Comparative Study of the Reinforcement Type Effect on the Thermomechanical Properties and Burning of Epoxy-Based Composites

Abstract

1. Introduction

2. Experimental

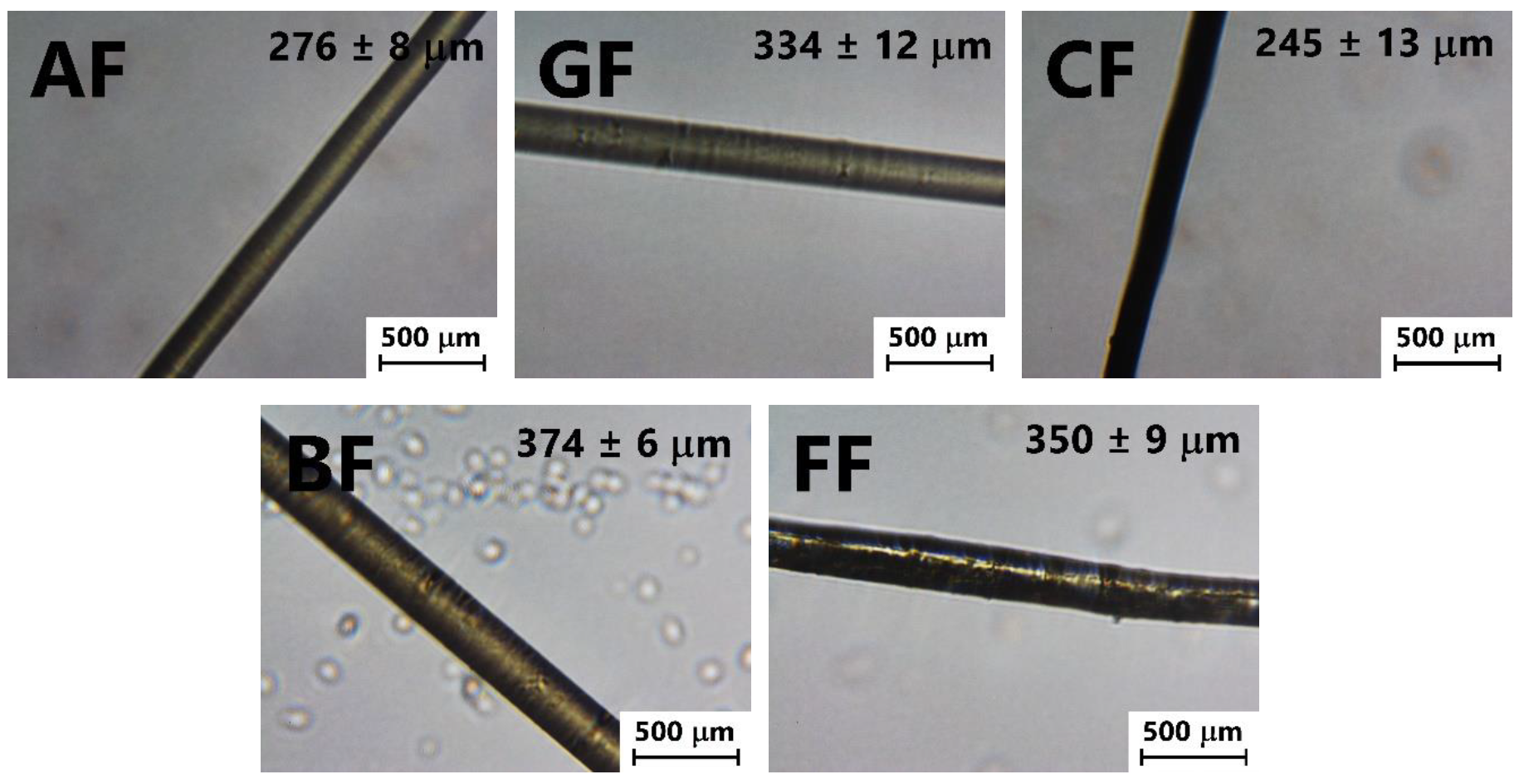

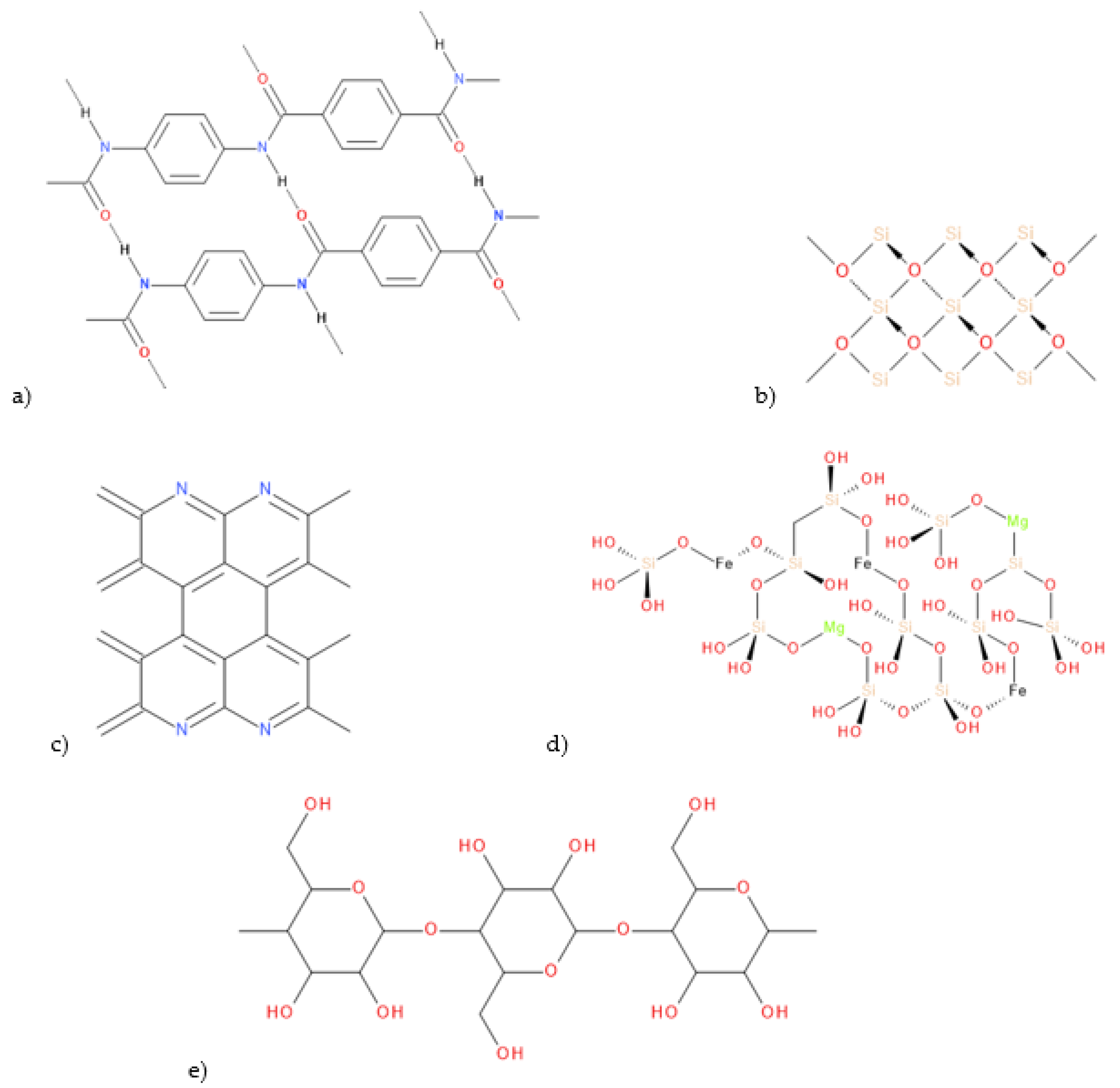

2.1. Materials and Sample Preparation

2.2. Methods

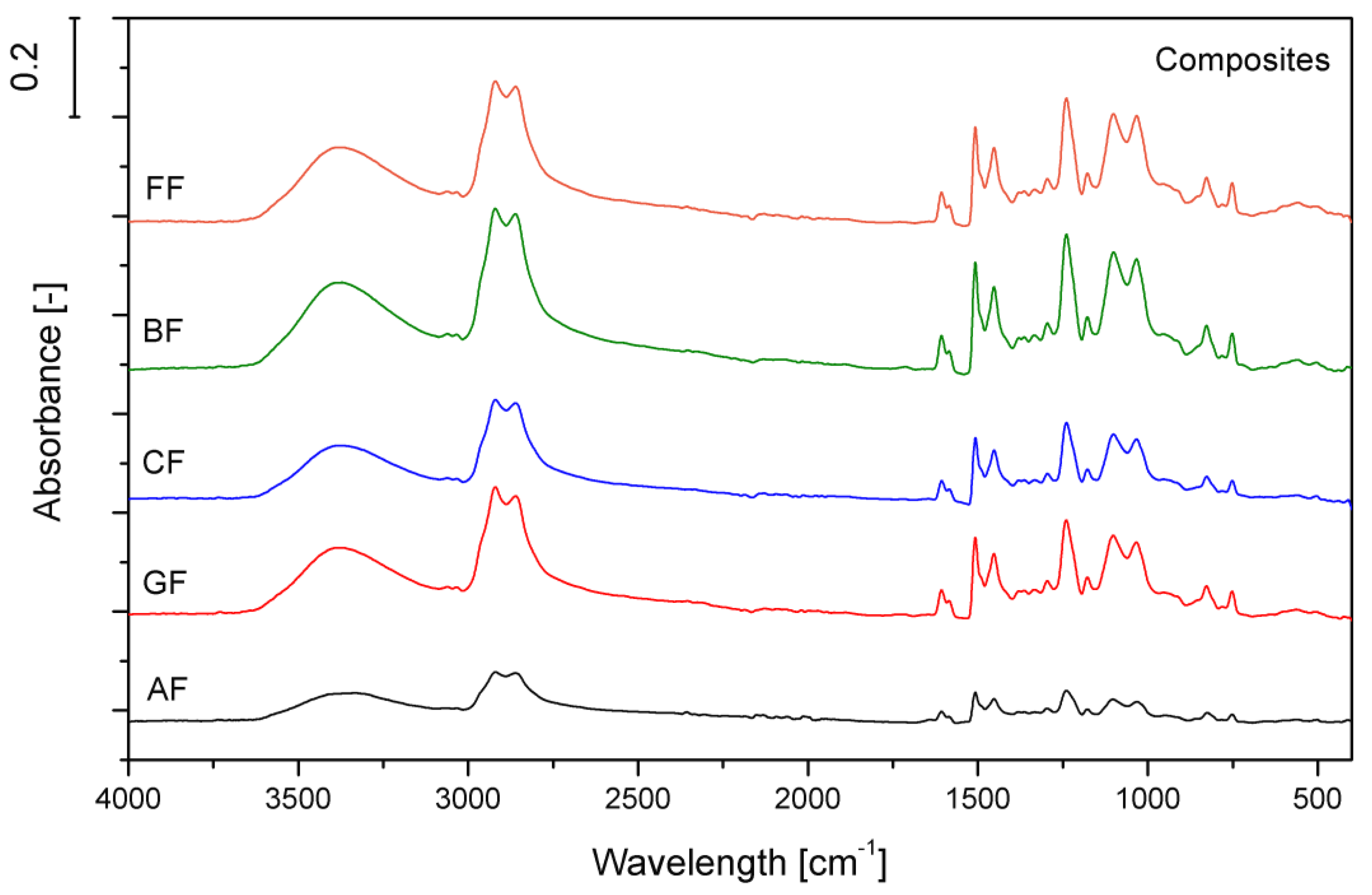

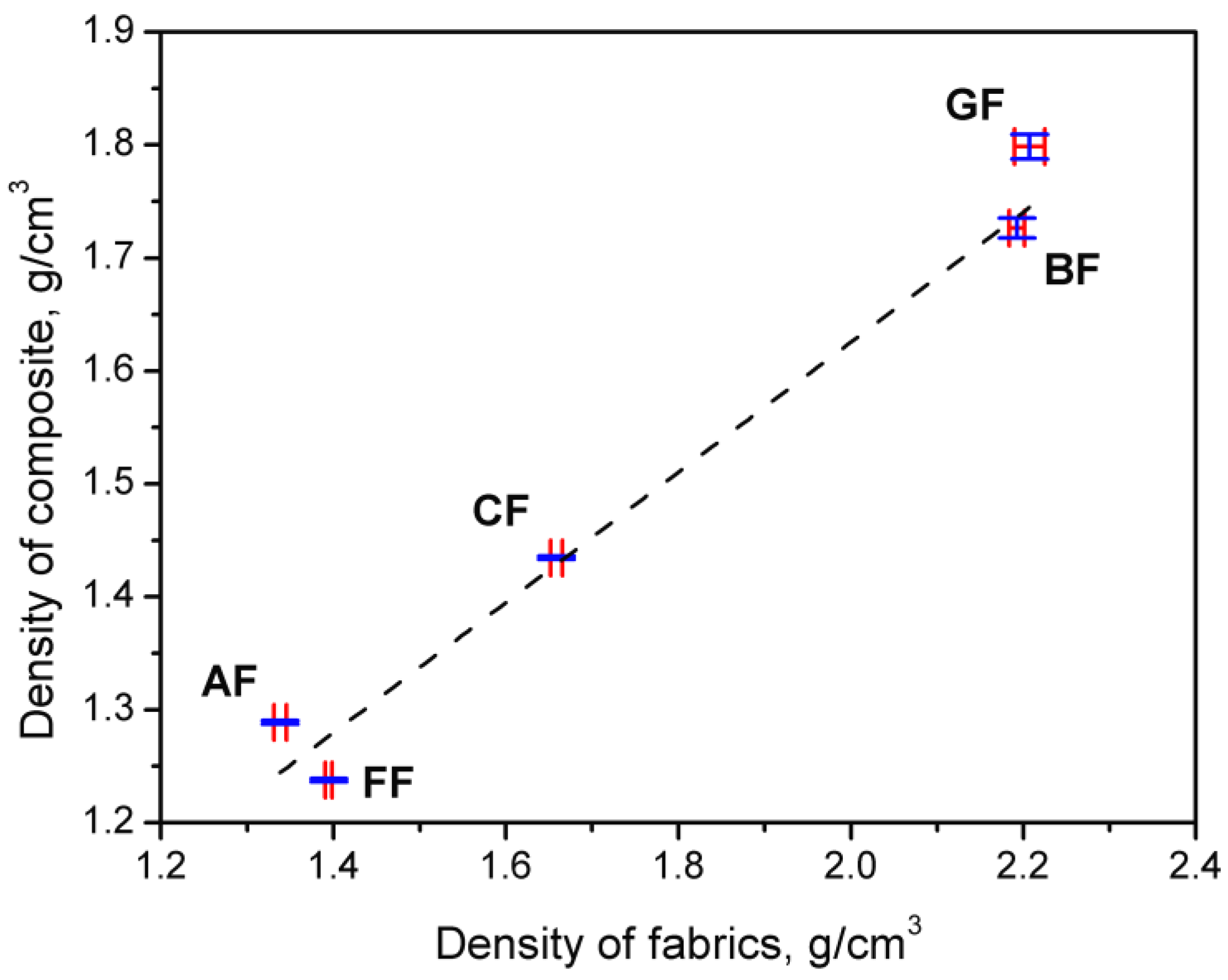

