1. Introduction

Pressure swing distillation (PSD) is a thermally driven separation method extensively used for breaking azeotropes and separating close-boiling mixtures [

1]. It is based on the principle that the azeotropic compositions of certain azeotropic mixtures are pressure-sensitive, which implies that a little change in pressure can significantly alter the azeotropic components of the azeotropic mixtures [

2]. PSD is feasible when there is a minimum 5% variation in azeotropic composition within a pressure range of up to 10 atm [

3]. While PSD has been established in both bulk chemical production and specialty chemical sectors, its inherent dependency on large thermal gradients and high energy input leads to significant inefficiencies and environmental concerns [

4]. Globally, the distillation sector is estimated to account for over 40% of total process heat consumption in chemical manufacturing [

5]. This demand is often satisfied through the use of fossil fuel-derived steam, exacerbating greenhouse gas (GHG) emissions [

6].

Several strategies have been proposed to address the energy burden of PSD. Process intensification techniques such as heat integration, thermal coupling, and column stacking have shown that considerable reductions in steam demand are achievable [

7]. Heat integration between the high-pressure and low-pressure columns allows waste heat recovery from the condenser of one column to supply the reboiler of the other, cutting energy consumption without altering separation performance [

8]. Similarly, thermal coupling and side rectifiers can improve thermodynamic efficiency by reducing entropy generation across column sections [

9]. While these approaches represent important steps forward, they still depend largely on steam as the primary energy source, limiting their contribution to long-term decarbonisation goals.

In the era of decarbonisation, electrification offers a promising route to transform traditional distillation practices [

10]. Electrification offers both operational flexibility and environmental benefits. By replacing steam-driven reboilers with electricity-powered alternatives such as heat pumps, electrification enables the use of renewable energy sources to power distillation. Heat pump-assisted distillation, in particular, is attractive because it not only substitutes the energy source but also recovers and upgrades low-grade waste heat to useful high-temperature duties [

11,

12]. This dual benefit directly lowers primary energy demand while significantly reducing CO

2 emissions when coupled with renewable electricity [

13].

Process control has been widely applied to distillation columns and other heat-integrated systems. Gopichand et al. [

14] designed a mechanical heat pump-assisted distillation system for separating ethanol from 7% aqueous mixtures and demonstrated that heat exchangers could enhance flexibility and control of column operation. Similarly, Annakou and Mizsey [

15] investigated a propylene–propane splitter assisted by a vapour recompression heat pump, comparing single- and double-compressor schemes with a conventional column, and evaluated operability using degrees of freedom and steady-state controllability analyses. They found both schemes to be approximately 37% cheaper, with the double-compressor offering superior operability and reducing flue gas emissions by about 60%. More recently, Boldyryev et al. [

12] examined the electrification of process industries through heat pump integration to improve economic feasibility and reduce emissions, optimising configurations in a polymer plant’s gas fractionation unit to achieve 174 MW heat recovery, 21.5 M EUR/y savings, and a 1.89 ktCO

2/y emission reduction. Notably, all these investigations were conducted in the time domain, with limited research addressing frequency-domain controllability of distillation-assisted heat pumps.

Another important dimension is the thermodynamic efficiency of distillation processes. Conventional evaluations often focus on energy consumption and economic performance, overlooking second-law efficiency and exergy losses, which are critical for understanding the true sustainability of separation technologies. Exergy analysis provides a rigorous framework to assess how effectively energy is utilised relative to theoretical minimum requirements [

16], thereby identifying opportunities for improvement beyond simple heat integration. For PSD, where large temperature gradients and pressure differences are involved, exergy destruction can be considerable [

17]. Integrating exergy analysis with energy, economic, and environmental assessments can therefore provide a holistic perspective on the potential of electrified PSD systems.

This paper investigates the integration of electrified heating systems into PSD, applied to the tetrahydrofuran (THF)–water azeotropic separation system. A systems-based sustainability framework that captures technical and environmental dimensions is employed. The study is based on process simulation, dynamic modelling, and emissions analysis. The findings support a case for electrified PSD systems as a sustainable advancement in chemical process engineering.

