Abstract

The Olavide Museum in Madrid, which was founded in the 19th century, preserves one of the most important collections in the world of three-dimensional dermatological models made of polychrome beeswax. These models have been used for the training of numerous generations of dermatologists in Spain. Unfortunately, many of the figures were preserved in precarious conditions during the time that the museum was closed in the middle of the 20th century, and some could not be found after its reopening. In this paper, we show a method for the recovery of a missing model of which only the original plaster cast remains. For this purpose, we use the combination of a structured light scanner and 3D printing, together with traditional techniques, to reproduce a copy of the original cast, in order to prevent its deterioration during the wax casting. As a result of this study, a highly realistic figure was obtained, which represented, in great detail, the small superficial reliefs of the skin lesions, as well as their colour. The conclusion of this research is that it is possible to recreate, with precision, a didactic model in beeswax from its mould, without the need to use the mould in the process, which avoids any risk of deterioration in the process.

1. Introduction

On 26 December 1882, the Museum of the Hospital San Juan de Dios in Madrid was inaugurated [1]. The institution was founded in the middle of the 19th century by Dr. Jose Eugenio Olavide (1836–1901), who, at that time, was the physician in charge of the wards of skin diseases in the hospital. An important collection of dermatological models that were made of polychrome beeswax was created in the institution in order to support the training of doctors in the science of dermatology.

Didactic models, produced by the technique known as “ceroplasty”, began to be used in Europe at the end of the 17th century to instruct new doctors in the field of anatomy [2]. This technique had an enormous diffusion during the 18th century as a means of transmitting anatomical knowledge [3]. The first ateliers were set up in Bologna, and later in Florence, where this activity developed considerably. Anatomical figures began to be in demand from the Florentine workshops in numerous European cities because of their scientific and artistic quality [4]. Models of enormous complexity were created in these ateliers, which represent even the smallest anatomical structures in minute detail. There are numerous examples of this type of figure in different universities and museums in many countries. Among them, “La Specola”, in Florence, is particularly noteworthy [5]. In Spain, there is a notable collection of wax models that were created in the 18th century for the Anatomical Cabinet of the Royal College of Surgery of San Carlos in Madrid, which are currently conserved in the “Javier Puerta” Anatomy Museum, which is located in the Complutense University of Madrid [6].

The use of this type of didactic sculpture specifically for the study of skin conditions began at the end of the 18th century, with pioneers such as Heinrich Martens (1778–1805), Joseph Towne (1806–1879), and Anton Elfinger (1821–1864). However, it was Jules Baretta (1833–1923), a wax sculptor at the Saint Louis Hospital, who provided the definitive impetus for these figures to acquire the definitive status of “didactic models” at the end of the 19th century [7].

The first wax figures in the Olavide Museum were made by the sculptor, Enrique Zofío (1835–1915?). They represented different dermatological conditions with a high degree of detail and verisimilitude, and they constitute an outstanding example of art in the service of medicine. Subsequently, other wax sculptors, such as José Barta Bernadotta (1875–1955) and Rafael López Álvarez (1898–1987), took over, making different modifications to the technique. After the death of Dr. Olavide in 1901, it was renamed, the Olavide Museum, in his honour [8].

After a few decades of great splendour, interest in the museum began to wane because of the development of colour photography, which allowed a faithful depiction of skin lesions, and also because of the introduction of new treatments, such as salvarsan or penicillin, which significantly reduced the number of patients with these pathologies. Finally, in 1966, the museum was closed, and the collection was packed and conserved in different institutions, which were not always in adequate conditions [9].

Years later, and thanks to an arduous recovery effort, the collection was rescued from oblivion by the Spanish Academy of Dermatology and Venerology [10]. In its new location, at the Faculty of Medicine of the Complutense University of Madrid (UCM), the dermatological wax pieces are exhibited, and they constitute an outstanding example of the important synergies that have existed in the past between science and art with the aim of contributing to knowledge. However, during the reopening of the museum, it was noticed that many of the pieces had been seriously damaged or had even disappeared. Since then, a team of doctors, conservators, and restorers has been working constantly to recover this important scientific and artistic heritage, and to ensure its preservation.

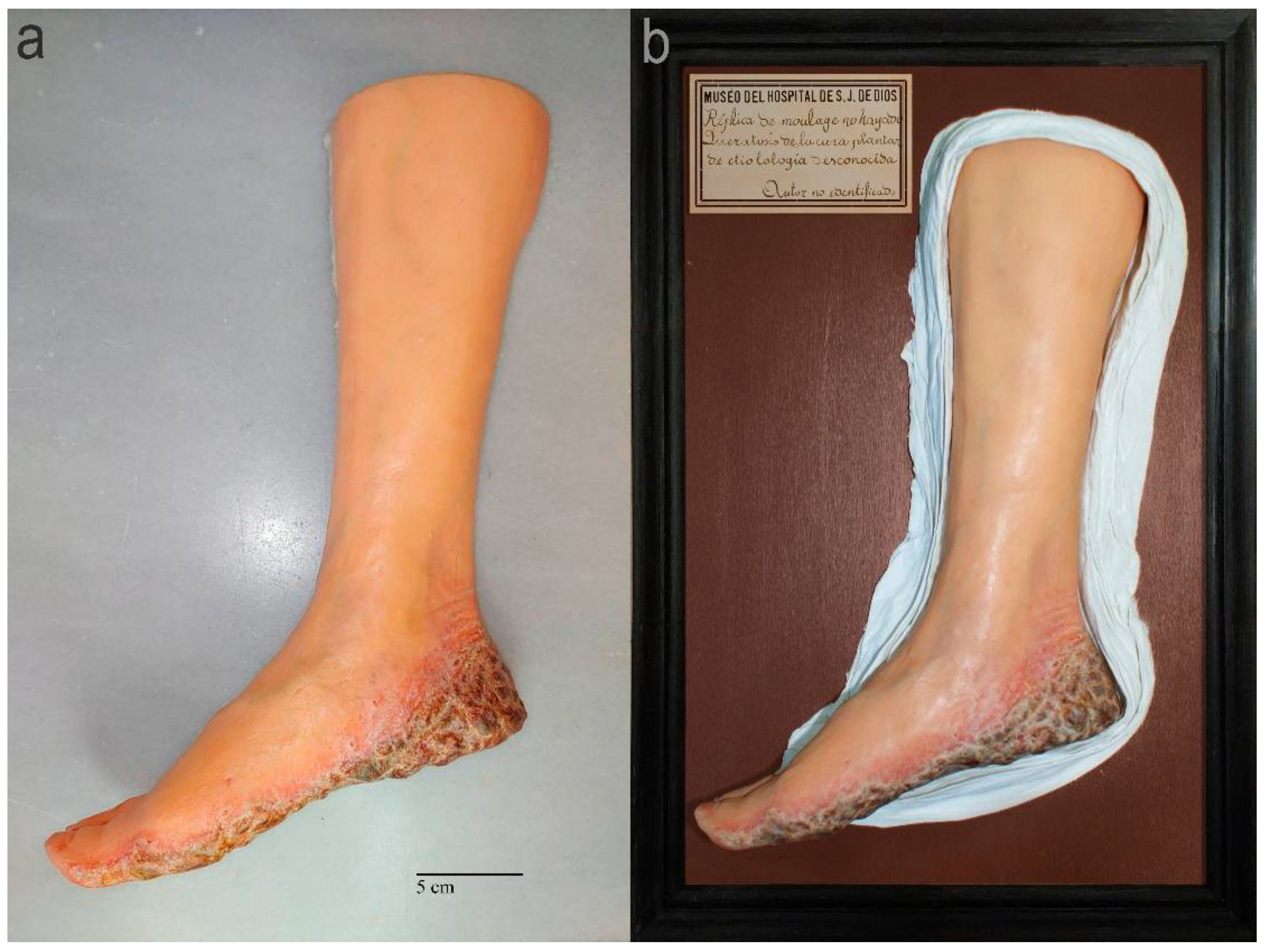

In recent years, the UCM research group (Art, Technology, Image and Conservation of Cultural Heritage) has been collaborating with the Olavide Museum to carry out the 3D digitization of the models that belong to the collection, and to propose new conservation–restoration methods that are based on 3D scanning and 3D printing technologies. In this research, we have analysed a plaster cast, which corresponds to an unfound moulage that represents the inner side of the foot and the distal part of the lower extremity, with a series of irregular-looking skin lesions in the plantar region of unidentified aetiology.

