A Review on Mechanical Properties of Natural Fibre Reinforced Polymer Composites under Various Strain Rates

Abstract

1. Introduction

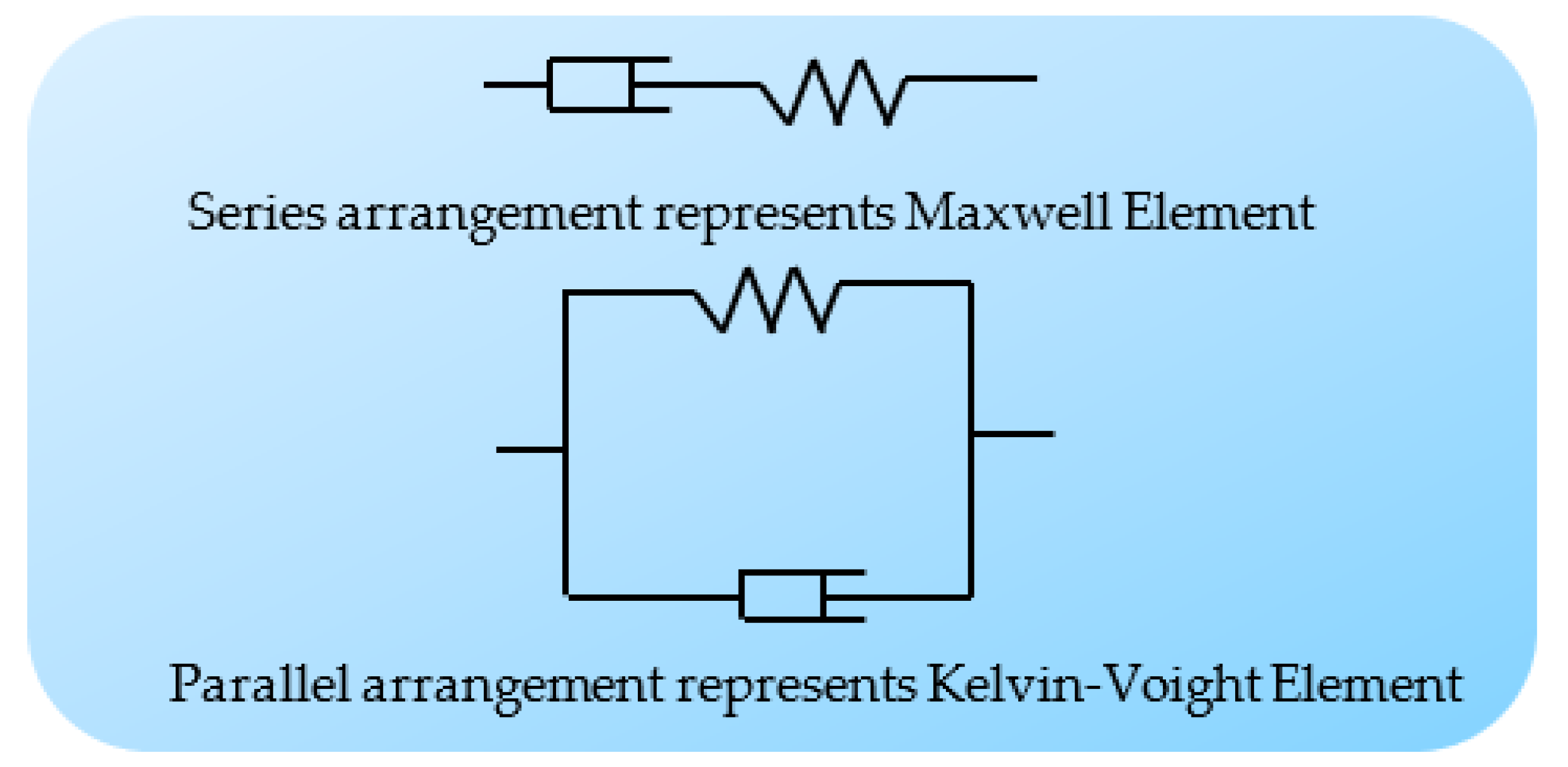

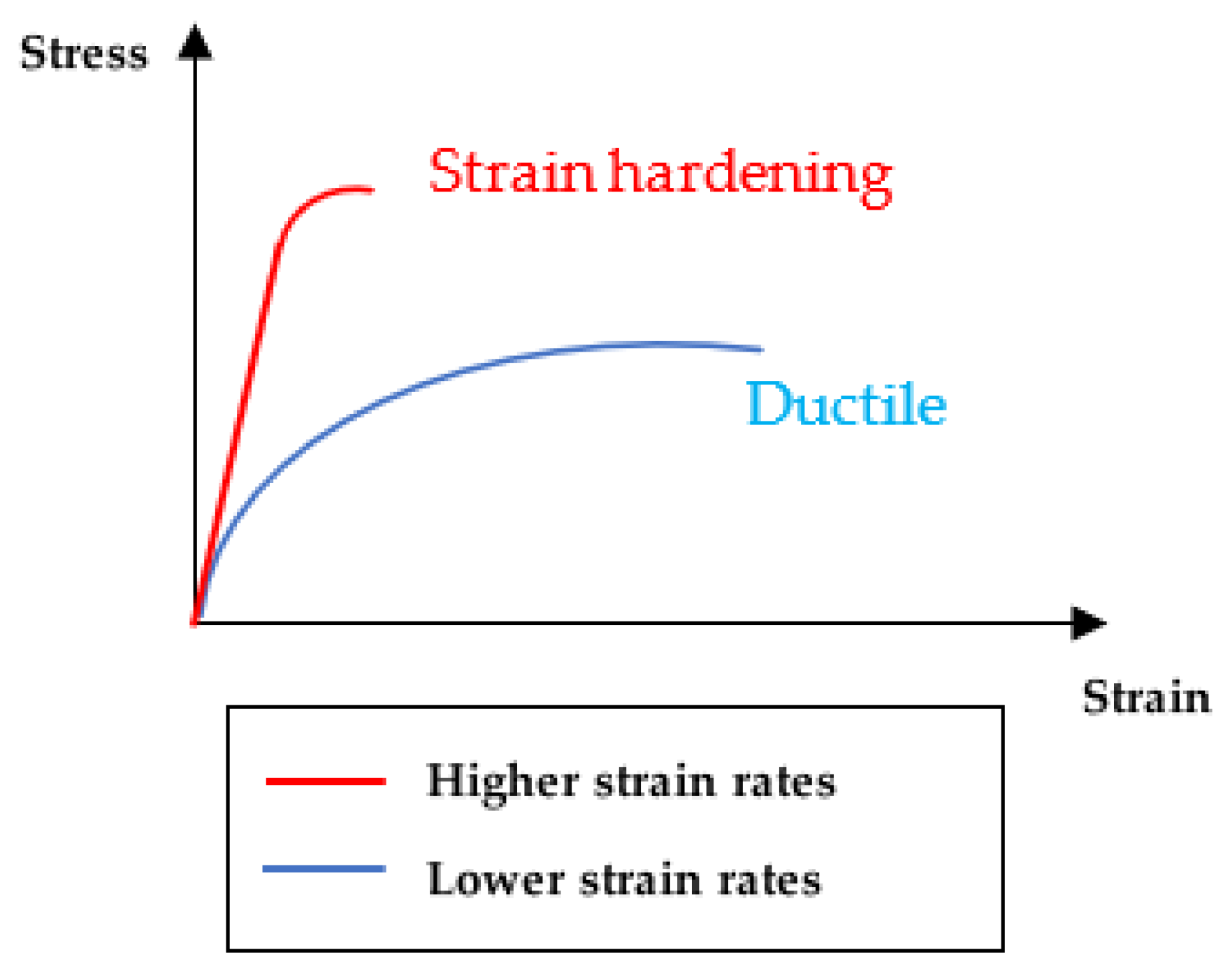

2. Strain Rates Characterisation

3. NFPCs under Different Forms of Strain Rates

3.1. Tensile Strain Rate

3.2. Compressive Strain Rate

3.3. Flexural Strain Rate

3.4. Literature Summary

4. Future Research Direction

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ferdous, W.; Manalo, A.; AlAjarmeh, O.; Mohammed, A.A.; Salih, C.; Yu, P.; Khotbehsara, M.M.; Schubel, P. Static behaviour of glass fibre reinforced novel composite sleepers for mainline railway track. Eng. Struct. 2021, 229, 111627. [Google Scholar] [CrossRef]

- Ferdous, W.; Ngo, T.D.; Nguyen, K.T.Q.; Ghazlan, A.; Mendis, P.; Manalo, A. Effect of fire-retardant ceram powder on the properties of phenolic-based GFRP composites. Compos. Part B Eng. 2018, 155, 414–424. [Google Scholar] [CrossRef]

- Dungani, R.; Karina, M.; Subyakto; Sulaeman, A.; Hermawan, D.; Hadiyane, A. Review Article Agricultural Waste Fibers Towards Sustainability and Advanced Utilization: A Review. Asian J. Plant Sci. 2016, 15, 42–55. [Google Scholar] [CrossRef]

- Gutierrez-Lemin, D. Fundamental Aspects of Viscoelastic Response. In Engineering Viscoelastic; Springer: Boston, MA, USA, 2014; pp. 1–25. [Google Scholar]

- Banavalkar, P.V. Structural systems to improve wind induced dynamic performance of high rise buildings. J. Wind Eng. Ind. Aerodyn. 1990, 36, 213–224. [Google Scholar] [CrossRef]

- Yao, X.; Han, Q.; Zhang, X.Q.; Zhao, L.M. Experimental study on arc windshield of fighter subjected to bird impact. Baozha Yu Chongji Explos. Shock Waves 2005, 25, 417–422. [Google Scholar]

