Comprehensive Review of Endogenous and Exogenous Parameters Influencing Dynamic Stab Impact Performance in Protective Textiles and Fibrous Composite Materials

Abstract

1. Introduction

2. The Endogenous Parameters in Stab Resistance of Textiles and Composite Materials

2.1. Effects of Raw Material, Types and Compositions

2.2. Effects of Textile Structural Parameters

2.2.1. Effects of Fabric Structures

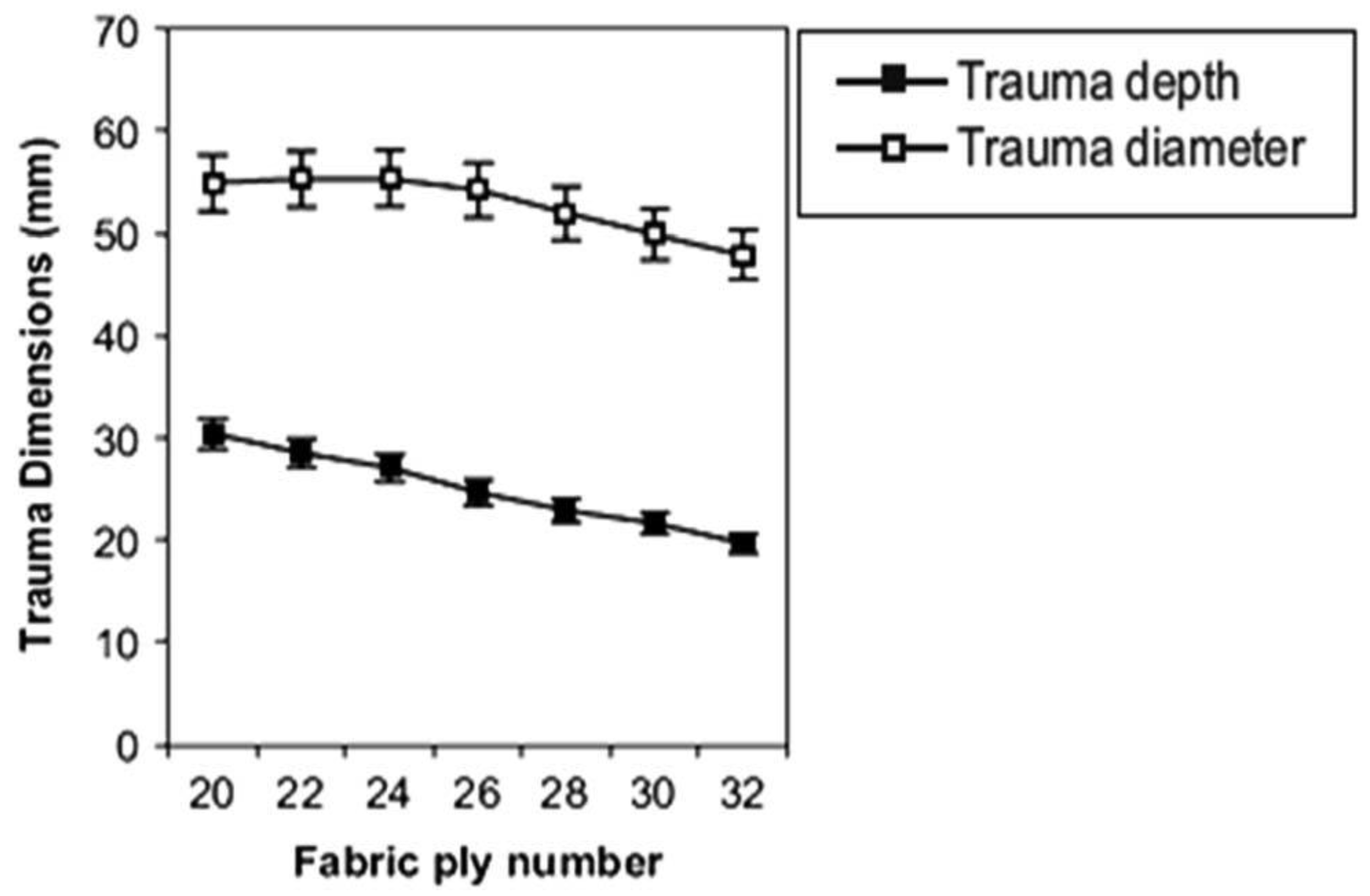

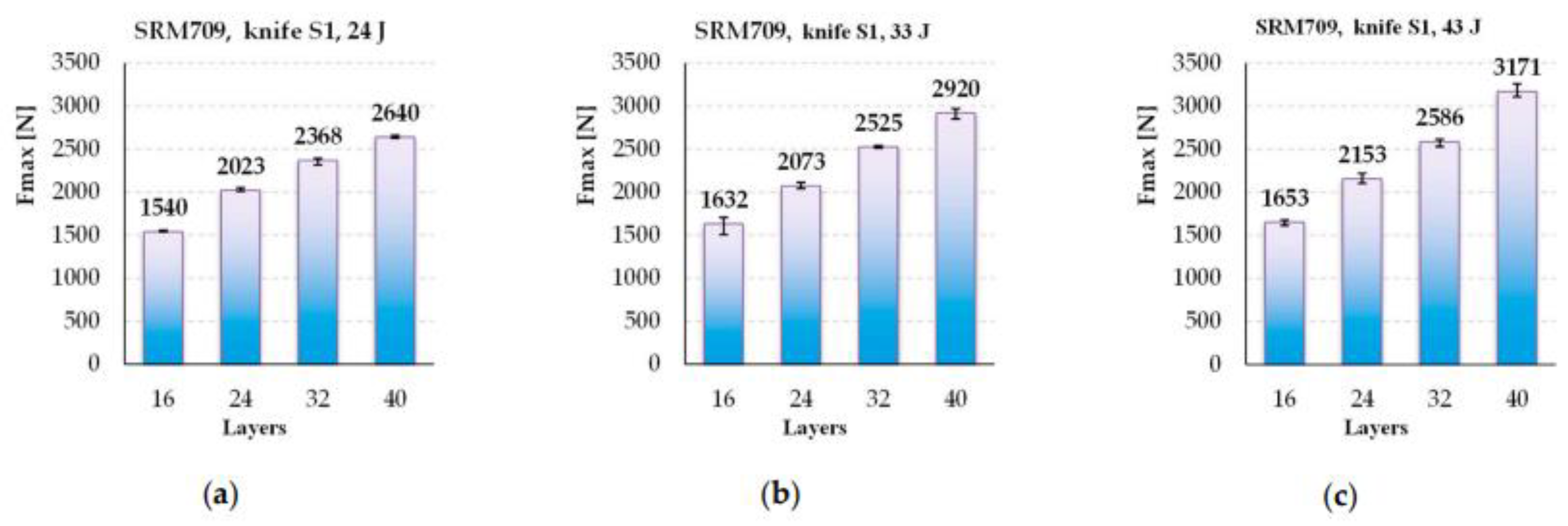

2.2.2. Effects of the Number of Fabric Layers and Stitching

2.2.3. Effects of the Orientation of Reinforcement Layers

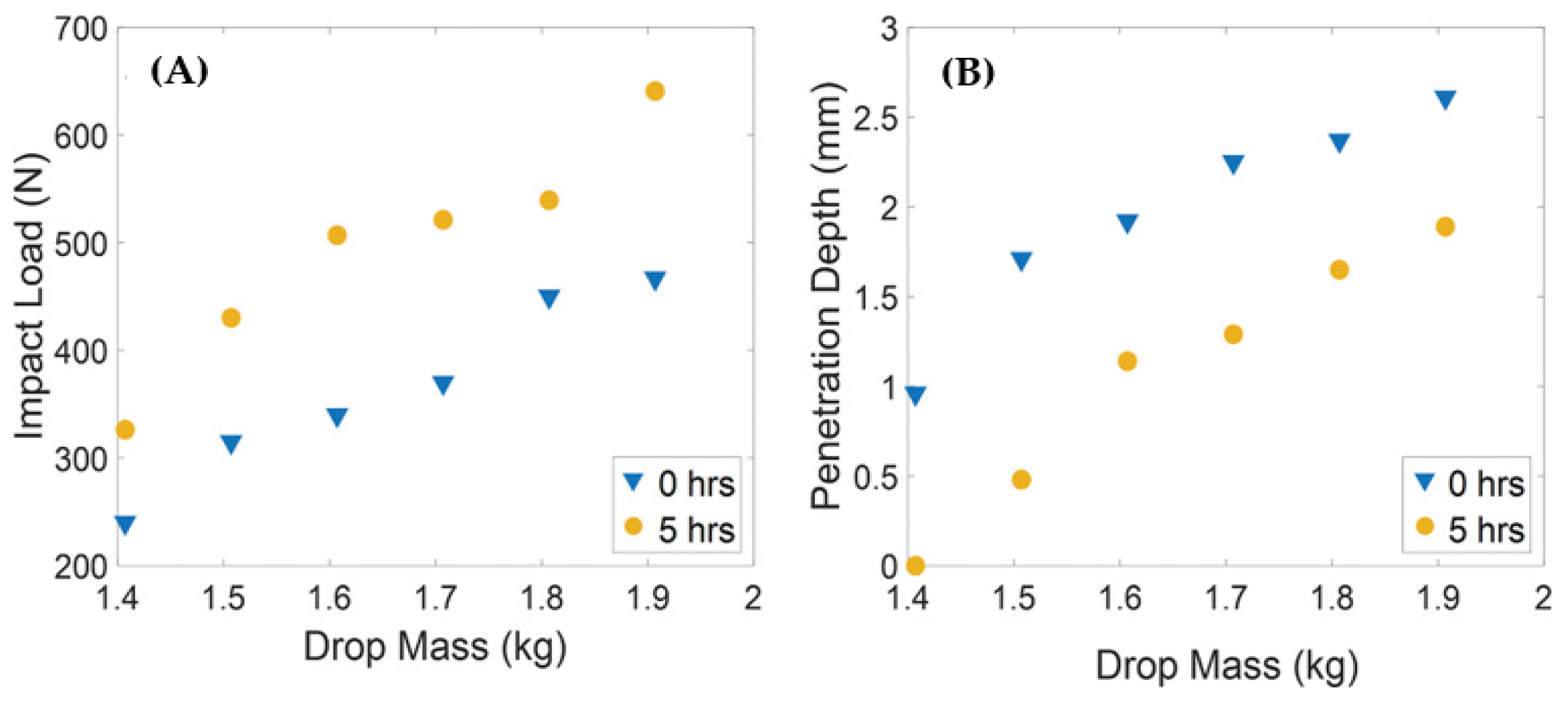

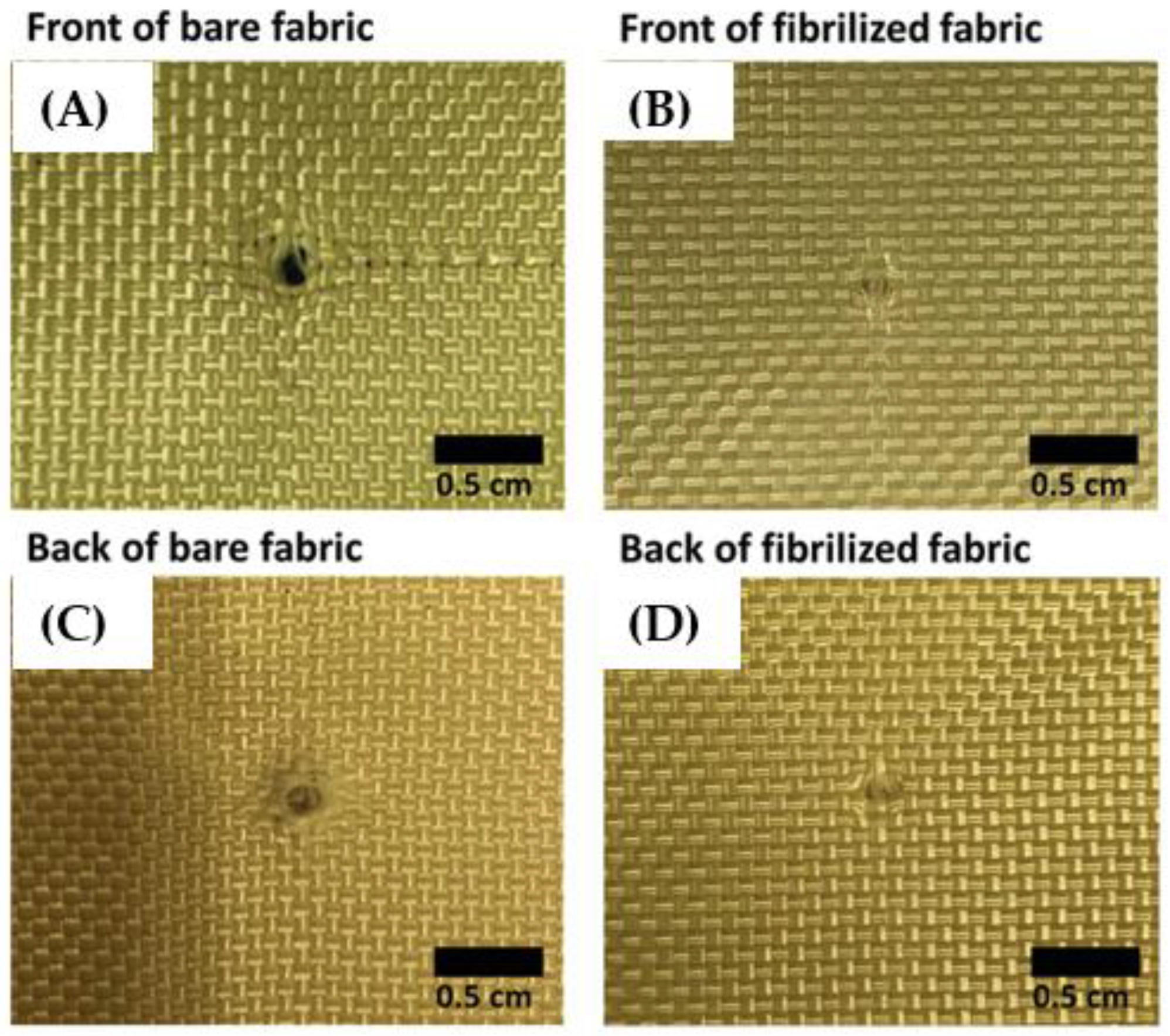

2.2.4. Effects of Textile Finishing and Treatment

3. Exogenous Parameters in Stab Resistance of Textiles and Composite Materials

3.1. Stabbing Methods and Conditions

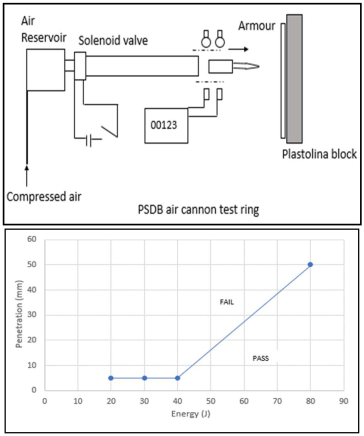

3.1.1. PSDB Standard

3.1.2. National Institute of Justice (NIJ) Standard

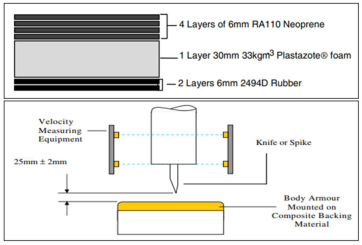

3.1.3. Home Office Scientific Development Branch Standard (HOSDB)

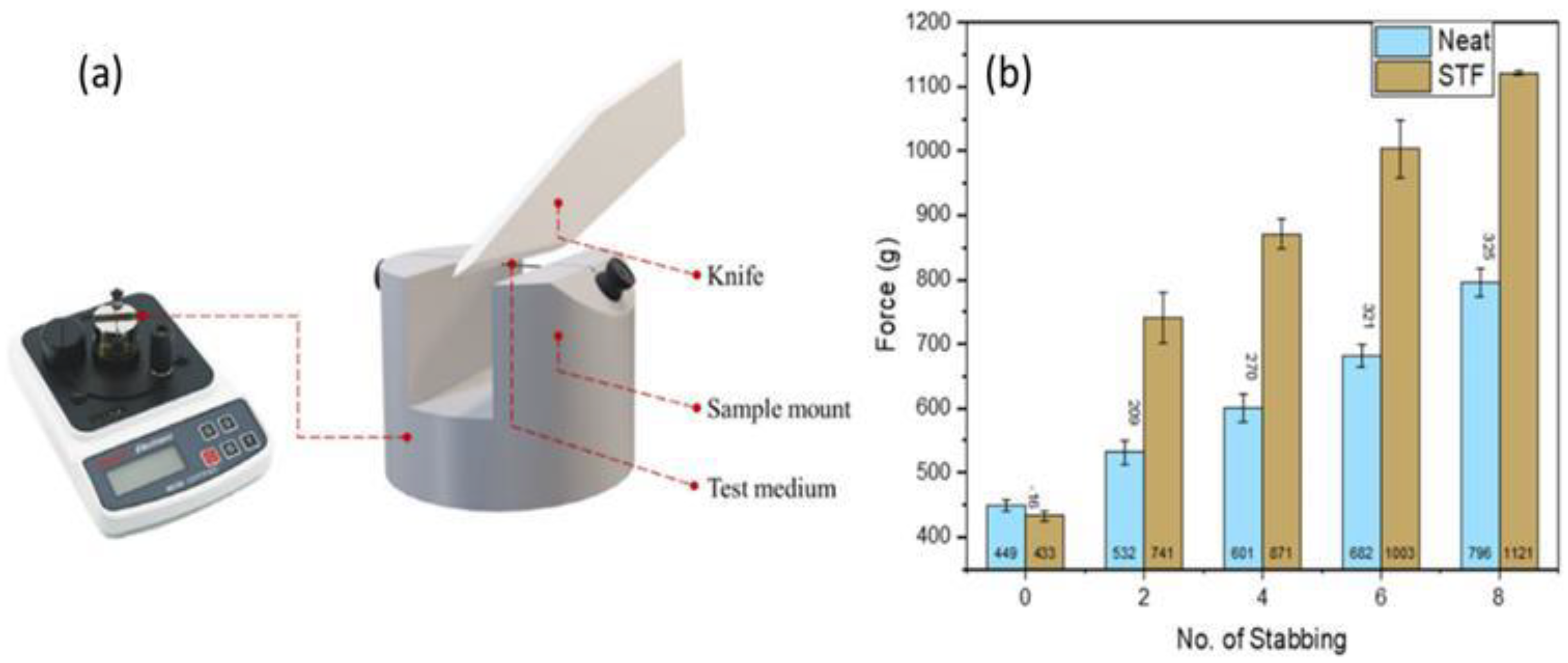

3.1.4. Quasi-Static Methods

3.1.5. Backing Materials for Stab and Spike Tests

3.2. Effects of Impact Velocity, Energy, and Angle of Incidence

3.2.1. Effects of Impact Velocity and Energy

3.2.2. Effects of Angle of Incidence

3.3. Effects of Stabbing Blade Conditions

3.3.1. Knife-Making Process

3.3.2. Shape and Sharpness of the Knife Blade

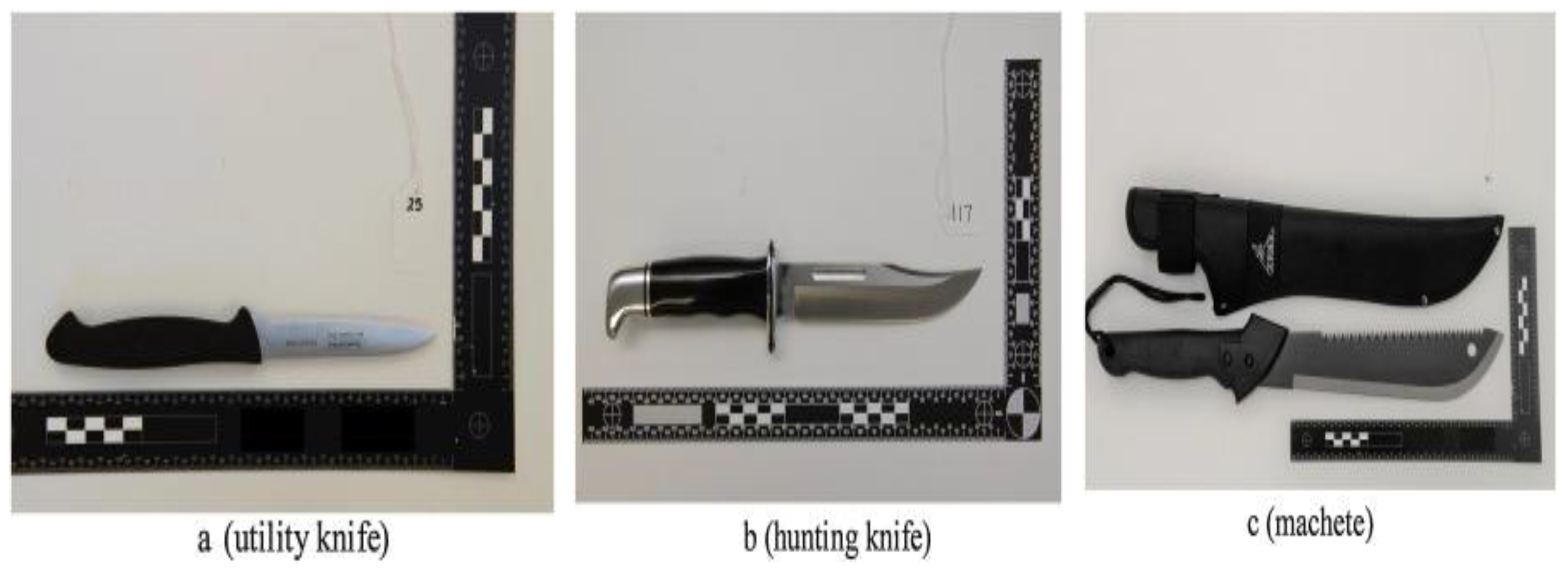

3.3.3. Types of Weapons

4. Challenges and Future Advancements in Dynamic Stab Resistance of Protective Textiles

4.1. Challenges in Developing Dynamic Stab Resistance of Textiles

4.2. Future Advancements and Directions in Stab-Resistant Textiles

