Torrefaction and Densification of Wood Sawdust for Bioenergy Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Feedstock Preparation

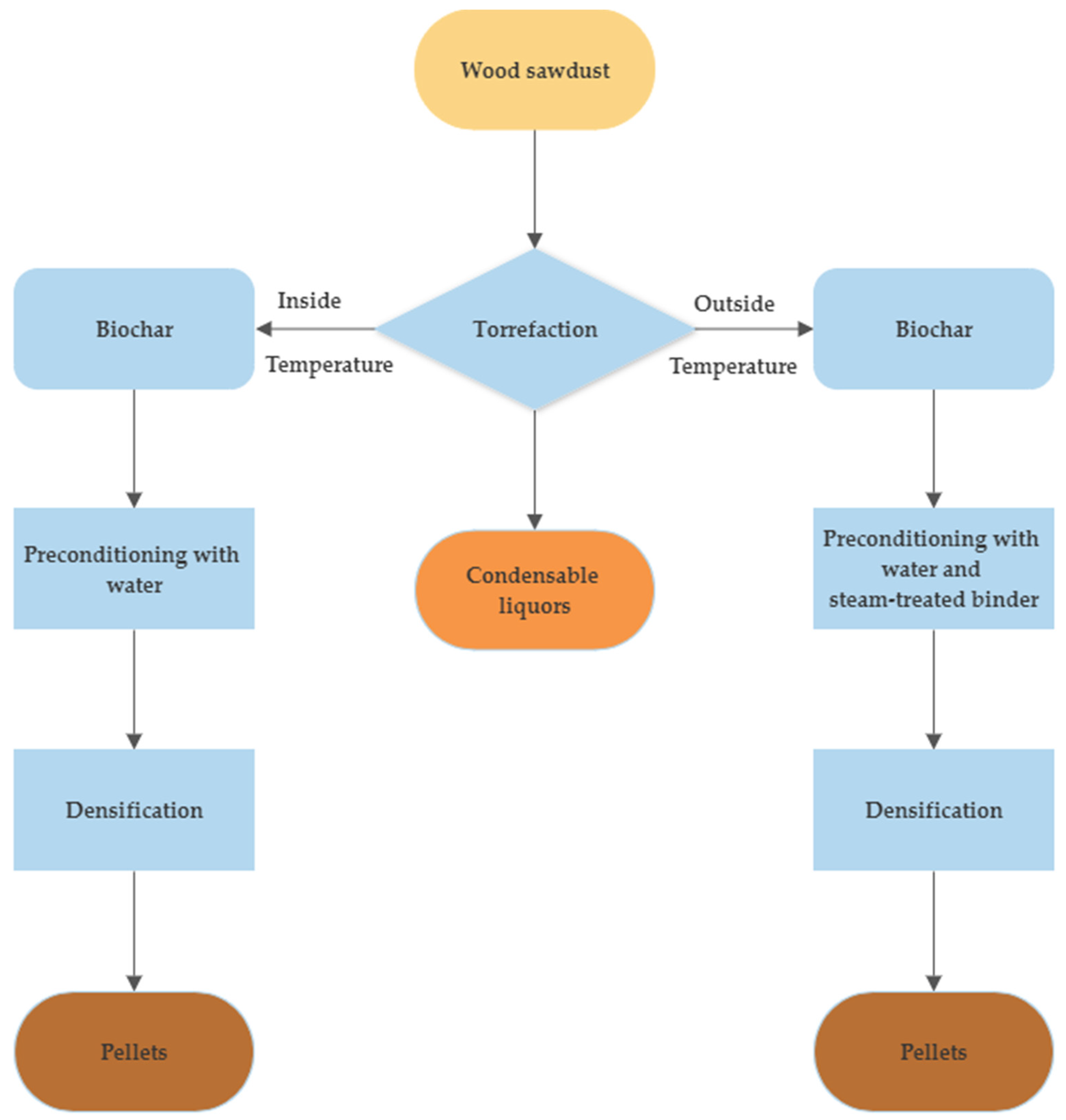

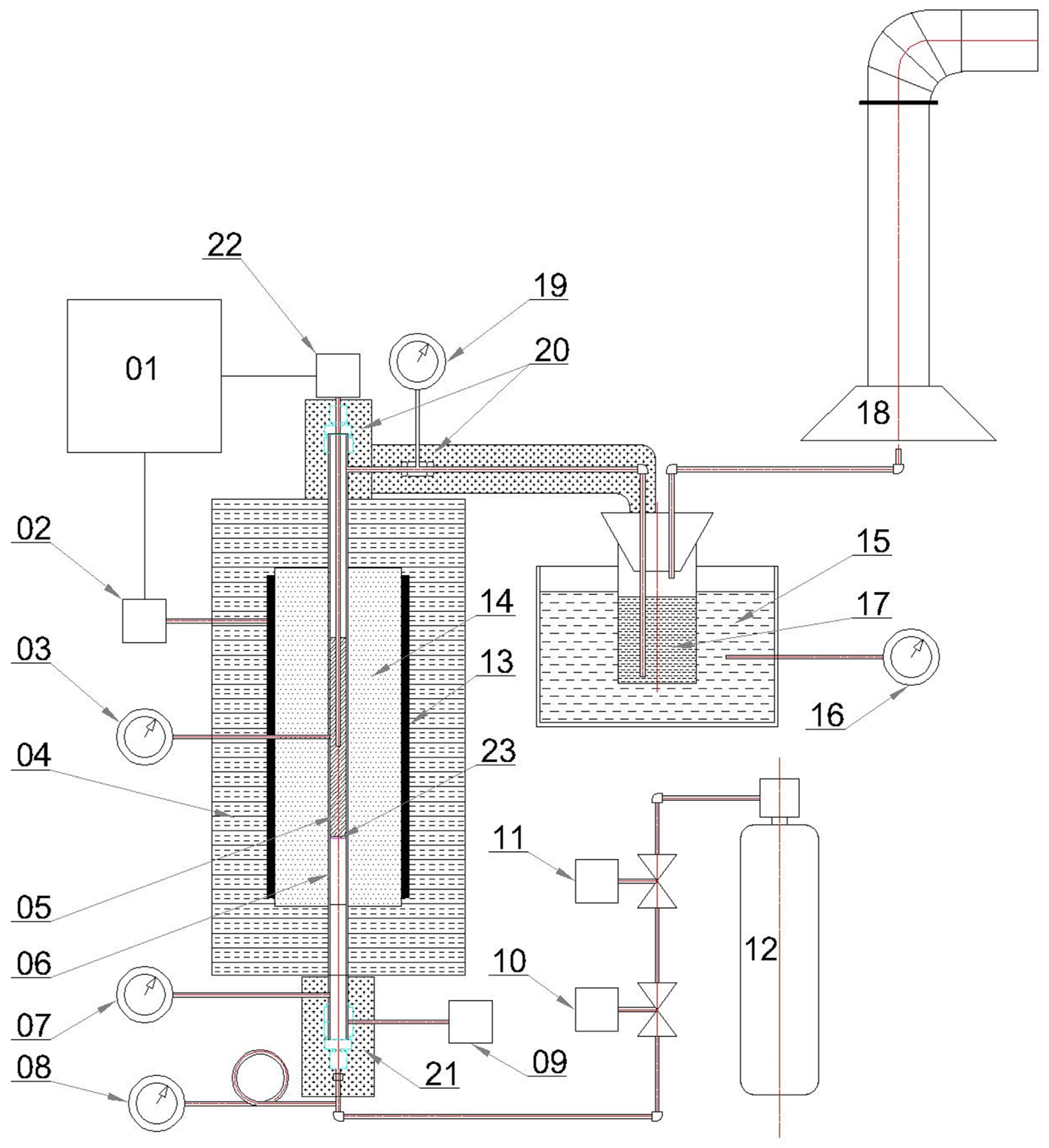

2.2. Torrefaction Process

2.3. Densification

2.3.1. Pellet Density and Dimensional Stability

2.3.2. Tensile Strength

2.4. Statistical Analysis

2.5. Sample Analysis and the Mass and Energy Yields

2.6. Liquor Analysis and GC/MS

2.7. Moisture Uptake

3. Results and Discussion

3.1. Design Parameters

3.2. Optimization

3.3. Relationship between Two Sets of Recorded Temperature

3.4. Particle Size Analysis

3.5. Chemical Composition

3.6. Mass and Energy Yield

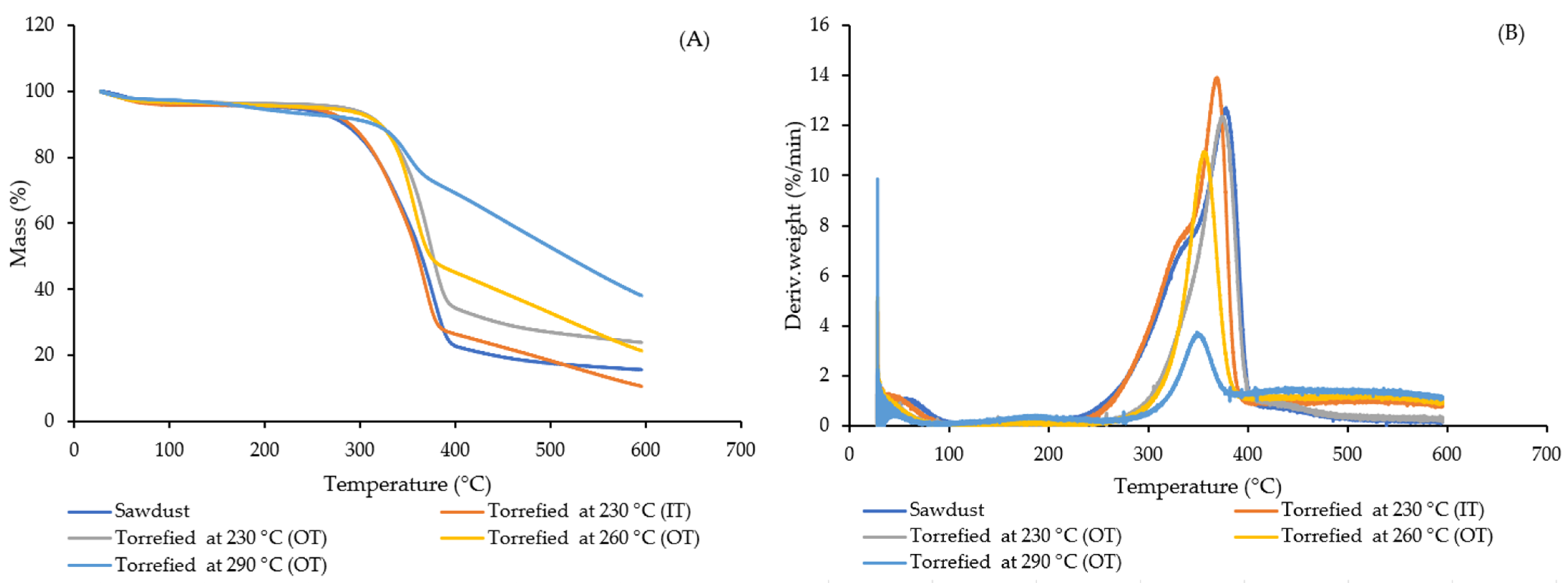

3.7. Thermochemical Analysis of Torrefied and Raw Sawdust

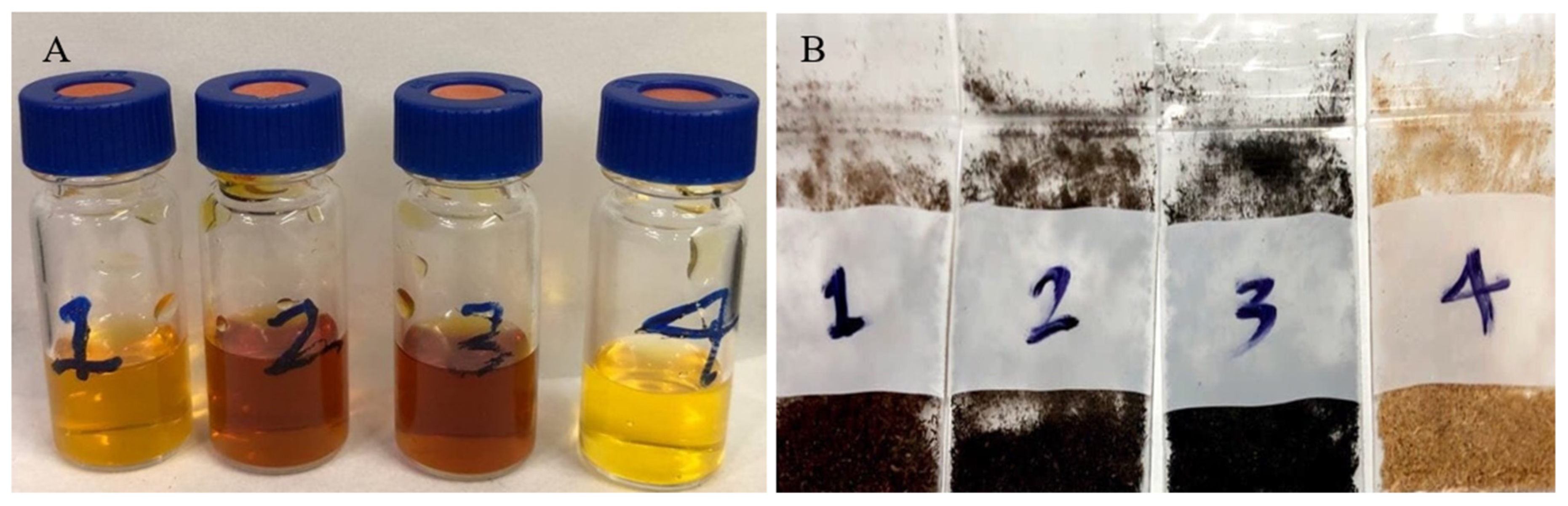

3.8. Torrefaction Liquid Composition

3.9. GC/MS Analysis

3.10. Pellet Properties

3.11. Thermochemical Analysis of Torrefied and Non-Torrefied Pellets

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| IT | Inside temperature |

| OT | Outside temperature |

| BTU | Batch torrefaction unit |

| CCD | Central composite design |

| HHV | Higher heating value |

| NDF | Neutral detergent fibre |

| ADF | Acid detergent fibre |

| GC/MS | Gas chromatography-mass spectrophotometer |

| ANOVA | Analysis of variance |

| ST | Steam treated |

| TGA | Thermogravimetric analysis |

| DTG | Differential thermogravimetric |

References

