Degradation Progress of Metallized Silicon Nitride Substrate Under Thermal Cycling Tests by Digital Image Correlation

Abstract

1. Introduction

2. Fundamentals of DIC

- Speckle pattern fabrication: To create an effective speckle pattern on the sample surface, a spraying process is typically required. First, a layer of white paint is applied as the background. Then, black paint is sprayed to generate a stochastic contrast dot pattern. The varying shades of darkness on the surface are represented as a matrix of natural numbers, which are tracked during the monitoring process.

- Calibration: This step is essential for three-dimensional digital image correlation (3D-DIC) methods. During the calibration of stereo DIC camera sensors, the relative positions of the two cameras in space and parameters for modeling the beam path, such as lens distortion and intrinsic parameters, are defined using a calibration sample.

- Digital image acquisition: Images of the measurement surface of the sample are captured and saved on a computer for post-processing.

- Displacement and strain calculation: Using a reference image from the beginning of the test, automated image processing can be performed with various software packages, such as Vic Volume 2D/3D software (Correlated Solutions, Inc., Irmo, SC, USA [64]), Strain Master software (La-Vision, Ypsilanti, MI, USA [65]), ZEISS ARAMIS software (ZEISS Group, Carl Zeiss IQS Deutschland GmbH, Germany [66]). Several approaches exist for identifying deformed image areas. Adaptive methods, including image correlation and the least squares method, are commonly used. The primary assumption is that a causal connection exists between the original state and the deformed state.

