Controlling Terahertz Dielectric Responses in Polymer Composites by Engineering α-Al2O3 Whisker Filler Distribution

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

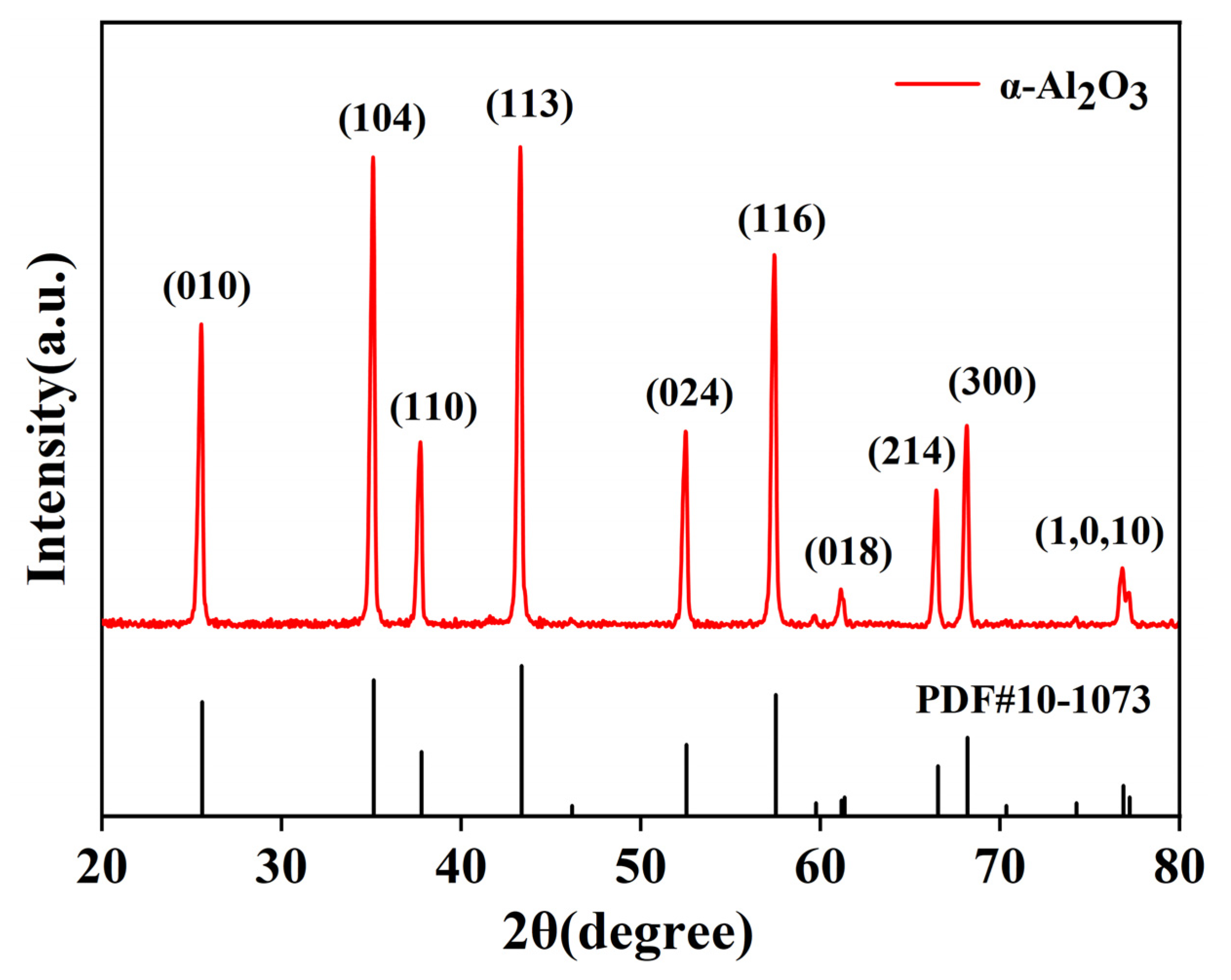

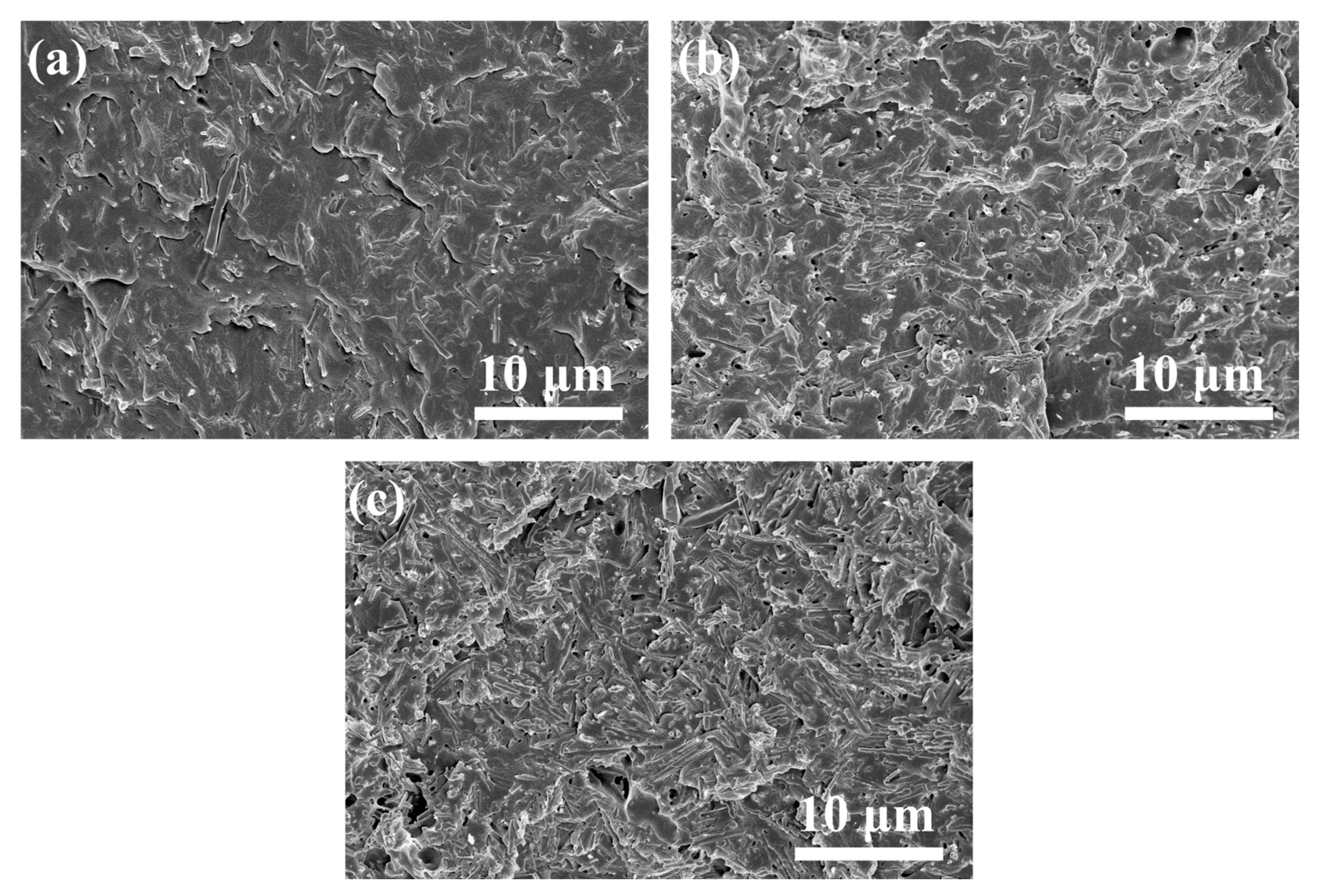

3.1. Synthesis of α-Al2O3 Whiskers