- Carbon Neutrality by 2050: The World’s Most Urgent Mission|United Nations Secretary-General. Available online: https://www.un.org/sg/en/content/sg/articles/2020-12-11/carbon-neutrality-2050-the-world’s-most-urgent-mission (accessed on 17 December 2021).

- Luo, H.; Niedzwiecki, L.; Arora, A.; Mościcki, K.; Pawlak-Kruczek, H.; Krochmalny, K.; Baranowski, M.; Tiwari, M.; Sharma, A.; Sharma, T.; et al. Influence of Torrefaction and Pelletizing of Sawdust on the Design Parameters of a Fixed Bed Gasifier. Energies 2020, 13, 3018. [Google Scholar] [CrossRef]

- Yun, H.; Clift, R.; Bi, X. Environmental and Economic Assessment of Torrefied Wood Pellets from British Columbia. Energy Convers. Manag. 2020, 208, 112513. [Google Scholar] [CrossRef]

- Government of Ontario Archived—The End of Coal. Available online: https://www.ontario.ca/page/end-coal (accessed on 12 December 2021).

- Masnadi, M.S.; Grace, J.R.; Bi, X.T.; Lim, C.J.; Ellis, N. From Fossil Fuels towards Renewables: Inhibitory and Catalytic Effects on Carbon Thermochemical Conversion during Co-Gasification of Biomass with Fossil Fuels. Appl. Energy 2015, 140, 196–209. [Google Scholar] [CrossRef]

- Amirante, R.; De Palma, P.; Distaso, E.; Pantaleo, A.M.; Tamburrano, P. Thermodynamic Analysis of a Small Scale Combined Cycle for Energy Generation from Carbon Neutral Biomass. Energy Procedia 2017, 129, 891–898. [Google Scholar] [CrossRef]

- Schipfer, F.; Kranzl, L. Techno-Economic Evaluation of Biomass-to-End-Use Chains Based on Densified Bioenergy Carriers (DBECs). Appl. Energy 2019, 239. [Google Scholar] [CrossRef]