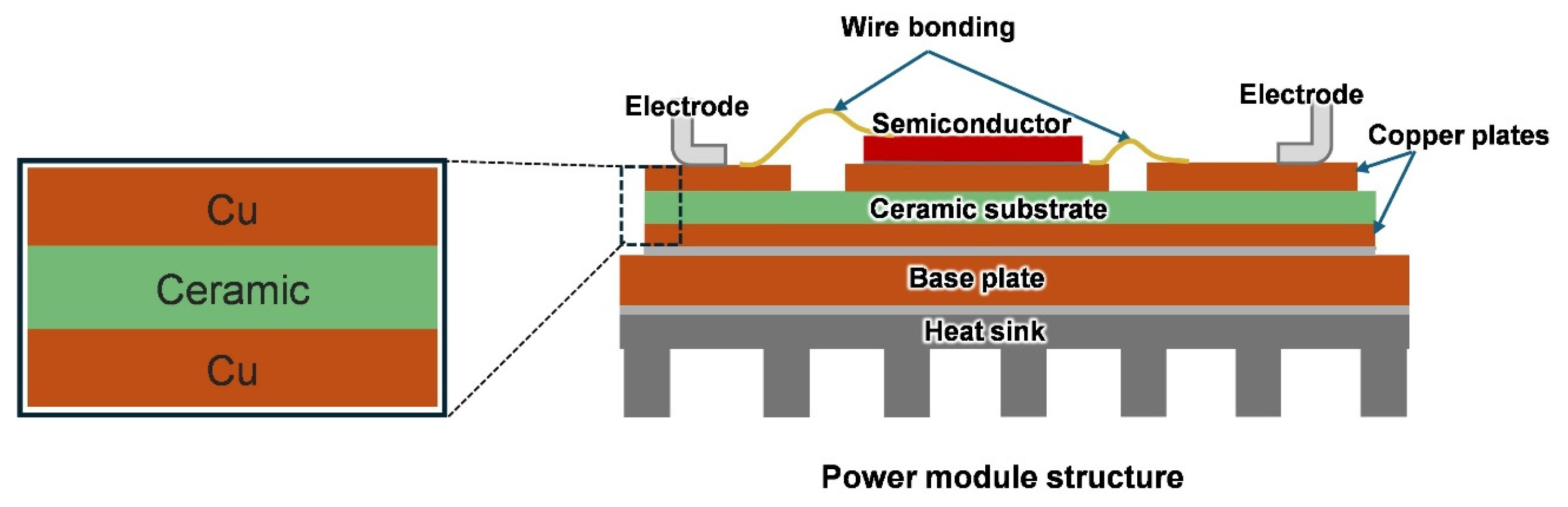

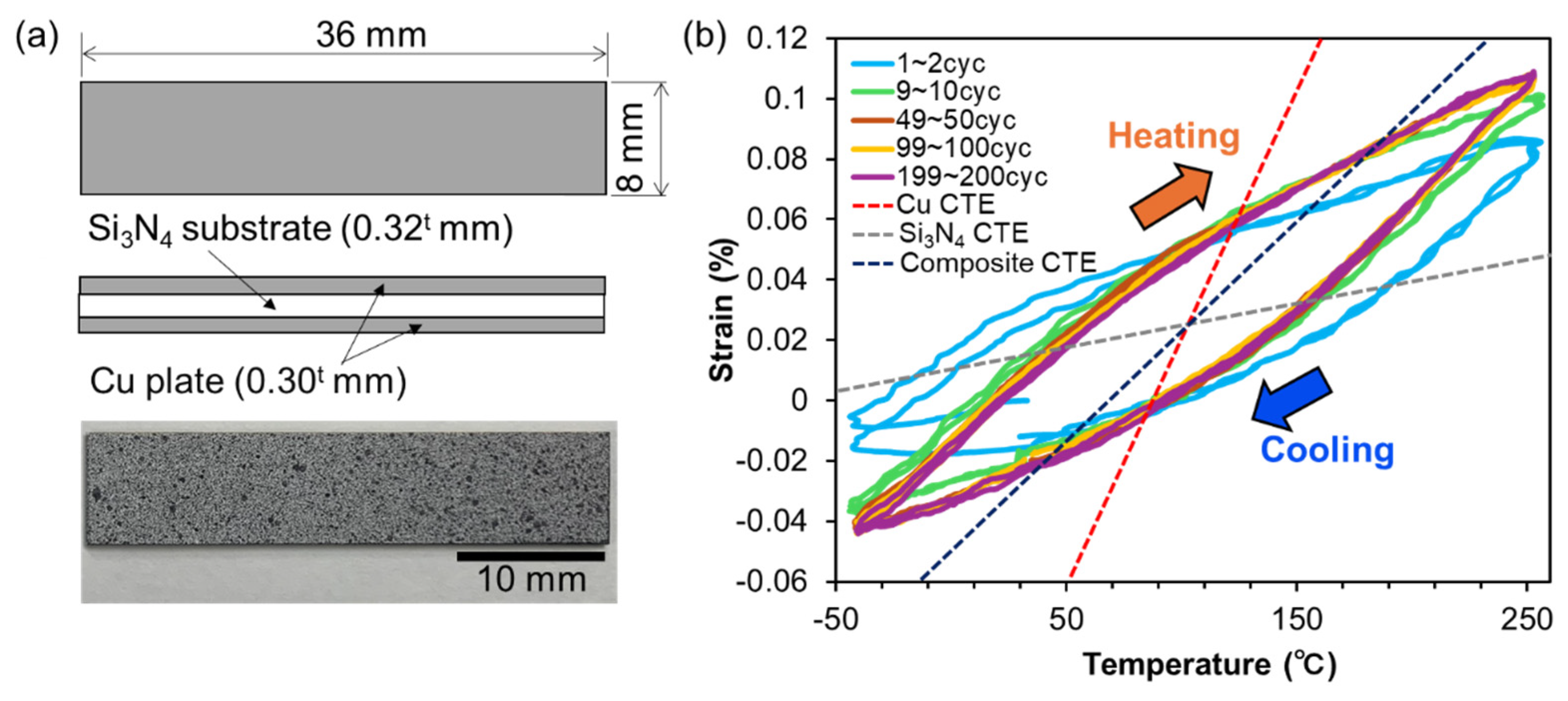

3. Thermal Strain of AMB-SN Substrate by DIC

3.1. Experimental

3.2. Substrate Delamination Inspected by SAM

3.3. Thermal Strain Before the Delamination

3.4. Thermal Strain After the Delamination

4. In Situ Observation of Warpage and Dynamic Bending Behaviors of the AMB-SN by DIC

4.1. Substrate Warpage During Thermal Cycling Test

4.2. Dynamic Bending Behaviors of the AMB-SN by DIC

5. Stress–Strain Analysis of Cu on Metallized Ceramics Substrate by DIC

6. Prospectives of DIC in Reliability Test of Ceramic Substrate

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Omahne, V.; Knez, M.; Obrecht, M. Social Aspects of Electric Vehicles Research—Trends and Relations to Sustainable Development Goals. World Electr. Veh. J. 2021, 12, 15. [Google Scholar] [CrossRef]