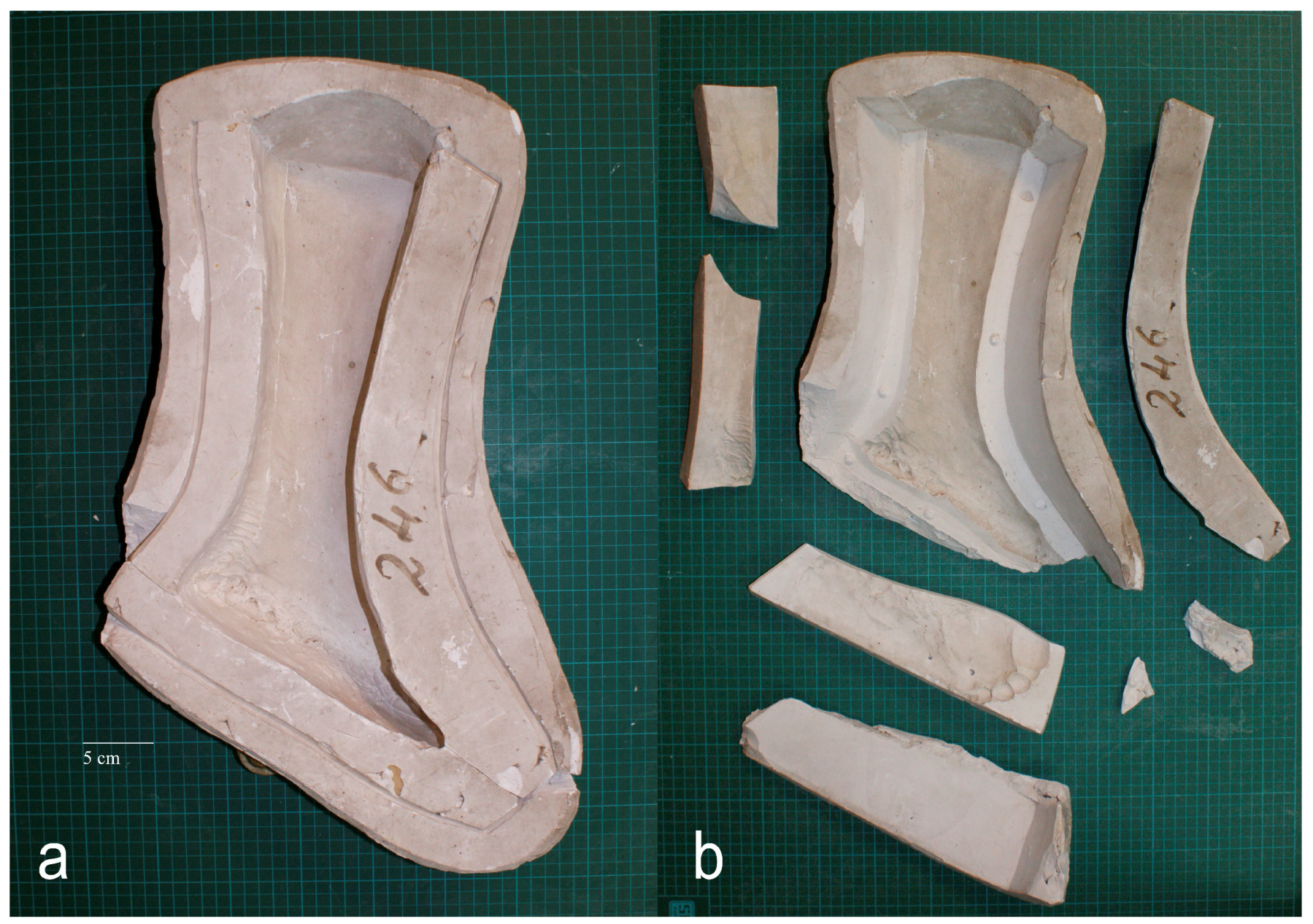

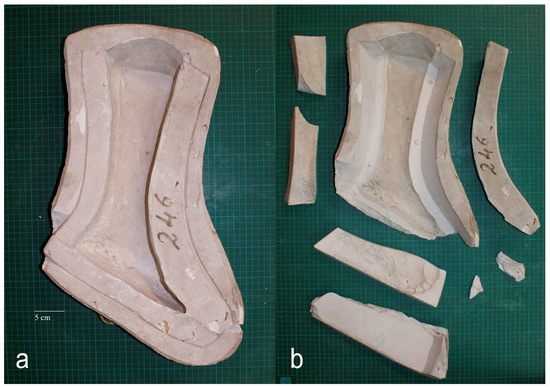

The various damages suffered in the moulage, such as dilatations, contractions, and even the collapse and breakage of the material, indicate the poor storage conditions and environmental parameters to which the work was subjected during the long years of abandonment (Figure 1 and Figure 2).

Figure 1.

Original plaster mould in its present state: (a) mould set assembled; (b) moulds disassembled to show all parts and fragments.

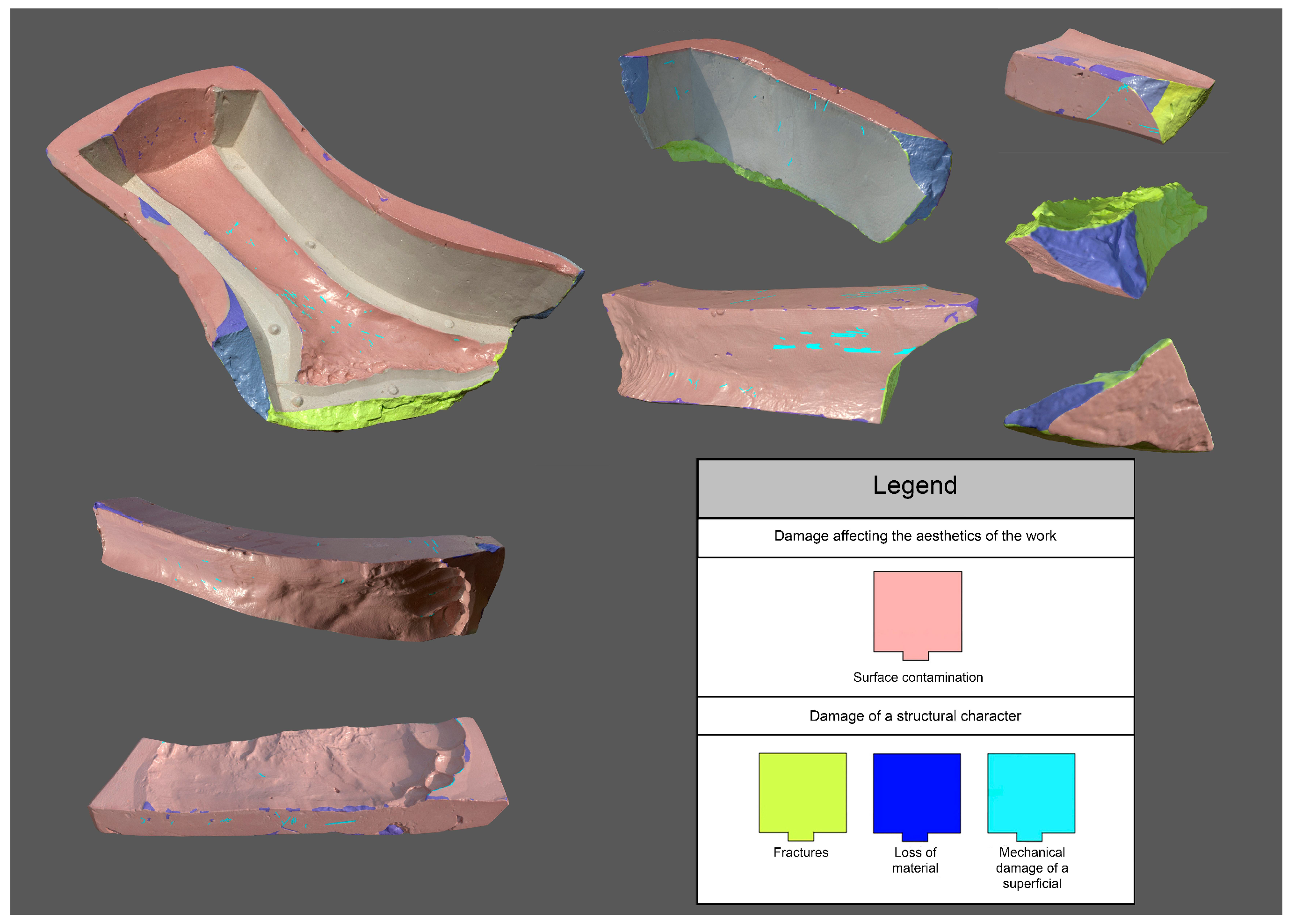

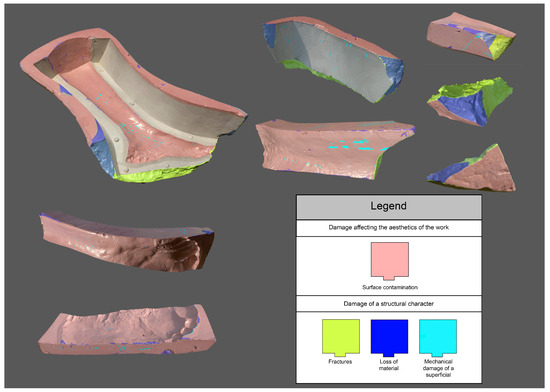

Figure 2.

3D pathology mapping of the different fragments that make up the mould.