- Riva, L.; Nielsen, H.K.; Skreiberg, Ø.; Wang, L.; Bartocci, P.; Barbanera, M.; Bidini, G.; Fantozzi, F. Analysis of Optimal Temperature, Pressure and Binder Quantity for the Production of Biocarbon Pellet to Be Used as a Substitute for Coke. Appl. Energy 2019, 256, 113933. [Google Scholar] [CrossRef]

- Junginger, M.; Goh, C.S.; Faaij, A. History Status & Outlook on Securing Sustainable Bioenergy Supply, Demand and Markets. In International Bioenergy Trade; Springer: Cham, Switzerland, 2014. [Google Scholar]

- Verhoeff, F.; Pels, J.R.; Boersma, A.R.; Zwart, R.W.R.; Kiel, J.H. ECN Torrefaction Technology Heading for Demonstration. In Proceedings of the 19th European Biomass Conference and Exhibition (EU BC&E), Berlin, Germany, 6–9 June 2011. [Google Scholar]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A Review of Biomass Densification Systems to Develop Uniform Feedstock Commodities for Bioenergy Application. Biofuels Bioprod. Biorefining 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Peng, J.H.; Bi, X.T.; Sokhansanj, S.; Lim, C.J. Torrefaction and Densification of Different Species of Softwood Residues. Fuel 2013, 111, 411–421. [Google Scholar] [CrossRef]

- Peng, J.H.; Bi, H.T.; Sokhansanj, S.; Lim, J.C.; Melin, S. An Economical and Market Analysis of Canadian Wood Pellets. Int. J. Green Energy 2010, 7, 128–142. [Google Scholar] [CrossRef]

- Larsson, S.H.; Lestander, T.A.; Crompton, D.; Melin, S.; Sokhansanj, S. Temperature Patterns in Large Scale Wood Pellet Silo Storage. Appl. Energy 2012, 92, 322–327. [Google Scholar] [CrossRef]