5. Conclusions and Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, M.; Abtew, M.A.; Chen, X.; Boussu, F. Stabbing and ballistic resistances of the predeformed multiply three-dimensional interlock fabrics. In Advanced Structural Textile Composites Forming; Woodhead Publishing: Cambridge, UK, 2025; pp. 495–526. [Google Scholar] [CrossRef]

- Panneke, N.; Ehrmann, A. Stab-Resistant Polymers—Recent Developments in Materials and Structures. Polymers 2023, 15, 983. [Google Scholar] [CrossRef] [PubMed]

- Abtew, M.A. A comprehensive review on advancements, innovations and applications of 3D warp interlock fabrics and its composite materials. Compos. Part B Eng. 2024, 278, 111395. [Google Scholar] [CrossRef]

- Sun, L.; Liu, S.; Zhao, H.; Muhammad, U.; Chen, D.; Li, W. Dynamic performance of fiber-reinforced ultra-high toughness cementitious composites: A comprehensive review from materials to structural applications. Eng. Struct. 2024, 317, 118647. [Google Scholar] [CrossRef]

- Sitotaw, D.B.; Ahrendt, D.; Kyosev, Y.; Kabish, A.K. A Review on the Performance and Comfort of Stab Protection Armor. Autex Res. J. 2022, 22, 96–107. [Google Scholar] [CrossRef]

- Nayak, R.; Crouch, I.; Kanesalingam, S.; Ding, J.; Tan, P.; Lee, B.; Miao, M.; Ganga, D.; Wang, L. Body armor for stab and spike protection, Part 1: Scientific literature review. Text. Res. J. 2017, 88, 812–832. [Google Scholar] [CrossRef]

- Arora, S.; Ghosh, A. Evolution of soft body armor. In Advanced Textile Engineering Materials; John Wiley & Sons: Hoboken, NJ, USA, 2018; pp. 499–552. [Google Scholar] [CrossRef]

- Deleanu, L.; Rusu, V.T.; Ojoc, G.G.; Cristea, G.C.; Boțan, M.; Vasiliu, A.V.; Popescu, C. The Behaviour of Stratified Fabrics of Aramid Fibres under Stabbing Conditions. Polymers 2024, 16, 882. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T. Three-Dimensional Printing and 3D Scanning: Emerging Technologies Exhibiting High Potential in the Field of Cultural Heritage. Appl. Sci. 2023, 13, 4777. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M.; Singh, R.P.; Rab, S.; Suman, R.; Kumar, L.; Khan, I.H. Exploring the potential of 3D scanning in Industry 4.0: An overview. Int. J. Cogn. Comput. Eng. 2022, 3, 161–171. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P. Dynamic impact protective body armour: A comprehensive appraisal on panel engineering design and its prospective materials. Def. Technol. 2021, 17, 2027–2049. [Google Scholar] [CrossRef]

- Wei, R.; Dong, B.; Zhai, W.; Li, H. Stab-Resistant Performance of the Well-Engineered Soft Body Armor Materials Using Shear Thickening Fluid. Molecules 2022, 27, 6799. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaus, P.; Loghin, C.; Cristian, I. Ballistic impact mechanisms-A review on textiles and fibre-reinforced composites impact responses. Compos. Struct. 2019, 223, 110966. [Google Scholar] [CrossRef]

- Mawkhlieng, U.; Majumdar, A.; Laha, A. A review of fibrous materials for soft body armour applications. RSC Adv. 2020, 10, 1066–1086. [Google Scholar] [CrossRef]

- Kemp, S.E.; Carr, D.J.; Kieser, J.; Niven, B.E.; Taylor, M.C. Forensic evidence in apparel fabrics due to stab events. Forensic Sci. Int. 2009, 191, 86–96. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Liu, T.; Zhang, J.; Qian, N.; Lu, Z.; Chang, C.; Wang, R.; Xiao, Q.; Qi, J.; You, F. Enhanced dynamic stab resistance and UV-resistance of flexible and lightweight Kevlar fabrics impregnated with multi-phase shear thickening fluid. J. Mater. Res. Technol. 2024, 29, 2533–2543. [Google Scholar] [CrossRef]

- Li, M.; Wang, P.; Boussu, F.; Soulat, D. Investigation of impact performance of 3-dimensional interlock polymer fabrics in double and multi-angle pass stabbing. Mater. Des. 2021, 206, 109775. [Google Scholar] [CrossRef]