The analysis of the plaster mould allowed us to infer the technique of the elaboration of the moulage, which made it possible to create a wax duplicate of the original sculpture that can be used as experimental material for future interventions in real work. Finally, this study represents a vindication and enhancement of this cultural heritage of great medical, historical, artistic, and social wealth. The aim is to prevent it from sinking back into oblivion.

The approach that was chosen for this work included digitization, 3D modelling, and 3D printing technologies, along with traditional casting and polychrome techniques.

In recent decades, different methods of 3D digitisation have been used in cultural heritage, and more and more extensively. Several reasons have led to this progressive increase in its use: the greater ease of access to this type of technology because of less expensive devices; the growing number of applications in conservation, research, and dissemination; and the risk of irretrievable loss due to different causes, such as natural disasters or armed conflicts [11]. In addition, the recent COVID-19 pandemic has further increased the interest in seeking alternative methods of accessing cultural heritage through digital technologies [12]. There are many benefits that can be derived from the use of a three-dimensional model, such as, for example, the possibility of studying the work without the need to have it present; the ability to plan an intervention on it, which minimises the risk that is derived from its manipulation; the ability to document its current state; and its dissemination through Internet platforms, etc. [13,14].

The most common noncontact 3D digitising methods comprise passive sensor systems, such as those that are used in image-based techniques (i.e., photogrammetry), as well as active optical sensor systems that are based on triangulation (close-range laser scanners and structured light scanners) or time delay (time-of-flight scanners and phase-based scanners).

These methods have different characteristics, such as 3D resolution, accuracy, acquisition time, and acquisition range, or texture resolution, among others. Despite the evolution in the technologies that are used for this purpose, currently, none of them alone can generate a high-quality model, both in terms of geometry and colour texture [15].

Close-range laser scanning and structured light scanners are characterised by their high accuracies and geometric resolutions at small-to-medium working distances. Photogrammetry, on the other hand, is particularly appreciated for its high-quality colour texture. In order to take advantage of the benefits that are offered by the different types of devices, a common strategy is to combine a range-based technique, such as CRLS or SLS, with an image-based technique, such as photogrammetry [16,17,18].

Different studies have used digital technologies to obtain physical reproductions of damaged or missing pieces that needed to be restored or reconstructed. In some of these works, the object was digitized by using photogrammetry or 3D scanning to obtain a virtual model that could be digitally restored and subsequently reproduced on a 3D printer [19,20,21,22,23]. In some cases, in order to obtain a copy in a material that cannot be used in 3D printing, moulds have been generated on the computer from the virtual model [24,25,26]. In this study, however, which lacked the figure in positive, and with the moulds being in a rather precarious state of preservation, it was decided to digitize all of the pieces to obtain a virtual model of each of them. For this task, we used a structured light scanner to acquire accurate high-resolution geometry information. Since the artefact to be scanned was a mould, it was not necessary to calculate a high-quality colour texture by using an image-based technique, such as photogrammetry. Therefore, we only gathered the colour information from the scanner’s camera. Once the mould was printed, it served to create by casting, in beeswax, a replica of the original sculpture. Finally, a polychrome process to recreate the characteristic appearance of the pathology that was represented was conducted, which took as a reference other dermatological models from the same collection.

In order to reproduce, as faithfully as possible, the manufacturing method that was followed by the wax sculptors who worked in the museum, the existing documentation in the archives was studied, as well as other works that are preserved in the institution, with the aim of determining the technique to be used and the sequence of steps to be followed during the process. For this analysis, the descriptions of the main phases of the production of the dermatological models in the museum conducted in previous research have also been very helpful [27].

2. Materials and Methods

The main premise that was contemplated during the decision-making process with regard to the techniques to be used to obtain the replica from the mould that was found was to avoid any process that would put its integrity at risk by taking into account the precarious situation in which it was found (with different fractures and fissures, as well as with some small missing fragments). In addition, some of the interior reliefs that correspond to skin folds are very fragile, and there was a risk of breaking them. With consideration to these factors, it was decided to use a conservative strategy based on the use of digitalization and 3D printing technologies in order to obtain the positives.

2.1. 3D Scanning

First, each of the mould parts was scanned using an Artec Space Spider 3D structure light scanner, Artec 3D (Luxembourg City, Luxembourg), which is a handheld device that uses a blue light source and that has a 3D point accuracy of up to 0.5 mm, a resolution of up to 0.1 mm, and an operating distance of 0.2 to 0.3 m.

The scanner was calibrated by using the calibration chart that was developed by Artec, and the corresponding support. Then, each of the parts of which the moulds are composed was placed on a rotating platform and was made to rotate, while the scanner was maintained in a fixed position, but oriented continuously perpendicular to the surface of the parts. In this way, volumetric and chromatic information was obtained for each element until its entire surface was completed. A laptop computer that was connected to the scanner made it possible to monitor the progress of the process at all times using Artec Studio 15 Professional®, Artec 3D (Luxembourg City, Luxembourg).

Once the registration process was completed, the stored information was processed by using the same software. First, the different scans were analysed for each of the pieces to check if there was any type of alteration that required correction or discarding. Those scans that had repetitions of a specific region with different orientations were divided in two, and it was confirmed that there were no holes on the surface. Secondly, all points that did not correspond to the parts of the mould, especially those on the surface of the rotating turntable, were removed. Next, each of the scans that was taken with the scanner was aligned until the parts were complete, and then it was placed in the centre of the scene and was rotated to orient it correctly by using the transformation tools of the editing panel. Once these operations were completed, the global registration function was executed in order to achieve an integral alignment of the whole set. After completing the global registration, some scans had excessive errors, and so the frames that they contained were inspected to remove those that exceeded an error value greater than 0.3 mm. The next step consisted of filtering out outliers, which are the points that are excessively distanced from the model surface. For this purpose, the Outlier removal function was used, with the following settings: a 3D noise level equal to 3, and a 3D resolution of 0.3 mm.

The generation of the three-dimensional model was performed by using the Sharp fusion method, which provides the most accurate results, by using a resolution of 0.3 mm. Once the fusion was performed and the mesh was obtained, the fragments of the isolated polygons that were created in an anomalous way were filtered by executing the “Small Object Filter” function in order to eliminate those with a size of less than 5000 polygons.

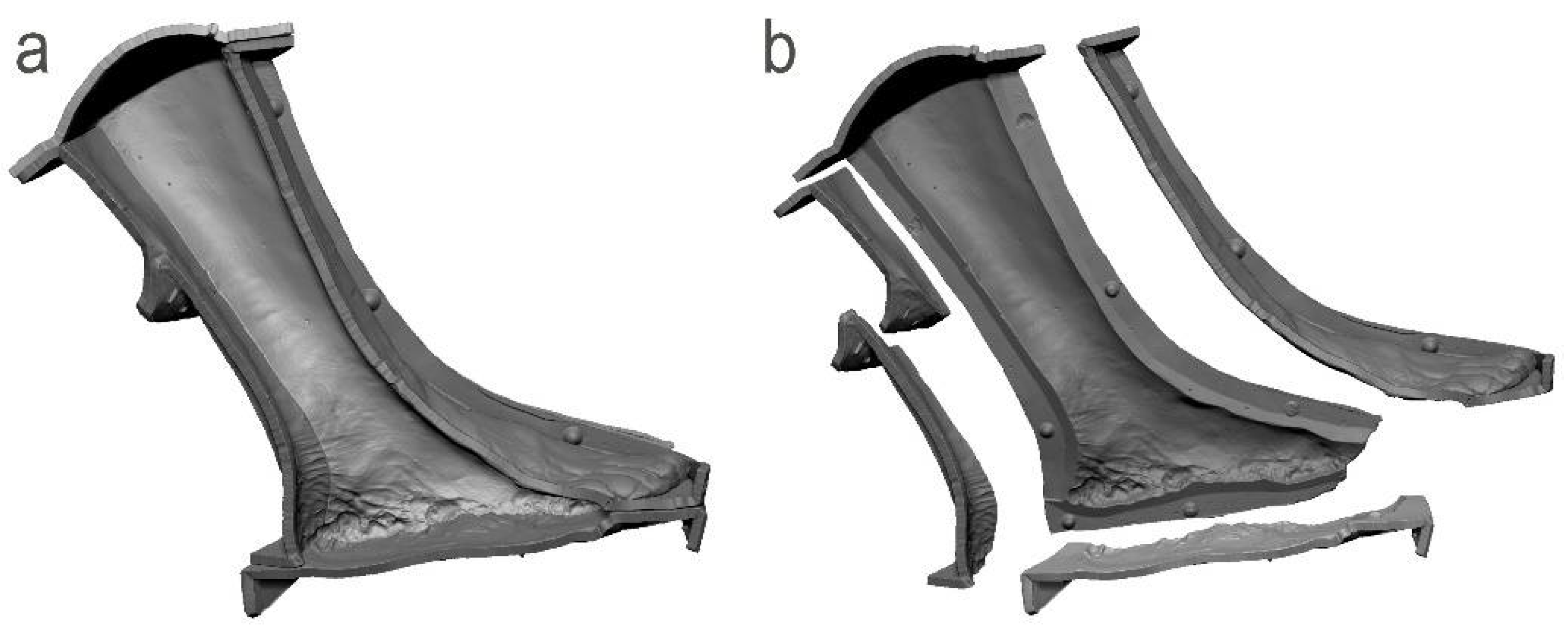

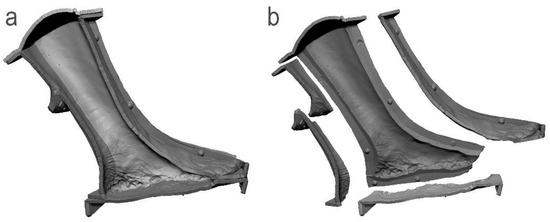

The 3D models that were created from the scans of each of the mould pieces had an adequate number of polygons for subsequent editing in a digital sculpting program, and so a reduction in the number of faces was not necessary (Figure 3).

