Numerical Investigation of Dual Fuel Combustion on a Compression Ignition Engine Fueled with Hydrogen/Natural Gas Blends

Abstract

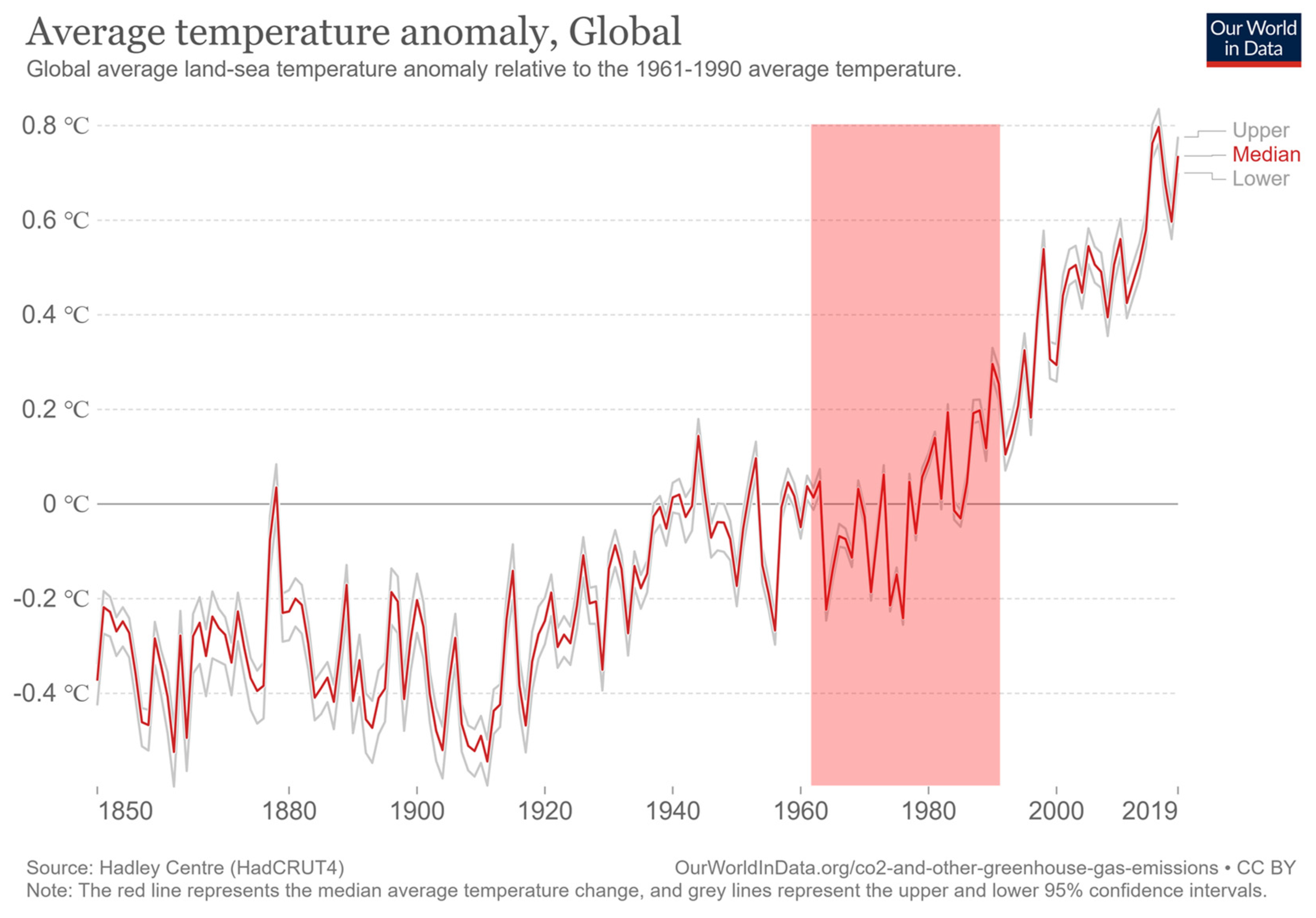

:1. Introduction

2. Materials and Methods

2.1. The Reference Engine

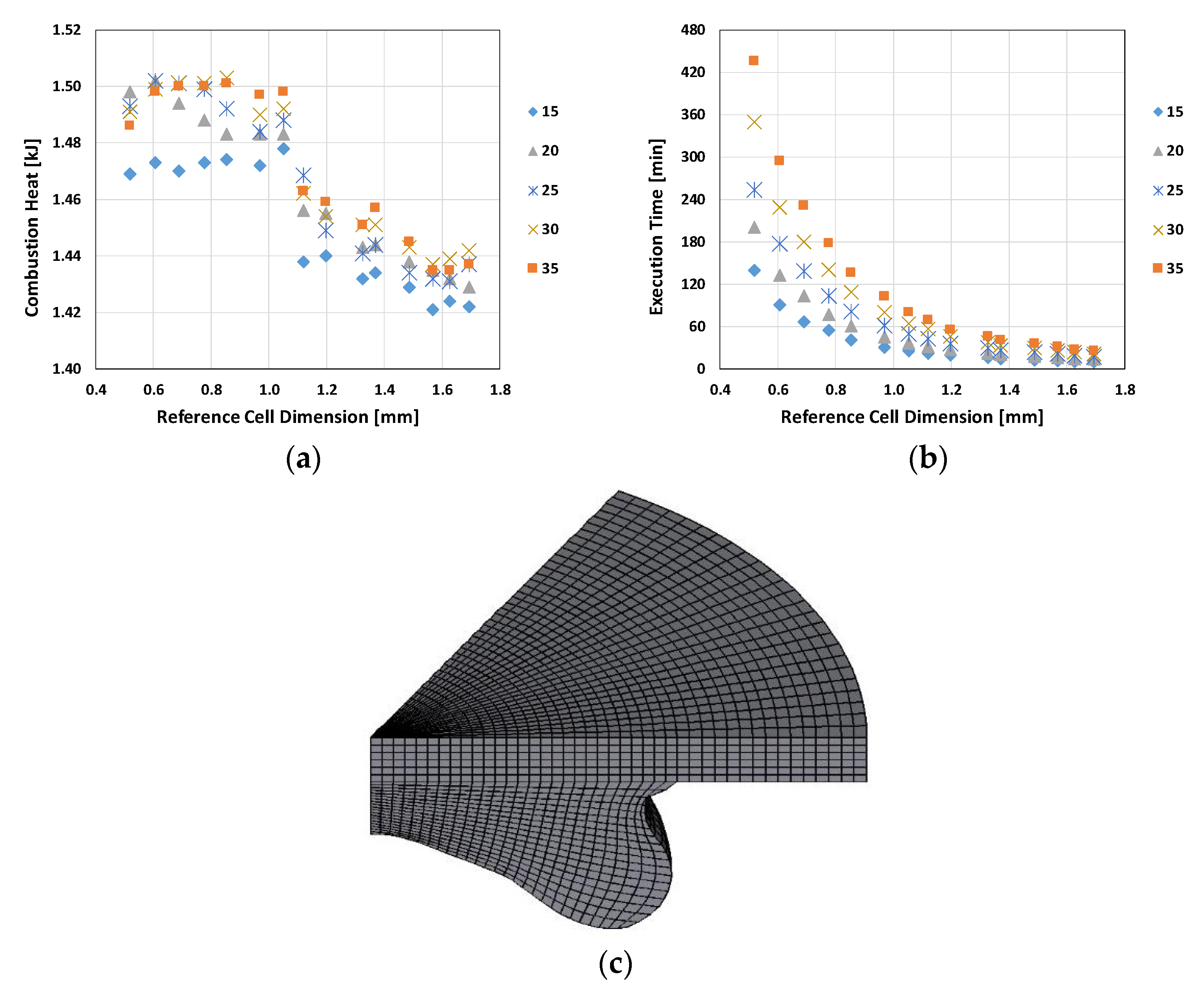