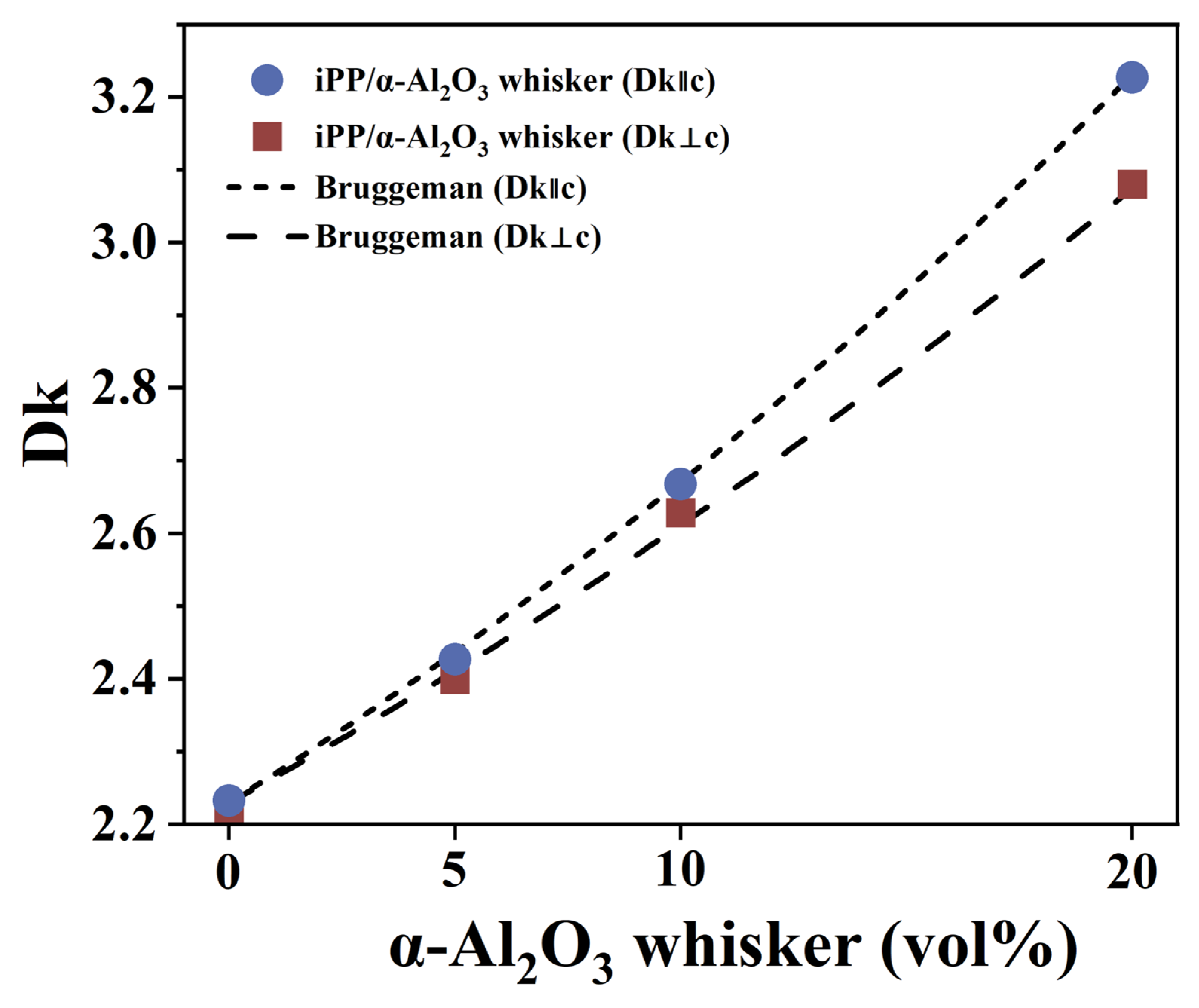

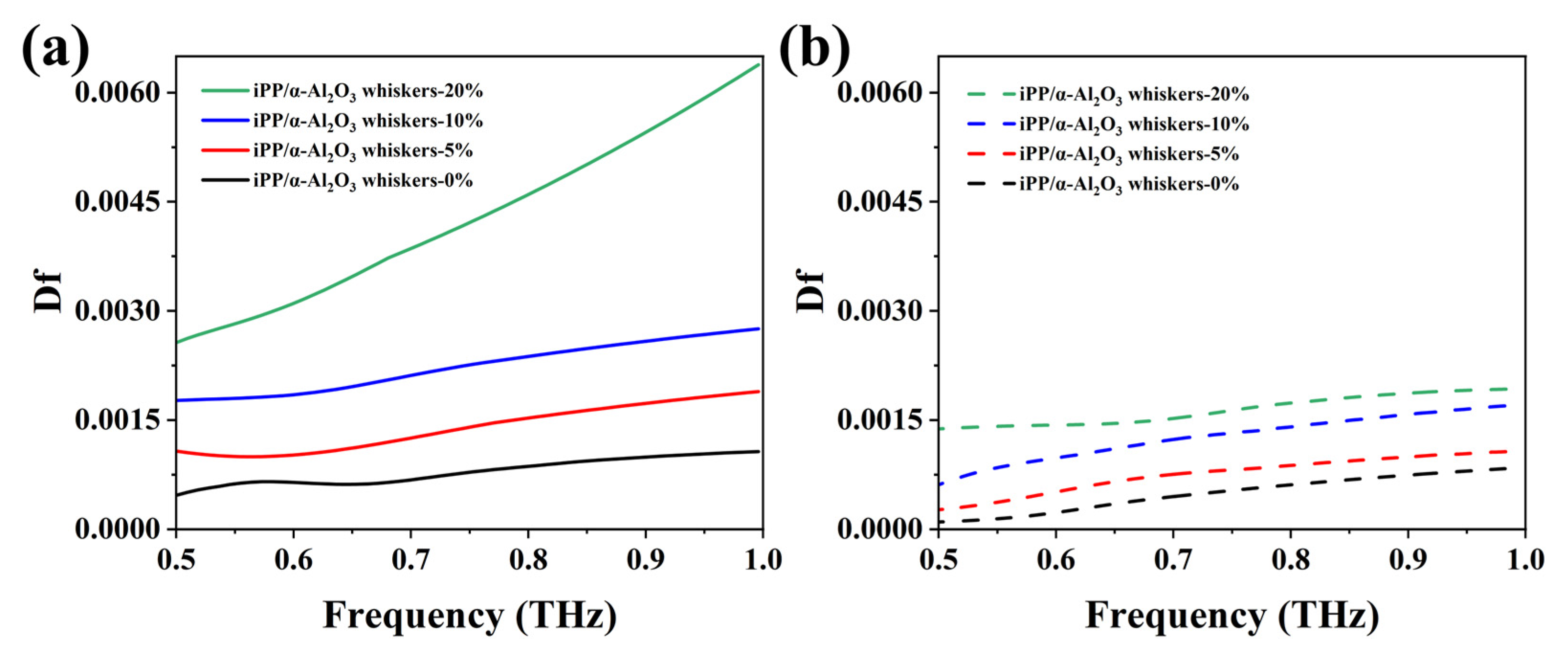

3.2. Dielectric Properties of Composites

3.3. Orientation of Filler in Composites of Dielectric Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| THz | Terahertz |

| Dk | Dielectric constant |

| Df | Loss tangent |

| iPP | Isotactic polypropylene |

| XRD | X-ray diffraction |

| SEM | Scanning electron microscopy |

References

- Elayan, H.; Amin, O.; Shihada, B.; Shubair, R.M.; Alouini, M.S. Terahertz Band: The Last Piece of RF Spectrum Puzzle for Communication Systems. IEEE Open J. Commun. Soc. 2020, 1, 1–32. [Google Scholar] [CrossRef]

- Huq, K.M.S.; Busari, S.A.; Rodriguez, J.; Frascolla, V.; Bazzi, W.; Sicker, D.C. Terahertz-Enabled Wireless System for Beyond-5G Ultra-Fast networks: A Brief Survey. IEEE Netw. 2019, 33, 89–95. [Google Scholar] [CrossRef]