- Cowper, E.J.; Carr, D.J.; Horsfall, I.; Fergusson, S.M. The effect of fabric and stabbing variables on severance appearance. Forensic Sci. Int. 2015, 249, 214–224. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Cristian, I. Exploring the Effects of angle of incidence on stabbing resistance in advanced protective textiles: Novel experimental framework and analysis. Def. Technol. 2024, 44, 67–82. [Google Scholar] [CrossRef]

- El Messiry, M.; Eltahan, E. Enhancement of silk fabric knife-stabbing resistance for soft body armor. J. Ind. Text. 2024, 54, 1–29. [Google Scholar] [CrossRef]

- Alpyildiz, T.; Rochery, M.; Kurbak, A.; Flambard, X. Stab and cut resistance of knitted structures: A comparative study. Text. Res. J. 2011, 81, 205–214. [Google Scholar] [CrossRef]

- El Messiry, M.; Ayman, Y.; Eid, E.M. Investigation of slashing mechanisms and behavior of high-performance fabrics. J. Eng. Fiber. Fabr. 2024, 19, 1–17. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Hong, Y. Dynamic impact surface damage analysis of 3D woven para-aramid armour panels using ndi technique. Polymers 2021, 13, 877. [Google Scholar] [CrossRef] [PubMed]

- Shim, V.P.W.; Lim, C.T.; Foo, K.J. Dynamic mechanical properties of fabric armour. Int. J. Impact Eng. 2001, 25, 1–15. [Google Scholar] [CrossRef]

- Soydan, A.M.; Tunaboylu, B.; Elsabagh, A.G.; Sarı, A.K.; Akdeniz, R. Simulation and Experimental Tests of Ballistic Impact on Composite Laminate Armor. Adv. Mater. Sci. Eng. 2018, 2018, 1–12. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Yu, J.; Chen, Y.; Zhu, M. The past, present and future of high-performance fibers. Natl. Sci. Rev. 2024, 11, 10–12. [Google Scholar] [CrossRef]

- Zhai, Y.; Mao, L.; Shen, Y.; Yan, X. Research Progress of Cut-Resistant Textile Materials. Front. Chem. 2021, 9, 745467. [Google Scholar] [CrossRef]

- Deitzel, J.M.; McDaniel, P.; Gillespie, J.W. High Performance Polyethylene Fibers; Elsevier Ltd.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Li, M.; Wang, P.; Boussu, F.; Soulat, D. Dynamic stab resistance of multi-ply three-dimensional warp interlock fabrics with high-performance high-molecular-weight polyethylene yarns for protective applications. J. Ind. Text. 2022, 51, 2391S–2411S. [Google Scholar] [CrossRef]

- Yu, X.; Su, T.; Liang, X.; Cong, H. Optimization the Stab Resistance and Flexibility of Ultra-High Molecular Weight Polyethylene Knitted Structure Fabric with Response Surface Method. Polymers 2023, 15, 4509. [Google Scholar] [CrossRef]

- Chuang, Y.C.; Bao, L.; Lin, M.C.; Lou, C.W.; Lin, T.A. Mechanical and static stab resistant properties of hybrid-fabric fibrous planks: Manufacturing process of nonwoven fabrics made of recycled fibers. Polymers 2019, 11, 1140. [Google Scholar] [CrossRef]

- Mayo, J.B.; Wetzel, E.D.; Hosur, M.V.; Jeelani, S. Stab and puncture characterization of thermoplastic-impregnated aramid fabrics. Int. J. Impact Eng. 2009, 36, 1095–1105. [Google Scholar] [CrossRef]

- Chitturi, S.K.; Shaikh, A.A. The dynamic performance of novel multilayered hybrid composite laminate. SN Appl. Sci. 2020, 2, 1000. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, H.; Wang, Y. Preparation and sports performance of multilayer flexible anti stabbing fabric martial arts sports composite conjugate materials. Front. Chem. 2023, 11, 1256541. [Google Scholar] [CrossRef] [PubMed]

- Crouch, I.G. Body armour—New materials, new systems. Def. Technol. 2019, 15, 241–253. [Google Scholar] [CrossRef]

- Tan, Y.; Ma, Y.; Li, Y. Shear thickening fabric composites for impact protection: A review. Text. Res. J. 2022, 93, 1419–1444. [Google Scholar] [CrossRef]

- Naveen, J.; Jawaid, M.; Goh, K.L.; Reddy, D.M.; Muthukumar, C.; Loganathan, T.M.; Reshwanth, K.N.G.L. Advancement in graphene-based materials and their nacre inspired composites for armour applications—A review. Nanomaterials 2021, 11, 1239. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, M.P.; da Silveira, P.H.P.M.; de Oliveira Braga, F.; Monteiro, S.N. Fabric Impregnation with Shear Thickening Fluid for Ballistic Armor Polymer Composites: An Updated Overview. Polymers 2022, 14, 4357. [Google Scholar] [CrossRef]

- Barnat, W.; Sokołowski, D.; Gieleta, R. Numerical and experimental research on stab resistance of a body armour package. Fibres Text. East. Eur. 2014, 22, 90–96. [Google Scholar]

- Liu, Y.; Zhang, H.; Huang, G.; Zhou, H.; Chen, J.; Wang, Z. Theoretical model for predicting stabbing resistance of soft body armor comprising fibrous composites. Int. J. Impact Eng. 2023, 180, 104716. [Google Scholar] [CrossRef]

- Gürgen, S. Numerical modeling of fabrics treated with multi-phase shear thickening fluids under high velocity impacts. Thin-Walled Struct. 2020, 148, 106573. [Google Scholar] [CrossRef]

- Ramaiah, G.B.; Chennaiah, R.Y.; Satyanarayanarao, G.K. Investigation and modeling on protective textiles using artificial neural networks for defense applications. Mater. Sci. Eng. B 2010, 168, 100–105. [Google Scholar] [CrossRef]

- Liu, M.; Liu, S.; Li, H.; Zhang, H.; Huang, G. Prediction of puncture key parameters in aramid stab-resistant fabrics based on surface damage images using artificial neural networks. Compos. Sci. Technol. 2024, 255, 110713. [Google Scholar] [CrossRef]

- Chu, Y.; Zhu, B.; Li, S.; Chen, C.; Huang, W.; Liu, Y.; Zhao, X.; Zhang, Z.; Fahaduzzaman; Wang, X.; et al. A novel flexible and breathable stab-resistance fabric composites with ZnO nanowires growing technology. J. Mater. Res. Technol. 2023, 24, 6438–6450. [Google Scholar] [CrossRef]

- Johnson, A.; Bingham, G.A.; Wimpenny, D.I. Additive manufactured textiles for high-performance stab resistant applications. Rapid Prototyp. J. 2013, 19, 199–207. [Google Scholar] [CrossRef]

- Maidin, S.; Chong, S.Y.; Heing, T.K.; Abdullah, Z.; Alkahari, R. Stab Resistant Analysis of Body Armour Design Features Manufactured via Fused Deposition Modelling Process. In Textile Manufacturing Processes; IntechOpen: London, UK, 2019; pp. 1–17. [Google Scholar] [CrossRef]

- Maidin, S.; Chong, S.Y. Finite element analysis of low velocity behaviour on fused deposition modeling printed stabresistant body armour design features. J. Adv. Manuf. Technol. 2018, 12, 475–490. [Google Scholar]

- Gu, J.; Huang, X.C.; Li, Y.; Wang, X.L.; Shi, M.W.; Zheng, Z. Improving the stab-resistance performance of ultra high molecular weight polyethylene fabric intercalated with nano-silica-fluid. J. Shanghai Jiaotong Univ. 2014, 19, 102–109. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, Y. Technical textiles for ballistic protection. In Handbook of Technical Textiles, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; pp. 169–192. [Google Scholar] [CrossRef]

- Mao, L.; Yu, H.; Yao, L.; Shen, Y.; Yan, X.; Ma, Y. Cut/puncture resistance and mechanisms of protective composite textiles reinforced with inorganic powder. Mater. Des. 2024, 237, 112575. [Google Scholar] [CrossRef]

- Sitotaw, D.B.; Ahrendt, D.; Kyosev, Y.; Kabish, A.K. Investigation of stab protection properties of aramid fibre-reinforced 3D printed elements. Fibres Text. East. Eur. 2021, 29, 67–73. [Google Scholar] [CrossRef]

- Alharbi, N.; Daraei, A.; Lee, H.; Guthold, M. The effect of molecular weight and fiber diameter on the mechanical properties of single, electrospun PCL nanofibers. Mater. Today Commun. 2023, 35, 105773. [Google Scholar] [CrossRef]

- Harris, M.; Potgieter, J.; Archer, R.; Arif, K.M. Effect of material and process specific factors on the strength of printed parts in fused filament fabrication: A review of recent developments. Materials 2019, 12, 1664. [Google Scholar] [CrossRef]

- Srivastava, A.; Majumdar, A.; Butola, B.S. Improving the impact resistance of textile structures by using shear thickening fluids: A review. Crit. Rev. Solid State Mater. Sci. 2012, 37, 115–129. [Google Scholar] [CrossRef]