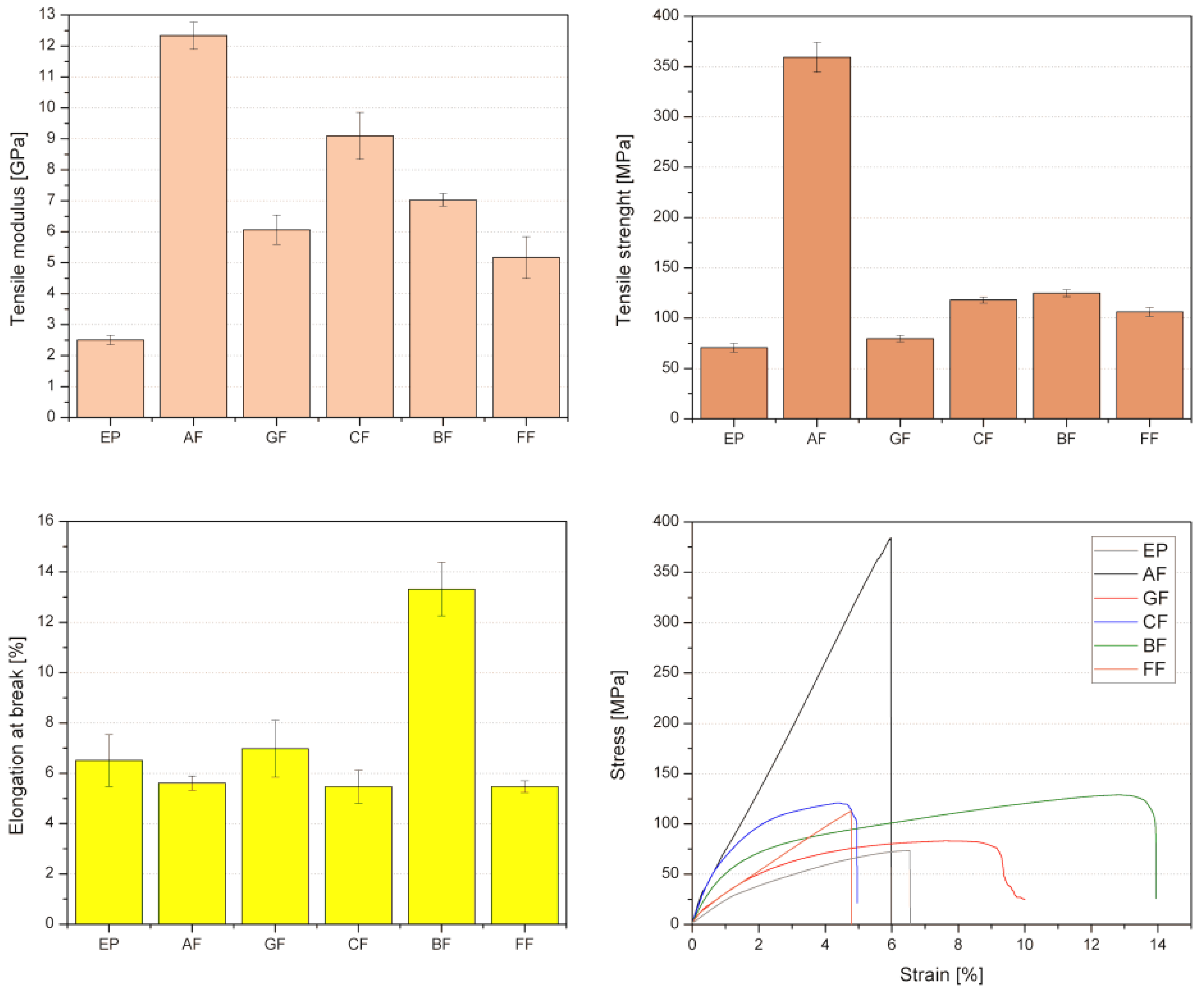

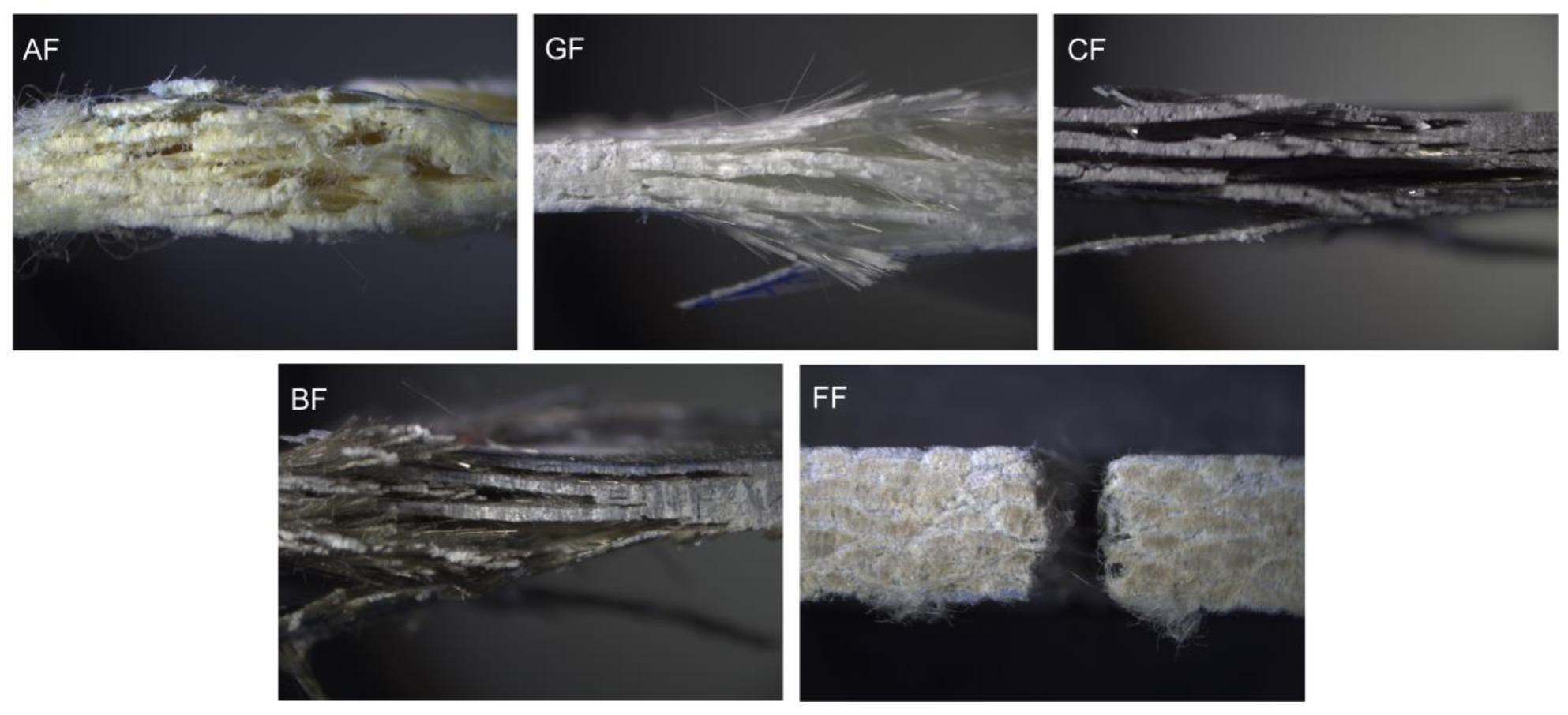

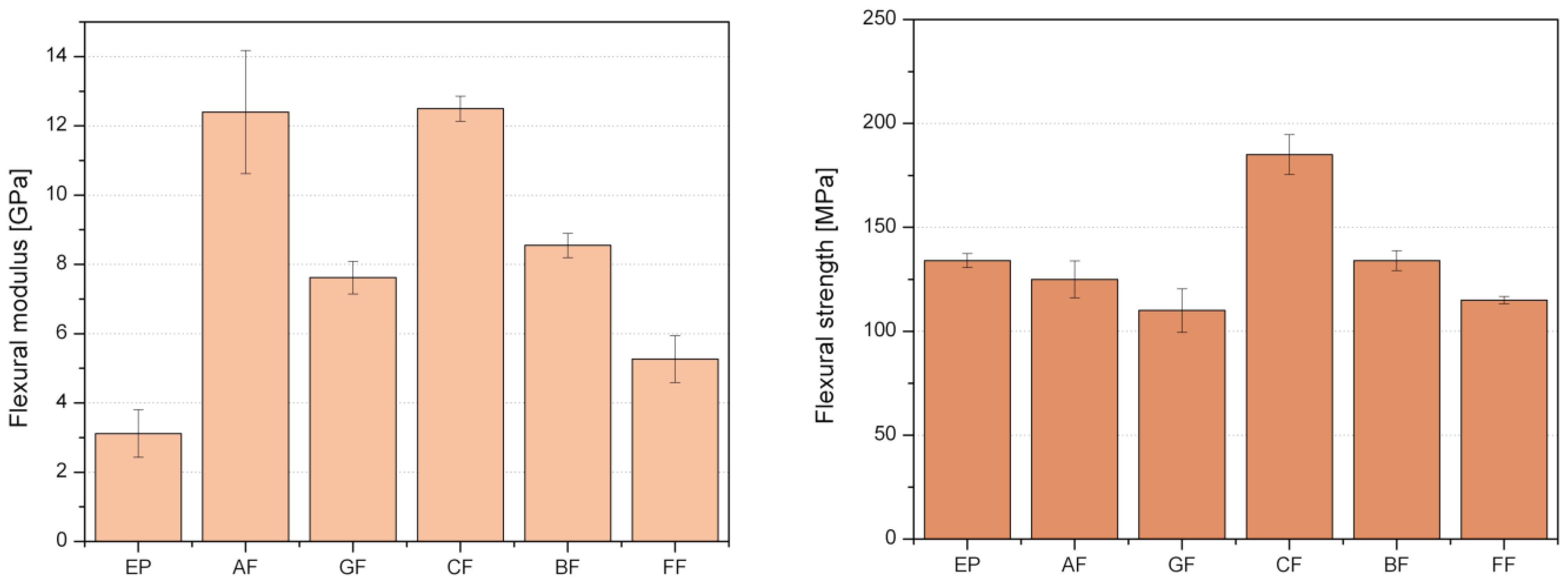

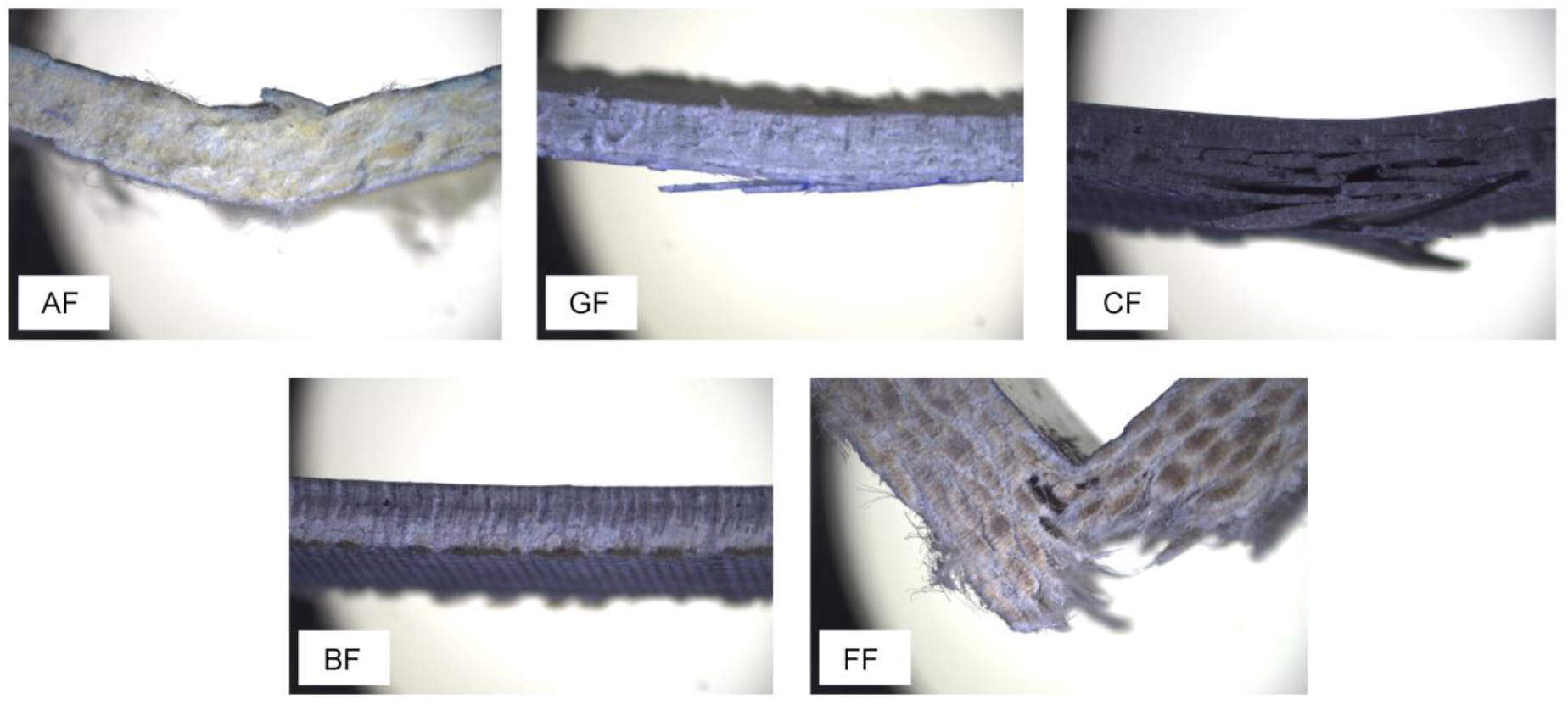

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.; Hassan, A. Recent advances in epoxy resin, natural fiber-reinforced epoxy composites and their applications. J. Reinf. Plast. Compos. 2016, 35, 447–470. [Google Scholar] [CrossRef]

- Sivasankaraiah, T.; Lokavarapu, B.R.; Venkata Rajesh, J. Post-curing effect on flexural strength of glass epoxy composites. Mater. Today Proc. 2021, 38, 3320–3331. [Google Scholar] [CrossRef]

- Benmokrane, B.; Ali, A.H.; Mohamed, H.M.; ElSafty, A.; Manalo, A. Laboratory assessment and durability performance of vinyl-ester, polyester, and epoxy glass-FRP bars for concrete structures. Compos. Part B Eng. 2017, 114, 163–174. [Google Scholar] [CrossRef]

- Wu, Q.; Zhao, R.; Ma, Q.; Zhu, J. Effects of degree of chemical interaction between carbon fibers and surface sizing on interfacial properties of epoxy composites. Compos. Sci. Technol. 2018, 163, 34–40. [Google Scholar] [CrossRef]