Figure 3.

3D models created by scanning the mould: (a) high-resolution polygonal mesh; (b) model with photographic texture applied; (c) disassembled model.

2.2. Creation of Virtual Moulds for 3D Printing

As explained above, the aim of this work was to obtain a replica of one of the wax models in the collection whose whereabouts are currently unknown, as well as to verify that 3D scanning and printing technologies, together, can be a valid method for making this reproduction, that avoids the use of the original mould and, therefore, possible deterioration during its handling and during the execution of the wax casting.

Taking into account that the plaster moulds have high volumes that can force the division of them into many pieces for adaptation to the maximum printing volume, and that can excessively prolong the time and cost of the process, it was decided to drastically reduce their thicknesses. Given the high hardness of the material that was chosen for printing, polylactic acid (PLA), and its sufficient resistance to the wax temperature during the layer-by-layer brushing process that has already been proven in previous studies, it was considered that a thickness of 5 mm would be adequate [17].

In order to reduce the thicknesses of the virtual casts, it was decided to edit the 3D model in a digital sculpting program to create new digital casts by deleting the external surfaces of the casts and preserving the negative impressions of the leg and foot, as well as the contact surfaces between the casts with their corresponding keys.

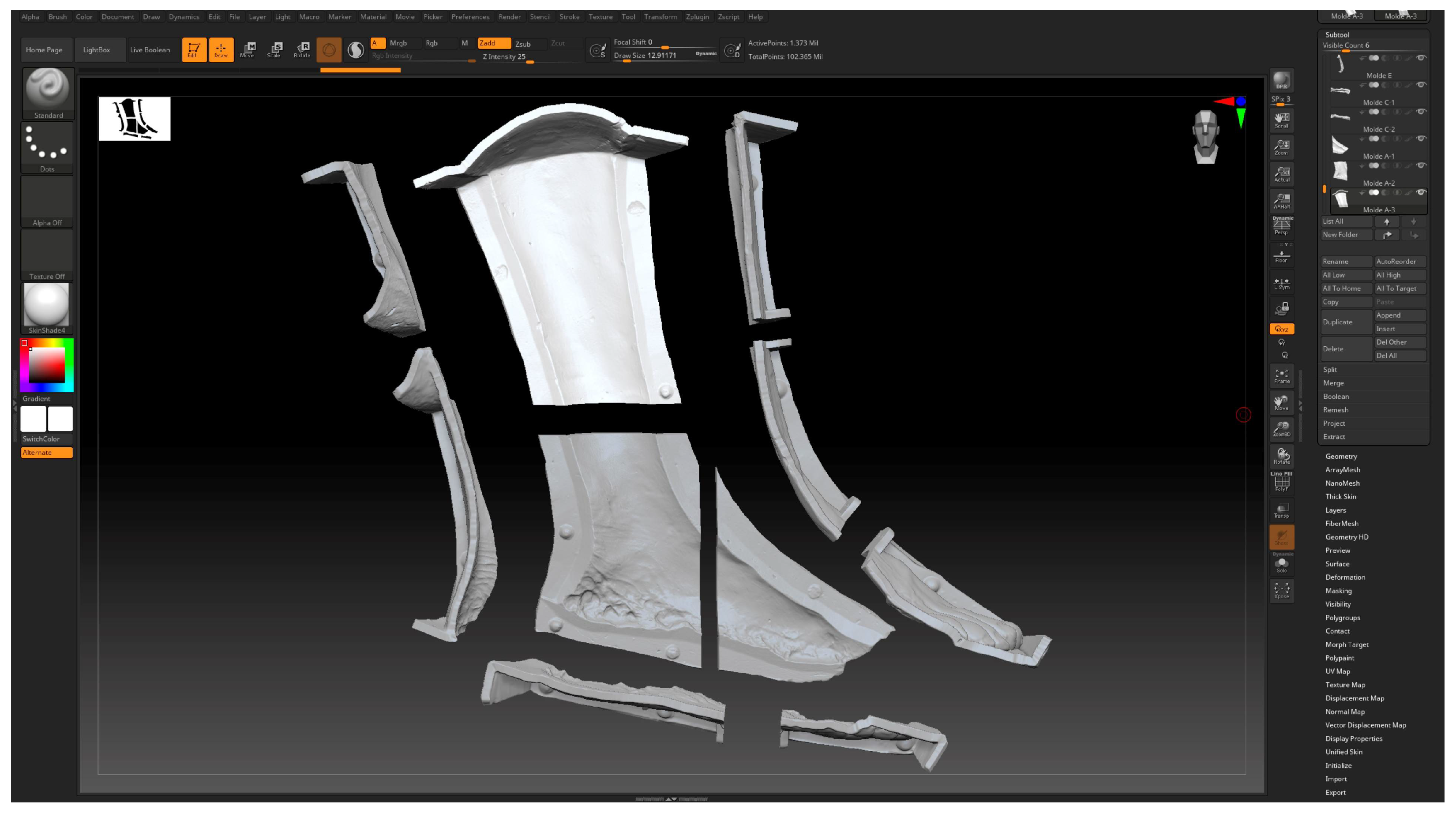

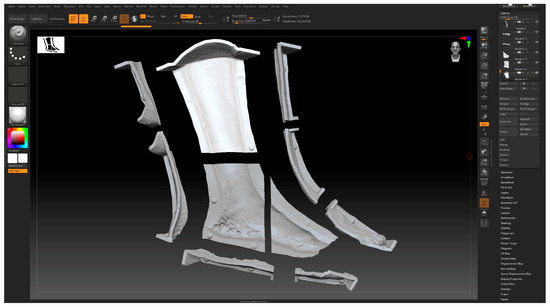

The file was exported in OBJ format and was imported into ZBrush 2021®, Pixologic (Los Angeles, CA, USA). Next, the external surfaces of the moulds were cut out by selecting them to hide them, and then by deleting those polygons with the “Delete Hidden” function. After this operation, each of the parts was given a thickness by using the procedure that is described below. First, the mesh normals for each of the mould parts were inverted so that the footprint of the lower limb took on the appearance of a positive. Second, each part was completely masked, and the “Extract” function was run by specifying the appropriate thickness in the Thickness value, and by leaving the “Double” option off so that only the thickness would grow outward. In this way, a thin mould was obtained from each of the parts that made up the mould (Figure 4).

Figure 4.

Digital moulds designed in ZBrush: (a) mould with all parts in position; (b) mould with parts separated showing keys to ensure correct assembly.