- Peng, J.; Bi, X.T.; Lim, C.J.; Peng, H.; Kim, C.S.; Jia, D.; Zuo, H. Sawdust as an Effective Binder for Making Torrefied Pellets. Appl. Energy 2015, 157, 491–498. [Google Scholar] [CrossRef]

- Chen, W.H.; Wang, C.W.; Kumar, G.; Rousset, P.; Hsieh, T.H. Effect of Torrefaction Pretreatment on the Pyrolysis of Rubber Wood Sawdust Analyzed by Py-GC/MS. Bioresour. Technol. 2018, 259, 469–473. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Su, Y.; Xu, D.; Zhu, S.; Zhang, H.; Liu, X. Effects of Torrefaction and Organic-Acid Leaching Pretreatment on the Pyrolysis Behavior of Rice Husk. Energy 2018, 149, 804–813. [Google Scholar] [CrossRef]

- Ong, H.C.; Chen, W.H.; Singh, Y.; Gan, Y.Y.; Chen, C.Y.; Show, P.L. A State-of-the-Art Review on Thermochemical Conversion of Biomass for Biofuel Production: A TG-FTIR Approach. Energy Convers. Manag. 2020, 209, 112634. [Google Scholar] [CrossRef]

- Chih, Y.K.; Chen, W.H.; Ong, H.C.; Show, P.L. Product Characteristics of Torrefied Wood Sawdust in Normal and Vacuum Environments. Energies 2019, 1, 3844. [Google Scholar] [CrossRef]

- Koukios, E.G. Progress in Thermochemical, Solid-State Refining of Biofuels—From Research to Commercialization. In Advances in Thermochemical Biomass Conversion; Springer: Cham, Switzerland, 1993. [Google Scholar]

- Wang, L.; Riva, L.; Skreiberg, Ø.; Khalil, R.; Bartocci, P.; Yang, Q.; Yang, H.; Wang, X.; Chen, D.; Rudolfsson, M.; et al. Effect of Torrefaction on Properties of Pellets Produced from Woody Biomass. Energy Fuels 2020, 34, 15343–15354. [Google Scholar] [CrossRef]

- Li, H.; Liu, X.; Legros, R.; Bi, X.T.; Jim Lim, C.; Sokhansanj, S. Pelletization of Torrefied Sawdust and Properties of Torrefied Pellets. Appl. Energy 2012, 93, 680–685. [Google Scholar] [CrossRef]

- Ghiasisis, B. Steam-Assisted Pelletization and Torrefaction of Lignocellulosic Biomass. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, 2020. [Google Scholar] [CrossRef]

- Wu, Y. Systems Analysis of Integrated Southern Pine Torrefaction and Granulation Technology. Master’s Thesis, University of Georgia, Athens, GA, USA, 2013. [Google Scholar]

- Mallory, E. Pelleting Torrefied Material. In Biomass Pelletization and Torrefaction Workshop. 2013, pp. 18–20. Available online: https://biomass.ubc.ca/2013/12/11/biomass-pelletization-and-torrefaction-workshop-presentations-now-available/ (accessed on 12 December 2021).

- Standard 15149-2; Solid Biofuels. Methods for the Determination of Particle Size Distribution. Vibrating Screen Method Using Sieve Apertures of 3.15 mm and Below. BSI: London, UK, 2010.

- Adapa, P.; Tabil, L.; Schoenau, G. Compaction Characteristics of Barley, Canola, Oat and Wheat Straw. Biosyst. Eng. 2009, 104, 335–344. [Google Scholar] [CrossRef]

- Tabil, L.; Adapa, P.; Kashaninej, M. Biomass Feedstock Pre-Processing—Part 1: Pre-Treatment. In Biofuel′s Engineering Process Technology; Intech Open: London, UK, 2011. [Google Scholar] [CrossRef]

- Adapa, P.; Tabil, L.; Schoenau, G. Pelleting Characteristics of Selected Biomass with and without Steam Explosion Pretreatment. Int. J. Agric. Biol. Emg. 2010, 3, 62–79. [Google Scholar] [CrossRef]

- Campbell, W.; Coller, A.; Noble, S.; Evitts, R.; Woytiuk, K. Application of NIRS to the Direct Measurement of Carbonization in Torrefied Wheat Straw Chars. Waste Biomass Valorization 2020, 11, 2949–2959. [Google Scholar] [CrossRef]

- Overend, R.P.; Chornet, E.; Gascoigne, J.A.; Hartley, B.S.; Broda, P.M.A.; Senior, P.J. Fractionation of Lignocellulosics by Steam-Aqueous Pretreatments. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1987, 321, 523–536. [Google Scholar] [CrossRef]

- Li, Y.; Liu, H. High-Pressure Densification of Wood Residues to Form an Upgraded Fuel. Biomass Bioenergy 2000, 19, 177–186. [Google Scholar] [CrossRef]

- Liu, H.W.; Walter, H.K.; Vogt, G.M.; Vogt, H.S.; Holbein, B.E. Steam Pressure Disruption of Municipal Solid Waste Enhances Anaerobic Digestion Kinetics and Biogas Yield. Biotechnol. Bioeng. 2002, 77, 121–130. [Google Scholar] [CrossRef] [PubMed]

- Kaliyan, N.R.; Morey, V. Factors Affecting Strength and Durability of Densified Products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Kashaninejad, M.; Tabil, L.G. Effect of Microwave-Chemical Pre-Treatment on Compression Characteristics of Biomass Grinds. Biosyst. Eng. 2011, 108, 36–45. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of Compressive Force, Particle Size and Moisture Content on Mechanical Properties of Biomass Pellets from Grasses. Biomass Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Fell, J.T.; Newton, J.M. The Tensile Strength of Lactose Tablets. J. Pharm. Pharmacol. 1968, 20, 657–659. [Google Scholar] [CrossRef]

- Fell, J.T.; Newton, J.M. Determination of Tablet Strength by the Diametral-Compression Test. J. Pharm. Sci. 1970, 59, 688–691. [Google Scholar] [CrossRef]

- Gilvari, H.; de Jong, W.; Schott, D.L. Breakage Behavior of Biomass Pellets: An Experimental and Numerical Study. Comput. Part. Mech. 2021, 8, 1047–1060. [Google Scholar] [CrossRef]

