Proportional Analysis and Microstructural Characterization of Threading Dies Manufactured Using Conventional and EDM Machining Methods †

Abstract

1. Introduction

2. Literature Review

2.1. Challenges in Conventional Machining of Dies

2.2. Advancements in Non-Conventional Machining Methods

2.3. Conventional vs. Non-Conventional Machining

3. Experimental Setup

3.1. Analysis Parameters

- Microstructure analysis

- Effect on hardness

- Die strength (number of pieces produced)

3.2. Experimental Methodology and Process Design

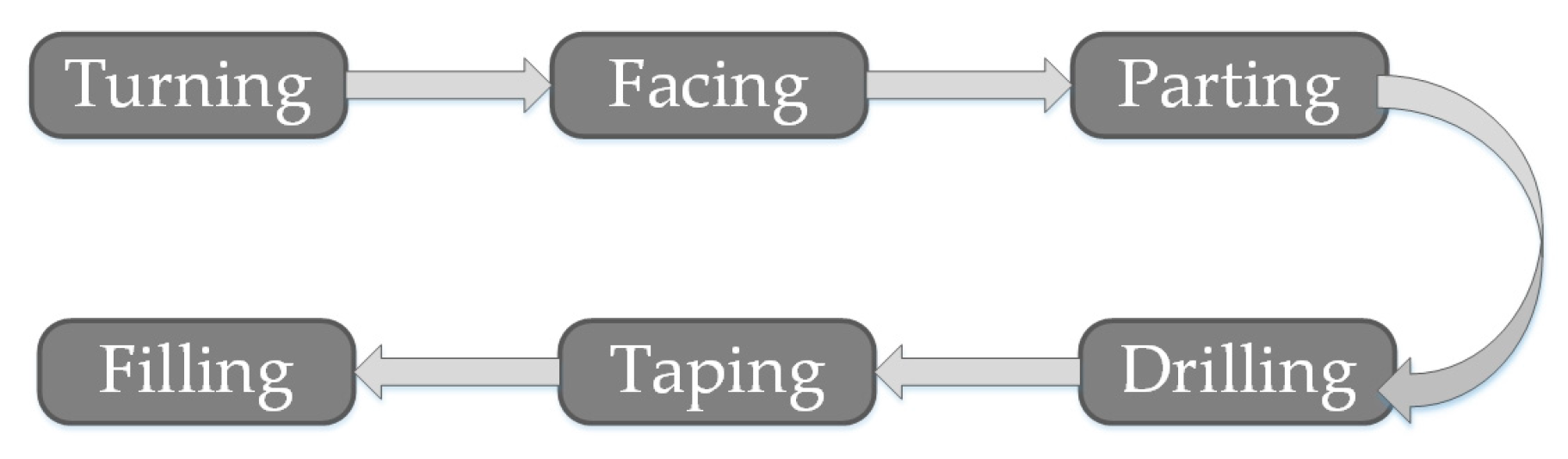