2. Methodology and Simulation of the Case Study

Simulation of the THF/water case study was performed in Aspen Plus using rigorous column models to represent both conventional and heat pump-assisted pressure swing distillation configurations. Key feed and purity targets were set as follows: an equimolar feed at 100.0 Kmol·h

−1 and a product purity of 99.99 mol% for the THF product. Thermophysical behaviour was modelled with the NRTL activity coefficient method [

18].

Columns were modelled with the RadFrac rigorous equilibrium stage block. A two-column PSD sequence, consisting of a low-pressure column (LPC) and a high-pressure column (HPC), was implemented as follows: the LPC operating at 1.0 bar and the HPC at 10.0 bar to exploit azeotrope pressure sensitivity [

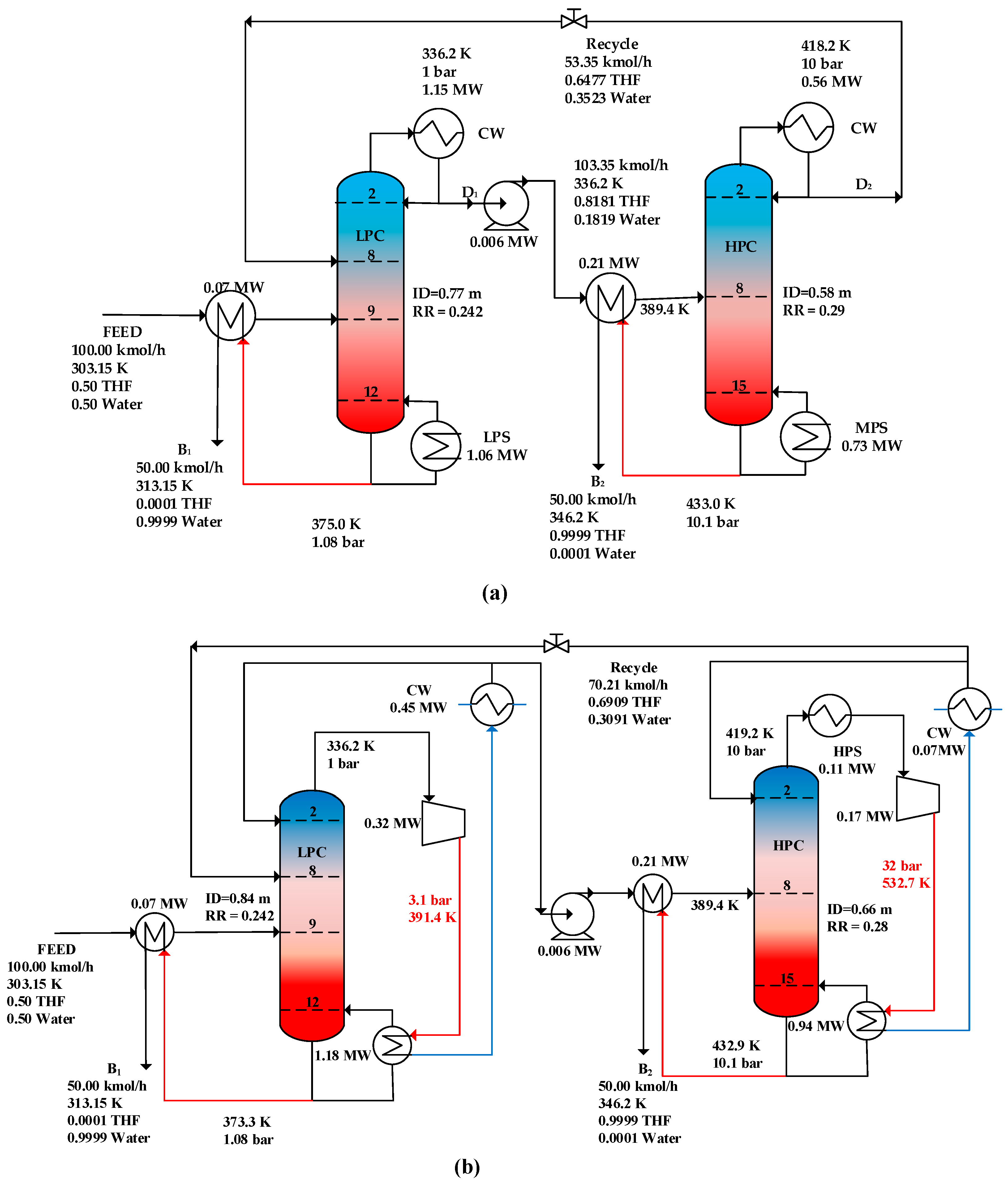

19]. The optimised design values are shown in

Table 1. Reflux ratios and boil-up were tuned to meet the 99.99 mol% product specification while minimising TAC.

For the HPAPSD case, vapour compression heat pump loops were added: overhead vapour from both the LPC and HPC was compressed (COP = 8.8 and 25.8, respectively) and routed to the reboilers via heat exchangers; pinch constraints and ΔTmin were enforced.

Convergence was achieved using tight tolerances; product flow, compositions, energy duties, and stream exergy were extracted for performance assessment. Outputs used for subsequent analysis included total reboiler/condenser duties, compressor work, reflux ratios, column temperatures and pressures, and stream compositions. These served as inputs to TAC, total energy consumption (TEC), CO

2 emissions, and second-law (exergy) calculations. The flowsheets are shown in

Figure 1.

The simulations were exported to Aspen Plus Dynamics. Dynamic controllability assessment was performed to evaluate the ability of the pressure swing distillation configurations to maintain stable operation under process disturbances and uncertainties. The analysis aimed to quantify how effectively key process variables could be regulated to achieve product purity and process stability. The dynamic behaviour of each system was represented using linearised state-space models derived from the Aspen Dynamics Control Design Interface (CDI). The CDI generated the differential equations describing the process near the steady-state setpoint, enabling the calculation of frequency-domain controllability indices.