2.2. The 3D-CFD Model

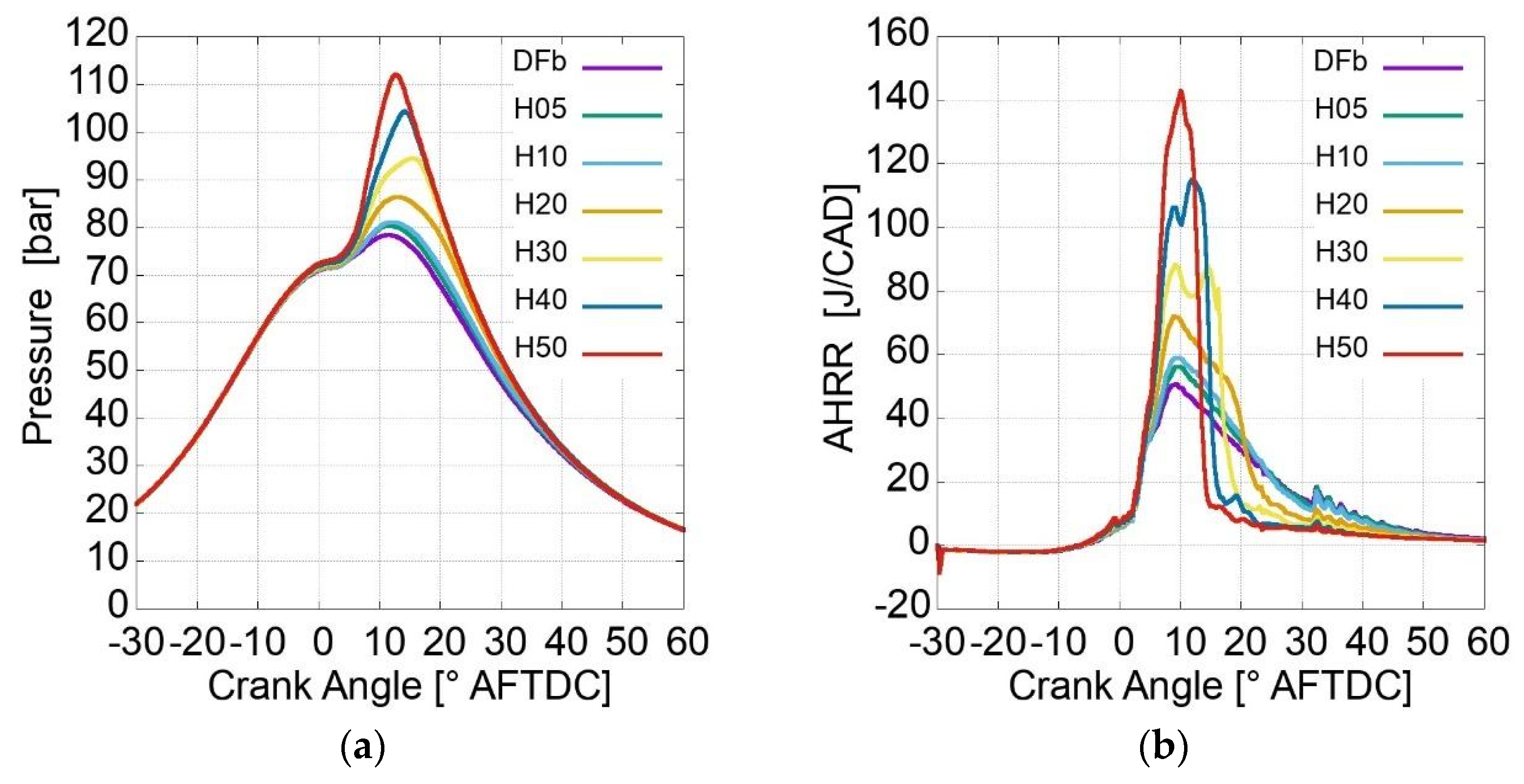

2.3. Combustion Model Validation

2.4. H2-NG Blend Simulations

3. Results and Discussion

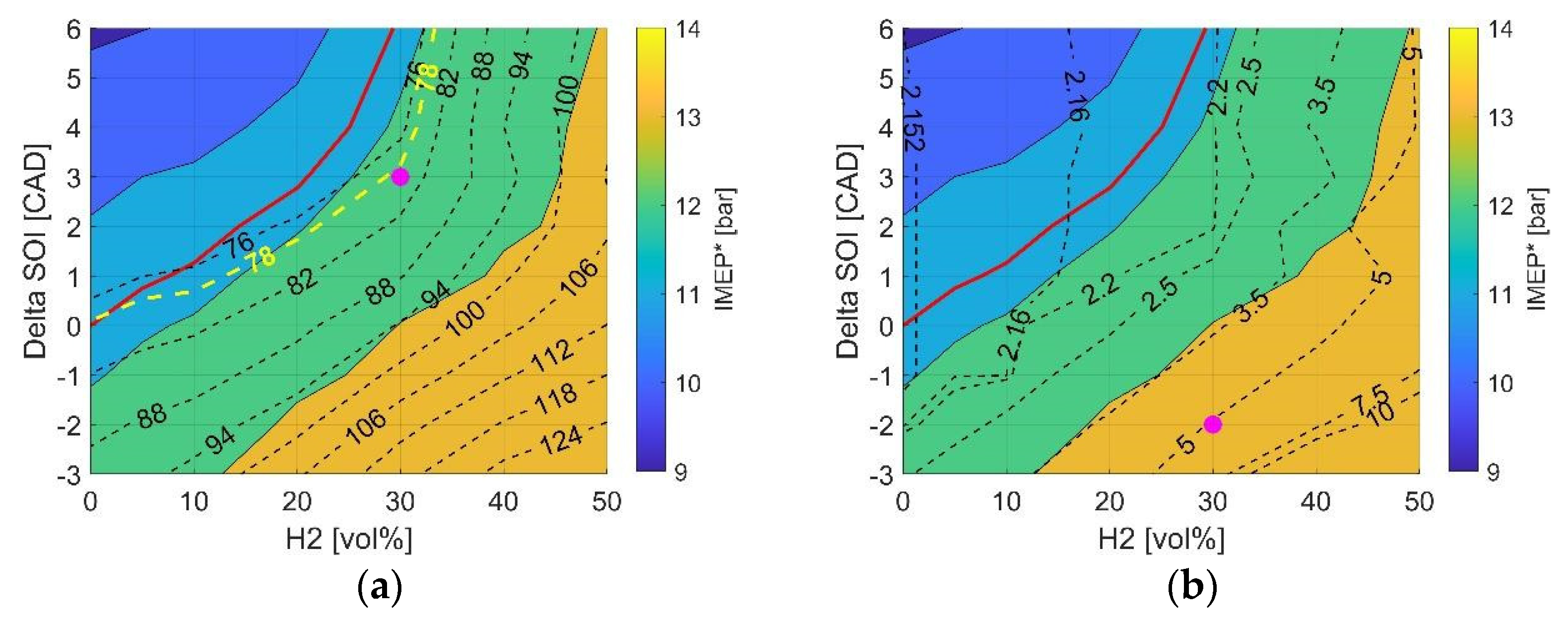

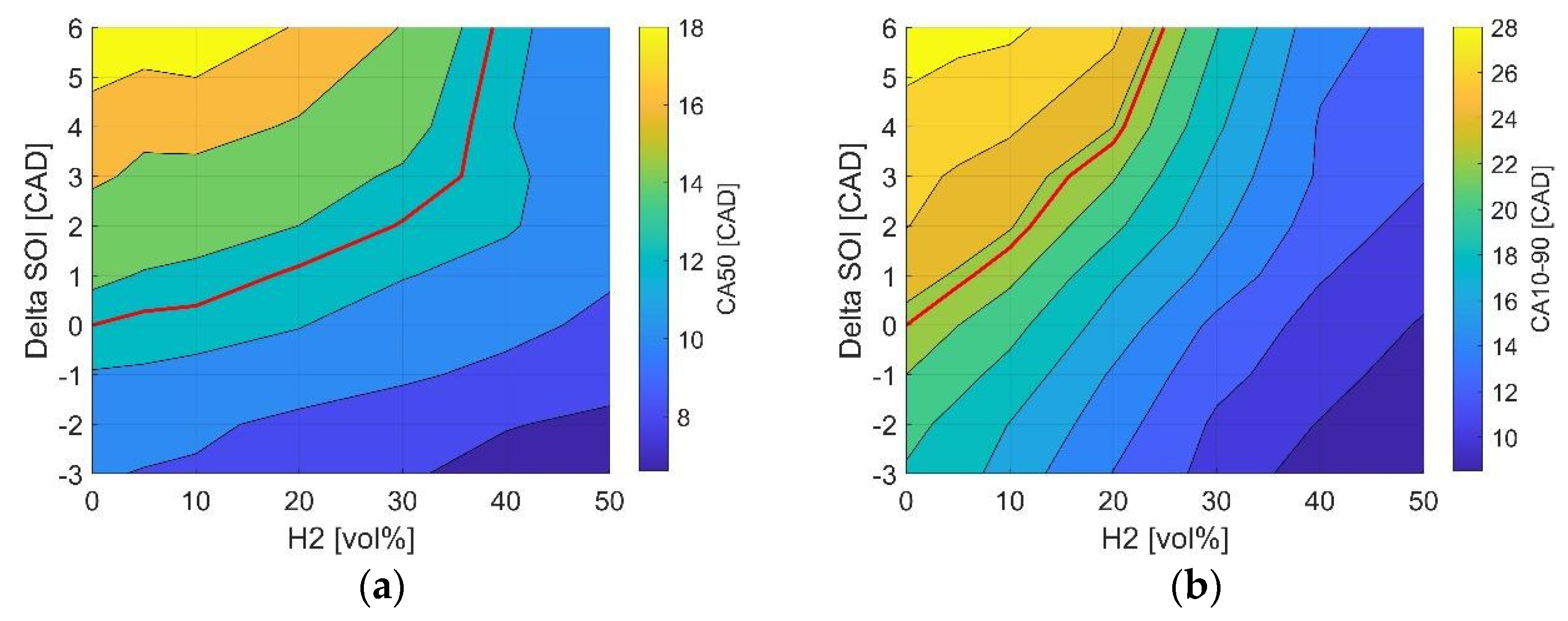

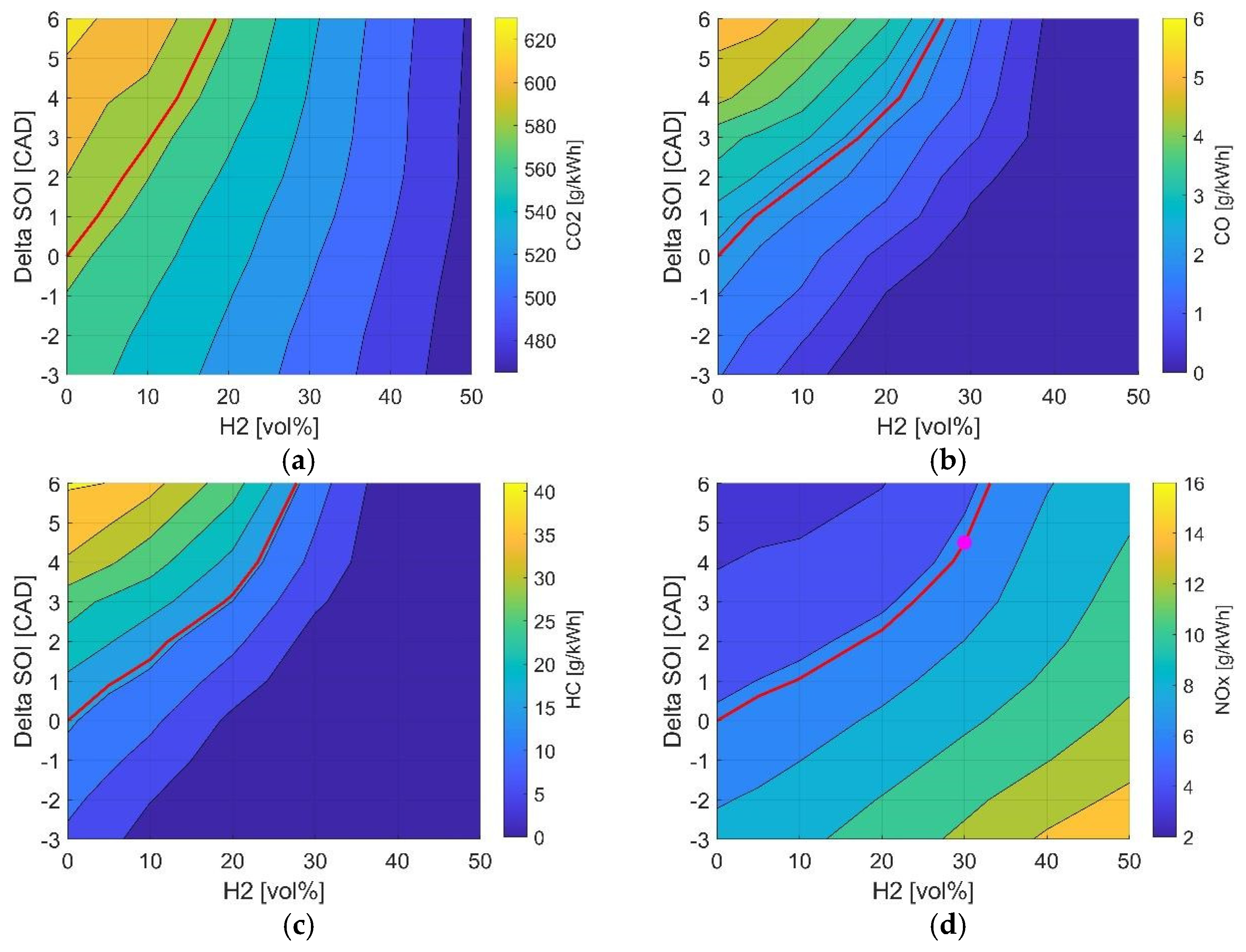

3.1. Influence of Hydrogen Content and Start of Injection

- friction losses mainly depend on engine speed, that does not change, and on in-cylinder peak pressures, that are quite similar;

- pumping losses are related to the mass flow rate delivered by the engine, that is kept almost constant throughout the cases.