- Davoodi, E.; Montazerian, H.; Mirhakimi, A.S.; Zhianmanesh, M.; Ibhadode, O.; Shahabad, S.I.; Esmaeilizadeh, R.; Sarikhani, E.; Toorandaz, S.; Sarabi, S.A.; et al. Additively manufactured metallic biomaterials. Bioact. Mater. 2022, 15, 214–249. [Google Scholar] [CrossRef]

- Karahan, M.; Jabbar, A.; Karahan, N. Ballistic impact behavior of the aramid and ultra-high molecular weight polyethylene composites. J. Reinf. Plast. Compos. 2015, 34, 37–48. [Google Scholar] [CrossRef]

- Bajaj, P. Ballistic protective clothing: An overview. Indian J. Fibre Text. Res. 1997, 22, 274–291. [Google Scholar]

- Cunniff, P.M.; Auerbach, M.A. High performance ‘M5’ fiber for ballistics/structural composites. In Proceedings of the 23rd Army Science Conference, Orlando, FL, USA, 2–5 December 2002. [Google Scholar]

- Hiremath, S.; Oh, J.; Zhang, Y.; Kim, T.-W. Impact Damage Caused by Sharp Objects on Fabric Materials. J. Fiber Sci. Technol. 2024, 80, 184–196. [Google Scholar] [CrossRef]

- Zhang, X.; Li, T.-T.; Sun, F.; Peng, H.-K.; Wang, Z.; Lin, J.-H.; Lou, C.-W. Stab/Puncture Resistance Performance of Needle Punched Nonwoven Fabrics: Effects of Filament Reinforcement and Thermal Bonding. Fibers Polym. 2022, 23, 2330–2339. [Google Scholar] [CrossRef]

- Cunniff, P.M. An Analysis of the System Effects in Woven Fabrics Under Ballistic Impact. Text. Res. J. 1992, 62, 495–509. [Google Scholar] [CrossRef]

- Cheeseman, B.A.; Bogetti, T.A. Ballistic impact into fabric and compliant composite laminates. Compos. Struct. 2003, 61, 161–173. [Google Scholar] [CrossRef]

- Ha-minh, C. Comportement Mécanique des Matériaux Tissés Soumis à un Impact Balistique: Approches Expérimentale, Numérique et Analytique. Ph.D. Thesis, Université de Lille, Lille, France, 2011. [Google Scholar]

- Parga-Landa, B.; Hernández-Olivares, F. An analytical model to predict impact behaviour of soft armours. Int. J. Impact Eng. 1995, 16, 455–466. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Motamedi, F. The ballistic impact characteristics of aramid fabrics: The influence of interface friction. Wear 1992, 158, 229–247. [Google Scholar] [CrossRef]

- Bazhenov, S. Dissipation of energy by bulletproof aramid fabric. J. Mater. Sci. 1997, 32, 4167–4173. [Google Scholar] [CrossRef]

- Duan, Y.; Keefe, M.; Bogetti, T.; Cheeseman, B.; Powers, B. A numerical investigation of the influence of friction on energy absorption by a high-strength fabric subjected to ballistic impact. Int. J. Impact Eng. 2006, 32, 1299–1312. [Google Scholar] [CrossRef]

- Zeng, X.S.; Tan, V.B.C.; Shim, V.P.W. Modelling inter-yarn friction in woven fabric armour. Int. J. Numer. Methods Eng. 2006, 66, 1309–1330. [Google Scholar] [CrossRef]

- Liu, H.; Fu, K.; Cui, X.; Zhu, H.; Yang, B. Shear Thickening Fluid and Its Application in Impact Protection: A Review. Polymers 2023, 15, 2238. [Google Scholar] [CrossRef] [PubMed]

- Gürgen, S.; Kuşhan, M.C.; Li, W. Shear thickening fluids in protective applications: A review. Prog. Polym. Sci. 2017, 75, 48–72. [Google Scholar] [CrossRef]

- Khodadadi, A.; Liaghat, G.; Sabet, A.; Hadavinia, H.; Aboutorabi, A.; Razmkhah, O.; Akbari, M.; Tahmasebi, M. Experimental and numerical analysis of penetration into Kevlar fabric impregnated with shear thickening fluid. J. Thermoplast. Compos. Mater. 2018, 31, 392–407. [Google Scholar] [CrossRef]

- Kostic, S.; Kocovic, V.; Savic, S.P.; Miljanic, D.; Miljojkovic, J.; Djordjevic, M.; Vukelic, D. The Influence of Friction and Twisting Angle on the Tensile Strength of Polypropylene Baling Twine. Appl. Sci. 2024, 14, 3046. [Google Scholar] [CrossRef]

- Rao, Y.; Farris, R.J. Modeling and experimental study of the influence of twist on the mechanical properties of high-performance fiber yarns. J. Appl. Polym. Sci. 2000, 77, 1938–1949. [Google Scholar] [CrossRef]

- Chen, X.; Yang, D. Use of 3D Angle-Interlock Woven Fabric for Seamless Female Body Armour: Part 1: Ballistic Evaluation. Text. Res. J. 2010, 80, 1581–1588. [Google Scholar] [CrossRef]

- Hosur, M.; Vaidya, U.; Ulven, C.; Jeelani, S. Performance of stitched/unstitched woven carbon/epoxy composites under high velocity impact loading. Compos. Struct. 2004, 64, 455–466. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Forming characteristics and surface damages of stitched multi-layered para-aramid fabrics with various stitching parameters for soft body armour design. Compos. Part A Appl. Sci. Manuf. 2018, 109, 517–537. [Google Scholar] [CrossRef]

- Miao, X.; Jiang, G.; Kong, X.; Zhao, S. Experimental investigation on the stab resistance of warp knitted fabrics. Fibres Text. East. Eur. 2014, 22, 65–70. [Google Scholar]

- El Messiry, M.; Eltahan, E. Stab resistance of triaxial woven fabrics for soft body armor. J. Ind. Text. 2014, 45, 1062–1082. [Google Scholar] [CrossRef]

- Karahan, M. Comparison of ballistic performance and energy absorption capabilities of woven and uni-directional aramid fabrics. Text. Res. J. 2008, 78, 718–730. [Google Scholar] [CrossRef]

- Chu, C.K.; Chen, Y.L. Ballistic-proof effects of various woven constructions. Fibres Text. East. Eur. 2010, 83, 63–67. [Google Scholar]

- Midha, V.K.; Dakuri, A. Spun bonding Technology and Fabric Properties: A Review. J. Text. Eng. Fash. Technol. 2017, 1, 126–133. [Google Scholar] [CrossRef]

- Chuang, Y.C.; Bao, L.; Lin, M.C.; Lin, T.A.; Lou, C.-W. Fabric composites reinforced with thermally bonded and irregularly aligned filaments: Preparation and puncture resistant performance. Polymers 2019, 11, 706. [Google Scholar] [CrossRef]

- Abtew, M.A.; Bruniaux, P.; Boussu, F. Development of adaptive bust for female soft body armour using three dimensional (3D) warp interlock fabrics: Three dimensional (3D) design process. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 052001. [Google Scholar] [CrossRef]

- Boussu, F.; Abtew, M.A.; Bruniaux, P. 3D Warp Interlock Fabric Structure and their Applications in Soft and Hard Armour Protections. Appl. Compos. Mater. 2022, 29, 65–82. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Effect of Structural Parameters on the Deformational Behaviors of Multiply 3D Layer-by-Layer Angle-Interlock Para-Aramid Fabric for Fiber-Reinforcement Composite. J. Compos. Sci. 2020, 4, 145. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Sachan, Y.; Ahmad, S.; Alagirusamy, R.; Bhatnagar, N. On the mechanical response of 2D plain woven and 3D angle-interlock fabrics. Compos. Part B Eng. 2017, 118, 135–148. [Google Scholar] [CrossRef]

- Sockalingam, S.; Chowdhury, S.C.; Gillespie, J.W.; Keefe, M. Recent advances in modeling and experiments of Kevlar ballistic fibrils, fibers, yarns and flexible woven textile fabrics—A review. Text. Res. J. 2017, 87, 984–1010. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Engineering of 3D warp interlock p-aramid fabric structure and its energy absorption capabilities against ballistic impact for body armour applications. Compos. Struct. 2019, 225, 111179. [Google Scholar] [CrossRef]

- Tan, V.B.C.; Shim, V.P.W.; Tay, T.E. Experimental and numerical study of the response of flexible laminates to impact loading. Int. J. Solids Struct. 2003, 40, 6245–6266. [Google Scholar] [CrossRef]