- Petrauskienė, K.; Galinis, A.; Kliaugaitė, D.; Dvarionienė, J. Comparative Environmental Life Cycle and Cost Assessment of Electric, Hybrid, and Conventional Vehicles in Lithuania. Sustainability 2021, 13, 957. [Google Scholar] [CrossRef]

- Shahzad, K.; Cheema, I.I. Low-Carbon Technologies in Automotive Industry and Decarbonizing Transport. J. Power Sources 2024, 591, 233888. [Google Scholar] [CrossRef]

- Ertugrul, N. Mine Electrification and Power Electronics: The Roles of Wide-Bandgap Devices. IEEE Electrif. Mag. 2024, 12, 6–15. [Google Scholar] [CrossRef]

- Mishra, U.K. Gallium Nitride versus Silicon Carbide: Beyond the Switching Power Supply [Industry View]. Proc. IEEE 2023, 111, 322–328. [Google Scholar] [CrossRef]

- Roccaforte, F.; Giannazzo, F.; Iucolano, F.; Eriksson, J.; Weng, M.H.; Raineri, V. Surface and Interface Issues in Wide Band Gap Semiconductor Electronics. Appl. Surf. Sci. 2010, 256, 5727–5735. [Google Scholar] [CrossRef]

- Chen, J.; Du, X.; Luo, Q.; Zhang, X.; Sun, P.; Zhou, L. A Review of Switching Oscillations of Wide Bandgap Semiconductor Devices. IEEE Trans. Power Electron. 2020, 35, 13182–13199. [Google Scholar] [CrossRef]

- Chaudhary, O.S.; Denaï, M.; Refaat, S.S.; Pissanidis, G. Technology and Applications of Wide Bandgap Semiconductor Materials: Current State and Future Trends. Energies 2023, 16, 6689. [Google Scholar] [CrossRef]

- Gombar, V. Electric Cars Have Dented Fuel Demand. By 2040, They’ll Slash It. Available online: https://about.bnef.com/blog/electric-cars-have-dented-fuel-demand-by-2040-theyll-slash-it (accessed on 1 June 2025).

- Ritchie, H.; Roser, M.; Rosado, P. CO2 Emissions by Fuel. Available online: https://ourworldindata.org/emissions-by-fuel (accessed on 1 June 2025).

- Singh, V.; Singh, V.; Vaibhav, S. A Review and Simple Meta-Analysis of Factors Influencing Adoption of Electric Vehicles. Transp. Res. Part D Transp. Environ. 2020, 86, 102436. [Google Scholar] [CrossRef]

- Pagani, M.; Korosec, W.; Chokani, N.; Abhari, R.S. User Behaviour and Electric Vehicle Charging Infrastructure: An Agent-Based Model Assessment. Appl. Energy 2019, 254, 113680. [Google Scholar] [CrossRef]

- Ghaffour, N.; Bundschuh, J.; Mahmoudi, H.; Goosen, M.F.A. Renewable Energy-Driven Desalination Technologies: A Comprehensive Review on Challenges and Potential Applications of Integrated Systems. Desalination 2015, 356, 94–114. [Google Scholar] [CrossRef]

- Bamati, N.; Raoofi, A. Development level and the impact of technological factor on renewable energy production. Renew. Energy 2020, 151, 946–955. [Google Scholar] [CrossRef]

- Maka, A.O.M.; Ghalut, T.; Elsaye, E. The Pathway toward Decarbonisation and Net-Zero Emissions by 2050: The Role of Solar Energy Technology. Green Technol. Sustain. 2024, 2, 100107. [Google Scholar] [CrossRef]

- Bogdanov, D.; Farfan, J.; Sadovskaia, K.; Aghahosseini, A.; Child, M.; Gulagi, A.; Oyewo, A.S.; de Souza Noel Simas Barbosa, L.; Breyer, C. Radical Transformation Pathway towards Sustainable Electricity via Evolutionary Steps. Nat. Commun. 2019, 10, 1077. [Google Scholar] [CrossRef] [PubMed]