- Yao, L.; Li, M.; Wu, Q.; Dai, Z.; Gu, Y.; Li, Y.; Zhang, Z. Comparison of sizing effect of T700 grade carbon fiber on interfacial properties of fiber/BMI and fiber/epoxy. Appl. Surf. Sci. 2012, 263, 326–333. [Google Scholar] [CrossRef]

- Rahmat, M.; Ashrafi, B.; Naftel, A.; Djokic, D.; Martinez-Rubi, Y.; Jakubinek, M.B.; Simard, B. Enhanced Shear Performance of Hybrid Glass Fiber–Epoxy Laminates Modified with Boron Nitride Nanotubes. ACS Appl. Nano Mater. 2018, 1, 2709–2717. [Google Scholar] [CrossRef]

- Michel, M.; Ferrier, E. Effect of curing temperature conditions on glass transition temperature values of epoxy polymer used for wet lay-up applications. Constr. Build. Mater. 2020, 231, 117206. [Google Scholar] [CrossRef]

- Cucinotta, F.; Guglielmino, E.; Sfravara, F. Life cycle assessment in yacht industry: A case study of comparison between hand lay-up and vacuum infusion. J. Clean. Prod. 2017, 142, 3822–3833. [Google Scholar] [CrossRef]

- Korol, J.; Hejna, A.; Burchart-Korol, D.; Chmielnicki, B.; Wypiór, K. Water Footprint Assessment of Selected Polymers, Polymer Blends, Composites, and Biocomposites for Industrial Application. Polymers 2019, 11, 1791. [Google Scholar] [CrossRef]

- Miwa, M.; Ohsawa, T.; Tahara, K. Effects of fiber length on the tensile strength of epoxy/glass fiber and polyester/glass fiber composites. J. Appl. Polym. Sci. 1980, 25, 795–807. [Google Scholar] [CrossRef]

- Abd El-baky, M.; Attia, M.; Abdelhaleem, M.; Hassan, M. Mechanical characterization of hybrid composites based on flax, basalt and glass fibers. J. Compos. Mater. 2020, 54, 4185–4205. [Google Scholar] [CrossRef]

- Oliwa, R.; Oleksy, M.; Czech-Polak, J.; Płocińska, M.; Krauze, S.; Kowalski, M. Powder-epoxy resin/glass fabric composites with reduced flammability. J. Fire Sci. 2019, 37, 155–175. [Google Scholar] [CrossRef]

- García-Moreno, I.; Caminero, M.; Rodríguez, G.; López-Cela, J. Effect of Thermal Ageing on the Impact and Flexural Damage Behaviour of Carbon Fibre-Reinforced Epoxy Laminates. Polymers 2019, 11, 80. [Google Scholar] [CrossRef] [PubMed]

- García-Moreno, I.; Caminero, M.; Rodríguez, G.; López-Cela, J. Effect of Thermal Ageing on the Impact Damage Resistance and Tolerance of Carbon-Fibre-Reinforced Epoxy Laminates. Polymers 2019, 11, 160. [Google Scholar] [CrossRef] [PubMed]

- Bogoeva-Gaceva, G.; Heraković, N.; Dimeski, D.; Stefov, V. Ultrasound assisted process for enhanced interlaminar shear strength of carbon fiber/epoxy resin composites. Maced. J. Chem. Chem. Eng. 2010, 29, 149–155. [Google Scholar] [CrossRef]

- Chand, S. Review Carbon fibers for composites. J. Mater. Sci. 2000, 35, 1303–1313. [Google Scholar] [CrossRef]

- Zhou, Y.; Pervin, F.; Rangari, V.K.; Jeelani, S. Influence of montmorillonite clay on the thermal and mechanical properties of conventional carbon fiber reinforced composites. J. Mater. Process. Technol. 2007, 191, 347–351. [Google Scholar] [CrossRef]

- Bolimowski, P.A.; Boczkowska, A. Autonomous self-healing based on epoxy resin-imidazole chemistry in carbon fiber-reinforced polymer composites. J. Appl. Polym. Sci. 2019, 136, 46938. [Google Scholar] [CrossRef]

- Rodzewicz, M.; Jaśkowski, P.; Boczkowska, A.; Kurzydłowski, K.J. Investigation into mechanical properties of unidirectional carbon fiber reinforced plastics. Kompozyty 2004, 12, 414–420. [Google Scholar]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Valente, M.; Ferrante, L.; Cioffi, S.; Iannace, S.; Sorrentino, L. Hybrid composites based on aramid and basalt woven fabrics: Impact damage modes and residual flexural properties. Mater. Des. 2013, 49, 290–302. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Lewandowski, K.; Dudziec, B. Evaluation of thermomechanical properties of epoxy–basalt fibre composites modified with zeolite and silsesquioxane. Compos. Interfaces 2017, 24, 489–498. [Google Scholar] [CrossRef]

- Kalantar, J.; Drzal, L.T. The bonding mechanism of aramid fibres to epoxy matrices. J. Mater. Sci. 1990, 25, 4186–4193. [Google Scholar] [CrossRef]

- Mai, Y.W.; Castino, F. The debonding and pull-out properties of coated Kevlar fibres from an epoxy resin matrix. J. Mater. Sci. Lett. 1985, 4, 505–508. [Google Scholar] [CrossRef]

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Pospiech, P.; Strzelec, K. Effects of Chemically Treated Eucalyptus Fibers on Mechanical, Thermal and Insulating Properties of Polyurethane Composite Foams. Materials 2020, 13, 1781. [Google Scholar] [CrossRef] [PubMed]

- Matykiewicz, D.; Mysiukiewicz, O. Epoxy composites reinforced with natural fillers such as flax fiber and linseed cakes. Polimery 2020, 65, 828–832. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Ranakoti, L.; Rakesh, P.K. Physio-mechanical characterization of tasar silk waste/jute fiber hybrid composite. Compos. Commun. 2020, 22, 100526. [Google Scholar] [CrossRef]

- Ugochukwu, S.; Ridzuan, M.J.M.; Abdul Majid, M.S.; Cheng, E.M.; Razlan, Z.M.; Marsi, N. Effect of thermal ageing on the scratch resistance of natural-fibre-reinforced epoxy composites. Compos. Struct. 2021, 261, 113586. [Google Scholar] [CrossRef]

- Ortega, R.; Monzón, M.D.; Ortega, Z.C.; Cunningham, E. Study and fire test of banana fibre reinforced composites with flame retardance properties. Open Chem. 2020, 18, 275–286. [Google Scholar] [CrossRef]

- Balaji, A.; Purushothaman, R.; Udhayasankar, R.; Vijayaraj, S.; Karthikeyan, B. Study on Mechanical, Thermal and Morphological Properties of Banana Fiber-Reinforced Epoxy Composites. J. Bio Tribo-Corros. 2020, 6, 60. [Google Scholar] [CrossRef]

- Joshi, S.; Drzal, L.; Mohanty, A.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Komuraiah, A.; Kumar, N.S.; Prasad, B.D. Chemical Composition of Natural Fibers and its Influence on their Mechanical Properties. Mech. Compos. Mater. 2014, 50, 359–376. [Google Scholar] [CrossRef]

- Gieparda, W.; Rojewski, S.; Wüstenhagen, S.; Kicinska-Jakubowska, A.; Krombholz, A. Chemical modification of natural fibres to epoxy laminate for lightweight constructions. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106171. [Google Scholar] [CrossRef]