- Sadegh, A.M.; Cavallaro, P.V. Mechanics of Energy Absorbability in Plain-Woven Fabrics: An Analytical Approach. J. Eng. Fibers Fabr. 2012, 7, 10–25. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Influences of fabric density on mechanical and moulding behaviours of 3D warp interlock para-aramid fabrics for soft body armour application. Compos. Struct. 2018, 204, 402–418. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Experimental investigation of effects of stitching orientation on forming behaviors of 2D P-aramid multilayer woven preform. AIP Conf. Proc. 2018, 1960, 020001. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Ahmad, W.Y.W.; Salleh, J.; Samsuri, A. Effect of fabric stitching on ballistic impact resistance of natural rubber coated fabric systems. Mater. Des. 2008, 29, 1353–1358. [Google Scholar] [CrossRef]

- Palta, E.; Fang, H. On a multi-scale finite element model for evaluating ballistic performance of multi-ply woven fabrics. Compos. Struct. 2019, 207, 488–508. [Google Scholar] [CrossRef]

- Wang, H.; Hazell, P.J.; Shankar, K.; Morozov, E.V.; Escobedo, J.P.; Wang, C. Effects of fabric folding and thickness on the impact behaviour of multi-ply UHMWPE woven fabrics. J. Mater. Sci. 2017, 52, 13977–13991. [Google Scholar] [CrossRef]

- Karahan, M.; Kuş, A.; Eren, R. An investigation into ballistic performance and energy absorption capabilities of woven aramid fabrics. Int. J. Impact Eng. 2008, 35, 499–510. [Google Scholar] [CrossRef]

- Sitotaw, D.B.; Muenks, D.; Kebash, A.K. 3D printing applications on textiles: Measurement of air permeability for potential use in stab-proof vests. J. Eng. Fiber. Fabr. 2024, 19, 1–10. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Cristian, I.; Dejene, B.K. Experimental investigation on dynamic stab resistance of high-performance multi-layer textile materials. Def. Technol. 2025; In press. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Young, R.; Kinloch, I.; Wells, G. A numerical study of ply orientation on ballistic impact resistance of multi-ply fabric panels. Compos. Part B Eng. 2015, 68, 259–265. [Google Scholar] [CrossRef]

- Chen, X.; Sun, D.; Wang, Y.; Zhou, Y. 2D/3D Woven Fabrics for Ballistic Protection. In Proceedings of the 4th World Conference on 3D Fabrics and Their Applications, Aachen, Germany, 10–11 September 2012; TexEng/RWTH Aachen: Manchester, UK, 2012; pp. 1–12. [Google Scholar]

- Zhang, W.; Liu, S.; Ma, P. Experimental investigation on stab-resistant properties of co-woven-knitted fabric. J. Eng. Fiber. Fabr. 2022, 17, 1–6. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Motamedi, F. Role of Interfacial Friction and Lubrication in Yarn and Fabric Mechanics. Text. Res. J. 1990, 60, 697–708. [Google Scholar] [CrossRef]

- Lee, W.; Lee, J.U.; Byun, J.-H. Catecholamine polymers as surface modifiers for enhancing interfacial strength of fiber-reinforced composites. Compos. Sci. Technol. 2015, 110, 53–61. [Google Scholar] [CrossRef]

- LaBarre, E.D.; Calderon-Colon, X.; Morris, M.; Tiffany, J.; Wetzel, E.; Merkle, A.; Trexler, M. Effect of a carbon nanotube coating on friction and impact performance of Kevlar. J. Mater. Sci. 2015, 50, 5431–5442. [Google Scholar] [CrossRef]

- Gorowara, R.L.; Kosik, W.E.; McKnight, S.H.; McCullough, R.L. Molecular characterization of glass fiber surface coatings for thermosetting polymer matrix/glass fiber composites. Compos. Part A Appl. Sci. Manuf. 2001, 32, 323–329. [Google Scholar] [CrossRef]

- Patterson, B.A.; Sodano, H.A. Enhanced Interfacial Strength and UV Shielding of Aramid Fiber Composites through ZnO Nanoparticle Sizing. ACS Appl. Mater. Interfaces 2016, 8, 33963–33971. [Google Scholar] [CrossRef]

- Qian, H.; Bismarck, A.; Greenhalgh, E.S.; Shaffer, M.S.P. Carbon nanotube grafted silica fibres: Characterising the interface at the single fibre level. Compos. Sci. Technol. 2010, 70, 393–399. [Google Scholar] [CrossRef]

- Gawandi, A.; Thostenson, E.T.; Gilllespie, J.W. Tow pullout behavior of polymer-coated Kevlar fabric. J. Mater. Sci. 2011, 46, 77–89. [Google Scholar] [CrossRef]

- Bilisik, K. Properties of yarn pull-out in para-aramid fabric structure and analysis by statistical model. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1930–1942. [Google Scholar] [CrossRef]

- Nilakantan, G.; Gillespie, J.W. Yarn pull-out behavior of plain woven Kevlar fabrics: Effect of yarn sizing, pullout rate, fabric pre-tension. Compos. Struct. 2013, 101, 215–224. [Google Scholar] [CrossRef]

- Li, D.; Wang, R.; Guan, F.; Zhu, Y.; You, F. Enhancement of the quasi-static stab resistance of Kevlar fabrics impregnated with shear thickening fluid. J. Mater. Res. Technol. 2022, 18, 3673–3683. [Google Scholar] [CrossRef]

- Zhang, X.; Li, T.-T.; Wang, Y.; Shiu, B.-C.; Peng, H.-K.; Lou, C.-W.; Lin, J.-H. Hydrogel with high toughness and strength for fabricating high performance stab-resistant aramid composite fabric. J. Mater. Res. Technol. 2021, 15, 1630–1641. [Google Scholar] [CrossRef]

- Manaee, P.; Valefi, Z.; Goodarz, M. The effect of bond coat type on the stab resistance of Al2O3–13 wt% TiO2 plasma sprayed ceramic coating on aramid fabrics. Surf. Interfaces 2020, 18, 100432. [Google Scholar] [CrossRef]

- Nasser, J.; Steinke, K.; Groo, L.; Sodano, H.A. Improved Interyarn Friction, Impact Response, and Stab Resistance of Surface Fibrilized Aramid Fabric. Adv. Mater. Interfaces 2019, 6, 1900881. [Google Scholar] [CrossRef]

- Sun, B.; Wang, Y.; Wang, P.; Hu, H.; Gu, B. Investigations of puncture behaviors of woven fabrics from finite element analyses and experimental tests. Text. Res. J. 2011, 81, 992–1007. [Google Scholar] [CrossRef]

- Croft, J.; Longhurst, D. HOSDB Body Armour Standards for UK Police (2007) Part 3: Knife and Spike Resistance; Home Office Scientific Development Branch, St Albans: Hertfordshire, UK, 2007; Available online: https://www.bodyarmornews.com/wp-content/uploads/2013/10/HOSDB__2007_-_part_3.pdf (accessed on 12 December 2024).

- Horsfall, I.; Champion, S.M.; Watson, C.H. The development of a quantitative flexibility test for body armour and comparison with wearer trials. Appl. Ergon. 2005, 36, 283–292. [Google Scholar] [CrossRef]

- Porwal, P.K.; Phoenix, S.L. Modeling system effects in ballistic impact into multi-layered fibrous materials for soft body armor. Int. J. Fract. 2005, 135, 217–249. [Google Scholar] [CrossRef]

- Bleetman, A.; Watson, C.H.; Horsfall, I.; Champion, S.M. Wounding patterns and human performance in knife attacks: Optimising the protection provided by knife-resistant body armour. J. Clin. Forensic Med. 2003, 10, 243–248. [Google Scholar] [CrossRef]

- Walker, C.A.; Gray, T.G.F.; Nicol, A.C.; Chadwick, E.K.J. Evaluation of test regimes for stab-resistant body armour. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2004, 218, 355–363. [Google Scholar] [CrossRef]

- Carr, D.J.; Wainwright, A. Variability of simulants used in recreating stab events. Forensic Sci. Int. 2011, 210, 42–46. [Google Scholar] [CrossRef]

- Shin, H.S.; Erlich, D.C.; Shockey, D.A. Test for measuring cut resistance of yarns. J. Mater. Sci. 2003, 38, 3603–3610. [Google Scholar] [CrossRef]

- Shin, H.-S.; Erlich, D.C.; Simons, J.W.; Shockey, D.A. Cut Resistance of High-strength Yarns. Text. Res. J. 2006, 76, 607–613. [Google Scholar] [CrossRef]

- Russell, S.J.; Pourmohammadi, A.; Ezra, I.; Jacobs, M. Formation and properties of fluid jet entangled HMPE impact resistant fabrics. Compos. Sci. Technol. 2005, 65, 899–907. [Google Scholar] [CrossRef]

- Bajya, M. Development of Soft Body Armour by Using Different High Performance Materials. Ph.D. Thesis, Institute of Technology, New Delhi, India, 2022. [Google Scholar]

- Jussila, J.; Leppäniemi, A.; Paronen, M.; Kulomäki, E. Ballistic skin simulant. Forensic Sci. Int. 2005, 150, 63–71. [Google Scholar] [CrossRef] [PubMed]

- Krishnan, K.; Sockalingam, S.; Bansal, S.; Rajan, S.D. Numerical simulation of ceramic composite armor subjected to ballistic impact. Compos. Part B Eng. 2010, 41, 583–593. [Google Scholar] [CrossRef]