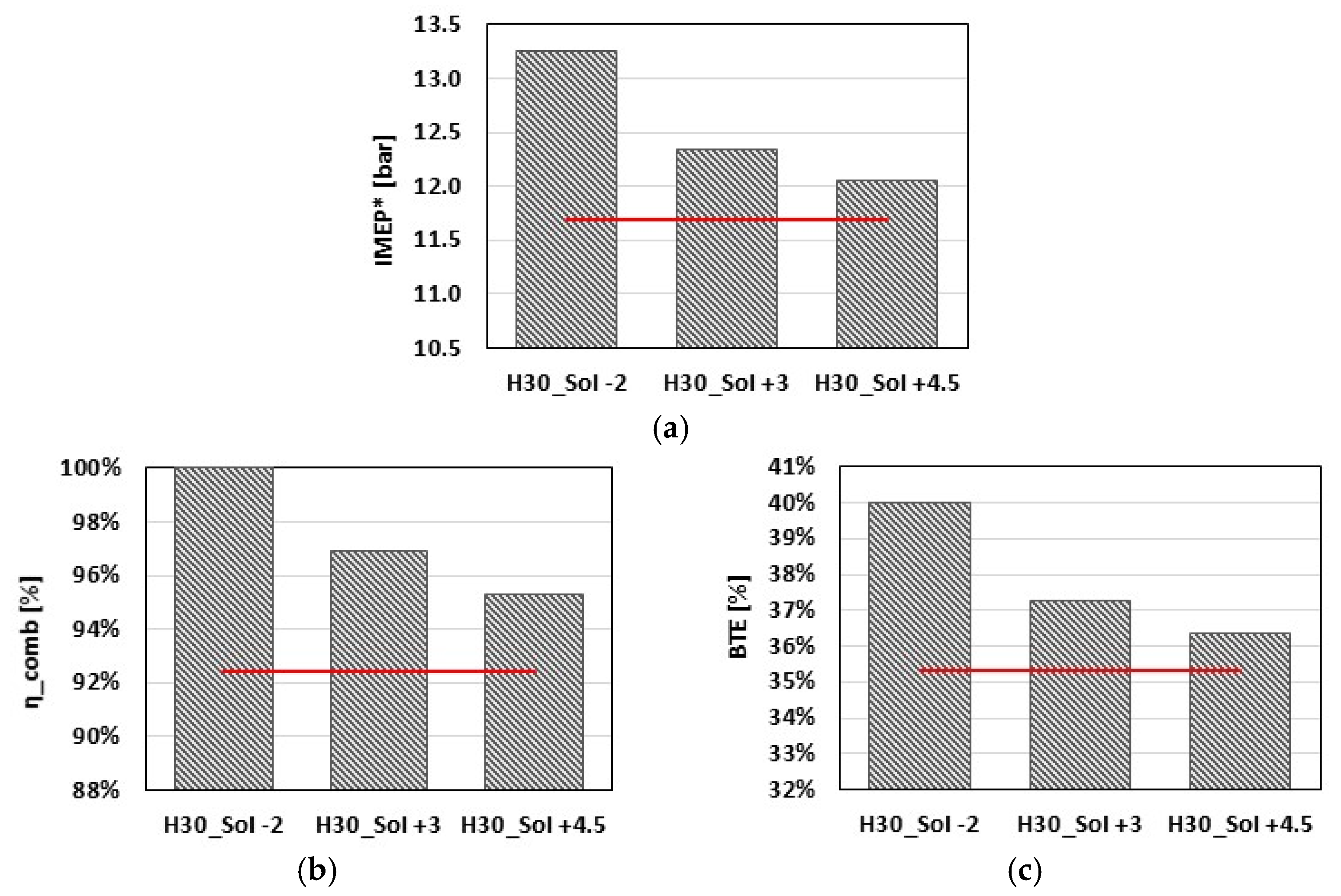

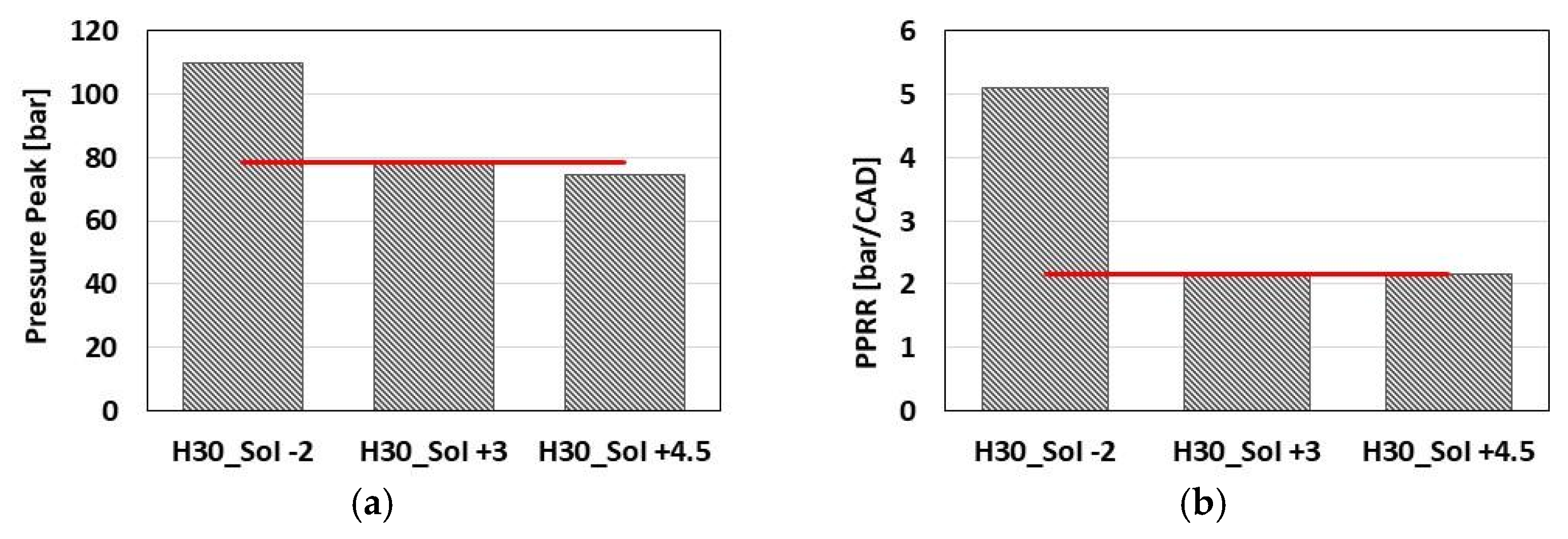

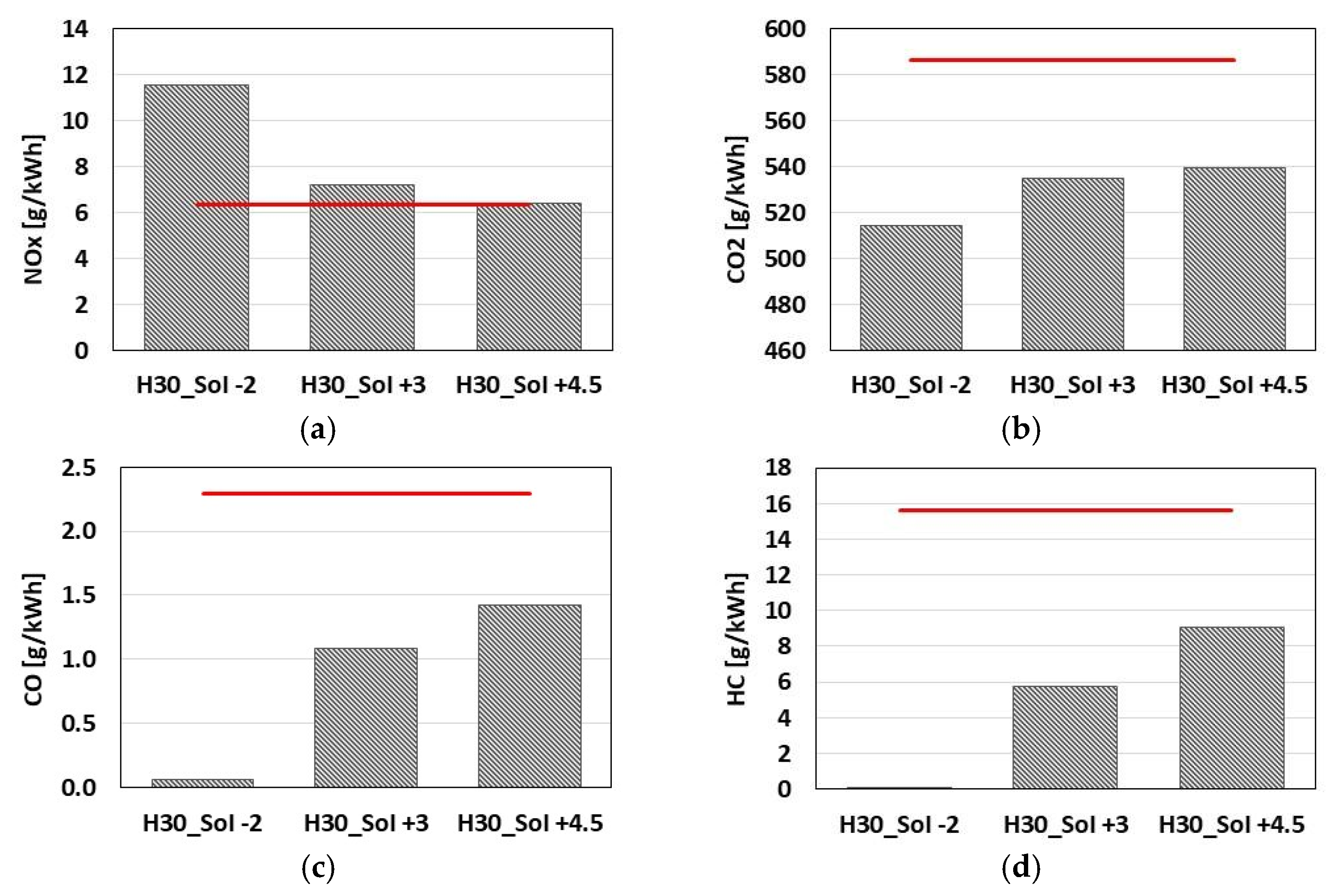

3.2. Engine Performace and Emissions of Selected Operating Points

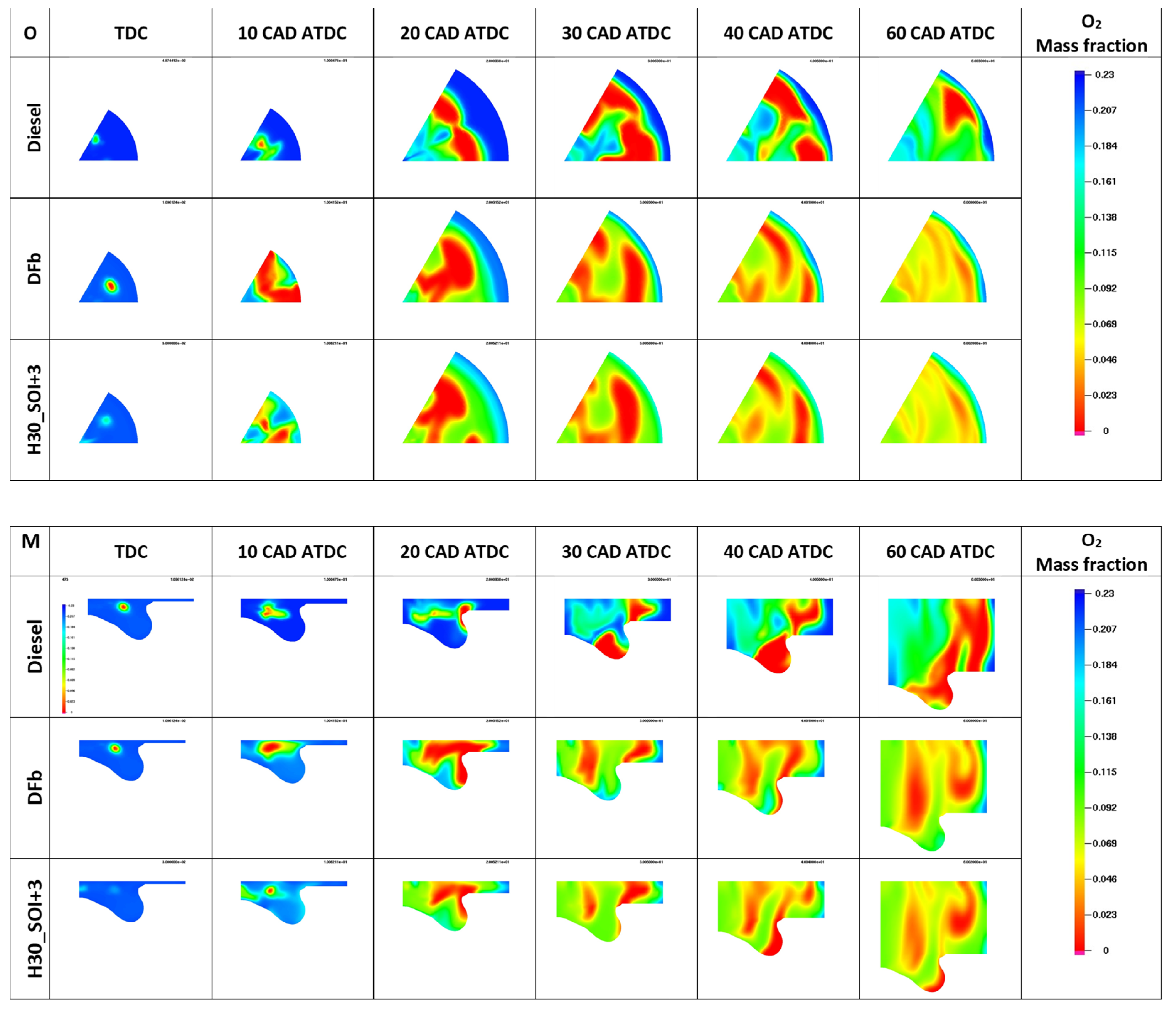

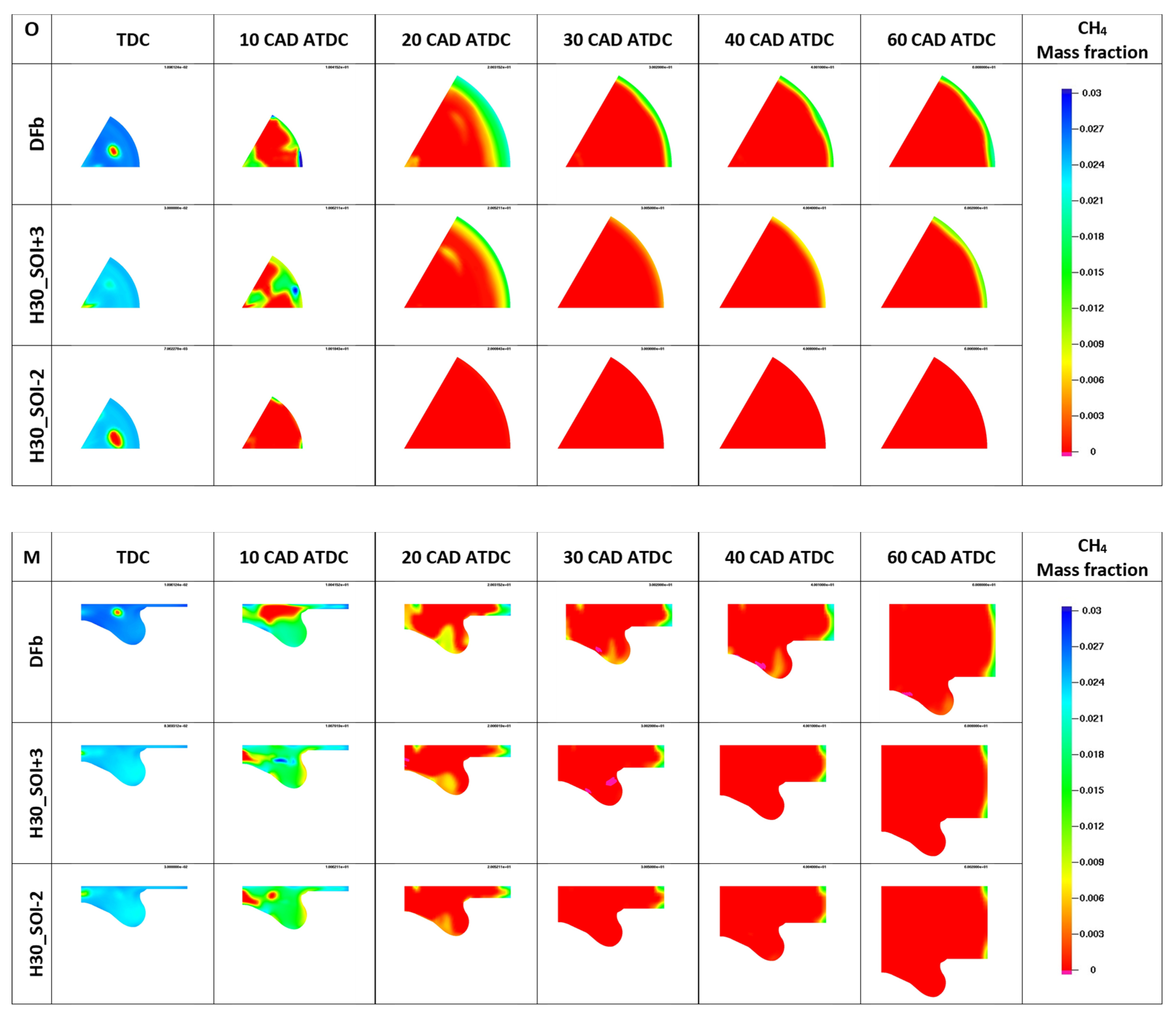

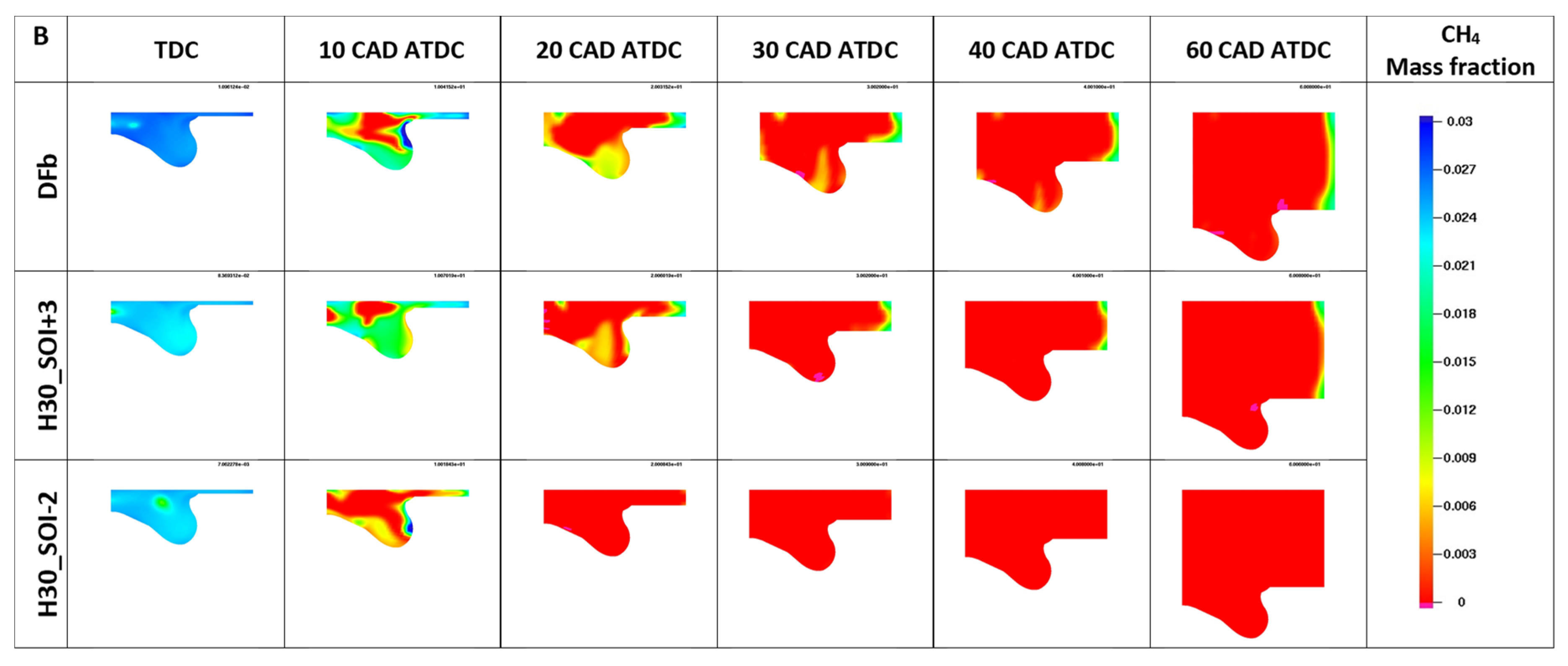

3.3. Combustion Anlysis of Selected Operating Points

- “O”: cut plane normal to the cylinder axis;

- “M”: cut plane coincident with the symmetry plane of the sector mesh;

- “B”: cut plane coincident with the periodic boundary of the sector mesh.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Acronyms and Abbreviations

| (A/F)premix | A-to-Fuel ratio of the premixed charge |

| (A/F)st,premix | stoichiometric A-to-Fuel ratio of the premixed charge |

| (A/F)st,tot | global stoichiometric A-to-Fuel ratio |

| (A/F)tot | global A-to-Fuel ratio |

| 3D | 3-Dimensional |

| AFTDC | After Firing Top Dead left |

| AHRR | Apparent Heat Release Rate |

| BDC | Bottom Dead left |

| BEV | Battery Electric Vehicle |

| BMEPexp | experimental Brake Mean Effective Pressure |