- Chapple, S.; Anandjiwala, R. Flammability of Natural Fiber-reinforced Composites and Strategies for Fire Retardancy: A Review. J. Thermoplast. Compos. Mater. 2010, 23, 871–893. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Paridah, M.T.; Al-othman, O.Y. A review on flammability of epoxy polymer, cellulosic and non-cellulosic fiber reinforced epoxy composites. Polym. Adv. Technol. 2016, 27, 577–590. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Matykiewicz, D.; Skórczewska, K.; Lewandowski, K.; Andrzejewski, J.; Piasecki, A. Development of polylactide composites with improved thermomechanical properties by simultaneous use of basalt powder and a nucleating agent. Polym. Compos. 2020, 41, 2947–2957. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Sultan, M.T.H. Thermal Stability and Dynamic Mechanical Properties of Kenaf/Bamboo FibreReinforced Epoxy Composites. BioResources 2017, 12, 7118–7132. [Google Scholar]

- Asim, M.; Paridah, M.T.; Chandrasekar, M.; Shahroze, R.M.; Jawaid, M.; Nasir, M.; Siakeng, R. Thermal stability of natural fibers and their polymer composites. Iran. Polym. J. 2020, 29, 625–648. [Google Scholar] [CrossRef]

- Naresh, K.; Shankar, K.; Velmurugan, R. Digital image processing and thermo-mechanical response of neat epoxy and different laminate orientations of fiber reinforced polymer composites for vibration isolation applications. Int. J. Polym. Anal. Charact. 2018, 23, 684–709. [Google Scholar] [CrossRef]

- Asadi, A.; Baaij, F.; Mainka, H.; Rademacher, M.; Thompson, J.; Kalaitzidou, K. Basalt fibers as a sustainable and cost-effective alternative to glass fibers in sheet molding compound (SMC). Compos. Part B Eng. 2017, 123, 210–218. [Google Scholar] [CrossRef]

- Chinnasamy, V.; Pavayee Subramani, S.; Palaniappan, S.K.; Mylsamy, B.; Aruchamy, K. Characterization on thermal properties of glass fiber and kevlar fiber with modified epoxy hybrid composites. J. Mater. Res. Technol. 2020, 9, 3158–3167. [Google Scholar] [CrossRef]

- Bakhtiyari, S.; Taghi Akbari, L.; Jamali Ashtiani, M. An investigation on fire hazard and smoke toxicity of epoxy FRP composites. Int. J. Disaster Resil. Built Environ. 2017, 8, 230–237. [Google Scholar] [CrossRef]

- Hshieh, F.-Y.; Beeson, H.D. Flammability Testing of Flame-retarded Epoxy Composites and Phenolic Composites. Fire Mater. 1997, 21, 41–49. [Google Scholar] [CrossRef]

- Hassan, M.H.; Othman, A.R.; Kamaruddin, S. A review on the manufacturing defects of complex-shaped laminate in aircraft composite structures. Int. J. Adv. Manuf. Technol. 2017, 91, 4081–4094. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, Y.; Ni, Q.; Fu, Y.; Fu, X. Surface modification and characterization of aramid fibers with hybrid coating. Appl. Surf. Sci. 2014, 321, 103–108. [Google Scholar] [CrossRef]

- Nasser, J.; Lin, J.; Steinke, K.; Sodano, H.A. Enhanced interfacial strength of aramid fiber reinforced composites through adsorbed aramid nanofiber coatings. Compos. Sci. Technol. 2019, 174, 125–133. [Google Scholar] [CrossRef]

- Chae, H.G.; Newcomb, B.A.; Gulgunje, P.V.; Liu, Y.; Gupta, K.K.; Kamath, M.G.; Lyons, K.M.; Ghoshal, S.; Pramanik, C.; Giannuzzi, L.; et al. High strength and high modulus carbon fibers. Carbon N. Y. 2015, 93, 81–87. [Google Scholar] [CrossRef]

- Kessler, R.W.; Becker, U.; Kohler, R.; Goth, B. Steam explosion of flax—A superior technique for upgrading fibre value. Biomass Bioenergy 1998, 14, 237–249. [Google Scholar] [CrossRef]

- Wang, J.; Shi, C.; Feng, J.; Long, X.; Meng, L.; Ren, H. Effects of oxygen plasma treatment power on Aramid fiber III/BMI composite humidity resistance properties. IOP Conf. Ser. Earth Environ. Sci. 2018, 108, 022034. [Google Scholar] [CrossRef]

- Mukherjee, M.; Kumar, S.; Bose, S.; Das, C.K.; Kharitonov, A.P. Study on the Mechanical, Rheological, and Morphological Properties of Short KevlarTM Fiber/s-PS Composites. Polym. Plast. Technol. Eng. 2008, 47, 623–629. [Google Scholar] [CrossRef]

- Abu Obaid, A.; Deitzel, J.M.; Gillespie, J.W.; Zheng, J.Q. The effects of environmental conditioning on tensile properties of high performance aramid fibers at near-ambient temperatures. J. Compos. Mater. 2011, 45, 1217–1231. [Google Scholar] [CrossRef]

- Shebanov, S.M.; Novikov, I.K.; Pavlikov, A.V.; Anańin, O.B.; Gerasimov, I.A. IR and Raman Spectra of Modern Aramid Fibers. Fibre Chem. 2016, 48, 158–164. [Google Scholar] [CrossRef]

- Ishida, H.; Koenig, J.L. Fourier transform infrared spectroscopic study of the structure of silane coupling agent on E-glass fiber. J. Colloid Interface Sci. 1978, 64, 565–576. [Google Scholar] [CrossRef]

- Huber, M.P.; Kelch, S.; Berke, H. FTIR investigations on hydrolysis and condensation reactions of alkoxysilane terminated polymers for use in adhesives and sealants. Int. J. Adhes. Adhes. 2016, 64, 153–162. [Google Scholar] [CrossRef]

- Li, J.; Su, S.; Zhou, L.; Kundrát, V.; Abbot, A.M.; Mushtaq, F.; Ouyang, D.; James, D.; Roberts, D.; Ye, H. Carbon nanowalls grown by microwave plasma enhanced chemical vapor deposition during the carbonization of polyacrylonitrile fibers. J. Appl. Phys. 2013, 113, 024313. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Barczewski, M.; Mysiukiewicz, O.; Skórczewska, K. Comparison of Various Chemical Treatments Efficiency in Relation to the Properties of Flax, Hemp Fibers and Cotton trichomes. J. Nat. Fibers 2019. [Google Scholar] [CrossRef]

- Titok, V.; Leontiev, V.; Yurenkova, S.; Nikitinskaya, T.; Barannikova, T.; Khotyleva, L. Infrared Spectroscopy of Fiber Flax. J. Nat. Fibers 2010, 7, 61–69. [Google Scholar] [CrossRef]

- Garside, P.; Wyeth, P. Identification of Cellulosic Fibres by FTIR Spectroscopy differentiation of flax and hemp by polarized atr ftir. Stud. Conserv. 2006, 51, 205–211. [Google Scholar] [CrossRef]

- Sathish, S.; Kumaresan, K.; Prabhu, L.; Gokulkumar, S. Experimental investigation of mechanical and ftir analysis of flax fiber/epoxy composites incorporating sic, Al2O3 and graphite. Rev. Rom. Mater. Rom. J. Mater. 2018, 48, 476–482. [Google Scholar]

- Fu, B.X.; Namani, M.; Lee, A. Influence of phenyl-trisilanol polyhedral silsesquioxane on properties of epoxy network glasses. Polymer 2003, 44, 7739–7747. [Google Scholar] [CrossRef]

- Nikolic, G.; Zlatkovic, S.; Cakic, M.; Cakic, S.; Lacnjevac, C.; Rajic, Z. Fast Fourier Transform IR Characterization of Epoxy GY Systems Crosslinked with Aliphatic and Cycloaliphatic EH Polyamine Adducts. Sensors 2010, 10, 684–696. [Google Scholar] [CrossRef] [PubMed]