- Wells, J. Faster Than Fiber: The Future of Multi-Gb/s Wireless. IEEE Microw. Mag. 2009, 10, 104–112. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Y.; Yu, X.Q.; Mao, M.M.; Liu, B.; Bafrooei, H.B.; Li, A.H.; Zhang, Y.Y.; Taheri-Nassaj, E.; Song, K.X.; et al. A high-performance, temperature-stable Mg1.99Ga0.01Si0.99Al0.01O4-CaTiO3 microwave dielectric ceramic and its 5G/6G waveguide filter. J. Eur. Ceram. Soc. 2023, 43, 7471–7477. [Google Scholar] [CrossRef]

- Chen, L.; Liu, H.; Jiang, Y.; Li, S.; Luo, X.J.; You, B.; Li, A.H.; Hu, Y.Y.; Baxter, H.; Yang, B.; et al. High quality of LiMg0.9Zn0.06Ni0.04PO4-TiO2 microwave ceramic and its application for 5G dielectric waveguide bandpass filter. Mater. Today Commun. 2023, 35, 105500. [Google Scholar] [CrossRef]

- Song, X.Q.; Zeng, F.F.; Yang, J.Q.; Yin, C.Z.; Wu, J.M.; Shi, Y.S.; Lu, W.Z.; Lei, W. Crystal structure and microwave dielectric properties of garnet-type Ca2YZr2−xTixAl3O12 ceramics for dual-band bandpass filters. J. Eur. Ceram. Soc. 2022, 42, 4962–4968. [Google Scholar] [CrossRef]

- Du, M.K.; Li, L.X.; Ni, L.Z.; Zhan, Y. Ultra-high Q Ba(Mg1/3Ta0.675)O3 microwave dielectric ceramics realized by slowly cooling step process and the simulation design for hairpin dielectric filters. Ceram. Int. 2021, 47, 19716–19726. [Google Scholar] [CrossRef]

- Hu, T.; Juuti, J.; Jantunen, H.; Vilkman, T. Dielectric properties of BST/polymer composite. J. Eur. Ceram. Soc. 2007, 27, 3997–4001. [Google Scholar] [CrossRef]

- Imai, Y.; Kodama, N.; Takahashi, S.; Kan, A.; Hotta, Y.; Ogawa, H. Suppression of dielectric loss of PPE/HIPS alloys in microwave region by utilization of MgO filler. J. Appl. Polym. Sci. 2019, 136, 47315. [Google Scholar] [CrossRef]

- Gonon, P.; Sylvestre, A.; Teysseyre, J.; Prior, C. Dielectric properties of epoxy/silica composites used for microlectronic packaging, and their dependence on post-curing. J. Mater. Sci.-Mater. Electron. 2001, 12, 81–86. [Google Scholar] [CrossRef]

- Carter, J.; Lees, H.; Wang, Q.G.J.; Chen, S.J.; Atakaramians, S.; Withayachumnakul, W. Terahertz Properties of Common Microwave Dielectric Materials. J. Infrared Millim. Terahertz Waves 2023, 44, 873–884. [Google Scholar] [CrossRef]

- Goulas, A.; Chow, T.Y.; Whittaker, T.; Reaney, I.M.; Vaidhyanathan, B.; Whittow, W.; Engstromb, D.S. A low-loss and medium dielectric permittivity SrTiO3/HIPS composite for rapid prototyping of next-generation microwave devices. Addit. Manuf. 2024, 92, 8. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, T.; Wen, L.; Zhang, A. Fabricating Metallic Circuit Patterns on Polymer Substrates through Laser and Selective Metallization. ACS Appl. Mater. Interfaces 2016, 8, 33999–34007. [Google Scholar] [CrossRef]