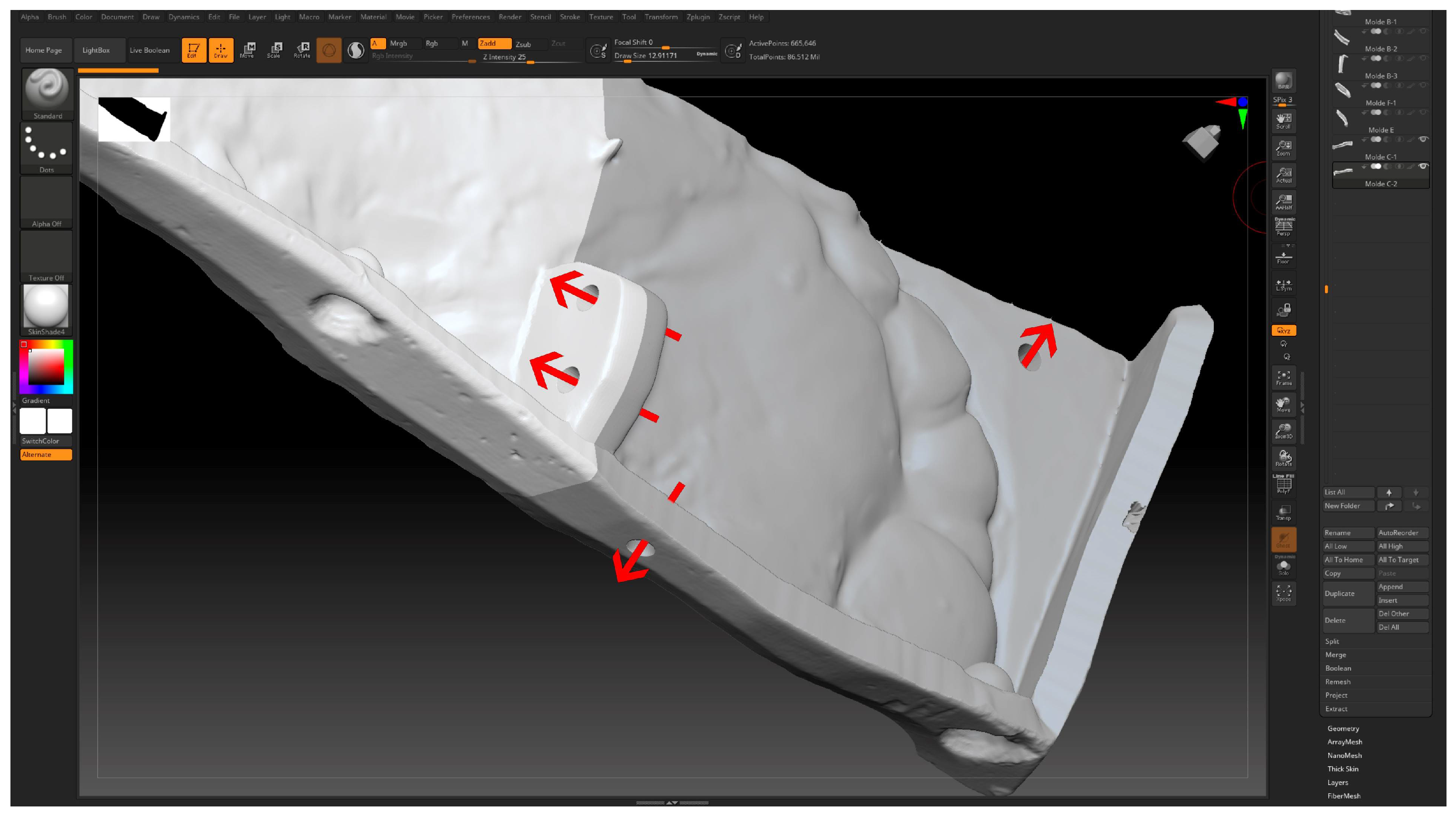

Since some of these pieces were still too large to fit within the printing area, they were sectioned into smaller elements by using the same software (Figure 5).

Figure 5.

Division of digital moulds in ZBrush 2021®, Pixologic (Los Angeles, CA, USA), to ensure that all parts properly fit the maximum print volume.

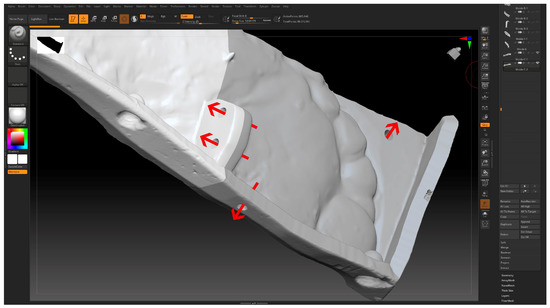

Once the moulds were conveniently divided, all their parts were repositioned to fit perfectly with each other in order to create several matching holes on either side of the joining surfaces for the insertion of fixing screws once printed. This was considered to be a convenient way to keep all the elements fixed in the correct position during the casting process, which minimises the formation of burrs in the joints, and also the outflow of the liquid wax through the cracks that might remain. The holes for the screws were made by means of Boolean subtraction operations, which created cylinders of a suitable diameter that, once placed through the thickness of both moulds in the joining area, were subtracted from them, which left a negative hole. To perform this task, a folder was created for each part of the mould and all of the cylinders that were to be drilled were saved in it. Then, the “Live Boolean” function was activated, and the subtraction icon was marked for each of the cylinders in the “SubTools” list, and finally, the “Boolean Folder” option was executed in the folder containing the mould and the cylinders. Small flaps were also modelled to join those elements of the mould that had been previously divided because they did not have any key in the contact area. These flaps were provided with screw holes by using the same method as described above (Figure 6).

Figure 6.

Creation of flaps and holes to insert the screws to fix the mould parts once printed.

2.3. Mould Impression

Once all the elements were already prepared, they were exported one by one to the chosen slicing software, Cura 4.5®, Ultimaker (Utrecht, The Netherlands), where they were oriented in such a way that the print of the mould was free of print supports to ensure the maximum reproduction quality. The layer height that was selected was 0.1 mm, after verifying in previous tests that the details of the figure were correctly reflected, and that the print layers were not visible to the naked eye on the surface of the mould, or in the final reproduction in beeswax. The printing temperature was set at 205 °C, the base temperature being 60 °C; the speed was set at 70 mm/s; and the fill density at 20% (Table 1).

Table 1.

Print settings used in Cura 4.5®, Ultimaker (Utrecht, The Netherlands).

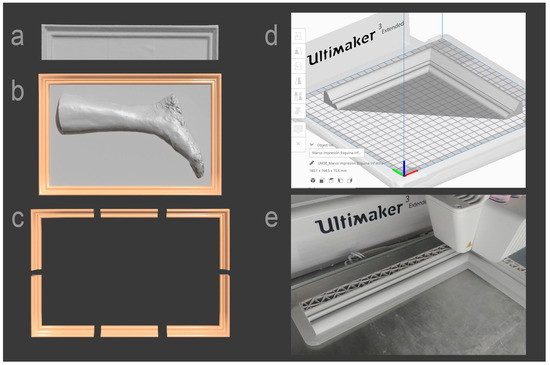

The files that were generated in Cura 4.5 were exported the to .gcode format and were opened in the 3D printer (Ultimaker 3 Extended), where they were reproduced. Once the printing of the parts was completed, the printing supports were removed, and the parts were assembled by using 2.5 mm-long and 4 mm-diameter metric thread bolts and their corresponding nuts.

The total printing time for all the parts in the mould was 156 h and 40 min, with an average printing time of 15 h and 40 min. The amount of PLA filament that was consumed was 664 g, with an average weight of 66.4 g per piece.

2.4. Wax Casting

In order to make the reproduction in the definitive material (beeswax), we first proceeded to calculate the proportion that was necessary to approximate the base colour of the copy to that of other wax sculptures that are preserved in the museum that have similar characteristics. For this purpose, different percentages of bleached wax and natural wax were mixed, and samples were created for comparison with other models. The final ratio that was chosen was 1-part natural wax to 12-parts bleached wax.

To calculate the amount of wax that was needed for the casting, a positive copy of the figure was created in ZBrush from the internal footprint of the mould, which eliminated both the internal face and the junction areas, and it was then given a thickness towards the inside of 7 mm by using the “Extract” function mentioned above. The volume was calculated by using the “Check Mesh Volume” option in the 3D Print Hub add-on module of the program.