- Gong, X.; Xu, Y.; Zhu, W.; Xuan, S.; Jiang, W.; Jiang, W. Study of the knife stab and puncture-resistant performance for shear thickening fluid enhanced fabric. J. Compos. Mater. 2014, 48, 641–657. [Google Scholar] [CrossRef]

- Cunniff, P.M. Dimensionless parameters for optimization of textile-based body armor systems. In Proceedings of the 18th International Symposium on Ballistics, Lancaster, PA, USA, 15–19 November 1999; pp. 1303–1310. [Google Scholar]

- Sharma, S.L.; Yadav, A.; Bajya, M. Stab Resistance Soft Body Armour: Stab Mechanism, Required Textile Raw Materials and Performance Evaluation Techniques. Annu. Technol. Vol. Text. Eng. Div. Board 2024, 6, 84–97. [Google Scholar]

- Das, J.; Butola, B.S.; Majumdar, A. Development of stab resistant armor for different energy levels using shear thickening fluid reinforced multi-layered-aramid fabrics. Polym. Compos. 2024, 46, 1843–1856. [Google Scholar] [CrossRef]

- Bajya, M.; Majumdar, A.; Butola, B.S.; Mawkhlieng, U.; Bhattacharjee, D. Parametric optimisation of shear thickening fluid treatment for ultra-high molecular weight polyethylene woven fabric. J. Ind. Text. 2022, 52, 1–22. [Google Scholar] [CrossRef]

- Bajya, M.; Majumdar, A.; Butola, B.S.; Verma, S.K.; Bhattacharjee, D. Design strategy for optimising weight and ballistic performance of soft body armour reinforced with shear thickening fluid. Compos. Part B Eng. 2020, 183, 107721. [Google Scholar] [CrossRef]

- Gürgen, S.; Kuşhan, M.C. The effect of silicon carbide additives on the stab resistance of shear thickening fluid treated fabrics. Mech. Adv. Mater. Struct. 2017, 24, 1381–1390. [Google Scholar] [CrossRef]

- Gürgen, S.; Kuşhan, M.C. The ballistic performance of aramid based fabrics impregnated with multi-phase shear thickening fluids. Polym. Test. 2017, 64, 296–306. [Google Scholar] [CrossRef]

- Gürgen, S.; Majumdar, A. Tuning the Frictional Properties of Carbon Fabrics Using Boron Carbide Particles. Fibers Polym. 2019, 20, 725–731. [Google Scholar] [CrossRef]

- Bilisik, K. Two-dimensional (2D) fabrics and three-dimensional (3D) preforms for ballistic and stabbing protection: A review. Text. Res. J. 2017, 87, 2275–2304. [Google Scholar] [CrossRef]

- Hogue, M.; Fairgrieve, S.I.; Lievers, W.B. Stabbing angle alters peak force and work during sharp force trauma of porcine ribs. Forensic Sci. Int. 2020, 314, 110373. [Google Scholar] [CrossRef]

- Hainsworth, S.V.; Delaney, R.J.; Rutty, G.N. How sharp is sharp? Towards quantification of the sharpness and penetration ability of kitchen knives used in stabbings. Int. J. Legal Med. 2008, 122, 281–291. [Google Scholar] [CrossRef]

- NIJ Standard-0115.00; NIST Stab Resistance of Personal Body Armor. National Institute of Standards and Technology: Gaithersburg, MD, USA, 2000. Available online: https://nij.ojp.gov/library/publications/stab-resistance-personal-body-armor-nij-standard-011500 (accessed on 10 November 2024).

- Carr, D.J. Failure mechanisms of yarns subjected to ballistic impact. J. Mater. Sci. Lett. 1999, 18, 585–588. [Google Scholar] [CrossRef]

- Hunold, T.; Spieß, R.; Wissenbach, D.K.; Hubig, M.; Mall, G.; Muggenthaler, H. Dependency of stabbing force on blade shape—Development of a measurement device and first results. Rechtsmedizin 2023, 33, 269–274. [Google Scholar] [CrossRef]

- Murray, L.A.; Green, M.A. Hilts and knives: A survey of ten years of fatal stabbings. Med. Sci. Law 1987, 27, 182–184. [Google Scholar] [CrossRef]

- Horsfall, I.; Watson, C.; Champion, S.; Prosser, P.; Ringrose, T. The effect of knife handle shape on stabbing performance. Appl. Ergon. 2005, 36, 505–511. [Google Scholar] [CrossRef]

- Abtew, M.A.; Loghin, C.; Cristian, I.; Boussu, F.; Bruniaux, P.; Chen, Y.; Wang, L. Mouldability and its Recovery Properties of 2D Plain Woven Para-Aramid Fabric for Soft Body Armour Applications. Fibres Text. East. Eur. 2019, 27, 54–62. [Google Scholar] [CrossRef]

- Sloan, K.; Robertson, J.; Fergusson, M.; Spratford, W. An evaluation of human stabbing performance to inform the standardisation of textile damage examinations: Do simulation trials correlate to reported stabbings? Forensic Sci. Int. 2020, 312, 110305. [Google Scholar] [CrossRef] [PubMed]

- Hu, Q.R.; Shen, X.Y.; Qian, X.M.; Huang, G.Y.; Yuan, M.Q. The personal protective equipment (PPE) based on individual combat: A systematic review and trend analysis. Def. Technol. 2023, 28, 195–221. [Google Scholar] [CrossRef]

- Siengchin, S. A review on lightweight materials for defence applications: Present and future developments. Def. Technol. 2023, 24, 1–17. [Google Scholar] [CrossRef]

- Cicek, U.I.; Southee, D.J.; Johnson, A.A. Assessing the stab resistive performance of material extruded body armour specimens. Int. J. Prot. Struct. 2023, 14, 335–356. [Google Scholar] [CrossRef]

- Hanif, M.; Zhang, G.Q.; Mahrukh, M.; Usman, T.; Li, X.; Cao, X. Brief review on stab and cut protection materials: Material science physics and applications. Arab. J. Chem. 2025, 18, 106083. [Google Scholar] [CrossRef]

- Jiang, F.; Su, T.; Fang, L.; Zhao, K.; Cong, H. Structural Design and Performance of Cut-Resistant Fabrics with Concave–Convex Arrays. Polymers 2024, 16, 2137. [Google Scholar] [CrossRef]

- Abtew, M.A.; Bruniaux, P.; Boussu, F.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. A systematic pattern generation system for manufacturing customized seamless multi-layer female soft body armour through dome-formation (moulding) techniques using 3D warp interlock fabrics. J. Manuf. Syst. 2018, 49, 61–74. [Google Scholar] [CrossRef]

- Abtew, M.A.; Bruniaux, P.; Boussu, F.; Loghin, C.; Cristian, I.; Chen, Y. Development of comfortable and well-fitted bra pattern for customized female soft body armor through 3D design process of adaptive bust on virtual mannequin. Comput. Ind. 2018, 100, 7–20. [Google Scholar] [CrossRef]

- Banhart, D.; Monir, S.; Durieux, O.; Day, R.J.; Jones, M.; Luhyna, N.; Vagapov, Y. A review of experimental and numerical methodologies for impact testing of composite materials. Sens. Technol. 2024, 2, 2304886. [Google Scholar] [CrossRef]

- Benson, N.; Dos Santos, R.O.; Griffiths, K.; Cole, N.; Doble, P.; Roux, C.; Blanes, L. The development of a stabbing machine for forensic textile damage analysis. Forensic Sci. Int. 2017, 273, 132–139. [Google Scholar] [CrossRef]

- Kemp, S.E. Forensic Analysis of Sharp Weapon Damage to Textile Products; Elsevier Ltd.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Williams, G.A. Forensic textile damage analysis: Recent advances. Res. Rep. Forensic Med. Sci. 2018, 8, 1–8. [Google Scholar] [CrossRef]

- Daroux, F.Y.; Carr, D.J.; Kieser, J.; Niven, B.E.; Taylor, M.C. Effect of laundering on blunt force impact damage in fabrics. Forensic Sci. Int. 2010, 197, 21–29. [Google Scholar] [CrossRef] [PubMed]

- Ziogos, S.; Dadour, I.R.; Pitts, K.; Magni, P.A. Qualitative Analyses of Textile Damage (Cuts and Tears) Applied to Fabrics Exposed to the Decomposition of Carcasses and Associated Insect Activity in an Austral Summer. Insects 2023, 14, 618. [Google Scholar] [CrossRef] [PubMed]

- Santos, T.; Santos, C.; Aquino, M.; Rangappa, S.M.; Siengchin, S.; Nascimento, J.; Medeiros, I. Effects of UV sensitivity and accelerated photo-aging on stab resistance of ρ-aramid fabrics impregnated with shear thickening fluids (STFs). Heliyon 2023, 9, e15020. [Google Scholar] [CrossRef]