- Tu, H.; Feng, H.; Srdic, S.; Lukic, S. Extreme Fast Charging of Electric Vehicles: A Technology Overview. IEEE Trans. Transp. Electrif. 2019, 5, 861–878. [Google Scholar] [CrossRef]

- Hirao, K.; Zhou, Y.; Miyazaki, H. Substrate. In Wide Bandgap Power Semiconductor Packaging; Elsevier: Amsterdam, The Netherlands, 2018; pp. 81–94. [Google Scholar] [CrossRef]

- Sheng, K.; Guo, Q. Recent Advances in Wide Bandgap Power Switching Devices. ECS Trans. 2013, 50, 179–188. [Google Scholar] [CrossRef]

- Utschig, T.; Descher, P.; Rauer, M.; Schwöbel, A.; Schnee, D. Metal Ceramic Substrates for Highly Reliable Power Modules—Not Only in Electric Vehicles. Int. Ceram. Rev. 2020, 69, 20–25. [Google Scholar] [CrossRef]

- Sanguesa, J.A.; Torres-Sanz, V.; Garrido, P.; Martinez, F.J.; Marquez-Barja, J.M. A Review on Electric Vehicles: Technologies and Challenges. Smart Cities 2021, 4, 372–404. [Google Scholar] [CrossRef]

- Wei, V.; Huang, M.; Lai, R.; Persons, R. A Comparison Study for Metalized Ceramic Substrate Technologies: For High Power Module Applications. In Proceedings of the 2014 9th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), Taipei, Taiwan, 1 October 2014; IEEE: New York, NY, USA. [Google Scholar]

- Xu, L.; Liu, S.; Wang, M.; Zhou, S. Crack Initiation and Propagation Mechanism of Al2O3-DBC Substrate during Thermal Cycling Test. Eng. Fail. Anal. 2020, 116, 104720. [Google Scholar] [CrossRef]

- Miyazakia, H.; Iwakiri, S.; Hirao, K.; Fukuda, S.; Izu, N.; Yoshizawa, Y.; Hyuga, H. Effect of High Temperature Cycling on Both Crack Formation in Ceramics and Delamination of Copper Layers in Silicon Nitride Active Metal Brazing Substrates. Ceram. Int. 2017, 43, 5080–5088. [Google Scholar] [CrossRef]

- Goetz, M.; Kuhn, N.; Lehmeier, B.; Meyer, A.; Voller, U. Comparison of Silicon Nitride DBC and AMB Substrates for Different Applications in Power Electronics. In Proceedings of the Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 14–16 May 2013; PCIM Europe 2013. Mesago PCIM GmbH: Stuttgart, Germany, 2013; pp. 57–65. [Google Scholar]

- Miyazaki, H.; Zhou, Y.; Iwakiri, S.; Hirotsuru, H.; Hirao, K.; Fukuda, S.; Izu, N.; Hyuga, H. Improved Resistance to Thermal Fatigue of Active Metal Brazing Substrates for Silicon Carbide Power Modules Using Tough Silicon Nitrides with High Thermal Conductivity. Ceram. Int. 2018, 44, 8870–8876. [Google Scholar] [CrossRef]

- Xu, L.; Wang, M.; Zhou, Y.; Qian, Z.; Liu, S. An Optimal Structural Design to Improve the Reliability of Al2O3–DBC Substrates under Thermal Cycling. Microelectron. Reliab. 2016, 56, 101–108. [Google Scholar] [CrossRef]

- Tanimoto, S.; Tanisawa, H.; Watanabe, K.; Matsui, K.; Sato, S. Power Module Package Structure Capable of Surviving Greater ΔTj Thermal Cycles. Mater. Sci. Forum 2013, 740–742, 1040–1043. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, L.; Gao, K.; Yang, H.; Yang, L.; Wang, Y.; Wan, X. Thermal Ratchetting Effect of AMB-AlN Ceramic Substrate: Experiments and Calculations. Ceram. Int. 2019, 45, 14669–14674. [Google Scholar] [CrossRef]

- Kim, D.; Nagao, S.; Wakasugi, N.; Yamamoto, Y.; Suetake, A.; Takemasa, T.; Suganuma, K. Power Cycle Tests of High Temperature Ag Sinter Die-Attach on Metalized Ceramic Substrate by Using Micro-Heater SiC Chip. Int. Symp. Microelectron. 2018, 2018, 000084–000087. [Google Scholar] [CrossRef]