- Othman, H.; Marzouk, H. Strain Rate Sensitivity of Fiber-Reinforced Cementitious Composites. ACI Mater. J. 2016, 113, 143–150. [Google Scholar] [CrossRef]

- Clifton, R.J. Response of Material under Dynamic Loading. Int. J. Solids Struct. 2000, 37, 105–113. [Google Scholar] [CrossRef]

- Prabu, S.B.; Padmanabhan, K.A. Metal Forming at Very Low Strain Rates. In Encyclopedia of Materials: Science and Technology; Elsevier: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Meyers, M.; Chawla, K. Elasticity and Viscoelasticity. In Mechanical Behavior of Materials; Cambridge University Press: New York, NY, USA, 2008. [Google Scholar]

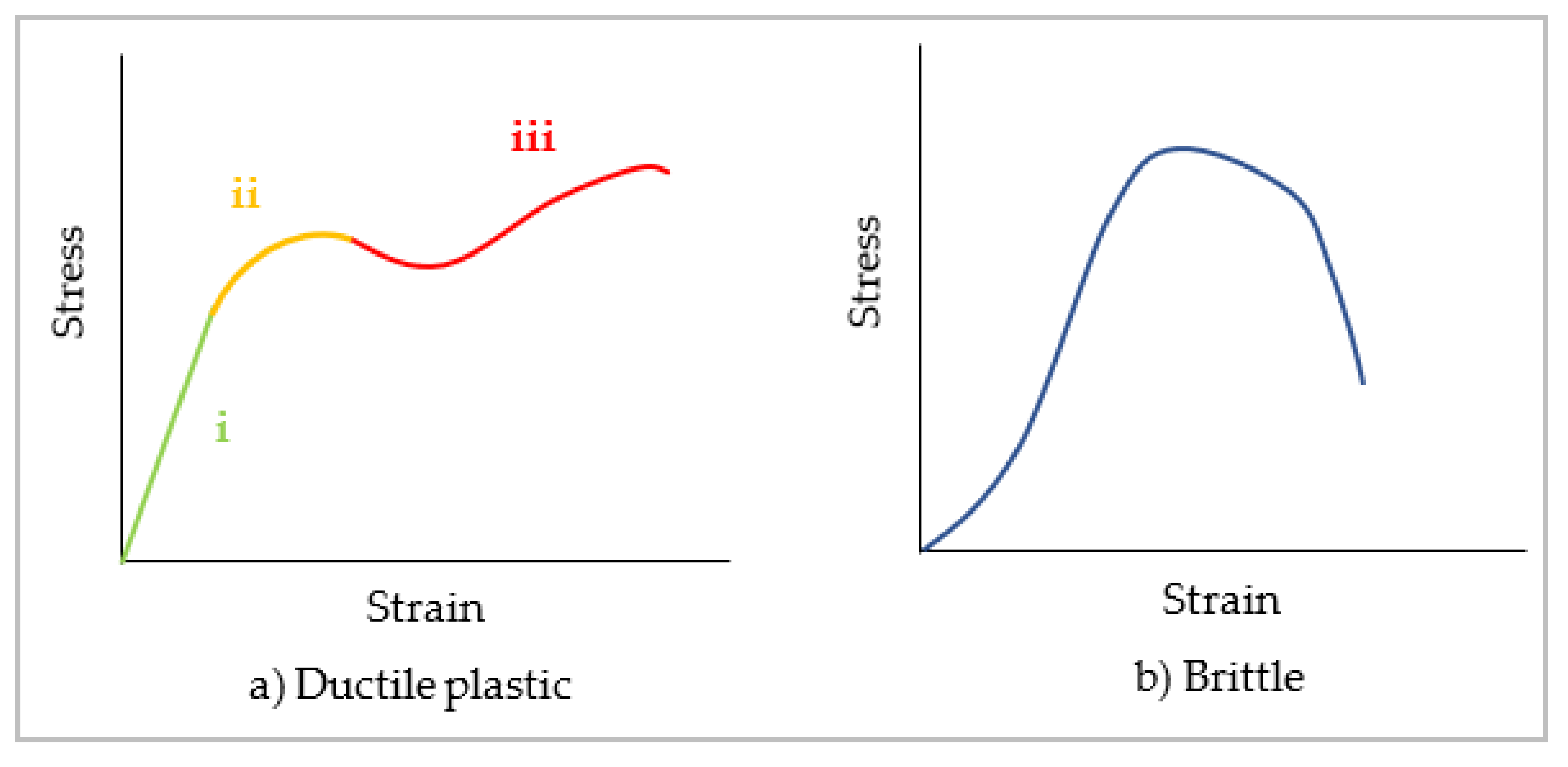

- Ashter, S.A. 6-Mechanics of Materials. In Thermoforming of Single and Multilayer Laminates; Ashter, S.A., Ed.; William Andrew Publishing: Oxford, UK, 2014; pp. 123–145. [Google Scholar]