- Adapa, P. Densification of Selected Agricultural Crop Residues as Feedstock for the Biofuel Industry. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2011. [Google Scholar]

- Valdez, E.; Tabil, L.G.; Mupondwa, E.; Cree, D.; Moazed, H. Microwave Torrefaction of Oat Hull: Effect of Temperature and Residence Time. Energies 2021, 14, 4298. [Google Scholar] [CrossRef]

- Colpas, F.; Tarón, A.; Fong, W. Analisis Del Desarrollo Textural de Carbones Activados Preparados a Partir de Zuro de Maíz. Temas Agrar. 2015, 20, 103–112. [Google Scholar] [CrossRef][Green Version]

- Park, J.; Lee, Y.; Ryu, C.; Park, Y.K. Slow Pyrolysis of Rice Straw: Analysis of Products Properties, Carbon and Energy Yields. Bioresour. Technol. 2014, 155, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Standard Test Method for Volatile Matter in the Analysis Sample of Coal and Coke. Available online: https://www.astm.org/d3175-20.html (accessed on 6 December 2021).

- Gong, C.; Huang, J.; Feng, C.; Wang, G.; Tabil, L.; Wang, D. Effects and Mechanism of Ball Milling on Torrefaction of Pine Sawdust. Bioresour. Technol. 2016, 214, 242–247. [Google Scholar] [CrossRef] [PubMed]

- ASTM. Standard Test Method for Gross Calorific Value of Coal and Coke; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Yue, Y.; Singh, H.; Singh, B.; Mani, S. Torrefaction of Sorghum Biomass to Improve Fuel Properties. Bioresour. Technol. 2017, 232, 372–379. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Li, K.; Zhu, X. Study on Two-Step Pyrolysis of Soybean Stalk by TG-FTIR and Py-GC/MS. J. Anal. Appl. Pyrolysis 2017, 127, 91–98. [Google Scholar] [CrossRef]

- Xin, X.; Pang, S.; de Miguel Mercader, F.; Torr, K.M. The Effect of Biomass Pretreatment on Catalytic Pyrolysis Products of Pine Wood by Py-GC/MS and Principal Component Analysis. J. Anal. Appl. Pyrolysis 2019, 138, 145–153. [Google Scholar] [CrossRef]

- González Martínez, M.; Dupont, C.; Thiéry, S.; Meyer, X.M.; Gourdon, C. Impact of Biomass Diversity on Torrefaction: Study of Solid Conversion and Volatile Species Formation through an Innovative TGA-GC/MS Apparatus. Biomass Bioenergy 2018, 119, 43–53. [Google Scholar] [CrossRef]

- Peng, J.H.; Bi, H.T.; Lim, C.J.; Sokhansanj, S. Study on Density, Hardness, and Moisture Uptake of Torrefied Wood Pellets. Energy Fuels 2013, 27, 967–974. [Google Scholar] [CrossRef]

- Wang, C.; Peng, J.; Li, H.; Bi, X.T.; Legros, R.; Lim, C.J.; Sokhansanj, S. Oxidative Torrefaction of Biomass Residues and Densification of Torrefied Sawdust to Pellets. Bioresour. Technol. 2013, 127, 318–325. [Google Scholar] [CrossRef]

- Lunguleasa, A.; Ayrilmis, N.; Spirchez, C.; Croitoru, C. Increasing the Calorific Properties of Sawdust Waste from Pellets by Torrefaction. BioResources 2019, 14, 7821–7839. [Google Scholar] [CrossRef]

- Stelte, W.; Clemons, C.; Holm, J.K.; Sanadi, A.R.; Ahrenfeldt, J.; Shang, L.; Henriksen, U.B. Pelletizing Properties of Torrefied Spruce. Biomass Bioenergy 2011, 35, 4690–4698. [Google Scholar] [CrossRef]

- Stępień, P.; Świechowski, K.; Hnat, M.; Kugler, S.; Stegenta-Dąbrowska, S.; Koziel, J.A.; Manczarski, P.; Białowiec, A. Waste to Carbon: Biocoal from Elephant Dung as New Cooking Fuel. Energies 2019, 12, 4344. [Google Scholar] [CrossRef]

- Syguła, E.; Koziel, J.A.; Białowiec, A. Proof-of-Concept of Spent Mushrooms Compost Torrefaction—Studying the Process Kinetics and the Influence of Temperature and Duration on the Calorific Value of the Produced Biocoal. Energies 2019, 12, 3060. [Google Scholar] [CrossRef]

- Poudel, J.; Karki, S.; Oh, S.C. Valorization of Waste Wood as a Solid Fuel by Torrefaction. Energies 2018, 11, 1641. [Google Scholar] [CrossRef]

- Wilk, M.; Magdziarz, A.; Kalemba, I. Characterisation of Renewable Fuels’ Torrefaction Process with Different Instrumental Techniques. Energy 2015, 87, 259–269. [Google Scholar] [CrossRef]

- Byron Bird, R.; Stewart, W.E.; Lightfoot, E.N. Transport Phenomena. Available online: https://books.google.ca/books?hl=en&lr=&id=L5FnNlIaGfcC&oi=fnd&pg=PR13&ots=LKddj3oNlG&sig=OAPO3pZdlZNxebN_yfVkPcnKMEE&redir_esc=y#v=onepage&q&f=false (accessed on 2 December 2021).