- Chen, C.; Kim, D.; Zhang, Z.; Wakasugi, N.; Liu, Y.; Hsieh, M.-C.; Zhao, S.; Suetake, A.; Suganuma, K. Interface-Mechanical and Thermal Characteristics of Ag Sinter Joining on Bare DBA Substrate during Aging, Thermal Shock and 1200 W/cm2 Power Cycling Tests. IEEE Trans. Power Electron. 2022, 37, 6647–6659. [Google Scholar] [CrossRef]

- Dupont, L.; Khatir, Z.; Lefebvre, S.; Bontemps, S. Effects of Metallization Thickness of Ceramic Substrates on the Reliability of Power Assemblies under High Temperature Cycling. Microelectron. Reliab. 2006, 46, 1766–1771. [Google Scholar] [CrossRef]

- Silva, M.I.; Malitckii, E.; Santos, T.G.; Vilaça, P. Review of Conventional and Advanced Non-Destructive Testing Techniques for Detection and Characterization of Small-Scale Defects. Prog. Mater. Sci. 2023, 138, 101155. [Google Scholar] [CrossRef]

- Zolfaghari, A.; Kolahan, F. Reliability and Sensitivity of Visible Liquid Penetrant NDT for Inspection of Welded Components. Mater. Test. 2017, 59, 290–294. [Google Scholar] [CrossRef]

- Hübschen, G.; Altpeter, I.; Tschuncky, R.; Herrmann, H.-G. (Eds.) Ultrasonic Techniques for Materials Characterization; Woodhead Publishing: Saarbrücken, Germany, 2016; pp. 177–224. ISBN 978-0-08-100040-3. [Google Scholar]

- Nsengiyumva, W.; Zhong, S.; Lin, J.; Zhang, Q.; Zhong, J.; Huang, Y. Advances, Limitations and Prospects of Nondestructive Testing and Evaluation of Thick Composites and Sandwich Structures: A State-of-The-Art Review. Compos. Struct. 2021, 256, 112951. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F. Infrared Thermography for Temperature Measurement and Non-Destructive Testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef]

- Singh, R. Acoustic Emission Testing (AET). In Applied Welding Engineering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 361–373. [Google Scholar] [CrossRef]

- Zarei, A.; Pilla, S. Laser Ultrasonics for Nondestructive Testing of Composite Materials and Structures: A Review. Ultrasonics 2024, 136, 107163. [Google Scholar] [CrossRef]

- Hassan, G.M. Deformation Measurement in the Presence of Discontinuities with Digital Image Correlation: A Review. Opt. Lasers Eng. 2021, 137, 106394. [Google Scholar] [CrossRef]

- Zhao, Z. Review of Non-Destructive Testing Methods for Defect Detection of Ceramics. Ceram. Int. 2021, 47, 4389–4397. [Google Scholar] [CrossRef]

- Blikharskyy, Y.; Kopiika, N.; Khmil, R.; Selejdak, J.; Blikharskyy, Z. Review of Development and Application of Digital Image Correlation Method for Study of Stress–Strain State of RC Structures. Appl. Sci. 2022, 12, 10157. [Google Scholar] [CrossRef]

- Sutton, M.A.; Wolters, W.J.; Peters, W.H.; Ranson, W.F.; McNeill, S.R. Determination of Displacements Using an Improved Digital Correlation Method. Image Vis. Comput. 1983, 1, 133–139. [Google Scholar] [CrossRef]

- Chu, T.C.; Ranson, W.F.; Sutton, M.A. Applications of Digital-Image-Correlation Techniques to Experimental Mechanics. Exp. Mech. 1985, 25, 232–244. [Google Scholar] [CrossRef]

- Lord, J.D.; Roebuck, B.; Morrell, R.; Lube, T. 25 Years Perspective Aspects of Strain and Strength Measurement in Miniaturised Testing for Engineering Metals and Ceramics. Mater. Sci. Technol. 2010, 26, 127–148. [Google Scholar] [CrossRef]

- Schreier, H.; Orteu, J.-J.; Sutton, M.A. Image Correlation for Shape, Motion and Deformation Measurements; Springer: Boston, MA, USA, 2009; pp. 1–24. ISBN 9780387787466. [Google Scholar]

