance decision-making, and improve operational efficiency, allowing companies to respond more effectively to unexpected disruptions.

- Clear Link Between AHP Results and Practical Significance: The AHP method showed that transport route diversification ranked highest among strategies. This is practically significant because firms able to quickly redirect cargo flows (e.g., from rail to sea or from sanctioned to alternative regions) can mitigate revenue loss and meet service level agreements. As the second-highest-ranked strategy, business continuity planning underlines the importance of financial and operational foresight in maintaining resilience.

- Need for More Critical Reflection on Results: Although all four strategies—diversification, continuity planning, collaboration, and telematics—ranked as important, some are more resource-intensive and harder to implement for SMEs. While AI offers benefits, its adoption is constrained by data availability and skilled workforce shortages, which suggests that technological strategies must be adapted to firm size and maturity.

- Empirical Evidence Still Limited: The expert insights provided rich qualitative data, but future research should expand empirical validation through quantitative surveys or case study analysis across subsectors (e.g., air, maritime, last-mile delivery).

- Literature and Methodological Enhancement: The article draws on relevant literature, but additional references published after 2020 on logistics digitalisation and crisis response tools (e.g., resilience frameworks, dynamic modelling) would enrich the discussion. For instance, recent research into dynamic AHP models or real-time scenario simulations could offer paths for overcoming static AHP limitations.

These findings highlight the importance of proactive and adaptive risk management strategies in ensuring the resilience of the logistics sector. By implementing the prioritised strategies and acknowledging contextual constraints, companies can better withstand crises and maintain competitiveness in an increasingly volatile global market.

4. Discussion

While previous studies have explored risk and crisis management in logistics, this study offers an integration of qualitative expert insights with structured decision analysis using the Analytic Hierarchy Process (AHP). Unlike traditional conceptual or single-method studies, our paper applies a hybrid methodology, combining semi-structured interviews with AHP, Boxplot, and heatmap analysis, which have rarely been jointly applied in logistics resilience literature.

Experts have evaluated risk management strategies in the logistics sector, which have revealed clear trends and significant insights. Route diversification has been identified as the most critical strategy for ensuring supply chain stability, with minimal variation in expert opinions. This consensus suggests a widespread understanding that reliance on a single supplier or transport route presents the most significant risk to the supply chain, particularly amid geopolitical disruptions. These findings align with Azadegan et al. [11], who emphasise that dependence on a single supply channel heightens vulnerability in logistics. The 2021 Suez Canal blockade is a clear example, highlighting how a single logistical bottleneck can disrupt global supply chains [32].

Business continuity planning (BCP) also received high ratings, although expert opinions on its importance varied slightly. Some respondents deemed it a critical component of crisis management, while others regarded it as an additional, though not primary, strategy. This discrepancy may stem from differences in organisational capacity—BCP is most effective in larger enterprises with well-defined risk management frameworks. In contrast, smaller logistics companies may prefer flexible, cost-effective solutions. This finding aligns with Durugbo and Al-Balushi [16], who discovered that, while BCP enhances resilience, its implementation often depends on available resources.

Supplier and customer collaboration received a moderate rating; however, expert opinions were divided. Some specialists emphasised that close co-operation between suppliers and customers fosters stability during crises, while others contended that it does not always prevent significant supply chain disruptions. This aligns with findings by Sydnes et al. [9], who suggest that the effectiveness of supplier collaboration depends on the nature of the crisis. For instance, during the pandemic, strong supplier-buyer relationships preserved supply chain stability, whereas, in geopolitical crises, companies tended to prioritise alternative sourcing over strengthening ties with existing partners.

Interestingly, experts rated the significance of telematics and technological solutions lower than other strategies, despite their frequent emphasis in academic literature as key innovations. Gutierrez-Franco et al. [12] suggest that real-time monitoring systems, AI-driven forecasting, and blockchain technologies facilitate rapid responses to supply chain disruptions; however, our study found that logistics companies predominantly concentrate on traditional risk mitigation methods, perceiving technological innovations as supplementary rather than primary tools for crisis management. Experts noted that the high costs of implementation, uncertainty regarding long-term returns, and reluctance to depend on automated solutions in critical situations fully contribute to this disparity between theoretical emphasis and practical application.