The controllability analysis considered input, output, and disturbance variables that reflect the operational objectives of PSD systems. Product mole fractions and flow rates, representing the primary separation targets, were controlled variables. For CPSD, the reboiler heat duties of the LPC and HPC, and reflux rates were the manipulated variables. For HPAPSD, heat input to the heat exchanger and the split fraction of the reflux stream were the manipulated variables. The disturbances were feed flow rate and feed composition variations.

Possible input–output pairings were systematically examined to identify combinations that provided the best controllability characteristics. The evaluation employed the following three frequency-domain indices: The Morari Resiliency Index (MRI), which is the smallest singular value of the process open-loop function matrix and is evaluated at the cut-off frequency in this study. MRI assesses dynamic resilience and disturbance rejection with higher values indicating better controllability. The Relative Gain Array-number (RGAno), which is a measure of loop interactions for decentralised control. RGAno evaluates loop interaction and suitability for decentralised control. The Condition Number (CN), which is the ratio of the maximum to the minimum singular value of the process open-loop frequency function. CN measures sensitivity to model uncertainty with lower values corresponding to improved robustness.

The simulations assumed ideal design point equipment performance consistent with early-stage process evaluation practices. Full probabilistic uncertainty analysis and equipment ageing effects, including reduced heat transfer efficiency or compressor wear, were not considered. Maintenance and labour costs were also omitted, as their impact on comparative sustainability is minor.

3. Results

The results showed that reboiler duty and reflux rate are important manipulated variables for maintaining product purity in PSD systems. For HPAPSD, using the heat exchanger duty and reflux split fraction as inputs provided the most stable control response. The analysis examined two key manipulated variable (MV) and controlled variable (CV) pairings, R1R2/XB1XB2 and Q1Q2 or QHX1QHX2/XB1XB2, where R1 and R2 denote the reflux ratios of the low-pressure (LPC) and high-pressure (HPC) columns, respectively, Q1 and Q2 represent the reboiler heat duties, and QHX1 and QHX2 are the heat duties from the heat exchangers. The controlled variables, XB1 and XB2, correspond to the bottom-product purities of the LPC and HPC, respectively.

The controllability analysis results, summarised in

Table 2, reveal distinct dynamic characteristics between the CPSD and the HPAPSD configurations.