- Rudolfsson, M.; Stelte, W.; Lestander, T.A. Process Optimization of Combined Biomass Torrefaction and Pelletization for Fuel Pellet Production—A Parametric Study. Appl. Energy 2015, 140, 378–384. [Google Scholar] [CrossRef]

- Serrano, C.; Monedero, E.; Lapuerta, M.; Portero, H. Effect of Moisture Content, Particle Size and Pine Addition on Quality Parameters of Barley Straw Pellets. Fuel Process. Technol. 2011, 92, 699–706. [Google Scholar] [CrossRef]

- Huang, Y.; Finell, M.; Larsson, S.; Wang, X.; Zhang, J.; Wei, R.; Liu, L. Biofuel Pellets Made at Low Moisture Content—Influence of Water in the Binding Mechanism of Densified Biomass. Biomass Bioenergy 2017, 98, 8–14. [Google Scholar] [CrossRef]

- Larsson, S.; Palmqvist, E.; Hahn-Hägerdal, B.; Tengborg, C.; Stenberg, K.; Zacchi, G.; Nilvebrant, N.O. The Generation of Fermentation Inhibitors during Dilute Acid Hydrolysis of Softwood. Enzyme Microb. Technol. 1999, 24, 151–159. [Google Scholar] [CrossRef]

- Phanphanich, M.; Mani, S. Impact of Torrefaction on the Grindability and Fuel Characteristics of Forest Biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef]

- Phanphanich, M. Pelleting Characteristics of Torrefied Forest Biomass. Master’s Thesis, University of Georgia, Athens, GA, USA, 2010. [Google Scholar]

- Verhoeff, F. TorTech: Torrefaction Technology for the Production of Solid Bioenergy Carriers from Biomass and Waste; ECN: Petten, The Netherlands, 2011. [Google Scholar]

- Chang, S.; Zhao, Z.; Zheng, A.; He, F.; Huang, Z.; Li, H. Characterization of Products from Torrefaction of Sprucewood and Bagasse in an Auger Reactor. Energy Fuels 2012, 26, 7009–7017. [Google Scholar] [CrossRef]

- Chen, W.H.; Kuo, P.C. A Study on Torrefaction of Various Biomass Materials and Its Impact on Lignocellulosic Structure Simulated by a Thermogravimetry. Energy 2010, 35, 2580–2586. [Google Scholar] [CrossRef]

- He, Q.; Ding, L.; Gong, Y.; Li, W.; Wei, J.; Yu, G. Effect of Torrefaction on Pinewood Pyrolysis Kinetics and Thermal Behavior Using Thermogravimetric Analysis. Bioresour. Technol. 2019, 280, 104–111. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Yuan, X.; Jiang, L.; Li, C.; Xiao, Z.; Huang, Z.; Chen, X.; Zeng, G.; Li, H. Thermogravimetric Characteristics and Kinetics Analysis of Oil Cake and Torrefied Biomass Blends. Fuel 2016, 175, 129–136. [Google Scholar] [CrossRef]

- Sidiras, D.K.; Nazos, A.G.; Giakoumakis, G.E.; Politi, D.V. Simulating the Effect of Torrefaction on the Heating Value of Barley Straw. Energies 2020, 13, 736. [Google Scholar] [CrossRef]

- Li, J.; Brzdekiewicz, A.; Yang, W.; Blasiak, W. Co-Firing Based on Biomass Torrefaction in a Pulverized Coal Boiler with Aim of 100% Fuel Switching. Appl. Energy 2012, 99, 344–354. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.J.; Oh, K.C.; Cho, L.H.; Kim, M.J.; Jeong, I.S.; Lee, C.G.; Kim, D.H. Characteristic Analysis of Torrefied Pellets: Determining Optimal Torrefaction Conditions for Agri-Byproduct. Energies 2020, 13, 423. [Google Scholar] [CrossRef]

- Świechowski, K.; Liszewski, M.; Bąbelewski, P.; Koziel, J.A.; Białowiec, A. Oxytree Pruned Biomass Torrefaction: Mathematical Models of the Influence of Temperature and Residence Time on Fuel Properties Improvement. Materials 2019, 12, 2228. [Google Scholar] [CrossRef]

- Bajcar, M.; Zaguła, G.; Saletnik, B.; Tarapatskyy, M.; Puchalski, C. Relationship between Torrefaction Parameters and Physicochemical Properties of Torrefied Products Obtained from Selected Plant Biomass. Energies 2018, 11, 2919. [Google Scholar] [CrossRef]

- Sh, L.; Lee, B.-H.; Lee, Y.-J.; Jeon, C.-H. Comparing the Physicochemical Properties of Upgraded Biomass Fuel by Torrefaction and the Ashless Technique. Appl. Sci. 2019, 9, 5519. [Google Scholar] [CrossRef]

- Dudek, M.; Świechowski, K.; Manczarski, P.; Koziel, J.A.; Białowiec, A. The Effect of Biochar Addition on the Biogas Production Kinetics from the Anaerobic Digestion of Brewers’ Spent Grain. Energies 2019, 12, 1518. [Google Scholar] [CrossRef]

- Rudolfsson, M.; Borén, E.; Pommer, L.; Nordin, A.; Lestander, T.A. Combined Effects of Torrefaction and Pelletization Parameters on the Quality of Pellets Produced from Torrefied Biomass. Appl. Energy 2017, 191, 414–424. [Google Scholar] [CrossRef]

- González-Peña, M.M.; Hale, M.D.C. Colour in Thermally Modified Wood of Beech, Norway Spruce and Scots Pine. Part 1: Colour Evolution and Colour Changes. Holzforschung 2009, 63, 385–393. [Google Scholar] [CrossRef]

- Patwardhan, P.R.; Brown, R.C.; Shanks, B.H. Product Distribution from the Fast Pyrolysis of Hemicellulose. ChemSusChem 2011, 4, 636–643. [Google Scholar] [CrossRef]

- Rasmussen, H.; Sørensen, H.R.; Meyer, A.S. Formation of Degradation Compounds from Lignocellulosic Biomass in the Biorefinery: Sugar Reaction Mechanisms. Carbohydr. Res. 2014, 385, 45–57. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. More Efficient Biomass Gasification via Torrefaction. Energy 2006, 31, 3458–3470. [Google Scholar] [CrossRef]

- Boerjan, W.; Ralph, J.; Baucher, M. Lignin Biosynthesis. Annu. Rev. Plant Biol. 2003, 54, 519–546. [Google Scholar] [CrossRef]

- Ghiasi, B.; Kumar, L.; Furubayashi, T.; Lim, C.J.; Bi, X.; Kim, C.S.; Sokhansanj, S. Densified Biocoal from Woodchips: Is It Better to Do Torrefaction before or after Densification? Appl. Energy 2014, 134, 133–142. [Google Scholar] [CrossRef]