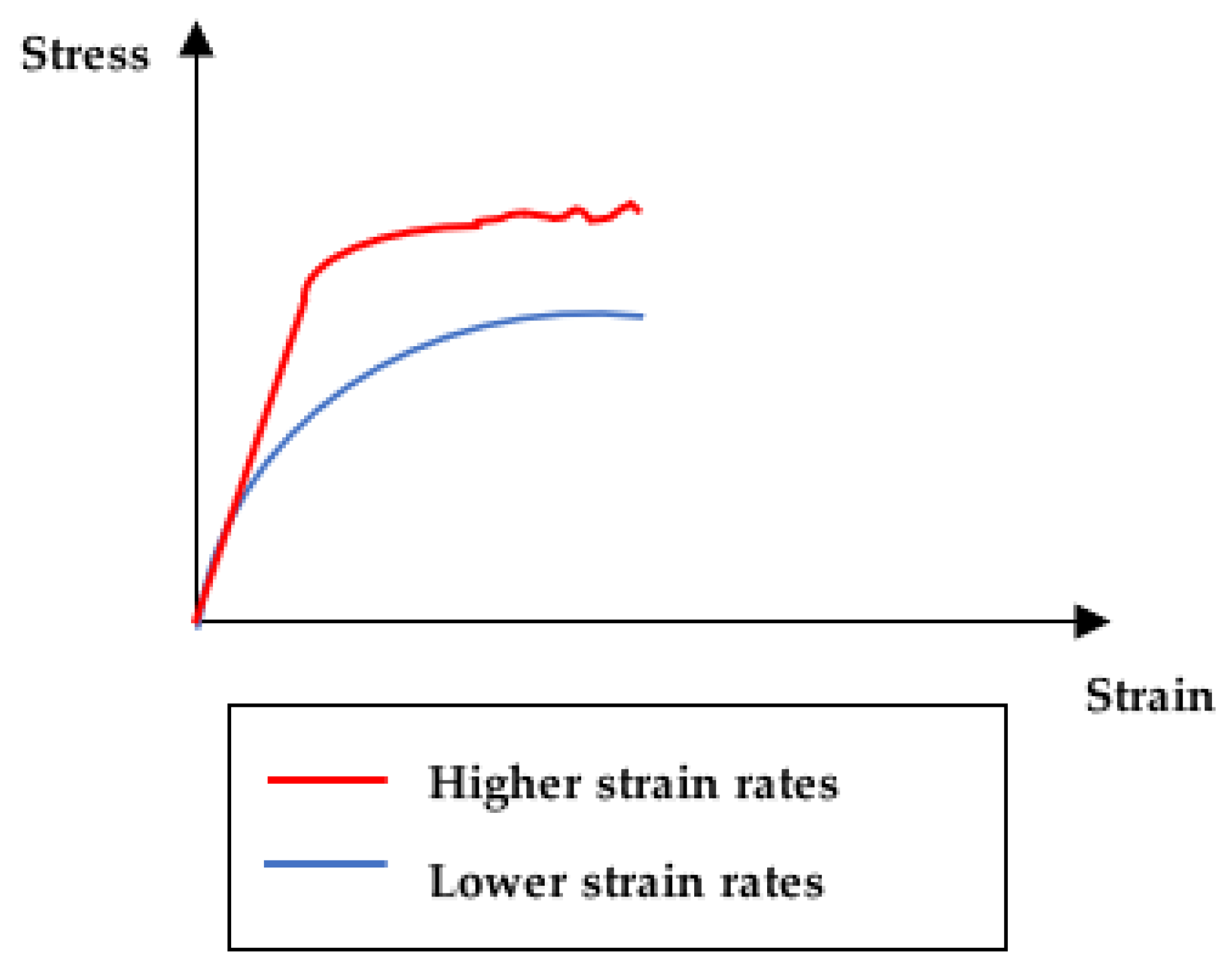

- Jacob, G.C.; Starbuck, J.M.; Fellers, J.F.; Simunovic, S.; Boeman, R.G. Strain rate effects on the mechanical properties of polymer composite materials. J. Appl. Polym. Sci. 2004, 94, 296–301. [Google Scholar] [CrossRef]

- Kumar, R.; Bhowmik, S. Elucidating the Coir Particle Filler Interaction in Epoxy Polymer Composites at Low Strain Rate. Fibers Polym. 2019, 20, 428–439. [Google Scholar] [CrossRef]

- Silva, M.P.; Santos, P.; Sousa, N.N.; Reis, P.N.B. Strain rate effect on composites with epoxy matrix filled by cork powder. Mater. Des. Process. Commun. 2019, 1, 1–9. [Google Scholar] [CrossRef]

- Xiang, C.; Hu, S.; Zhang, S.; Gupta, N. Compressive Characterization of Hemp Fiber–Epoxy Matrix Composite for Lightweight Structures. JOM 2020. [Google Scholar] [CrossRef]