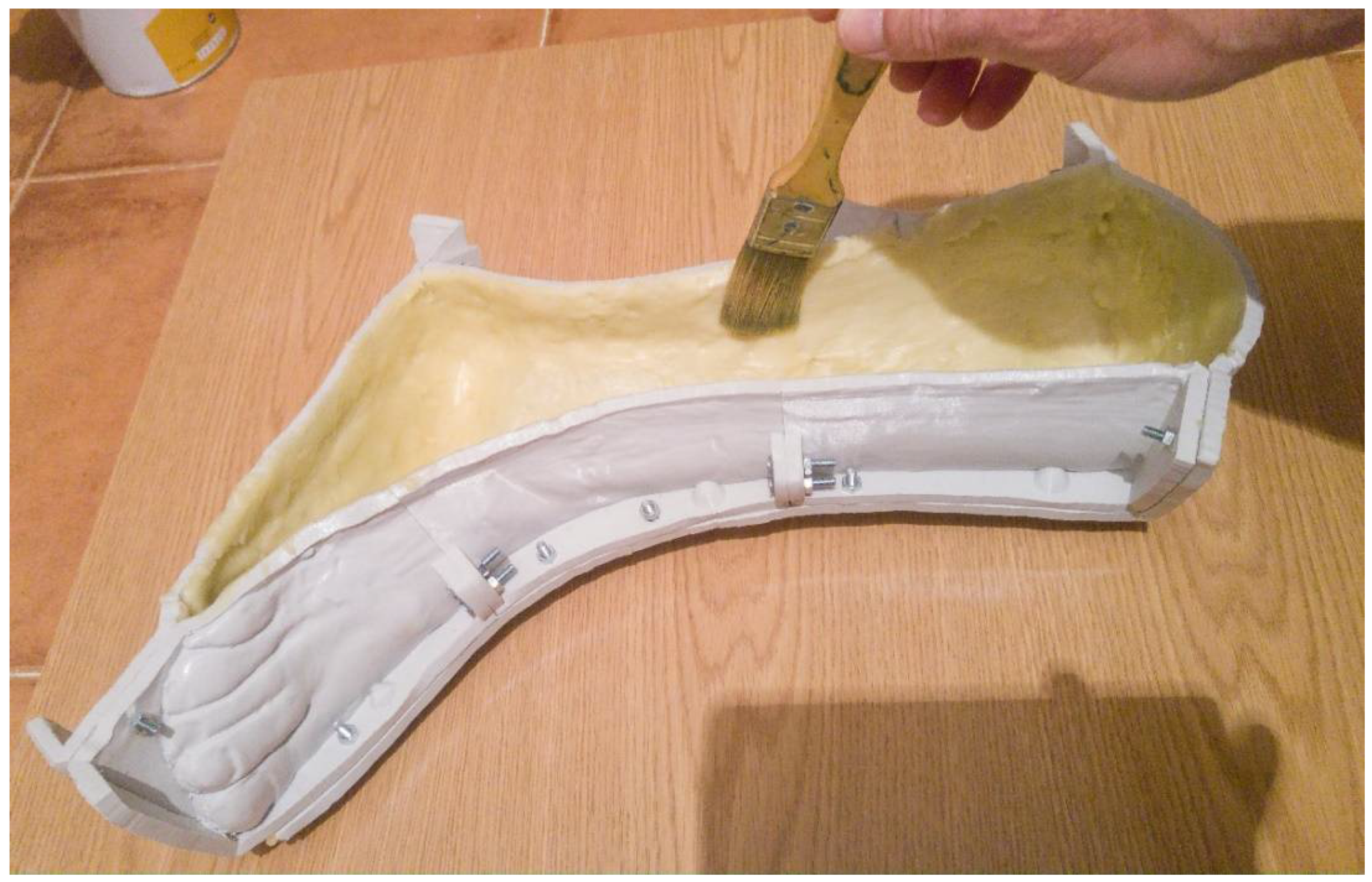

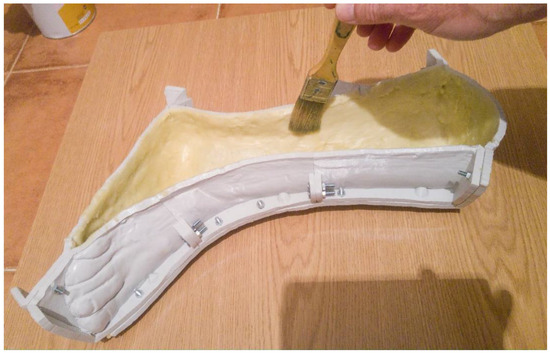

Before casting, petroleum jelly was applied to the inner side of the mould and to all the mould joints, which acted as a release agent.

Subsequently, the beeswax was heated with a melter, with the temperature regulated to 70 °C, and, once in a liquid state, it was spread over the entire surface of the mould with a soft-haired brush. The operation was repeated successively with a brush, layer by layer, until the desired thickness was reached (Figure 7).

Figure 7.

Brushing, layer by layer, of the liquid wax on the internal surface of the mould printed in PLA.

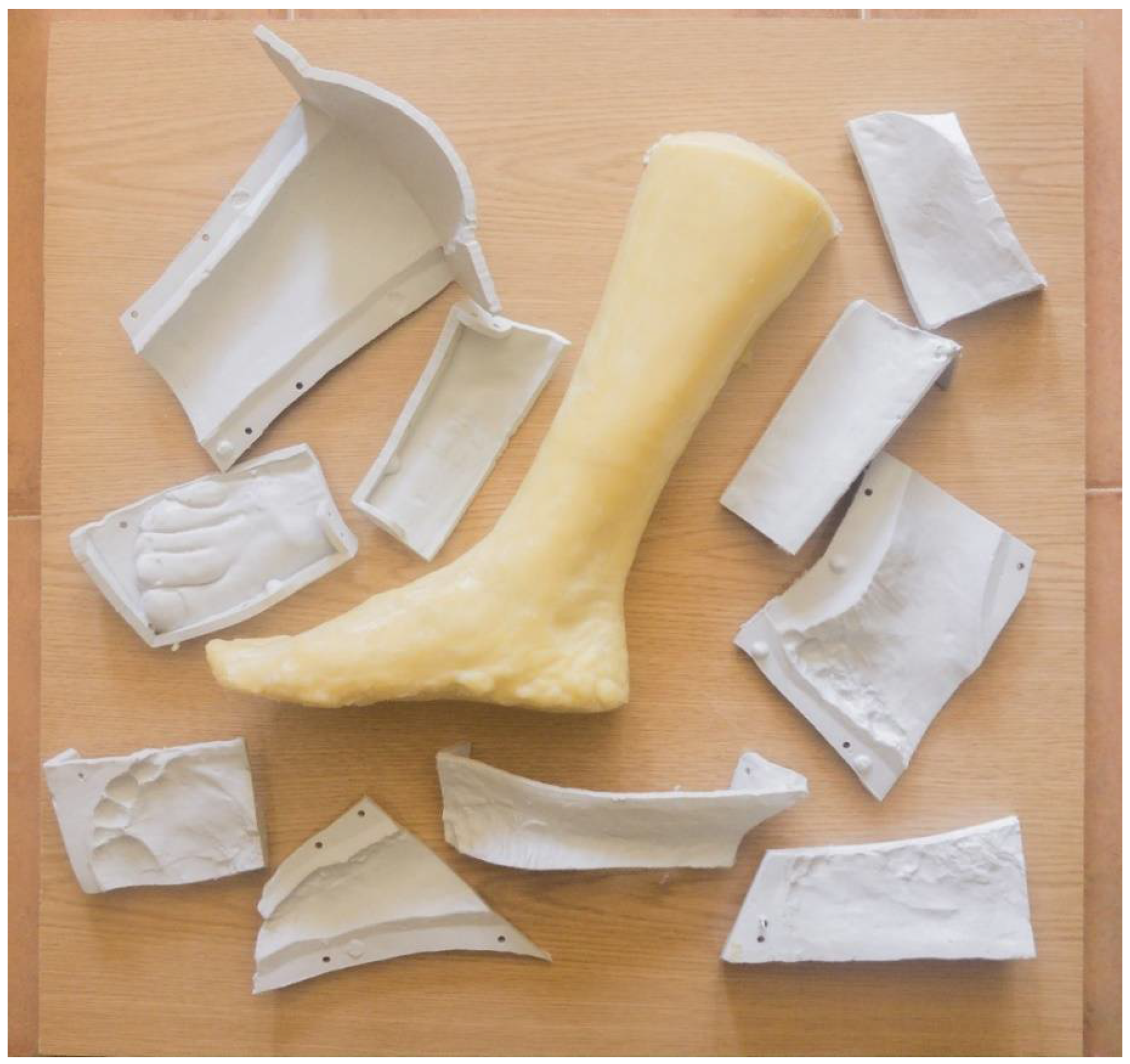

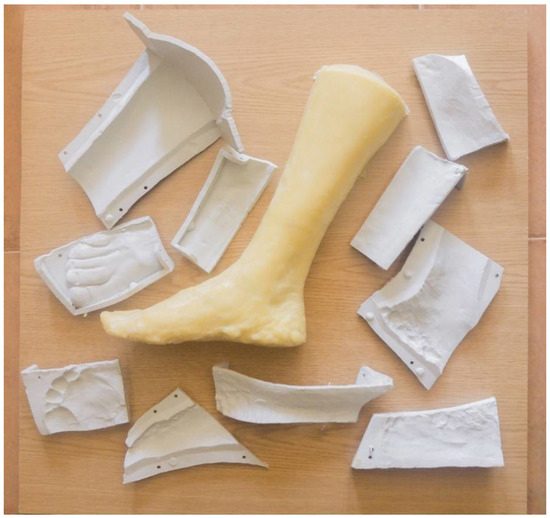

Twelve hours after completing this process, the positives were removed by removing the moulds one by one, and by eliminating the remains of the petroleum jelly from their surfaces (Figure 8).

Figure 8.

Beeswax positive once demoulded, next to the pieces of the moulds printed in PLA.

The reproduction that was obtained had small burrs on its surface that corresponded to the mould joints, and so they were removed with the help of specific tools for wax refinishing: files, a thermal spatula, and conventional spatulas.

2.5. Differential Diagnosis of the Pathology Depicted

One of the objectives of this study was to make a diagnosis of the dermatologic disorder that was intended to be represented with this moulage, and, in order to establish it, the positive was shown to different dermatologist members of the Fundación Piel Sana de la Academia Española de Dermatología y Venereología (the Healthy Skin Foundation of the Spanish Academy of Dermatology and Venerology). All of them agreed that the disease that was most likely to be reflected in the work was a palmoplantar keratoderma, although it was impossible to determine a specific aetiology for it. The diagnosis was based on the characteristic shape, size, thickness, and location of this type of lesion.

2.6. Polychrome of the Wax

The polychromy of the piece was based on a critical interpretation from the visual study of the work, a retrospective diagnosis, and consultation on the secondary sources of the 19th century that contained illustrations of the figures of the museum with this pathology, as well as several pictures of patients with plantar keratoderma, since there are many similarities in the aspect of this condition that are produced by different diseases. This process is necessary for the conservation and emission of the integrity of the didactic message of the moulage that is based on the dermatological pathology, which is supported by the clinical diagnosis that appears on the informative label that is located on the front side of the board, and the medical history that is located on the back of it.