- Bing, P.; Hui-min, X.; Tao, H.; Asundi, A. Measurement of Coefficient of Thermal Expansion of Films Using Digital Image Correlation Method. Polym. Test. 2009, 28, 75–83. [Google Scholar] [CrossRef]

- Moreira, D.C.; Sphaier, L.A.; Reis, J.M.L.; Nunes, L.C.S. Determination of Young’s Modulus in Polyester-Al2O3 and Epoxy-Al2O3 Nanocomposites Using the Digital Image Correlation Method. Compos. Part A Appl. Sci. Manuf. 2011, 43, 304–309. [Google Scholar] [CrossRef]

- Pan, B.; Wu, D.; Wang, Z.; Xia, Y. High-Temperature Digital Image Correlation Method for Full-Field Deformation Measurement at 1200 °C. Meas. Sci. Technol. 2010, 22, 015701. [Google Scholar] [CrossRef]

- Reynolds, A.P.; Duvall, F. Digital Image Correlation for Determination of Weld and Base Metal Constitutive Behavior. Weld. J. 1996, 78, 355-s. [Google Scholar]

- Kartal, M.; Molak, R.M.; Turski, M.; Gungor, S.; Fitzpatrick, M.E.; Edwards, L. Determination of Weld Metal Mechanical Properties Utilising Novel Tensile Testing Methods. Appl. Mech. Mater. 2007, 7–8, 127–132. [Google Scholar] [CrossRef]

- Fonseca, J.Q.; Preuss, M.; Ryan, P.; Withers, P.J. Mechanical Property Mapping Using Image Correlation and Electronic Speckle Interferometry. Appl. Mech. Mater. 2004, 1–2, 147–152. [Google Scholar] [CrossRef]

- Sachtleber, M.; Zhao, Z.; Raabe, D. Experimental Investigation of Plastic Grain Interaction. Mater. Sci. Eng. 2002, 336, 81–87. [Google Scholar] [CrossRef]

- Ngo, M.C.; Miyazaki, H.; Hirao, K.; Fukushima, M. Analysis of Thermal Strain of Metallized Silicon Nitride Substrate under Cyclic Thermal Loading by Digital Image Correlation. Int. J. Appl. Ceram. Technol. 2023, 21, 1032–1041. [Google Scholar] [CrossRef]

- Ngo, M.C.; Miyazaki, H.; Hirao, K.; Ohji, T.; Fukushima, M. Dynamic Bending Analysis of Metallized Silicon Nitride Substrate during Thermal Cycling via Digital Image Correlation. Int. J. Appl. Ceram. Technol. 2024, 22, e14875. [Google Scholar] [CrossRef]

- Ngo, M.C.; Miyazaki, H.; Hirao, K.; Ohji, T.; Fukushima, M. Stress–Strain Behavior of Cu on the AMB-Si3N4 Substrate Undergoing Thermal Cycles via in Situ Strain Measurement. J. Am. Ceram. Soc. 2024, 107, 8415–8425. [Google Scholar] [CrossRef]

- Russell, S.S.; Sutton, M.A. Strain-Field Analysis Acquired through Correlation of X-Ray Radiographs of a Fiber-Reinforced Composite Laminate. Exp. Mech. 1989, 29, 237–240. [Google Scholar] [CrossRef]

- Loh, T.B.; Chua, M.; Goh, S.H.; Hau, K.K.; Goh, K.L.; Chong, J.J. Determination of Static and Dynamic Young’s Modulus of a Cantilever Beam Using Digital Image Correlation (DIC) Method. In Proceedings of the 24th International Conference on Mechatronics Technology (ICMT), Singapore, 18 December 2021; pp. 1–5. [Google Scholar]

- Pritchard, R.H.; Lava, P.; Debruyne, D.; Terentjev, E.M. Precise Determination of the Poisson Ratio in Soft Materials with 2D Digital Image Correlation. Soft Matter 2013, 9, 6037. [Google Scholar] [CrossRef]

- Khoo, S.-W.; Karuppanan, S.; Tan, C.-S. A Review of Surface Deformation and Strain Measurement Using Two-Dimensional Digital Image Correlation. Metrol. Meas. Syst. 2016, 23, 461–480. [Google Scholar] [CrossRef]