- Wong, E.H.; Mai, Y.W. 12-Rate-dependent stress–strain properties of solders. In Robust Design of Microelectronics Assemblies Against Mechanical Shock, Temperature and Moisture; Wong, E.H., Mai, Y.W., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 411–446. [Google Scholar]

- Unger, R.; Nocke, A.; Gerlach, G.; Cherif, C. Evaluation of a novel test method for the determination of strain rate-dependent material properties of high-performance fibers. Procedia Struct. Integr. 2019, 17, 942–948. [Google Scholar] [CrossRef]

- Fowles, G.R.; Duvall, G.E.; Asay, J.; Bellamy, P.; Feistmann, F.; Grady, D.; Michaels, T.; Mitchell, R. Gas Gun for Impact Studies. Rev. Sci. Instrum. 1970, 41, 984–996. [Google Scholar] [CrossRef]

- Kermouche, G.; Aleksy, N.; Bergheau, J.M. Viscoelastic-Viscoplastic Modelling of the Scratch Response of PMMA. Adv. Mater. Sci. Eng. 2013, 2013, 289698. [Google Scholar] [CrossRef][Green Version]

- Giuliania, P.M.; Giannini, O.; Panciroli, R. Viscoelastic experimental characterisation of flax/epoxy composites. Procedia Struct. Integr. 2018, 12, 296–303. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Peauril, J.; Salih, C.; Kakarla, R.; Yu, P.; Schubel, P.; Heyer, T. Testing and modelling the fatigue behaviour of GFRP composites—Effect of stress level, stress concentration and frequency. Eng. Sci. Technol. An Int. J. 2020, 23, 1223–1232. [Google Scholar] [CrossRef]

- Lubarda, V.A.; Benson, D.J.; Meyers, M.A. Strain-rate effects in rheological models of inelastic response. Int. J. Plast. 2003, 19, 1097–1118. [Google Scholar] [CrossRef]

- Fotouh, A.; Wolodko, J.D.; Lipsett, M.G. Characterisation and modeling of strain rate hardening in natural-fiber-reinforced viscoplastic polymer. Polym. Compos. 2014, 35, 2290–2296. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, X.; Chouw, N.; Lib, Z.; Shib, Y. Strain rate effect on the dynamic tensile behaviour of flax fibre reinforced polymer. Compos. Struct. 2018, 200, 135–143. [Google Scholar] [CrossRef]

- Chokshi, S.; Gohill, P. Effect of Strain Rate on Tensile Strength of Natural Fiber Reinforced Polyester Composites. Int. J. Mech. Eng. Technol. 2018, 9, 861–869. [Google Scholar]

- Kumar, R.; Kumar, K.; Bhowmik, S. Mechanical characterisation and quantification of tensile, fracture and viscoelastic characteristics of wood filler reinforced epoxy composite. Wood Sci. Technol. 2018, 52, 677–699. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, K.; Bhowmik, S. Assessment and Response of Treated Cocos nucifera Reinforced Toughened Epoxy Composite Towards Fracture and Viscoelastic Properties. J. Polym. Environ. 2018, 26, 2522–2535. [Google Scholar] [CrossRef]

- Patel, M.; Chokshi, S. Experimental Investigation on Tensile Strength of Natural Fiber Composites with Varying Strain Rate. Int. J. Electron. Electr. Comput. Syst. 2017, 6, 477–484. [Google Scholar]

- Debnath, S.; Khieng, T.K.; Anwar, M.; Basak, A.K.; Pramanik, A. Strain Rate Sensitivity of Epoxy Composites Reinforced with Varied Sizes of Bagasse Particles. J. Compos. Sci. 2020, 4, 110. [Google Scholar] [CrossRef]

- Sinebe, J.E.; Chukwuneke, J.L.; Omenyi, S.N. Understanding Fiber-Matrix Integrity in Fiber-Reinforced Polymer Composites from Strain Rate Sensitivity Concept. Univers. J. Mech. Eng. 2020, 8, 243–250. [Google Scholar] [CrossRef]

- Hu, D.; Dang, L.; Zhang, C.; Zhang, Z. Mechanical Behaviors of Flax Fiber-Reinforced Composites at Different Strain Rates and Rate-Dependent Constitutive Model. Materials 2019, 12, 854. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.; Argento, A.; Lee, E.; Flanigan, C.; Houston, D.; Harris, A.; Mielewski, D.F. High strain-rate behavior of natural fiber-reinforced polymer composites. J. Compos. Mater. 2012, 46, 1051–1065. [Google Scholar] [CrossRef]

- Hu, J.; Yin, S.; Xu, J.; Buzaud, E.; Cosculluela, A.; Couque, H.; Cadoni, E. Compression behavior and energy absorption capacity of woven flax-epoxy composite under various stain rates. EPJ Web Conf. 2018, 183, 02062. [Google Scholar] [CrossRef][Green Version]