For the CPSD system, the variable pair Q1Q2/XD1XD2 exhibited the most favourable controllability performance, with a high MRI and the lowest CN, indicating comparatively strong disturbance rejection and minimal sensitivity to model uncertainties. In contrast, the corresponding HPAPSD pairing, QHX1QHX2/XB1XB2, showed a substantially lower MRI and a higher CN, indicating reduced robustness and higher interaction between control loops due to the added complexity from vapour recompression. Similarly, the R1R2/XB1XB2 pairing in CPSD demonstrated better dynamic resilience compared to HPAPSD. The Dagg and RGAno values also support these findings, with CPSD showing lower interaction and improved loop independence. CPSD exhibited superior overall controllability when the LPC and HPC reboiler duties were selected as manipulated variables. In HPAPSD, the introduction of the compressor and additional heat integration increased system complexity and nonlinear thermal–compressor interactions.

The heat pump-assisted pressure swing distillation significantly enhances energy and environmental performance compared with the conventional pressure swing distillation scheme. In HPAPSD, the reboiler duty of the low-pressure column is supplied primarily by compressed top vapour from the high-pressure column, effectively recycling energy within the system. This integration eliminates the large steam demand typical of CPSD, while only a small amount of auxiliary steam is required to preheat the top vapour prior to compression, ensuring adequate temperature lift and pure vapour composition. Cooling water use is limited to auxiliary condensers, making HPAPSD the most utility-efficient configuration.

Energy consumption decreased substantially by 1065 kW, corresponding to a 59% reduction in total energy consumption. This reduction translated into 82% lower CO2 emissions, highlighting the environmental advantage of electrification. The thermodynamic assessment confirmed the improved performance: exergy efficiency increased from 11% in CPSD to 23% in HPAPSD, with substantially lower exergy losses.