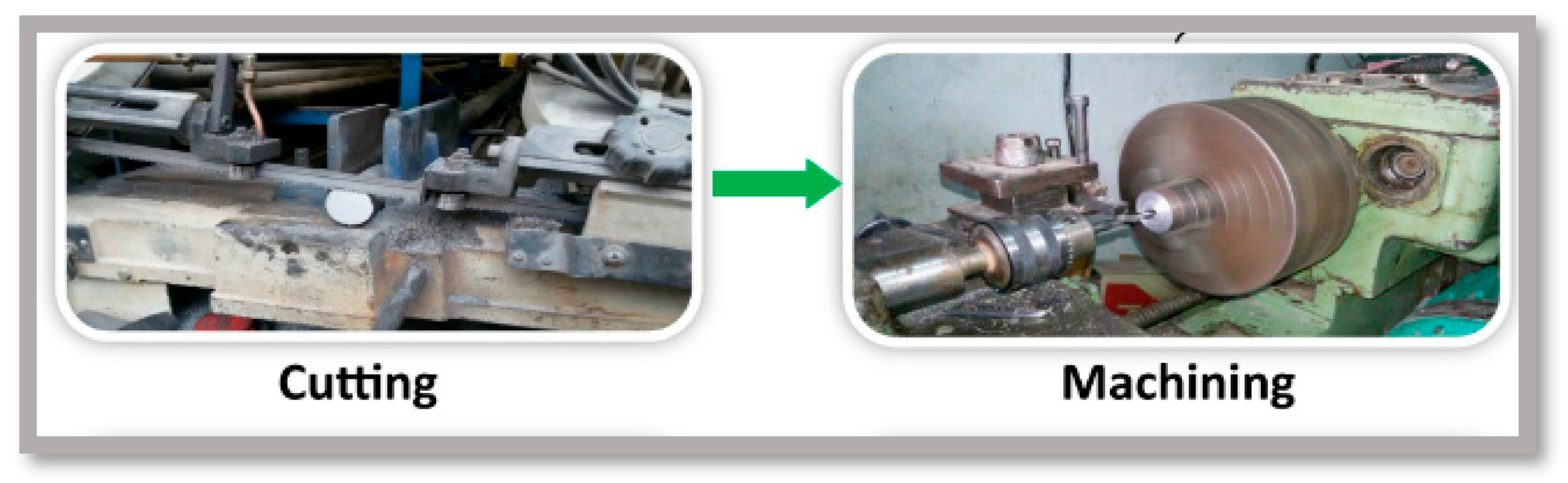

3.2.1. Conventional Experimental Procedure

3.2.2. EDM

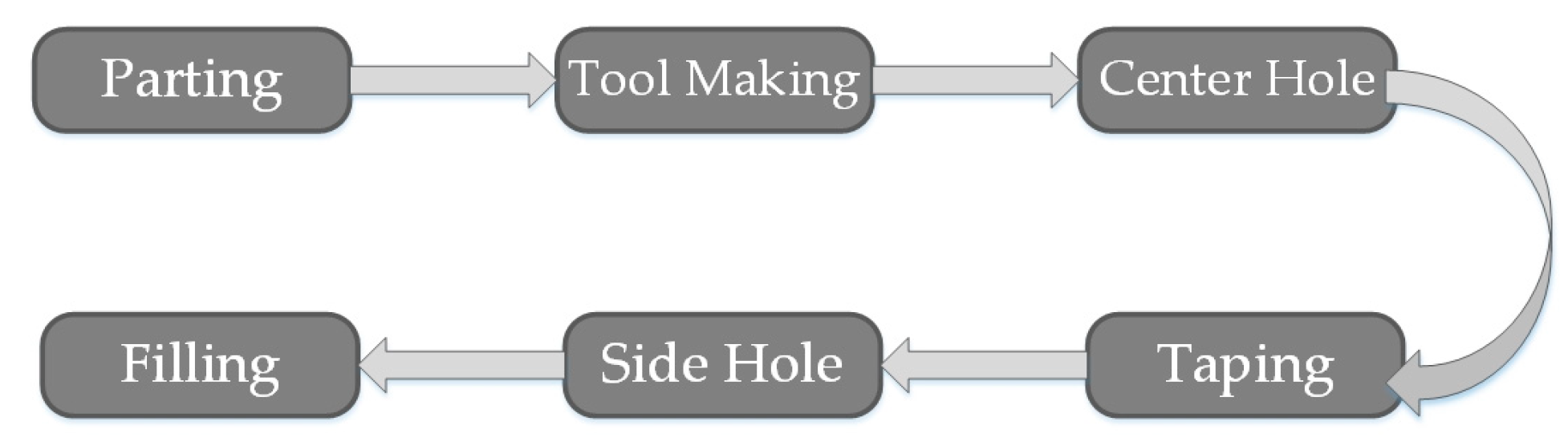

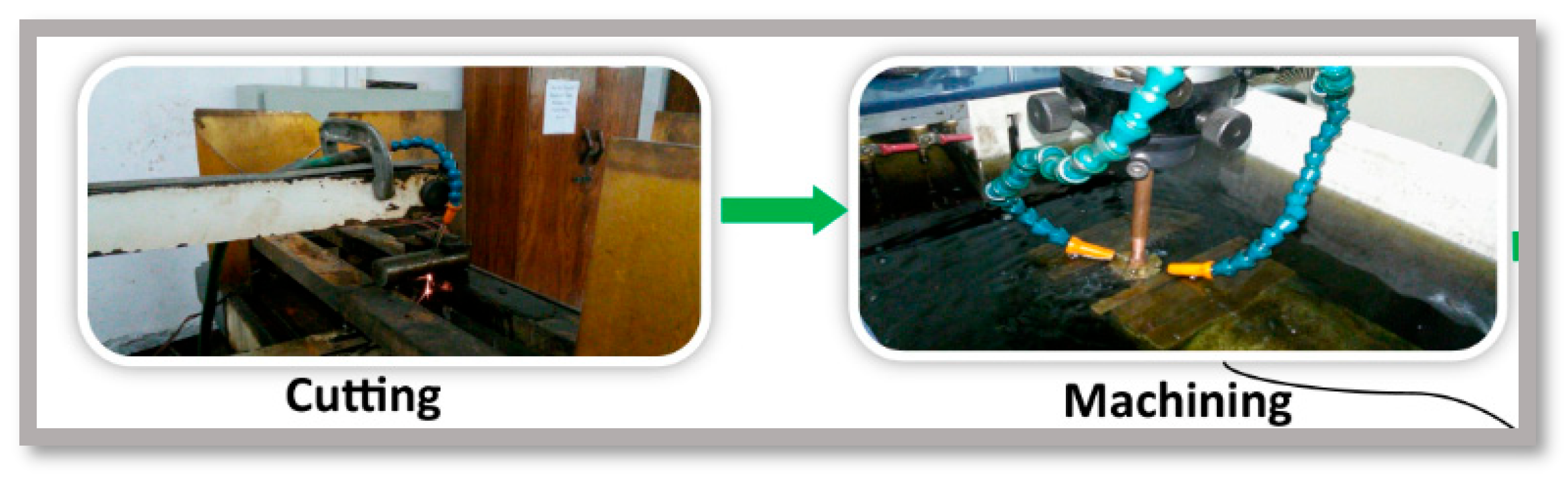

3.2.3. EDM Experimental Procedure

3.2.4. Hardness Testing

3.2.5. Heating

3.2.6. Quenching

3.2.7. Tempering of Threading Dies

4. Results and Discussion

4.1. Hardness

4.2. Microstructure Analysis

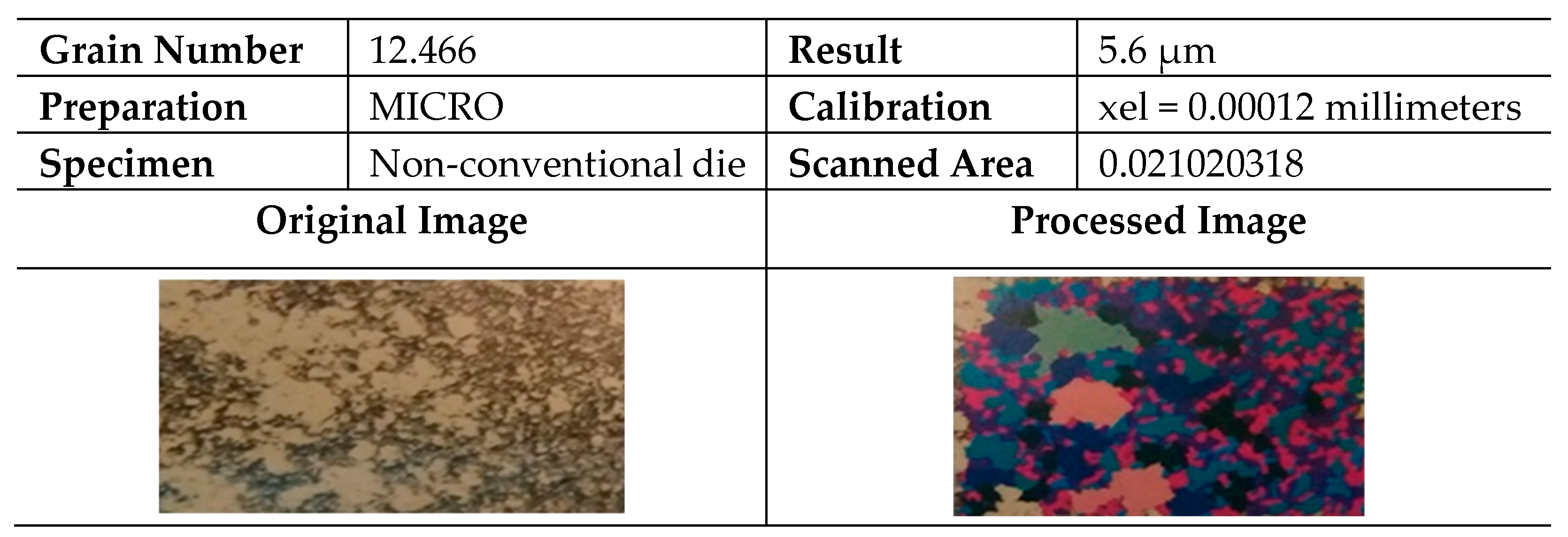

4.2.1. Non-Conventional Grain Size

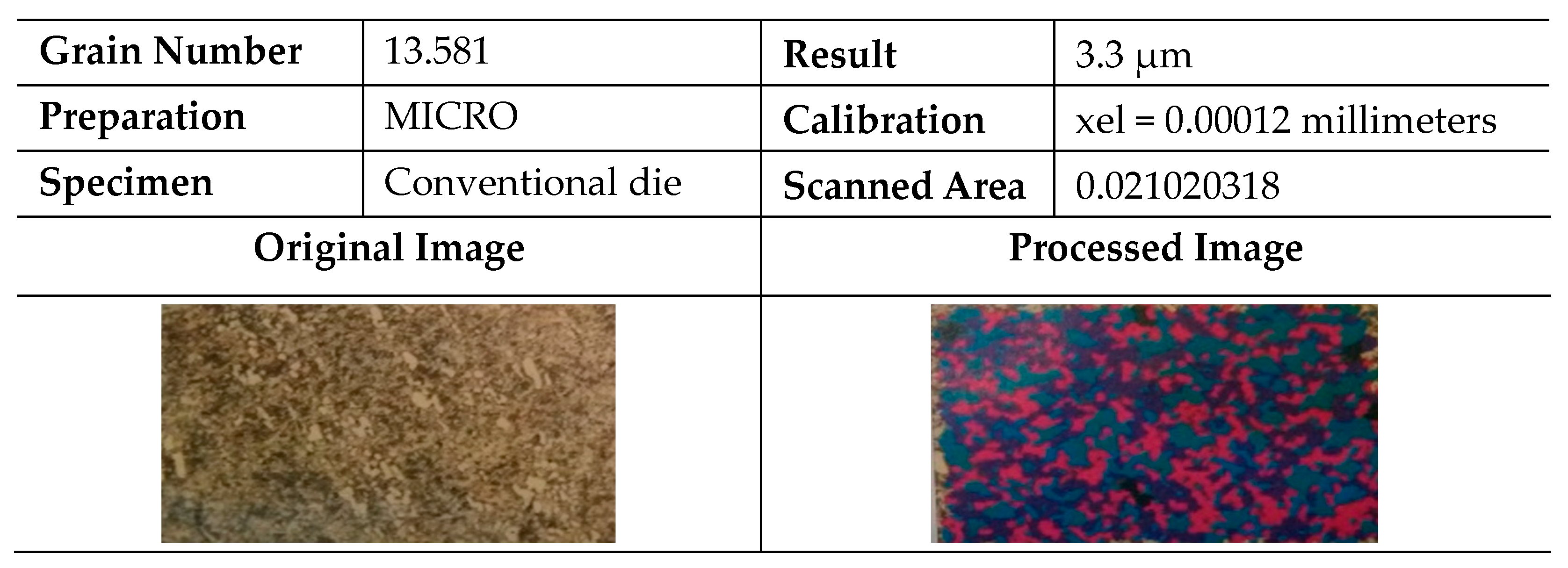

4.2.2. Conventional Die Grain Size

4.2.3. Number of Parts to Be Produced

- Conventional Die: Dies are used to cut threads on small steel bars. We formed threads in the middle of the stick. The tool is made for MS bar thread lengths up to 16 inches (406.6 mm). It is brittle and its efficiency is low due to the hardness increase and change in its internal structure.

- Non-Conventional Die: These dies are very strong and very efficient. These are also used for the purpose of threading on the surface of MS steel rod. Non-conventional dies make thread up to 20 inches (508 mm) and these dies are now in working order.

5. Conclusions and Recommendations

5.1. Conclusions

5.2. Recommendations

- (1)

- Other tool steels or advanced materials with superior machinability, wear resistance, and thermal stability may be considered to enhance productivity. Potential alternatives includeAISI D2 Steel High: Good wear resistance and good toughness.AISI P20 Steel: Suitable for plastic mold applications with better machinability.AISI M2 High-Speed Steel: Offers excellent hardness and heat resistance.Titanium Alloys (Ti-6Al-4V): Lightweight with high strength and corrosion resistance.Carbide Composites: Enhanced durability for high-performance applications.