- Seman, A.; Hilmi, S.A.; Ahmad, R.; Akil, H.M. Meso-scale modelling and failure analysis of kenaf fiber reinforced composites under high strain rate compression loading. Compos. Part B Eng. 2019, 163, 403–412. [Google Scholar] [CrossRef]

- Wang, W.; Chouw, N. Flexural behaviour of FFRP wrapped CFRC beams under static and impact loadings. Int. J. Impact Eng. 2017, 111, 46–54. [Google Scholar] [CrossRef]

- Wang, W.; Guo, X.; Liu, L.; Zhang, R.; Yu, J. Effect of Temperature and Strain Rate on the Flexural Behavior of Wood-Polypropylene Composites. Materials 2019, 12, 3987. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Tiwari, M.; Makhatha, M.E.; Dey, A.; Verma, B.B. Effect of Rate of Loading on Jute Fibre-Reinforced Polymer Composite. Trans. Indian Inst. Met. 2020, 73, 1573–1577. [Google Scholar] [CrossRef]

- Schmack, T.; Righi, R.; Hülsbusch, D.; Rausch, J.; Roquette, D.; Deinzer, G.; Kothmann, M.; Kassapoglou, C.; Walther, F. A newly-developed fixture and testing method for strain rate-dependent flexural properties determination of carbon/epoxy. In Proceedings of the 21th International Conference on Composite Materials, Xi’an, China, 20–25 August 2017. [Google Scholar]

| Strain Rate Regime | Experimental Technique |

|---|---|

| Low rate | Conventional mechanical universal tester Electronic universal testing machine |

| Medium rate | Mechanical tester with ultra-capacity Split Hopkinson pressure bar (SHPB) Drop weight Servo-hydraulic testing machine |

| High rate | Split Hopkinson pressure bar (SHPB) Taylor rod impact |

| Very high rate | Flyer plate impact |

| Strain Rate Forms | Authors and Date | Composite | Key Findings |

|---|---|---|---|

| Tensile | Fotouh et al. (2014) | Hemp-HDPE | Young modulus and tensile strength of composite increase as the strain rate increase due to strain hardening effect. |

| Patel and Chokshi (2017) | Bamboo-polyester | Fluctuating composites tensile strengths under varied low strain rates. | |

| Giuliania et al. (2018) | Flax-epoxy | Composite exhibits both viscoelastic and viscoelastic behaviours which cause its properties to be highly dependent on strain rate. | |

| Chokshi and Gohill (2018) | Bamboo, Banana, Flax-polyester | Composite strain rate sensitivity is reliant on the type and form of natural fibres reinforcement. | |

| Wang et al. (2018) | Flax-epoxy | Composite shows significant increment of strength under high strain rate loading compare to low strain rate. Fibre sensitivity affects overall sensitivity of NFPCs. | |