- Liu, B.S.; Haw, K.G.; Zhang, C.; Yu, G.L.; Li, J.L.; Zhang, P.P.; Li, S.Y.; Wu, S.; Li, J.Y.; Zou, X.Q. Flexible films derived from PIM-1 with ultralow dielectric constants. Microporous Mesoporous Mat. 2020, 294, 7. [Google Scholar] [CrossRef]

- Krupka, J.; Geyer, R.G.; Hinken, J.H.; Kuhn, M. Dielectric Properties of Single Crystals of A12O3, LaAIO3, NdGaO3, SrTiO3, and MgO at Cryogenic Temperatures. IEEE Trans. Microw. Theory Tech. 1994, 42, 1886–1890. [Google Scholar] [CrossRef]

- Walpita, L.M.; Ahern, M.R. Temperature compensated high-dielectric-constant thermoplastic microwave materials. IEE Proc.-Microw. Antennas Propag. 2000, 147, 285–288. [Google Scholar] [CrossRef]

- Qi, L.; Lee, B.I.; Chen, S.; Samuels, W.D.; Exarhos, G.J. High-Dielectric-Constant Silver–Epoxy Composites as Embedded Dielectrics. Adv. Mater. 2005, 17, 1777–1781. [Google Scholar] [CrossRef]

- Rajesh, S.; Nisa, V.S.; Murali, K.P.; Ratheesh, R. Microwave dielectric properties of PTFE/rutile nanocomposites. J. Alloys Compd. 2009, 477, 677–682. [Google Scholar] [CrossRef]

- Takahashi, S.; Imai, Y.; Kan, A.; Hotta, Y.; Ogawa, H. Improvements in the temperature-dependent properties of dielectric composites by utilizing MgO whiskers as the dielectric filler in an iPP matrix. J. Alloys Compd. 2015, 640, 428–432. [Google Scholar] [CrossRef]

- Ata, S.; Ono, T.; Tsuruta, A.; Mimura, K.I.; Shimamura, A.; Kato, Y.; Sue, K. Effect of the Alumina Particle Filler Structure and Particle Size on the Dielectric Constant and Dielectric Loss in the Millimeter-Wave Band. ACS Omega 2023, 8, 9379–9384. [Google Scholar] [CrossRef]

- Ma, M.S.; Wang, Y.; Navarro-Cía, M.; Liu, F.; Zhang, F.Q.; Li, Z.F.; Li, Y.X.; Hanham, S.M.; Hao, Z.C. The dielectric properties of some ceramic substrate materials at terahertz frequencies. J. Eur. Ceram. Soc. 2019, 39, 4424–4428. [Google Scholar] [CrossRef]

- Zhang, H.W.; Zhu, D.G.; Grasso, S.; Hu, C.F. Tunable morphology of aluminum oxide whiskers grown by hydrothermal method. Ceram. Int. 2018, 44, 14967–14973. [Google Scholar] [CrossRef]

- Zhou, W.Y. Thermal and Dielectric Properties of the Aluminum Particle Reinforced Linear Low-Density Polyethylene Composites. Polym. Eng. Sci. 2011, 51, 917–924. [Google Scholar] [CrossRef]

- Takahashi, S.; Imai, Y.; Kan, A.; Hotta, Y.; Ogawa, H. Dielectric and thermal properties of isotactic polypropylene/hexagonal boron nitride composites for high-frequency applications. J. Alloys Compd. 2014, 615, 141–145. [Google Scholar] [CrossRef]

- Rodriguez-Canov, R.; Lanagan, M.; Perini, S.; Li, X.; Gopalan, V. Broadband dielectric characterization of glasses and other silicates up to the THz frequencies. In Proceedings of the 2023 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting (USNC-URSI), Portland, OR, USA, 23–28 July 2023; pp. 287–288. [Google Scholar] [CrossRef]

- Weizhuo, Z.; Guangzhao, L.; Erwei, S.; Sukun, H.; Dingyuan, T.; Qinglan, Z. Growth Units and Formation Mechanisms of the Crystals Under Hydrothermal Conditions. Sci. China Chem. 1994, 37, 1288–1297. [Google Scholar]