- (2)

- Advanced machining techniques like Water Jet Machining (WJM), Electrochemical Machining (ECM), and other precision manufacturing methods may be used to improve efficiency, accuracy, and overall part quality. The selection of the most suitable process should align with the material properties and desired performance characteristics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hazra, R.; Doloi, B. Non-conventional machining of SiC reinforced Aluminum metal matrix composites: A Review. J. Phys. Conf. Ser. 2024, 2818, 012035. [Google Scholar] [CrossRef]

- Pereira, T.; Kennedy, J.V.; Potgieter, J. A comparison of traditional manufacturing vs additive manufacturing, the best method for the job. Procedia Manuf. 2019, 30, 11–18. [Google Scholar] [CrossRef]

- Manjaiah, M.; Narendranath, S.; Basavarajappa, S. Review on non-conventional machining of shape memory alloys. Trans. Nonferrous Met. Soc. China 2014, 24, 12–21. [Google Scholar] [CrossRef]

- Altan, T.; Lilly, B.; Yen, Y.C. Manufacturing of dies and molds. CiRP Ann. 2001, 50, 404–422. [Google Scholar] [CrossRef]

- Shabadi, A.M.H.; Ramesh, S.R.; Sharma, S.S. A comprehensive review on the conventional and non-conventional machining of nickel-titanium shape memory alloys. Metals 2023, 13, 585. [Google Scholar]

- Kim, K.S.; Okuyucu, C.; Pottore, N.S.; Zhu, H.; Tasan, C.C. Understanding cutting-induced reduction in sheet metal formability: An in-situ investigation of microstructural effects. J. Mater. Process. Technol. 2025, 341, 118894. [Google Scholar] [CrossRef]

- Li, Y.; Chen, X.; Zhang, J. The microstructure and properties change of dies manufactured by the bimetal-gradient-layer surfacing method. Int. J. Adv. Manuf. Technol. 2015, 78, 147–157. [Google Scholar]

- Younas, T.; Manzoor, M.; Kumari, J. Non-conventional machining processes as expedient alternatives for conventional machining processes. In Proceedings of the 2017 IEEE 3rd International Conference on Engineering Technologies and Social Sciences (ICETSS), Bangkok, Thailand, 7–8 August 2017. [Google Scholar]

- Hölker, R.; Tekkaya, A.E. Advancements in the manufacturing of dies for hot aluminum extrusion with conformal cooling channels. Int. J. Adv. Manuf. Technol. 2016, 83, 1209–1220. [Google Scholar] [CrossRef]

- Huang, Y.; Liang, S.Y. Material microstructure affected machining: A review. Int. J. Adv. Manuf. Technol. 2017, 88, 383–404. [Google Scholar]

- Kwame, J.S.; Yakushina, E.; Blackwell, P. Effect of machining induced microstructure changes on the edge formability of titanium alloys at room temperature. In Forming the Future; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Saoud, F.B.; Korkmaz, M.E. A review on machinability of shape memory alloys through traditional and non-traditional machining processes: A review. İmalat Teknol. Uygulamaları 2022, 3, 14–32. [Google Scholar] [CrossRef]

- Dunleavey, J.; Marimuthu, S.; Antar, M. Non-conventional machine of metal matrix composites. In Advances in Machining of Composite Materials: Conventional and Non-Conventional Processes; Springer International Publishing: Cham, Switzerland, 2021; pp. 183–217. [Google Scholar]

- Jawahir, I.S.; Stephenson, D.A.; Wang, B. A review of advances in modeling of conventional machining processes: From merchant to the present. J. Manuf. Sci. Eng. 2022, 144, 110801. [Google Scholar] [CrossRef]

- Bao, Z.J.; Yang, H.Y.; Dong, B.X.; Chang, F.; Li, C.D.; Jiang, Y.; Chen, L.Y.; Shu, S.L.; Jiang, Q.C.; Qiu, F. Development trend in composition optimization, microstructure manipulation, and strengthening methods of die steels under lightweight and integrated die casting. Materials 2023, 16, 6235. [Google Scholar] [CrossRef] [PubMed]

- Schlegel, J. Manufacturing Processes. In The World of Steel: On the History, Production and Use of a Basic Material; Springer: Wiesbaden, Germany, 2023; pp. 297–355. [Google Scholar]