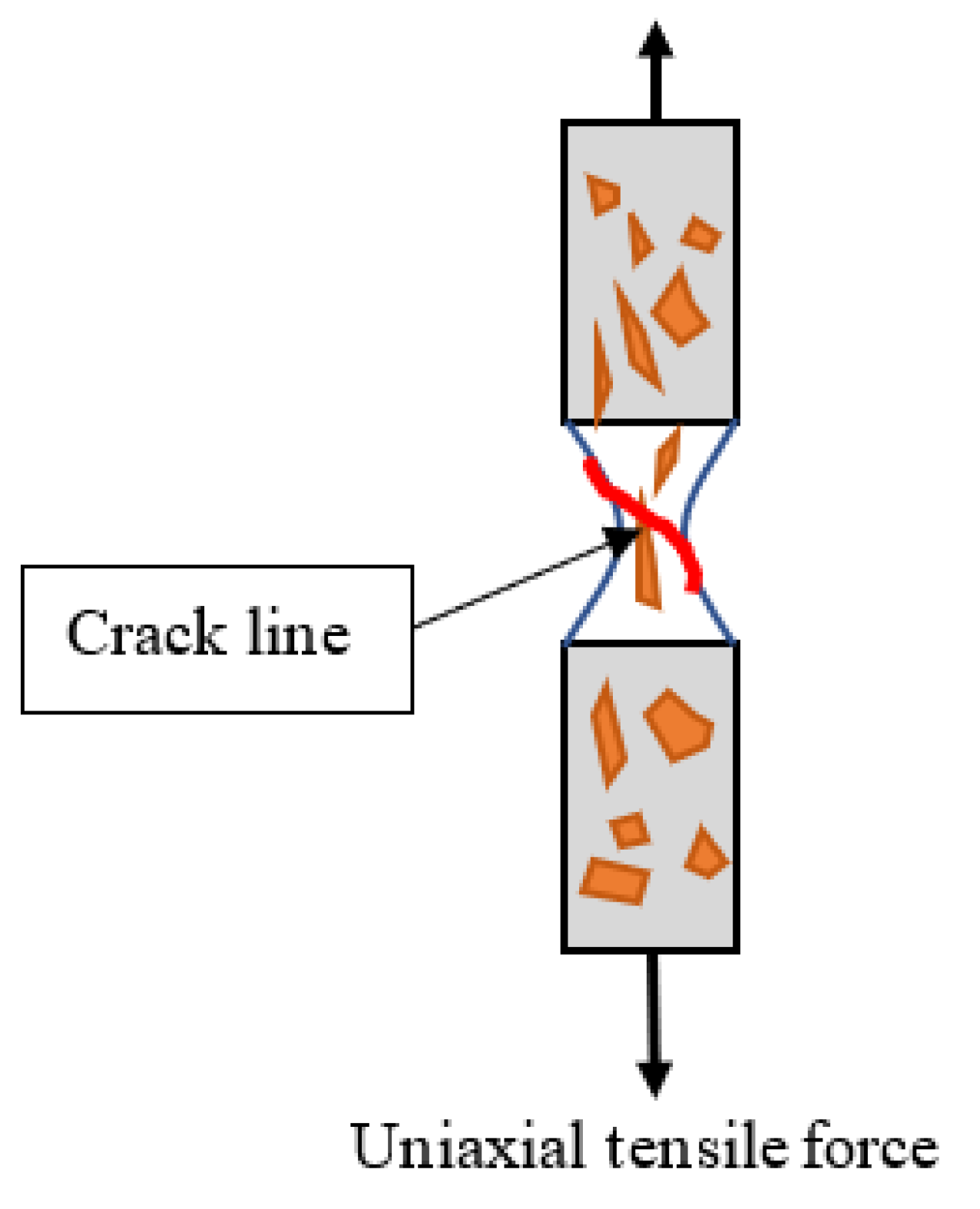

| Kumar et al. (2018) | Coir-epoxy | The rate of crack initiation and propagation are extremely affected by strain rate variation. | |