A cross-analysis with literary sources was conducted to validate empirical findings to further ascertain how expert assessments align with or contradict existing research. The heatmap analysis revealed significant correlations between crisis management strategies. Expressly, it indicated that business continuity planning and route diversification are closely linked strategies, supporting the findings of Panjehfouladgaran and Lim [18], who suggest that companies with robust BCP frameworks often invest in supply chain diversification, as these elements operate synergistically in crisis management. In contrast, telematics solutions and supplier collaboration exhibited weaker correlations, implying that these strategies are generally implemented independently.

The AHP results demonstrated that the perceived importance of crisis management strategies varies according to organisational context and financial resources. Feng and Cui [20] analysed environmental challenges in logistics and found that, while technological solutions are essential for risk mitigation, companies often lack the financial and operational capacity for widespread implementation. This finding explains why experts in our study did not rate telematics and AI-driven technologies higher.

The AHP-based prioritisation results guide logistics decision-makers navigating increasingly complex risk environments. The top-ranked strategies—such as transportation route diversification and business continuity planning—reflect immediate operational imperatives, particularly during geopolitical disruptions or infrastructure breakdowns [7]. It is essential, however, to recognise that these strategies do not function in isolation. Technological solutions like telematics and AI-powered tracking enhance both operational visibility and supply chain collaboration, indicating that risk mitigation strategies are interdependent and mutually reinforcing [22]. At the same time, the practical implementation of advanced technologies remains uneven across the sector. Small and medium-sized enterprises (SMEs) encounter significant barriers, including limited investment capacity and a lack of in-house expertise [14]. Consequently, resilience may become concentrated among large players, which could increase sectoral inequality. Policymakers and industry associations may need to consider collaborative digitalisation initiatives or targeted support for SMEs [29]. Methodologically, while the AHP framework offers clarity and structure, its static nature and reliance on subjective pairwise comparisons can limit adaptability in rapidly changing environments [21]. Future research should explore dynamic or fuzzy-enhanced AHP models and aim to expand the empirical base to include diverse regions and stakeholder groups, thereby increasing the robustness and generalisability of strategic insights.

Expert assessments and literature reviews affirm that route diversification and business continuity planning remain critical factors in crisis management; however, while technological solutions possess significant potential, their adoption continues to be secondary to more established crisis management methods. This indicates that, although innovations can provide a competitive edge in the long term, logistics companies prioritise strategic and structural crisis management approaches that ensure supply chain stability during periods of uncertainty.

We fully recognise the limitations of a small qualitative sample. The seven expert interviews were not intended to provide statistical generalisability but to inform the qualitative structuring of the AHP model, helping to ground it in the lived experiences of professionals from various stakeholder groups (customs, international carriers, technology providers, national associations).

We believe that, although modest in size, the qualitative sample enhances the interpretive depth of the AHP structure and aligns with accepted practice in early-stage hybrid-method studies.

5. Conclusions

The logistics sector is essential in sustaining global commerce, ensuring the smooth movement of goods and services across international markets. This study has investigated both theoretical frameworks and practical applications for mitigating these risks, highlighting the need for proactive and adaptive approaches to ensure resilience in logistics operations.

This research highlights that route diversification is crucial in safeguarding supply chain stability among the various crisis management strategies. Logistics networks that rely on single-source suppliers, limited trade routes, or inflexible operational structures face increased exposure to disruptions. Conversely, companies that adopt diversification strategies—establishing alternative trade corridors, engaging multiple suppliers, and utilising multimodal transport options—exhibit greater adaptability and resilience during crises. The expert evaluations in this study reinforce the prevailing view that diversification serves as a cornerstone of crisis mitigation, allowing logistics firms to adjust to evolving risks and swiftly maintain operational continuity.

Another key strategy identified in this study is business continuity planning, ensuring companies remain prepared for potential disruptions. Business continuity planning encompasses structured risk assessments, contingency planning, and crisis simulations, enabling firms to minimise operational downtime during unforeseen events. Although expert opinions on business continuity planning varied depending on organisational size and industry sector, the findings suggest that companies with well-defined continuity frameworks are better positioned to navigate crises effectively. Larger enterprises, in particular, benefit from formalised business continuity plans that incorporate predictive risk assessment models, financial contingency measures, and workforce preparedness programmes. For small and medium-sized logistics firms, however, resource constraints often limit the scope of business continuity planning, rendering flexibility and cost-effective crisis responses more essential.