For this operation, the figure was illuminated with a 5×-magnification fluorescent magnifying lamp and a luminous flux of 130–300 lumens. This circular type of lamp provides a light without shadows or heating, which allows for a more precise execution and which avoids the risk of wax melting.

Winsor & Newton watercolour pigments were used, using deionized water as a diluent, and synthetic ox gall as binder. The application technique was by glazing. Likewise, J.G. Vibert, Lefrac and Bourgeois retouching varnish was used, which is based on synthetic resins and which ensures cohesion and texture unity, with which those regions that needed brightness because of the suppurative aspect of the lesion were painted. A final protective film was sprayed with a Winsor & Newton dammar finish varnish (Figure 9).

Figure 9.

Polychrome process: (a–c) different phases of application of colour glazes; (d) detail of the figure showing the final finish.

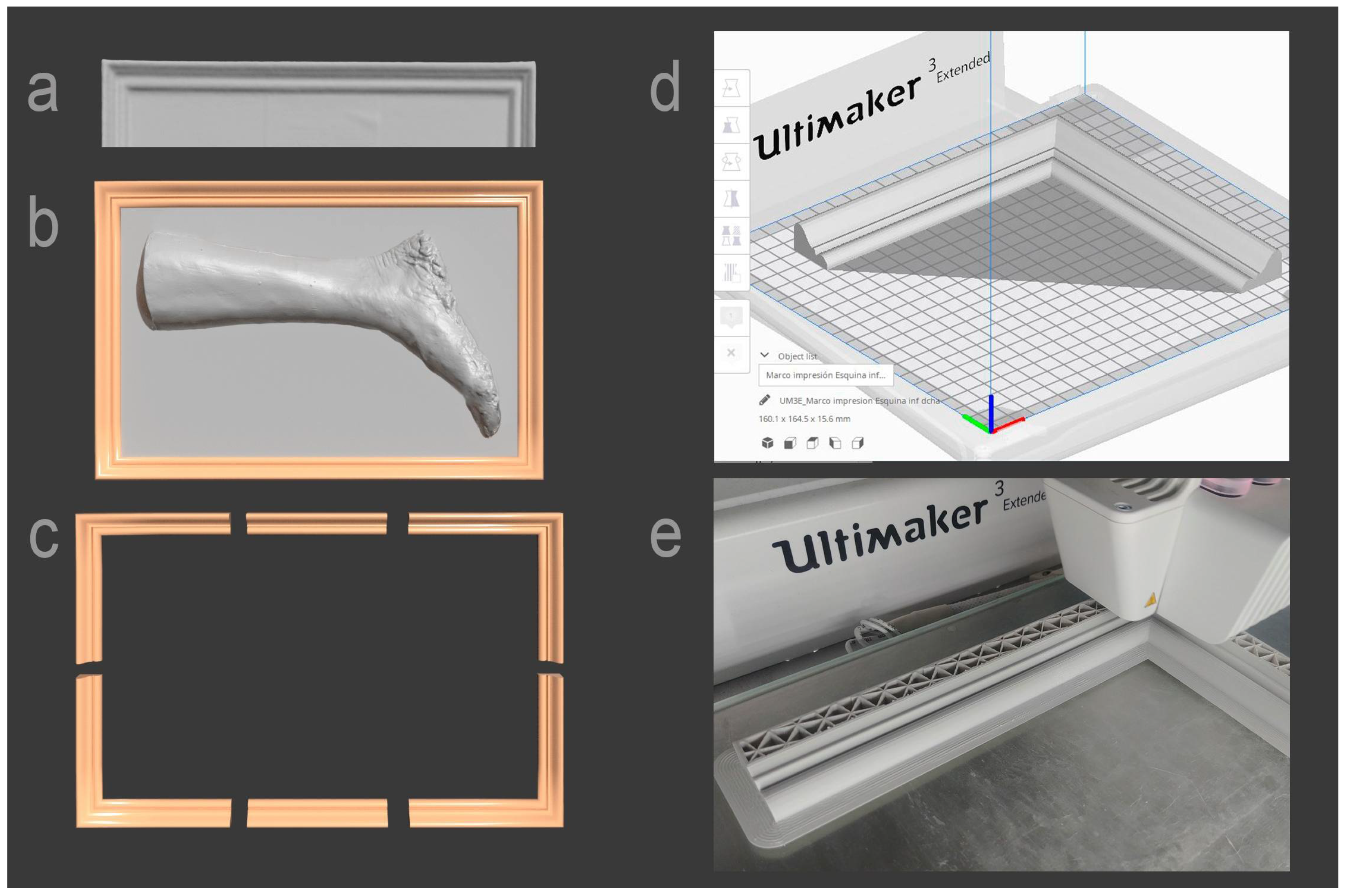

2.7. Creation of a Labelled Frame

Since it was not possible to locate any type of documentary material for the model, it was decided to polychrome the replica for its exhibition in the museum, and to provide it with a frame that is similar to those of the other pieces in the collection that share the same characteristics, with a label indicating the probable diagnosis, and explaining that it is a current replica that was obtained from a mould of a model that was not found after the reopening of the museum. A poster will be displayed next to it that explains, with image support, the process that was developed to obtain it.

For the creation of the frame, a previously digitized model of another of the dermatological models that is kept in the museum, and that also represents a pathology of the lower limb, was taken as a reference. Using a cross section of it as a template, a frame with the same profile and dimensions was modelled by using 3ds Max 2022, Autodesk (San Rafael, CA, USA), and was sectioned into 6 parts in order to fit it onto the 3D printer platform (Figure 10).

Figure 10.

Process of elaboration of the frame: (a) polygonal mesh obtained by digitizing the frame of another figure exhibited in the Olavide Museum; (b) frame elaborated by taking as reference the digitized model and using the 3D modelling software: Autodesk 3dsMax; (c) division of the frame into pieces for 3D printing in the same program; (d) preparation of a part in Ultimaker Cura for printing; (e) reproduction of the frame in the Ultimaker 3 Extended printer.

The 3D model was then exported to an OBJ file for preparation in the Ultimaker Cura 4.5 slicing program for subsequent reproduction by 3D printing with PLA filament. It was necessary to divide the strips into several segments so that they would fit onto the printing area. After all of them were reproduced, they were joined with cyanoacrylate, the joints were filled with epoxy putty, and the whole was painted with black acrylic paint.

The support board for the wax figure was created with a 10 mm-thick wooden board. The paper label with the description of the pathology, which is depicted in the lower right corner of the frame, was designed in Adobe Photoshop on the basis of the reference images that were taken from other labels of works that are conserved in the museum.

Once all of the pieces that formed part of the model had been made, the wax figure was attached to the already painted frame by using a cloth dipped in liquid wax, which was also attached by using nails, and the paper label with the information about the piece was also attached.

3. Results

A 3D digital model was created that contains the eight pieces and fragments of the mould that was found in the museum. The mesh had a total of 15.3 million polygons and accurately recorded the smallest details that are observable to the naked eye in the plaster cast (Figure 3).

The 10 pieces that made up the set of printed moulds fitted perfectly together and were completely fixed in position once the screws and nuts were placed in the holes that were provided for that purpose (Figure 8). The new divisions that were created to adjust the volumes of the parts to the printing area were barely evident visually, or to the touch once joined, and they left hardly any burrs after casting. The printed moulds also reflected, with sufficient fidelity, the small surface inflexions that existed on the original mould.

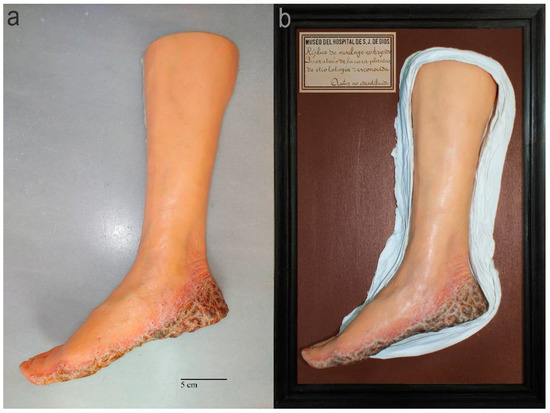

By means of the casting process described above, a beeswax positive of the figure was obtained that retained the small details of the printed moulds. After the polychrome phase, and once the wax model had been adhered to the frame with the white cloth, and once the paper label with the description had been added, the final appearance was remarkably similar to that of the original models that are exhibited in the museum (Figure 11).

Figure 11.

Final result: (a) polychrome beeswax model; (b) recreation of the model mounted in a frame containing a label in English which describes the model: “Replica of a moulage not found. Keratosis of the plantar face of unknown aetiology. Author not identified”.

4. Conclusions

The use of a mixed approach that employs both 3D digital technologies and traditional procedures has been proven to be an effective method for obtaining the reproduction of a didactic dermatological model, starting from the original cast that was preserved in precarious conditions, and without putting its integrity at risk. The risk of manipulation was considerably reduced by obtaining a highly accurate digital copy to work with by 3D scanning, and by eliminating any possible alteration that could result from a direct casting process, by obtaining a faithful reproduction of the mould, thanks to digital printing.