- Yue, H.; Worrell, E.; Crijns-Graus, W.; Zhang, S. The Potential of Industrial Electricity Savings to Reduce Air Pollution from Coal-Fired Power Generation in China. J. Clean. Prod. 2021, 301, 126978. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, F.; Chen, D.; Cen, K.; Zhang, J.; Cao, X. Upgrading of Biomass Pellets by Torrefaction and Its Influence on the Hydrophobicity, Mechanical Property, and Fuel Quality. Biomass Convers. Biorefinery 2020. [Google Scholar] [CrossRef]

- Pimchuai, A.; Dutta, A.; Basu, P. Torrefaction of Agriculture Residue to Enhance Combustible Properties. Energy Fuels 2010, 24, 4638–4645. [Google Scholar] [CrossRef]

- Ren, S.; Lei, H.; Wang, L.; Bu, Q.; Wei, Y.; Liang, J.; Liu, Y.; Julson, J.; Chen, S.; Wu, J.; et al. Microwave Torrefaction of Douglas Fir Sawdust Pellets. Energy Fuels 2012, 26, 5936–5943. [Google Scholar] [CrossRef]

| Independent Variable | Code | Real Factor Level at Coded Factor Levels |

|---|---|---|

| −1 0 1 | ||

| Temperature (°C) | X1 | 230 260 290 |

| Residence time (min) | X2 | 15 30 45 |

| Biomass | Pellet | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Run | Temperature (°C) | Time (min) | Bulk Density (kg/m3) | Particle Density (kg/m3) | Ash Content (%) | HHV 1 (Dry) (MJ/kg) | Pellet Density (kg/m3) | Tensile Strength (MPa) | Dimensional Stability (%) |

| 0 | - | - | 117.38 | 1410 | 0.22 | 17.49 | 1044.6 | 0.31 | 2.62 |

| 1 | 230 | 15 | 154.14 | 1396.40 | 0.27 | 17.20 | 1026.72 | 0.19 | 0.43 |

| 2 | 230 | 30 | 156.25 | 1371.50 | 0.23 | 17.30 | 1048.41 | 0.23 | 1.05 |

| 3 | 230 | 45 | 161.955 | 1356.10 | 0.22 | 17.36 | 1039.77 | 0.21 | 1.81 |

| 4 | 260 | 15 | 146.045 | 1390.10 | 0.29 | 17.39 | 983.69 | 0.14 | 1.24 |

| 5 | 260 | 30 (1) | 159.06 | 1381.10 | 0.28 | 17.66 | 981.53 | 0.12 | 1.12 |

| 6 | 260 | 30 (2) | 176.77 | 1370.30 | 0.25 | 17.58 | 992.55 | 0.16 | 0.30 |

| 7 | 260 | 30 (3) | 170.31 | 1352.10 | 0.28 | 17.49 | 1000.67 | 0.14 | 0.49 |

| 8 | 260 | 30 (4) | 164.54 | 1400.10 | 0.26 | 17.52 | 1002.45 | 0.16 | 2.47 |

| 9 | 260 | 30 (5) | 165.285 | 1375.20 | 0.29 | 17.50 | 989.36 | 0.17 | 0.53 |

| 10 | 260 | 45 | 162.94 | 1408.30 | 0.28 | 17.87 | 991.95 | 0.15 | 1.18 |

| 11 | 290 | 15 | 149.32 | 1341.70 | 0.30 | 18.49 | 976.82 | 0.13 | 2.18 |

| 12 | 290 | 30 | 151.935 | 1328.80 | 0.31 | 18.59 | 993.53 | 0.15 | 1.65 |

| 13 | 290 | 45 | 153.045 | 1338.60 | 0.28 | 18.56 | 955.96 | 0.08 | 1.49 |

| Sample | dgw (mm) | Sgw (mm) |

|---|---|---|

| Sawdust | 0.33 | 0.20 |

| Torrefied at 230 °C (IT 1) | 0.33 | 0.17 |

| Torrefied at 230 °C (OT 2) | 0.32 | 0.14 |

| Torrefied at 260 °C (OT 2) | 0.32 | 0.15 |

| Torrefied at 290 °C (OT 2) | 0.38 | 0.21 |

| Components | Sawdust | Torrefied at 230 °C (IT 1) | Torrefied at 230 °C (OT 2) | Torrefied at 260 °C (OT 2) | Torrefied at 290 °C (OT 2) |

|---|---|---|---|---|---|

| Ash (%) | 0.23 | 0.50 | 0.37 | 0.36 | 0.55 |

| Lignin (%) | 25.17 | 25.66 | 39.14 | 49.39 | 73.95 |

| Hemicellulose (%) | 14.47 | 18.03 | 5.56 | 2.49 | 1.68 |

| Cellulose (%) | 50.39 | 49.44 | 48.88 | 42.03 | 12.77 |

| Solubles (%) | 9.74 | 6.42 | 6.09 | 11.60 | 6.86 |

| Outputs | Torrefied at 230 °C (IT 1) | Torrefied at 230 °C (OT 2) | Torrefied at 260 °C (OT 2) | Torrefied at 290 °C (OT 2) |

|---|---|---|---|---|

| Solid (wet) (%) | 90.97 | 72.48 | 64.83 | 47.55 |

| Liquid (%) | 7.73 | 13.72 | 19.69 | 27.98 |

| Gas (%) | 1.30 | 13.8 | 15.48 | 24.47 |

| Components | Torrefied at 230 °C (IT 1) (% Area) | Torrefied (OT 2) (% Area) | ||