- Elgabbas, F.; Ahmed, E.A.; Benmokrane, B. Physical and mechanical characteristics of new basalt-FRP bars for reinforcing concrete structures. Constr. Build. Mater. 2015, 95, 623–635. [Google Scholar] [CrossRef]

- Tanner, D.; Fitzgerald, J.A.; Phillips, B.R. The Kevlar Story?an Advanced Materials Case Study. Angew. Chem. Int. Ed. Engl. 1989, 28, 649–654. [Google Scholar] [CrossRef]

- Behera, R.P.; Rawat, P.; Singh, K.K.; Ha, S.K.; Gaurav, A.; Tiwari, S.K. Fracture analysis and mechanical properties of three phased glass/epoxy laminates reinforced with multiwalled carbon nanotubes. J. Sci. Adv. Mater. Devices 2019, 4, 299–309. [Google Scholar] [CrossRef]

- Behera, R.P.; Rawat, P.; Singh, K.K. Tensile Behavior of Three Phased Glass/Epoxy Laminate Embedded with MWCNTs: An Experimental Approach. Mater. Today Proc. 2018, 5, 8176–8183. [Google Scholar] [CrossRef]

- Iwahori, Y.; Ishiwata, S.; Sumizawa, T.; Ishikawa, T. Mechanical properties improvements in two-phase and three-phase composites using carbon nano-fiber dispersed resin. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1430–1439. [Google Scholar] [CrossRef]

- Naghipour, P.; Schneider, J.; Bartsch, M.; Hausmann, J.; Voggenreiter, H. Fracture simulation of CFRP laminates in mixed mode bending. Eng. Fract. Mech. 2009, 76, 2821–2833. [Google Scholar] [CrossRef]

- Bulut, M. Mechanical characterization of Basalt/epoxy composite laminates containing graphene nanopellets. Compos. Part B Eng. 2017, 122, 71–78. [Google Scholar] [CrossRef]

- Papa, I.; Ricciardi, M.R.; Antonucci, V.; Pagliarulo, V.; Lopresto, V. Impact behaviour of hybrid basalt/flax twill laminates. Compos. Part B Eng. 2018, 153, 17–25. [Google Scholar] [CrossRef]

- Srinivasa, V.; Shivakumar, V.; Nayaka, V.; Jagadeeshaiaih, S.; Seethram, M.; Shenoy, R.; Nafidi, A. Fracture morphology of carbon fiber reinforced plastic composite laminates. Mater. Res. 2010, 13, 417–424. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E.; Khoja, S. Brittleness and toughness of polymers and other materials. Mater. Lett. 2015, 159, 478–480. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E. Survey of Relations of Chemical Constituents in Polymer-Based Materials with Brittleness and its Associated Properties. Chem. Chem. Technol. 2016, 10, 595–600. [Google Scholar] [CrossRef]

- Hejna, A.; Sulyman, M.; Przybysz, M.; Saeb, M.R.; Klein, M.; Formela, K. On the Correlation of Lignocellulosic Filler Composition with the Performance Properties of Poly(ε-Caprolactone) Based Biocomposites. Waste Biomass Valorization 2020, 11, 1467–1479. [Google Scholar] [CrossRef]

- Pogany, G.A. The α relaxation in epoxy resins. Eur. Polym. J. 1970, 6, 343–353. [Google Scholar] [CrossRef]

- Pothan, L.A.; Oommen, Z.; Thomas, S. Dynamic mechanical analysis of banana fiber reinforced polyester composites. Compos. Sci. Technol. 2003, 63, 283–293. [Google Scholar] [CrossRef]

- Muralidhar, M.; Kaliveeran, V.; Arumugam, V.; Reddy, I.S. Dynamic mechanical characterization of epoxy composite reinforced with areca nut husk fiber. Arch. Mech. Eng. 2020, 67, 57–72. [Google Scholar]

- Jyoti, J.; Singh, B.P.; Arya, A.K.; Dhakate, S.R. Dynamic mechanical properties of multiwall carbon nanotube reinforced ABS composites and their correlation with entanglement density, adhesion, reinforcement and C factor. RSC Adv. 2016, 6, 3997–4006. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, Q.; Zhang, X.; Pan, H.; Lu, Y. Graphene oxide-filled multilayer coating to improve flame-retardant and smoke suppression properties of flexible polyurethane foam. J. Mater. Sci. 2016, 51, 10361–10374. [Google Scholar] [CrossRef]

- Ahmed, L.; Zhang, B.; Shen, R.; Agnew, R.J.; Park, H.; Cheng, Z.; Mannan, M.S.; Wang, Q. Fire reaction properties of polystyrene-based nanocomposites using nanosilica and nanoclay as additives in cone calorimeter test. J. Therm. Anal. Calorim. 2018, 132, 1853–1865. [Google Scholar] [CrossRef]

- Schartel, B.; Wilkie, C.A.; Camino, G. Recommendations on the scientific approach to polymer flame retardancy: Part 2—Concepts. J. Fire Sci. 2017, 35, 3–20. [Google Scholar] [CrossRef]