- Čubrić, I.S.; Čubrić, G.; Križmančić, I.K.; Kovačević, M. Evaluation of Changes in Polymer Material Properties Due to Aging in Different Environments. Polymers 2022, 14, 1682. [Google Scholar] [CrossRef]

- Dobilaitė, V.; Jucienė, M.; Bliūdžius, R.; Šveikauskaitė, L. Investigation of some weathering impacts on tearing properties of PVC-coated fabrics used for architectural purposes. J. Ind. Text. 2022, 51, 5328S–5346S. [Google Scholar] [CrossRef]

- Zhao, C.; Gong, X.; Wang, S.; Jiang, W.; Xuan, S. Shear Stiffening Gels for Intelligent Anti-impact Applications. Cell Rep. Phys. Sci. 2020, 1, 100266. [Google Scholar] [CrossRef]

- Li, D.; Wang, R.; Liu, X.; Fang, S.; Sun, Y. Shear-thickening fluid using oxygen-plasma-modified multi-walled carbon nanotubes to improve the quasi-static stab resistance of Kevlar fabrics. Polymers 2018, 10, 1356. [Google Scholar] [CrossRef]

- Wang, R.; Zhou, Y.; Wang, Q.; Sun, R.; Jia, X.; Tian, M. The Influence of Carbon Nanotube Addition on the Shear-Thickening Performance of Suspensions. Therm. Sci. 2023, 27, 1787–1793. [Google Scholar] [CrossRef]

- Nakonieczna, P.; Wierzbicki, Ł.; Wróblewski, R.; Płociński, T.; Leonowicz, M. The influence of carbon nanotube addition on the properties of shear thickening fluid. Bull. Mater. Sci. 2019, 42, 2–5. [Google Scholar] [CrossRef]

- Gürgen, S.; Kuşhan, M.C. The stab resistance of fabrics impregnated with shear thickening fluids including various particle size of additives. Compos. Part A Appl. Sci. Manuf. 2017, 94, 50–60. [Google Scholar] [CrossRef]

- Hasanzadeh, M.; Mottaghitalab, V.; Babaei, H.; Rezaei, M. The influence of carbon nanotubes on quasi-static puncture resistance and yarn pull-out behavior of shear-thickening fluids (STFs) impregnated woven fabrics. Compos. Part A Appl. Sci. Manuf. 2016, 88, 263–271. [Google Scholar] [CrossRef]

- Li, S.; Xu, J.; Zhang, J.; Wu, L.; Zhang, H.; Wei, H.; Wang, D.; Chen, Y.; Gao, Y. Research progress of numerical simulation method based on the protection performance of stf-kevlar fabric liquid armor composites. J. Phys. Conf. Ser. 2021, 1855, 012023. [Google Scholar] [CrossRef]

- Weerasinghe, D.; Mohotti, D.; Anderson, J. Numerical Modelling of the Rate-sensitive Behaviour of High-performance Fabrics. J. Dyn. Behav. Mater. 2021, 7, 107–126. [Google Scholar] [CrossRef]

- Tan, V.B.C.; Ching, T.W. Computational simulation of fabric armour subjected to ballistic impacts. Int. J. Impact Eng. 2006, 32, 1737–1751. [Google Scholar] [CrossRef]

- Li, T.-T.; Fang, J.; Huang, C.-H.; Lou, C.-W.; Lin, J.-Y.; Lin, M.-C.; Chen, Y.-S.; Lin, J.-H. Numerical simulation of dynamic puncture behaviors of woven fabrics based on the Finite Element Method. Text. Res. J. 2017, 87, 1308–1317. [Google Scholar] [CrossRef]

- Lei, X.D.; Wu, X.Q.; Zhang, Z.; Xiao, K.L.; Wang, Y.W.; Huang, C.G. A machine learning model for predicting the ballistic impact resistance of unidirectional fiber-reinforced composite plate. Sci. Rep. 2021, 11, 6503. [Google Scholar] [CrossRef]

- Shokrollahi, Y.; Dong, P.; Gamage, P.T.; Patrawalla, N.; Kishore, V.; Mozafari, H.; Gu, L. Finite Element-Based Machine Learning Model for Predicting the Mechanical Properties of Composite Hydrogels. Appl. Sci. 2022, 12, 10835. [Google Scholar] [CrossRef]

- Stephen, C.; Thekkuden, D.T.; Mourad, A.H.I.; Shivamurthy, B.; Selvam, R.; Behara, S.R. Prediction of impact performance of fiber reinforced polymer composites using finite element analysis and artificial neural network. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 408. [Google Scholar] [CrossRef]

- Cosma, M.P.; Brighenti, R. From responsiveness in biological matter to functional materials: Analogies and inspiration towards the systematic design and synthesis of new smart materials and systems. Appl. Mater. Today 2023, 32, 101842. [Google Scholar] [CrossRef]

- Png, Z.M.; Wang, C.-G.; Yeo, J.C.C.; Lee, J.J.C.; Surat’Man, N.E.B.; Tan, Y.L.; Liu, H.; Wang, P.; Tan, B.H.; Xu, J.W.; et al. Stimuli-responsive structure-property switchable polymer materials. Mol. Syst. Des. Eng. 2023, 8, 1097–1129. [Google Scholar] [CrossRef]

| Protection Class | Protection Class E1 with a Maximum Penetration of 7 mm | Protection Class E2 with a Max. Penetration of 20 mm | |

|---|---|---|---|

| Protection level | Threat level | Strike energy E1 (J) | Overset strike Energy E2 (J) |

| 1 | Low | 24 ± 0.50 | 36 ± 0.60 |

| 2 | Medium | 33 ± 0.60 | 50 ± 0.70 |

| 3 | High | 43 ± 0.60 | 65 ± 0.80 |

| Protection Levels | Energy Level E1 (J) | Maximum Penetration at E1 (mm) | Energy Level E2 (J) | Maximum Penetration at E2 (mm) |

|---|---|---|---|---|

| KR1 | 24 | 7 | 36 | 20 * |

| KR1 + SP1 | KR1 = 7, SP1 =0 * | KR1 = 20, SP1 = N/A | ||

| KR2 | 33 | 7 | 50 | 20* |

| KR2 + SP2 | KR2 = 7, SP2 =0 * | KR2 = 50, SP2 = N/A | KR2 = 20 *, SP2 = N/A | |

| KR3 | 43 | 7 | 65 | 20* |

| KR3 + SP3 | KR3 = 7, SP3 =0 * | KR3 = 65, SP3 = N/A | KR3 = 20 *, SP3 = N/A |

| Standard | The Setup Used for the Test | Pass/Fail Criteria |

|---|---|---|

| (Method 1) PSDB air-cannon test rig |  | On the left, a visual representation of the maximum permitted penetration for a pass or fail is displayed (energy penetration). |

| (Method 2) NIJ 0115.00 |  | E1 strike energies: at impact angles of incidence of 0° and 45°, the armor should not permit penetration of a knife blade or spike larger than 7 mm. E2 strike energies: at a 0° angle of incidence, the body armor cannot permit the penetration of a knife blade or spike longer than 20 mm. The armor fails the stab resistance drop test if a hit with energy less than E1 results in more than 7 mm of penetration. |

| (Method 3) HOSDB Body Armour Standards for UK Police-part 3 |  | At different knife alignments, a maximum of 7 mm of knife penetration into the backing material is permitted. It is not allowed for the spike to penetrate. |

| Knife | Total Length (mm) | Blade Length (mm) | Blade Width (mm) | Spine Width (mm) | Weight (g) |

|---|---|---|---|---|---|

| Utility | 208 | 90 | 15 | 1 | 29 |

| Hunting | 267 | 137 | 28 | 4 | 224 |

| Machete | 473 | 245 | 55 | 2 | 448 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abtew, M.A.; Sitotaw, D.B.; Bajya, M. Comprehensive Review of Endogenous and Exogenous Parameters Influencing Dynamic Stab Impact Performance in Protective Textiles and Fibrous Composite Materials. J. Compos. Sci. 2025, 9, 138. https://doi.org/10.3390/jcs9030138

Abtew MA, Sitotaw DB, Bajya M. Comprehensive Review of Endogenous and Exogenous Parameters Influencing Dynamic Stab Impact Performance in Protective Textiles and Fibrous Composite Materials. Journal of Composites Science. 2025; 9(3):138. https://doi.org/10.3390/jcs9030138

Chicago/Turabian StyleAbtew, Mulat Alubel, Dereje Berihun Sitotaw, and Mukesh Bajya. 2025. "Comprehensive Review of Endogenous and Exogenous Parameters Influencing Dynamic Stab Impact Performance in Protective Textiles and Fibrous Composite Materials" Journal of Composites Science 9, no. 3: 138. https://doi.org/10.3390/jcs9030138

APA StyleAbtew, M. A., Sitotaw, D. B., & Bajya, M. (2025). Comprehensive Review of Endogenous and Exogenous Parameters Influencing Dynamic Stab Impact Performance in Protective Textiles and Fibrous Composite Materials. Journal of Composites Science, 9(3), 138. https://doi.org/10.3390/jcs9030138