|---|---|---|---|---|

| 230 °C | 260 °C | 290 °C | ||

| Furfural | 41.79 | 30.18 | 0.43 | 2 |

| Carbonyl sulphide | 22.48 | |||

| Aminoguanidine | 6.14 | 5.76 | 5.08 | |

| Phenol, 2-methoxy- | 3.84 | 7.45 | 3.69 | 7.21 |

| 2-Hexene | 3.03 | 6.86 | 0.91 | 14.29 |

| Hydroquinone | 2.43 | 2.36 | ||

| 1-Propanamine, 3-ethoxy- | 1.98 | 1.73 | ||

| Vanillin | 1.84 | 2.36 | ||

| 1,2:5,6-Dianhydrogalactitol | 1.82 | 1.78 | 2.51 | 1.98 |

| Phenol, 2-methoxy-4-methyl- | 1.53 | 4.51 | 0.48 | 14.87 |

| 1-Penten-3-ol | 1.37 | 0.86 | ||

| 9-Octadecenoic acid (Z)-, methyl ester | 1.37 | |||

| Gibberellic acid | 1.25 | 1.54 | 1.56 | 0.45 |

| 2-Butenal, 2-ethyl- | 0.86 | 0.81 | 1.78 | |

| Acetic acid | 17.12 | 7.93 | ||

| Cyclohexanone | 3.28 | 6.99 | 7.35 | |

| Propanoic acid, anhydride | 3.32 | |||

| Undecanoic acid, hydroxy-, lactone | 1.35 | 1.18 | 5.93 | |

| Oxirane, [[(2-ethylhexyl)oxy]methyl]- | 0.16 | 0.33 | 1.88 | |

| 2-Tridecanone | 18.04 | |||

| Digitoxin | 17.54 | 2.94 | ||

| Cyclohexanone, 2-nitro- | 5.69 | |||

| Butane, 1,1′-[oxybis(2,1-ethanediyloxy)]bis- | 2.77 | |||

| Propanoic acid, 2,2-dimethyl- | 2.72 | |||

| 1-Propene, 3-ethoxy- | 1.93 | |||

| Benzaldehyde, 3-hydroxy-4-methoxy- | 1.65 | |||

| 2,4-Dimethoxytoluene | 0.92 | 2.34 | ||

| 2-Butenal, 2-ethyl- | 0.81 | |||

| 2-Cyclopenten-1-one, 2-hydroxy-3-methyl- | 0.66 | 18.47 | ||

| Propanal | 2.1 | |||

| Total | 91.73 | 90.62 | 83.82 | 83.59 |

| Sample | Binder (ST 1) (%) | Moisture Content (Dry) (%) | Pellet Density (kg/m3) | Tensile Strength (MPa) | Dimensional Stability (%) | Moisture Absorption (%) |

|---|---|---|---|---|---|---|

| Sawdust | 0 | 8.70 | 1044.6 | 0.31 | 2.62 | 16.85 |

| 10 | 8.21 | 1095.92 | 0.56 | 2.75 | 14.99 | |

| 20 | 8.00 | 1114.14 | 0.74 | 2.41 | 14.65 | |

| Steam-treated (Spruce sawdust) | NA 2 | 5.53 | 1262.51 | 2.80 | 2.64 | 9.93 |

| Torrefied at 230 °C (IT 3) | 0 | 10 | 1039.77 | 0.21 | 1.81 | 13.72 |

| 10 | 9.21 | 1035.28 | 0.27 | 2.84 | 14.54 | |

| 20 | 7.47 | 1068.67 | 0.72 | 2.83 | 13.65 | |

| Torrefied at 230 °C (OT 4) | 0 | 10 | 955.31 | - | - | - |

| 20 | 5.74 | 1054.79 | 1.08 | 1.56 | 10.74 | |

| Torrefied at 260 °C (OT 4) | 0 | 10 | 892.79 | - | - | - |

| 20 | 5.28 | 1023.48 | 0.98 | 2.63 | 10.36 | |

| Torrefied at 290 °C (OT 4) | 0 | 10 | NA 2 | NA 2 | NA 2 | NA 2 |

| 20 | 4.85 | 871.73 | 0.60 | 4.68 | 9.40 |

| Pellet Sample | Binder (ST 1) | HHV 4 (Dry) (MJ/kg) | Proximate Analysis (% wt., Dry) | Ultimate Analysis (% wt., Dry) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (%) | Fixed Carbon | Volatile | Ash | N 5 | C 6 | H 7 | S 8 | O 9 | O/C | H/C | ||

| Sawdust | 10 | 17.48 | 18.20 | 74.94 | 0.09 | 0.04 | 48.46 | 6.66 | 0.01 | 44.84 | 0.93 | 0.14 |

| 20 | 17.64 | 18.40 | 74.70 | 0.11 | 0.02 | 48.57 | 6.63 | 0.03 | 44.75 | 0.92 | 0.14 | |

| Torrefied at 230 °C (IT 2) | 10 | 17.83 | 17.29 | 76.42 | 0.2 | 0.07 | 49.05 | 6.50 | 0.10 | 44.29 | 0.90 | 0.13 |

| 20 | 18.03 | 17.74 | 76.08 | 0.2 | 0.06 | 48.90 | 6.46 | 0.09 | 44.49 | 0.91 | 0.13 | |

| Torrefied at 230 °C (OT 3) | 20 | 19.29 | 24.58 | 69.24 | 0.50 | 0.05 | 51.22 | 6.15 | 0.03 | 42.55 | 0.83 | 0.12 |

| Torrefied at 260 °C (OT 3) | 20 | 20.16 | 32.04 | 61.95 | 0.40 | 0.06 | 53.89 | 6.04 | 0.17 | 39.85 | 0.74 | 0.11 |

| Torrefied at 290 °C (OT 3) | 20 | 22.72 | 44.45 | 49.47 | 0.51 | 0.05 | 60.90 | 5.72 | 0.05 | 33.28 | 0.55 | 0.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alizadeh, P.; Tabil, L.G.; Adapa, P.K.; Cree, D.; Mupondwa, E.; Emadi, B. Torrefaction and Densification of Wood Sawdust for Bioenergy Applications. Fuels 2022, 3, 152-175. https://doi.org/10.3390/fuels3010010

Alizadeh P, Tabil LG, Adapa PK, Cree D, Mupondwa E, Emadi B. Torrefaction and Densification of Wood Sawdust for Bioenergy Applications. Fuels. 2022; 3(1):152-175. https://doi.org/10.3390/fuels3010010

Chicago/Turabian StyleAlizadeh, Peyman, Lope G. Tabil, Phani K. Adapa, Duncan Cree, Edmund Mupondwa, and Bagher Emadi. 2022. "Torrefaction and Densification of Wood Sawdust for Bioenergy Applications" Fuels 3, no. 1: 152-175. https://doi.org/10.3390/fuels3010010

APA StyleAlizadeh, P., Tabil, L. G., Adapa, P. K., Cree, D., Mupondwa, E., & Emadi, B. (2022). Torrefaction and Densification of Wood Sawdust for Bioenergy Applications. Fuels, 3(1), 152-175. https://doi.org/10.3390/fuels3010010