| BMEP | Brake Mean Effective Pressure |

| BTE | Brake Thermal Efficiency |

| C2H6 | ethane |

| C3H8 | propane |

| CA10-90 | Crank Angle interval between 10% and 90% of mass fraction burnt |

| CA50 | Crank Angle at 50% of mass fraction burnt |

| CAD | Crank Angle Degree |

| CFD | Computational Fluid Dynamics |

| CH4 | methane |

| CI | Compression Ignition |

| CNG | Compressed Natural Gas |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| DF | Dual Fuel |

| DFb | baseline Dual Fuel |

| DME | Dimethyl Ether |

| EGR | Exhaust Gas Recirculation |

| EVC | Exhaust Valve Closing |

| EVO | Exhaust Valve Opening |

| FMEP | Friction Mean Effective Pressure |

| GHG | Greenhouse Gas |

| H2 | hydrogen |

| HD | Heavy-Duty |

| HSDI | High-Speed Direct-injection |

| ICE | Internal Combustion Engine |

| experimental gross Indicated Mean Effective Pressure | |

| IMEP | Indicated Mean Effective Pressure |

| IMEP* | gross Indicated Mean Effective Pressure |

| IVC | Intake Valve Closing |

| IVO | Intake Valve Opening |

| KH-RT | Kelvin–Helmholtz/Rayleigh–Taylor |

| LPG | Liquefied Petroleum Gas |

| LRF | Low Reactivity Fuel |

| n | engine revolution speed |

| ND | Normal Diesel |

| NG | Natural Gas |

| NOx | nitrogen oxides |

| Ny | Number of cells along the circumferential direction |

| P | engine brake Power |

| PaSR | Partially Stirred Reactor |

| PC | Pre-Chamber |

| PMEP | Pumping Mean Effective Pressure |

| PPRR | Peak Pressure Rise Rate |

| PRR | Pressure Rise Rate |

| RNG | Renormalization Group |

| SI | Spark Ignition |

| SOC | Start Of Combustion |

| SOI | Start Of Injection |

| TDC | Top Dead Center |

| TFC | Turbulent Flame Closure |

| UHC | Unburnt Hydrocarbons |

| Vd | total displacement |

| VGT | Variable Geometry Turbine |

| λpremix | lambda of the premixed charge |

| λtot | global lambda |

| ηcomb | combustion efficiency |

| gross indicated efficiency |

Appendix A

References

- Ritchie, H.; Roser, M. CO2 and Greenhouse Gas Emissions. Our World in Data. May 2020. Available online: https://ourworldindata.org/co2-and-other-greenhouse-gas-emissions (accessed on 12 September 2021).