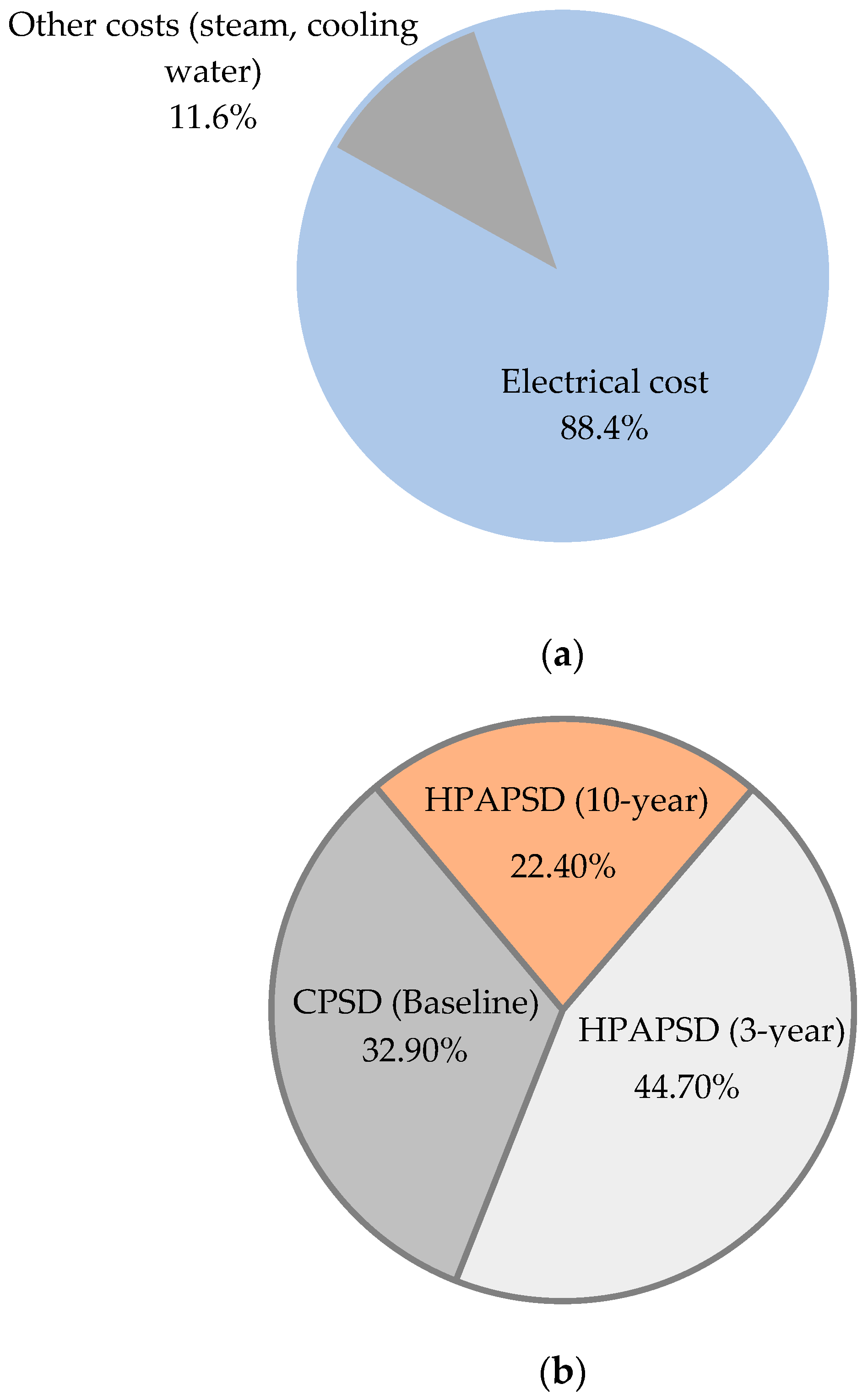

The economic analysis showed a mixed trend. Although the three-year total annual cost (TAC) of HPAPSD increased by 36% due to higher capital and electrical costs, the ten-year TAC decreased by 31%, reflecting long-term profitability. Notably, electricity accounted for 88% of HPAPSD operating costs, underscoring the shift towards electricity-driven distillation as industrial systems increasingly integrate renewable power. The results are summarised in

Figure 2.

Overall, the CPSD configuration exhibited stronger disturbance rejection and faster recovery to setpoints, whereas HPAPSD, despite its superior energy and environmental performance, presented more challenging control behaviour. This highlights a clear trade-off between energy efficiency and controllability in advanced, electrified PSD systems.

4. Conclusions

This study investigated the potential of heat pump-assisted pressure swing distillation as an energy-efficient and environmentally sustainable alternative to conventional pressure swing distillation for separating a tetrahydrofuran–water azeotropic mixture. The HPAPSD achieves substantial energy, environmental, and thermodynamic performance improvements while presenting a new pathway towards electrification in distillation systems.

Frequency-domain controllability analysis revealed that the CPSD model had higher MRI values, implying better inherent resilience to process disturbances. Its lower CN values further indicated reduced multivariable coupling and greater robustness against model uncertainty. Conversely, HPAPSD demonstrated lower MRI, higher CN values, and a higher RGAno, suggesting that the introduction of the compressor and additional heat integration increased system complexity and dynamic interactions.

The integration of a heat pump minimised overall utility consumption, reducing total energy consumption compared to CPSD. As a direct consequence, carbon dioxide emissions were significantly lowered, demonstrating the environmental benefits of adopting electrified systems powered by low-carbon or renewable energy sources. Thermodynamic analysis further revealed that HPAPSD nearly doubled second-law efficiency, thereby reducing exergy losses and demonstrating improved system sustainability.

Economic evaluation presented a dual outcome: although the three-year total annual cost (TAC) of HPAPSD is increased due to higher capital and electrical expenses, the ten-year TAC decreased, suggesting that long-term operation favours HPAPSD profitability. The dominance of electricity costs further strengthens the case for electrification, especially in regions transitioning to renewable energy.

Overall, HPAPSD demonstrates significant potential to decarbonise azeotropic separations by combining energy integration, improved exergy efficiency, and reduced emissions. The findings advocate for broader industrial adoption of heat pump-assisted distillation systems and provide a framework for integrating electrification into chemical process design.