- Zhou, W.; Xiaohu, C.; Donghong, L.; Wubin, L. Preparation of nano ammonium aluminium carbonate hydroxide. Light Met. 2012, 48, 14–16. [Google Scholar] [CrossRef]

- Hu, X.; Liu, Y.; Tang, Z.; Li, G.; Zhao, R.; Liu, C. Fabrication of high-surface-area γ-alumina by thermal decomposition of AACH precursor using low-temperature solid-state reaction. Mater. Res. Bull. 2012, 47, 4271–4277. [Google Scholar] [CrossRef]

- Ameer, A.; Hassan, S.M.U.; Husnain, S.; Ahmad, J.; Shahzad, F.; Iqbal, Z.; Mehmood, M. Preparation of Al2O3 Whiskers from AACH Using Hydrothermal Method and its Use for the Removal of Lead Ions by Adsorption. Key Eng. Mater. 2021, 875, 177–183. [Google Scholar] [CrossRef]

- Sreenivasan, D.P.; Sujith, A.; Asokan, A.N.; Rajesh, C. Dielectric Properties of Composites of Natural Rubber and Keratin Fibre from Chicken Feather. Fibers Polym. 2021, 22, 2588–2601. [Google Scholar] [CrossRef]

- Vovchenko, L.; Matzui, L.; Zagorodnii, V.; Yakovenko, O. The effect of filler distribution on electromagnetic properties of nanocarbon/magnetic particles/polymer composites. J. Appl. Phys. 2024, 136, 185101. [Google Scholar] [CrossRef]

- Çelik, K.; Kurt, E.; Korkmaz, O. A Novel Multiple-Slot Pixel Patch Antenna for Wideband Terahertz Applications. JOM 2024, 76, 1–9. [Google Scholar] [CrossRef]

- Ausden, L.; Stokes, D.; Skinner, J.; Ridler, N.; Shang, X. Characterisation of Dielectric Substrates at Millimetre-wave and Sub-terahertz Frequencies Using a VNA-based Guided-wave Technique. In Proceedings of the 2024 54th European Microwave Conference (EuMC), Paris, France, 24–26 September 2024; pp. 640–643. [Google Scholar] [CrossRef]

- Takahashi, S.; Imai, Y.; Kan, A.; Hotta, Y.; Ogawa, H. Preparation and characterization of isotactic polypropylene/MgO composites as dielectric materials with low dielectric loss. J. Ceram. Soc. Jpn. 2013, 121, 606–610. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, G.; Gao, C.; Leng, J.; Wu, Y.; Chen, L.; Jing, R.; Xie, P.; Deng, H.; Shi, Q. Controlling Terahertz Dielectric Responses in Polymer Composites by Engineering α-Al2O3 Whisker Filler Distribution. J. Compos. Sci. 2025, 9, 136. https://doi.org/10.3390/jcs9030136

Huang G, Gao C, Leng J, Wu Y, Chen L, Jing R, Xie P, Deng H, Shi Q. Controlling Terahertz Dielectric Responses in Polymer Composites by Engineering α-Al2O3 Whisker Filler Distribution. Journal of Composites Science. 2025; 9(3):136. https://doi.org/10.3390/jcs9030136

Chicago/Turabian StyleHuang, Gang, Chengzhe Gao, Jin Leng, Yang Wu, Liying Chen, Ran Jing, Pengshu Xie, Hua Deng, and Qiwu Shi. 2025. "Controlling Terahertz Dielectric Responses in Polymer Composites by Engineering α-Al2O3 Whisker Filler Distribution" Journal of Composites Science 9, no. 3: 136. https://doi.org/10.3390/jcs9030136

APA StyleHuang, G., Gao, C., Leng, J., Wu, Y., Chen, L., Jing, R., Xie, P., Deng, H., & Shi, Q. (2025). Controlling Terahertz Dielectric Responses in Polymer Composites by Engineering α-Al2O3 Whisker Filler Distribution. Journal of Composites Science, 9(3), 136. https://doi.org/10.3390/jcs9030136