The use of traditional casting and polychrome techniques allowed us to gain a deeper understanding of the handcrafting processes that the wax sculptors used to create the original models, which could facilitate decision making and the planning of interventions that are aimed at their future conservation and restoration.

One of the difficulties that was encountered during the reproduction of the mould with PLA was that the printing volume was not large enough to cover the parts completely, and so we were forced to split them. This increased the processing time and also led to the appearance of small burrs on the wax positive in the areas where the parts were joined, which had to be removed by using files and spatulas. It would be interesting to use larger printers in future research in order to avoid these problems.

Author Contributions

Conceptualization, Ó.H.-M.; funding acquisition, Ó.H.-M. and A.S.-O.; investigation, Ó.H.-M., D.A.G., A.M.P., E.S.M. and A.S.-O.; methodology, Ó.H.-M., D.A.G. and A.M.P.; project administration, Ó.H.-M.; resources, Ó.H.-M., D.A.G., A.M.P. and A.S.-O.; visualization, Ó.H.-M., D.A.G., A.M.P. and E.S.M.; writing—original draft, Ó.H.-M., D.A.G. and A.M.P.; writing—review and editing, Ó.H.-M., D.A.G., E.S.M. and A.S.-O. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by the Ministry of Science, Innovation and Universities (Spain), within the State Program for Knowledge Generation and Scientific and Technological Strengthening of the R+D+I System, the State Subprogram for Knowledge Generation (grant number: PGC2018-098396-B-100), and the Predoctoral Grant (FPI ref.: PRE2019-087870), funded by the Ministry of Science and Innovation (Spain), the ESF European Social Fund, and the State Research Agency.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

A sincere thanks to the Museo Olavide museum of the Spanish Academy of Dermatology and Venereology, Madrid, Spain, and especially to Luis Conde-Salazar.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Conde-Salazar Gómez, L.; Heras Mendaza, F. El Museo Olavide de Figuras de Cera de La Dermatología Española. Una Reliquia Del Pasado y Un Ejemplo Para El Futuro. Med. Cutan. Ibero-Lat. Am. 2013, 41, 193–196. [Google Scholar] [CrossRef]

- Ballestriero, R. Anatomical Models and Wax Venuses: Art Masterpieces or Scientific Craft Works? J. Anat. 2010, 216, 223–234. [Google Scholar] [CrossRef] [PubMed]

- Morente, M. Modelando Ciencia. La Ceroplástica de Ignacio Lacaba En El Colegio de Cirugía de San Carlos de Madrid. Dynamis 2016, 36, 27–45. [Google Scholar] [CrossRef]

- Di Rocco, C. Dandy Walker Variant and Persistent Occipital Sinus at the Museum La Specola in Florence. Child’s Nerv. Syst. 2006, 22, 225–226. [Google Scholar] [CrossRef]

- Sánchez Ortiz, A.; Moral Azanza, N.; Ballestriero, R. Anatomía Femenina En Cera: Ciencia, Arte y Espectáculo En El Siglo XVIII. Lab. Arte 2013, 2, 603–622. [Google Scholar] [CrossRef]

- Sánchez Ortiz, A.; Del Moral, N.; Micó, S. Entre La Ciencia y El Arte. Ceroplástica Anatómica Para El Real Colegio de Cirugía de San Carlos (1786–1805). Arch. Esp. Arte 2012, 85, 329–349. [Google Scholar] [CrossRef] [Green Version]

- Schnalke, T. Diseases in Wax: The History of the Medical Moulage; Quintessence Pub. Co.: Chicago, IL, USA, 1995. [Google Scholar]

- Maruri, A.; Aranda, D. Sick Skin. The History of the Dermatological Representations in Olavide Museum. Eur. J. Anat. 2020, 24, 15–22. [Google Scholar]

- Julián Quiroga, I. El Museo Olavide o el Sueño del Olvido; Hospital Gregorio Marañon: Madrid, Spain, 1997. [Google Scholar]

- Conde-Salazar, L.; Heras-Mendaza, F. Museo Olavide (III): Recuperación. Acta Dermosifiliogr. 2007, 98, 209–212. [Google Scholar] [CrossRef]

- De Stefano, A.; Tausch, R.; Santos, P.; Kuijper, A.; Di Gironimo, G.; Fellner, D.W.; Siciliano, B. Modeling a virtual robotic system for automated 3D digitization of cultural heritage artifacts. J. Cult. Herit. 2016, 19, 531–537. [Google Scholar] [CrossRef]

- Farella, E.M.; Morelli, L.; Grilli, E.; Rigon, S.; Remondino, F. Handling critical aspects in massive photogrammetric digitization of museum assets. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2022, 46, 215–222. [Google Scholar] [CrossRef]

- Georgopoulos, A.; Stathopoulou, E.K. Data Acquisition for 3D Geometric Recording: State of the Art and Recent Innovations; Springer: Cham, Switzerland, 2017; pp. 1–26. [Google Scholar] [CrossRef]

- Santos, P.; Ritz, M.; Fuhrmann, C.; Fellner, D. 3D mass digitization: A milestone for archeological documentation. Virtual Archaeol. Rev. 2017, 8, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Ceccarelli, S.; Guarneri, M.; De Collibus, M.F.; Francucci, M.; Ciaffi, M.; Danielis, A. Laser Scanners for High-Quality 3D and IR Imaging in Cultural Heritage Monitoring and Documentation. J. Imaging 2018, 4, 130. [Google Scholar] [CrossRef] [Green Version]

- Koch, M.; Kaehler, M. Combining 3D laser-Scanning and close-range Photogrammetry—An approach to Exploit the Strength of Both methods. In Proceedings of the Computer Applications to Archaeology, Williamsburg, VA, USA, 22–26 March 2009; pp. 22–26. [Google Scholar]

- Serna, C.G.; Pillay, R.; Trémeau, A. Data fusion of objects using techniques such as laser scanning, structured light and photogrammetry for cultural heritage applications. Swarm Evol. Memetic Comput. 2015, 9016, 208–224. [Google Scholar] [CrossRef] [Green Version]

- Yastikli, N. Documentation of cultural heritage using digital photogrammetry and laser scanning. J. Cult. Herit. 2007, 8, 423–427. [Google Scholar] [CrossRef]

- Arbace, L.; Sonnino, E.; Callieri, M.; Dellepiane, M.; Fabbri, M.; Iaccarino Idelson, A.; Scopigno, R. Innovative Uses of 3D Digital Technologies to Assist the Restoration of a Fragmented Terracotta Statue. J. Cult. Herit. 2013, 14, 332–345. [Google Scholar] [CrossRef]

- De Luca, D.; Del Giudice, M.; Grasso, N.; Matrone, F.; Osello, A.; Piras, M. Handheld Volumetric Scanner for 3D Printed Integrations of Historical Elements: Comparison and Results. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2019, XLII-2/W5, 381–388. [Google Scholar] [CrossRef] [Green Version]

- Di Paola, F.; Milazzo, G.; Spatafora, F. Computer Aided Restoration Tools to Assist the Conservation of an Ancient Sculpture, The Colossal Statue of Zeus Enthroned. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, XLII-2/W5, 177–184. [Google Scholar] [CrossRef] [Green Version]

- Fragkos, S.; Tzimtzimis, E.; Tzetzis, D.; Dodun, O.; Kyratsis, P. 3D Laser Scanning and Digital Restoration of an Archaeological Find. MATEC Web Conf. 2018, 178, 03013. [Google Scholar] [CrossRef]

- Laycock, S.D.; Bell, G.D.; Corps, N.; Mortimore, D.B.; Cox, G.; May, S.; Finkel, I. Using a Combination of Micro-Computed Tomography, CAD and 3D Printing Techniques to Reconstruct Incomplete 19th-Century Cantonese Chess Pieces. J. Comput. Cult. Herit. 2015, 7, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Brinkmann, V.; Koch-Brinkmann, U. The Experimental Reconstruction of the Bronze Warriors of Riace as Part of the Frankfurt “Liebieghaus Polychromy Research Project”. Technè 2019, 48, 120–132. [Google Scholar] [CrossRef]

- Hernández-Muñoz, Ó.; Sánchez-Ortiz, A. Digitization and 3D Printing for the Reconstruction of Volumetric Losses in an Anatomical Wax Model of the 18th Century. Conserv. Patrim. 2019, 30, 59–72. [Google Scholar] [CrossRef] [Green Version]

- Hernández-Muñoz, Ó.; Sánchez Ortiz, A.; Matía Martín, P. Anatomía Animal. Técnicas Digitales Para La Reconstrucción Escultórica de La Apariencia Original de Un Modelo de Cera Del Siglo XIX. Intervención 2019, 10, 64–76. [Google Scholar] [CrossRef]

- Aranda, D.; Maruri, A.; Mora, A. Restauración de Las Figuras. In Piel de cera. Olavide, San Juan de Dios y el Museo; Conde-Salazar Gómez, L., Ed.; Luzán Ediciones: Madrid, Spain, 2006; pp. 49–55. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).