- Lehmhus, D. Advances in metal casting technology: A review of State of the art, challenges and trends—Part II: Technologies new and revived. Metals 2024, 14, 334. [Google Scholar] [CrossRef]

| Parameter (Value) | Parameter Description | Rationale |

|---|---|---|

| High Tension (0) | Peak voltage during EDM discharge. | Set to zero to prevent arcing and dielectric failure. |

| Low Tension (6) | Base voltage for spark stability. | Selected from literature; refined for stable discharge [2]. |

| Pulse On Time (0) | Duration of current flow per spark. | Minimized due to the use of quick discharge mode. |

| Pulse Off Time (200) | Cooling interval between discharges. | Literature-based; avoids overheating and maintains stability [4]. |

| Quick Discharge On (7) | Controls rapid discharge efficiency. | Optimized experimentally for improved MRR. |

| Quick Discharge Up (6) | Controls electrode retraction speed. | Based on EDM studies for flushing and gap control. |

| Spindle Speed (3) | Electrode rotation rate. | Low RPM ensures spark uniformity and reduces wear. |

| SERVO Voltage (80 V) | Controls electrode–workpiece gap. | Tuned for consistent discharge initiation. |

| Quick Approach Voltage (50 V) | Voltage for rapid tool positioning. | Adjusted for setup speed and minimal tool wear. |

| Polarity (+) | Electrode polarity direction. | Positive polarity is preferred for steel in EDM. |

| MRR (480 mm3/min) | Volume of material removed per unit time. | Trial-validated; aligns with H13 machining benchmarks. |

| AISI H13 | Ni | Mn | C | Mo | Si | V | Cr | Fe |

|---|---|---|---|---|---|---|---|---|

| wt% | 0.19 | 0.28 | 0.48 | 0.93 | 1.04 | 1.12 | 5.39 | Rest |

| Die Segments | Dimensions |

|---|---|

| Outer Diameter | 38 mm |

| Inner Diameter | 10 mm |

| Thickness | 13 mm |

| Side Holes Diameter | 10 mm |

| Type of Material | H13 die steel |

| Speed | Feed | Depth of Cut | MRR |

|---|---|---|---|

| 310 | 0.06 | 0.2 | 480.4 |

| Hardness Test | Parameters |

|---|---|

| Load | 150 kg |

| Indenter size | 120° diamond sphero-conical |

| Indenter | Diamond |

| Machine | Rockwell Hardness Testing |

| Unit | HRC |

| Standard | ASTM E18 |

| Hardness (HRC) | ||||

|---|---|---|---|---|

| Dies | Original Material | After Machining | After Heat Treatment | After Temperature (Tempering) |

| Conventional | 18 | 28 | 52 | 44 |

| Non-conventional | 18 | 19 | 48 | 42 |

| Grain Number | Average Grain Diameter (µm) | Average Grain Area (µm2) | |

|---|---|---|---|

| Conventional Die | 13.581 | 3.3 | 11.1 |

| Non-conventional Die | 12.46 | 5.6 | 31.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, Z.; Uzair, M.; Khan, A.; Huzaifa, M.; Khurshid, S.H. Proportional Analysis and Microstructural Characterization of Threading Dies Manufactured Using Conventional and EDM Machining Methods. Eng. Proc. 2025, 111, 35. https://doi.org/10.3390/engproc2025111035

Ahmad Z, Uzair M, Khan A, Huzaifa M, Khurshid SH. Proportional Analysis and Microstructural Characterization of Threading Dies Manufactured Using Conventional and EDM Machining Methods. Engineering Proceedings. 2025; 111(1):35. https://doi.org/10.3390/engproc2025111035

Chicago/Turabian StyleAhmad, Zaheer, Muhammad Uzair, Afrasyab Khan, Muhammad Huzaifa, and Syed Hamza Khurshid. 2025. "Proportional Analysis and Microstructural Characterization of Threading Dies Manufactured Using Conventional and EDM Machining Methods" Engineering Proceedings 111, no. 1: 35. https://doi.org/10.3390/engproc2025111035

APA StyleAhmad, Z., Uzair, M., Khan, A., Huzaifa, M., & Khurshid, S. H. (2025). Proportional Analysis and Microstructural Characterization of Threading Dies Manufactured Using Conventional and EDM Machining Methods. Engineering Proceedings, 111(1), 35. https://doi.org/10.3390/engproc2025111035