- Pankow, M.; Justusson, B.; Waas, A.M. Three-Dimensional Digital Image Correlation Technique Using Single High-Speed Camera for Measuring Large Out-of-Plane Displacements at High Framing Rates. Appl. Opt. 2010, 49, 3418. [Google Scholar] [CrossRef]

- Yu, L.; Pan, B. High-Speed 3D Shape and Deformation Measurements Using Stereo-Digital Image Correlation and a Single Color High-Speed Camera. Opt. Lasers Eng. 2017, 95, 17–25. [Google Scholar] [CrossRef]

- Zhong, F.Q.; Indurkar, P.P.; Quan, C.G. Three-Dimensional Digital Image Correlation with Improved Efficiency and Accuracy. Measurement 2018, 128, 23–33. [Google Scholar] [CrossRef]

- Ramos, T.; Braga, D.F.O.; Eslami, S.; Tavares, P.J.; Moreira, P.M.G.P. Comparison between Finite Element Method Simulation, Digital Image Correlation and Strain Gauges Measurements in a 3-Point Bending Flexural Test. Procedia Eng. 2015, 114, 232–239. [Google Scholar] [CrossRef]

- LaVision. GmbH Strain Master: 2D and Stereo Digital Image Correlation (DIC). Available online: https://www.lavision.de/en/products/strainmaster/2d-stereo-dic/index.php (accessed on 2 September 2025).

- ZEISS. ZEISS INSPECT Optical 3D|The Software for 3D Evaluation. Available online: https://www.zeiss.com/metrology/en/software/zeiss-inspect/zeiss-inspect-optical-3d.html (accessed on 2 September 2025).

- Bigger, R.; Blaysat, B.; Boo, C.; Grewer, M.; Hu, J.; Jones, A.; Klein, M.; Raghavan, K.; Reu, P.; Schmidt, T.; et al. A Good Practices Guide for Digital Image Correlation (IDICs). Int. Digit. Image Correl. Soc. 2018, 5–29. [Google Scholar] [CrossRef]

- Pan, B.; Wang, B.; Lubineau, G.; Moussawi, A. Comparison of Subset-Based Local and Finite Element-Based Global Digital Image Correlation. Exp. Mech. 2015, 55, 887–901. [Google Scholar] [CrossRef]

- Li, J.; Xie, X.; Yang, G.; Zhang, B.; Siebert, T.; Yang, L. Whole-Field Thickness Strain Measurement Using Multiple Camera Digital Image Correlation System. Opt. Lasers Eng. 2017, 90, 19–25. [Google Scholar] [CrossRef]

- ISO 17841:2015; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Test Method for Thermal Fatigue of Fine Ceramics Substrate. International Standard Organization: Geneva, Switzerland, 2015. Available online: https://www.iso.org/cms/%20render/live/en/sites/isoorg/contents/data/standard/06/07/60763.html (accessed on 2 September 2025).

- Fukuda, S.; Shimada, K.; Izu, N.; Miyazaki, H.; Iwakiri, S.; Hirao, K. Thermal-Cycling-Induced Surface Roughening and Structural Change of a Metal Layer Bonded to Silicon Nitride by Active Metal Brazing. J. Mater. Sci. Mater. Electron. 2017, 28, 12168–12175. [Google Scholar] [CrossRef]

- Feltner, C.E.; Laird, C. Cyclic Stress-Strain Response of F.C.C. Metals and Alloys—I Phenomenological Experiments. Acta Metall. 1967, 15, 1621–1632. [Google Scholar] [CrossRef]

- Hassan, T.; Kyriakides, S. Ratcheting of Cyclically Hardening and Softening Materials: I. Uniaxial Behavior. Int. J. Plast. 1994, 10, 149–184. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, J. Benchmark Experiments and Characteristic Cyclic Plasticity Deformation. Int. J. Plast. 2008, 24, 1481–1515. [Google Scholar] [CrossRef]

- Kang, G.; Li, Y.; Gao, Q. Non-Proportionally Multiaxial Ratcheting of Cyclic Hardening Materials at Elevated Temperatures: Experiments and Simulations. Mech. Mater. 2005, 37, 1101–1118. [Google Scholar] [CrossRef]