- Allan, R.P.; Arias, P.A.; Berger, S.; Canadell, J.G.; Cassou, C.; Chen, D.; Cherchi, A.; Connors, S.L.; Coppola, E.; Cruz, F.A.; et al. (Eds.) Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2021. [Google Scholar]

- COP26 Goals. UN Climate Change Conference (COP26) at the SEC—Glasgow 2021. Available online: https://ukcop26.org/cop26-goals/ (accessed on 2 December 2021).

- Dimitriou, P.; Tsujimura, T. A review of hydrogen as a compression ignition engine fuel. Int. J. Hydrog. Energy 2017, 42, 24470–24486. [Google Scholar] [CrossRef]

- AVL. Press Release: AVL Advances Development of Hydrogen Internal Combustion Engine for CO2 Neutral Transportation. Available online: https://www.avl.com/all-press-releases/-/asset_publisher/0RuLfhkFPSCT/content/press-release-avl-advances-development-of-hydrogen-internal-combustion-engine-for-co2-neutral-transportation?_com_liferay_asset_publisher_web_portlet_AssetPublisherPortlet_INSTANCE_0RuLfhkFPSCT_redirect=https%3A%2F%2Fwww.avl.com%3A443%2Fall-press-releases%3Fp_p_id%3Dcom_liferay_asset_publisher_web_portlet_AssetPublisherPortlet_INSTANCE_0RuLfhkFPSCT%26p_p_lifecycle%3D0%26p_p_state%3Dnormal%26p_p_mode%3Dview%26_com_liferay_asset_publisher_web_portlet_AssetPublisherPortlet_INSTANCE_0RuLfhkFPSCT_cur%3D0%26p_r_p_resetCur%3Dfalse%26_com_liferay_asset_publisher_web_portlet_AssetPublisherPortlet_INSTANCE_0RuLfhkFPSCT_assetEntryId%3D40114324 (accessed on 29 September 2021).

- A Hydrogen Strategy for a Climate-Neutral Europe. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52020DC0301&from=EN (accessed on 30 September 2021).

- The European Green Deal. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52019DC0640&from=EN (accessed on 11 April 2021).

- NextGenerationEU. Available online: https://europa.eu/next-generation-eu/index_en (accessed on 30 September 2021).

- Attard, W.P.; Parsons, P. Flame Kernel Development for a Spark Initiated Pre-Chamber Combustion System Capable of High Load, High Efficiency and Near Zero NOx Emissions. SAE Int. J. Engines 2010, 3, 408–427. [Google Scholar] [CrossRef] [Green Version]

- Shim, E.; Park, H.; Bae, C. Comparisons of advanced combustion technologies (HCCI, PCCI, and dual-fuel PCCI) on engine performance and emission characteristics in a heavy-duty diesel engine. Fuel 2020, 262, 116436. [Google Scholar] [CrossRef]

- Wei, L.; Geng, P. A review on natural gas/diesel dual fuel combustion, emissions and performance. Fuel Process. Technol. 2016, 142, 264–278. [Google Scholar] [CrossRef]

- Pedrozo, V.B.; May, I.; Guan, W.; Zhao, H. High efficiency ethanol-diesel dual-fuel combustion: A comparison against conventional diesel combustion from low to full engine load. Fuel 2018, 230, 440–451. [Google Scholar] [CrossRef]

- Saccullo, M.; Benham, T.; Denbratt, I. Dual Fuel Methanol and Diesel Direct Injection HD Single Cylinder Engine Tests; SAE Technical Paper No. 2018-01-0259; SAE: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Cardone, M.; Marialto, R.; Ianniello, R.; Lazzaro, M.; di Blasio, G. Spray Analysis and Combustion Assessment of Diesel-LPG Fuel Blends in Compression Ignition Engine. Fuels 2020, 2, 1–15. [Google Scholar] [CrossRef]

- Zheng, Z.; Xia, M.; Liu, H.; Wang, X.; Yao, M. Experimental study on combustion and emissions of dual fuel RCCI mode fueled with biodiesel/n-butanol, biodiesel/2,5-dimethylfuran and biodiesel/ethanol. Energy 2018, 148, 824–838. [Google Scholar] [CrossRef]

- Chen, Z.; Yao, M.; Zheng, Z.; Zhang, Q. Experimental and Numerical Study of Methanol/Dimethyl Ether Dual-Fuel Compound Combustion. Energy Fuels 2009, 23, 2719–2730. [Google Scholar] [CrossRef]

- Schefer, R.W. Hydrogen enrichment for improved lean flame stability. Int. J. Hydrog. Energy 2003, 28, 1131–1141. [Google Scholar] [CrossRef]

- Miao, H.; Lu, L.; Huang, Z. Flammability limits of hydrogen-enriched natural gas. Int. J. Hydrog. Energy 2011, 36, 6937–6947. [Google Scholar] [CrossRef]

- Rahnama, P.; Paykani, A.; Reitz, R.D. A numerical study of the effects of using hydrogen, reformer gas and nitrogen on combustion, emissions and load limits of a heavy duty natural gas/diesel RCCI engine. Appl. Energy 2017, 193, 182–198. [Google Scholar] [CrossRef]

- Zhou, J.H.; Cheung, C.S.; Leung, C.W. Combustion, performance and emissions of a diesel engine with H2, CH4 and H2–CH4 addition. Int. J. Hydrog. Energy. 2014, 39, 4611–4621. [Google Scholar] [CrossRef]

- Liu, F.; Kang, Y.; Wu, H.; Lee, C.-F.; Li, Y. Effect of Hydrogen Volume Ratio on the Combustion Characteristics of CNG-Diesel Dual-Fuel Engine; SAE Technical Paper No. 2017-01-2270; SAE: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Tripathi, G.; Sharma, P.; Dhar, A.; Sadiki, A. Computational investigation of diesel injection strategies in hydrogen-diesel dual fuel engine. Sustain. Energy Technol. Assess. 2019, 36, 100543. [Google Scholar] [CrossRef]

- Mattarelli, E.; Rinaldini, C.A.; Savioli, T.; Scrignoli, F. Optimization of a High-Speed Dual-Fuel (Natural Gas-Diesel) Compression Ignition Engine for Gen-sets. SAE Int. J. Engines 2021, 14, 369–386. [Google Scholar] [CrossRef]

- Amsden, A. KIVA-3: A KIVA Program with Block-Structured Mesh for Complex Geometries; No. LA-12503-MS; Los Alamos National Lab.: New Mexico, NM, USA, 1993. [Google Scholar]

- Golovitchev, V.I.; Nordin, N.; Jarnicki, R.; Chomiak, J. 3-D Diesel Spray Simulations Using a New Detailed Chemistry Turbulent Combustion Model. SAE Trans. 2000, 109, 1391–1405. [Google Scholar]

- Golovitchev, V.I.; Imren, A. Development of dual fuel combustion models for direct injected heavy duty diesel engines. In Diesel Fuels: Characteristics, Performance and Environmental Impacts; Nova Science Publishers: Hauppauge, NY, USA, 2013; pp. 85–118. [Google Scholar]