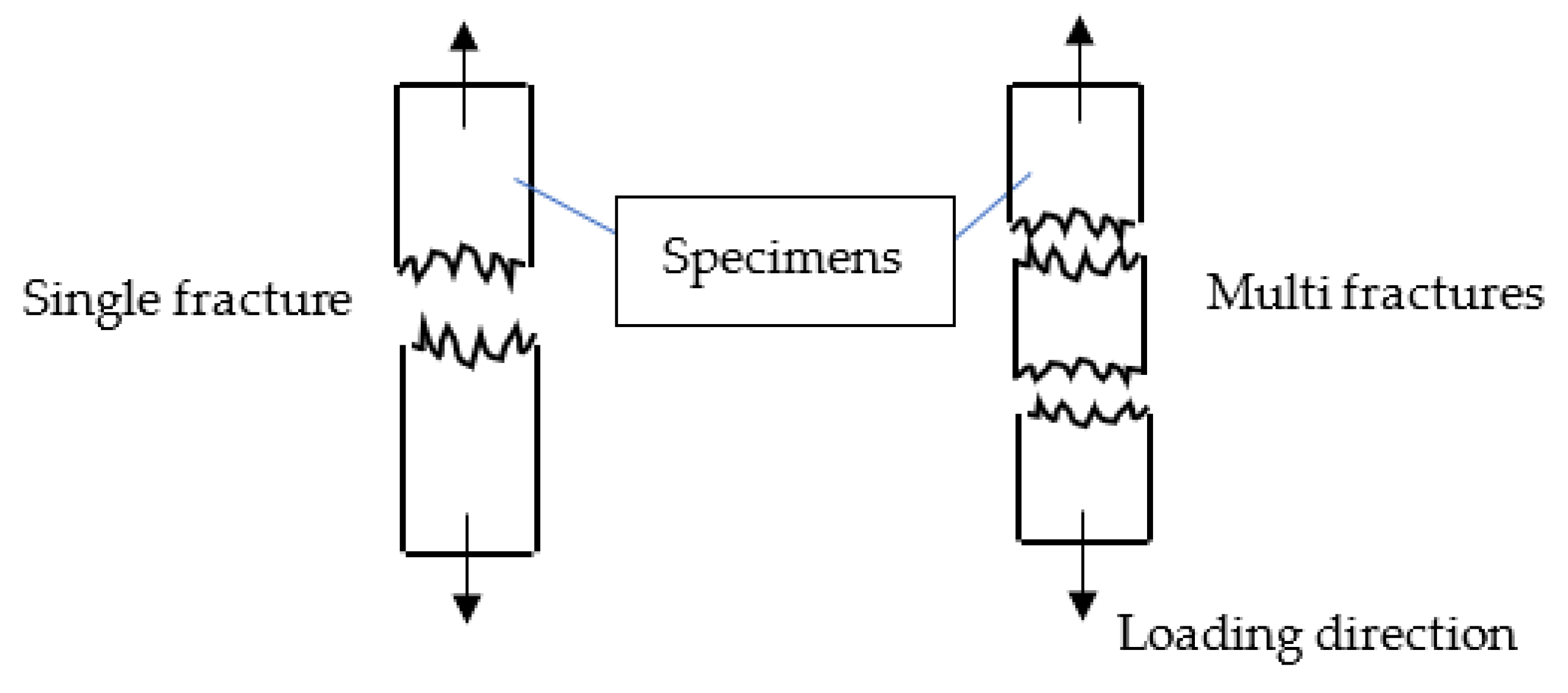

| Kumar et al. (2018) | Wood-epoxy | The tensile strengths of wood filler composites, in general, were decreasing as the strain rate increases. Crack blunting, crack pining, crack front-twisting as fracture mechanism with micro-sized particle reinforcement. | |

| Kumar and Bhowmik (2019) | Coir-epoxy | The rate of crack initiation and propagation are extremely affected by strain rate variation. Uneven particle sizes result in micro-cracks and act as localised stress generators, initiating structural heterogeneities and resulting in early failure. | |

| Debnath et al. (2020) | Bagasse-epoxy | The composites with smaller filler size exhibit higher tensile strength and toughness under various low strain rates. | |

| Sinebe et al. (2020) | Plantain-polyester | Different chemical treated fibre can influence the strain rate sensitivity of polymer composites through the interface adhesion strength. | |

| Compressive | Kim et al. (2012) | Hemp-vinyl ester, glass-vinyl ester, hemp/glass-vinyl ester, wheat straw-polypropylene (homopolymer & copolymer) | Hemp-vinyl ester was found less strain-rate dependent compared to glass-vinyl ester at strain rates higher than 1400 s−1. Hybrid reinforcement using hemp and glass resulted in composite behaviour intermediate between glass and hemp cases. Polypropylene copolymer composite was found to exhibit better energy absorption properties at high strain rates compared to homopolymer. |

| Hu et al. (2018) | Flax-epoxy | Significant increment in ultimate Compressive strength (61.2%) under varied strain rates. Composites broken into small pieces under highest compressive strain rates (2800 s−1) due to flax weave rupture. | |

| Abu Seman et al. (2019) | Kenaf-polyester | Validated that the composite failed at more shattered fragment at higher compressive strain rates causing a non-linear behaviour using finite element analysis (meso-scale model). | |

| Hu et al. (2019) | Flax-epoxy | Use of simplified Johnson-Cook model to describe compressive strain-rate dependent of flax fibre reinforced composites. | |

| Xiang et al. (2020) | Hemp-epoxy | The stress–strain behaviour of the composite was found different between quasi-static and high compression strain rate. | |

| Flexural | Wang and Chouw (2017) | Woven flax fabric-epoxy wrapped coir-concrete | 3% coconut fibre reinforced composite can absorb about 83.23 J of energy under flexural high impact strain rates. |

| Silva et al. (2019) | Kevlar/cork powder-epoxy & Carbon/cork powder-epoxy hybrid composites | Hybrid reinforcement of cork-powder epoxy composite using Kevlar and Carbon can cause the different bending strain rate sensitivity depending on the filler properties. | |

| Wang et al. (2019) | Wood-polypropylene | Flexural strength of composite increased linearly as the strain rate increase. The strain at break of composite decreased as the strain rate increased due to shortened stress relaxation time. | |

| Kumar et al. (2020) | Jute-polyester | Alkali-treated jute fibre could increase the loading rate sensitivity of composite under three-point bending. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khieng, T.K.; Debnath, S.; Ting Chaw Liang, E.; Anwar, M.; Pramanik, A.; Basak, A.K. A Review on Mechanical Properties of Natural Fibre Reinforced Polymer Composites under Various Strain Rates. J. Compos. Sci. 2021, 5, 130. https://doi.org/10.3390/jcs5050130

Khieng TK, Debnath S, Ting Chaw Liang E, Anwar M, Pramanik A, Basak AK. A Review on Mechanical Properties of Natural Fibre Reinforced Polymer Composites under Various Strain Rates. Journal of Composites Science. 2021; 5(5):130. https://doi.org/10.3390/jcs5050130

Chicago/Turabian StyleKhieng, Tan Ke, Sujan Debnath, Ernest Ting Chaw Liang, Mahmood Anwar, Alokesh Pramanik, and Animesh Kumar Basak. 2021. "A Review on Mechanical Properties of Natural Fibre Reinforced Polymer Composites under Various Strain Rates" Journal of Composites Science 5, no. 5: 130. https://doi.org/10.3390/jcs5050130

APA StyleKhieng, T. K., Debnath, S., Ting Chaw Liang, E., Anwar, M., Pramanik, A., & Basak, A. K. (2021). A Review on Mechanical Properties of Natural Fibre Reinforced Polymer Composites under Various Strain Rates. Journal of Composites Science, 5(5), 130. https://doi.org/10.3390/jcs5050130