| Fiber Type | Elasticity Modulus | Tensile Strength | Reference |

|---|---|---|---|

| (GPa) | (GPa) | ||

| AF | 102 | 2.8 | [47,48] |

| GF | 76 | 1.4–2.5 | [33] |

| CF | 354–375 | 5.5–5.8 | [49] |

| BF | 89 | 2.8 | [20] |

| FF | 30–38 | 0.45–1.5 | [33,50] |

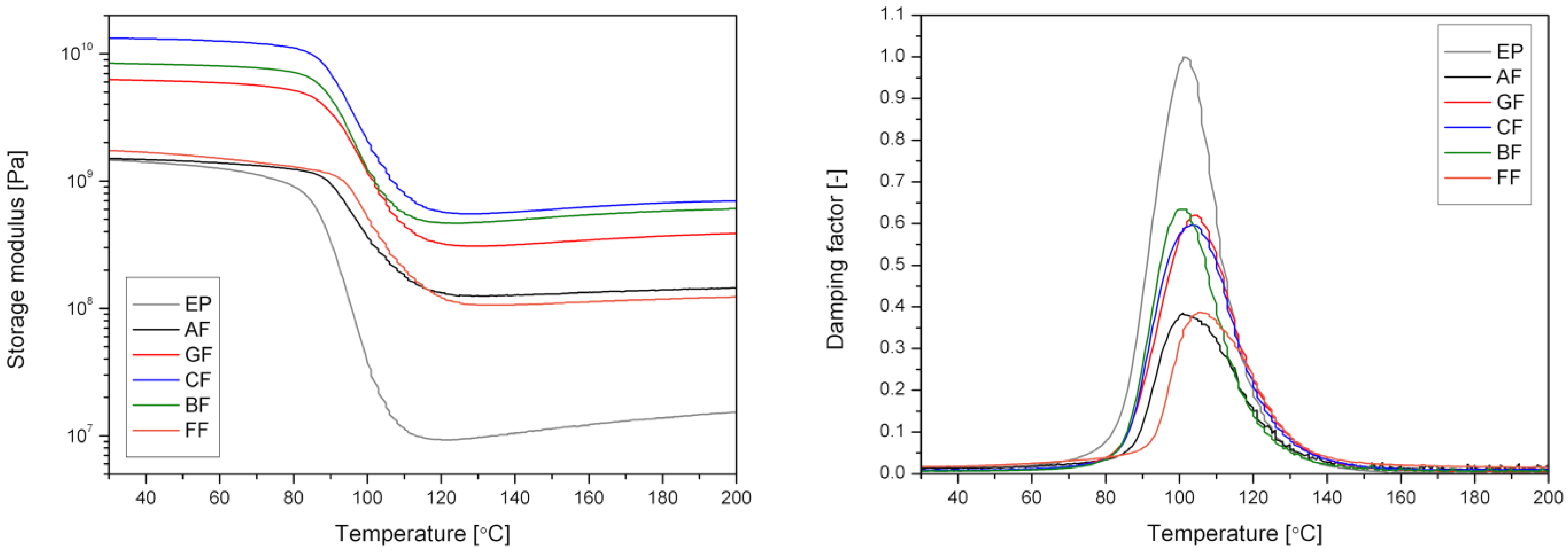

| Sample | G’30°C | G’80°C | G’140°C | Tg | tanδ at Tg | C | B |

|---|---|---|---|---|---|---|---|

| (Pa) | (°C) | (-) | (-) | (1010/Pa·%) | |||

| EP | 1.46 × 109 | 9.01 × 108 | 1.05 × 107 | 101 | 0.999 | - | 1.052 |

| AF | 1.05 × 109 | 1.23 × 109 | 1.27 × 108 | 101 | 0.385 | 16.81 | 1.180 |

| GF | 6.26 × 109 | 5.13 × 109 | 3.16 × 108 | 104 | 0.62 | 7.02 | 0.227 |

| CF | 13.25 × 109 | 11.13 × 109 | 5.72 × 108 | 103 | 0.597 | 6.00 | 0.138 |

| BF | 8.42 × 109 | 7.11 × 109 | 4.94 × 108 | 101 | 0.634 | 8.16 | 0.089 |

| FF | 1.73 × 109 | 1.29 × 109 | 1.07 × 108 | 106 | 0.387 | 8.60 | 1.051 |

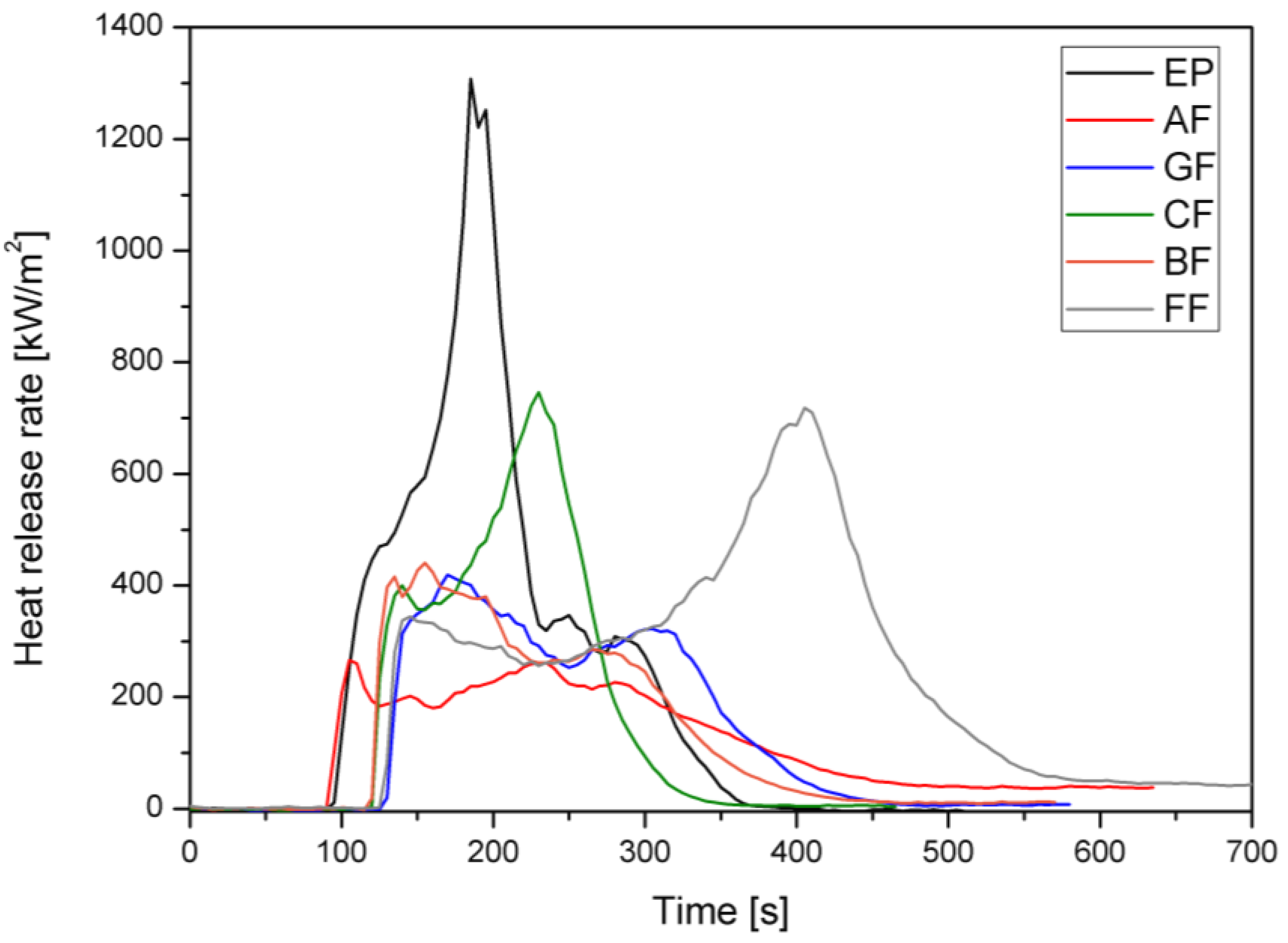

| Sample | TTI, s | pHRR, kW/m2 | MARHE, kW/m2 | THR, MJ/m2 | SEA, m2/kg | TSR, m2/m2 |

|---|---|---|---|---|---|---|

| EP | 102 (8 a) | 1313 (109) | 385 (7) | 119 (3) | 606 (15) | 2969 (80) |

| AF | 92 (0) | 429 (229) | 177 (34) | 77 (10) | 557 (103) | 1855 (74) |

| GF | 133 (3) | 408 (15) | 187 (11) | 75 (1) | 662 (17) | 2099 (38) |

| CF | 119 (2) | 740 (9) | 263 (1) | 79 (1) | 623 (18) | 2078 (70) |

| BF | 105 (12) | 460 (28) | 201 (9) | 72 (1) | 617 (2) | 1819 (30) |

| FF | 129 (7) | 669 (143) | 274 (18) | 151 (5) | 423 (14) | 3220 (73) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salasinska, K.; Barczewski, M.; Aniśko, J.; Hejna, A.; Celiński, M. Comparative Study of the Reinforcement Type Effect on the Thermomechanical Properties and Burning of Epoxy-Based Composites. J. Compos. Sci. 2021, 5, 89. https://doi.org/10.3390/jcs5030089

Salasinska K, Barczewski M, Aniśko J, Hejna A, Celiński M. Comparative Study of the Reinforcement Type Effect on the Thermomechanical Properties and Burning of Epoxy-Based Composites. Journal of Composites Science. 2021; 5(3):89. https://doi.org/10.3390/jcs5030089

Chicago/Turabian StyleSalasinska, Kamila, Mateusz Barczewski, Joanna Aniśko, Aleksander Hejna, and Maciej Celiński. 2021. "Comparative Study of the Reinforcement Type Effect on the Thermomechanical Properties and Burning of Epoxy-Based Composites" Journal of Composites Science 5, no. 3: 89. https://doi.org/10.3390/jcs5030089

APA StyleSalasinska, K., Barczewski, M., Aniśko, J., Hejna, A., & Celiński, M. (2021). Comparative Study of the Reinforcement Type Effect on the Thermomechanical Properties and Burning of Epoxy-Based Composites. Journal of Composites Science, 5(3), 89. https://doi.org/10.3390/jcs5030089