- Golovitchev, V.I.; Rinaldini, C.A.; Montorsi, L.; Rosetti, A. CFD combustion and emission formation modeling for a HSDI diesel engine using detailed chemistry. In American Society of Mechanical Engineers, Internal Combustion Engine Division (Publication) ICE; ASME: New York, NY, USA, 2006. [Google Scholar] [CrossRef]

- Mattarelli, E.; Rinaldini, C.A.; Golovitchev, V.I. CFD-3D analysis of a light duty Dual Fuel (Diesel/Natural Gas) combustion engine. Energy Procedia 2014, 45, 929–937. [Google Scholar] [CrossRef] [Green Version]

- Gustavsson, J.; Golovitchev, V.I. Spray Combustion Simulation Based on Detailed Chemistry Approach for Diesel Fuel Surrogate Model; SAE Technical Paper 2003-01-1848; SAE International: Warrendale, PA, USA, 2003. [Google Scholar] [CrossRef]

- Ehleskog, R.; Golovitchev, V.; Denbratt, I.; Andersson, S.; Rinaldini, C.A. Experimental and numerical investigation of split injections at low load in an hddi diesel engine equipped with a piezo injector. In Proceedings of the Powertrain & Fluid Systems Conference and Exhibition, Toronto, ON, Canada, 16–19 October 2006; pp. 932–946. [Google Scholar] [CrossRef]

- Cantore, G.; Mattarelli, E.; Rinaldini, C.A.; Savioli, T.; Scrignoli, F. Numerical optimization of the injection strategy on a light duty diesel engine operating in dual fuel (CNG/diesel) mode. Int. J. Heat Technol. 2019, 37, 682–688. [Google Scholar] [CrossRef]

- Rinaldini, C.A.; Mattarelli, E.; Golovitchev, V.I. Potential of the Miller cycle on a HSDI diesel automotive engine. Appl. Energy 2013, 112, 102–119. [Google Scholar] [CrossRef]

- Eng, J.A. Characterization of Pressure Waves in HCCI Combustion; SAE Technical Paper No. 2002-01-2859; SAE: Warrendale, PA, USA, 2002. [Google Scholar] [CrossRef]

| Engine Type | HSDI 4-S Diesel, EURO IV |

| Cylinders | 4 in-line |

| Total displacement [L] | 2.78 |

| Bore × Stroke [mm] | 94 × 100 |

| Compression ratio | 17.5:1 |

| N. of valves per cylinder | 4 |

| Exhaust valve timing [CA °AFTDC] | 114 (EVO)/389 (EVC) |

| Intake valve timing [CA °AFTDC] | 337 (IVO)/590 (IVC) |

| Air Metering | Turbocharger with VGT + Intercooler |

| Injection system | Common Rail |

| Max. Injection press. [MPa] | 160 |

| Number of injector holes | 6 |

| Injector hole diameter [mm] | 0.153 |

| Max. brake power [kW@rpm] | 130@3800 |

| Max. brake torque [Nm@rpm] | 440@1750 |

| Max. Engine Speed [rpm] | 4600 |

| Parameter | ND | DF NG-Diesel |

|---|---|---|

| Engine speed × BMEP [rpm × bar] | 3000 × 8 | 3000 × 8 |

| Brake Torque [Nm] | 177 | 177 |

| Brake Power [kW] | 55.6 | 55.6 |

| Amount of Diesel fuel per cylinder [mg/cycle] | 36.31 | 7.6 |

| Energy provided by diesel fuel [%] (*) | 100.0 | 20.9 |

| Amount of NG per cylinder [mg/cycle] | - | 25.26 |

| Energy provided by NG [%] (*) | 0.0 | 75.2 |

| ND | DF | ||

|---|---|---|---|

| Numerical IMEP* | [bar] | 12.65 | 11.69 |

| Experimental IMEP* | [bar] | 13.13 | 11.64 |

| IMEP* difference | [%] | 3.683 | 0.467 |

| Numerical peak in-cylinder pressure | [bar] | 91.13 | 78.44 |

| Experimental peak in-cylinder pressure | [bar] | 89.64 | 77.44 |

| Peak in-cylinder pressure difference | [%] | 1.665 | 0.655 |

| NG | 5 vol% H2 | 10 vol% H2 | 20 vol% H2 | 30 vol% H2 | 40 vol% H2 | 50 vol% H2 | ||

|---|---|---|---|---|---|---|---|---|

| Composition [vol%] | CH4 | 96.000 | 91.200 | 86.400 | 76.800 | 67.200 | 57.600 | 48.000 |

| C2H6 | 2.500 | 2.375 | 2.250 | 2.000 | 1.750 | 1.500 | 1.250 | |

| C3H8 | 0.500 | 0.475 | 0.450 | 0.400 | 0.350 | 0.300 | 0.250 | |

| N2 | 1.000 | 0.950 | 0.900 | 0.800 | 0.700 | 0.600 | 0.500 | |

| H2 | 0.000 | 5.000 | 10.000 | 20.000 | 30.000 | 40.000 | 50.000 |

| CH4 [mg] | H2 [mg] | (A/F)premix [-] | (A/F)st,premix [-] | λpremix [-] | (A/F)tot [-] | (A/F)st,tot [-] | λtot [-] | H2 Energy Fract. [%] | H2 Mass Fract. [%] | |

|---|---|---|---|---|---|---|---|---|---|---|

| NG | 23.39 | 0.00 | 30.78 | 16.84 | 1.83 | 23.57 | 16.23 | 1.45 | - | - |

| 5 vol% H2 | 23.07 | 0.16 | 30.94 | 16.95 | 1.82 | 23.66 | 16.31 | 1.45 | 1.21% | 0.51% |

| 10 vol% H2 | 22.67 | 0.33 | 31.19 | 17.08 | 1.83 | 23.79 | 16.40 | 1.45 | 2.52% | 1.08% |

| 20 vol% H2 | 21.77 | 0.71 | 31.78 | 17.37 | 1.83 | 24.10 | 16.60 | 1.45 | 5.46% | 2.37% |

| 30 vol% H2 | 20.78 | 1.17 | 32.42 | 17.72 | 1.83 | 24.43 | 16.85 | 1.45 | 8.93% | 3.96% |

| 40 vol% H2 | 19.60 | 1.70 | 33.22 | 18.16 | 1.83 | 24.84 | 17.16 | 1.45 | 13.00% | 5.89% |

| 50 vol% H2 | 18.06 | 2.37 | 34.42 | 18.76 | 1.83 | 25.45 | 17.56 | 1.45 | 18.08% | 8.44% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scrignoli, F.; Vecchio, F.; Legrottaglie, F.; Mattarelli, E.; Rinaldini, C.A. Numerical Investigation of Dual Fuel Combustion on a Compression Ignition Engine Fueled with Hydrogen/Natural Gas Blends. Fuels 2022, 3, 132-151. https://doi.org/10.3390/fuels3010009

Scrignoli F, Vecchio F, Legrottaglie F, Mattarelli E, Rinaldini CA. Numerical Investigation of Dual Fuel Combustion on a Compression Ignition Engine Fueled with Hydrogen/Natural Gas Blends. Fuels. 2022; 3(1):132-151. https://doi.org/10.3390/fuels3010009

Chicago/Turabian StyleScrignoli, Francesco, Filippo Vecchio, Francesco Legrottaglie, Enrico Mattarelli, and Carlo Alberto Rinaldini. 2022. "Numerical Investigation of Dual Fuel Combustion on a Compression Ignition Engine Fueled with Hydrogen/Natural Gas Blends" Fuels 3, no. 1: 132-151. https://doi.org/10.3390/fuels3010009

APA StyleScrignoli, F., Vecchio, F., Legrottaglie, F., Mattarelli, E., & Rinaldini, C. A. (2022). Numerical Investigation of Dual Fuel Combustion on a Compression Ignition Engine Fueled with Hydrogen/Natural Gas Blends. Fuels, 3(1), 132-151. https://doi.org/10.3390/fuels3010009