- Turner, P.S. Thermal-Expansion Stresses in Reinforced Plastics. J. Res. Natl. Bur. Stand. 1946, 37, 239. [Google Scholar] [CrossRef]

- Fernlund, G.; Griffith, J.; Courdji, R.; Poursartip, A. Experimental and Numerical Study of the Effect of Caul-Sheets on Corner Thinning of Composite Laminates. Compos. Part A Appl. Sci. Manuf. 2002, 33, 411–426. [Google Scholar] [CrossRef]

- Lei, Z.; Li, J.; Wan, D.; Cheng, C.; Wu, D.; Shen, W.; Liang, K.; Liu, S. A Simplified Method for Analyzing PCB Warpage during Reflow: Focusing on Warpage Change and Initial Warpage Shape. IEEE Trans. Compon. Packag. Manuf. Technol. 2025, 15, 1502–1510. [Google Scholar] [CrossRef]

- Hei, C.; Abdullah, M.Z.; Hwa, H.; Wong, S.F. Dynamic Warpage Simulation of Molded PCB under Reflow Process. Circuit World 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Oon, S.J.; Tan, K.S.; Tou, T.Y.; Yap, S.S.; Lau, C.S.; Chin, Y.T. Warpage Studies of Printed Circuit Boards with Shadow Moiré and Simulations. In Proceedings of the 2018 IEEE 38th International Electronics Manufacturing Technology Conference (IEMT), Melaka, Malaysia, 4–6 September 2018; Volume 15, pp. 1–5. [Google Scholar] [CrossRef]

- Hopkins, D.C.; Baltis, T.; Pitaress, J.M.; Hazelmyer, D.R. Extreme Thermal Transient Stress Analysis with Pre-Stress in a Metal Matrix Composite Power Package. Addit. Conf. (Device Packag. HiTEC HiTEN CICMT) 2012, 2012, 000361–000372. [Google Scholar] [CrossRef]

- Shirasu, K.; Nakamura, A.; Yamamoto, G.; Ogasawara, T.; Shimamura, Y.; Inoue, Y.; Hashida, T. Potential Use of CNTs for Production of Zero Thermal Expansion Coefficient Composite Materials: An Experimental Evaluation of Axial Thermal Expansion Coefficient of CNTs Using a Combination of Thermal Expansion and Uniaxial Tensile Tests. Compos. Part A Appl. Sci. Manuf. 2017, 95, 152–160. [Google Scholar] [CrossRef]

| Characteristics of Ceramic Substrates | ||||

|---|---|---|---|---|

| Ceramic Material | Thermal Conductivity (W m−1K−1) | Coefficient of Thermal Expansion by DIC (ppm/°C) | Strength (MPa) | Fracture Toughness (MPam1/2) |

| Si3N4 | 140 | 1.5 | 669 ± 29 | 10.4 |

| AlN | 180 | 5.3 | 461 ± 62 | 3.2 |

| Al2O3 | 30 | 5.8 | 350 ± 50 | 3.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ngo, M.C.; Miyazaki, H.; Hirao, K.; Ohji, T.; Fukushima, M. Degradation Progress of Metallized Silicon Nitride Substrate Under Thermal Cycling Tests by Digital Image Correlation. J. Compos. Sci. 2025, 9, 536. https://doi.org/10.3390/jcs9100536

Ngo MC, Miyazaki H, Hirao K, Ohji T, Fukushima M. Degradation Progress of Metallized Silicon Nitride Substrate Under Thermal Cycling Tests by Digital Image Correlation. Journal of Composites Science. 2025; 9(10):536. https://doi.org/10.3390/jcs9100536

Chicago/Turabian StyleNgo, Minh Chu, Hiroyuki Miyazaki, Kiyoshi Hirao, Tatsuki Ohji, and Manabu Fukushima. 2025. "Degradation Progress of Metallized Silicon Nitride Substrate Under Thermal Cycling Tests by Digital Image Correlation" Journal of Composites Science 9, no. 10: 536. https://doi.org/10.3390/jcs9100536

APA StyleNgo, M. C., Miyazaki, H., Hirao, K., Ohji, T., & Fukushima, M. (2025). Degradation Progress of Metallized Silicon Nitride Substrate Under Thermal Cycling Tests by Digital Image Correlation. Journal of Composites Science, 9(10), 536. https://doi.org/10.3390/jcs9100536